Heidolph Hei-VAP User Manual

Hei-VAP Value

Hei-VAP Advantage

Operating Instructions

Translation of the original operating instructions.

The operating instructions must be read prior to the initial

start-up for your safety and ease of use! Follow safety instructions to prevent unnecessary accidents from occurring

associated with misuse of product!

Store for future use in a safe location!

This documentation is not subject to any modification service!

Table of contents

EN

Table of contents

1 About this Document .................................................................................................... 1

1.1 Versions references ........................................................................................................................... 1

1.2 About this manual .............................................................................................................................. 1

1.2.1 Reference documents ...................................................................................................................... 1

1.2.2 Icons and symbols ........................................................................................................................... 2

2 Basic safety instructions .............................................................................................. 5

2.1 General Safety Instructions .............................................................................................................. 5

2.2 Intended use ....................................................................................................................................... 5

2.3 Improper Use ...................................................................................................................................... 5

2.4 Use in explosion-prone areas ........................................................................................................... 6

2.5 Responsibilities of the operator ....................................................................................................... 6

2.6 Responsibilities of the operating personnel ................................................................................... 6

2.7 Qualifications of Personnel ............................................................................................................... 7

2.8 Safety Conscious Working ................................................................................................................ 7

2.9 Safety devices on the equipment ..................................................................................................... 7

2.10 Signs on the equipment .................................................................................................................... 8

2.11 Remaining hazards ............................................................................................................................ 8

3 Unit Description ...........................................................................................................11

4 Set-up and Start-up ......................................................................................................12

4.1 Scope of delivery ............................................................................................................................. 12

4.2 Transport .......................................................................................................................................... 14

4.2.1 Removing the transportation safety device .................................................................................... 14

4.2.2 Attaching the transportation protection device before packing ...................................................... 14

4.3 Setting up the basic unit ................................................................................................................. 15

4.4 Start-up ............................................................................................................................................. 15

4.4.1 Installing the heating bath .............................................................................................................. 15

4.4.2 Fill the heating bath ....................................................................................................................... 16

4.4.3 Offsetting the heating bath ............................................................................................................. 16

4.4.4 Heating bath set-up when using Rotacool ..................................................................................... 16

4.4.5 Connect the base unit .................................................................................................................... 17

4.4.6 Operating the lift ............................................................................................................................ 19

4.5 Assemble glassware sets ................................................................................................ ................ 19

4.5.1 Install the condenser mounting (G3-G6) ........................................................................................ 20

4.5.2 Install the vapor tube ..................................................................................................................... 21

4.5.3 Install the condenser ...................................................................................................................... 23

4.5.4 Mount the vertical condenser (G3-G6) in the condenser bracket................................................... 25

4.5.5 Install the evaporator flask ............................................................................................................. 26

4.5.6 Setting the evaporator flask inclination .......................................................................................... 27

4.5.7 Setting the immersion depth of the evaporator flask ...................................................................... 28

4.5.8 Release the evaporator flask from the vapor tube ......................................................................... 29

4.5.9 Insert the inlet tube ........................................................................................................................ 30

4.5.10 Assemble the inlet tube ................................................................................................................. 30

4.5.11 Assemble the collecting flask ......................................................................................................... 31

4.5.12 Connect the cooling medium (except G5) ...................................................................................... 31

4.5.13 Connect the vacuum ...................................................................................................................... 32

Table of contents

EN

4.6 Feed the distilled material ............................................................................................................... 37

4.7 Ventilate manually ........................................................................................................................... 37

4.8 Assemble / connect accessories .................................................................................................... 38

4.9 Operating the control panel ............................................................................................................ 40

5 Switching on the base unit ..........................................................................................44

6 Operation of the Hei-VAP Value ..................................................................................45

6.1 Set the rotation speed ..................................................................................................................... 45

6.2 Setting the heating bath temperature ............................................................................................. 46

6.3 Error messages ................................................................................................................................ 46

7 Operation of the Hei-VAP Advantage .........................................................................47

7.1 Setting the heating bath temperature ............................................................................................. 48

7.1.1 Select heating bath medium .......................................................................................................... 48

7.1.2 Setting the heating bath temperature ............................................................................................. 49

7.2 Set the rotation speed ..................................................................................................................... 49

7.3 Calculating the boiling temperature (Hei-VAP Advantage) .......................................................... 50

7.4 Timing functions .............................................................................................................................. 51

7.4.1 Timer ............................................................................................................................................. 51

7.5 Error messages ................................................................................................................................ 51

7.6 Upgrading ......................................................................................................................................... 51

8 Errors and Troubleshooting ........................................................................................52

8.1 General errors .................................................................................................................................. 52

8.2 Additional conditions ...................................................................................................................... 53

8.3 Hei-VAP Value .................................................................................................................................. 54

8.4 Hei-VAP Advantage.......................................................................................................................... 55

9 Maintenance, cleaning, service ...................................................................................57

9.1 Maintenance ..................................................................................................................................... 57

9.1.1 Resetting the maximum temperature limiter .................................................................................. 57

9.1.2 Evacuate the heating bath ............................................................................................................. 58

9.1.3 Readjust the vacuum seal (glassware set G6)............................................................................... 58

9.2 Replacing the fuses ......................................................................................................................... 59

9.3 Cleaning ............................................................................................................................................ 60

9.4 Service .............................................................................................................................................. 60

10 Dismantling, storage, disposal ..............................................................................61

10.1 Disassembly ..................................................................................................................................... 61

10.1.1 Remove the Woulff bottle .............................................................................................................. 61

10.1.2 Disconnecting the coolant / vacuum .............................................................................................. 62

10.1.3 Remove the heating bath ............................................................................................................... 62

10.2 Storage .............................................................................................................................................. 62

10.3 Disposal ................................................................ ................................................................ ............ 62

11 Accessories, spare parts .......................................................................................63

11.1 Glass devices ................................................................................................................................... 63

11.2 Accessories ...................................................................................................................................... 67

Table of contents

EN

12 Appendix .................................................................................................................68

12.1 Technical data .................................................................................................................................. 68

12.2 Technical data o the vacuum box Hei-VAP .................................................................................... 70

12.3 Solvent data ...................................................................................................................................... 71

12.4 EC Declaration of Conformity ......................................................................................................... 73

12.5 Warranty Statement ......................................................................................................................... 74

12.6 Declaration of non-objection .......................................................................................................... 75

EN

Version

Modification

1.0

07/2009

Information for the Heidolph vacuum pumps Rotavac valve control

and Rotavac valve tec, along with the Vac control automatic controller are contained in a separate operating instruction # 01-005004-80.

Information regarding the Heidolph emission condensate cooler

vacuum pumps, Rotavac vario control and Rotavac vario tec are

contained in a separate operating instruction, # 01-005-004-90-0.

Versions references

Notes regarding

this manual

Reference documents

1 About this Document

1.1 Versions references

1.2 About this manual

These instructions use icons and notes that will help simplify the process of locating

information quickly. Read the explanations regarding these notes and icons in the following section.

Please read the safety guidelines and warnings in these instructions very carefully to

ensure safe operation of the product. You will find the safety instructions in chapter 2.

Warnings may be found in the introductions throughout of the chapters and prior to instruction sections.

Heidolph Instruments GmbH & Co. KG has the copyright for images and texts.

1.2.1 Reference documents

Hei-VAP Value, Hei-VAP Advantage 1

About this Document

EN

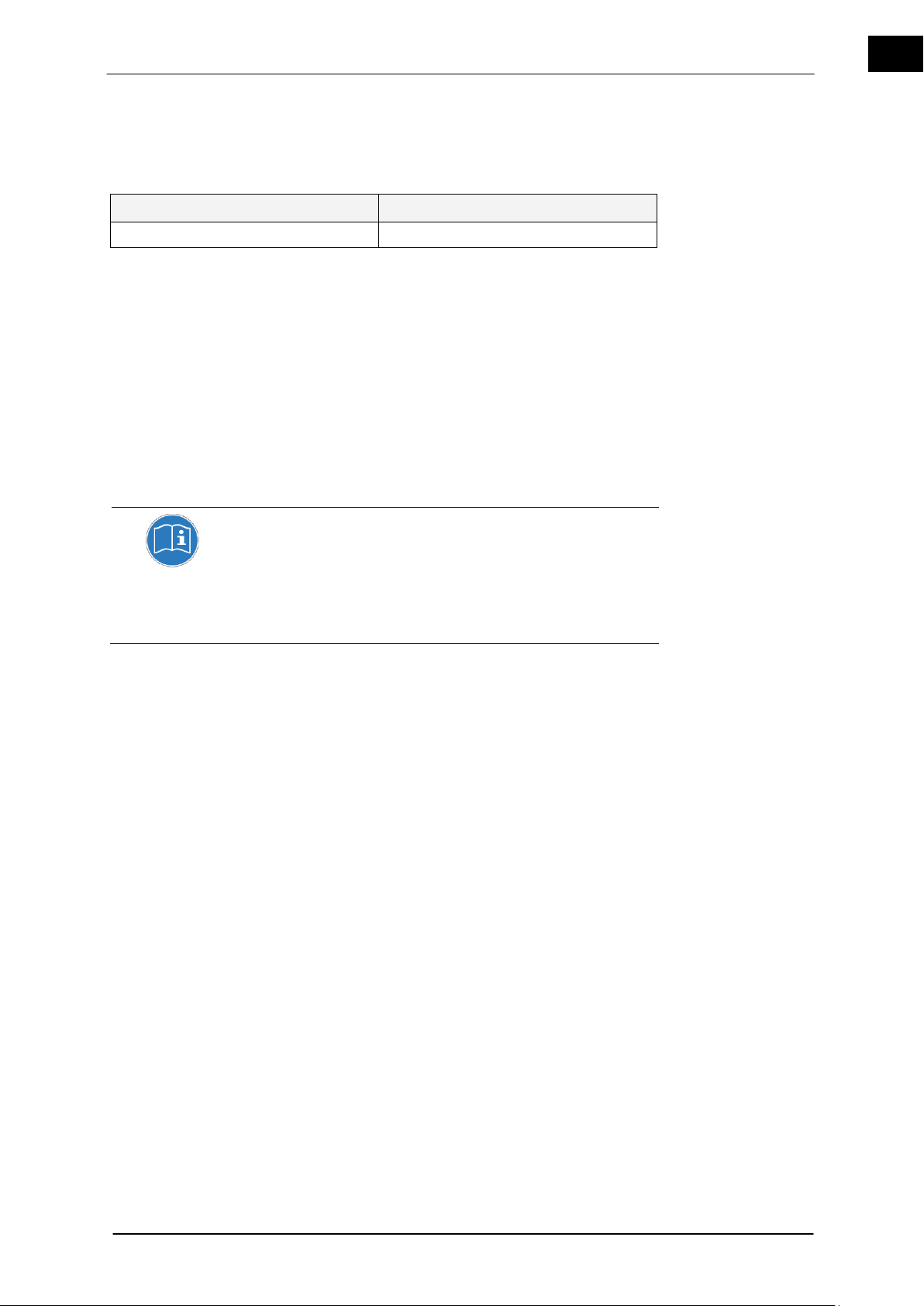

Icon

Designation

Death

RISK

This signal word must be used, if death or irreversible health

impairments may develop when the non-compliance of operator regarding the hazard warning.

