Hilti DS TS20-E 1.6 Operating Instructions Manual

Operating instructions en

DS TS20-E 1.6

Printed: 09.03.2015 | Doc-Nr: PUB / 5139344 / 000 / 01

2

Contents

1. General information 4

2. Description 5

3. Accessories 6

4. Technical data 7

5. Safety precautions 9

6. Preparations at the workplace 13

7. Setting up the wall saw system 15

8. Operation 24

9. Care and maintenance 28

10. Troubleshooting 30

11. Disposal 33

12. Manufacturer's warranty – tools 34

13. EC declaration of conformity (original) 34

ORIGINAL OPERATING INSTRUCTIONS

DS TS20-E 1.6 3×400 V electric wall saw

It is essential that the operating instructions are read

before the machine is operated for the first time.

Always keep these operating instructions together

with the machine.

Ensure that the operating instructions are with the

machine when it is given to other persons.

Printed: 09.03.2015 | Doc-Nr: PUB / 5139344 / 000 / 01

3

Parts and equipment

Saw head

Power unit

Remote control unit

Power cable, control cable and water hose

Transport trolley – saw head

Blade guard - center section

Blade guard – side section

Guide rail with end stop

Accessory box with rail support and toolbox

Transport trolley - accessories

Printed: 09.03.2015 | Doc-Nr: PUB / 5139344 / 000 / 01

4

General information

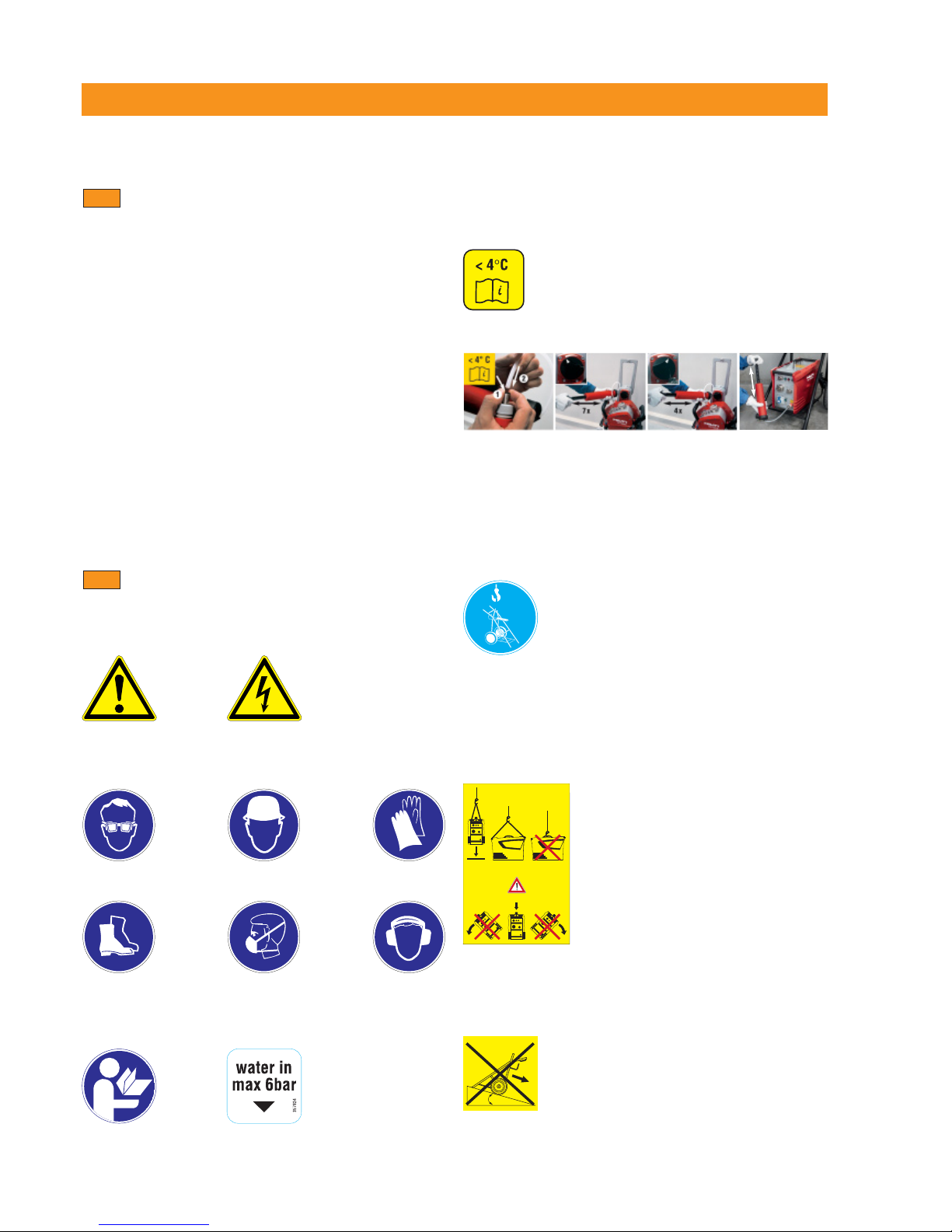

Read the operating

instructions before use.

General warning Warning:

electricity

4x

Removing cooling water from the saw head and power unit

1. Connect the blow-out adapter to the hose on the HIT pump.

2. Turn the bypass valve to the “closed” position and blow out the

saw head 7 times with the HIT pump.

3. Turn the bypass valve to the “open” position and blow out the

saw head 4 times with the HIT pump.

4. Blow out the power unit at the water outlet 4 times with the HIT

pump.

To avoid damage to the equipment,

water pressure must not exceed 6 bar.

358092

To avoid damage when temperatures below freezing are expected, the cooling system must be fully drained by blowing out with the pump provided.

Please refer to the instructions provided in the toolbox.

3

57860

max. 150kg

The saw head and accessory transport trolleys may be lifted by

crane only at the lifting points provided.

Before transport, all items of equipment must be secured to prevent movement or falling.

Never loiter in the vicinity of loads suspended by cranes.

Use only tested and approved lifting gear.

