Hill-Rom Resuscitaire User manual

OPERATING PRECAUTIONS

GENERAL PRECAUTIONS

.

Federal Law restricts this device to sale by or on order of a physician.

.

Infant radiant warmers should be used only by properly trained personnel as directed by an appropriately

qualified physician aware of currently known hazards and benefits.

.

The functional checkout procedure should be performed before each use and after disassembly for

cleaning, servicing or maintenance. Refer to qualified service personnel if the unit does not perform as

specified.

.

The Cart/Bassinet End and Side panels cannot be used for pushing or pulling the Cart/Bassinet and or

Warmer.

.

Do not leave the infant unattended in the Cart/Bassinet when the side panels orthefront panel arefolded

down.

.

To avoid overheating or underheating, skin temperature must be continuously monitored and controlled

either manually or automatically. Rectal temperature should never be used to control skin temperature.

.

To avoid overheating or underheating when operating in manual mode, observe the infant constantly and

monitor the temperature using the temperature probe supplied with the equipment or another electronic

thermometer.

.

The skin temperature sensing probe must be in direct contact with the skin to provide accurate monitor-

ing of the infant’s skin temperature. Failure to maintain direct skin contact can result in overheating and

possible burning. Check infant’s condition at least every fifteen minutes for correct Sensor attachment,

reddened skin areas, and proper skin temperature.

.

The skin temperature sensing probe should be placed at least 1.5 inches from any transcutaneous moni-

(TcPOz

tor

should not be placed on an area previously used by a

.

To avoid overheating the skin, the location of the skin temperature probe must be such that the skin

around the Sensor is in direct line with the radiation from the warmer. Do not place anything between the

radiant warmer and the infant that will interfere with the radiation from the warmer.

.

Radiant warming increases insensible water loss. Appropriate measures to maintain proper fluid bal-

ance should be considered.

.

For effective heating, make sure the Warmer Module is positioned on the center axis and locked with its

detent.

.

This Warmer is intended for use with the Cart/Bassinet. If the Warmer is used to warm the mother im-

mediately after delivery, all warnings and instructions should be followed with particular regard to the

heater-to-mattress distance and skin probe location. Avoid placement of objects near the mother which

can absorb heat and become hot to the touch.

.

Compressed gas cylinders, such as oxygen cylinders, can become hazardous projectiles if the gas is

released rapidly due to damage or other causes. Cylinders must be securely fastened.

.

To avoid overheating the Warmer, do not place objects (equipment, blankets, clothing or sterile packs) on

top of the Warmer.

TcPCOz)

or

probe to prevent false temperature indications. The skin temperature probe

TcPOz

or

COPYRIGHT@3

TcPC02

1998, HILL-ROM AIR-SHIELDS, INC.

probe.

OPERATING PRECAUTIONS (Continued)

l

Avoid placement of objects between the infant and the Warmer Module that can block heat transfer or

absorb heat. These objects may be heated directly by the heater and can cause skin burns.

a

Temperature uniformity (per IEC 601-2-21) across the mattress surface may not be maintained when

the Bassinet is tilted in the

l

During calibration, inspect the secondary reflector directly under the warmer heater element for particles.

If particles are present, replace the heater element. The life expectancy of the heater element is 1000

hours of operation.

0

Evidence that the safety certification of the ACCESSORY has been performed in accordance with the

appropriate IEC 601-l and/or IEC 601-l-l harmonized national standard.

RESUSCITATION PRECAUTIONS

A one-way valve is installed at the Patient Outlet connection. This valve opens when pressure in the

hose delivering gas to the patient falls below -4 cm

unlikely event of failure of the gas supply.

5-

and 1 O-degree positions.

Its purpose is to allow patient inspiration in the

H20.

A humidifier, when used, must be placed between the

Patient Outlet

connection and the patient circuit.

DO NOT PLACE A HUMIDIFIER IN THE SUPPLY LINE.

Humidifier must have low series flow resistance and not be placed between exhalation valve and patient

airway.

Gas going to the patient should not be super-saturated as evidenced by excessive condensation in the

tubing. Condensation droplets on the inner walls of the tubing are normal.

Periodic blood gas measurements should be made to ensure proper levels of ventilation.

Always confirm the airway pressure relief valve setting before patient use.

Confirm that the oxygen/air blender control of the Blended Gas Supply Module is correctly set prior to

use.

Confirm that the patient circuit contains all the parts needed prior to use.

Ensure that the patient breathing circuit connections are secure and free of obstructions.

The Aux Outlet circuit does not provide adjustable pressure limiting.

HzO.

Auxiliary Gas Supply Pressure is internally limited to 160 cm

Always use a patient resuscitation

circuit that includes appropriate pressure relief.

Always monitor Airway Pressure and/or provide appropriate pressure relief during infant resuscitation.

Confirm that the oxygen supply is turned off and that the equipment is disconnected from the oxygen

supply when performing cleaning and maintenance procedures; a fire and explosion hazard exists when

performing cleaning and/or maintenance procedures in an oxygen-enriched environment.

Gas supplies

(02 and Air) should always be clean and dry. Water/Trap Filters should be used in the sup-

ply lines if necessary.

All hoses should be securely fastened to fittings. Hand-tighten to avoid damage to fittings.

Gas supplies should be maintained at 40 to 75 psi.

Flow restrictions (e.g., flowmeter, valve, etc.) must not be placed in the supply line.

If a compressor is used as the air source, steps should be taken to filter and dehumidify the room air

before introducing it into the Gas Supply Module.

_ ii _

OPERATING PRECAUTIONS (Continued)

ELECTRICAL PRECAUTIONS

a

An electrical shock hazard exists within the Warmer Module and Controller. Any substitution of compo-

nents within the Controller or Warmer Module may impair the intrinsic safety of the unit. Service should

be performed by qualified personnel.

0

Connect the power cord only to a properly grounded receptacle that is approved for hospital use and of

the correct voltage. DO NOT USE EXTENSION CORDS.

l

Use only with power cords supplied with the Warmer.

EXPLOSION PRECAUTIONS

l

Do not use in the presence of flammable anesthetics.

0

Confirm that the oxygen supply is turned off and that the equipment is disconnected from the oxygen

supply when performing cleaning and maintenance procedures; a fire and explosion hazard exists when

performing cleaning and/or maintenance procedures in an oxygen-enriched environment.

OXYGEN PRECAUTIONS

l

Improper use of supplemental oxygen may be associated with serious side effects including blindness,

brain damage, and death. The risks vary with each infant. The method, the concentration, and the dura-

tion of oxygen administration should be prescribed by the attending physician.

.

If it is necessary to

diately.

administer oxygen in an emergency, the attending physician should be notified imme-

NOTE:

See the current edition of “Guidelines for Perinatal

Care”of

the American Academy of Pediatrics/The

American College of Obstetricians and Gynecologists.

.

The oxygen concentration inspired by an infant does not predictably determine the partial pressure of

PO2

oxygen

(PO,) in the blood. When deemed advisable by the attending physician, blood

should be

measured by accepted clinical techniques.

.

Oxygen flow rates cannot be used as an accurate indication of oxygen concentrations. Oxygen concen-

trations should be measured with acalibrated oxygen analyzer at intervals directed by the attending phy-

sician.

