THE POWER OF PERFORMANCE

RADIO CONTROLS

C4

Service Manual

Rev. 2

07-2008

GB

Radio controls

THE POWER OF PERFORMANCE

2

Radio controls HETRONIC BMS1

THE POWER OF PERFORMANCE

HETRONIC

Radio control BMS 1

GA610 BMS NOVA - 6L

C4.1

Features: Working Range approx. 100 m

Operating temperature -20° ÷ +70° C

Transmission speed 4800 Baud

Watertight Degree IP 65

836

3

Radio controls HETRONIC BMS1

THE POWER OF PERFORMANCE

4

C4.1

Radio controls HETRONIC BMS1

Radio controls HETRONIC BMS1

THE POWER OF PERFORMANCE

C4.1

1 - Operation

u The radio remote controls tted on the EFFER cranes consist with a transmitter, (also called key-board), of very

reduced size and weight, supplied with adjustable support and carrying belt to help the operator in his/her work,

and with a receiver applied on the crane, connected electrically to the controlbank.

u The electric signals sent to the receiver by the operator whenever he/she moves the transmitter paddles, are

transformed by the receiver itself into small shifts of the levers of the crane controlbank.

u Many crane movements may occur simultaneously. Moreover, as the movements are proportional, small shifts

of the transmitter paddles performed by the operator correspond to low speed crane movements, whereas the

higher is the shift of the joystick, the higher is the crane operating speed.

u The dialogue between the transmitter and the receiver occurs thru a preset radio frequency. In order to avoid

possible interferences with other radio control units, which might cause an accidental operation of the crane,

the radio remote control is equipped with an electronic device. That device will send the received signal to the

controlbank only after having checked that it really came from the combined transmitter.

NOTE: Read in whole the following sections before trying any modication or repair to the radio remote

controls. You might nd these modications unnecessary once you know how the whole system works and

how the settings are carried out!

1930744

5

Radio controls HETRONIC BMS1

THE POWER OF PERFORMANCE

6

C4.1

Radio controls HETRONIC BMS1

2 - Radio remote control,

u This radio remote control is specially appreciated for the reduced size of its receiver unit (160 x 210, depth: 90

mm). It is available with either 12 V. DC or 24 V. DC.

u In case of 24 V. DC power supply, when six functions are selected simultaneously, the max. absorption is 3.8

Ampere.

u The safety fuse located in the receiver, is sized to max. 7.5 A.

u The transmitter features the typical “Binoculars” shape of Hetronic.

