HIKVISION EURO 280 Installation Manual

(EC)

EURO 280

Installation Manual

Security Grade (SG) 3

Environment Class

II

For Castle/Pyronix Technical Support please call:

08456 434 999 (local rate) or:

01709 535 225

or visit:

www.pyronix.com

When calling Technical Support, please have ready

your software version number. This will enable the

correct advice to be given for your panel and can be

found in the engineer menu under ‘software

revisions’.

RINS1862-5

(Different case sizes available)

For use with EURO 280 software: Version 9.51 or

above

EURO 280 Installation Manual

Contents Page

1. System Overview ......................................................................................................................................................................................................... 3

1.1 System Overview ................................................................................................................................................................................................... 3

1.2 The Devices ............................................................................................................................................................................................................ 4

1.3 EURO 280 Input Mapping Table: ........................................................................................................................................................................... 6

1.4 EURO 280 Output Mapping Table:......................................................................................................................................................................... 7

2. Installation ................................................................................................................................................................................................................... 8

The Printed Circuit Board ................................................................................................................................................................................................. 9

2.3 Technical Specification ........................................................................................................................................................................................ 10

2.1 Important Installation Notes ............................................................................................................................................................................... 11

2.2 Communication ATE Loom .................................................................................................................................................................................. 12

2.3 Battery Connection .............................................................................................................................................................................................. 12

2.4 AC Mains Supply Connection ............................................................................................................................................................................... 12

2.5 Engineer Keypad Connection ............................................................................................................................................................................... 13

3. Input Connections ...................................................................................................................................................................................................... 14

3.1 Default Grade 2 DEOL (Double End of Line) Input Wiring .................................................................................................................................... 15

3.2 Grade 3 Mask/Fault Input Wiring ........................................................................................................................................................................ 15

4. Output (PGM) Connections ........................................................................................................................................................................................ 16

4.1 Negative Applied Wiring ...................................................................................................................................................................................... 16

4.2 Positive Applied Wiring ........................................................................................................................................................................................ 16

5. External Sounder Connections ................................................................................................................................................................................... 17

5.1 Grade 3 External Sounder Wiring ........................................................................................................................................................................ 17

5.2 Grade 2 External Sounder Wiring with a Grade 3 Bell ......................................................................................................................................... 17

5.3 Grade 2 External Sounder Wiring ........................................................................................................................................................................ 18

6. Connecting the EURO Peripherals .............................................................................................................................................................................. 19

6.1 Connecting the LCD Keypad (EURO-LCDPZ) ......................................................................................................................................................... 19

6.2 Connecting the Internal Tag Reader (EURO-PROXI – EUR-107) ........................................................................................................................... 22

6.3 Connecting the External Proximity Reader (EURO-PROXE - EURO-108X) ............................................................................................................ 24

6.4 Connecting the Zone Expander Module (EURO-ZEM8) ....................................................................................................................................... 27

6.5 Connecting the Zone Expander Module with 4 PGMs (EURO-ZEM8+) ................................................................................................................ 30

6.6 Connecting the Zone Expander Module with PSU (EURO-ZEM8+PSU) ................................................................................................................ 34

6.7 Connecting the Enforcer Wireless Zone Expander Module (EURO-ZEM32-WE) .................................................................................................. 38

6.8 Connecting the Output Expander Module (EURO-OEM8R8T) ............................................................................................................................. 40

6.9 Connecting the Output Expander Module with PSU (EURO-OEM16R+PSU) ....................................................................................................... 42

7. The Inovonics Radio Expander ................................................................................................................................................................................... 44

7.1 The Inovonics Radio Expander ............................................................................................................................................................................. 44

7.2 The Inovonics Radio PIR ....................................................................................................................................................................................... 44

7.3 Addressing the Radio Expander ........................................................................................................................................................................... 44

7.4 Assigning Radio Detectors ................................................................................................................................................................................... 45

7.5 Deleting Radio Detectors ..................................................................................................................................................................................... 45

7.6 Display the Signal Strength ............................................................................................... ................................................................................... 45

7.7 Assigning Repeaters to the Expander .................................................................................................................................................................. 45

7.8 Supervision Time ................................................................................................................................................................................................. 45

7.9 Problem Solving ................................................................................................................................................................................................... 46

7.10 Technical Specification ...................................................................................................................................................................................... 46

8. The PSTN Modem ...................................................................................................................................................................................................... 47

9. The RS232 Module ........................................................................................................... .......................................................................................... 49

9.1 Connecting to the Upload/Download Software .................................................................................................................................................. 50

10. Access Levels ............................................................................................................................................................................................................ 51

Default User Code: 1234

Default Master Manager: 2222

Default Engineer Code: 1111

Page: 2

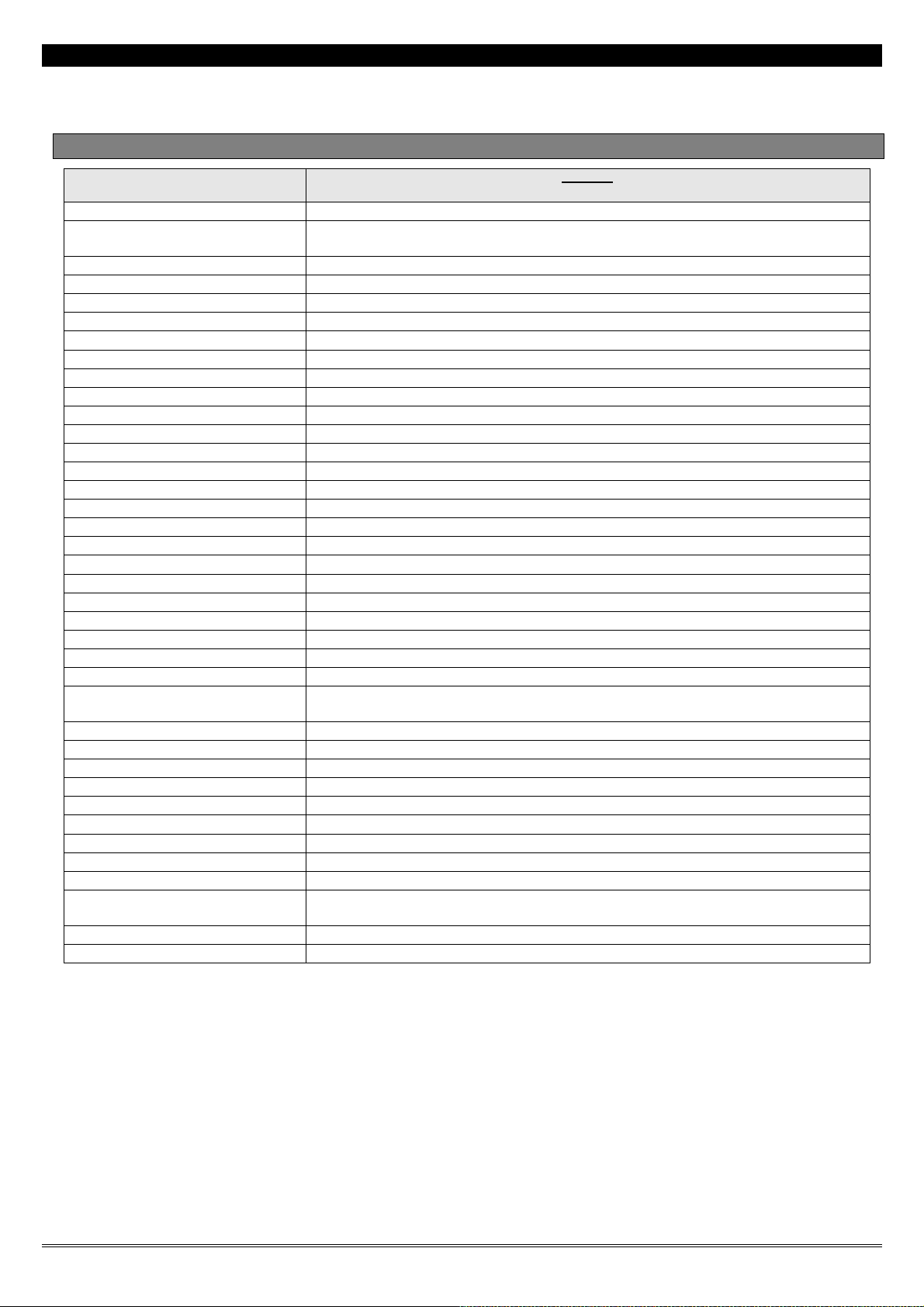

1. System Overview

The EURO 280 is a wired control panel that can have a maximum of 280 inputs. It is also compatible with Two-Way

Enforcer wireless peripherals using the EURO-ZEM32-WE (wireless expander).