!!

Handle with care!

320489

The power unit may be lifted by crane only at the lifting points

provided.

Never loiter in the vicinity of loads suspended by cranes.

Use only tested and approved lifting gear.

> 5°

357985

The transport trolley may become unstable or run away if stood on

an inclined surface.

Wear

protective gloves.

Wear ear

protection.

Wear

safety footwear.

Wear

respiratory

protection.

Wear

eye protection.

Wear

a hard hat.

1. General information

Safety notices and their meaning

DANGER

Draws attention to imminent danger that could lead to

serious bodily injury or fatality.

WARNING

Draws attention to a potentially dangerous situation that

could lead to serious personal injury or fatality.

CAUTION

Draws attention to a potentially dangerous situation that

could lead to slight personal injury or damage to the

equipment or other property.

NOTE

Draws attention to instructions and other useful information.

Explanation of the pictograms and other

information

1.2

1.1

Symbols

Obligation signs

Warning signs

A

AmpsVVolts

mm

Millimeters

Hz

Hertz

/min

Revolutions

per minute

n

Rated

no-load

speed

rpm

Revolutions

per minute

Printed: 09.03.2015 | Doc-Nr: PUB / 5139344 / 000 / 01

5

General information / Description

Other information

In these operating instructions, the DS TS20-E electric

wall saw is referred to as “the machine”.

Location of identifying data on the machine

The type designation, item number, serial number, year

of manufacture and technical status can be found on the

rating plate on the machine.

Make a note of this data in your operating instructions

and always refer to it when making an enquiry to your

Hilti representative or service department.

1.3

Power unit:

Type: DS EB-TS20 serial no.

Saw head:

Type: DS TS20-E serial no.

Remote control unit:

Type: DS RC-TS20 serial no.

2. Description

Use of the equipment as intended

1. The DS TS20-E is an electrically-powered, rail-guided wall saw designed for cutting lightly to heavily-reinforced concrete, stone or masonry structures with

diamond saw blades of 600 mm, 800 mm, 900 mm,

1000 mm, 1200 mm or 1600 mm in diameter (max-

imum blade diameter for initial cut: 800 mm).

2. All functions of the machine are controlled by an electric remote control unit. The speed of rotation of the

saw blade can be controlled smoothly and steplessly

between 0 and maximum speed.