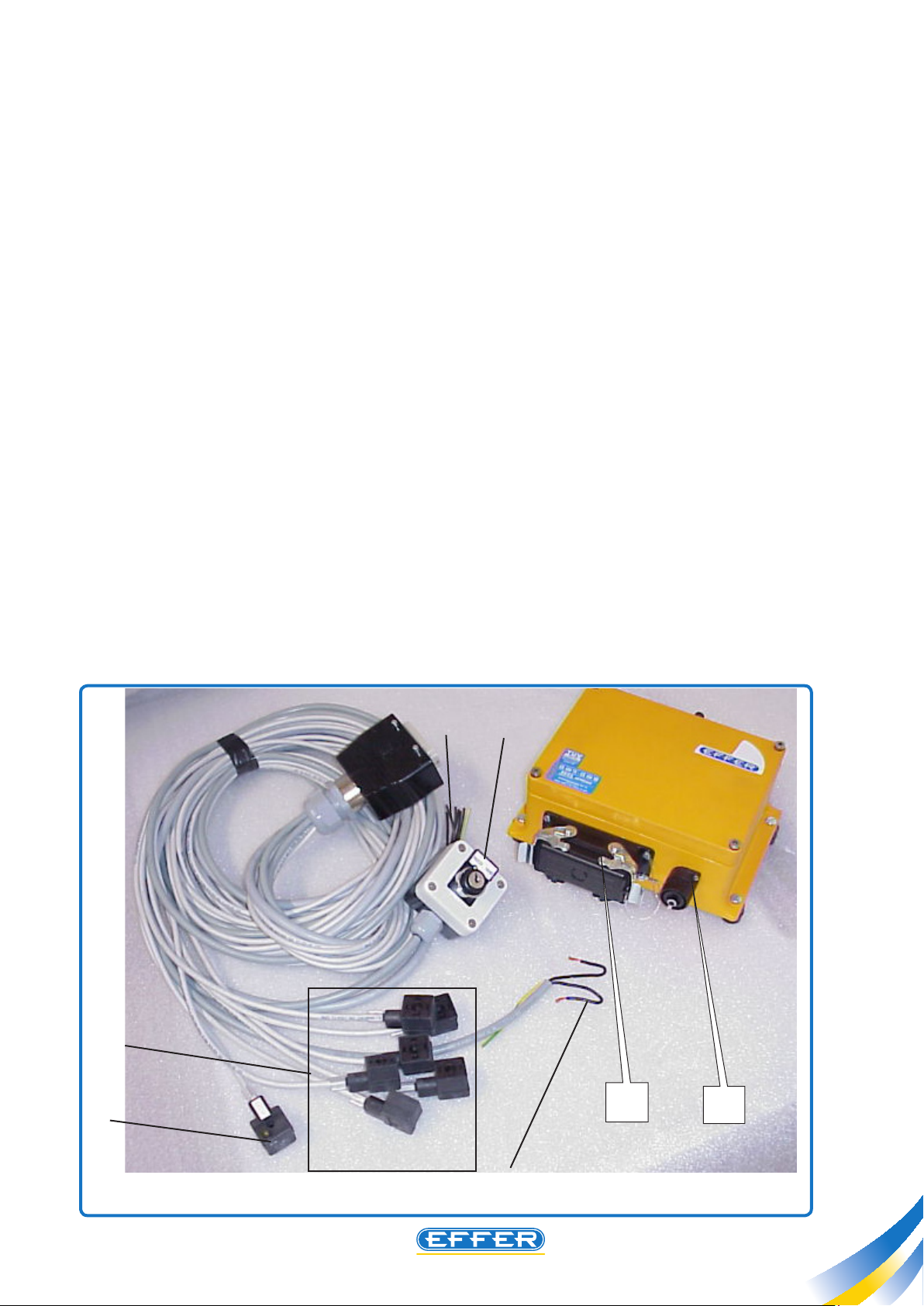

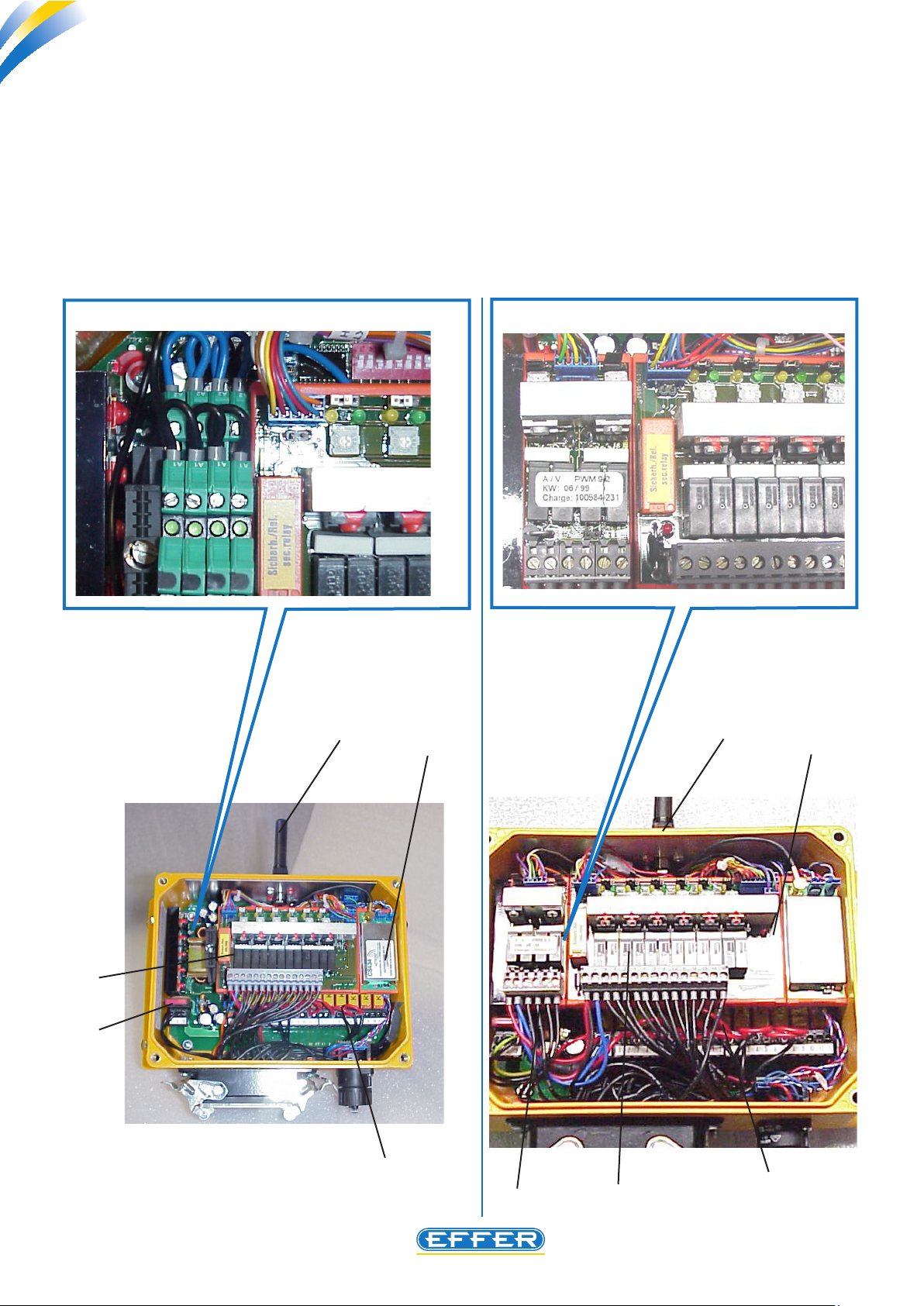

u The standard supply includes:

1 Receiver unit see section 2.1

2 Transmitter unit see section 2.2

3 Battery charger with spare battery see section 2.3

4 Emergency cable, length: 20 mt. see section 2.4

5 Programming red key see section 2.5

type“GA610 BMS NOVA - 6 L”

2

1

4

5

029

3

Radio controls HETRONIC BMS1

THE POWER OF PERFORMANCE

C4.1

2.1 Receiver unit

The receiver unit features two electric connectors:

A- to connect the wires for the controlbank operation and for the power supply

B- to connect the emergency cable (see information on this cable in section 2.4)

THE CONNECTOR APPLIED ON THE POINT “A” HAS 32 PINS SOME OF THEM VOID FOR THE FOLLOWING

CONNECTIONS:

u Six equal electric connectors, to connect six proportional activators located on the crane hydraulic controlbank

(ref. M).

u Additional electric connector (ref. N), with a LED included, to supply the main oil relief valve on the

controlbank.

u Electric supply, connected to the cable (ref. O) with three pins (marked: 1-2-yellow / green). The negative polarity

shall be connected to the wire marked 1, whereas the positive polarity goes to the wire marked 2. The yellow/green

pin is not employed for the normal use of the radio control as it was designed for special accessories such as for

example aerial platforms, or warning signals indicating that the radio-controls are at use.

u The box (ref. P) with key for the selection of the type of crane operation (manual operation / radio remote

control operation) is connected to the same group of wires mentioned above and is applied to the point “A” on

the receiver.

u When selecting the manual operation, the connector ref. N is powered up continuously, whereas in radio remote

control operation, that connecter is powered up only when a transmitter paddle is activated.

u An additional cable (ref. Q) of 10-mm diameter, is applied to the same connector “A”; six black wires marked

from 1 to 6, and one yellow/green wire are gathered inside the cable. The output wires of the radio remote control,

marked from 1 to 5, are to be connected to the truck accessories: by selecting the corresponding controls on the

transmitter, these wires will convey an electric signal.