1.1 System Overview

PANEL: EURO 280

End of Line

Inputs (max) 280

Inputs (max wireless inputs)

Using EURO-ZEM32-WE

Inputs (max wired ZEMs) 30

Set Points (Max) $ 30

Of which max keypads 16

Other Devices Max $ 29

Wireless Arming Stations 4*

Wireless Bells 2*

Level Sets 14

Full Areas 14

Wards (Max) 29

Shunts 140

Wireless Keyfobs 32*

User / Manager Codes £ 500

Duress / Guard Codes 20

Logs Mandatory 1000

Logs Access 500

Logs Optional 600

Output Modules 16

EN Grade 2 (Smaller case) or 3 (Larger case)

Environment Class II

Comms Modem, ATE Pins, ARM®

Modem Type PSTN-MODEM

Modem card compatible

Autoset & Gates

Shunt, Day Alarm, Unset Input Types

Follow Input

Special Log

Intelligent Inputs Multiple

Display when Set

Selectable Resistance Ranges

Download When Set

Remote Set and Soak

Event Signalling to Insite

Dial Out Menu Test Dial / ARM Service / Upload / Download / Diagnostics / Commission

Power Supply

£ Plus engineer and master manager codes

$ Includes keypads and tag readers

Grade 1: 2.25A / Grade 2: 1.4A / Grade 3: 0.9A

96

(3 x ZEM32-WE)

3.4A.

* Requires 1 x ZEM32-WE added to Euro 280

Page: 3

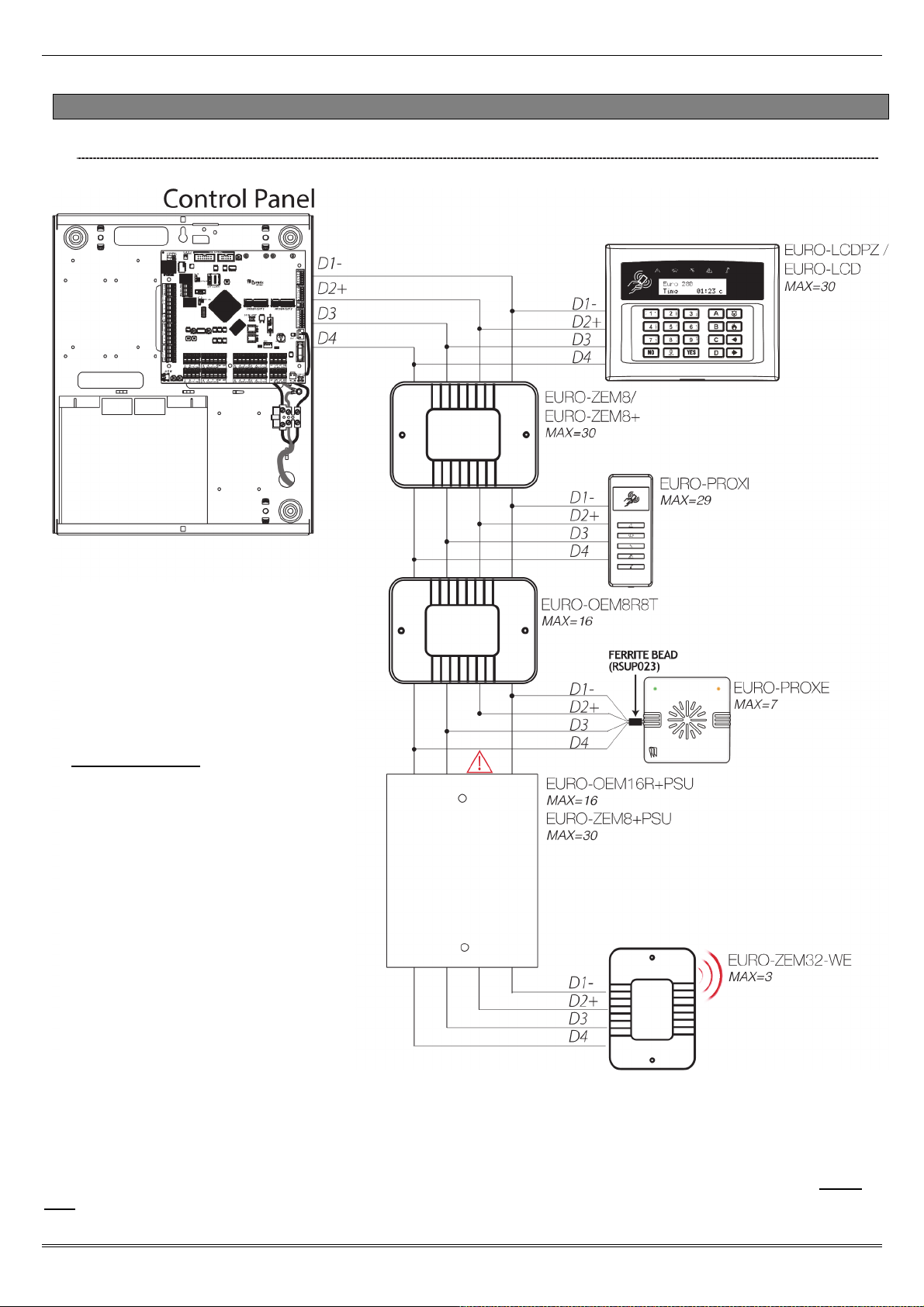

1.2 The Devices

1.2.1 The EURO 280 Bus Diagram

EURO 280 Installation Manual

All EURO peripherals; LCD keypads,

readers, expanders etc. are connected

via the D1-, D2+, D3 and D4 terminals.

This is an example of what a typical

Euro 280 bus may look like.

General Principles:

NOTE 1: No alarm system cable should

be run with other cables carrying AC or

digital signals.

NOTE 2: The cables should be

protected by the use of grommets

where appropriate.

NOTE 3: For greater than 1000m range

standard isolated RS485 repeaters are

required.

NOTE 4: There MUST be a ferrite bead

fitted to the data wires of a EUROPROXE (if connected). The Ferrite bead

is supplied with the reader.

NOTE 5: (IMPORTANT!) If an expansion module with a power supply on board is connected, the D2+ terminal MUST

NOT be connected between the main bus and module.

Page: 4

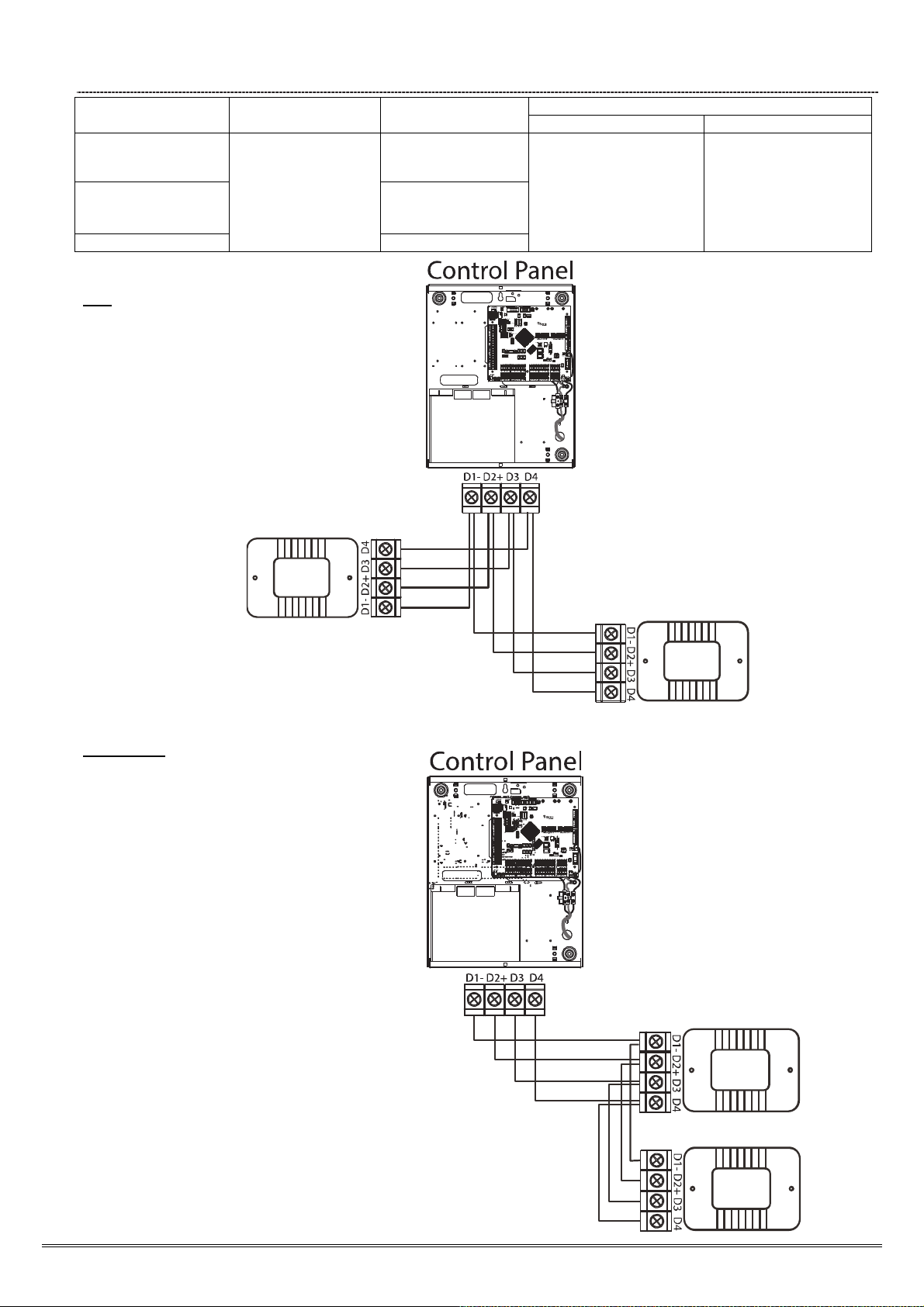

1.2.2 RS-485 Wiring

Cable type Screened Cable Bus range (m)