3. The saw blade drive motor provides a constant power output. Saw advance can be controlled manually

and/or automatically. Thanks to load-dependent advance

control, the saw is very easy to operate. The saw operates virtually fully automatically at the maximum power set on the control unit.

4. Best sawing performance is achieved when the

DS TS20-E is used with the specially-matched Hilti

DS-B wall saw blades. Use only diamond wall saw

blades that comply with the EN 13236 standard and

which have been approved for use at a peripheral cutting speed of at least 63 m/s. Wall saw blades in diameters between 1200 mm and 1600 mm must be

approved for a peripheral cutting speed of at least 80

m/s.

5. Use only anchors of adequate size and load capacity

to secure the machine to the object to be cut.

6. Do not cut materials that may release hazardous or

explosive dust or vapors during the cutting process.

Do not cut inflammable materials.

7. Overhead sawing is possible when additional precautionary measures are taken. For this application,

the blade guard must be equipped with a means of

2.1

water drainage. Care must be taken to ensure that no

persons are present beneath the equipment when sawing overhead. Please consult your Hilti representative for further information and advice.

8. Use only genuine Hilti accessories (available as options)

for angled or stepped cuts or for flush cutting.

9. Check that the electric supply provided at the construction site, no matter whether mains or generator

power, is always equipped with an earth/ground conductor and a ground fault circuit interrupter (PRCD

type A, trigger current max. 30 mA) and that these are

connected. If suspected that the electric supply is not

earthed/grounded, the power unit must be earthed/

grounded by way of the earth/ground terminal provided.

Items supplied as standard

The items supplied on the saw head trolley include:

● Saw head

● Power unit

● Remote control unit

● Power and control cables

● Cooling water hose

● Transport trolley

● Tool set

● Operating instructions

The items supplied on the accessories trolley include:

● DS-BG 80 blade guard for 900 mm dia. saw blade

● Rail supports (4 supports)

● Transport box

● Transport trolley

● Rail connector

Using the accessories listed, the wall saw can be adapted to suit the particular conditions of the application you

intend to carry out.

2.2

Printed: 09.03.2015 | Doc-Nr: PUB / 5139344 / 000 / 01

6

Accessories

3. Accessories

Item no. Designation Use

238000 DS-BG65 blade guard Blade guard for blades up to 650 mm dia.

2051935 DST-BG 80 blade guard Blade guard for 600 to 800 mm dia. saw blades

238002 DS-BG80 center section Blade guard for 600 to 900 mm dia. saw blades *

238003 DS-BG80 side section Blade guard for 600 to 900 mm dia. saw blades

238004 DS-BG120 center section Blade guard for 1000 to 1200 mm dia. saw blades *

238005 DS-BG120 side section Blade guard for 1000 to 1200 mm dia. saw blades

2064904 DST-BG 160 blade guard Blade guard for 1200 to 1600 mm dia. saw blades

Item no. Designation Use

238006 DS-BGF80 center section Blade guard for 600 to 900 mm dia. saw blades

for flush cutting *

238007 DS-BGF80 side section Blade guard for 600 to 900 mm dia. saw blades

for flush cutting

238008 DS-BGF120 center section Blade guard for 1000 to 1200 mm dia. saw blades

for flush cutting *

238009 DS-BGF120 side section Blade guard for 1000 to 1200 mm dia. saw blades

for flush cutting

Item no. Designation Use

284808 DS-R100-L rail Saw guidance

284809 DS-R200-L rail Saw guidance

284810 DS-R230-L rail Saw guidance

371703 DS-ES-L end stop Safety stop for saw head

207137 DS-CP-ML rail clamp Fastening rails

284814 DS-RF-L rail support Fastening rails

284816 DS-RFP-L rail support Fastening rails for angled and stepped cuts

232241 D-CO-ML double taper Extending rails

232244 D-EP-ML eccentric pin Extending rails

Item no. Designation Use

258436 DS-FCA-110 flush-cutting flange Saw blade mounting flange for flush cutting

307188 DS-FCA-110FF auxiliary flange Saw blade mounting flange for flush cutting

* Only to be used with the corresponding side sections!