Q

P

M

N

O

A

B

030

7

Radio controls HETRONIC BMS1

THE POWER OF PERFORMANCE

8

C4.1

Radio controls HETRONIC BMS1

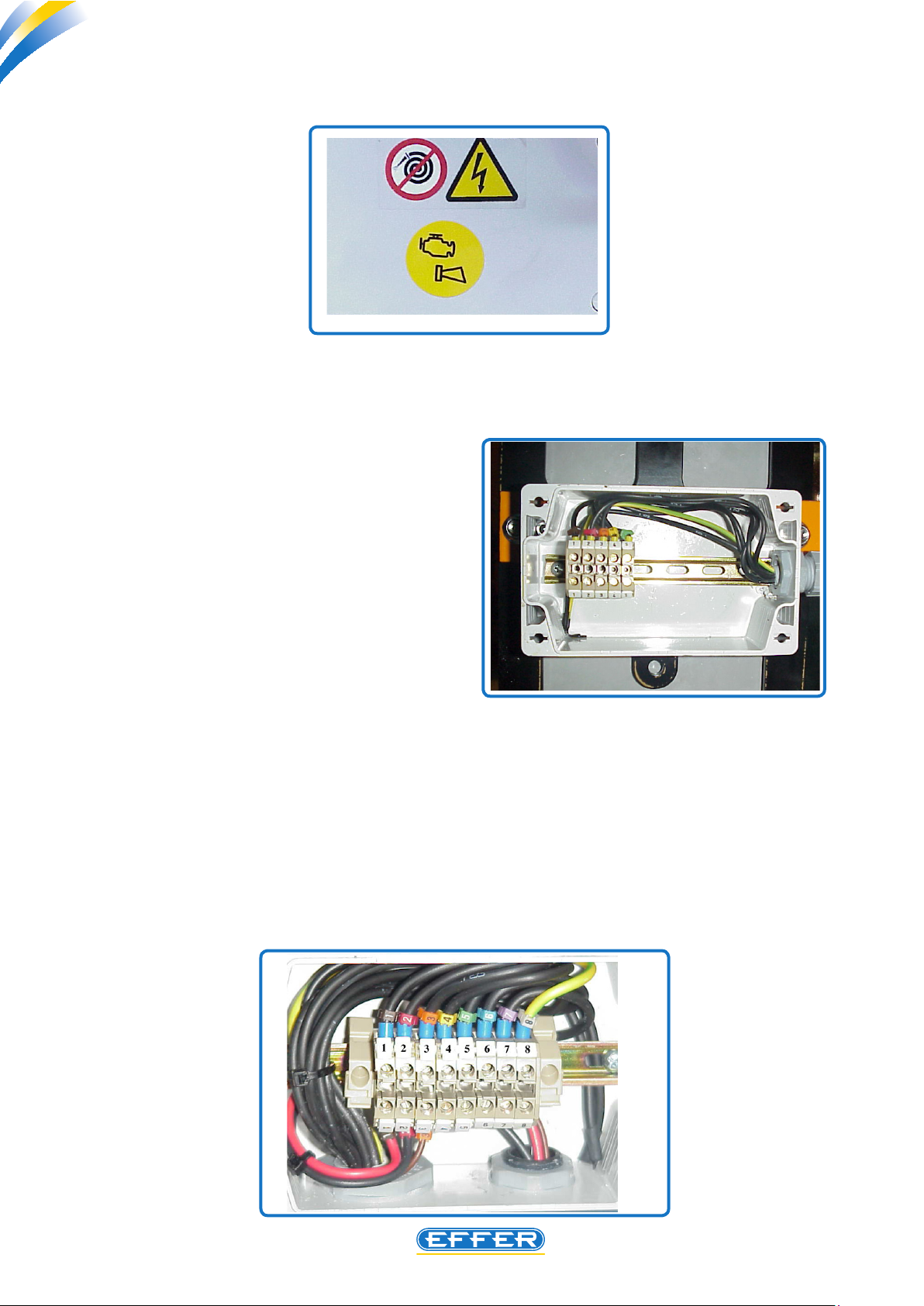

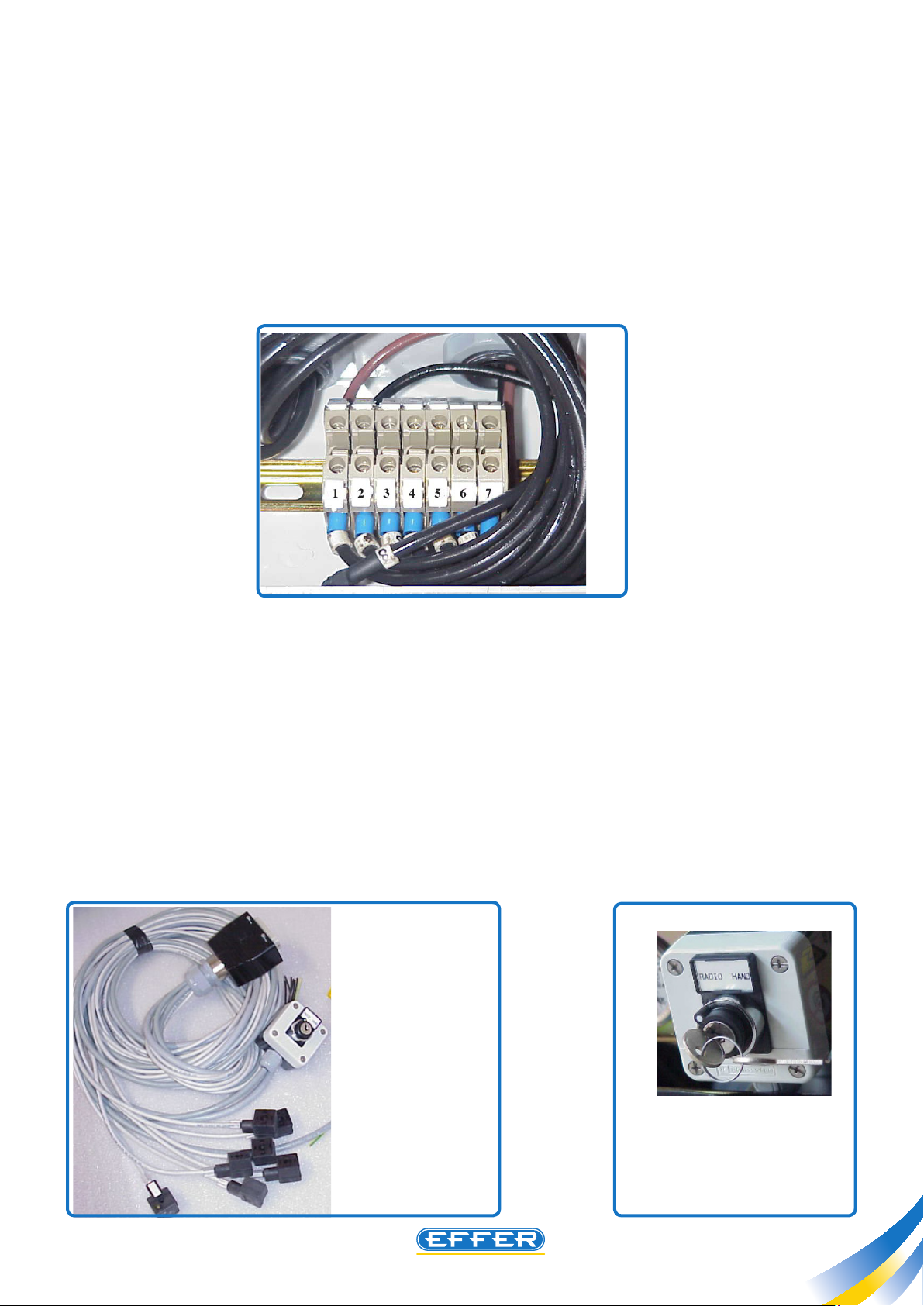

Box for electric accessory connection

272

1st example:

u Crane with bottom-side controlbank (mounted on the crane base). The a.m. connections are inside the electric

box (ref. W) mounted on the crane base. The terminal board bears the number/markings of the single wires.

Terminal 1: Signal for buzzer connection. When

connected, it operates if activated by the operator

(see transmitter unit instructions, section 2.2.8) or

while programming the radio control (see section

2.5/2.6).

Terminal 2: Signal for truck engine start

Terminal 3: Signal for truck engine stop

Terminal 4: Signal for truck engine RPM increase

Terminal 5: Sign al for truck engine RPM

decrease

Spare wire: Signal available for special accessories

(excluding PFI version cranes).

2nd example:

u Crane with controlbank on the column (mounted on the column side) - no operator’s seat, supplied or

not with the anti-tilting device, or with top-seat controls (but only when an anti-tilting device is tted to the crane

as well).

A terminal board is located inside the box (ref. T) applied on the crane base and the terminals for the connection

of the truck accessories are the following:

T

Radio controls HETRONIC BMS1

THE POWER OF PERFORMANCE

Terminal 4: Signal for buzzer connection. When connected, it operates if activated by the operator (see transmitter