.

Keep matches and all other sources of ignition out of the room in which the Warmer is located and keep

spark-producing equipment or any sources of ignition out of the Bassinet. Wood, textiles, oils, and other

combustibles are easily ignited and burn with great intensity in air enriched with oxygen.

.

Although oxygen compatible materials are used in the oxygen delivery system, special care must be tak-

en when high pressure oxygen such as found in a medical oxygen cylinder is used. Violent ignition of oil,

grease, greasy substances, small particles of dust, dirt or other particulate contaminants (even small

particles of metal), can occur in the presence of high pressure oxygen if their ignition temperature is

reached. An instantaneous increase in temperature can occur due to friction, particle acceleration, or

adiabatic compression, if the oxygen cylinder valve is opened too rapidly. SERIOUS INJURY MAY RE-

SULT! Always observe the following precautions:

-

Oil, grease, greasy substances, dust, dirt and other particulate contaminants must be kept away

from oxygen regulators, cylinder valves, tubing and all other oxygen equipment.

-

III

-

OPERATING PRECAUTIONS (Continued)

-

Always open oxygen cylinder shut-off valves very slowly and carefully.

-

On high pressure oxygen cylinders use only pressure regulators or reducing valves approved for

oxygen service. Do not use oxygen pressure regulators or reducing valves for air or gases other

than oxygen as they may be hazardous. Operate such devices in strict accordance with the

manufacturer’s recommendations.

-

When new or replacement oxygen cylinders are to be installed, they should have their outlet ports

cleared by cracking the cylinder valve momentarily before attachment to the equipment.

LOW FLOW MICROBLENDER WARNINGS

l

If either the air or oxygen gas source pressure is reduced or increased creating a pressure

differential of 30 psi, the microblender alarm will sound. This condition significantly alters the

FiO2

and flow output from the microblender.

l

Always operate the low flow microblender with clean/dry medical grade gases.

.

Air inlet water filters are recommended for use with the low flow microblender.

.

The level of oxygen and the partial pressure of oxygen within the patient’s blood

should be monitored.

(Pa02)

iv

--

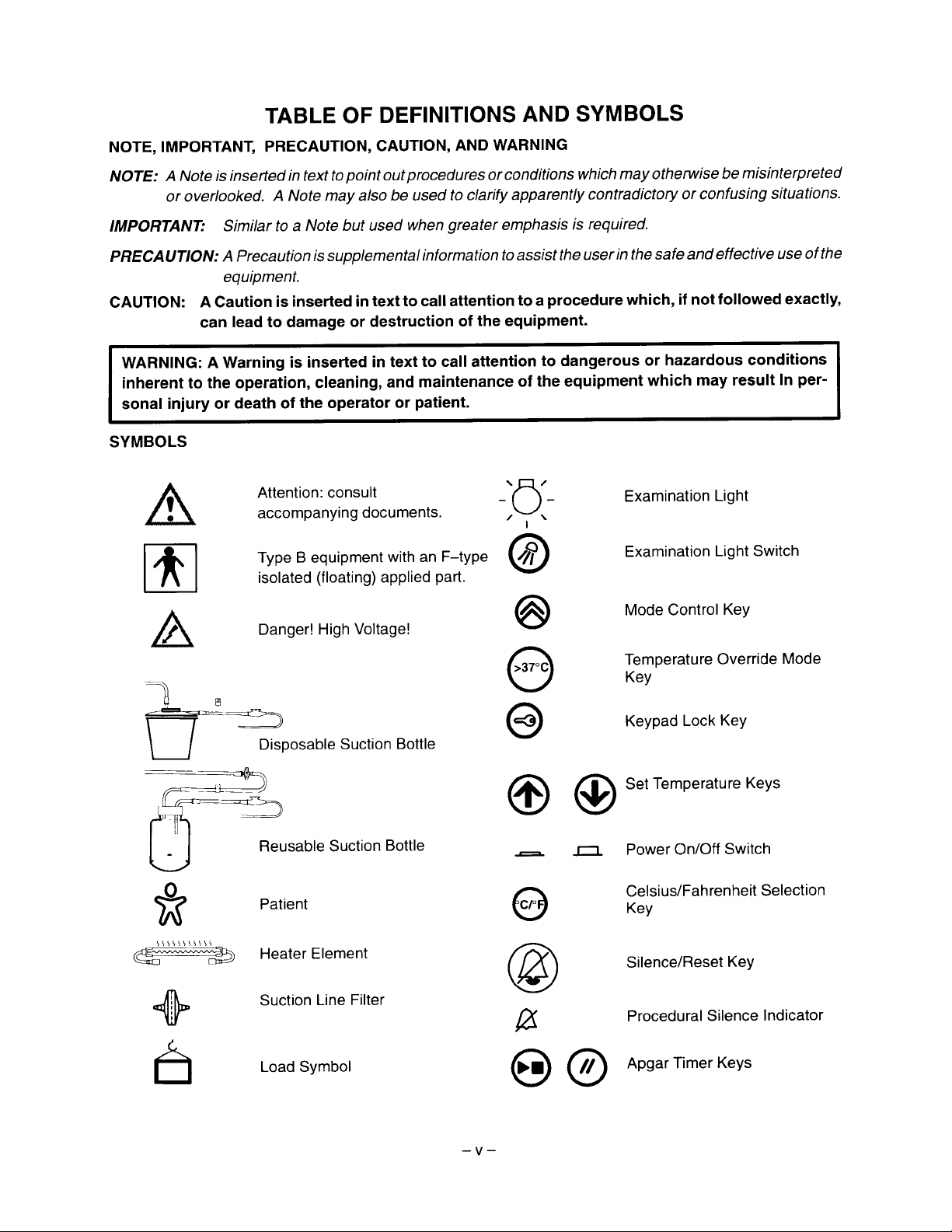

TABLE OF DEFINITIONS AND SYMBOLS

NOTE, IMPORTANT, PRECAUTION, CAUTION, AND WARNING

NOTE:

IMPORTANT

PRECAUTION: A Precaution is supplementalinformation

CAUTION:

SYMBOLS

A Note is inserted in text to point outprocedures or conditions which may otherwise be misinterpreted

or overlooked.

Similar to a Note but used when greater emphasis is required.

equipment.

A Caution is inserted in text to call attention to a procedure which, if not followed exactly,

can lead to damage or destruction of the equipment.

WARNING: A Warning is inserted in text to call attention to dangerous or hazardous conditions

inherent to the operation, cleaning, and maintenance of the equipment which may result In per-

sonal injury or death of the operator or patient.

A Note may also be used to clarify apparent/y contradictory or confusing situations.

user

in the safe and effective use of the

Examination Light

Examination Light Switch

Mode Control Key

Attention: consult

accompanying documents.

Type B equipment with an F-type

isolated (floating) applied part.