Injury + property damages

WARNING

This signal word points to injuries and property damages,

including injury, accident and health risks.

WARNING

This signal word provides a reference to the risk of property

damages. In addition, there is a low risk of injuries.

No damages

CAUTION

This signal word may only be used, if health risks cannot

develop. It warns of malfunctions and is presented without an

icon, since the degree of the risk to operator is low.

IM-

PORTANT

This signal word points to operation simplifications and crossreferences. It excludes any risks of property damages or risks

of injuries and is therefore without an icon.

RISK

The type and source of the risk is located here!

The potential consequences, if actions are not taken to prevent

the risk are listed here.

The action to prevent the risk is listed here.

WARNING

Risk of injury based on disregarding the safety icons!

Risks exist here based on disregarding the warnings on the device and in the operating instructions.

Observe warnings.

Warnings

Structure of warnings

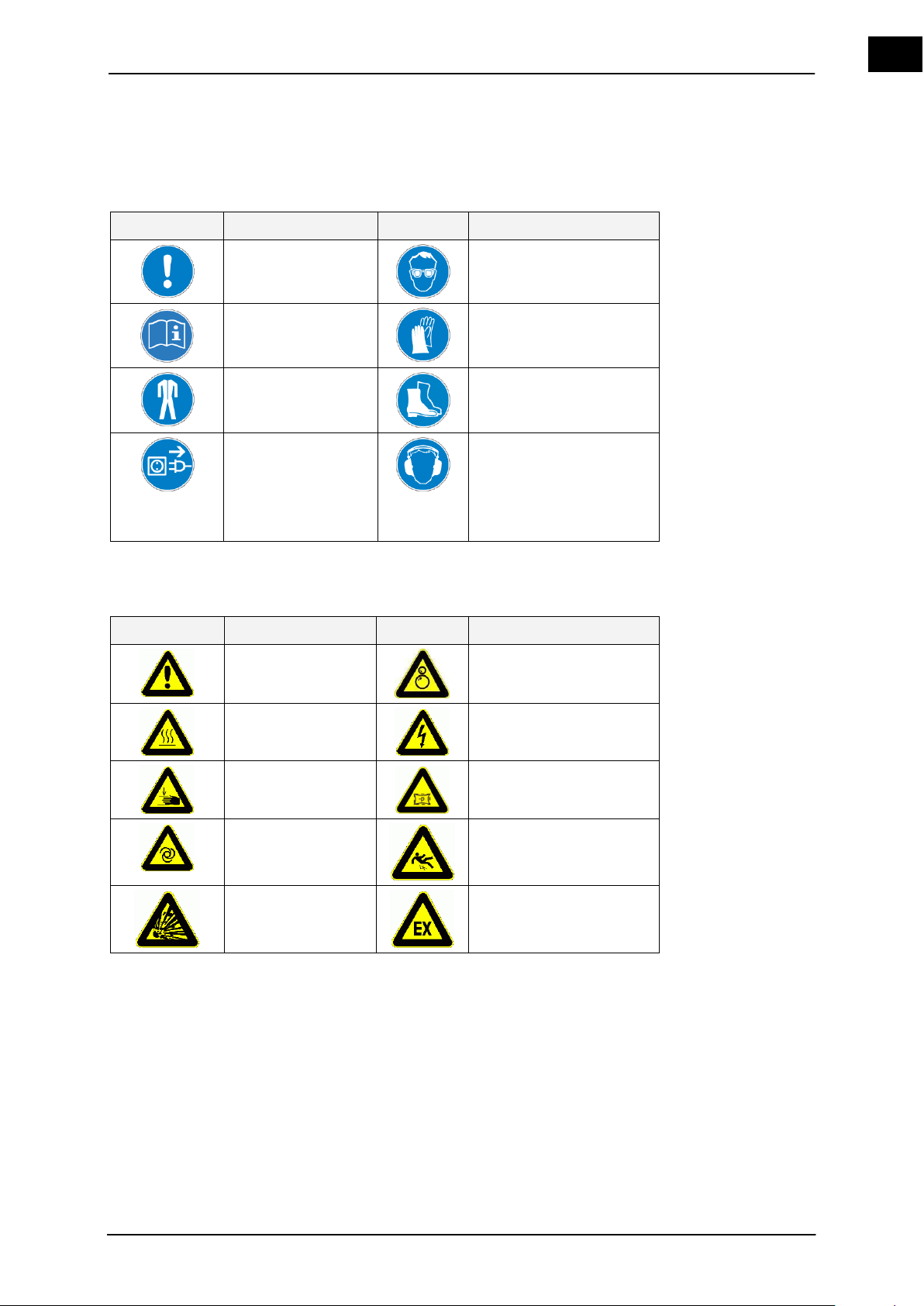

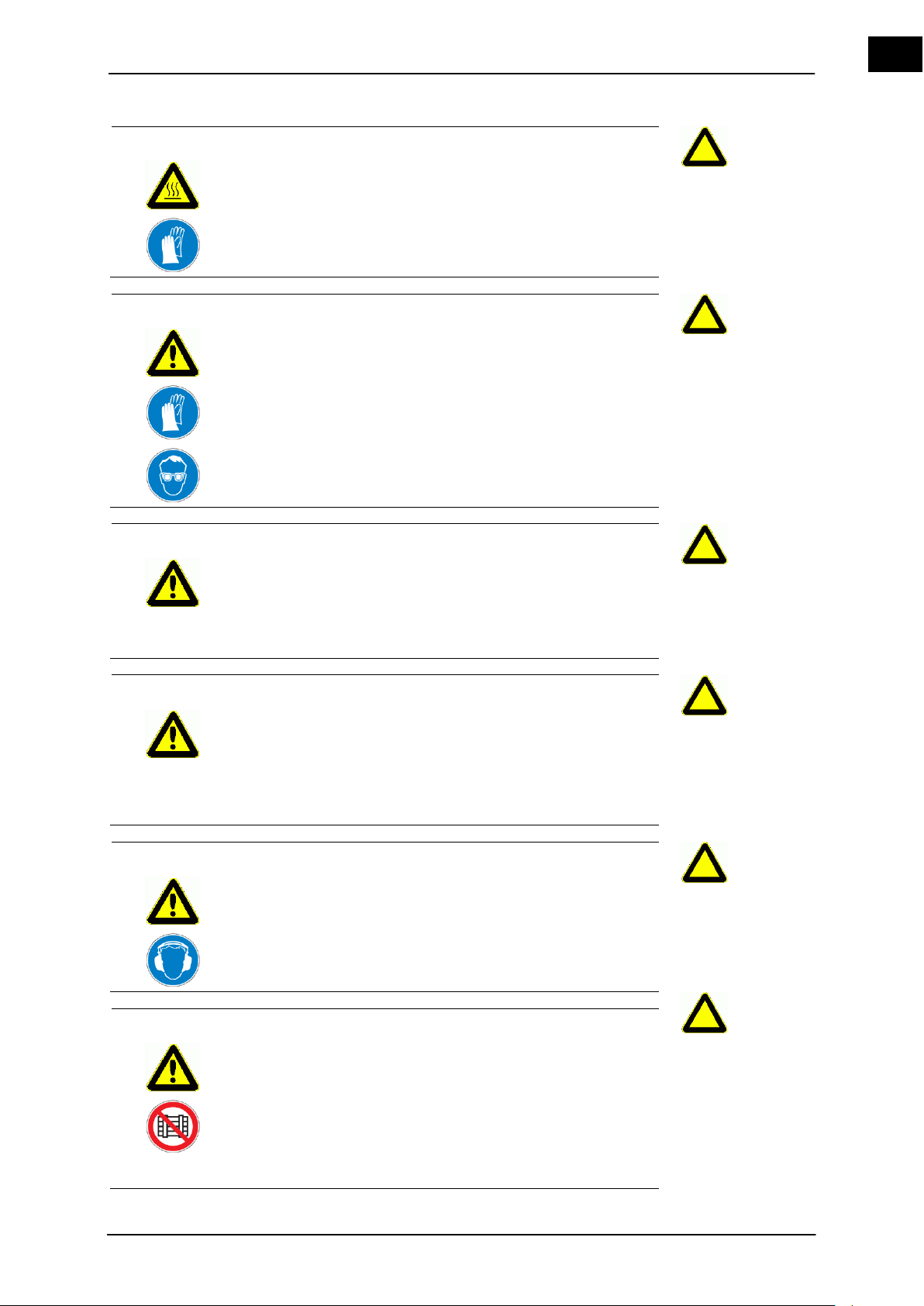

1.2.2 Icons and symbols

Warnings

The following symbols and signal words will be continuously used in this documentation.

The combination of icon and a signal word classifies the respective safety instruction.

The symbol can vary according on the type of risk.