Item no. Designation Use

284842 DS TS tool set Fastening rails, personal protection, maintenance and

operation

Item no. Designation Use

206856 DS TS20-E power cable, 10 m System cable

206857 DS TS20-E control cable, 10 m System cable

400768 RC extension cable

Extending distance between remote control and power unit 10 ➩ 20 m

228150 Water hose, 10 m System water hose

Printed: 09.03.2015 | Doc-Nr: PUB / 5139344 / 000 / 01

7

Technical data

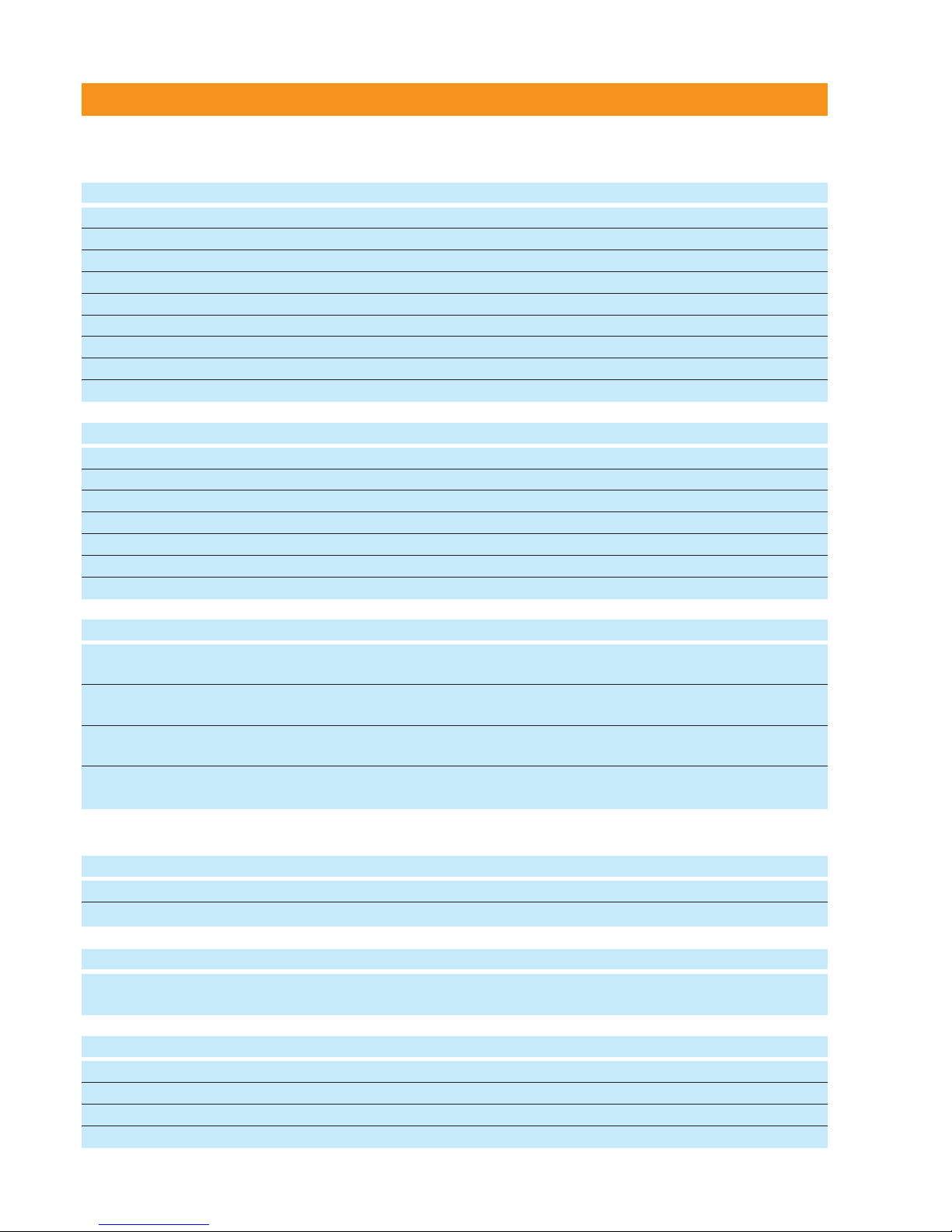

4. Technical data

Technical data for the DS TS20-E power unit*

DS EB-TS20 3 × 400 V DS EB-TS20 3 × 200 V

Rated voltage 380 to 480 V ~ 200 to 280 V ~

Voltage tolerance ± 10%

Mains frequency 50 / 60 Hz

Pin assignment 3P+N+PE / 3P+PE 3P+PE

Rated current 16 / 25 / 32 A 32 / 50 / 63 A

Mains fuse rating min. / max. 16 / 32 A 32 / 63 A

Power input, max. 19 kW

Generator power rating, min. 20 kVA @ 16 A / 40 kVA @ 32 A 20 kVA @ 32 A / 40 kVA @ 63 A

Ground fault circuit breaker in supply 30 mA (type A)

Cooling water temperature at 4l/min. 4 to 30°C

Cooling water pressure min. / max. 2 to 6 bar

Protection class **** IP 65

Weight 38 kg

Power outlet 230 V / 10 A none

Dimensions l × w × h 73 × 35 × 59 cm

Operating / storage temperature –15°C to +50°C ***

Operating / ambient temperature –15°C to +45°C ***

Leakage current ≤ 10 mA

Insulation resistance at least 300 k Ω

Technical data for the DS TS20-E saw head*

DS TS20-E

Motor power S1** 15 kW

Drive spindle speed 100 to 940 r.p.m.

Protection class **** IP 65

Saw blade diameter 600 mm to 1600 mm dia.

