Operator Manual

BMS-1 System

HETRONIC AUSTRALIA PTY LTD CRANE CONTROL AND MONITORING

Trading as HETRONIC AUSTRALIA remote controls

4/11 DURIE RD / PO BOX 619 hoist limits

CARDIFF NSW 2285. antisway

PHONE: 02 4953 7931 load display

FAX : 02 4953 7932 ABN : 71 100 928 050 www.hetronic.com.au

……………………………….……..…………………..………control your bottom line

TABLE OF CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

The Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Production and System Numbers . . . . . . . . . . 3

Unauthorized Replacement Parts . . . . . . . . . . 3

Before Attempting to Operate This System . . . 3

Theory of Operation. . . . . . . . . . . . . . . . . . . . . 3

Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety Alerts. . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Notations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Practices and Laws . . . . . . . . . . . . . . . . . . . . . 4

Required Operator Training . . . . . . . . . . . . . . . 4

Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Possible Sources of Danger . . . . . . . . . . . . . . 4

Operation and Work Area Safety . . . . . . . . . . . 4

Protective Features . . . . . . . . . . . . . . . . . . . . . 4

To Stop In An Emergency . . . . . . . . . . . . . . . . 4

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Mount the Receiver . . . . . . . . . . . . . . . . . . . . . 5

Install Receiver and Output Wiring . . . . . . 5

Mount the Actuators . . . . . . . . . . . . . . . . . 6

Attach Wiring Harness. . . . . . . . . . . . . . . . 6

Connect Electrical Wiring . . . . . . . . . . . . . 6

ME-3 Module Calibration (Optional) . . . . . 6

Install Battery Charger . . . . . . . . . . . . . . . . . . . 6

Battery Handling . . . . . . . . . . . . . . . . . . . . . . . 6

Insert the Battery - GL and Nova . . . . . . . . . . . 6

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Quick-Set System . . . . . . . . . . . . . . . . . . . . . . 7

Function Speed Adjustment. . . . . . . . . . . . . . . 7

Address Settings . . . . . . . . . . . . . . . . . . . . . . . 8

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Holding the Transmitter . . . . . . . . . . . . . . . . . . 8

Visual Check . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Start-Up Procedure . . . . . . . . . . . . . . . . . . . . . 8

Speed Control . . . . . . . . . . . . . . . . . . . . . . . . . 9

Emergency Stop . . . . . . . . . . . . . . . . . . . . . . . 9

Safe Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Proportional Functions. . . . . . . . . . . . . . . . . . . 9

Joysticks or Paddle Levers . . . . . . . . . . . . . . 10

Option Controls . . . . . . . . . . . . . . . . . . . . . . . 10

Transmitter Shutdown . . . . . . . . . . . . . . . . . . 10

Optical Displays and Acoustic Signals. . . . . . 10

Transmitter . . . . . . . . . . . . . . . . . . . . . . . 10

Receiver . . . . . . . . . . . . . . . . . . . . . . . . . 10

Frequencies and Addresses . . . . . . . . . . . . . 10

Transmitter Options . . . . . . . . . . . . . . . . . . . . 10

Back-up Transmitter . . . . . . . . . . . . . . . . 10

ADMO Address Plugs . . . . . . . . . . . . . . . 11

Optical Low Battery Indicator. . . . . . . . . . 11

Advanced Low Battery Indication . . . . . . 11

Feedback. . . . . . . . . . . . . . . . . . . . . . . . . 11

RF Booster . . . . . . . . . . . . . . . . . . . . . . . 11

Priority Transmitters . . . . . . . . . . . . . . . . 11

RF Units. . . . . . . . . . . . . . . . . . . . . . . . . . 11

Crane/Machine Control Multiple Transmitters 11

Pitch and Catch . . . . . . . . . . . . . . . . . . . . 11

Independent/Combined Control. . . . . . . . 11

Universal Transmitter . . . . . . . . . . . . . . . 11

Optional Safety Features . . . . . . . . . . . . . . . . 12

"Press to Operate" (PTO) Safety Switch . 12

"Lift to Operate" (LTO) Joystick . . . . . . . . 12

"Lift to Operate" (LTO) Toggle Switch . . . 12

Tilt Sensor Switch . . . . . . . . . . . . . . . . . . 12

Range Limitation . . . . . . . . . . . . . . . . . . . 12

Interlocking Functions . . . . . . . . . . . . . . . 12

Magnet Switch . . . . . . . . . . . . . . . . . . . . . 12

Corrosion Protection . . . . . . . . . . . . . . . . 12

Solid State DC Outputs . . . . . . . . . . . . . . 12

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Battery Charging System . . . . . . . . . . . . . . . . 13

Features . . . . . . . . . . . . . . . . . . . . . . . . . 13

The Battery Charger . . . . . . . . . . . . . . . . 13

Battery Charger Technical Specs . . . . . . 13

LED Description. . . . . . . . . . . . . . . . . . . . 13

Charging the Battery . . . . . . . . . . . . . . . . 14

Fast Charge. . . . . . . . . . . . . . . . . . . . . . . 14

Hetronic Battery Information . . . . . . . . . . 14

Battery Technical Specs . . . . . . . . . . . . . 14

Changing the Battery. . . . . . . . . . . . . . . . 14

Battery Disposal. . . . . . . . . . . . . . . . . . . . . . . 14

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . 15

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Installation / Safety Data Sheet . . . . . . . . . . . . . 17

Definitions & Metric Conversions . . . . . . . . . . . 18

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Frequency Chart CS 458 . . . . . . . . . . . . . . . . . . 20

Frequency Chart CS 447 . . . . . . . . . . . . . . . . . . 21

Frequency Chart CS 434 . . . . . . . . . . . . . . . . . . 22

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2

INTRODUCTION

INTRODUCTION

Thank you for purchasing the Hetronic radio remote

control system. Hetronic radio remote controls are the

highest caliber in remote control value, performance

and safety.

Hetronic radio remote controls use the latest frequency

synthesizer technology to eliminate the problems

typically associated with radio remote control systems.

The Hetronic radio remote control system includes a

transmitter and a receiver. These systems operate over

the 400-470 MHz radio band range (70 cm band) and

are FCC approved.

The transmitter generates the electronic signal that

communicates with the receiver. The transmitter and

receiver are set with identical address codes and

frequency channels. This allows operation of multiple

systems within the same area without signal

interference.

THE MANUAL

Before operation of unit, carefully and completely read

your manuals. The contents will provide you with an

understanding of safety instructions and controls

during normal operation and maintenance.

PRODUCTION AND SYSTEM NUMBERS

When contacting your dealer or Hetronic about service,

repair or replacement parts, know the Production and

System numbers of the transmitter and receiver.

The numbers are located on the label that is affixed to

the unit itself.

1

2

1. Specific approvals such as BTZ, FCC, CE, etc.

2. The type of transmitter or receiver.

3. Frequency and RF unit.

4. Production Number - The first digit indicates the

manufacturing facility (1=H-Germany, 2=H-Malta,

3=H-US, 4=H-International). The next four digits

are the production month and year. The last 6

digits are the manufacturing number.

5. System Number - Eleven digit system

identification number. Transmitter and receiver

must match.

3

4

5

Record the Production and System numbers here:

Transmitter Production Number

Receiver Production Number

System Number

UNAUTHORIZED REPLACEMENT PARTS

Use only Hetronic replacement parts. The replacement

of any part with anything other than a Hetronic

authorized replacement part may adversely affect the

performance, durability, and safety of this system and

may void the warranty. Hetronic disclaims liability for

any claims or damages, whether warranty, property

damage, personal injury or death arising out of the use

of unauthorized replacement parts.