4 core alarm cable

6 core alarm cable

doubling D1 (0V) and

D2 (12V)

Twisted pair 1000m

Use when bus

located near

230VAC mains

power line

Star Wiring

Diagram

(Example #1)

Wiring Format

Daisy Chain Range Star Range

300m

1km 50m

1000m

Daisy Chain Wiring

Diagram

(Example #2)

Page: 5

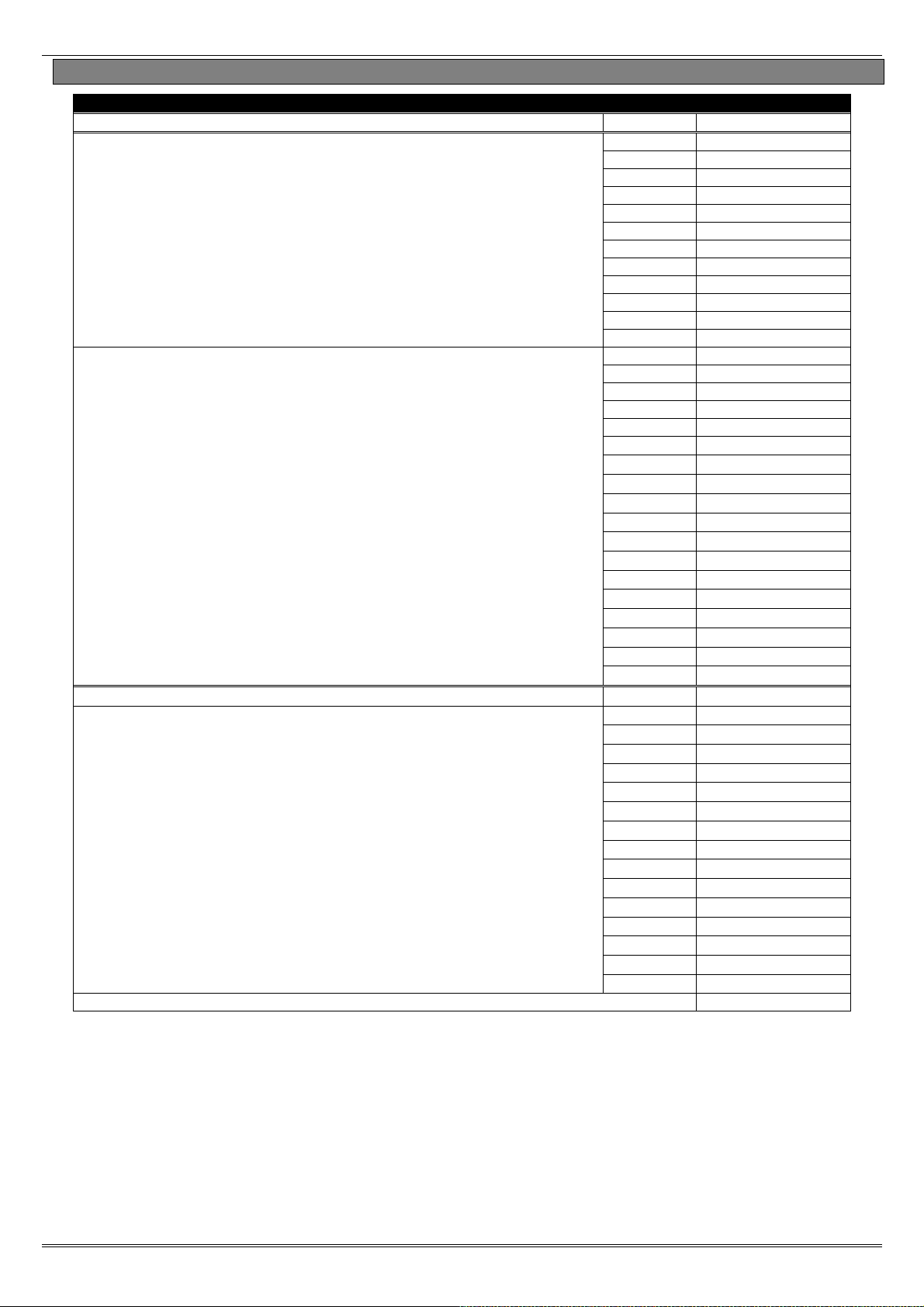

EURO 280 Installation Manual

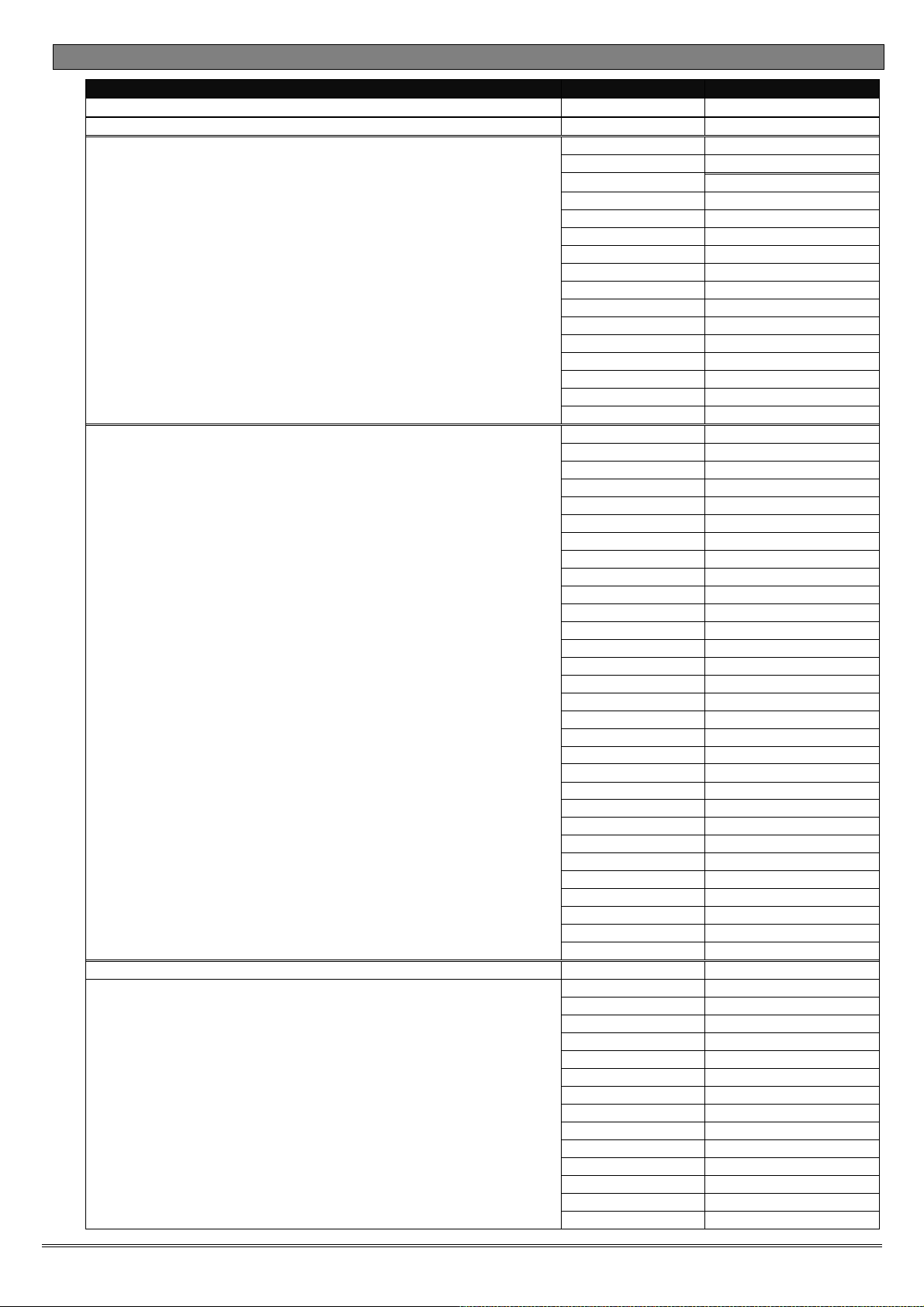

1.3 EURO 280 Input Mapping Table:

DEVICES Address Input Numbers

EURO 280 PCB PCB 1-8

0 9-16

1 17-24

2 25-32

3 33-40

4 41-48

EURO-ZEM8 / EURO-ZEM8+ / EURO-ZEM8+PSU / EURO-ZEM32-WE

EURO-ZEM8 / EURO-ZEM8+ / EURO-ZEM8+PSU

EURO-LCDPZ 0

EURO-LCDPZ / EURO-PROXI*

Total 280

5 49-56

6 57-64

7 65-72

8 73-80

9 81-88

10 89-96

11 97-104

12 105-112

13 113-120

14 121-128

15 129-136

16 137-144

17

18

19

20

21

22

23

24

25

26

27

28

29

1

2 253-254

3 255-256

4 257-258

5 259-260

6 261-262

7 263-264

8 265-266

9 267-268

10 269-270

11 271-272

12 273-274

13 275-276

14 277-278

15 279-280

145-152

153-160

161-168

169-176

177-184

185-192

193-200

201-208

209-216

217-224

225-232

233-240

241-248

249-250

251-252

NOTE 1: 3 x EURO-ZEM32-WE can be connected to the EURO 280. This expander allows 32 inputs which are

separated into 4 addresses (each address enables 8 wireless inputs). It is possible to mix the wired and wireless

remote expanders. When installing a EURO-ZEM32-WE, the first wireless expander will learn the 32 wireless

keyfobs and 2 wireless sounders. If this expander is disconnected, the keyfobs and sounders will need to be

learnt on another expander again.