Max. cutting depth 73 cm

Weight 37 kg

Dimensions l × w × h 37.5 × 44 × 32 cm

Operating / storage temperature –15°C to +50°C ***

Operating / ambient temperature –15°C to +45°C ***

4.2

4.1

Printed: 09.03.2015 | Doc-Nr: PUB / 5139344 / 000 / 01

8

Technical data

Technical data for the DS TS20-E remote control unit

DS RC-TS20 remote control unit

Cable length 10 m

Voltage 24 V DC

Protection class **** IP 65

Weight 2.2 kg

Dimensions l × w × h 39 × 19 × 12.5 cm

**** Rated values guaranteed at max. 18°C and heights of up to 2,000 m above sea level.

**** Continuous operation 100%

**** At temperatures below zero, allow the machine to warm up slowly before subjecting to load and drain (blow out) the water from

the cooling circuit after use (a pump is supplied for this purpose).

**** Protection class IP65 in accordance with EN 60529, 6 = protection against entry of dust, 5 = protection against water jets (hose proof)

Technical data for the transport trolleys

Saw head trolley Accessory trolley

Dimensions loaded, L × W × H 106 × 75 × 108 cm 106 × 75 × 140 cm*

Weight loaded ** 121.5 kg 91 kg

Max. permissible total weight 150 kg 150 kg

** With 1 m rail. Height with 2.3 m rail = 245 cm.

** Contents in accordance with list of items supplied, see section 2.2

Noise information (measured in accordance with EN 61029)

Typical A-weighted noise

(power) level: 117.8 dB (A)

Typical A-weighted noise

(pressure) level: 100.3 dB (A)

Wear ear protectors!

Note: The noise pressure level can be reduced by approx. 10 dB(A) when noise-reducing (silent) saw blades are used.