Table 1-1: Identification of warnings

Structure of warnings

2 Hei-VAP Value, Hei-VAP Advantage

EN

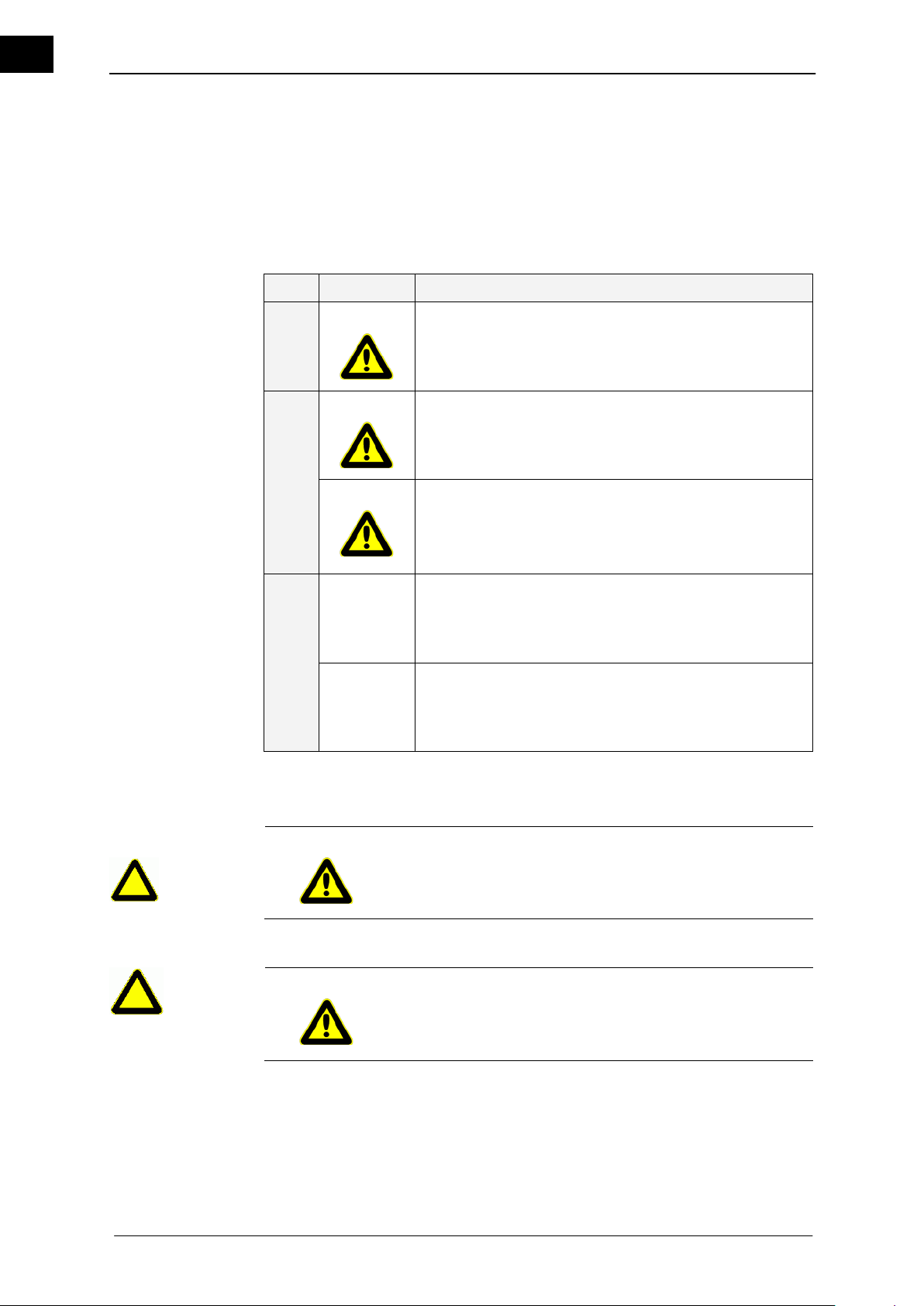

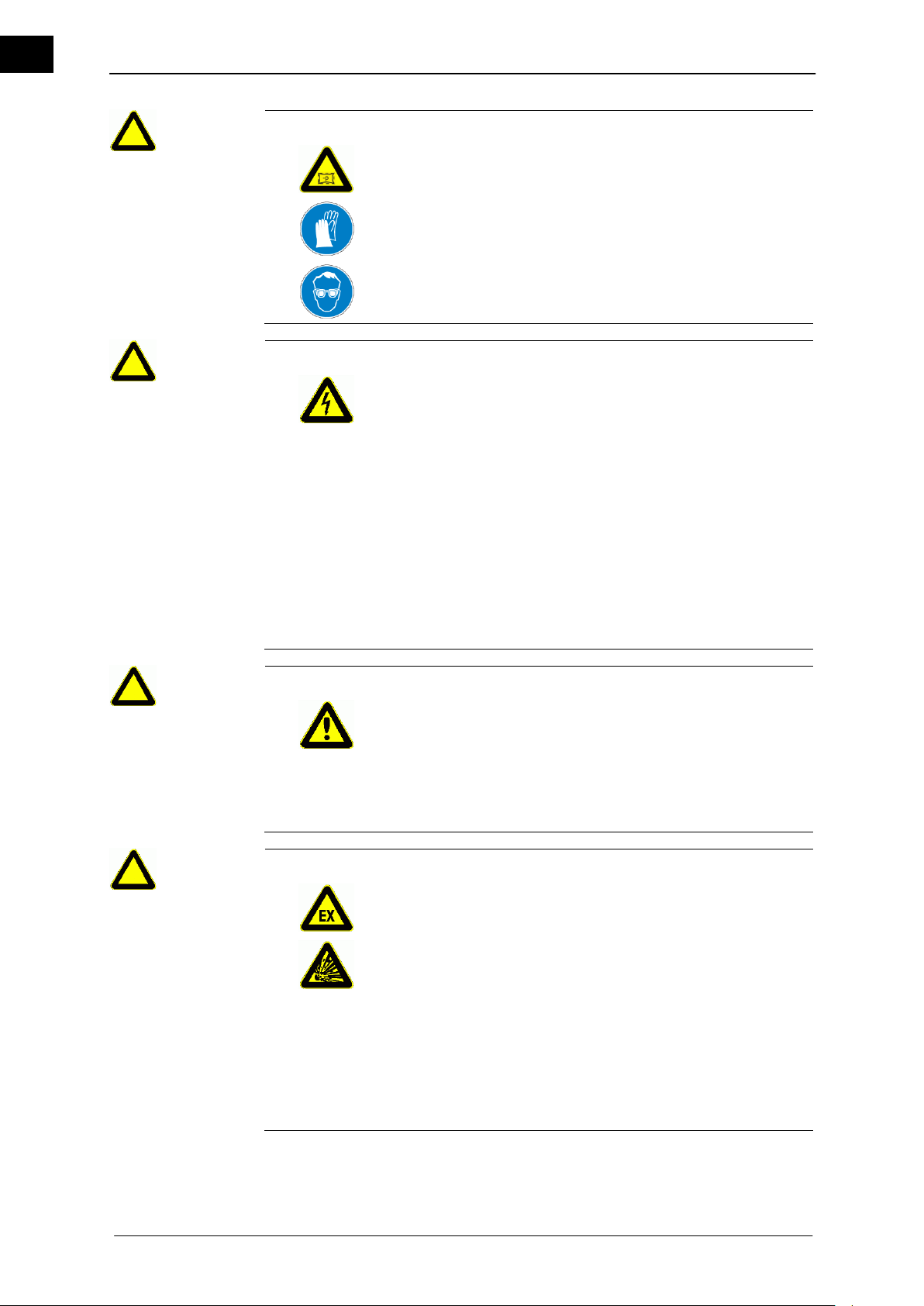

The following specific safety icons in correspondence with BGV A8 regulations will be

Icon

Explanation

Icon

Explanation

Observe

information

Use eye protection

Follow additional

information

Use hand protection

Use protective

clothing

Use foot protection

Pull the power plug

after use

Pull the power plug

prior to opening the

housing

Use ear protectors

Icon

Explanation

Icon

Explanation

Warning of a dangerous location

Warning of a risk of entanglement

Warning of a hot

surface

Warning of dangerous

electric voltage

Warning of hand

injuries

Warning of vacuum

Warning of automatic start

Warning of slippery conditions

Warning of explosive materials

Warning of explosion-risk

area

Mandatory signs

Warning signs

used at the respective text locations of these operating instructions and require special

attention depending on the combination of the signal word and icon:

Mandatory signs

Table 1-2: Icons and symbols

Warning signs

Table 1-3: Icons and symbols

Hei-VAP Value, Hei-VAP Advantage 3

About this Document

EN

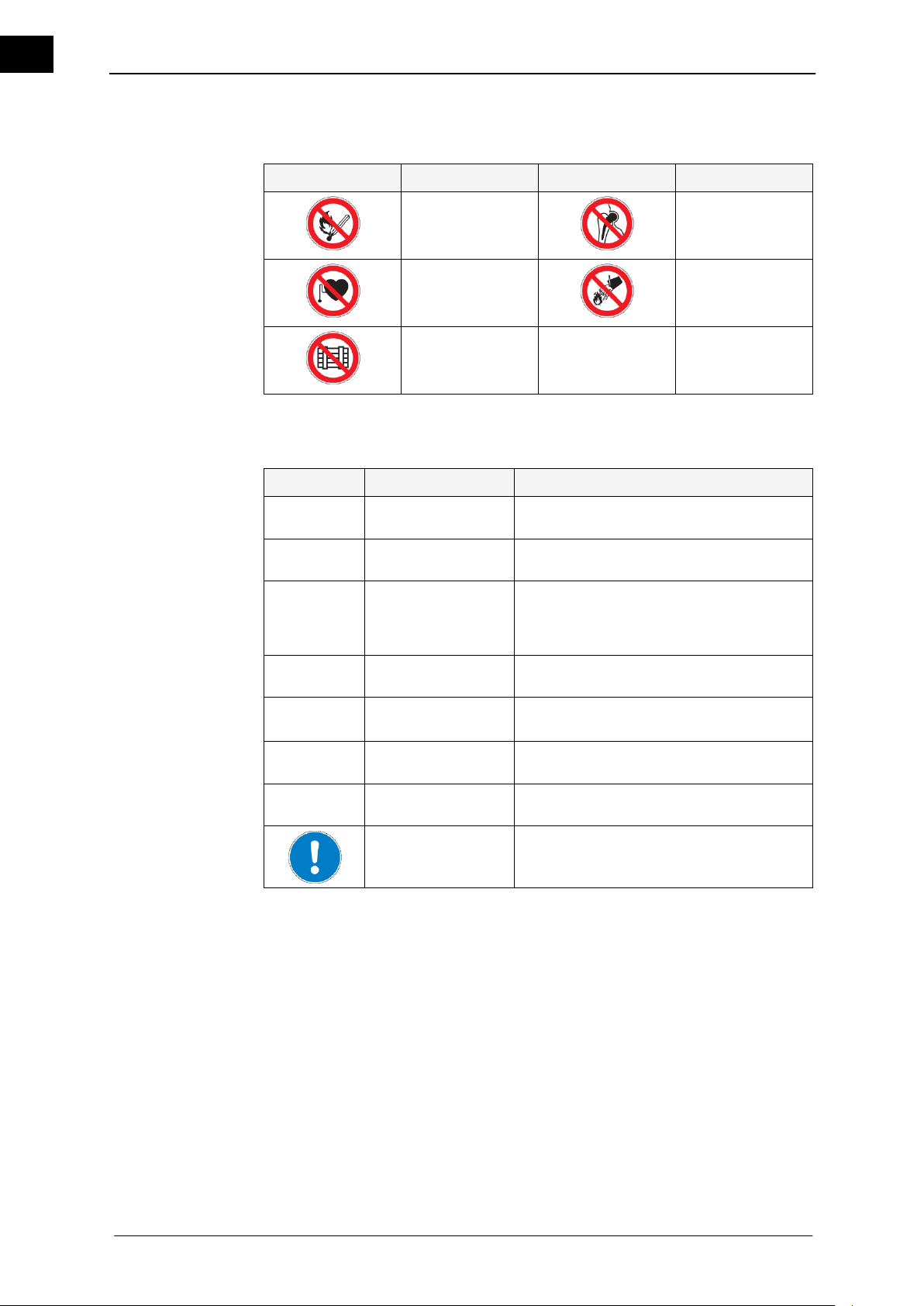

Icon

Explanation

Icon

Explanation

Fire, open flame

and smoking

prohibited

Prohibition for

people with metal

implants

Prohibition for

persons with a

pacemaker

extinguishing

with water is

prohibited

Depositing or

storing is prohibited

Icon

Use

Explanation

Prerequisite

This must be met prior to following any operating instructions

Operating instructions

You must do something here

1.

2.

Operating instructions, multi-step

Operating instructions must be performed in

the listed sequence. Deviations from the

specified sequence may result in damages of

the equipment and in accidents

Actual

result

The result of a previous activity is described

when indented

Listing,

two-tiered

Something is listed here

(see chapter

2)

Cross-reference

References for images, tables, other chapters or other instructions.

Example

Switch description

Emphasizing the description of switches/buttons

Note

Important information for the understanding

of the equipment or for improved operation

sequences

Prohibitory signs

Other icons and

symbols

Images

Prohibitory signs

Table 1-4: Icons and symbols

Other icons and symbols

Table 1-5: Icons and symbols

Item numbers in the images in the text are conveyed in parentheses. If no image number

is listed, the item number refers to the image/graphic directly above the text. If the reference is made to another image/graphic, the image number is specified accordingly, i.e.

(Fig. 4-1 (11)).

4 Hei-VAP Value, Hei-VAP Advantage

EN

2 Basic safety instructions

Basic safety instructions

General Safety

Instructions

Intended use

Improper Use

The rotary evaporator is constructed according to current state of the art methods and

accepted safety regulations. However, risks still exist during the installation, operation

and maintenance of the product.