Danger! High Voltage!

to

assist the

/

\

-

o-

’

I ’

8

0

A

8

Disposable Suction Bottle

Reusable Suction Bottle

Patient

Heater Element

Suction Line Filter

Load Symbol

00

I

w@

Temperature Override Mode

Key

Keypad Lock Key

Set Temperature Keys

Power On/Off Switch

Celsius/Fahrenheit Selection

Key

Silence/Reset Key

Procedural Silence Indicator

Apgar Timer Keys

-V-

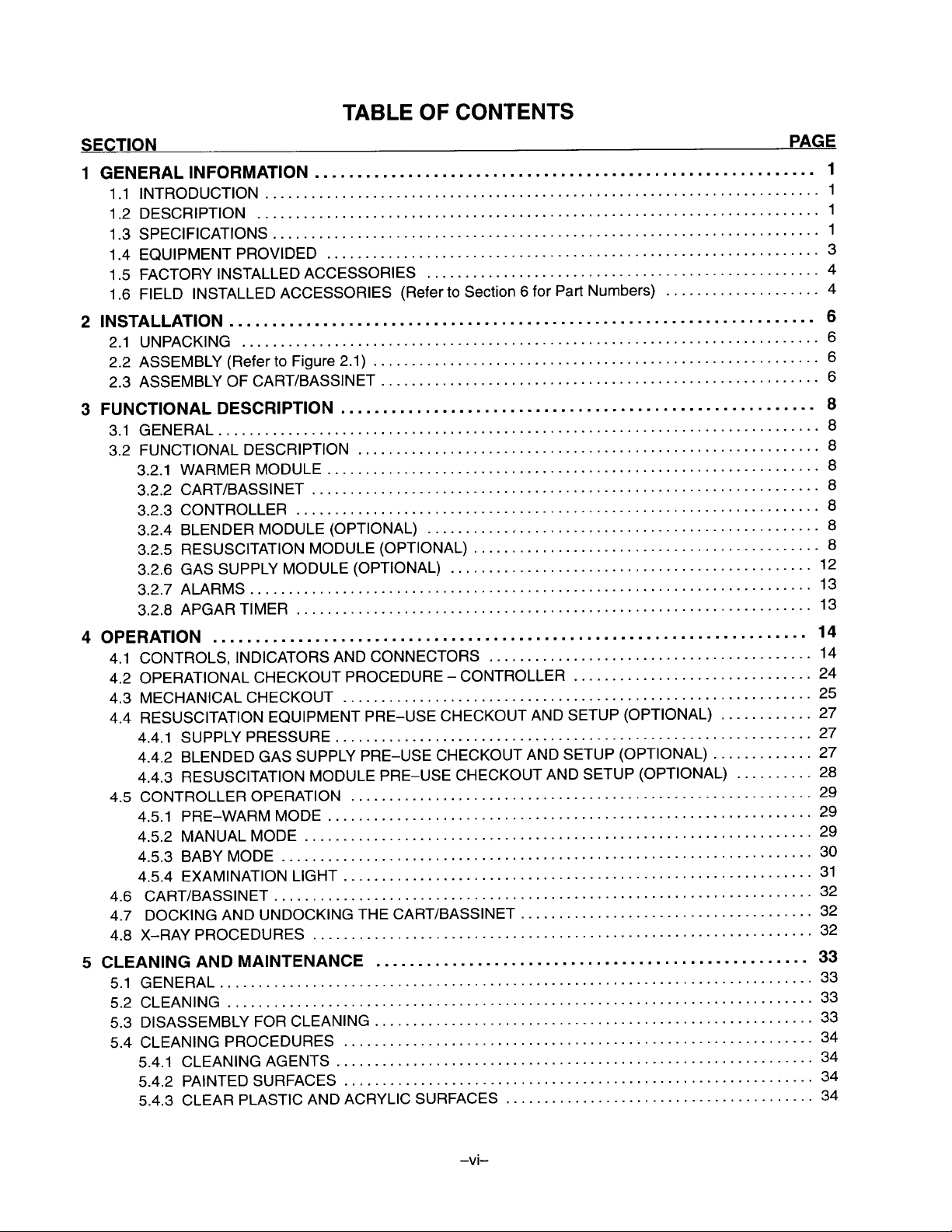

TABLE OF CONTENTS

SECTION

1

GENERALINFORMATION..

1.1

INTRODUCTION..

1.2 DESCRIPTION

1.3 SPECIFICATIONS

1.4 EQUIPMENTPROVIDED

1.5 FACTORY INSTALLED ACCESSORIES

1.6 FIELD INSTALLED ACCESSORIES (Refer to Section 6 for Part Numbers)

2 INSTALLATION .....................................................................

2.1

UNPACKING

2.2 ASSEMBLY (Refer to Figure 2.1)

2.3 ASSEMBLY OF CART/BASSINET

3 FUNCTIONAL DESCRIPTION

3.1 GENERAL ..............................................................................

3.2 FUNCTIONALDESCRIPTION

3.2.1 WARMERMODULE..

3.2.2 CART/BASSINET

3.2.3 CONTROLLER

3.2.4 BLENDER MODULE (OPTIONAL)

3.2.5 RESUSCITATION MODULE (OPTIONAL)

3.2.6 GAS SUPPLY MODULE (OPTIONAL)

3.2.7 ALARMS .........................................................................

APGARTIMER

3.2.8

4 OPERATION

4.1 CONTROLS, INDICATORS AND CONNECTORS

4.2 OPERATIONAL CHECKOUT PROCEDURE

4.3 MECHANICALCHECKOUT

4.4 RESUSCITATION EQUIPMENT PRE-USE CHECKOUT AND SETUP (OPTIONAL)

4.4.1 SUPPLYPRESSURE ..............................................................

4.4.2 BLENDED GAS SUPPLY PRE-USE CHECKOUT AND SETUP (OPTIONAL)

4.4.3 RESUSCITATION MODULE PRE-USE CHECKOUT AND SETUP (OPTIONAL)

4.5 CONTROLLEROPERATION

4.5.1

4.5.2 MANUALMODE

4.5.3

4.5.4 EXAMINATION LIGHT

4.6 CART/BASSINET ......................................................................

DOCKlNGANDUNDOCKlNGTHECART/BASSlNET

4.7

4.8 X-RAYPROCEDURES

CLEANINGANDMAINTENANCE

5

5.1 GENERAL .............................................................................

5.2 CLEANING

DISASSEMBLYFORCLEANING

5.3

5.4 CLEANINGPROCEDURES

5.4.1 CLEANING AGENTS..

5.4.2 PAINTEDSURFACES

54.3 CLEAR PLASTIC AND ACRYLIC SURFACES

......................................................................

PRE-WARMMODE

BABYMODE

............................................................................

......................................................................

.........................................................................

.......................................................................

...........................................................................

.....................................................................

.........................................................

................................................................

...................................................

..........................................................

.........................................................

........................................................

............................................................

..............................................................

..................................................................

....................................................................

....................................................

.............................................

...............................................

...................................................................

..........................................

-

CONTROLLER

.............................................................

............................................................

...............................................................

..................................................................

.............................................................

......................................

.................................................................

...................................................

.........................................................

.............................................................

............................................................

.............................................................

........................................

...............................

....................

............

.............

..........