unit instructions, section 2.2.8) or while programming the radio control (see section 2.5/2.6 ).

Terminal 5: Signal for truck engine start

Terminal 6: Signal for truck engine stop

Terminal 7: Signal for truck engine RPM increase

Terminal 8: Signal for truck engine RPM decrease

C4.1

3rd example:

u Crane with top-seat controls, with operator’s seat but no anti-tilting device

Y

A terminal board is located inside the box (ref. Y) on the crane base and the terminals for the connection of the

truck accessories are the following:

Terminal 3: Signal for buzzer connection. When connected, it operates if activated by the operator (see transmitter

unit instructions, section 2.2.8) or while programming the radio control (see section 2.5/2.6).

Terminal 4: Signal for truck engine start

Terminal 5: Signal for truck engine stop

Terminal 6: Signal for truck engine RPM increase

Terminal 7: Signal for truck engine RPM decrease.

NOTE: These signals have been designed for relay activation. Their direct connection to claxson, solenoid valves

or to any device with absorption more than 0.5 Ampere is not possible.

The above mentioned signals have positive polarity.

EFFER Parts Numbers:

E FF E R p a r t #

899 123 5 - wi re

for the connection

“A ”, c o m p l e te

with conne cting

p lu g, b o x f or

cran e ope ration

selection, and cable

fo r ac cess or ies

connection.

EFFER part # 8990768

box ref. P with key switch.