BEFORE ATTEMPTING TO OPERATE THIS

SYSTEM:

1. Make sure all installation has been properly

completed.

2. Understand all Safety Precautions provided in the

manuals.

3. Review control functions and operation of the

machine and this radio remote control system.

THEORY OF OPERATION

The BMS System includes a transmitter and a receiver.

The transmitter generates the electronic signal that

communicates with the receiver. Hetronic radio remote

control systems operate in the 400-470 MHZ range (70

cm band). The transmitter and receiver are set with

identical address codes and frequency channels. This

allows operation of multiple systems within the same

area without signal interference

.

3

SAFETY

SAFETY ALERTS

Look for this symbol to point out

important safety precautions. They

mean:

Attention!

Personal Safety Is Involved!

Become Alert!

Obey The Message!

The safety alert symbol is used in decals on the unit

and with proper operation procedures in this manual.

Understand the safety message. It contains important

information about personal safety on or near the unit.

DANGER: IMMINENTLY HAZARDOUS

SITUATION! If not avoided, WILL RESULT in

death or serious injury.

WARNING: POTENTIALLY HAZARDOUS

SITUATION! If not avoided, COULD RESULT

in death or serious injury.

CAUTION: POTENTIALLY HAZARDOUS

SITUATION! If not avoided, MAY RESULT in

minor or moderate injury. It may also be used

to alert against unsafe practices.

NOTATIONS

NOTE: General reference information for proper operation and maintenance practices.

IMPORTANT: Specific procedures or information

required to prevent damage to unit or attachment.

PRACTICES AND LAWS

Practice usual and customary safe working

precautions, for the benefit of yourself and others.

Understand and follow all safety messages. Be alert to

unsafe conditions and the possibility of minor,

moderate, or serious injury or death. Learn applicable

rules and laws in your area.

REQUIRED OPERATOR TRAINING

Original purchaser of this unit was instructed by the

seller on safe and proper operation. If unit is to be used

by someone other than original purchaser; loaned,

rented or sold, ALWAYS provide this manual and any

needed safety training before operation.

ALWAYS review the operators manual of any machine

to be controlled by radio remote control.

SAFETY RULES

This radio remote control system is equipped with

electronic and mechanical safety features. Processing

of control signals transmitted from other transmitters is

not possible, since transmission coding is unique to

each system.

POSSIBLE SOURCES OF DANGER

This system makes remote control via radio signals

possible. However, the transmission of control

commands can take place around obstacles and out of

the operator’s direct sight. To prevent accidental

start-up and possible injury or damage:

1. Always engage the E-stop button and switch

"OFF" the transmitter when it is not in use.

Remove the key if the unit is placed any distance

away from the operator.

2. Disconnect the power supply before any

assembly, maintenance or repair work is done.

3. Never remove or alter any of the safety features

of this system.

OPERATION AND WORK AREA SAFETY

The work area must be free from obstacles, debris or

other tripping hazards. Avoid uneven work areas and

any rough terrain. Always be sure of your footing.

Be aware of overhead obstacles that may interfere with

machine operation.

Always operate the transmitter with its carrying belt.

PROTECTIVE FEATURES

These safety features help protect the operator, as well

as others within the work area. The machine functions

can be stopped by pushing the emergency stop button

on the transmitter control panel (EMERGENCY STOP).

NOTE: The e-stop command is transmitted within

approximately 0.5 seconds (450 ms) after the switch is

turned to the "OFF" position.

The protective guard around the upper section of the

transmitter housing helps protect against accidental

activation of controls and unintentional operation.

WARNING: Accidental start-up can cause

serious injury or death. NEVER remove or

modify any safety feature.

TO STOP IN AN EMERGENCY

1. Press the red "EMERGENCY STOP" pushbutton.

2. Turn the key to "OFF".

3. Wait for all moving machine parts to stop.

4

4. Refer to machine’s operator manual for further

instructions.

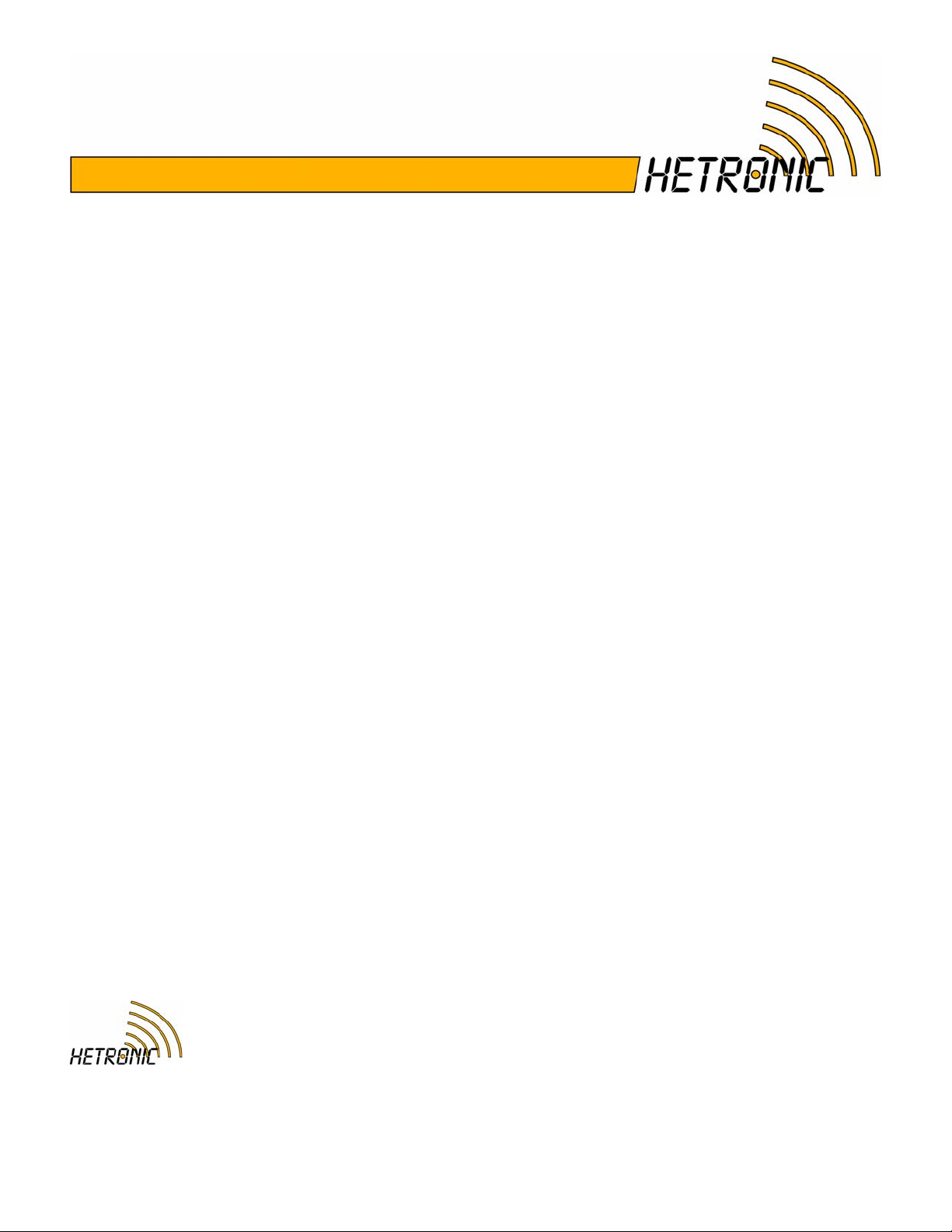

GL-2

Emergency

Stop

Pushbutton

Nova-L

GL2_0020

INSTALLATION

WARNING: FAILURE TO FOLLOW

INSTRUCTIONS could result in personal

injury and/or damage to equipment. Read and

understand the safety instructions in all

manuals provided.