PAGE

1

1

1

1

3

4

4

6

6

6

6

8

8

8

8

8

8

8

8

12

13

13

14

14

24

25

27

27

27

28

29

29

29

30

31

32

32

32

33

33

33

33

34

34

34

34

-vi-

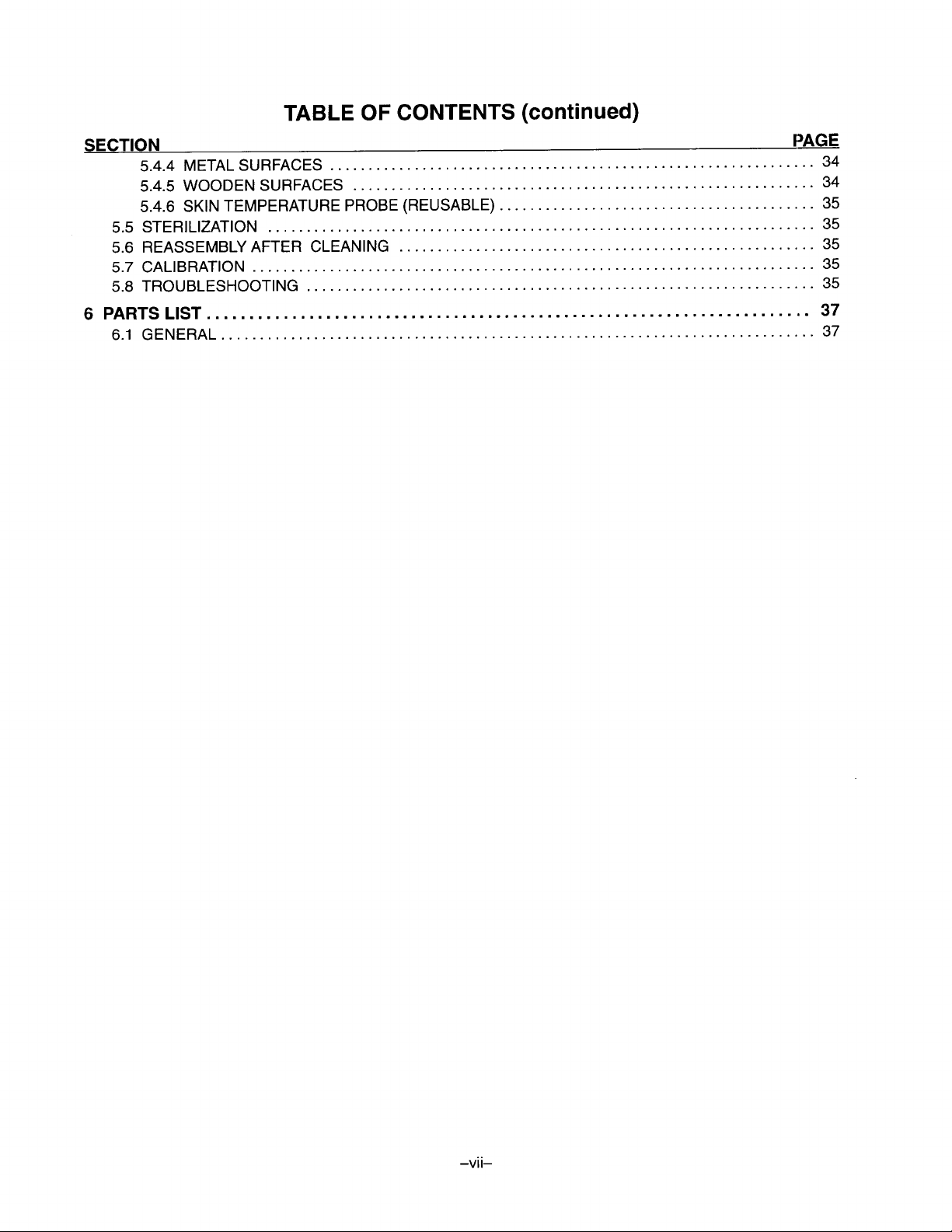

TABLE OF CONTENTS (continued)

SECTION

5.4.4 METAL SURFACES

5.4.5 WOODEN SURFACES

5.4.6 SKIN TEMPERATURE PROBE (REUSABLE)

5.5 STERILIZATION

5.6 REASSEMBLY AFTER CLEANING

5.7 CALIBRATION .........................................................................

5.8 TROUBLESHOOTING ..................................................................

6 PARTS LIST .......................................................................

6.1 GENERAL

.............................................................................

.......................................................................

...............................................................

............................................................

.........................................

......................................................

