Hellwig 7810 User Manual

INSTALLATION INSTRUCTIONS

REAR STABILIZER BAR

88-00 C/K 3500 DUALLY

Thank you for purchasing a quality Hellwig Product.

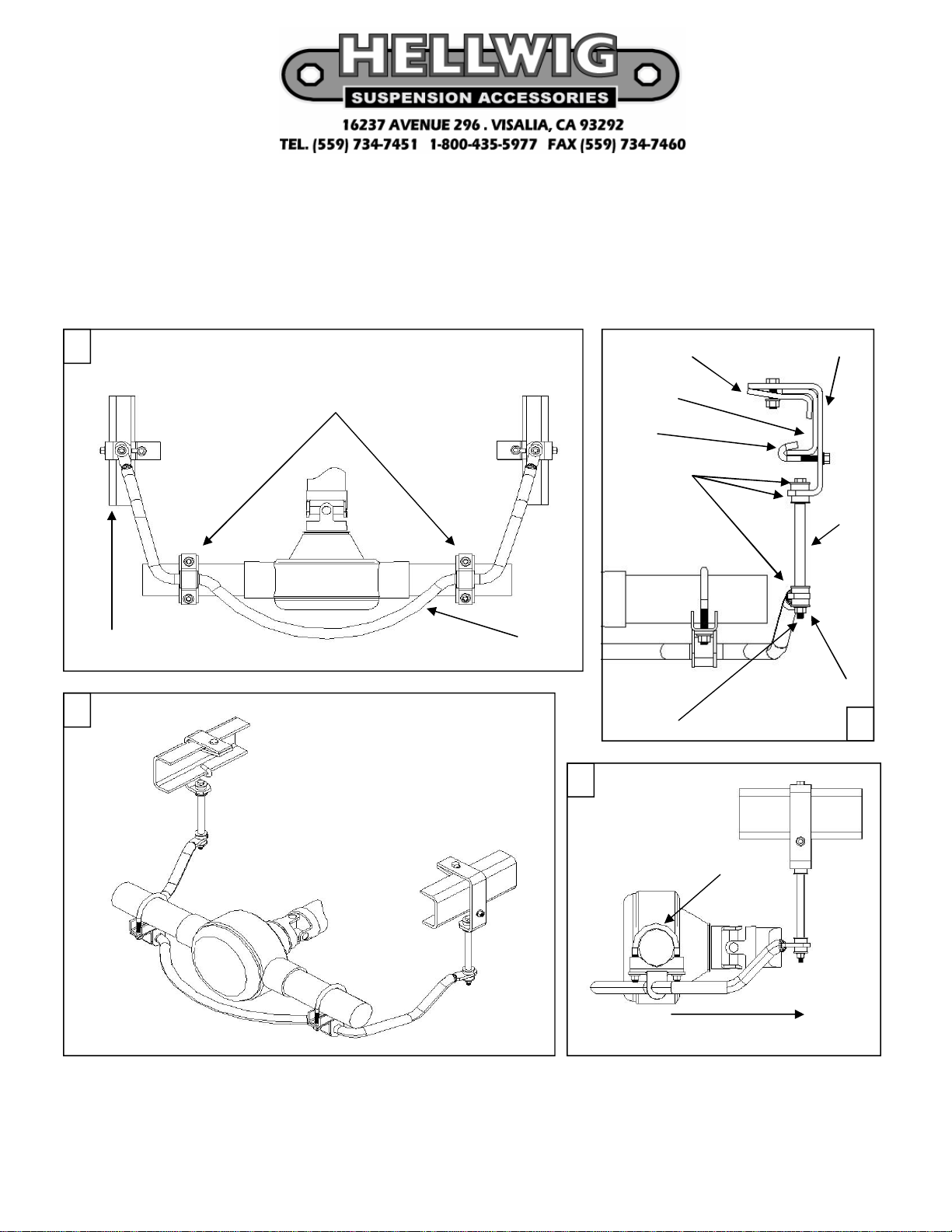

1

VEHICLES FRAME

3

BOTTOM VIEW

SWAY BAR MOUNTING LOCATIONS OF U-PLATE,

D-BUSHING, U-BOLTS AND SADDLE BRACKETS

REAR VIEW

SWAY BAR

VEHICLES FRAME

J-BOLT

WASHER & END

LINK BUSHINGS

AXLE`

END LINK ASSY

SIDE VIEW

4

SWAY BAR IS FLAT & EVEN

WITH THE GROUND & END

LINKS STRAIGHT UP AND

DOWN

OUTER FRAME BRACKET INNER FRAME BRACKET

SLEEVE

LOCK NUT

2

U-BOLT, SADDLE BRACKET

D-BUSHING & U-PL`ATE

FRONT OF VEHICLE

7609 ( R-375 ) 06/08/07

TORQUE TABLE

BOLT SIZE: 3/8” = 20-30 ft. lbs. – 7/16” = 35-45 ft. lbs. – ½” = 50-70 ft. lbs. – 9/16” = 70-90 ft. lbs.

SAFETY: BEFORE STARTING YOUR INSTALLATION, BE SURE TO SET PARKING BRAKE AND CHOCK

TIRES.

NOTE: TO EASE INSTALLATION AND TO PROPERLY ADJUST BAR, THE WEIGHT OF THE VEHICLE

MUST BE ON THE SUSPENSION, AS IF DRIVING DOWN THE ROAD.

DO NOT RAISE VEHICLE BY FRAME.

1. As per photo ( 1 ) place the U-bolts over the axle tubes just inside of the lower shock mount brackets.

Be sure to put the U-bolts under any brake lines, wires or hoses on the axle to avoid any damage. The

brake lines may have to be slightly bend to allow for clearance for the U-bolts.

2. Place the D-bushings on the sway bar at the flat areas between the center hump and the arms. See

photo ( 1 ).

3. Locate and position the Saddle brackets on the U-bolts that are on the axle tubes. Position the U-plates

on the D-bushings on the sway bar. Raise the sway bar up to the axle, insert U-bolts thru the slotted

holes on the U-plates. Attach with mounting hardware supplied. Tighten just enough to support the