*NOTE 2: If the EURO-PROXI (Internal Tag Reader) is programmed as a 'Set/Unset' device, 2 inputs can be

programmed. If the EURO-PROXI is programmed as 'Entry Control' or 'Access Control' only 1 input can be

programmed.

Page: 6

1.4 EURO 280 Output Mapping Table:

DEVICES Address Output Numbers

EURO 280 PCB PCB 4

ATE Outputs (using communication ribbon) Ribbon 9

0 1-16

1 1-16

2 1-16

3 1-16

4 1-16

5 1-16

6 1-16

EURO-OEM8R8T / EURO-OEM16R+PSU

EURO-ZEM8+ / EURO-ZEM8+PSU

EURO-LCDPZ 0 1

EURO-LCDPZ / EURO PROXI / EURO PROXE

(Continued overleaf)

7 1-16

8 1-16

9 1-16

10 1-16

11 1-16

12 1-16

13 1-16

14 1-16

15 1-16

0 1-4

1 1-4

2 1-4

3 1-4

4 1-4

5 1-4

6 1-4

7 1-4

8 1-4

9 1-4

10 1-4

11 1-4

12 1-4

13 1-4

14 1-4

15 1-4

16 1-4

17 1-4

18 1-4

19 1-4

20 1-4

21 1-4

22 1-4

23 1-4

24 1-4

25 1-4

26 1-4

27 1-4

28 1-4

29 1-4

1 1

2 1

3 1

4 1

5 1

6 1

7 1

8 1

9 1

10 1

11 1

12 1

13 1

14 1

Page: 7

EURO 280 Installation Manual

15 1

16 1

17 1

18 1

19 1

20 1

21 1

22 1

23 1

24 1

25 1

26 1

27 1

28 1

29 1

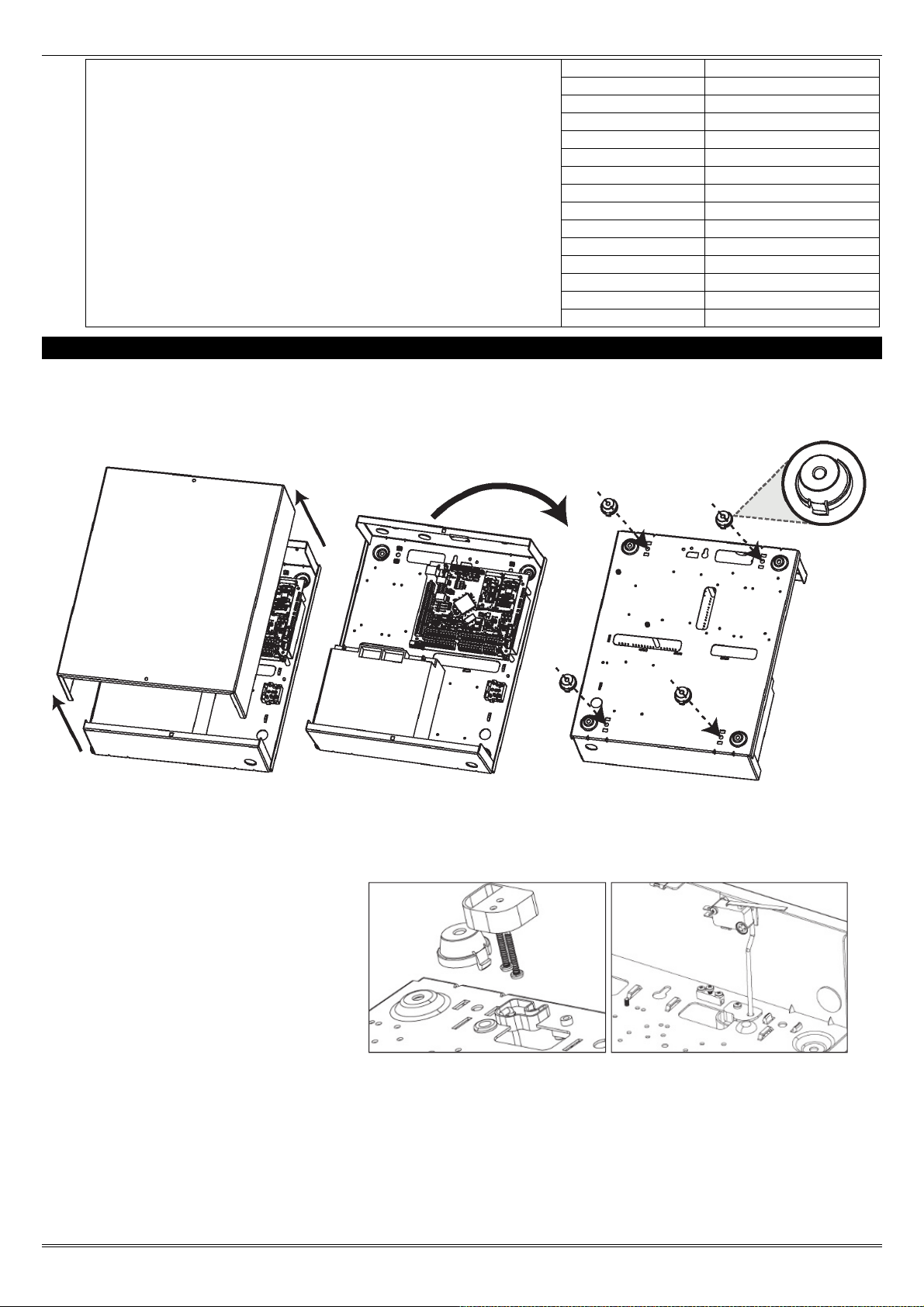

2. Installation

1. Unscrew and remove the cover of the EURO 280 control panel (Figure 1).

2. Install the supplied stand offs if needed before you mount the metal case to the wall (Figure 3).

Figure 1. Figure 2. Figure 3.

3. Screw the back metal plate to the wall.

4. The tamper mechanism comes

already fitted and will operate

properly once the casing is fitted

to the wall. If using the stand offs,

the following will need to be used

for the rear tamper mechanism

to work correctly.

5. If required, connect any other

devices (input expanders, output expanders etc.) before powering up the system.