PAGE

34

34

35

35

35

35

35

37

37

-vii-

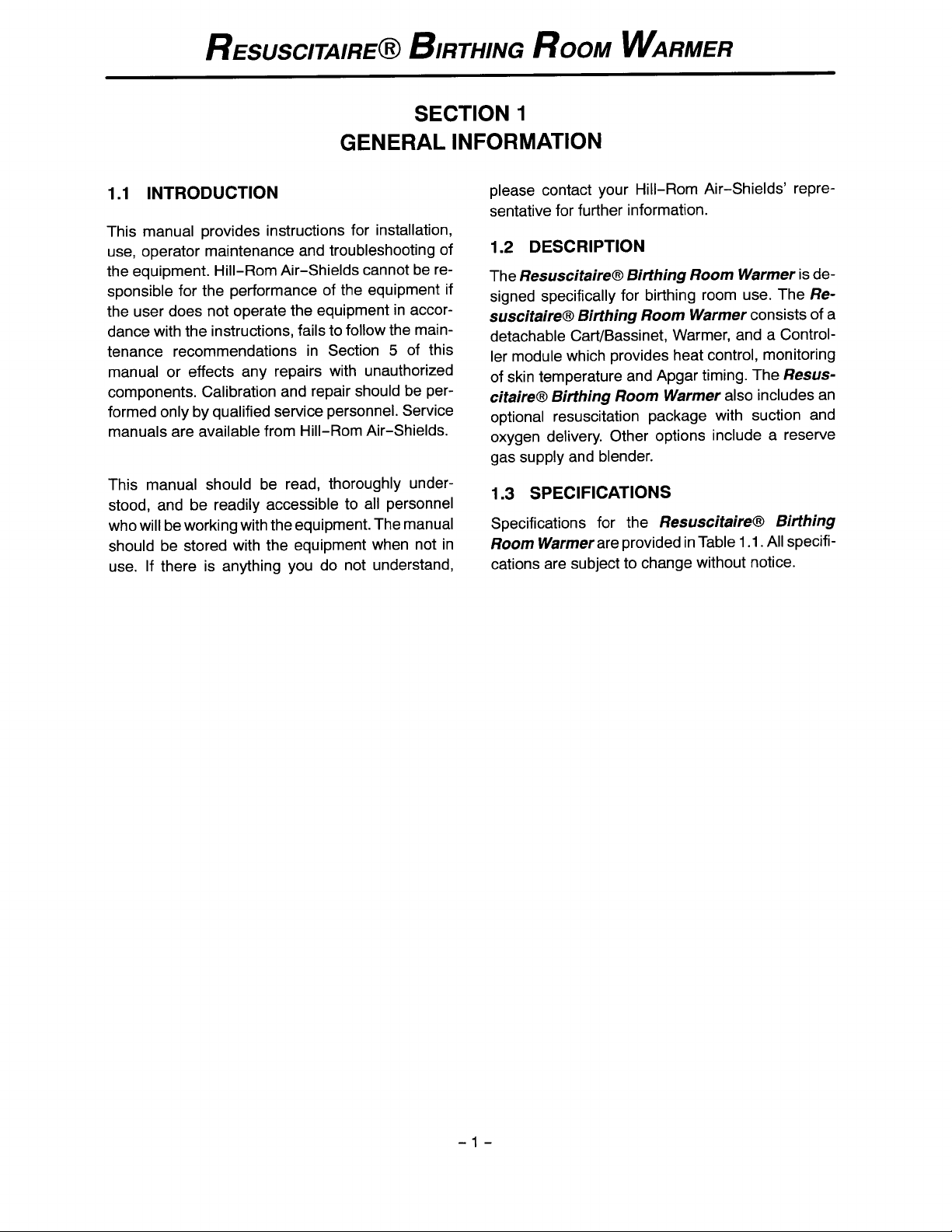

RESUSCITAIREB

B

IRTHING ROOM

SECTION 1

GENERAL INFORMATION

W

ARMER

.l

INTRODUCTION

1

This manual provides instructions for installation,

use, operator maintenance and troubleshooting of

the equipment. Hill-Rom Air-Shields cannot be re-

sponsible for the performance of the equipment if

the user does not operate the equipment in accor-

dance with the instructions, fails to follow the main-

tenance recommendations in Section 5 of this

manual or effects any repairs with unauthorized

components. Calibration and repair should be per-

formed only by qualified service personnel. Service

manuals are available from Hill-Rom Air-Shields.

This manual should be read, thoroughly under-

stood, and be readily accessible to all personnel

who will be working with the equipment. The manual

should be stored with the equipment when not in

use. If there is anything you do not understand,

please contact your Hill-Rom Air-Shields’ repre-

sentative for further information.

1.2 DESCRIPTION

ResuscitaireB

The

signed specifically for birthing room use. The

suscitaire8

detachable Cart/Bassinet, Warmer, and a Control-

ler module which provides heat control, monitoring

of skin temperature and Apgar timing. The

citaire8

optional resuscitation package with suction and

oxygen delivery. Other options include a reserve

gas supply and blender.

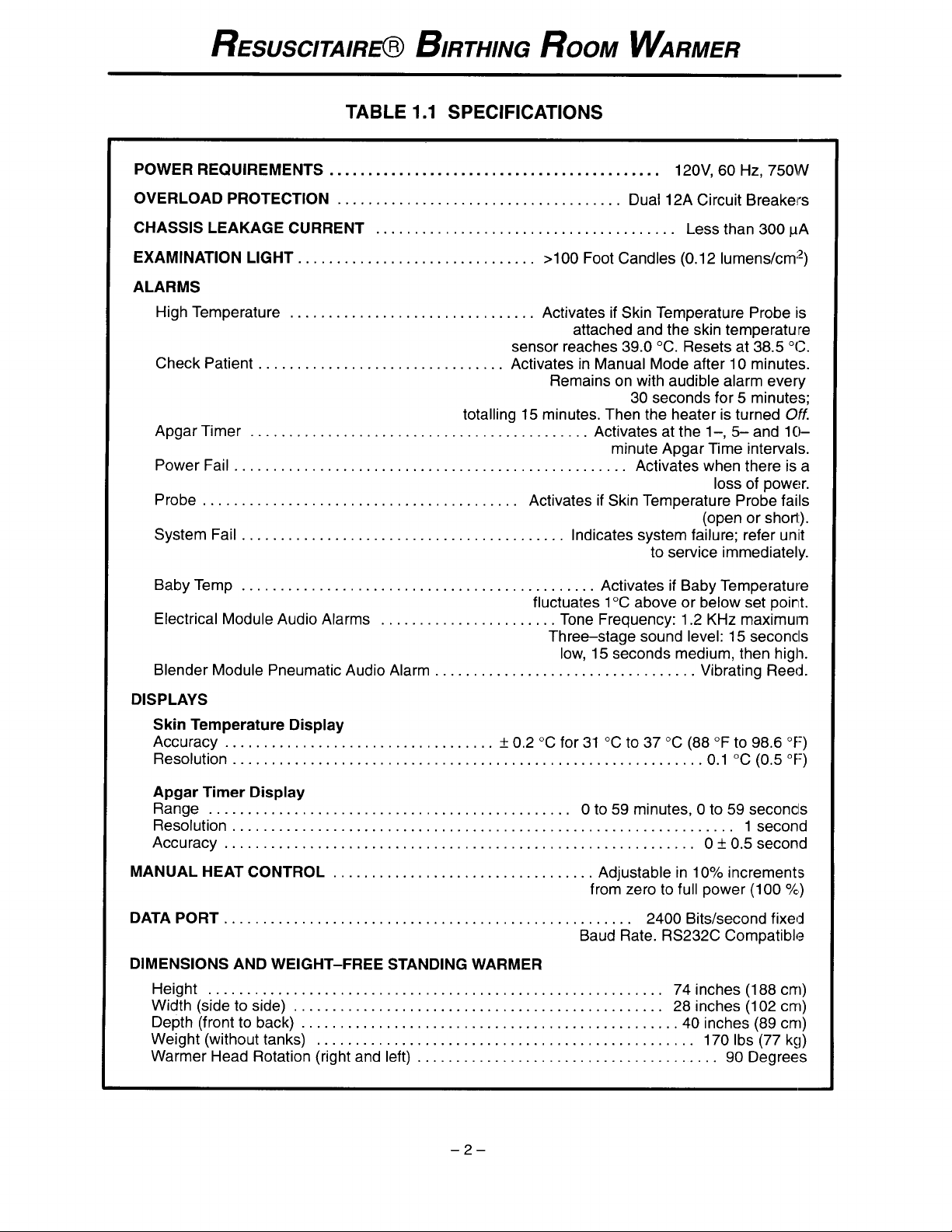

1.3 SPECIFICATIONS

Specifications for the

Room

cations are subject to change without notice.

Birthing Room Warmer consists of a

Birthing Room Warmer also includes an

Warmer are provided in Table 1

Birthing Room Warmer

Resus-

ResoscitaireB Birthing

.l

. All specifi-

is de-

Re-

-l-

RESUSCITAIREGI

B

IRTHING

TABLE 1.1 SPECIFICATIONS

R

OOM

W

ARMER

POWER REQUIREMENTS ...........................................

OVERLOAD PROTECTION

CHASSIS LEAKAGE CURRENT

EXAMINATION LIGHT.

ALARMS

High Temperature

Check Patient

Apgar Timer

Power Fail

Probe.. .......................................

SystemFail

BabyTemp ..............................................

Electrical Module Audio Alarms

Blender Module Pneumatic Audio Alarm

...................................................

..........................................

................................

................................

............................................

.....................................

.......................................

..............................

totalling 15 minutes. Then the heater is turned Off.

.......................

..................................

12OV,

60 Hz, 750W

12A

Dual

>lOO

Foot Candles (0.12

Activates if Skin Temperature Probe is

attached and the skin temperature

sensor reaches 39.0

Activates in Manual Mode after 10 minutes.