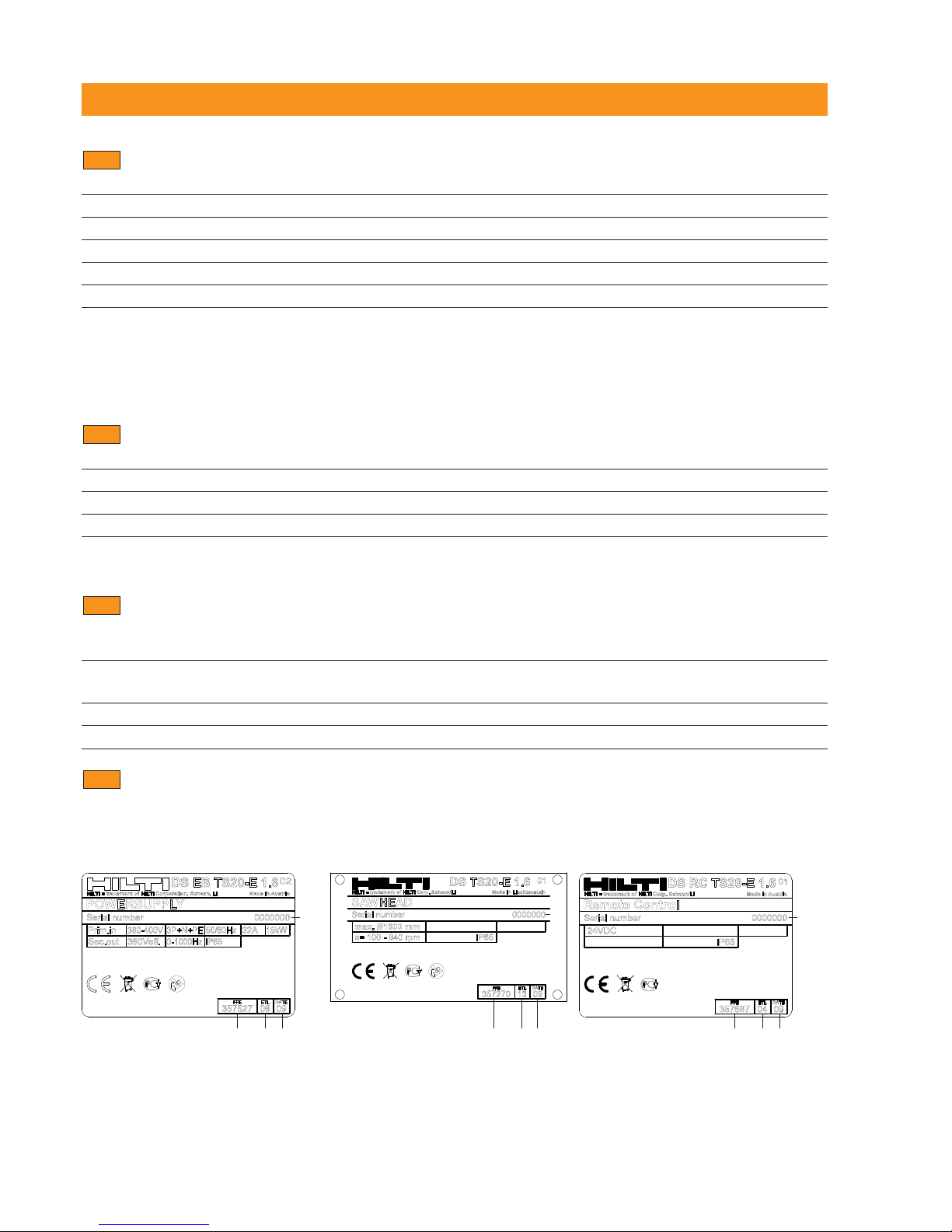

Type plates

4.3

4.4

4.6

4.5

Power unit type plate Saw head type plate Remote control unit type plate

On the rear of the power unit On the underside of the saw head On the side of the remote control unit

= Engineering number

= Spare parts list index

= Serial number

= Year of manufacture

Printed: 09.03.2015 | Doc-Nr: PUB / 5139344 / 000 / 01

9

Safety precautions

5. Safety precautions

WARNING

Failure to observe the instructions listed below may

lead to potentially fatal injury and serious damage to

property or equipment.

Proper organization of the work area

a) Approval must be obtained from the site engineer

or architect prior to beginning drilling or sawing work.

Drilling or sawing work on buildings and other structures may influence the statics of the structure, especially when steel reinforcing bars or load-bearing components are cut through.

b) Ensure that the workplace is well lit.

c) Ensure that the workplace is well ventilated. Expo-

sure to dust at a poorly ventilated workplace may result

in damage to the health.

d) Keep the workplace tidy. Objects which could cause

injury should be removed from the working area. Untidiness at the workplace can lead to accidents.

e) In order to avoid injury and to prevent the diamond

blade becoming trapped or jammed, steel wedges and/or

supports must be used to prevent uncontrolled movement of parts of the structure being cut.

f) Ensure that adequately-sized supports are correctly

installed so that the remaining structure maintains its

stability after completion of the cutting work and removal

of the part cut away.

g) Never loiter in the vicinity of loads suspended by

cranes.

h) The area of the cut or the opening created by the cutting process must be safely and visibly cordoned off

in order to avoid the possibility of persons falling.

i) Wear personal protective equipment. Wear safety

shoes or boots, protective gloves, a hard hat, ear protection and eye protection.

j) Wear respiratory protection if the work causes dust.