Observe safety instructions and warnings.

The basic safety instructions in this chapter are supplemented in the following chapters

of the operating instructions by concrete warnings. These warnings will precisely explain

how you must conduct yourself to protect yourself, other persons and objects from injuries or damages.

These instructions are for the following evaporator models, the Hei-VAP Value and HeiVAP Advantage rotary evaporator.

Always keep the instructions available.

Pass the instructions on to subsequent owners.

2.1 General Safety Instructions

The rotary evaporator may only be used

in an operational condition consistent with full functionality of equipment,

for the intended use described in section 2.2,

if the operator has the required safety protection and awareness to hazards,

if the instructions of these operating instructions are observed.

Malfunctions, especially those that may affect safety, must be repaired immediately!

2.2 Intended use

Hei-VAP Value and Hei-VAP Advantage are rotary evaporators for:

distillation or evaporation of solvents

purification of chemicals, substances, mixtures and preparations

processing reaction batches

drying of powder

If the equipment is used in corrosive atmospheres, the service life of the equipment

will decrease based on concentration, volumes, and frequency of exposures to these

corrosive materials, for example concentrated Hydrochloric Acid (HCl).

Any other or additional use is considered not to be in accordance with its designated

use.

The manufacturer is not liable for damage resulting from this action.

The operator alone carries the responsibility to comply with the intended use outlined

above. Observing these instructions and all references, especially safety instructions, as

well as the adherence to inspection and maintenance requirements (see chapter 9.1) are

a part of the designated use of Hei-VAP rotary evaporator.

2.3 Improper Use

Applying excess pressure to the equipment is not permitted and can result in explo-

sion of the system.

Do not use the equipment in explosion-prone areas based on local ordinance and

compliance of general laboratory equipment. The equipment is not protected against

explosions in excessively volatile and poorly ventilated environments.

Hei-VAP Value, Hei-VAP Advantage 5

Basic safety instructions

EN

Use in explosionprone areas

Responsibilities of

the operator

Responsibilities of

the operating personnel

2.4 Use in explosion-prone areas

Do not use the equipment in explosion-prone areas. The equipment is not protected

against explosions. It is not equipped with Ex or ATEX protection.

2.5 Responsibilities of the operator

Only operate the equipment in perfect condition, contact a certified Heidolph Service

representative if equipment does not meet the outlined conditions for operation.

Verify that only qualified personnel operate the equipment with the appropriate per-

sonal protective protection.

Verify that personnel have received safety instructions for working responsibly and

safely in the laboratory.

Verify that the rotary evaporator is set up in a safe and suitable location.

Verify that the basic device is only plugged to or unplugged from the heating bath if

the main switch is switched off and/or the main power supply is disconnected.

Depending on the media (chemicals) used:

Verify that the set up and the operation are only within the designated buildings with

the proper equipment for laboratories.

Verify that the rotary evaporator is only operated in conjunction with a ventilation

system (refer to DIN EN 14175 and DIN 12924).

Ventilation system:

at least 10 times the air exchange

monitored for malfunctions

2.6 Responsibilities of the operating personnel

Verify that the distillation material can be evaporated safely and that the distillation

residue is not explosive.

Verify that work using an open flame is not conducted in the surroundings of the

rotary evaporator (explosion risk).

Verify that the flow rate of < 1 m/s is guaranteed when suctioning liquids that contain

combustible materials (electrostatic charge; ignition risk).

Verify that gases of explosion group IIC do not occur in materials or chemical reac-

tions, such as hydrogen.

Verify that equipment that is an emission or radiation source (electromagnetic

waves) for the frequency range (3*1011Hz to 3*1015Hz) is not operated or attached.

Verify that equipment that is an emission or radiation source for ionizing waves or

that is within the ultrasound range is not operated or attached.

Verify that adiabatic compression and shock waves do not occur (shock wave igni-

tion).

Verify that the use of substances with the risk of an uncontrolled release of energy

associated with a rise in pressure is prohibited (exothermic reaction; self-ignition of

dust).

Verify that the glass surfaces are wiped off by using only damp cloths.

Wear suitable protective clothing for activities on the rotary evaporator a (with gog-

gles and gloves, if necessary).

Avoid pressure on the LCD screen, it is not intended to be a touch screen interface.

Verify that the maximum excess pressure of the coolant equals no more than 1 bar

in the condenser.

Verify that the basic device is only plugged to or unplugged from the heating bath if

the main switch is switched off and/or the main power supply is disconnected.

6 Hei-VAP Value, Hei-VAP Advantage

EN

2.7 Qualifications of Personnel

This user's manual and all safety instructions must be observed,

read and understood by all personnel working on the fixture (in

particular in reference to the safety instructions).

Heating bath

Electronic and mechanical excess temperature protection

Electronic temperature control

Base unit

Clamps to secure evaporation and receiving flasks

Adjustable immersion depth of the evaporator flask

The evaporator flask may be lifted from the heating bath, if

required

Overcurrent protection on lift motors (only Hei-VAP Ad-

vantage and Hei-VAP Precision)

Thermal overtemperature protection on the drive motor

Torque restrictor

Glassware set

Borosilicate glass

Screw connectors on the connections

Support rod and clamp for glassware sets G3, G5 and G6

Optional

Surlyn coating (Safecoat coating for glassware set G5) of

the glassware parts

Protective hood

Protective shield

Qualifications of

Personnel

Safety Conscious

Working

Safety devices on

the equipment

The target group of the rotary evaporator is qualified personnel only. The rotary evaporator may only be used by personnel that have been trained in the proper operation by

qualified personnel determined in accordance with the internal safety regulations of the

facility in which the rotary evaporator is operated.

2.8 Safety Conscious Working

Heidolph Instruments is not liable for personal injuries and / or property damages caused

by an incorrect and improper usage of the rotary evaporator.

Observe the following regulations:

Laboratory guidelines

Accident prevention regulations

Ordinance on Hazardous Substances

Other generally accepted rules of safety engineering and occupational health

Local regulations

2.9 Safety devices on the equipment

Hei-VAP Value, Hei-VAP Advantage 7

Basic safety instructions

EN

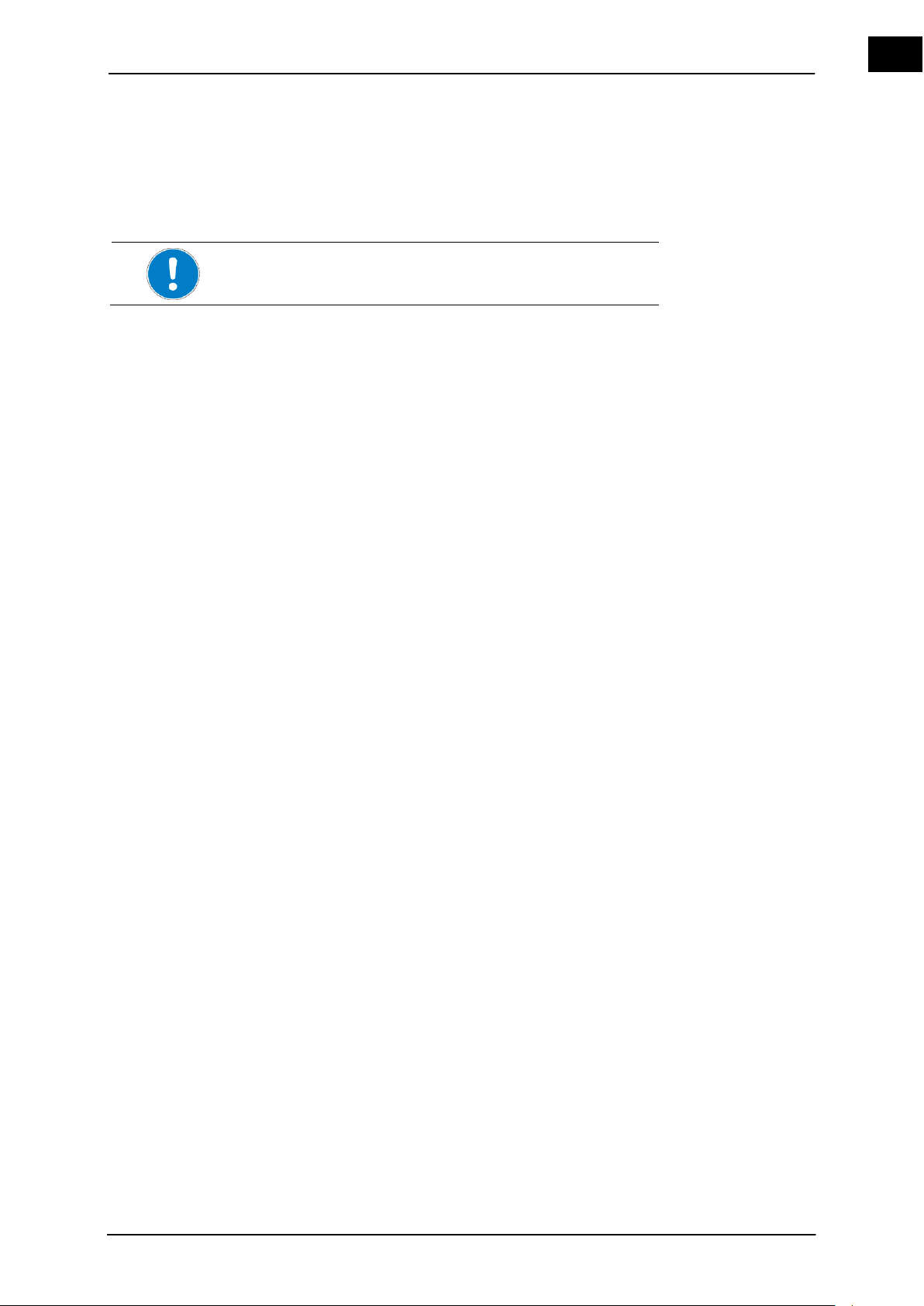

Sign

Designation

Hot surface

Risk of entanglement

Model tag

Fuse label (bottom of the device)

CAUTION

Unintentionally rotating drive!

Injuries to hands.

Verify that the rotation is displayed.

WARNING

Danger of slipping!

Risk of injury.

The floor near the machine may be dirty after the operation or

during malfunctions in the machine. Water from the bath may spill

or condensation from coolant may drip on to the floor near equipment.

Watch for contaminated areas and clean the floor, if neces-

sary.

Signs on the

equipment

Remaining hazards

2.10 Signs on the equipment

Table 2-1: Signs on the equipment

2.11 Remaining hazards

Obvious residual risks may still exist, despite all precautions!

Residual risks can be reduced if the safety instructions for the intended use and the

operating instructions are all observed!

8 Hei-VAP Value, Hei-VAP Advantage

EN

WARNING

Hot surfaces!

Scalding and burns.

Let the heating bath and glass devices cool before handling.

WARNING

Glass breakage!

Cuts.

Work carefully.

WARNING

Malfunctions!

Risk of injury.

Malfunctions or operating conditions that may affect the safety of

operating personnel require a shutdown of the equipment by

disconnecting the power supplies.

A proper restoration of the normal state is required.

WARNING

Unauthorized access is prohibited!

Risk of injury.

Risks exist, if unauthorized personnel enter the danger zone of

the evaporator.