Remains on with audible alarm every

30 seconds for 5 minutes;

Activates at the l-,

minute Apgar Time intervals.

Activates when there is a

Activates if Skin Temperature Probe fails

Indicates system failure; refer unit

Activates if Baby Temperature

“C

fluctuates 1

Tone Frequency: 1.2 KHz maximum

Three-stage sound level: 15 seconcls

low, 15 seconds medium, then high.

above or below set

Circuit

Less than 300

“C.

Resets at 38.5

to service immediately.

Breakers

uA

lumens/cm:z)

“(3.

5-and

loss of power.

(open or short).

Vibrating Reed.

lo-

poirit.

DISPLAYS

Skin Temperature Display

Accuracy.. .................................

Resolution

Apgar Timer Display

Range

Resolution

Accuracy .............................................................

MANUAL HEAT CONTROL

DATA PORT

DIMENSIONS AND WEIGHT-FREE STANDING WARMER

Height

Width (side to side)

Depth (front to back)

Weight (without tanks)

Warmer Head Rotation (right and left)

.............................................................

...............................................

.................................................................

..................................

.....................................................

...........................................................

................................................

................................................

.................................................

....................................... 90 Degrees

-2-

f

0.2

“C

“C

“C

for 31

to 37

0 to 59 minutes, 0 to 59 seconcls

Adjustable in 10% increments

from zero to full power (100

Baud Rate.

(88

0.1

Of0.5second

2400 Bits/second fixed

RS232C

74 inches (188 cm)

28 inches (102 cm)

.40

inches (89 cm)

170 Ibs (77 kg)

“F to 98.6

“C

(0.5

lsecond

Compatible

“F)

“F)

%#)

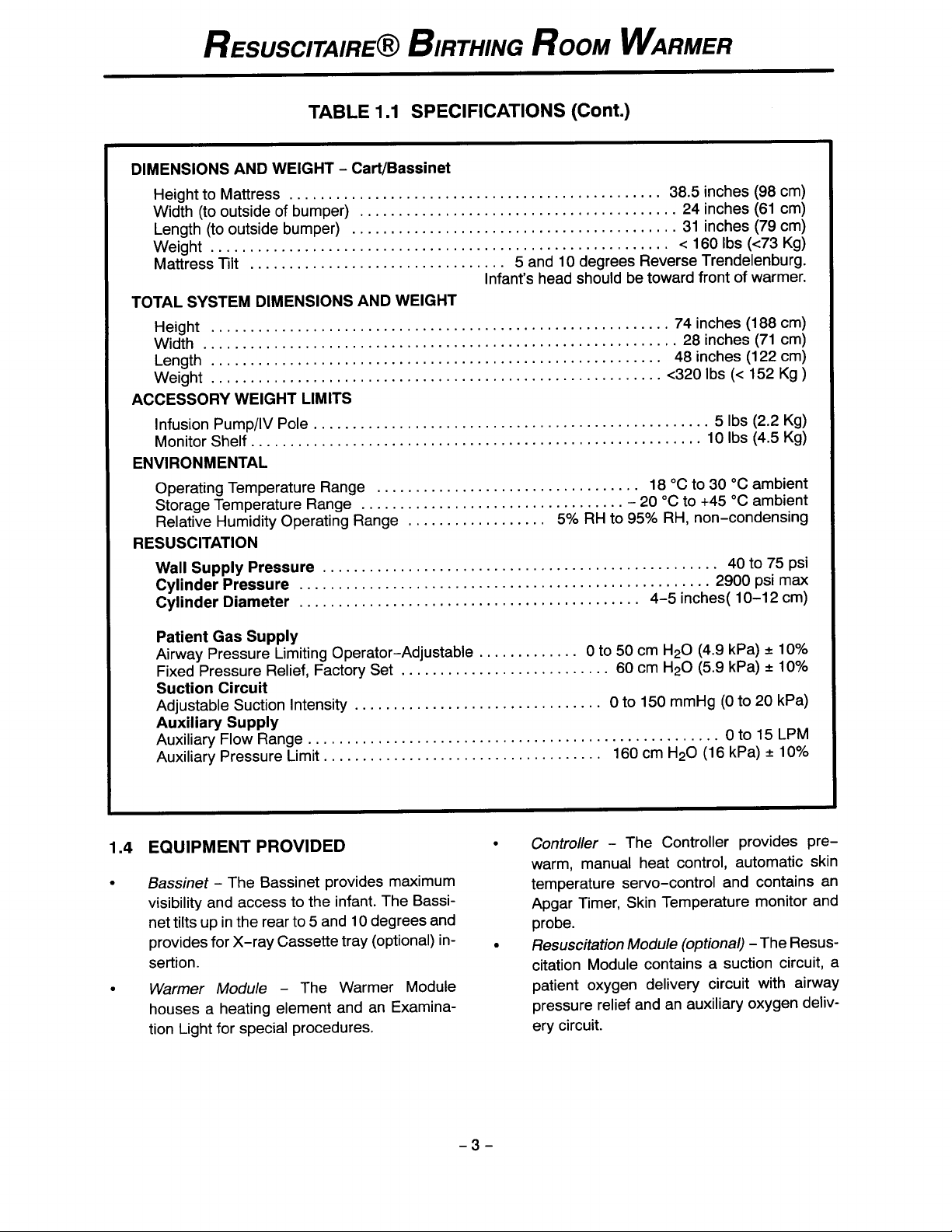

RESUSCITAIREGO

TABLE 1

DIMENSIONS AND WEIGHT

Height to Mattress

Width (to outside of bumper)

Length (to outside bumper)

Weight

MattressTilt

TOTAL SYSTEM DIMENSIONS AND WEIGHT

Height

Width

Length

Weight

ACCESSORY WEIGHT LIMITS

Infusion Pump/IV Pole

Monitor Shelf

ENVIRONMENTAL

Operating Temperature Range

Storage Temperature Range

Relative Humidity Operating Range

RESUSCITATION

Wall Supply Pressure

Cylinder Pressure

Cylinder Diameter

...........................................................

.........................................................

.............................................................

..........................................................

........................................................

................................................

.................................

...................................................

..........................................................

...................................................

.....................................................

............................................

B

IRTHING ROOM

.I

SPECIFICATIONS (Cont.)

-

Cart/Bassinet

.........................................

..........................................

..................................

..................................

..................

W

ARMER

38.5 inches (98 cm)

24 inches (61 cm)

31 inches (79 cm)

(c73

ambfent

ambient

“C

psi

Kg)

75

max

psi

c

160 Ibs

5 and 10 degrees Reverse Trendelenburg.

Infant’s head should be toward front of warmer.

..74inches(188cm)

28inches (71 cm)

48inches(122cm)

..c320Ibs(c152Kg

5 Ibs (2.2 Kg)

10 Ibs (4.5 Kg)

“C

to 30

18

“C

+45

“C

20

4-5

to

inches(

-

5% RH to 95% RH,

non-condensrng

40 to

2900

1 O-l 2 cm)

)

Patient Gas Supply

Airway Pressure Limiting Operator-Adjustable

Fixed Pressure Relief, Factory Set

Suction Circuit

Adjustable Suction Intensity

Auxiliary Supply

Auxiliary Flow Range

Auxiliary Pressure Limit

1.4 EQUIPMENT PROVIDED

.