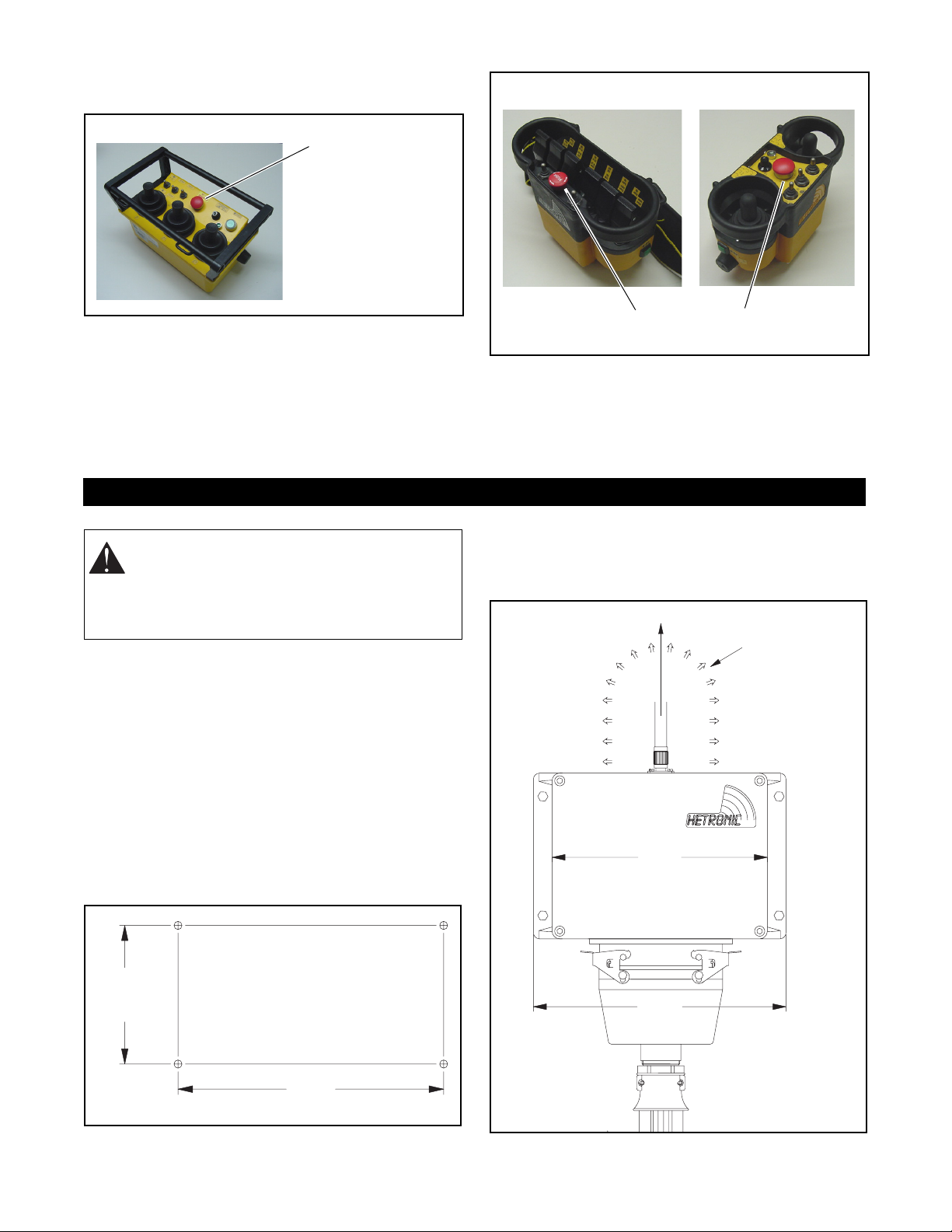

MOUNT THE RECEIVER

Install Receiver and Output Wiring

Select a position for the receiver that provides

protection from violent impact from debris or thrown

materials and is easily accessible. The receiver

housing is rated IP65 and can withstand direct water jet

spray and is protected against penetration of dust.

Therefore, weather and elements should not be the

primary concern when installing the receiver.

Four mounting holes are required when installing the

receiver unit. The drill pattern and recommended

hardware are shown in the following illustration.

NVL_0010

Emergency

Stop

NVL_0020

Pushbuttons

MAINTENANCE

Always shut off power to the machine and the radio

remote control before any assembly, maintenance or

repair.

If the receiver includes an attached antenna, mount the

receiver so that the antenna points straight up. The

area around the antenna should be free of

obstructions, especially metal.

Antenna must be

vertical (pointing up).

8.29"

(210.5 mm)

Area must be

free of

obstructions

4.57"

(116 mm)

DRILL PATTERN

Drill 4 holes 9/32" (7mm).

Use 1/4" or 6mm bolts.

9.13"

(232 mm)

BMS_0030

9.72"

(246.8 mm)

BMS_0040

5

Be sure that the diagnostic LED panel is clearly visible.

Area must be free

of obstructions

ME-3 Module Calibration (Optional)

Determine the maximum stroke of the actuator and set

the ME-3 module accordingly. See the ME-3 Module

Instruction Sheet in the Technical Data Sheet section

for detailed instructions.

2.80"

(71.1 mm)

Operation

Signal

Error

Normal

6.38"

(162 mm)

4.47"

(113.5 mm)

Do not block

visibility of

diagnostic

panel.

6.61"

(167.9 mm)

BMS_0040

The receiver wiring is critical for proper system

operation. Make all connections with good quality

contacts or solder joints to ensure proper electrical

contact.

Supply voltage and ground wiring are crucial and must

be connected to reliable connecting circuitry. Do not

use a chassis ground for this equipment. The ground

wire must be connected directly to the vehicle battery

negative post.

The output control signals to the proportional control

valves should be routed separately from any wiring that

could produce transient voltage interference.

Interference or "induced voltage spikes" could cause

erratic performance of the proportional controls.

INSTALL BATTERY CHARGER

The battery charger unit should be installed in the

vehicle and connected to the vehicle battery with a

fuse. The charger must be operational even when the

vehicle ignition is turned off. The battery charger’s

energy consumption impact is minimal. The charging

system is protected against polarity reversal. Install

and operate the charger in a dry, protected location

inside the vehicle. Optional battery chargers may be

powered by an AC wall plug or a DC cigarette lighter

adapter.

BATTERY HANDLING

Each Hetronic radio remote control system is delivered

with two fully charged batteries. One is inserted in the

battery compartment located on the bottom of the

transmitter. The operating time of the 3.6 V charged

battery is approximately 25-30 hours.

INSERT THE BATTERY

Be sure the battery compartment is clean. Dirt or debris

can cause contact problems.

GL

1. Insert the battery with both guide pins in the

corresponding guide bars of the battery

compartment.

2. Press the battery on the marked spot until it

latches into place.

GL-2

Battery

Mount the Actuators (Optional)

Mount and attach the actuators to the hydraulic valves

or to the mechanical linkage with the brackets supplied.