The operator has to ensure that unauthorized persons (e.g.

visitors) do not have any access to dangerous areas (service

area, protected areas).

WARNING

Risk of injury from operational noise!

Hearing impairment from the continuous sound pressure level of

the equipment may occur.

Protect against noise-induced hearing loss with ear protec-

tion.

DANGER

Disregarding the danger, work and service area!

There are risks due to electrical and mechanical energies, as well

as specific residual risks.

Guarantee a safe distance of 800 mm around the evaporator

components.

Do not deposit or store anything within the work and service area.

Accessories, chemicals or tools must be stored so that no risks

arise for personnel.

Hei-VAP Value, Hei-VAP Advantage 9

Basic safety instructions

EN

WARNING

Imploding glass devices!

Serious injuries from shattering glass.

Check glass devices for damages (stars, breaks, cracks, etc.)

Only use perfect glass devices and replace all damaged

glassware as soon as possible..

Verify that the interior and exterior pressure variance equals

no more than 2 bar.

DANGER

Potential loss of life due to dangerous electrical voltage!

Serious risk of injuries.

Residual electrical energy remains in the electrical wires, equip-

ment and machines, when the evaporator is switched off.

Inform operating personnel of outlets. Disconnect the sockets

from the power source to completely de-energize.

Work on the power supply must only be performed by an

electrician. Switch off the power switch.

Disconnect the evaporator from the power supply. Routinely

check the electrical equipment (power lines) of the evaporator

for any wear or fraying of wires.

Replace burned or melted power lines. Routinely check all

power cables for damages within the scope of maintenance

and repair services.

Only disconnect the basic device with the heating bath if the device is de-energized. Unplug main power supply.

DANGER

Risks of injuries and mortal danger when disregarding safety

instructions and safe distances!

Risk of injury.

Risks exist when disregarding safety instructions and the safe

distance to the machine.

Observe safety instructions and signs on the evaporator and

in these operating instructions. Adhere to the corresponding

safe distance to the equipment.

DANGER

Danger of fire and explosions!

Serious risk of fire and explosions.

A risk of fire and explosions exists in the vicinity of the evaporator.

Fire, open flame and smoking are prohibited near the equipment.

Flammable liquids may not be stored within the danger zone

of the evaporator. A fire extinguisher must be kept near the

equipment.

Avoid potential ignition sources, such as ignitable atmos-

pheres or reactions or electrostatic charges.

Avoid exothermic reactions or the spontaneous ignition of

dust.

Avoid adiabatic compression and shock waves.

Particular caution to reactions of explosion group IIC, in which

hydrogen can develop.

10 Hei-VAP Value, Hei-VAP Advantage

EN

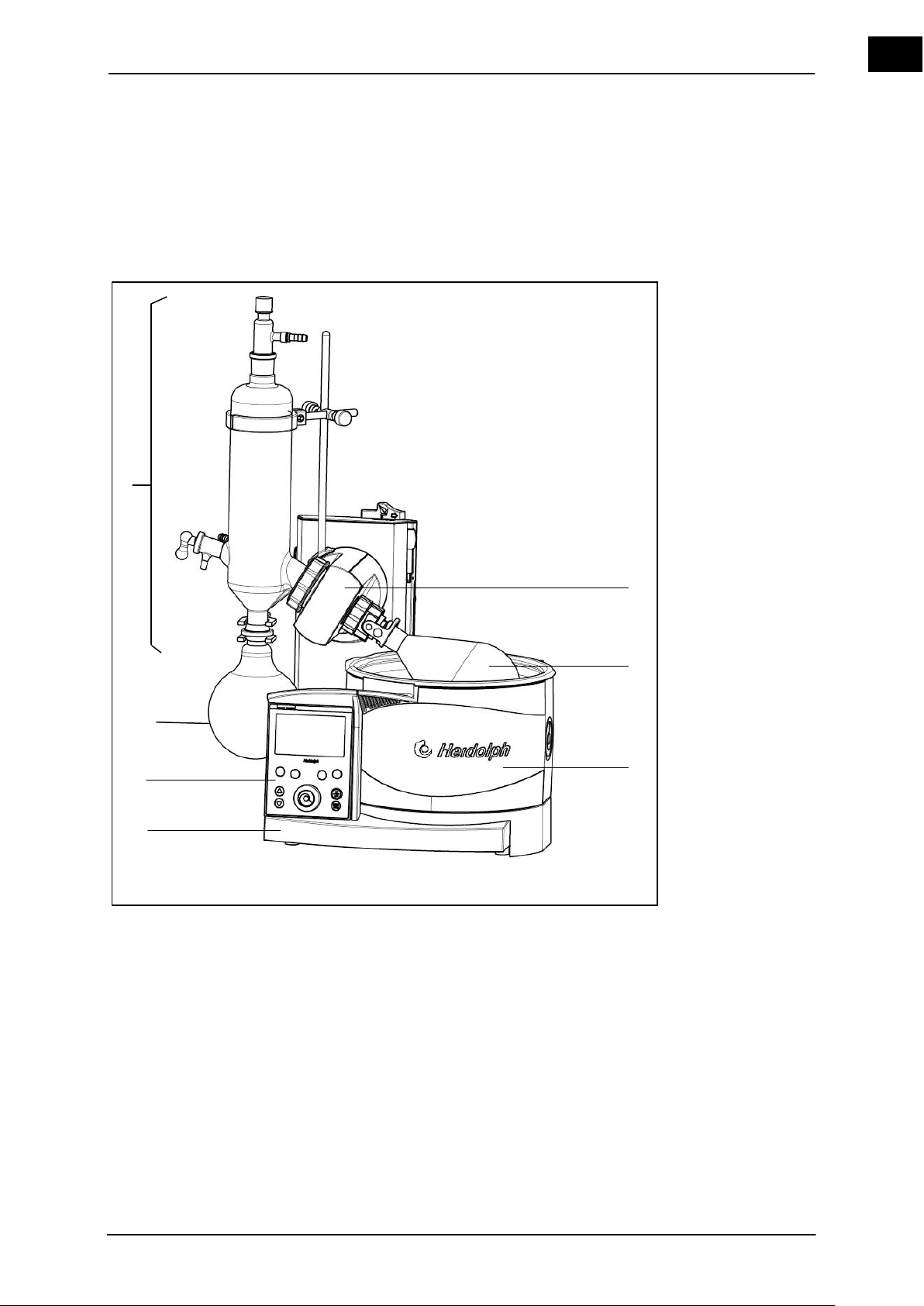

3 Unit Description

1

Drive unit with vapor tube and

coupling clamp

4

Base unit

duct 5 Control panel

2

Evaporator flask

6

Receiving flask

3

Heating bath

7

Condenser

Unit Description

1 2 3 4 5

7 6

Rotary evaporators Hei-VAP Value, Hei-VAP Advantage, Hei-VAP Precision serve the

distillation or evaporation of solvents (chemicals)

purification of chemicals, substances, mixtures and preparations

processing reaction batches

drying of powder

Figure 3–1: Rotary evaporator, here a Hei-VAP Precision with glassware set G3

The solvent to be evaporated is present in the evaporator flask (2). Depending on the

thermodynamic properties of the solvent, the solvent is evaporated by a suitably selected

combination of the heating bath temperature (3) and the vacuum. The settings are made

on the control panel (5) of the base unit (4). The drive unit (1) provides a rotation, which

reduces the risk of boiling evaporation and accelerates the evaporation process by increasing the surface area of the solvent. The solvent vapor reaches the condenser (7)

via the vapor tube, is condensed and then flows into the receiving flask (6).