Bassinet

visibility and access to the infant. The Bassi-

net tilts up in the rear to 5 and 10 degrees and

provides for X-ray Cassette tray (optional) in-

sertion.

.

Warmer Module

houses a heating element and an Examina-

tion Light for special procedures.

-

The Bassinet provides maximum

.....................................................

-

The Warmer Module

................................

....................................

..................................... ..

.

Controller

warm, manual heat control, automatic skin

temperature servo-control and contains an

Apgar Timer, Skin Temperature monitor and

probe.

.

Resuscitation Module (optional) -The Resus-

citation Module contains a suction circuit, a

patient oxygen delivery circuit with airway

pressure relief and an auxiliary oxygen deliv-

ery circuit.

0 to 50 cm

.

60 cm

0 to 150

160 cm

-

The Controller provides pre-

mmHg

kPa)

kPa)

(0 to 20

0 to 15 LPM

kPa)

+

Hz0 (4.9

2

Hz0 (5.9

-c

Hz0 (16

10%

10%

kPa)

10%

-3-

RESUSCITAIR~

1.5 FACTORY INSTALLED OPTIONS

.

Resuscitation Module

.

Integrated Precision Blender

.

Gas Supply Module

-

02 Pipeline and Cylinder

-

Oz/Air Pipeline and Cylinder

B

IRTHING

R

OOM

1.6

FIELD INSTALLED ACCESSORIES

(Refer to Section 6 for Part Numbers)

.

X-ray Cassette Tray

.

Air Hose Assembly

.

Oxygen Hose Assembly

.

Monitor Shelf

.

I.V.

Pole

.

Drawer Organizer

W

ARMER

-4-

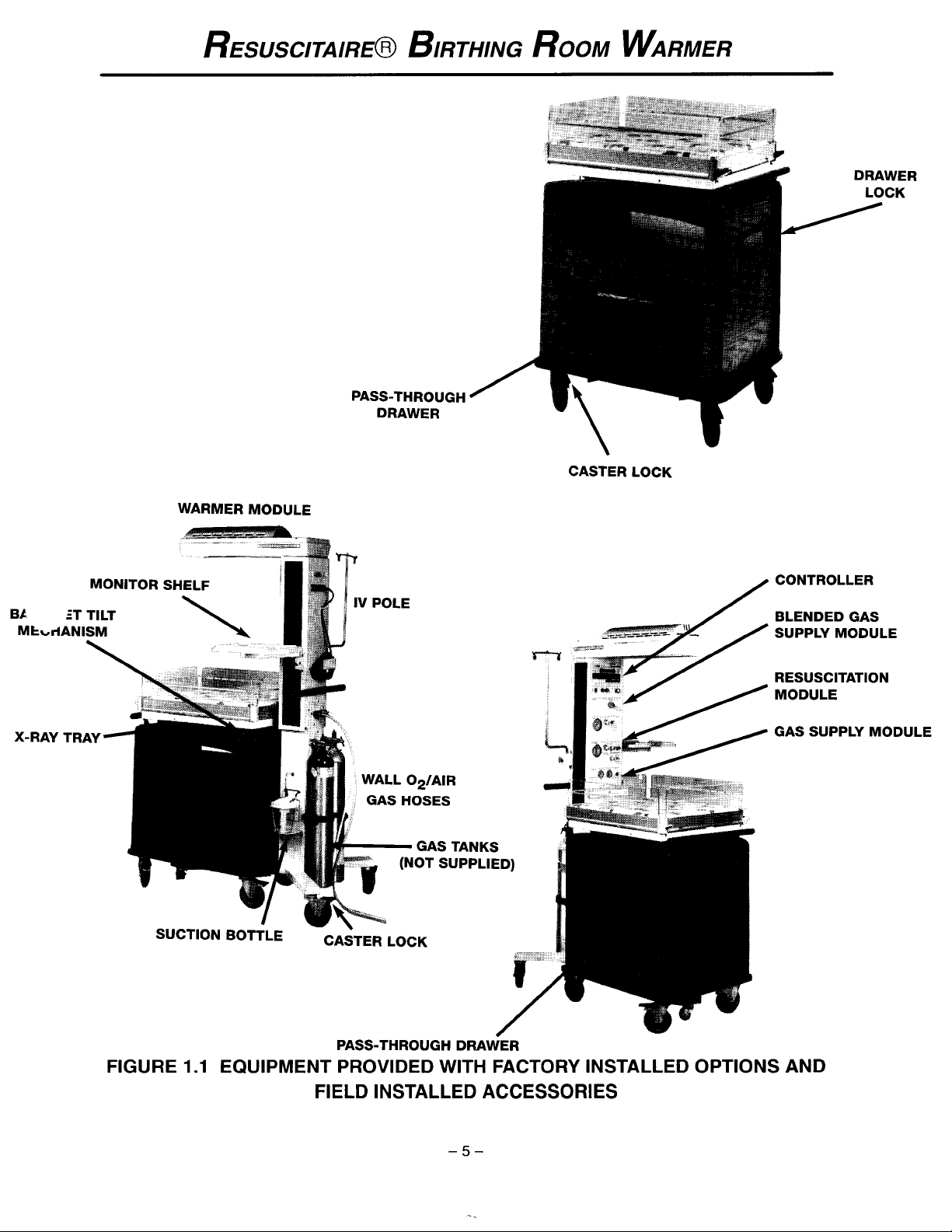

RESUSCITAIREB

B

IRTHING ROOM

PASS-THROUGH

DRAWER

W

ARMER

CASTER LOCK

DRAWER

LOCK

MONITOR SHELF

3c.

MtwiANISM

X-RAY TRAY

iT

TILT

\

WARMER MODULE

CONTROLLER

/

4

02/AIR

WALL

GAS HOSES

SUCTION BOTTLE

-

CAiTER

GAS TANKS

(NOT SUPPLIED)