9

Radio controls HETRONIC BMS1

THE POWER OF PERFORMANCE

10

C4.1

Radio controls HETRONIC BMS1

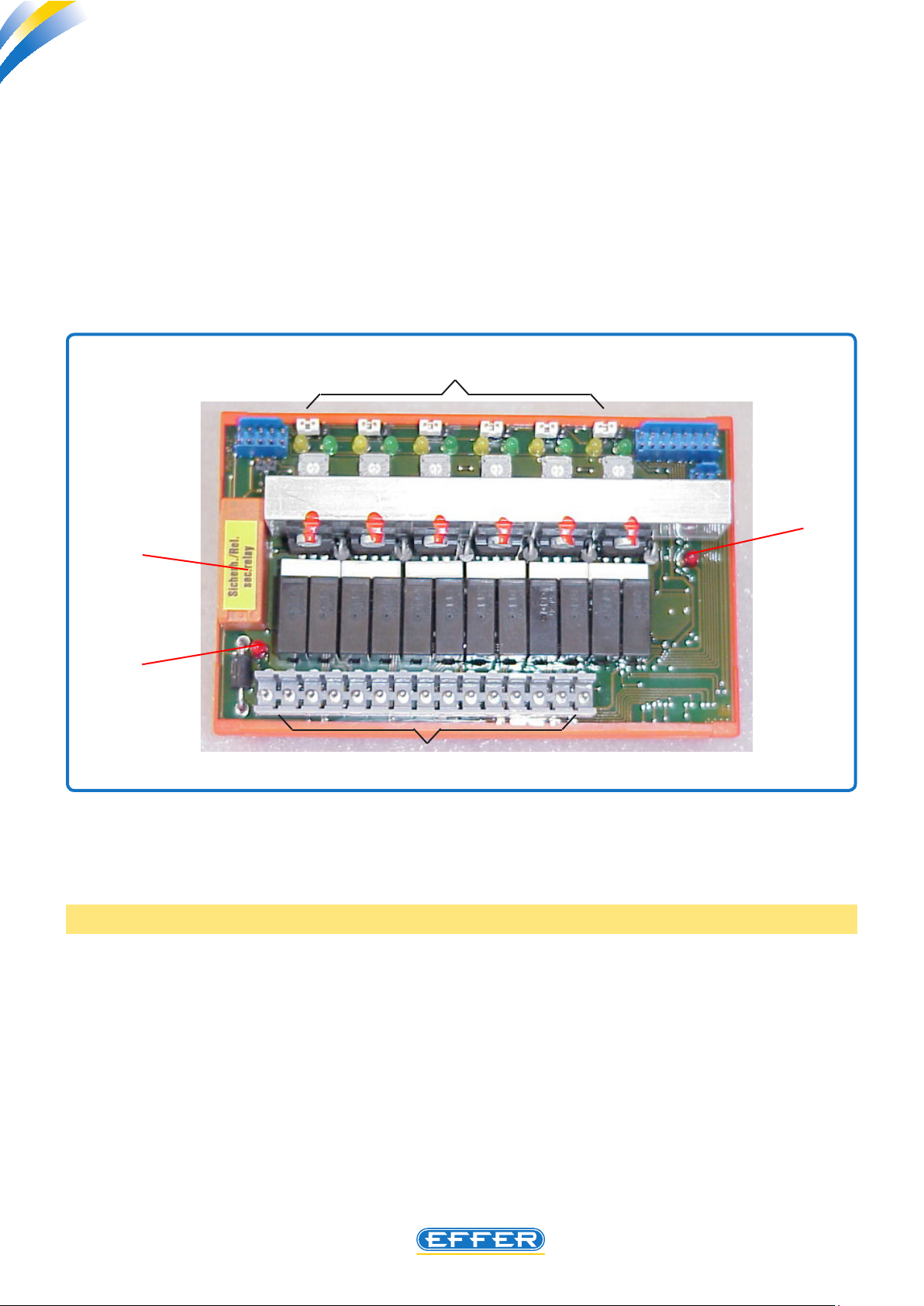

On the receiver unit the following parts can be identied :

1. Radio antenna (see section 2.1.1)

2. Fuse 7.5 A

3. Electronic module for the activation of the Hawe controlbank levers

4. Radio receiver Module

5. Electronic module transforming the signals from the transmitter into controls to the controlbank

6. Module for the activation of the 7

th

/ 8th function

OPTIONAL

1

4

900x

OPTIONAL

1

4

3

3

2

2

5

2

3

5

Radio controls HETRONIC BMS1

THE POWER OF PERFORMANCE

C4.1

2.1.1 Radio remote control antenna, EFFER part # 8990710

u We recommend that you do not crash or bend it. In order to avoid damaging the thread, do not over-fasten

the lock ring nut.

The inner contact should be clean. As it is a gold-plated contact, no protective antioxidant treatment is required.

EFFER part # 8991442

EFFER part # 8990710

234L

231L

2.1.2 Fuse, EFFER part # 9394876

u This fuse is of a standard Automotive type, with bayonet joint.

Safety Standards for Fire Prevention command that a fuse is applied to the whole system. Do not exceed the

Amperage limit of 7.5 Ampere.

038

11

Radio controls HETRONIC BMS1

THE POWER OF PERFORMANCE

12

C4.1

Radio controls HETRONIC BMS1

2.1.3 Electronic module for controlbank paddle operation, EFFER part # 8991236

for HAWE, EFFER part # 8991380 for DANFOSS

u A red LED (ref. Y) is located on the module bottom, on its left side. It lights up whenever any paddle of the

transmitter is moved, indicating that there is actually a power supply to the main solenoid valve tted on the

controlbank.