Hei-VAP Value, Hei-VAP Advantage 11

EN

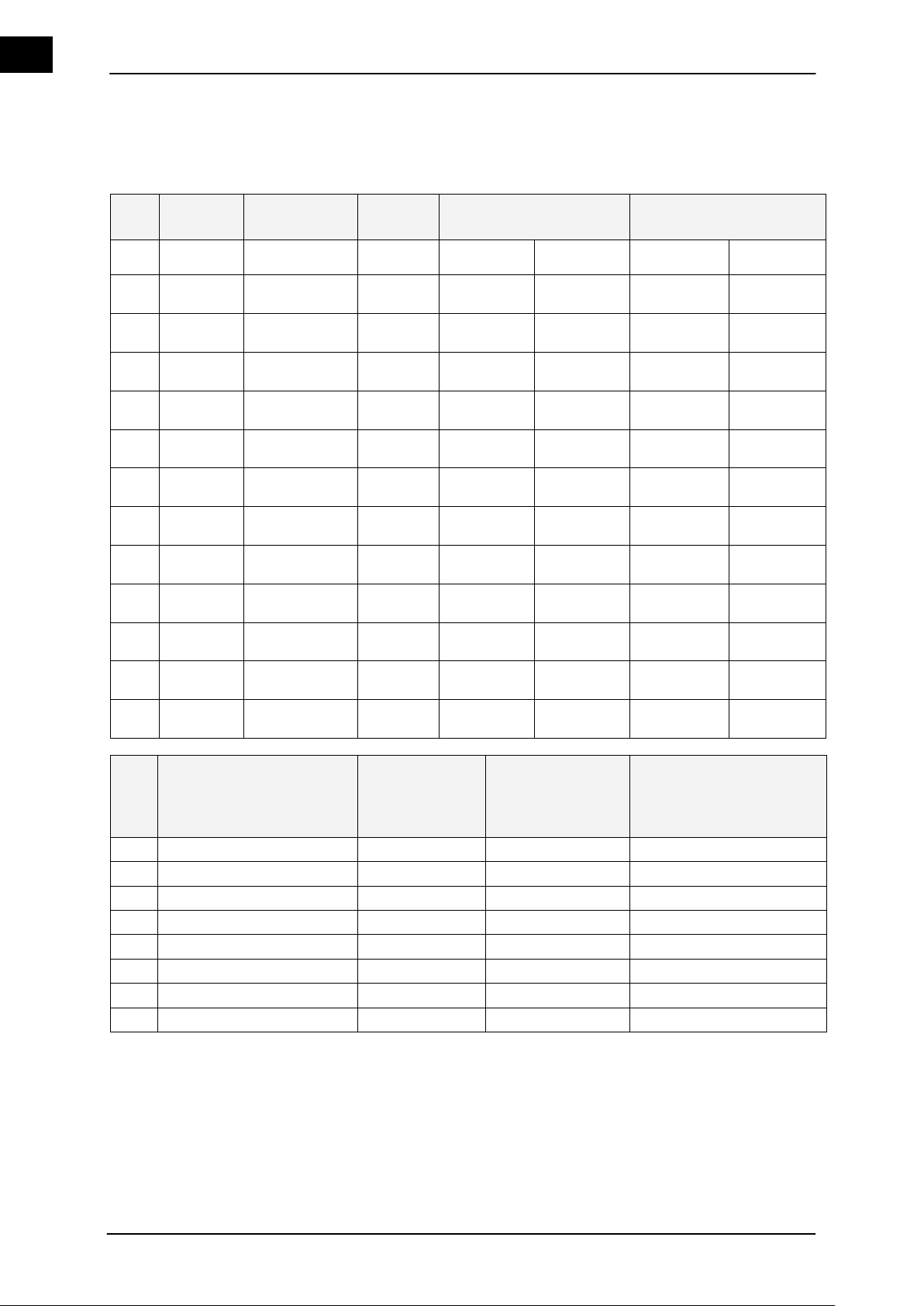

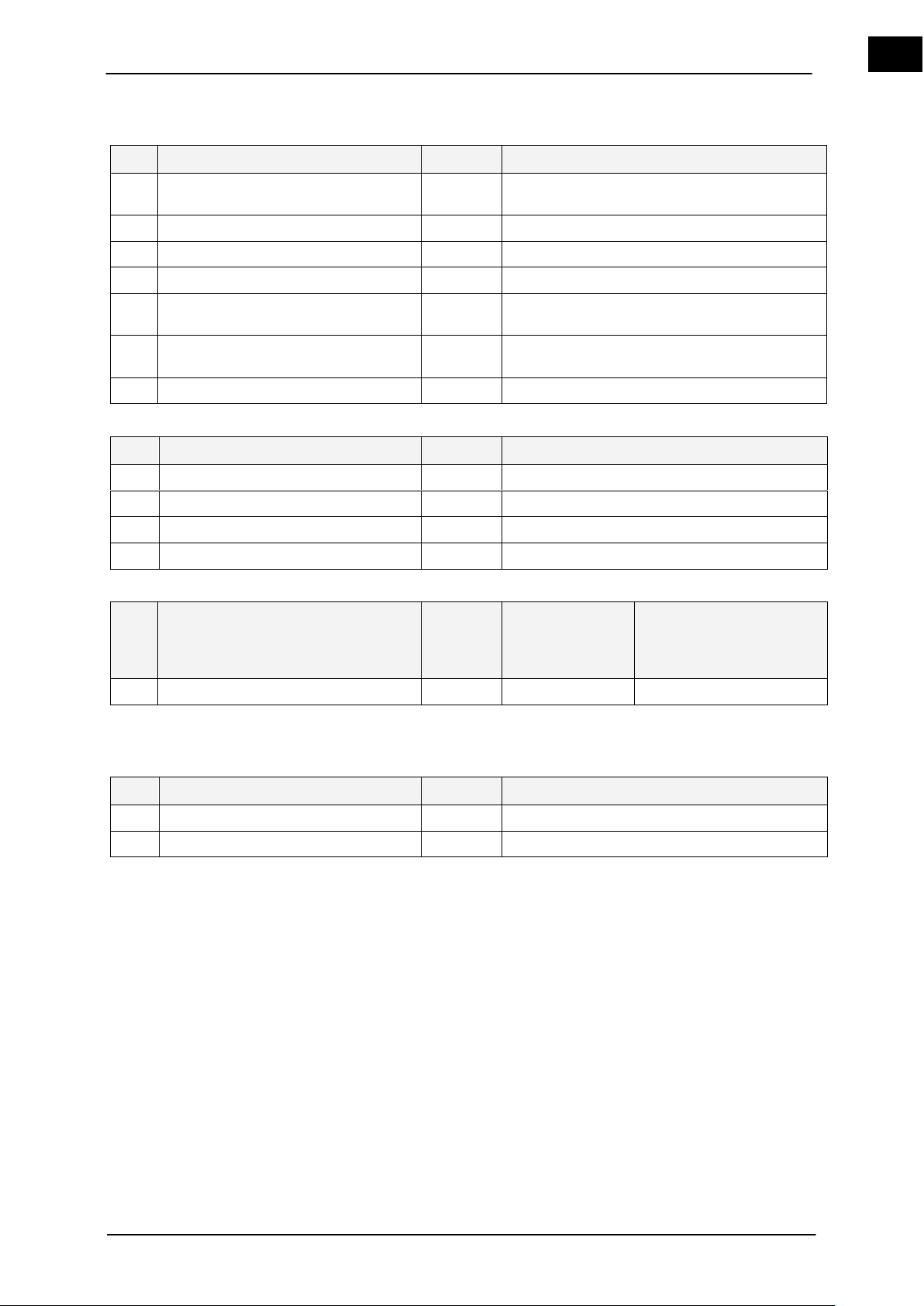

Description

Completion

Quantity

Hand lift truck (HL)

Motor lift (ML)

Glassware set

Standard

coated

Standard

coated

Hei-VAP

Value

G1 diagonal

condenser

1

560-01100-00

560-01110-00

or

Hei-VAP

Value

G3 vertical condenser

1

560-01300-00

560-01310-00

or

Hei-VAP

Value

G5 cold trap

1

560-01500-00

560-01510-00

or

Hei-VAP

Value

G6 return condenser

1

560-01600-00

560-01610-00

or

Hei-VAP

Advantage

G1 diagonal

condenser

1

561-01100-00

561-01110-00

562-01100-00

562-01110-00

or

Hei-VAP

Advantage

G3 vertical condenser

1

561-01300-00

561-01310-00

562-01300-00

562-01310-00

or

Hei-VAP

Advantage

G5 cold trap

1

561-01500-00

561-01510-00

562-01500-00

562-01510-00

or

Hei-VAP

Advantage

G6 return condenser

1

561-01600-00

561-01610-00

562-01600-00

562-01610-00

or

Hei-VAP

Precision

G1 diagonal

condenser

1

563-01100-00

563-01110-00

564-01100-00

564-01110-00

or

Hei-VAP

Precision

G3 vertical condenser

1

563-01300-00

563-01310-00

564-01300-00

564-01310-00

or

Hei-VAP

Precision

G5 cold trap

1

563-01500-00

563-01510-00

564-01500-00

564-01510-00

or

Hei-VAP

Precision

G6 return condenser

1

563-01600-00

563-01610-00

564-01600-00

564-01610-00

Description

Quantity

Order No.

Standard

NS 29 / 32

Order No.

NS 24 / 40

Glassware set G1

1

513-00100-00

513-00140-00

or

Glassware set G3

1

513-00300-00

513-00340-00

or

Glassware set G5

1

513-00500-00

513-00540-00

or

Glassware set G6

1

513-00600-00

513-00640-00

or

Glassware set G1 coated

1

513-00110-00

513-00150-00

or

Glassware set G3 coated

1

513-00310-00

513-00350-00

or

Glassware set G5 coated

1

513-00510-00

513-00550-00

or

Glassware set G6 coated

1

513-00610-00

513-00650-00

4 Set-up and Start-up

4.1 Scope of delivery

12 Hei-VAP Value, Hei-VAP Advantage

Set-up and Start-up

EN

Description

Quantity

Order number

Vapor tube coupling clamp with swing

clamp

1

23-09-03-01-03

Tension spring

1

22-03-02-01-05

PTFE 26 vacuum seal

1

23-30-01-01-30

Clamping piece 26

1

23-30-01-05-31

Operating instructions

Hei-VAP Value / Hei-VAP Advantage

1

01-005-004-79

Operating instructions Hei-VAP Precision

1

01-005-004-92

Warranty / declaration of non-objection

1

01-006-002-58

Description

Quantity

Order number

Power cable (EC)

1

14-300-009-81

Power cable for the US

1

14-300-009-82

Power cable for GB

1

14-300-009-83

Power cable for Switzerland

1

14-300-009-84

Description

Quantity

Order No.

Standard

NS 29

Order No.

NS 24

Swing clamp

1

23-30-01-05-29

23-30-01-05-57

Description

Quantity

Order number

Upgrade kit Advantage Precision-HL

1

569-30009-00

Upgrade kit Advantage Precision-ML

1

569-40009-00

Included with the equipment:

Table 4-1: Scope of delivery

Accessories

Table 4-2: Accessories

Unpack the rotary evaporator and check for completeness and any potential shipping damages.

Inform the Service Department of Heidolph Instruments in case of any damages (see chapter 9.4).