Attach Wiring Harness (Optional)

Plug the wiring harness into the receiver and into the

corresponding actuators.

Connect Electrical Wiring

Connect all remaining wires (power supply, engine

start-stop, etc.) according to the wiring diagram of the

crane and the radio remote control.

GL2_0010

Nova

1. Insert the battery with both guide bars on the

lower side of the battery in the corresponding

guide slots of the battery compartment.

2. Press the battery until it latches into place.

Nova-L

Battery

NVL_0040

6

ADJUSTMENTS

QUICK-SET SYSTEM

The Quick-Set System provides easier installation,

adjustment and service of the radio remote control

system. Quick-Set allows adjustment of all proportional

function speeds (valve travel) from the transmitter. A

red Program Key is provided to control the

programming mode. When adjustments are complete,

remove the Program Key and store it in a secure

location. Function speeds can be readjusted at any

time.

The system includes a base board, or mother board,

which includes all of the common function circuitry

found in most Hetronic receivers. These functions

include power regulation, decoding the received signal,

12 digital output functions, and the Quick-Set function.

The base board also contains diagnostic LEDs that are

visible on the outside of the transmitter housing to help

quickly diagnose problems.

FUNCTION SPEED ADJUSTMENT

This procedure requires that the receiver is connected

to the machine, all necessary wiring is complete and a

fully charged battery is in the transmitter.

IMPORTANT: The crane must be located in an open

area so that sudden or unexpected crane movements

will not damage buildings or property. All power lines

must be out of reach of the boom. Set the outriggers in

the "out and down" position as recommended by the

crane manufacturer and be sure the crane is stable.

For specific instructions, refer to the crane

manufacturer’s operator manual. Allow the truck

engine to run at "Idle".

5. Insert the red programming key into the

keyswitch.

6. Turn the transmitter "ON".

7. Wait approximately 3 seconds until the second

buzzing sound has finished.

8. Twist the key one quarter turn further to the

program position. (This is only possible with the

red programming key.) Press the "Start/horn"

button for at least one second.

9. To set minimum speed - Deflect the requested

joystick slowly until you hear the vehicle’s horn. If

the horn is connected to the receiver, it will sound

for a brief moment when the joystick reaches the

minimum movement position. Keep the joystick in

this position.

10. Adjust the speed of this function by using the

program "T-O-T" toggle switch (momentary - zero

- momentary). Push the toggle switch toward "+"

to increase speed, toward "-" to decrease speed.

Adjust the function speed to move as slowly as

possible. This helps to achieve a smooth start

when this function is activated.

11. To set maximum speed - Deflect the joystick to its

maximum position. Push the program toggle

switch toward "+" to increase speed, toward "-" to

decrease speed.

WARNING: AVOID INJURY - The crane is

moving during the adjustment of the

functions. Be sure the work area is clear of

obstacles and bystanders.

CAUTION: AVOID INJURY AND PROPERTY

DAMAGE - The crane may respond differently

with radio remote controls than with manual

controls. During the adjustment procedure,

use extreme caution with joystick/lever

movements. Avoid sudden movements and

observe crane motions carefully. The operator

must be standing on dry, level, stable ground

that is free of oil and debris.

1. Use the crane’s manual controls to raise the

boom from its rest. Extend the boom to a safe

starting point.

2. The transmitter must be attached to the operator

with the belt adjusted to a firm fit.

3. Turn the receiver power "ON".

4. Remove the black key from the transmitter

keyswitch.

The receiver can program only one function at a time.

Make sure that only one axis is deflected at a time.

When function adjustment is complete in one direction,

repeat the procedure above for the other directions and

functions. Remember to set values for both high and

low ranges.

After all adjustments are complete, wait at least 10

seconds before turning the transmitter off. The new

values will be automatically stored into the system’s

memory.

If problems occur during the adjustment procedure,

you can revert to the default values of the system.

Remove the receiver lid and press the reset button on

the board. Reinstall the receiver lid.

7

Reset

Button

BMS_0010

OPERATION

WARNING: FAILURE TO FOLLOW

INSTRUCTIONS could result in personal

injury and/or damage to equipment. Read and

understand the safety instructions in all

manuals provided.

HOLDING THE TRANSMITTER

Hold the transmitter with the control panel facing you.

Be sure that you are able to easily read any text and

understand operation symbols. If your transmitter

contains a Tilt Sensor Switch, be sure it is not activated

or the transmitter will not start.

If a belt or strap is provided with your transmitter, use it

at all times. The belt or strap is designed to reduce

stress and increase safety.

WARNING: FAILURE TO FOLLOW

INSTRUCTIONS could result in personal

injury and/or damage to equipment. Always

hold the transmitter in the proper orientation.

Holding the transmitter improperly while

operating the crane/machine could result in

unexpected crane/machine response.

The safety checks described in the following

paragraphs must be completed before the radio remote

control system is activated. These checks must be

performed at least once a day, before the start of any

operation and at all shift changes.

IMPORTANT: A transmitter drawing is included with

each system. Transmitter layout and inscriptions may

vary according to customer requests.

WARNING: FAILURE TO FOLLOW

INSTRUCTIONS could result in personal

injury and/or damage to equipment. Test the

"E-STOP" function as described in the

crane/machine manufacturer’s operator

manual before beginning any operation.

ADDRESS SETTINGS

The address settings are pre-set at the factory in the

ADMO module. However, if the transmitter coder

board, the BMS-1 Base Board, or if the entire

transmitter or receiver are replaced, the ADMO

address must match the system.

IMPORTANT: If the ADMO settings of the transmitter

and receiver do not match, the system will not function.

VISUAL CHECK

Always check the transmitter for any physical damage

before any operation.

• Always keep safety features, guards and controls

in good repair, in place and securely fastened.

• Check equipment for wear or damage.

• Check rubber cuffs and pushbutton caps for wear

or damage.

IMPORTANT: Never operate a transmitter with worn or

damaged parts. Replace immediately with only

Hetronic parts. Contact Hetronic or your Dealer.

START-UP PROCEDURE

This procedure must be carefully followed before

beginning any operation.

1. Be sure that all safety measures required by the

equipment manufacturer have been followed. (i.e.

crane level, stabilizers down, etc.)

2. Be sure the transmitter battery is fully charged.

3. Push in the transmitter E-stop pushbutton.

4. Be sure that all controls, joysticks or paddle

levers are in the Off (neutral) position.

NOTE: If any control, joystick or paddle lever is NOT in

the Off (neutral) position when the Start/Horn button is

pushed, the transmitter will not turn on.

5. Switch the transmitter "ON". A short buzzer signal

will sound.

6. Wait for the second buzzer signal (approx. 3

seconds).

7. The green LED on the transmitter control panel

will flash.This indicates that the transmitter is

working and is ready to use.

8. Disengage the E-stop pushbutton.

9. Push the green pushbutton "Start/horn" on the

transmitter.

10. Check that the machine functions correspond

with the transmitter functions.

IMPORTANT: The machine functions will operate

during this check. Be certain that there are no

obstacles near the machine.

8

11. Push the "EMERGENCY STOP" pushbutton on

the transmitter. Be sure that no functions can be

activated with the "EMERGENCY STOP"

pushbutton depressed.

IMPORTANT: If any function of the radio remote

control activates with the "EMERGENCY STOP"

engaged, the radio remote control must not be used

until it is repaired.

12. Pull out the "EMERGENCY STOP" pushbutton.

13. Push the green pushbutton "Start/horn" on the

transmitter.

14. Both the radio remote control and the machine

are now ready for operation.