5.1

k) Dress properly for the work. Do not wear loose cloth-

ing or jewelry as it could be caught in moving parts.

Contain long hair.

l) Keep children away. Keep other persons away from

the working area.

m) Do not allow other persons to touch the machine

or the extension cord.

n) Avoid unfavorable body positions. Make sure you

work from a safe stance and stay in balance at all times.

o) To avoid presenting a tripping hazard, always ensure

that cables and hoses leading to the machine are laid

flat on the floor.

p) Keep cables and hoses away from rotating parts.

q) In cooperation with the site engineer or architect, ensu-

re that no gas, water, electricity or other supply lines are

located in the cutting area. Any supply pipes or cables

located close to the cutting area present a serious hazard

if damaged while the work is in progress. External metal

parts of the machine could become live if, for example,

an electric supply cable is damaged.

r) Ensure that the cooling water used is drained or

extracted in a suitably controlled manner. Water that is

allowed to drain away or spray around in an uncontrolled manner can lead to damage or accidents. The

fact that water could drain away into internal, hidden

cavities, e.g. in brickwork or masonry, must also be

taken into account.

s) Do not work from a ladder.

t) The machine is not intended for use by children, by

debilitated persons or those who have received no

instruction or training.

u) Children must be instructed not to play with the

machine.

v) Dust from material such as paint containing lead, some

wood species, minerals and metal may be harmful.

Contact with or inhalation of the dust may cause allergic reactions and/or respiratory diseases to the operator or bystanders.

Certain kinds of dust are classified as carcinogenic such

as oak and beech dust especially in conjunction with

additives for wood conditioning (chromate, wood pre-

Printed: 09.03.2015 | Doc-Nr: PUB / 5139344 / 000 / 01

CAUTION

Secure the working area. Ensure that no persons can be

injured or property / equipment damaged by falling objects

or debris that may fly off during the sawing operation.

10

Safety precautions

servative). Material containing asbestos must only be

treated by specialists.

Where the use of a dust extraction device is possible

it shall be used. To achieve a high level of dust collection, use a suitable vacuum cleaner of the type recommended by Hilti for wood dust and/or mineral dust

together with this tool. Ensure that the workplace is

well ventilated. The use of a dust mask of filter class

P2 is recommended. Follow national requirements for

the materials you want to work with.

Safety measures at the danger areas

Safety measures must be implemented in the area where sawing is taking place to ensure that operators and

bystanders cannot be injured or property damaged by

debris that may fly off or fall down (broken-off diamond

segments, small stones, sawing slurry, etc.) while

sawing is in progress. Safety measures must also be

implemented in the area not directly visible to the operator, i.e. behind where sawing is taking place.

Persons must NEVER enter the danger area (3 meters

in all directions from the line of the cut to be made)

while the blade drive is switched on.

5.2

3m 3m

3m

1m ∞m

STOP

STOP

STOPSTOP

3m

3m ∞m

3m3m

STOP

STOP

STOP

STOP

1. Approval must be obtained from the site engineer or

site management before beginning the sawing work.

2. Find out whether overcutting at corners is permitted.

If not, the corresponding corner holes must be planned

and drilled first.

3. Check that the area is cordoned off, that supports are

in place and warnings to third parties are displayed.

When setting up and operating the saw system and

when removing parts that have been cut away, always

ensure that no persons are below the area in which you

are working. Falling objects could cause serious injury.

General safety instructions

a) Use the machine only when you have read the oper-

ating instructions and you are familiar with the points

described, and when you have received appropriate

training from a Hilti specialist on safe operating procedures. All warnings and instructions must be observed.

b) Use the right machine for the job. Do not use the

machine for purposes for which it was not intended.