sway bar to the axle. ( Leave loose at this time to allow for adjustment later ).

4. Looking at photo ( 2 ) assemble the end link assemblies. End link bolt, washer, poly bushing insert

thru outer frame bracket. Position the outer frame brackets, attach the inner frame brackets with

mounting hardware provided. Leave loose at this time to allow for adjustment later. Insert ploybushing, washer, steel sleeve, washer, poly bushing. Insert thru eye of sway bar arm, poly-bushing,

washer and tighten with lock washer provided. Tighten just slightly that the poly-bushings start to

bulge. Over tightening can damage the poly-bushings. Do the same on opposite side. ( Check for

clearance on wires, fuel or brake lines that run thru the vehicles frame ).

5. With the sway bar attached at the axle and end link assemblies attached to the frame brackets. The

frame brackets can be moved forward or backwards and the U-bolts at the axle can also be rotated to

allow the sway bar to be flat against the ground and the end links as straight up and down as possible.

See photos ( 3 & 4 ).

6. With the sway bar properly aligned check for clearance on all under carriage components. Check for

clearance on electrical wires, exhaust, brake and fuel lines. Torque all mounting hardware to specified

rates.

7. Using the J-bolts attach the bottom of the outer frame brackets to the lower lip of the vehicles frame.

Tighten top specified rate.

8. Bounce the vehicle check for clearance on all under carriage components. Test drive your vehicle recheck your installation re-adjust as needed. Re-check your installation on a monthly regular basis

thereafter.

ATTENTION INSTALLER: BE SURE THAT THE CUSTOMER RECEIVES THIS INSTRUCTION

7609 ( R-375 ) 06/08/07

Loading...

Loading...