Hei-VAP Value, Hei-VAP Advantage 13

Set-up and Start-up

EN

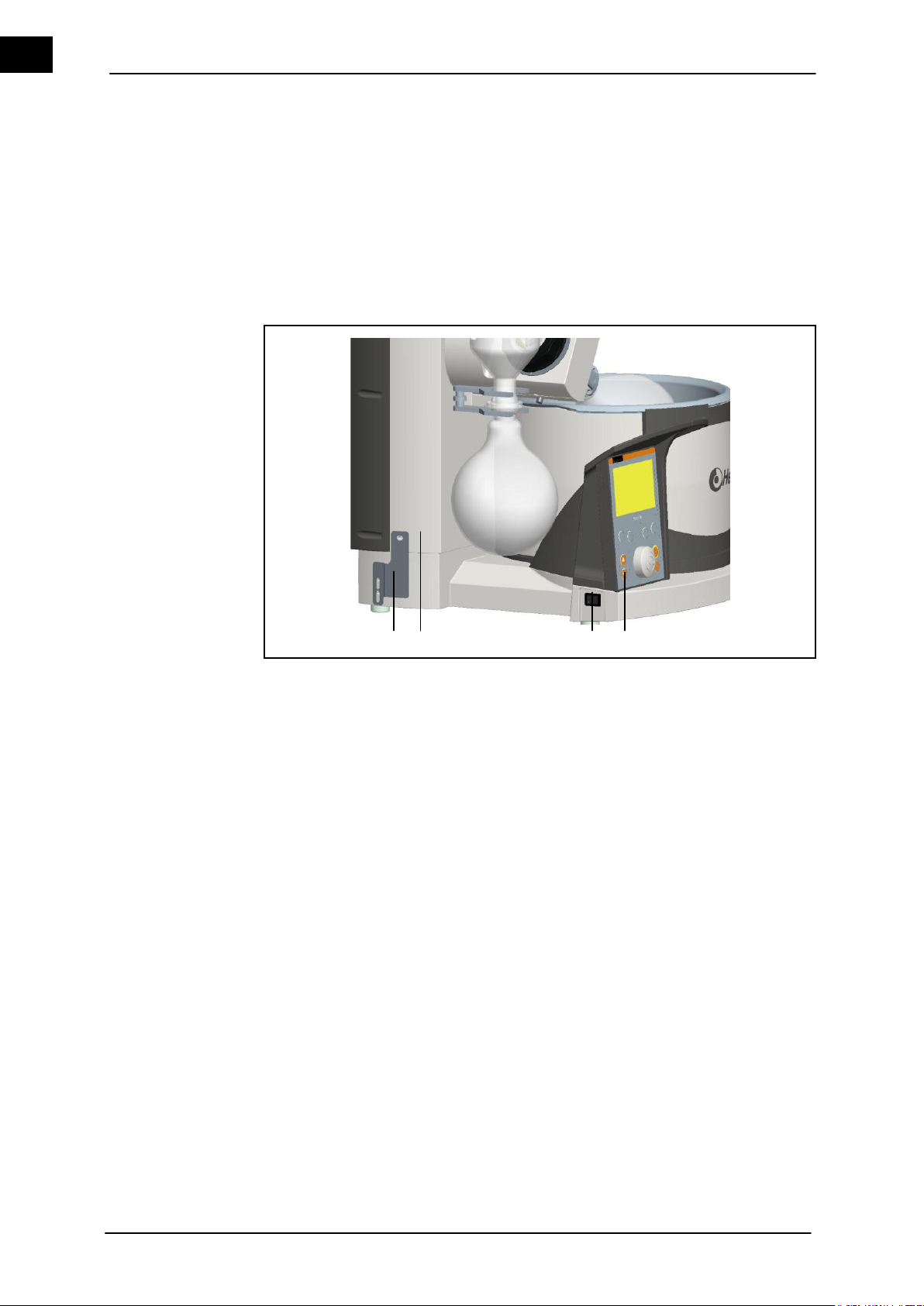

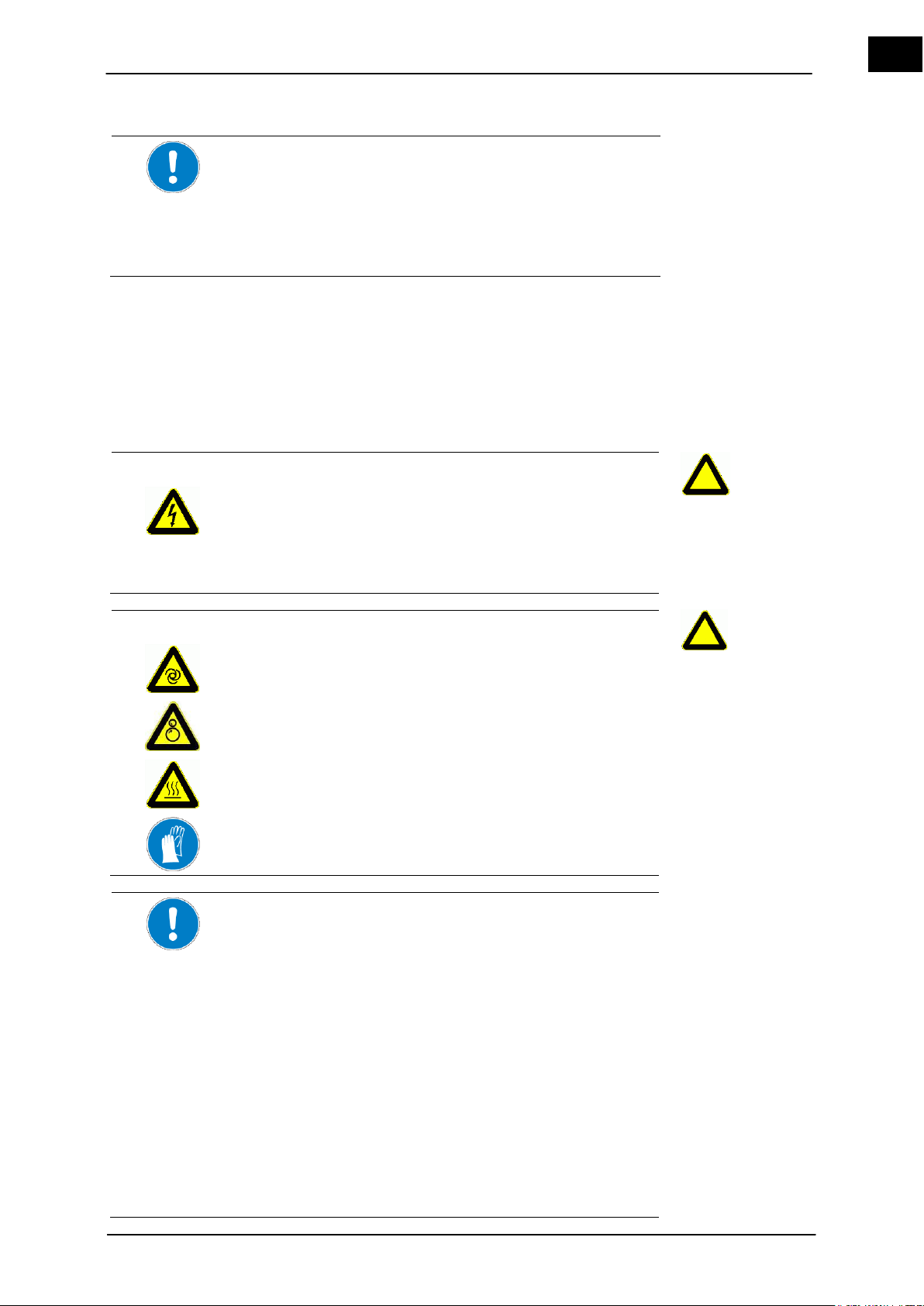

1

Transportation safety device

4

Button – lift down

2

Front shell of lift

5

Button – lift up

3

Power switch

Transportation

safety device

1 2 3

4 & 5

4.2 Transport

The motor lift units have a transportation safety device, which must be removed prior to

the initial start-up of the unit or reattached prior to the return shipment. This is very important in shipping any return or repair of motor lift unit to make sure transport lock is

assembled.

A brief description of the procedure for removing and reattaching the transportation safety device may be found in the following.

The transportation safety device consists of three M5x8 screws and a connecting plate

with holes for fixing the position.

Figure 4–1: Transportation safety device

4.2.1 Removing the transportation safety device

All hose and cable connections to other devices, and the coolant/vacuum connec-

tion are disconnected.

Connect the unit and set the power switch (3) at on.

1. Remove the top screw (in the front shell of the lift (2)) and the lower screw of the

transportation safety device (1) in the switched state. Never tighten in the top position!

2. Remove the screws and the transportation safety device (1) and store.

3. Move the hoist up by using the "lift up" (5) button. Switch the unit off and on.

4.2.2 Attaching the transportation protection device before packing

All hose and cable connections to other devices and the coolant/vacuum connection

are disconnected.

Connecting the unit

1. Continue pressing the lift position contact down when switching the unit on (this will

suppress the "lift to the top when power off" function).

2. Move the hoist down by using the "lift down" (4) button.

Please pay attention to the lift-height stop!

3. Hold the transport safety device as shown in Image 4-1 and fix it with the screws

M5x8 (3 pieces).

14 Hei-VAP Value, Hei-VAP Advantage

Set-up and Start-up

EN

CAUTION

Vibrations and shocks!

Damaging the housing and the mechanical system of the equipment.

Avoid vibrations and shocks.

Avoid setting up the rotary evaporator in corrosive atmospheres.

This reduces the service life of the equipment.

CAUTION

Tilting the heating bath!

Damaging the housing and risk of injuries.

Place the basic unit on a solid level surface with sufficient

room.

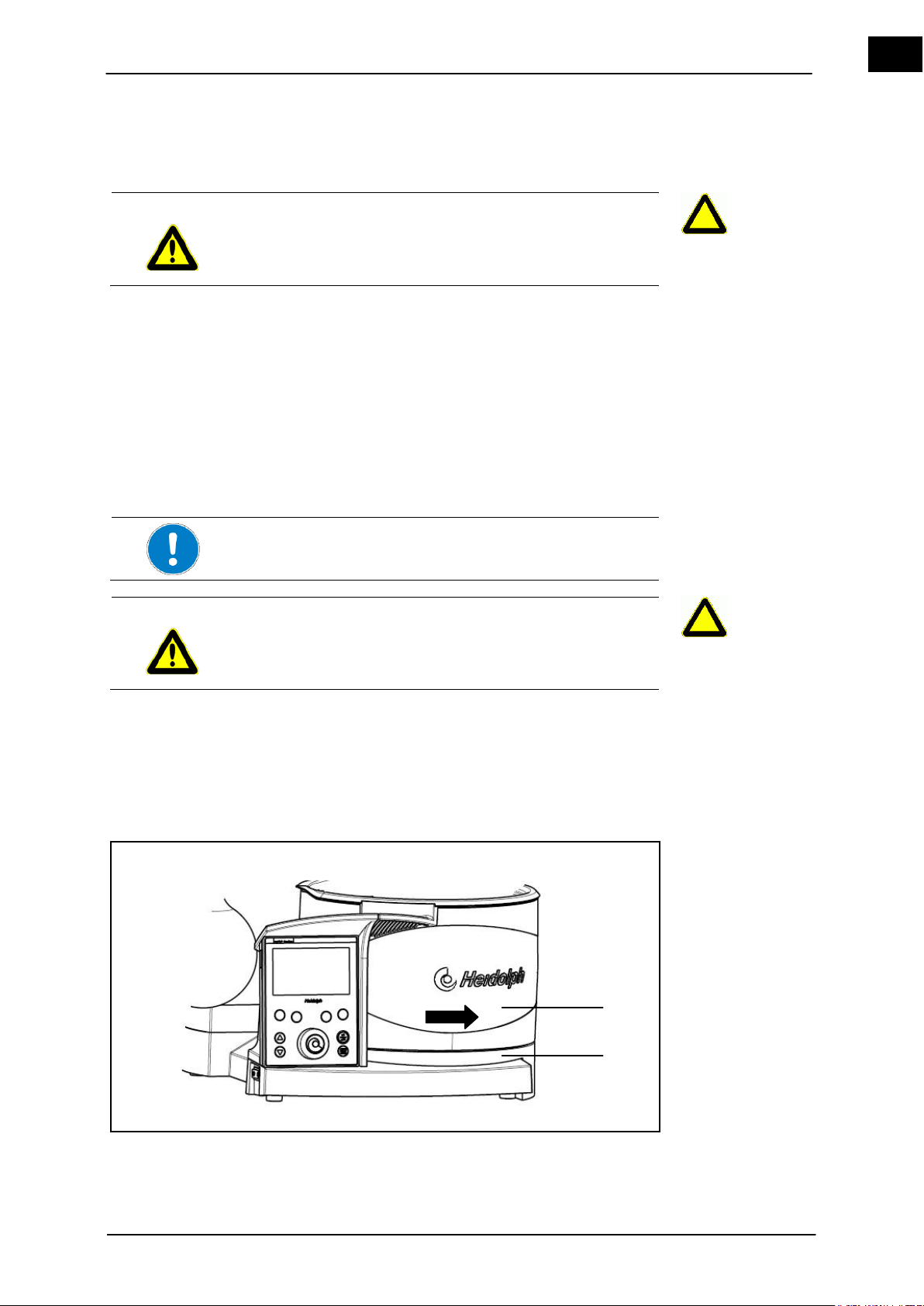

1

Heating bath

2

Base plate

Where?

Start-up

Installing the heating bath

2

1

4. Switch off the unit.

5. Remove the plug.

6. Package the unit.

Carry the basic unit from below.

4.3 Setting up the basic unit

Chemicals may reach the atmosphere (via the pump) when handling hazardous materials and distilling solvents.

Verify that harmful fumes or gases do not affect the operating personnel. The pump

exhaust air must be channeled to an exhaust hood or condensate condenser.

Verify that the interior and exterior pressure variance equals no more than 2 bar.

Verify that the emergency stop for the power supply is always easy to reach.

Select a level, solid, and heat resistant surface.

4.4 Start-up

4.4.1 Installing the heating bath

The basic unit is located on a suitable place.

Figure 4–2: Heating bath

Hei-VAP Value, Hei-VAP Advantage 15

Set-up and Start-up

EN

When using de-ionized or distilled water:

Offset water with 0.2 % borax (Na2B4O7 *10 H2O) to prevent

corrosion associated with these purified waters to the stainless steel of the heating bath.

The minimum-/maximum specifications in the heating bath refer

to the liquid level when the evaporator flask is immersed.

Location of the heating bath

The base unit is located on a suitable surface.

Verify that sufficient space (approx. 20 cm around the evaporator) and a solid seating are available in the shifting area.

Verify a solid seating of the heating bath base and the bath.

1

Rotacool

2

Rotacool extension plate

Fill the heating bath

Offsetting the heating bath

Heating bath set-up

when using Rotacool

1

2

1. Place the base plate (2) on the surface for the heating bath (1) into the provided rail,

so that the heating bath cannot tilt.