Use it only as directed and when in faultless condition.

c) Use the machine, accessories and saw blades etc.,

in accordance with these instructions and in the manner intended for the particular type of machine, taking

into account the working conditions and the work to

be performed. Use of this machine for operations other

than those intended could result in hazardous situations.

d) Use only the genuine Hilti accessories or ancillary

equipment listed in the operating instructions. Use of

accessories or ancillary equipment not listed in the

operating instructions may present a risk of personal

injury.

e) Take the influences of the surrounding area into

account. Do not use the machine where there is a risk

of fire of explosion. Electric tools and machines generate sparks which may ignite dust or gas.

f) Keep the grips dry, clean and free from oil and grease.

g) Do not overload the machine. It will work more effi-

ciently and more safely within its intended performance

range.

h) Never leave the machine unattended.

i) Store machines in a secure place when not in use.

5.3

Printed: 09.03.2015 | Doc-Nr: PUB / 5139344 / 000 / 01

11

Safety precautions

When not in use, machines must be stored in a dry,

high place or locked away out of reach of children.

j) Always disconnect the machine from the electric supply when it is not in use (e.g. during breaks between

working), before making adjustments, before carrying

out care and maintenance and before changing saw

blades. This safety precaution prevents the machine

starting unintentionally.

k) Remove any adjusting key or wrench before switching the machine on. A wrench or a key left attached to

a rotating part of the machine may cause personal injury.

l) Before use, the machine, the saw blade and accessories must be checked carefully to ensure that all items

function faultlessly and as intended. Check that moving parts function correctly without sticking and that

no parts are damaged. All parts must be fitted correctly

and fulfill all conditions necessary for correct operation of the machine. Damaged parts must be repaired

or replaced properly by an authorized service center.

m) Avoid skin contact with drilling slurry.

n) Wear a protective mask during work that generates

dust. Cutting materials hazardous to the health (e.g.

asbestos) is not permissible.

o) Follow the instructions concerning care and maintenance.

Electrical safety

a) Take steps to avoid the risk of electric shock. Avoid

body contact with earthed or grounded surfaces such

as pipes, radiators, ranges and refrigerators.

b) Check the machine’s supply cord at regular intervals

and have it replaced by a qualified specialist if found to

be damaged. Check extension cords at regular intervals and replace them if found to be damaged.

c) Check the condition of the machine and its accessories. Do not operate the machine and its accessories

if damage is found, if the machine is incomplete or if

its controls cannot be operated faultlessly.

d) Do not touch an electric cable that has been damaged while working. Switch off at the main switch and

unplug the cable at the power outlet.

5.4

e) Damaged or faulty switches must be replaced at a

Hilti service center. Do not use the machine if it cannot

be switched on and off correctly.

f) Have the machine repaired only by a trained electrical specialist (Hilti service center) using genuine Hilti

spare parts. Failure to observe this point may result in

risk of accident to the user.

g) Do not use the supply cord for purposes for which

it is not intended. Never carry the machine by the supply cord. Never pull the plug out of the power outlet by

pulling the supply cord.

h) Do not expose supply cords to heat, oil or sharp

edges.

i) Connect the machine and its ancillary equipment only

to a power source equipped with an earth/ground conductor and ground fault circuit breaker (PRCD). Check

that these items are in perfect working order before

operating the equipment. Install an earth/ground rod

if a generator is used or if no earth/ground conductor

is present in the on-site electric supply. Operation of

the machine without an earth/ground connection is not

permissible under any circumstances. With no

earth/ground connection, faulty insulation on a part of

the machine or inadvertently sawing into a live cable

presents a risk of fatal accident.

j) Make sure that the mains voltage corresponds to the

specification given on the type plate.

k) Electric cables and their plug connectors must be

kept dry. When not in use, close power outlets with the

cover provided.

l) Use only extension cables which have an adequate

conductor cross-section and are approved for the intended field of use. Do not work with extension cables when

they are rolled up. This can result in a drop in output

at the equipment and may cause the cable to overheat.

m) Disconnect the power cable before beginning cleaning and maintenance work or in the event of a lengthy

interruption between periods of operation.

n) Please note that certain components of the power

converter retain an extremely dangerous (potentially

fatal) high voltage for up to 10 minutes after disconnection from the electric supply.

Printed: 09.03.2015 | Doc-Nr: PUB / 5139344 / 000 / 01

Loading...

Loading...