6. The modem is already connected and will need the telephone line connecting. See page 48.

7. Secure all the wires and close the enclosure making sure the tamper is operational

8. Turn on the power to the EURO 280 control panel.

Page: 8

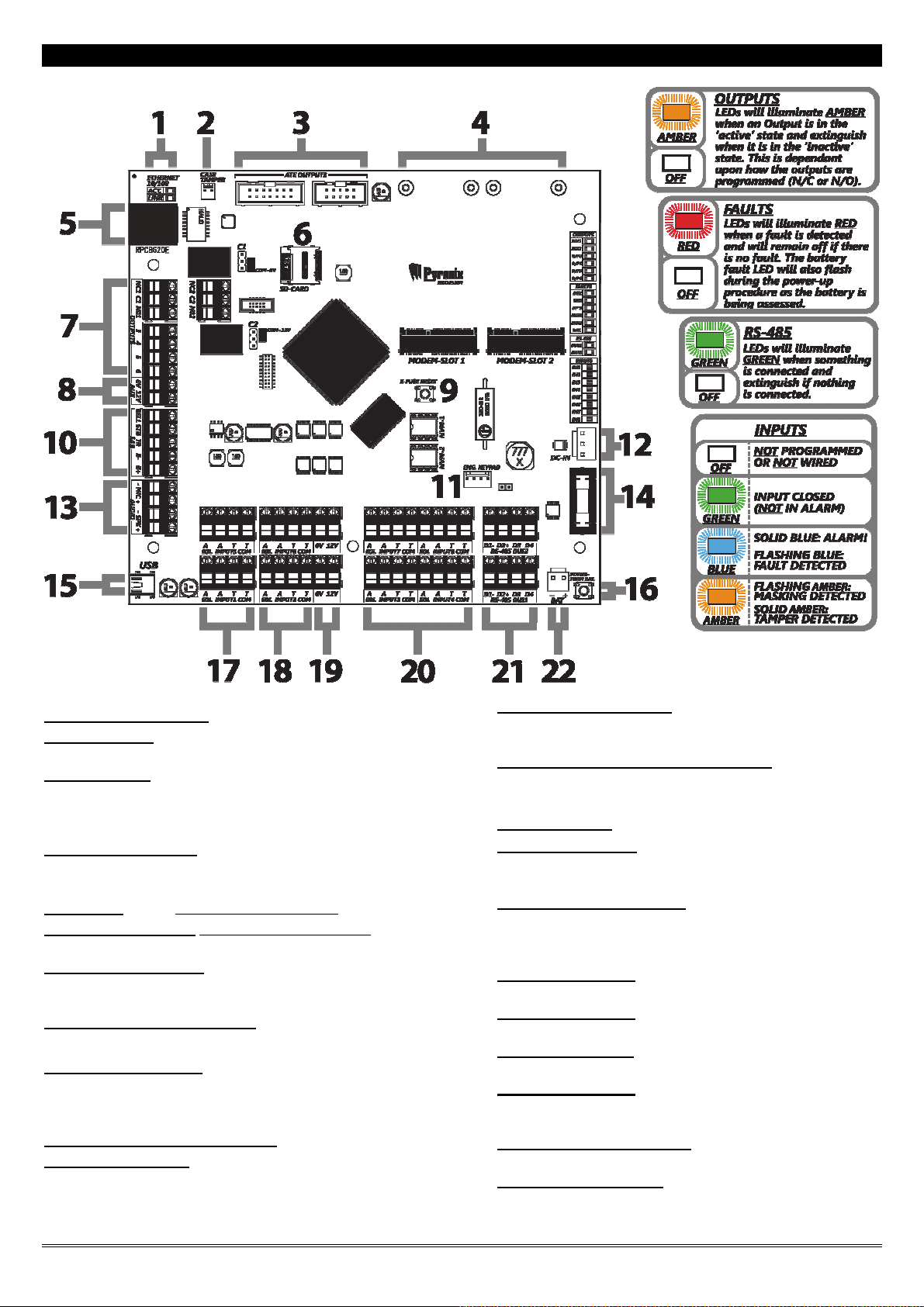

The Printed Circuit Board

1] Ethernet Status LEDs

2] Case Tamper

Connect the tamper switch cable here or use a jumper for Hold-off.

3] ATE Outputs

Connects the supplied communication loom to enable an additional 9

programmable outputs. These are low current and would normally be used

to connect a stand-alone communicator to the panel. See page: 12.

4] Modem Slots 1 & 2

Communications modules are inserted here. See page: 47

5] Ethernet (LAN)

(For future use – DO NOT USE)

6] Micro-SD Card Slot (For future use – DO NOT USE)

7] Output Connections

Output connection terminals (1- 6) see page:

8] Auxiliary 12V power supply

9] E-Fuse Reset Switch

Press to reset the switchable input / output / peripheral fuses once the

issue has been resolved.

10] External Sounder Connection

11] Engineer Keypad

An addressed keypad can be connected here to allow access to the

engineer menu. See page: 13.

12] 0V & 17V connection

Connects the 0V and 17V supply from the power supply

transformer (DC-IN).

13] Microphone & Speaker Connection

For future use

14] Battery Fuse

15] USB Connection

This connection is used to connect to a PC to allow uploading and

downloading of data using the InSite software (see page: 50).

16] Battery connect switch

Press to power up the control panel without the mains supply

connected. See page: 12.

17] Input Terminals

2 x Input terminals (block 1 and block 5)

18] Input Terminals

2 x Input terminals (block 2 and block 6)

19] 12V Power rails

2 x 12V Power rails

20] Input Terminals

4 x Input terminals (blocks 3, 4, 7 and 8)

21] 2 x RS485 bus terminals

Connects peripherals. See from page: 4.

22] Battery connection:

See page: 12.

Page: 9

EURO 280 Installation Manual

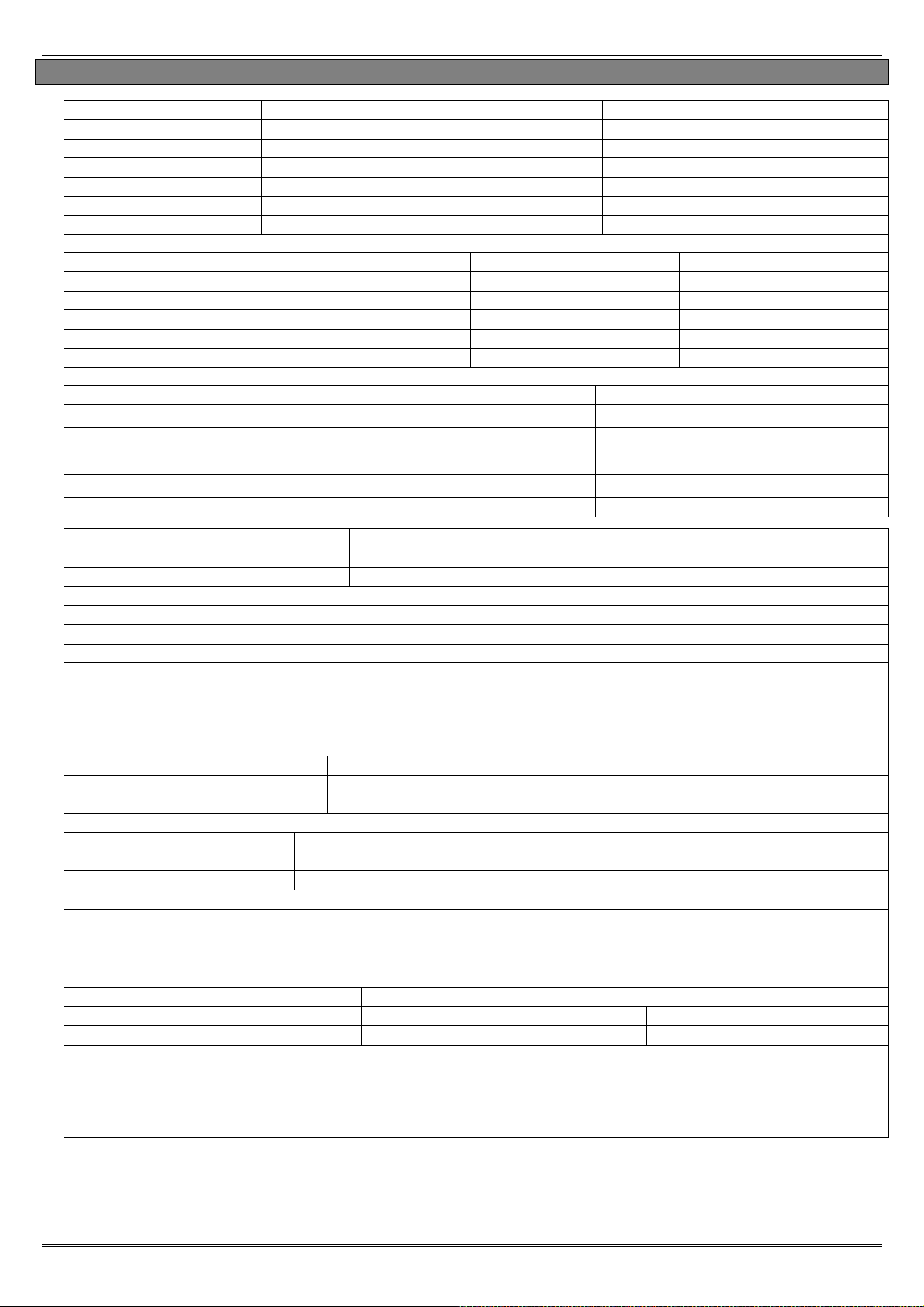

2.3 Technical Specification

Programmable Outputs Ratings Normal State Active State

Output 1 Relay, 3A, max 30V Normally Closed Normally Open

Output 2 Relay, 3A, max 30V Normally Closed Normally Open

Speaker 16 ohms No tones Repeat RKP tones & internal sounder

Strobe Output 500mA 12v 0v

Bell Output 500mA 12v 0v

ATE Outputs 2mA 5v 0v

All outputs are programmed in "CHANGE OUTPUTS" in the Engineer menu.

Input Resistance 1k / 1k DEOL Range 4k7 / 2k2 DEOL Range 4k7 / 4k7 DEOL Range

Normal 0k5 to 1k4 1k4 to 2k9 3k7 to 8k3

Burglary Alarm 1k5 to 5k9 4k2 to 7k8 8k4 to 10k2

Fault 6k to 8k1 8k to 11k3 10k3 to 14k9

Masking 8k2 to 17k 11k6 to 22k 15k to 22k

Tamper <0k5 or >17k <1k4 or >22k <3k7 or >23k

All inputs are programmed in "CHANGE INPUTS" in the Engineer menu.

Fuses Value Type

Bell fuse for Bell terminals 800mA

Inputs fuse for Input terminals 800mA

Auxiliary fuse for Aux terminals 800mA

RS485 Bus Fuse for bus terminals 800mA

Battery Fuse for battery terminals 3.15A anti-surge timed blow 250V Glass

Panel Power Supply Output Nominal Range

Output Voltage 15V DC 13.5-18V DC

Output Current 2.0A Continuous 0 ~ 3.4A

Power Supply Type A.