IMPORTANT: To avoid accidental start-up, always

engage the E-stop pushbutton and switch the

transmitter "OFF" when not in use. When the

transmitter is not attached to the operator, the key

switch should be removed and stored in a secure

place.

WARNING: TO AVOID SERIOUS INJURY

OR DEATH. Switch the machine "OFF" if

there is a fault or any problems with the safety

check. Contact Hetronic or your dealer

immediately to repair the system. NEVER

operate the machine when the

"EMERGENCY STOP" function does not

operate properly.

Improper operation, maintenance or

adjustment may cause serious injury or

damage to equipment and may void the

warranty.

SPEED CONTROL

This radio remote control system is equipped with a

dual range speed control. The switch allows selection

between high range (rabbit) and low range (snail). The

low range provides <70% of full speed.

NVL_0010

GL-2

GL2_0020

Nova-L

Start

Pushbutton

Start

Pushbuttons

NVL_0020

EMERGENCY STOP

For all emergency situations, push the E-Stop

pushbutton in. To restart the system, disengage the

E-Stop pushbutton and press the Start/Horn

pushbutton. Be sure any dangerous conditions are

corrected and follow the Start Up Procedure above.

SAFE MODE

When the transmitter battery voltage drops below

approximately 3.4 volts, the system automatically goes

into Safe Mode. A buzzer will sound to indicate a low

battery. At the end of the 30 seconds, the transmitter

sends the E-Stop signal and all crane/machine motion

commands are stopped.

To restart the system, a fully charged battery must be

inserted into the transmitter. Proceed with startup

instructions. Always place the discharged battery

directly into the charger.

PROPORTIONAL FUNCTIONS

The proportional functions and speed ranges are

pre-set by Hetronic according to the valve types. Your

dealer can refer to the basic adjustments at any time.

Only the crane manufacturer, dealer or authorized

service representative is allowed to adjust individual

functions, direction and speed range.

CAUTION: DO NOT OPEN THE RECEIVER.

All relay and proportional outputs are

accessible on the connection plug.

Unauthorized entry into the receiver could

result in damage to equipment and may void

the warranty.

9

JOYSTICKS OR PADDLE LEVERS

Joysticks and paddle levers are equipped with a spring

return to the center (OFF) position. If the

crane/machine motion is multi-speed, the farther the

lever is pushed, the faster the crane/machine motion

will move. Return the lever to the center position to

stop the crane/machine motion.

OPTION CONTROLS

Each transmitter can be equipped with a variety of

rotary switches, toggle switches or pushbuttons. Each

function is labeled. For specific operational

instructions, refer to the technical documentation

supplied with your transmitter, or contact Hetronic.

TRANSMITTER SHUTDOWN

To shut down the transmitter, turn the key switch to

OFF. Remove the key and place it in a secure location

to prevent unauthorized or unintentional use.

OPTICAL DISPLAYS AND ACOUSTIC

SIGNALS

The radio remote control system uses optical displays

and acoustic signals to show current working status.

Off: Indicates E-Stop condition.

On: Normal operating condition.

• The yellow "Operation" LED

Off: Indicates no power to the base board.

Flashing: Indicates power to the base board.

• The red "Error" LED

Off: Normal operating condition.

Flashing: Failure in the system circuitry. The

transmitter will initialize a self-test routine which

may re-initialize the system. If not, the failure

must be diagnosed.

CAUTION: After pressing the start

pushbutton for approximately 1 second, the

red "Error" LED should stop flashing or go off.

If the LED stays lit, there is a malfunction in

the system. Contact your Dealer or Hetronic

for repairs. Unauthorized entry into the

receiver could result in damage to equipment

and may void the warranty.

Transmitter

1. Turn keyswitch to "ON".

2. One long acoustic signal (buzzer) sounds.

3. After the self-test routine, another buzzer sounds

to indicate that the system is ready to operate.

4. Then press the Start/Horn button to begin system

operation.

NOTE: If the Start/Horn button is pressed before the

second buzzer, the system will not start up.

During transmitter operation, a buzzer signal indicates

when the battery is nearly discharged. The transmitter

will operate for another 30 seconds before going into

E-Stop. Use this time to place the crane/machine in a

safe position.

Receiver

There are four LEDs on the right side of the receiver.

They indicate proper system operation and

malfunctions.

• The green "Signal" LED

Off: No data reception (no communication with

transmitter.

Flashing in a continuous rhythm: The transmitter

is turned "ON" and valid data are received.

Flashing at increased rate: E-Stop signal is being

received.

Flashing, out of rhythm: Indicates RF

interference, transmitter out of range or bad

receiver reception.

• The yellow "Normal" LED

BMS_0020

FREQUENCIES AND ADDRESSES

Each Hetronic radio remote control system contains a

registration-free radio frequency unit, CS 434 or CS

458. Each system consists of a transmitter RF unit and

a receiver RF unit.

CAUTION: AVOID INJURY OR DAMAGE Operating the transmitter without its antenna

could destroy the final stage of the RF

module. DO NOT attempt to change the

Hetronic pre-set frequency or the 16-bit

address. Personal injury and property

damage could result from transmission

interference and may void the warranty.

TRANSMITTER OPTIONS

Each Hetronic radio remote control system is built to

customer specifications. You may have features that

are not described in this manual. Some possible

options are described below. If you have questions,

please contact your dealer or Hetronic.

Back-up Transmitter

Spare transmitters are frequently used in the event that

the primary transmitter is damaged or misplaced. Only

one transmitter is allowed to be active at any given

time.

10

NOTE: If the primary and back-up transmitter are

turned on at the same time, the receiver enters the

Safe Mode.

ADMO Address Plugs

If several radio remote control systems are used,

address plugs can configure a spare transmitter to be

used on any of the cranes/machines. Each address

plug corresponds to a specific crane/machine. When a

specific crane/machine address plug is inserted into

the plug receptacle of the spare transmitter, the

transmitter is automatically configured to operate that

crane/machine.

Optical Low Battery Indicator

This feature is a LED indicator of the low battery

condition. It can be used as an alternative to or in

addition to the buzzer signal.

Advanced Low Battery Indication

This feature is basically a timer that indicates a low

battery condition 10 minutes before the Safe Mode is

entered. This feature is beneficial where placing the

crane or machine in a safe position takes more time

after the low battery is indicated.

Feedback

This feature allows the transmitter to receive and

display information such as crane/machine status,

warnings, etc. The feedback can be displayed as visual

graphics or buzzers.

RF Booster

This feature boosts the RF transmission power for

extended range operation of up to 1 mile. It is to be

used only in applications that are safe to operate

outside of the operator’s visual range.

Priority Transmitters

This feature is the capability to have several

independent cranes/machines controlled by one

transmitter. Priority levels can be set to allow the main

transmitter to override the control of individual

crane/machine transmitters.

RF Units

AUTX - Auto Synthesizer - The function of a transmitter

to automatically search a range to find a frequency

without interference.

SCRX - Scan Synthesizer - The function of a receiver

to respond only to a designated transmitter and finding

the frequency that the transmitter is transmitting on.

CRANE/MACHINE CONTROL WITH

MULTIPLE TRANSMITTERS

Multiple crane/machine applications may require the

use of more than one transmitter. Or a single

transmitter may be required to control several

cranes/machines simultaneously. The common

methods of control for these situations are "Pitch and

Catch" and "Independent/Combined Control."

Pitch and Catch

Multiple (usually two) transmitters control one receiver,

but not at the same time. All transmitters must be

configured with the same address code as the receiver,

but set at a different frequency channel.