LOCK

BLENDED GAS

SUPPLY MODULE

RESUSCITATION

GAS SUPPLY MODULE

FIGURE 1

PASS-THROUGH DRAWER

.I

EQUIPMENT PROVIDED WITH FACTORY INSTALLED OPTIONS AND

FIELD INSTALLED ACCESSORIES

-5-

RESUSCITAIREGQ

B

IRTHING

SECTION 2

INSTALLATION

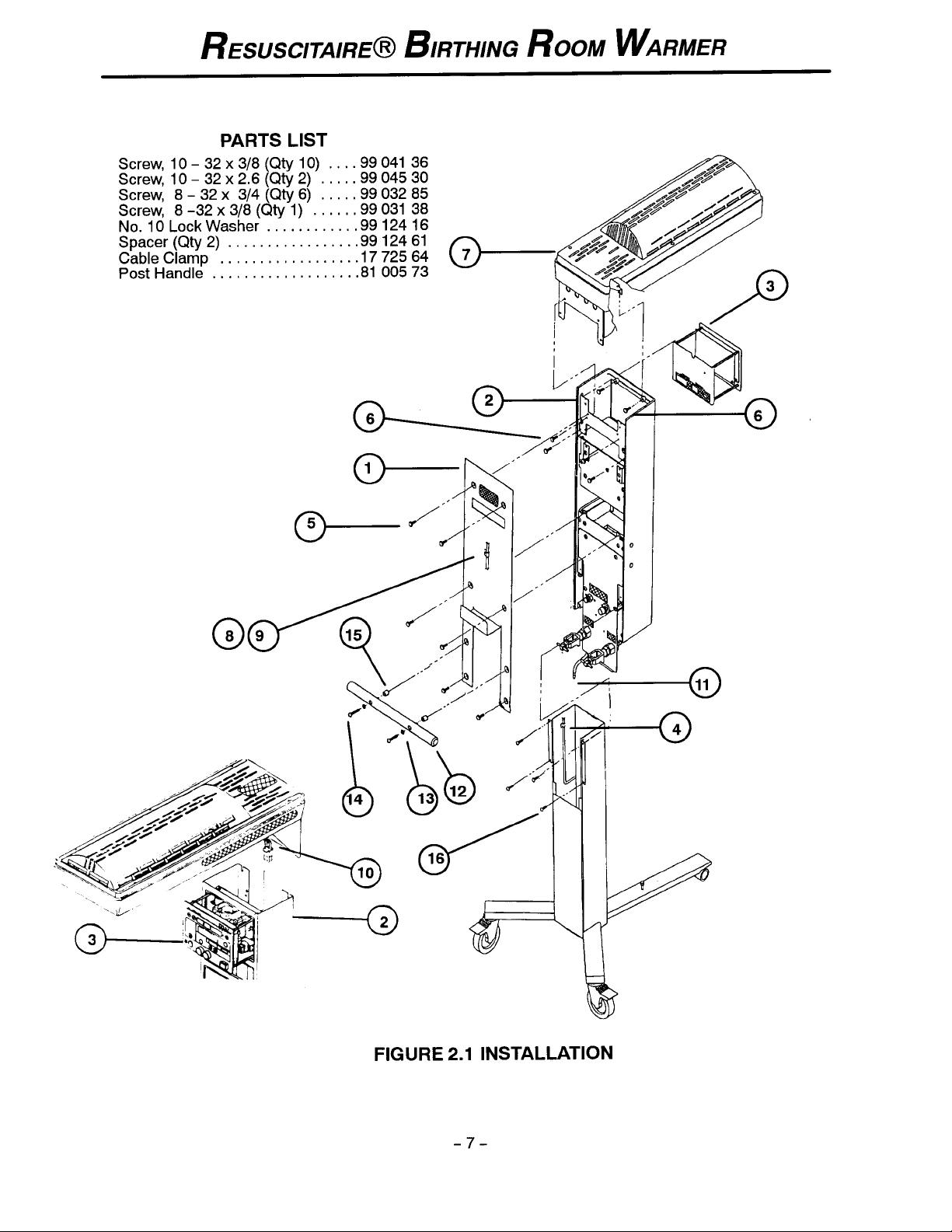

2.1 UNPACKING

The

ResuscitaireB Birthing Room Warmer is

shipped in two cartons. One carton contains the fol-

lowing assemblies:

.

Upper Post Assembly

.

Lower Post Assembly

.

Warmer Module Assembly

.

Post Handle

.

Any user installed Accessories that were or-

dered

The other carton contains the Cart/Bassinet.

2.2

ASSEMBLY OF THE WARMER (RE-

FER TO FIGURE 2.1)

When removing the equipment from the carton, use

care not to scratch or otherwise damage unpro-

tected surfaces; remove all packing material.

NOTE: If a Monitor Shelf is to be installed on the

unit, refer to the instructions provided with

the Monitor Shelf and install the weights

provided with these accessories in the bot-

tom of the Lower Post.

1.

REMOVE THE CONTROLLER (3) from the

Upper Post (2).

CAUTION: Two persons of sufficient strength

are required when performing Steps

3 through 6.

2.

REST THE UPPER POST (2) on top of the

Lower Post opening.

CONNECT THE SUCTION HOSE (4) to the

3.

Suction Hose (11). Release the joined Suction

Hoses from the Neat Clip inside the Lower Col-

umn.

4.

MOUNT THE UPPER POST (2) on the Lower

3/8

-

Post using four 10

provided.

5.

INSTALL TWO 10

(6) IN THE UPPER HOLES OF THE UPPER

POST. Do not tighten the screws.

RAISE THE WARMER (7) above the open end

6.

of the Upper Post (2) and insert the Power

Cable (10) into the open end of the column.

32 x

-

32 X

inch screws (16)

3/8

INCH SCREWS

R

OOM

7.

SLOWLY LOWER THE WARMER (7)

Upper Post. Tighten the upper screws and

install the remaining four 10

screws (6).

THREAD THE WARMER POWER CABLE

8.

out through the Controller opening. Connect

the Power Cable (10) to connector J4 on the

Controller (3).

REMOUNTTHE CONTROLLER on the Upper

9.

Post.

MOUNT THE BACK COVER (1) on the Upper

10

Column using the six 8

screws (5).

MOUNT THE HANDLE (12) on the Post using

11.

the two 10

Screws, No. 10 Lock Washers and Spacers

(14 1

(13

CONNECT THE LINE CORD to the Power

12.

Connector on the rear of the Controller (refer to

Figure 4.2).

SECURE THE LINE CORD to the Back Cover

13.

(1) using the Cable Clamp (8) and 8

screw (9).

CAUTION: Securing the Line Cord to the Back

14.

INSTALL ANY ACCESSORIES that were or-

dered using the installation instructions pro-

vided with the accessory.

2.3

ASSEMBLY OF THE CART/BASSINET

1.

Refer to Paragraph 5.6, Step 4, and install the

Rear and Side Panels. Raise the Front Panel

from its storage slot and lock it in place.

2.

ENGAGE THE CART/BASSINET TO THE

WARMER by pushing the Cart/Bassinet

straight onto the Warmer until it latches. Pull on

the Cart/Bassinet to ensure that it is latched

properly.

To disengage the Cart/Bassinet from the

Warmer, push and hold the release switch

(Figure 4.14) and pull the Cart/Bassinet away

from the Warmer.

W

ARMER

onto the

3/8

-

32 x

32 x

3/4

-

-

32 x 2.6 inch Phillips Head

).

(15 1

Panel is required to prevent removal

of the Controller chassis with the ac

power applied.

inch

painted

-

32 x

3/8

-6

RESUSCITAIREB

PARTS LIST

Screw,

Screw, 10

Screw, 8

Screw, 8 -32 x

No.iOLockWasher

Spacer (Qty 2) . . . . . . . . . . . . . . . .

Cable Clamp

Post Handle

lo-32~3/8(QtylO)

-

32 x 2.6 (Qty 2) . . . .

3/4

-

32 x

(Qty 6) . . . .

3/8

(Qty 1) . . . . .

. . . . . . . . . . . . 9912416

...99041

.

. : 1: : : : : : : : 1: : : : : .

B

.99

045 30

.99

032 85

.99

031 38

.99 124 61

..1772564

.81

005 73

IRTHING

36

R

OOM

W

ARMER

FIGURE 2.1 INSTALLATION

-7-

Loading...

Loading...