Maximum output peak ripple voltage: Max 120mVp-p

SD Voltage which the deep discharge protection function will operate at: 10.5V

Over Voltage Protection Trigger Voltage: 18.75V ~ 21.75V

NOTE 1. EURO 280 power supplies are NOT designed for use with multiple batteries connected.

NOTE 2. System load should not exceed the panel power supply output shown above, or the maximum load supportable by the battery for the

specified backup time, as in the table shown below.

NOTE 3. The power ratings are based on battery shown in table – but ANY battery capable of supporting the system load for the required time

may be used without affecting these ratings.

Panel Power Supply Input Nominal Range

Mains Supply Voltage AC 230V AC at 50Hz -15% +10%

PSU Rating 51VA 18.5V at 2.5A

Battery Charging Specification

Float Voltage 13.8v DC Current Limit 700mA

Battery low voltage cut off 10.5v Standby battery capacity 7A to 17A

Recharge time <24 Hours

EN50131-6:2008 Rated Output

In accordance with EN50131-6:2008, the control panel standby times and effective output currents depend on the Security Grade of the

system and how 230V mains missing fault is signaled to the Alarm Receiving Centre. Power supplies are rated in accordance with the

requirements of EN50131-6, which are related to the maximum battery size that can be accommodated in the housing and vary according to

the grade of the system in which they are installed, as per the following table:

Electrical Capability EN50131-6 Rating. Maximum Load

Example Battery Model Grade 2 Grade 3

Yuasa NP7-12 1.4A 0.9A

EN50131-1:2006+A1:2009 (30 hrs if notified to an ARC) for 17Ah battery = 477mA (Grade 3).

EN50131-1:2006+A1:2009 (60 hrs if not notified to an ARC) for 17Ah battery = 193mA (Grade 3).

E-fuse, resettable, non-replaceable

E-fuse, resettable, non-replaceable

E-fuse, resettable, non-replaceable

E-fuse, resettable, non-replaceable

Page: 10

EURO PCB Current Consumption Environmental

Quiescent 75-90mA Operational -10°C to +40°C, Certified

User Code and Tag Guessing Storage -20°C to +60°C

4-digit codes 10,000 Humidity 75%

6-digit codes 100,000 Dimensions

Disallowed codes None

All codes 1612

According to EN50131-3:2009 Annex B EURO Printed Circuit Board 159 x 175 x 25mm

According to spec of manufacturer of RFID components

used

Metal Casing

EN50131 Grading

EURO 280 Grade 3

(L) 390 x 305 x 100mm

Weight: 6kg

The below table specifies ATS (Alarm Transmission System) performance criteria in accordance with the

requirements of EN50136-1.

Notification Equipment

Remotely powered external

sounder

Self-powered external sounder Optional 1 Optional Optional

Main Communication Path (ATS) ATS 2 ATS 2 ATS 2 ATS 3

Second Communication Path (ATS) Optional Optional ATS 1 Optional

Notification Equipment Grade 3 Criteria

Option A Option B Option C Option D

Remotely powered external sounder 2 Optional Optional Optional

Self-powered external sounder Optional 1 Optional Optional

Main Communication Path (ATS) ATS 4 ATS 4 ATS 4 ATS 5

Second Communication Path (ATS) Optional Optional ATS 3 Optional

Option A Option B Option C Option D

2 Optional Optional Optional

Grade 2 Criteria

When used with a supervised premises transceiver, options 'Grade 3 Option D' are supported. The use of the Digi

Modem restricts the options up to 'Grade 2 Option B'.

2.1 Important Installation Notes

Ensure wiring is done to the national wiring regulations in the country where the installation is taking place. In

the UK, this is BS 7671 Requirements for electrical installations; IET Wiring Regulations (17th edition). If in

doubt, consult a local qualified electrician.

Ensure that a readily accessible disconnect device incorporated in the premises installation wiring shall be

provided external to the equipment with a contact separation of at least 3,0mm and connected as closely as

possible to the supply. Example: Unswitched Fused Spur Unit

When fixing external wires, ensure that means are provided in the installation to prevent the SELV (Safety

Electrical Low Voltage) or signal circuits from coming into contact with live parts of the power supply circuit.

Wires shall be fixed near their terminal blocks.

The end of stranded conductor shall not be consolidated by soft soldering at places where the conductor is

subjected to contact pressure. Example: Must not solder ends of wires which are to be secured in detector and

control panel terminal connectors.

On completion of wiring use tie-wraps to prevent any loose wires causing a safety hazard (material of cables tie

shall be rated at least HB or better).

Cables ties and hoses shall be separate for power supply cable and SELV (Safety Electrical Low Voltage) wirings.

Size of protective bonding conductors: minimum section 1.5mm². Example: Electrical Earth wire connections.

Page: 11

EURO 280 Installation Manual

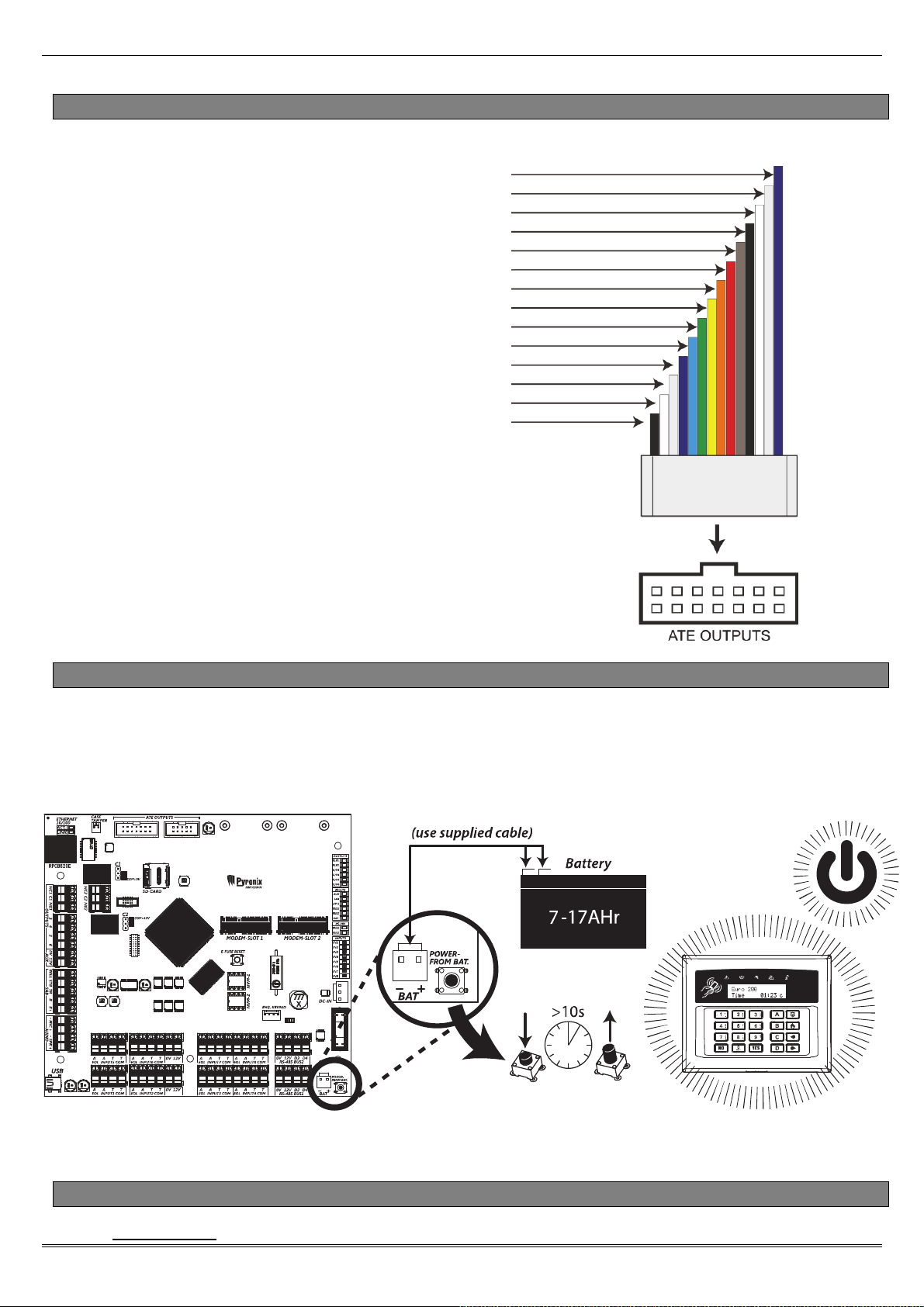

2.2 Communication ATE Loom

ATE low power outputs are programmed in the engineer menu: “CHANGE OUTPUTS->Endstation Outputs”.