The first transmitter turned on controls the

crane/machine. The operator moves the load to a

hand-off location and turns the transmitter off. The

second operator turns his transmitter on and takes

control of the crane/machine. The receiver only

accepts commands from one transmitter at a time.

Independent/Combined Multiple

Crane/Machine Control

This configuration is for applications that require

multiple (usually two) cranes/machines on a single

runway. Each crane/machine can be controlled

independently. The cranes/machines may also be

operated in tandem by one operator.

The transmitters built for these applications contain

Selector switches. These switches select each

crane/machine individually or any combination of

designated cranes/machines.

With transmitter interlocks, each transmitter contains a

different address code and frequency channel. The

receivers have a RF module and decoder set for each

transmitter. A special module inside the receiver

determines which transmitter is requesting control of

each crane/machine. The module locks the transmitter

signal to the receiver and all other transmitter signals

are ignored.

When that transmitter is turned OFF, the

cranes/machines are available to be controlled by a

different transmitter.

Universal Transmitter

One transmitter is engineered to communicate with

several different systems. The transmitter can be

quickly modified to control any crane or machine in a

designated facility or fleet.

11

OPTIONAL SAFETY FEATURES

"Press to Operate" (PTO) Safety Switch

To release a crane/machine load, it may be necessary

to incorporate a two-handed activation with a "Press to

Operate" (PTO) safety switch. The PTO switch must be

activated at the same time the load release switch is

activated. This feature ensures that the load is not

released by incidental activation of the release switch.

Typical applications for a PTO switch are magnetic and

vacuum lifting devices or grabs of any type.

A PTO safety switch can also be incorporated into a

joystick as a button on top of a joystick lever.

"Lift to Operate" (LTO) Joystick

"Lift to Operate" (LTO) joysticks have a mechanical

device located near the top of the joystick handle. It

must be held and lifted upward to activate the joystick.

LTO ensures that the joystick is not accidentally

activated. This feature is available on GR transmitters.

"Lift to Operate" (LTO) Toggle Switch

LTO toggle switches must be lifted from their static

positions in order for the switch to be activated. LTO

toggle switches can be "maintained" or "momentary".

This feature is mechanically activated and is available

on Nova, GL, and GR transmitters.

Magnet Switch

The magnet switch is used mainly in transmitter

docking station situations. Its function is to enable

certain functions only when the transmitter is secured

in a predetermined location.

Corrosion Protection

To resist damage in corrosive environments, all metal

components are fabricated of stainless steel. This can

include receiver housings, hardware, screws, etc.

Solid State DC Outputs

This feature enables Hetronic to eliminate costly

intermediate relay panels for DC crane/machine

operations. There are no moving parts in the

contactors, thereby lowering maintenance costs.

Tilt Sensor Switch

The tilt sensor switch activates if the transmitter is tilted

more than 30 or 45 degrees from level. The switch has

a delay time of 0-5 seconds.The delay time is set at the

factory to customer specifications. If this switch senses

an unacceptable tilt for as long as the time delay is set,

the transmitter either sends the E-stop signal to the

receiver or enables/disables certain functions

according to customer specifications. This safety

device is useful if the operator is in danger of losing his

footing or control of the transmitter. It is available on GL

and GR transmitters.

Range Limitation

This feature uses a RF signal to restrict operator

movement to a predetermined range limit. It can be

preset at the factory, or adjusted in the field.

Interlocking Functions

This feature prevents contradictory operator

commands from the transmitter. Certain functions can

be enabled or disabled when another function is

activated or inactive. An example is hoist up and hoist

down. Activating both functions would most likely

damage the equipment. Therefore, hoist up is

interlocked with hoist down so that when one is

activated the other can not be. The systems are

capable of interlocking any functions.

12

MAINTENANCE

BATTERY CHARGING SYSTEM

The Hetronic UCH-2 is a new and improved battery

charging system. It includes upgraded features to

better charge and troubleshoot the battery.

Battery and charger contacts are gold-plated and

self-cleaning to ensure positive connection. The battery

and charger contacts are mechanically cleaned each

time the battery is removed from or inserted into the

battery compartment.

CHARGE LED

FAST

CHARGE LED

READY LED

Features

• Normal charge or Fast charge of Hetronic

standard batteries

• Trickle charge - After charging process is

complete, battery can remain in charger without

being damaged by over-charge.

• Battery diagnostics - Charger determines if

battery is damaged.

• Gold plated contacts ensure clean, positive

contact between battery and charger.

• LED status lights indicate charging process as

well as battery diagnostics

The Battery Charger

One battery charger is designed for 115/230 VAC and

plugs into a typical wall outlet. Another charger is

designed for 12/24 VDC and is wired into the constant

crane/machine power source.

When the battery is inserted into the charger, a flashing

“CHARGE” LED lights. The charge process is

terminated by detecting peak battery voltage or after 5

hours and the “READY” light goes on. When the

“READY” light is lit, the charger continues to "trickle"

charge the battery.

NOTE: If the battery is bad and has an open cell, no

LEDs will light up. If the battery has a shorted cell, the

“CHARGE” LED will blink continuously. In either case,

the battery must not be used. Properly dispose of the

bad battery.

FAST

CHARGE

Button

Battery

Battery Charger Technical Specifications

Charging current Normal: 200 mAh

Fast charge: 680 mAh

Charge time

(Standard Hetronic

1200 mAh battery)

Temperature range -20C to +75C

Power supply DC - 12-24 VDC, polarity

NOTE: Will also charge 9.6 V batteries. Internal

modification (jumper 2) and mechanical limiters must be

removed.

Normal: approx. 6 hours

Fast charge: less than 2 hours

(no damage to battery, or

negative effect to duty cycles)

protected

AC - 110-220 VAC, US/Japan or

EU plug

LED Description

Yellow LED

Red LED

Green LED

Yellow CHARGE

LED

Lights constantly - Charging

Continuous flashing -

Damaged battery cell (short)

Red FAST

On - Fast charge in process

CHARGE LED

Green READY

LED

No LED on after

battery inserted

On - Battery fully charged,

trickle mode in process

Damaged battery cell (open

cell)

Charging the Battery

1. Insert the battery with both guide pins in the

corresponding guide bars into the battery

compartment of the battery charger.

2. Press the battery on the marked spot until it

latches into its compartment. The LED labeled

“CHARGE” flashes for two seconds, then stays lit

during the charging process.

13

3. When the battery is fully charged, the “READY”

LED lights up and the “CHARGE” LED goes off.

Charging time could take up to 5 hours,

depending on the condition of the battery.

4. Leave the battery in the charger until it is needed.

The charger supplies a “trickle” charge but will not

over-charge the battery.

CHARGE LED

FAST

CHARGE

Button

FAST

CHARGE LED

Battery

READY LED

DC Only

Battery Technical Specifications

Battery type NiMh (nickel metal hydride)

Capacity (typical) 1200 mAh

Typical operation

time

Memory effect None

Duty cycle Can be recharged at least 500 times

10 - 20 hours with one charge

(depending on TX configuration)

(after 500 charges, over 80% of

capacity remains and will diminish

gradually)

Changing the Battery

The battery voltage is monitored continuously by the

transmitter.

A buzzer in the transmitter sounds when the battery is

nearly discharged. When the transmitter signals, the

battery must be changed immediately.

1. Position the crane/machine into a safe place or

safe condition within 30 seconds after hearing the

signal.