The signal output is on the terminal 3, marked YO.

of the main solenoid valve on the controlbank light up. If the LED does not light up, check the electric connection

or the correct operation of the relay (ref. Z).

The same signal makes also the LED tted on the connector

T

V

Z

Y

033

S

Six yellow LEDs and six green LEDs are located on the upper side of the electronic module (ref. T): they light up when

one of the paddle is moved. Starting from the left, you nd the LEDs connected to the paddles corresponding to

the following functions: crane slewing, rst (main) boom, second (knuckle) boom, extension, 1st supplementary

control, and 2nd supplementary control.

NOTE: When the crane is equipped with a winch, this is activated by the 2nd supplementary control.

u The yellow LEDs light up when a function is occurring, sending oil to the port B of the controlbank, while

the green LEDs light up when oil is sent to the port A of the controlbank (see also Service manual of the HAWE

controlbanks).

u Under the LEDs row, six small potentiometers control the feathering intensity of the controlbank lever. The

feathering of the lever is necessary to perform even very small movements, avoiding the interference of mechanic

frictions at the start-up stage.

u Note however, that HAWE levers shall not vibrate visibly (they’ll rather look steady while moving by radio); you’ll

just feel they slightly vibrate while touching the levers when radio-controlling the crane.

In general, we can state that adjusting the potentiometer at half stroke grants the best performance of the HAWE

controlbank.

Radio controls HETRONIC BMS1

THE POWER OF PERFORMANCE

12 more electric connections (ref. S) are located on the lower side of the electronic module. These are connected

to the cables conveying the signals to the six functions of the crane controlbank. These connections are marked

by numbers 4 to 15 on the female connectors and bear the references marked A1, A2 etc. on the male connectors.

They are connected to the 12 LEDs ref. T , upwards, in the same position order.

The transmitted electric signal of these connections is dened as “under power”.

In order to verify the presence of this signal, use a tester for power check (or even a simple test lamp), providing

a connection at the point 2 (negative cable connection).

As a consequence of what has been explained above, when a transmitter paddle is activated, the red LED and the

LED corresponding to the selected manoeuvre will light up.

If many manoeuvres are performed simultaneously, many LEDs will light up on the upper side.

u On the right side of the board, an additional red LED is tted (ref. V). It lights up when a short-circuit occurs. If

it lights up while a specic manoeuvre is occurring, check the electric circuit corresponding to that manoeuvre,

included the activator tted to the corresponding lever on the crane controlbank.

On the upper side of the board, above the LEDs ref. T, six jumpers are tted.

u When jumpers are located between the central pin and the left pin, the radio remote control can operate

controlbanks equipped with 24-volt coils, while if the jumpers are located between the central pin and the right

pin, the radio remote control can operate controlbanks equipped with 12-volt coils.

C4.1

Z

Y

T

V

033

S

13

Radio controls HETRONIC BMS1

THE POWER OF PERFORMANCE

14

C4.1

Radio controls HETRONIC BMS1

2.1.4 Receiver radio module:

EFFER part # 8991237 (European Frequency and other countries Ref. CS434)

EFFER part # 8991238 (American Frequency and other countries Ref. CS458)

NOTE: The two references above indicate the type of radio transmission frequency, according to the

homologation obtained by Hetronic in your country.

u Upon specic request, the EFFER Technical Department will give you the exact reference code according to

the country in which the radio remote control shall be used. This module receives the signals transmitted to the

radio antenna.

This module is excluded when you operate with the emergency cable (see section 4).

u In case of a fault occurred to the radio remote

control, where there is no physical damage to the

antenna, and the fault disappears when using the

emergency cable, the most probable cause has to be

investigated in the receiver radio module (or in the

transmitter module located inside the transmitter,

see section 2.2.13), or in a wire disconnected in the

electric circuit.