Purple (ATE Output 8: Mains Fail (0052))

Light Grey (ATE Output 10: Test ATS (0064))

White (ATE Output 9: Global Fault 2 (0056))

Black (ATE Output 7: Confirmed Any (0006))

Brown (ATE Output 4: Final Set All (0004))

Red (0V)

Orange (ATE Output 2: HU Device Any (0009))

Yellow (ATE Output 3: Unconfirmed Any (0018))

Green (ATE Output 6: Omit Rearm Any (0017)))

Blue (ATE Output 1: Fire (0001))

Purple (ATE Output 5: Tamper Any (0007))

Light Grey (+12V)

White (DO NOT USE)

Black (Line Fault)

Normal Status: 5V

Active Status: 0V

Current: 2mA

The polarity of the ATE outputs can be inverted from the

function 'SITE OPTIONS' under 'Invert ATE Outputs'.

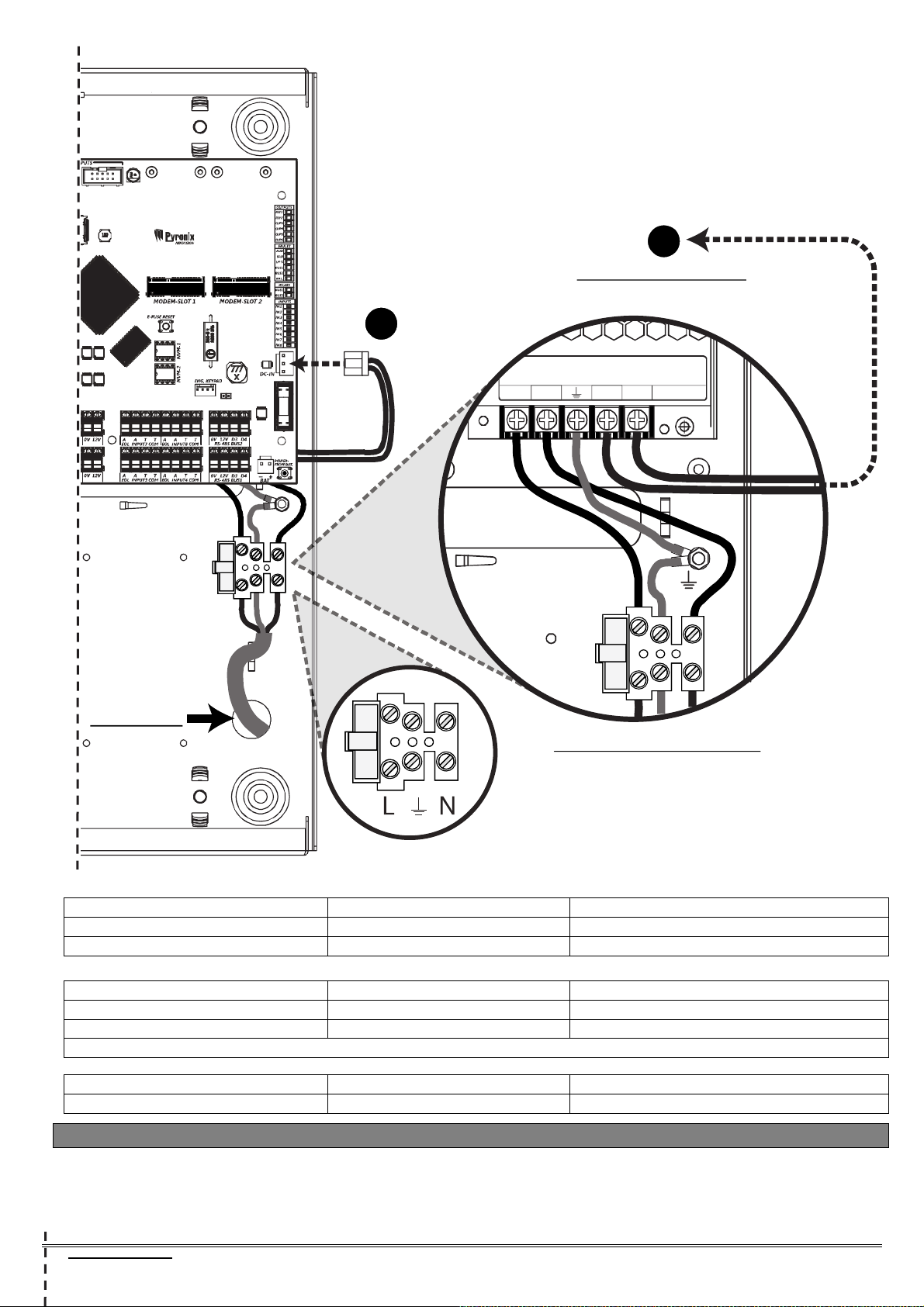

2.3 Battery Connection

The back-up battery is an essential part of this security system in the event of a mains failure (malicious or otherwise). It

can also be used to power the panel without mains so that the panel can be programmed before the mains supply to a

building has been established (e.g. in a new-build property).

NOTE: The battery connect button is only used if no mains is present and a battery power up is required.

2.4 AC Mains Supply Connection

Control Panel

Page: 12

A

Connects to DC-IN

(DC-IN)

(See Fig. A)

A

L N -V +V

MAINS IN:

VIEW: PSU TERMINALS

(Underneath Main PCB)

Panel Power Supply Input Nominal Range

Mains Supply Voltage AC 230V AC at 50Hz -15% +10%

PSU Rating 51VA 18.5V at 2.5A

Panel Power Supply Output Nominal Range

Output Voltage 15V DC 13.5-18V DC

Output Current 2.0A Continuous 2.5A peak, during battery charging

Power Supply Type A.

Fuses Value Type

230V Mains Fuse for mains terminals T500mA anti-surge slow blow 250V Ceramic

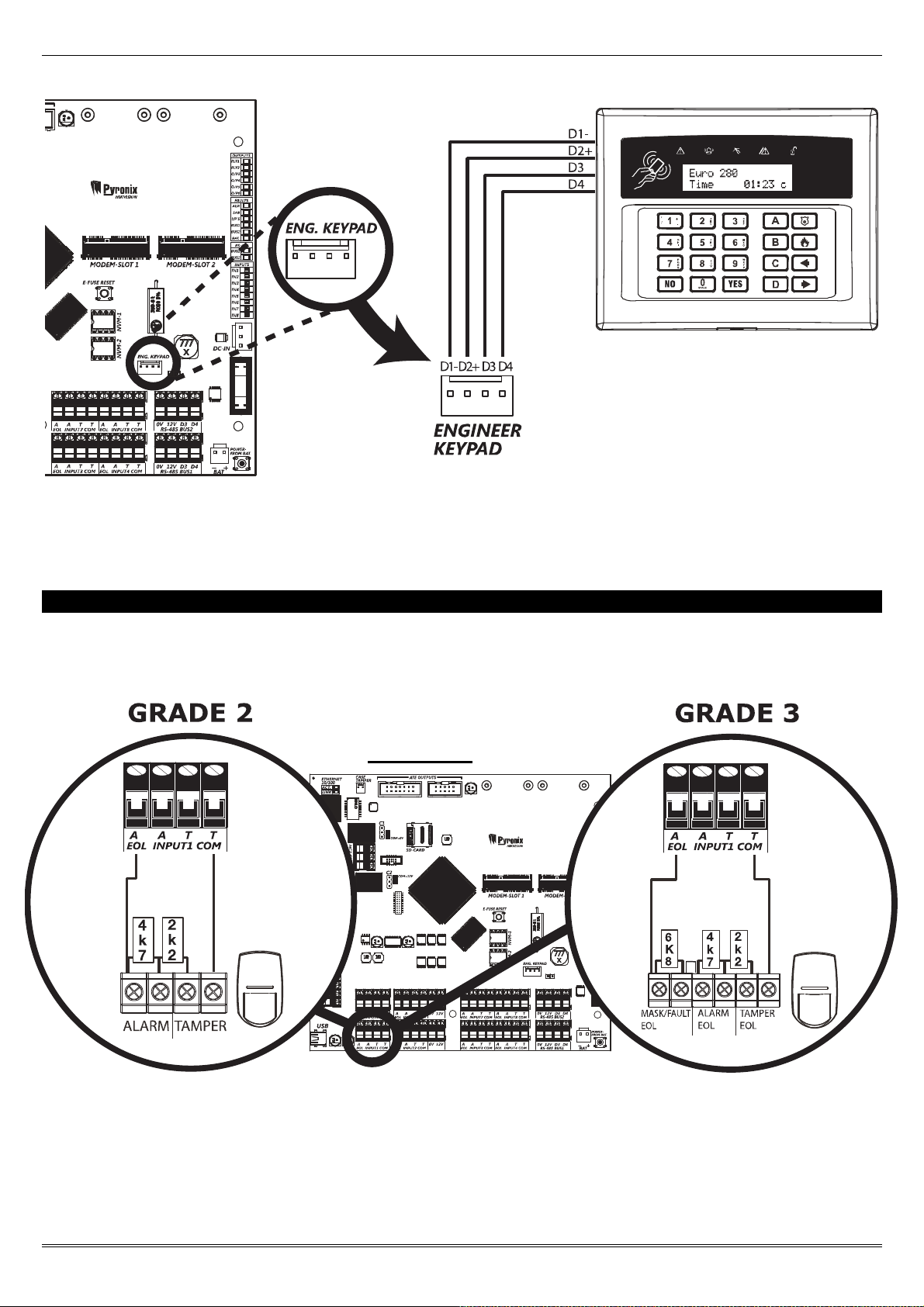

2.5 Engineer Keypad Connection

If required, any keypad can be connected to the 'Engineer Keypad' connections as shown below. This enables quick

access to the Engineer menu without having to walk to the nearest keypad.