Optional

DC

US/Japan AC

European AC

Cigarette

Lighter

Adapter

Battery Charger Power Options

Fast Charge

1. Insert the battery into the charger as described

above. The LED labeled “CHARGE” flashes for

two seconds, then stays lit.

2. Press the “FAST CHARGE” button. The FAST

CHARGE LED lights also and stays lit during the

charge process.

3. When the battery is fully charged, the “READY”

LED lights up and the “CHARGE” and “FAST

CHARGE” LEDs turn off.

If you have questions or problems operating your

battery charger, please contact your dealer or Hetronic.

Hetronic Battery Information

Standard Hetronic rechargeable batteries are the nickel

metal hydride type. These batteries have no “memory

effect” when charging a battery that is not fully

discharged.

WARNING: The transmitter will switch to the

EMERGENCY STOP condition after 30

seconds.

NOTE: If your transmitter is equipped with Advanced

Low Battery Indication, you have up to 10 minutes to

place the crane/machine in a safe position. The exact

amount of time is determined by customer

specifications. Refer to the technical drawings for each

radio remote control system.

2. Press the E-stop pushbutton.

3. Switch the transmitter "OFF".

4. Push the discharged battery slightly forward and

lift it out of the battery compartment.

5. Insert a fully charged battery.

6. Follow "Start-up Procedure" to begin operation.

BATTERY DISPOSAL

IMPORTANT: AVOID ENVIRONMENTAL

POLLUTION. Electronic equipment and components

are considered to be hazardous waste. Discarded

rechargeable batteries are hazardous waste and must

not be disposed of with typical refuse. Contact a

professional hazardous waste disposal service.

14

WARNING: EXPLOSIVE GASES AND

FLYING DEBRIS can cause death or serious

injury. Use only Hetronic replacement

batteries. Use of unauthorized replacement

batteries could cause a battery explosion,

resulting in injury or death of the operator or

other people in the work area.

TROUBLESHOOTING

If the system does not operate after normal start-up as

described in Operation Section of this manual, follow

the recommended troubleshooting sequence to help

isolate the cause and determine corrective action.

PROBLEM PROBABLE CAUSE CORRECTION

If the system will not respond to the steps below or the

LEDs indicate a failure, contact the Hetronic Service

Department or your authorized dealer.

System will not initialize

after normal start-up

procedure

E-Stop reset Push the Start button again. If the system is

being initialized from an E-Stop condition,

the Start button must be pressed twice - first

to clear the E-Stop, then to start the system.

Joystick or paddle lever not in

center position

E-Stop switch engaged Pull out E-Stop switch. Restart system by

Battery fully discharged Check battery to ensure a full charge.

No power to the receiver Check the diagnostic LEDs on the side of

Ensure that all joysticks and paddle levers

are in center position when the Start button

is activated.

pressing Start twice.

Replace with fully charged battery if

necessary.

the receiver to be sure power is applied.

Ensure that the system is grounded to the

negative battery terminal. The LEDs also

indicate normal transmitter communication,

interference, and E-Stop conditions.

15

SPECIFICATIONS

Model BMS

(Baseboard Module System)

System GA 610

General Data

Frequency 70 cm Band (Selectable

458.800 Mhz to 459.175

Mhz) or CS434

Range approx. 100 m ( 328 ft.)

Address 20-bit - 1,000,000 possible

Operating temperature -30° to +70° C

(-22° F to 158° F)

Data Format 2400/4800 Baud, even

parity, 8 data bits, 2 stop bits,

hamming distance 4

Receiver

Protective System IP 65

System Synthesizer Technology

Voltage Supply 12 to 24 VDC (-50% - +20%)

Current rating,

Transmission

GL - Dimensions - with

protection frame

GL - Weight - including

battery and belt

Nova - Dimensions - with

protection frame

Nova - Weight - including

battery and belt

approx. 83 mA

300 mm x 180 mm x 180 mm

(11.8 in x 7.0 in x 7.0 in)

2.4 Kg (5.28 lbs)

230 mm x 170 mm x 106 mm

(9.0 in x 6.7 in x 4.2 in)

1.8 Kg (3.96 lbs)

Decoding Multiple bit scanning,

self-monitoring

Fuses 7.5 amp. / 80 V car fuse

Output Intrinsically safe emergency

stop with two MOS - FET transistors, 12 digital

outputs, potential free 250 V

/ 8 A, 6 analog outputs, 2

speed ranges

Static current 260 mA, Stand-by

Antenna connection TNC - socket

Dimensions - approx. with

rubber buffer

L x B x H

Weight - 2,5 kg ( 5.5 lbs)

265 mm x 161 mm x 111 mm

(10.4 in x 6.3 in x 4.4 in)

Transmitter

Protective System IP 65

Battery Pack 3.6 V / 1200 mAh (NiMh)

Operating time approx 20 h

Transmitting power < 10 mW

Current rating, Self test approx. 75 mA

16

INSTALLATION AND SAFETY TEST DATA

This for must be completed and signed by the person

responsible for installation of this radio remote control

system.

Crane Data

Manufacturer

Model Number

Serial Number

Year of Production

Radio Remote Control Data

Manufacturer Hetronic

Hetronic assumes no responsibility for the correct

installation of the radio remote control system. The

equipment operator must ensure that the radio remote

control system and the crane/machine operate

correctly together. The operator must also ensure that

all safety devices and features are in place and

operating correctly. The operator is responsible for

understanding and following all safety precautions in

this and other applicable operator manuals.

Model BMS

System Type GA 610

System Number

I/We installed the radio remote control system, performed the safety test and inspected the crane/machine. The

appropriate instructions and rules of this machine type are followed.

Place

Date

Company

Name of Installation Technician

Signature

17

DEFINITIONS

Acoustic signal A buzzer or other sound intended to be heard as an alert.

Analog signal Proportional - stepless or infinite control

Belly box A transmitter that is secured to the front of the operator’s body by a belt,

strap or breastplate/harness.

Coder Converts parallel signals into a serial data message

Decoder Coverts a serial data message into parallel signals

Digital signal On/off control

Latching control The function activates when the control is pushed and released. The function

stays on until the control is pushed and released again.

Mainline contactor The primary power supply contactor to the crane/machine controls.

Maintained control The function activates when the control is placed in the ON position. The

function stops when the control is placed in the OFF position.

Momentary control The function activates when the control is placed in the ON position. The

control must be held in place to stay ON. When the control is released, it

returns to the OFF position and the function is stopped.

Proportional control A multi-speed function control that goes faster as the control is pressed

further.

AWG - METRIC CONVERSIONS

AWG Metric Equivalent mm sq. Metric Cable Size mm sq.