2. Place the heating bath into the rails by its feet. Be careful that the heating bath connection points to the right rear.

4.4.2 Fill the heating bath

The heating bath can be filled with various heat transfer fluids.

1. Select a liquid suitable for your application, such as tap water, water-soluble polyethylene glycol or oil of a lower viscosity (40 cP) and flash point (observe the Safety

Data Sheet)> 260 ° C.

2. Immerse the evaporator flask.

3. Fill the heating bath with the media of choice. The level should be within the minimum and the maximum marking in the heating bath.

4.4.3 Offsetting the heating bath

It will be necessary to expand the distance of the heating bath to the drive unit when

using large evaporator flasks or intermediate pieces between evaporator flasks and the

vapor tube, such as bump flasks or foam brake flasks.

Shift the heating bath including the base plate by the handle on the rail and position

accordingly (Figure 4–2: Heating bath).

4.4.4 Heating bath set-up when using Rotacool

16 Hei-VAP Value, Hei-VAP Advantage

Set-up and Start-up

EN

Location of the heating bath when using Rotacool

The base unit is located on a suitable surface.

Verify that sufficient space (approx. 20 cm around the evaporator) and a solid seating are available in the shifting area and

the Rotacool.

Verify a solid seating of the heating bath base and the bath as

well as the Rotacool extension.

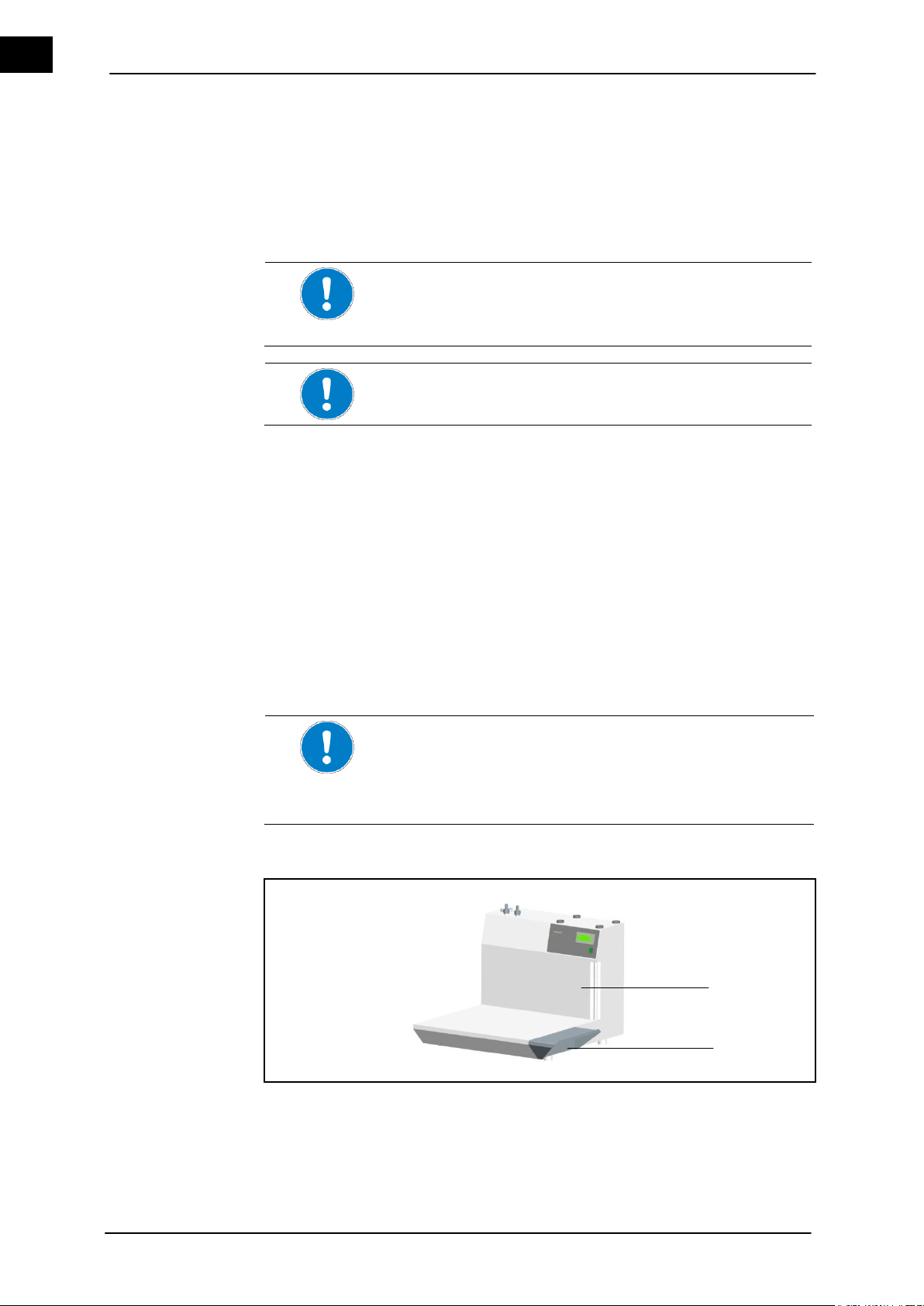

CAUTION

Supply voltage and the voltage information on model tag do not

match!

Damage due to incorrect voltage.

Verify that the voltage specified on the model tag corre-

sponds with the mains voltage.

Only disconnect the basic device with the heating bath if the device is de-energized. Unplug main power supply.

CAUTION

The drive unit and the heating bath may be switched on accidentally!

Injuring and burning hands.

Risk of entanglement

Injuries to hands.

Verify that the power switch for the base unit and the heating

bath is switched off by the rocker switch.

Country-specific equipment connection cable

The design of the equipment is equipped with a Euro connector

(EN 50075) for 230/240 V by default, and with a US standard plug

(NEMA Pub. No. WDI. 1961 ASA C 73.1 for a design for 120 V.

1961, page 8, 15 A 125 V).

The main power cable of the device has an integrated protective

ground connection.

Please note if the appropriate equipment connection cable for

your country was included and use it.

Equipment connection cable for:

EU

Great Britain

Switzerland

USA

Connect the base

unit

1. Place the two screws on the right side of the extension plate of the Rotacool.

Contact a local Heidolph Distributor if using a previously purchased Rotacool before

July, 2009 for proper attachments of the extension plate.

2. Check the extension plate (2) for proper seating.

4.4.5 Connect the base unit

Hei-VAP Value, Hei-VAP Advantage 17

Set-up and Start-up

EN

In order to operate the equipment in a country with a different

connector system, one can use approved adapters only or have a

licensed electrician replace the plug with one suitable and approved for the power supply with protective ground connection.

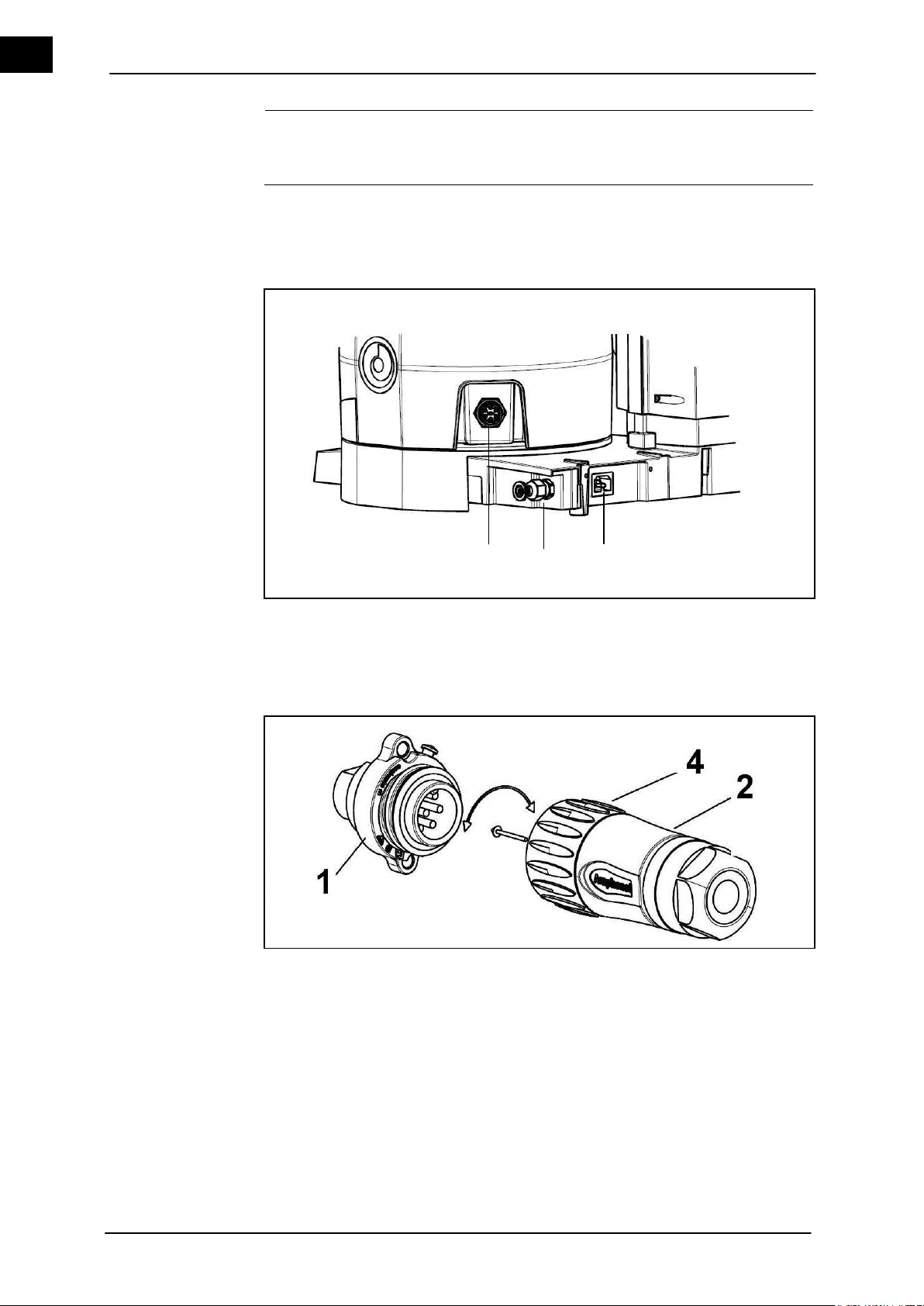

1

Heating bath unit plug

2

Heating bath connecting line (symbolically without a cable and connector)

3

Power supply connector

Connection versions

1 2 3

The plug sockets are located on the back of the unit.

The unit is switched off.

The heating bath is installed on the base console.

Figure 4–3: Connections

Figure 4–4: Heating bath connector

1. Plug the socket of the heating bath connecting cable (2) of the Hei-VAP base into

the appropriate connector (1).

2. Plug the socket (2) with the cap nut (4) of the heating bath connecting cable (7-pin)

into the heating bath:

Press the socket into the connector so that the locking stub fits into the groove.

Grab the socket (2) on the knurled nut (4) and turn the knurled nut clockwise to

fix it.

3. Plug the power supply cable into the power supply plug on the back panel of the

base unit.

4. Connect the power cable to the power supply.

18 Hei-VAP Value, Hei-VAP Advantage

Loading...

Loading...