Control Panel

Page: 13

EURO 280 Installation Manual

NOTE: Before an Engineer keypad is enabled, it should be addressed as an additional keypad on the control panel

before operation. See page: 19 for adding keypads to the control panel.

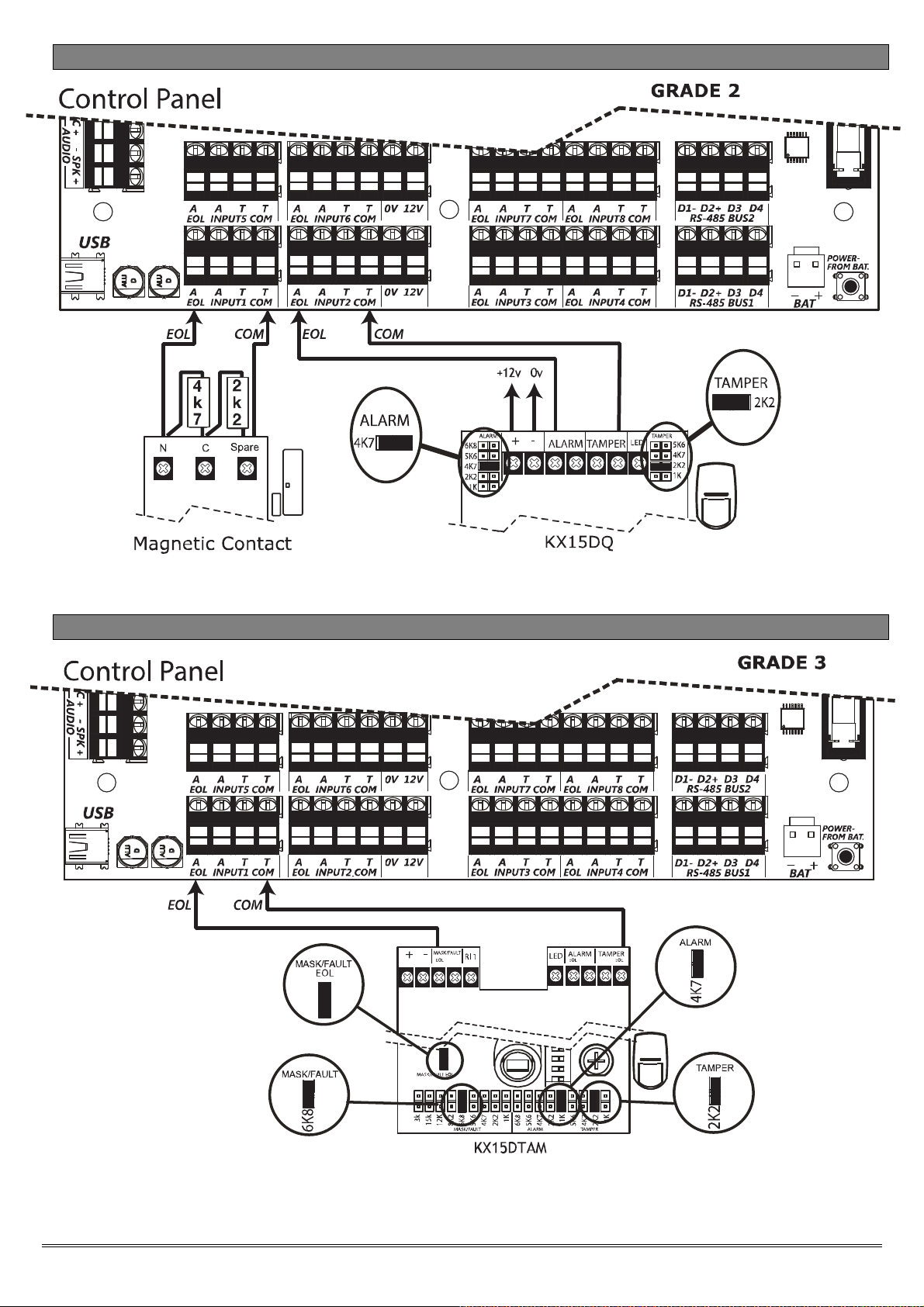

3. Input Connections

Here are some examples of a typical connection to a wired detector, for grade 2 and grade 3 respectively:

Control Panel

Page: 14

3.1 Default Grade 2 DEOL (Double End of Line) Input Wiring

The above wiring example shows the connections for a Grade 2 KX15DQ PIR detector.

3.2 Grade 3 Mask/Fault Input Wiring

The above wiring example shows the connections for a Grade 3 KX15DTAM detector.

Page: 15

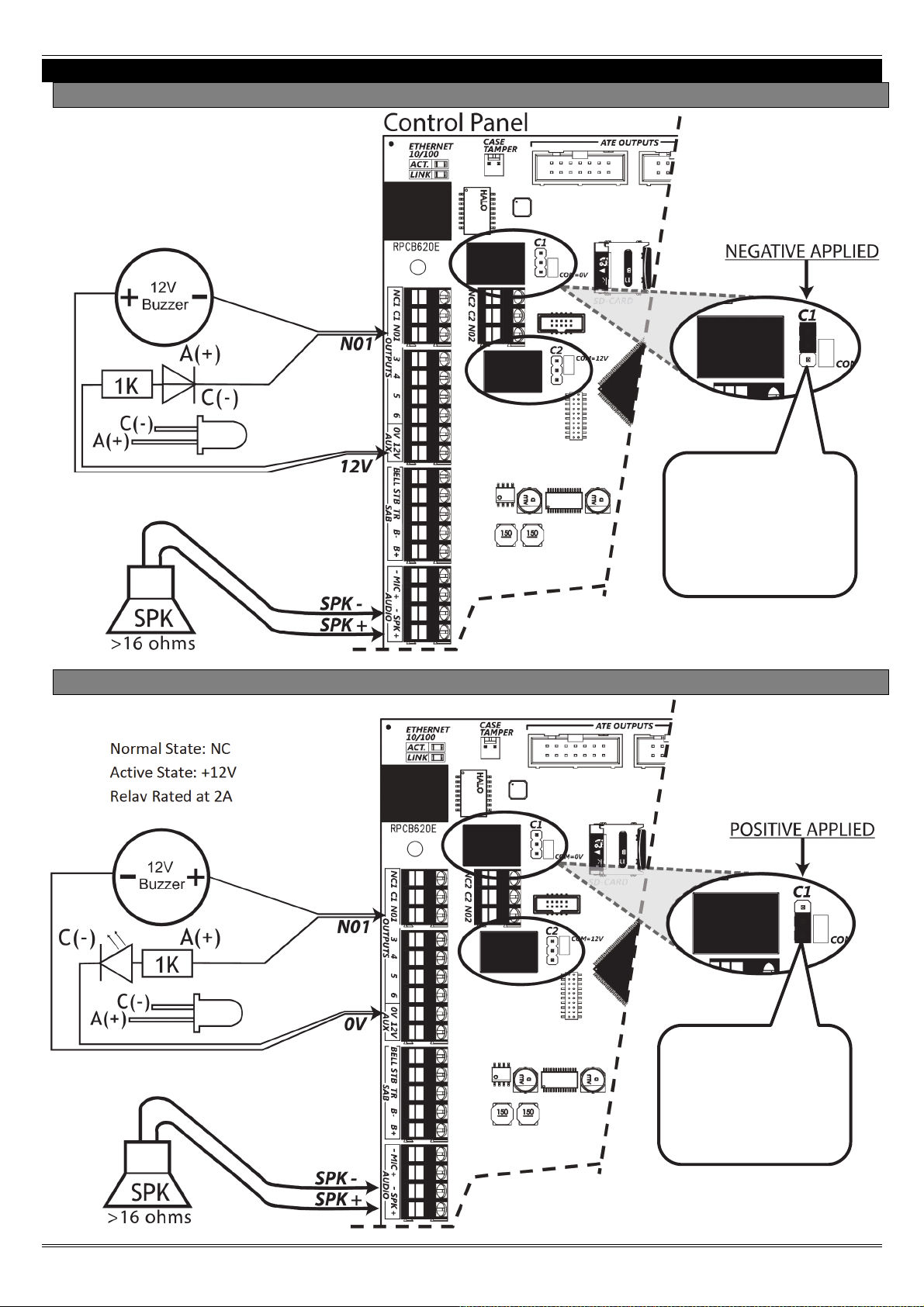

4. Output (PGM) Connections

4.1 Negative Applied Wiring

Normal State: NC

Active State: 0V

Relay Rated at 2A

EURO 280 Installation Manual

Place the jumper /

link in the position

shown to set the

wiring to negative

applied.

4.2 Positive Applied Wiring

Normal State: NC

Active State: +12V

Place the jumper /

link in the position

shown to set the

wiring to positive

applied.

Page: 16

Loading...

Loading...