20 0.52 0.75

18 0.82 1.0

16 1.32 1.5

14 2.1 2.5

12 3.3 4

10 5.32 6

8 8.5 10

6 13.5 15

4 21.3 25

2 33.7 35

1/0 (0) 53 70.0 (50.0 if current capacity not

exceeded)

2/0 (00) 67.6 70

3/0 (000) 84.4 95

4/0 (0000) 107 120

18

ABBREVIATIONS

A/D Analog to digital conversion

AK Analog channel (German: Analog Kanal)

AMP Ampere

AWG American Wire Gauge

BPS Bits per second

CPU Central Processing Unit

DK Digital channel (German: Digital Kanal)

EMC Electromagnetic compatibility

EMI Electromagnetic immunity

EPROM Electrical programmable read-only memory

FM Frequency modulation

GND Ground

HF High frequency

KHz Kilohertz

LED Light emitting diode

LTO Lift to operate

mAH Milliampere hours

mA Millampere

msec Millisecond

MHz Megahertz

MOV Metal Oxide Varistor type of surge suppressor

mW Milliwatt

NiCd Nickel Cadmium

NiMH Nickel Metal Hydrite

PLC Programmable logic controller

PLL Phased locked loop

PTO Press to operate

PWM Pulse width modulation

R/C Resistor/Capacitor type of surge suppressor

RF Radio frequency

RMS Root mean squared

Rx Receiver

RxD Receiving data

SMD Surface mount device

SMT Surface mount technology

TTL Transistor transistor logic

Tx Transmitter

TxD Transmitting data

Ub Operating power

Uv Microvolts

VAC Volts alternating current

VDC Volts direct current

19

FREQUENCY CHART CS 458

CS 458 Frequency

Hetronic

& Jumper Settings

The Hetronic Radio Remote Control System address code and frequency channel are set at the

factory. The address code and frequency channel may need to be set if you have purchased a

replacement or spare transmitter.

• Never change the address code or frequency channel of the original transmitter

purchased with your system.

• Never change the address code settings in the receiver.

• Never operate two transmitters at the same time that are set with the same

frequency channel and address code.

Group USA - Jumper "J3" Open Group GB - Jumper "J3" Closed

Channel

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

Frequency (MHz)

458.800

458.825

458.850

458.875

458.900

458.925

458.950

458.975

459.000

459.025

459.050

459.075

459.100

459.152

459.150

459.175

D0

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

D1

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

D2

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

D3

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

Frequency (MHz)

458.525

458.550

458.575

458.600

458.625

458.650

458.675

458.700

458.725

458.750

458.775

458.825

458.8375

458.900

458.825

458.900

SALS_008.0_CS 458

May 2003

Channel

B0

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

TX

X1

J3

RX

AD0D1D2D3

20

X7

D0D1D2D3

J3

www.hetronic.com

FREQUENCY CHART CS 447

CS 447 Frequency

Hetronic

& Jumper Settings

The Hetronic Radio Remote Control System address code and frequency channel are set at the

factory. The address code and frequency channel may need to be set if you have purchased a

replacement or spare transmitter.

• Never change the address code or frequency channel of the original transmitter

purchased with your system.

• Never change the address code settings in the receiver.

• Never operate two transmitters at the same time that are set with the same

frequency channel and address code.

Group A - Jumper "J3" Closed Group B - Jumper "J3" Open

Channel

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

Frequency (MHz)

447.8625

447.8750

447.8875

447.9000

447.9125

447.9250

447.9375

447.9500

447.9625

447.9750

447.9875

447.8750

447.9000

447.9250

447.9500

447.9750

D0

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

D1

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

D2

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

D3

Frequency (MHz)

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

447.275

447.300

447.325

447.350

447.400

447.450

447.500

447.550

447.600

447.650

447.700

447.750

447.775

447.800

447.825

447.850

SALS_011.0_CS 447

May 2003

Channel

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

B16

TX

X1

J3

RX

AD0D1D2D3

21

X7

D0D1D2D3

J3

www.hetronic.com

FREQUENCY CHART CS 434

CS 434 Frequency

Hetronic

& Jumper Settings

The Hetronic Radio Remote Control System address code and frequency channel are set at the

factory. The address code and frequency channel may need to be set if you have purchased a

replacement or spare transmitter.

• Never change the address code or frequency channel of the original transmitter

purchased with your system.

• Never change the address code settings in the receiver.

• Never operate two transmitters at the same time that are set with the same

frequency channel and address code.

Group A - Jumper "J3" Closed Group B - Jumper "J3" Open

Channel

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

Frequency (MHz)

433.875

433.925

433.975

434.025

434.075

434.125

434.175

434.225

434.275

434.325

434.375

434.425

434.475

434.525

434.575

434.625

D0

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

D1

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

D2

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

Frequency (MHz)

D3

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

433.900

433.950

434.000

434.050

434.100

434.150

434.200

434.250

434.300

434.350

434.400

434.450

434.500

434.550

434.600

434.650

SALS_009.0_CS 434

May 2003

Channel

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

B16

TX

X1

J3

RX

AD0D1D2D3

22

X7

D0D1D2D3

J3

www.hetronic.com

WARRANTY

Limited Warranty and

Hetronic USA

Terms of Sale

Price: Subject to Change Without Notice

Terms: Net 30 Days

F.O.B: Hetronic USA, Inc.

Oklahoma City, Oklahoma

Hetronic, Inc., hereafter referred to as Company, guarantees all items manufactured by it against any defects

of material and/or workmanship for a period of one year from the date of shipment. Company makes NO

OTHER WARRANTY, EXPRESSED OR IMPLIED, AS TO THE MERCHANTABILITY OR FITNESS OF THE

ITEMS FOR THEIR INTENDED USE OR AS TO THEIR PERFORMANCE. Any statement, description or

specification in Company's literature is for the sole purpose of identification of items sold by the Company

and imparts no guarantee, warranty or undertaking by Company of any kind. Components and accessories

not manufactured by Hetronic are not included in this warranty and are warranted separately by their

respective manufacturers.

Company's sole liability shall to be to repair at its factory, or replace, any item returned to it within one year

from date of shipment, which Company finds to contain defective material or workmanship. All items to be

repaired or replaced shall be shipped to Company (Note: return authorization by Company is required) within

said one year period, freight prepaid, as a condition to repair or replace defective material or workmanship.

Company's herein assumed responsibility does not cover defects resulting from improper installation,

maintenance, or improper use. Any corrective maintenance performed by anyone other than the Company

during the warranty period shall void the warranty. Company shall not be liable for damages of any kind from

any cause whatsoever beyond the price of the defective Company supplied items involved. Company shall

not be liable for economic loss, property damage, or other consequential damages or physical injury

sustained by the purchaser or by any third party as a result of the use of any Company supplied items or

materials.

List prices or discounts are subject to change without notice. Quoted prices will be honored for a period of 90

days from the date of the written quotation unless otherwise stated.

Orders are not subject to alteration or cancellation except upon written consent of Company and payment of

proper cancellation charges, when deemed applicable by Company.

Materials or items may not be returned for credit, without the prior written consent of the Company. Any

authorized return of materials or items shall be subject to a restocking charge equal to 20% of the net

invoiced amount after Company determines that the material or item is in good condition and may be resold

without alteration or service.

Terms of payment are NET 30 days. All materials and items are sold F.O.B. Company's shipping point.

Company retains a security interest in all items sold by it so long as they remain in Company's possession to

secure all obligations of purchaser to Company. A processing fee will be applied to all invoices for requested

prepaid freight charges other than UPS. A service charge will be incurred on past due accounts extending

beyond the terms of sale described above, at a rate of 1.5% per month of the net balance extending beyond

30 days.

The buyer should inspect the goods immediately on their arrival and shall within five days of their arrival give

written notice to the Company of the claim that the goods do not conform with the terms of the contract. If the

buyer shall fail to give such notice, the goods shall be deemed to conform with the terms of the contract. Any

claim for material or item shortages must be accompanied by copies of the bill of lading and packing slip.

Delivery schedules or commitments are based upon current production

capacities, material or component availability and inventory and may be

changed as conditions require. Company shall not be liable for loss or

damage of any kind resulting from delay or inability to deliver on account of

fire, labor troubles, accident, acts of civil or military authorities, or from any

other cause beyond Company's control.

WRTY_002 Warranty & Terms

April 2003

23

www.hetronic.com

Loading...

Loading...