034

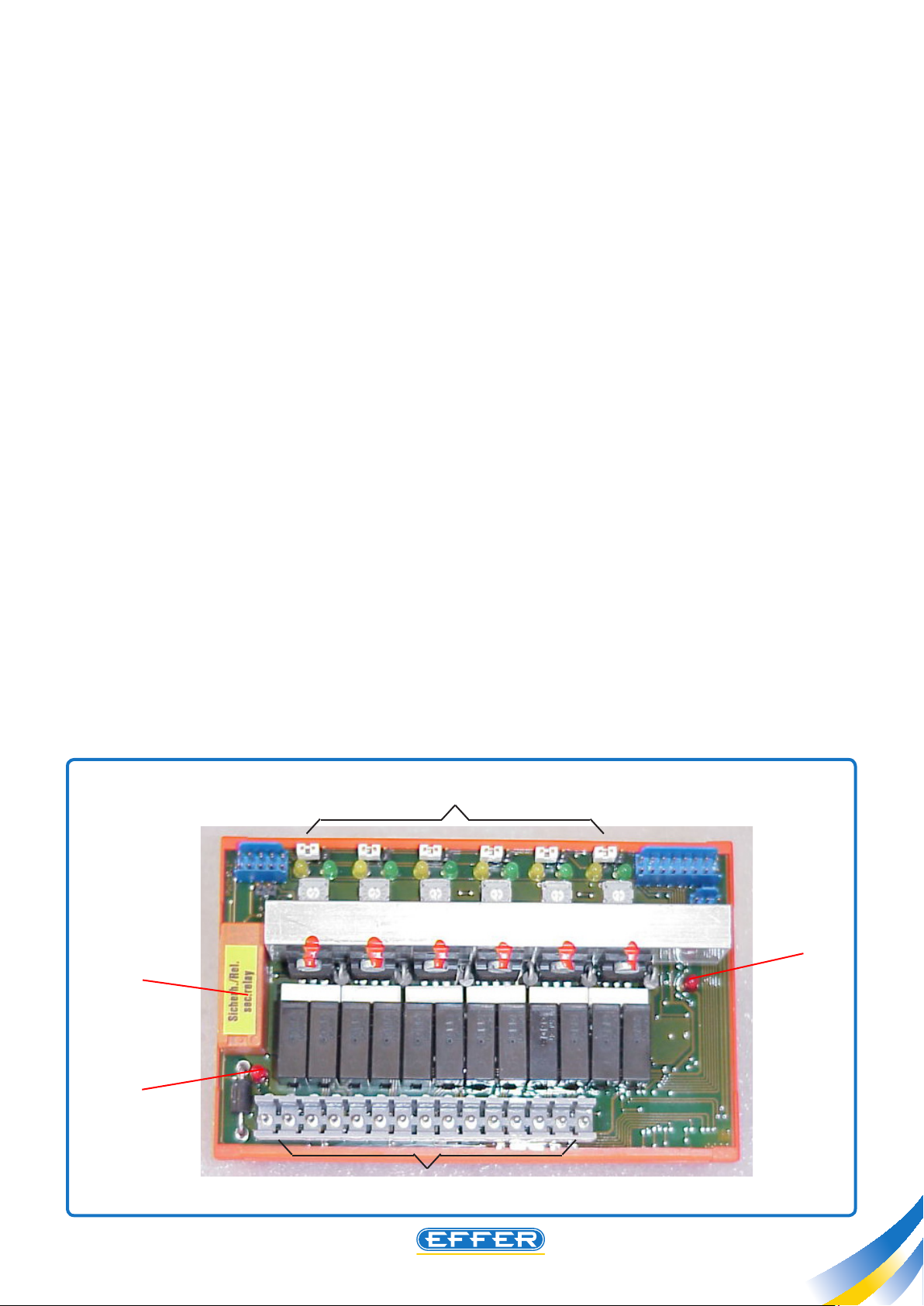

2.1.5 Electronic basic module, to turn the transmitter output signals into

controls to the controlbank

EFFER part # 8991239 until rst months 2001 (Fig. A),

EFFER part # 8991239A since rst months 2001 (Photo B, not shown)

This module is tted with twelve relays, each of them having a small red lamp on the upper side to show when

they are being activated electrically.

Those relays (ref. E) not only send the signals to the wires of the accessories (k2=buzzer; k3=truck engine rpm

increase; k4= truck engine rpm decrease; k8= truck engine start; k9= truck engine stop), but also control the

operation of the radio remote control or of the crane (k5 or K6 =enabling the 7th and 8th function; k10= for crane

equipped with the

On the upper side of the module of the radio remote controls delivered until the beginning of 2001, 16 switches

(ref. F) are located. They dene the dialogue Code between the transmitter unit and the receiver unit. 16 more

similar switches are tted in the transmitter unit to the same purpose.

That Code must never be changed, as no trouble can be solved by changing the dialogue Code. Electronic module

EFFER part # 8991239.

The radio remote controls delivered since the beginning of 2001 are equipped with a single part with xed code

“Ref. F” instead of the switches. Electronic module EFFER part # 8991239A.

Four LEDs visible from the outside too, are located on the upper side, on the right. They have the following

meaning:

Yellow: turning the key applied to the box ref. P (see section 2.1).

OperatiOn- It starts ashing after approximately 3 sec. since the radio remote control is powered up, by

FPI device only). The remaining relays are not used normally (k1, k7, k11, k12).

Loading...

Loading...