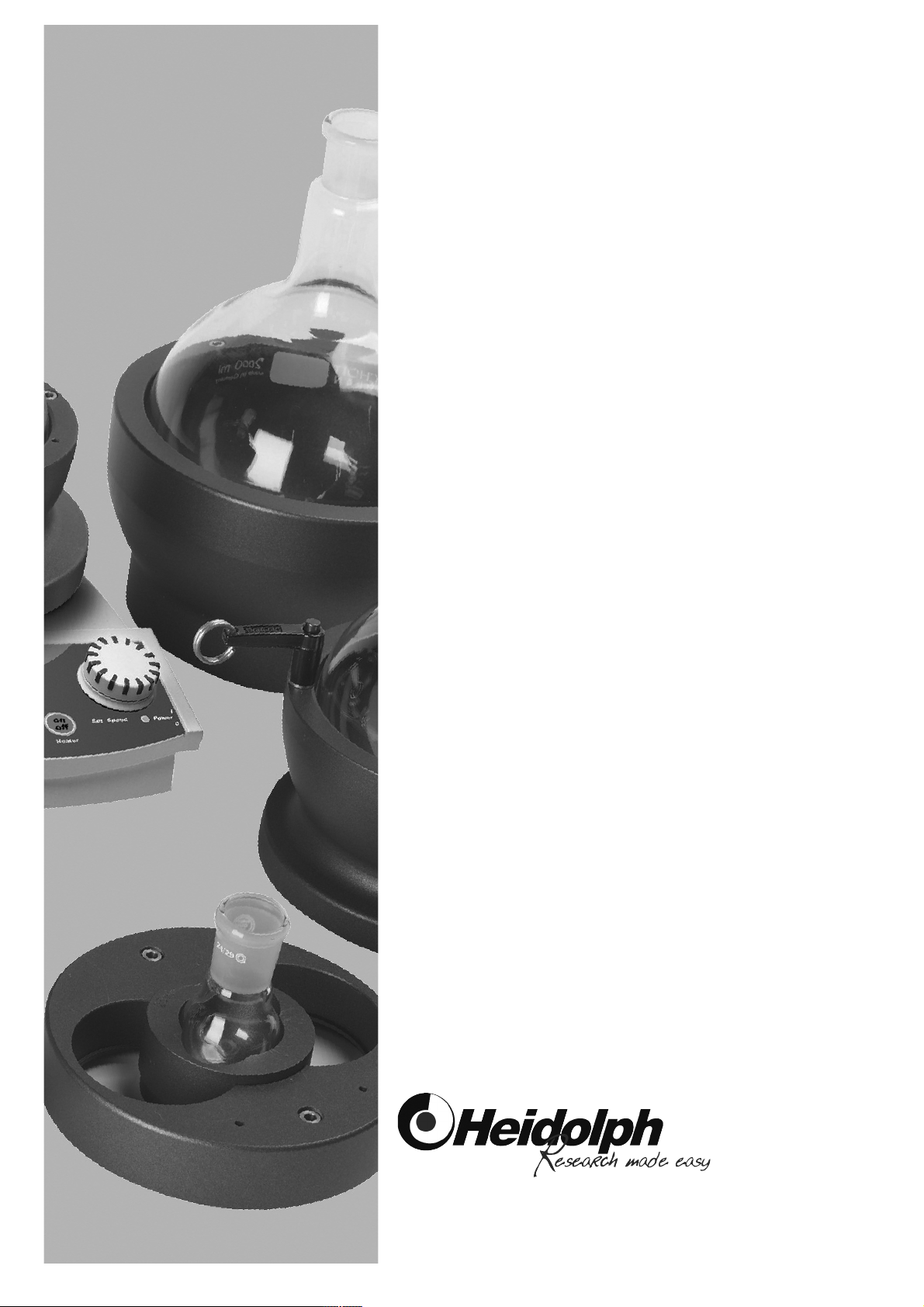

Heidolph Heat-On User Manual

March 2009 Issue 1

Instructions

™

Heat-On

Simply the safest, fastest,

most efficient way of heating

a round bottom flask

Heidolph Instruments GmbH & Co.KG

Walpersdorfer Str. 12.D - 91126 Schwabach

Tel: (+49) 0 91 22 - 99 20 69.Fax - 99 20 65

sales@heidolph.de.www.heidolph.com

Heat-On Instructions

Index

Page 1 Index

Page 2 Introduction

Page 3 Safety Information

Important WARNINGS

Page 4 Products & Accessories

Page 5 Set-up

Select your stirring hotplate

Do you need an adapter plate?

Optimising the temperature performance of Heat-On

Page 6 Set-up - continued

Using a separate temperature controller

Optimising the stirring performance of your Heat-On

Wide choice of magnetic stirring bars

Page 7 Set-up - continued

Beginning your experiment

Page 8 Set-up - continued

Multi-well formats for smaller flasks

Anodised Blocks or Fluoropolymer Coated

Page 9 Set-up - continued

Fitting optional safety lifting handles to Heat-On blocks

Using a Retort stand

Page 10 Set-up - continued

Flask Selection Process

Page 11 Warranty & Liability

Questions & Repairs

Page 1

Heat-On Instructions

hank you for purchasing Heat-On

T

Please read this Instruction Manual thoroughly before operating your unit.

Introduction

Heat-On is a modular heating and stirring work station designed to accept either one or two round bottom flasks from 10ml to 5 litres.

Heat-On offers the following features and benefits:

• All Heat-On blocks are manufactured from solid aluminium providing excellent, even heat transfer to the

entire block, preventing hot spots.

• Sleek weight saving design reduces the mass of the block to be heated, improving heat-up times.

• Uniquely shaped deep wells maximise heated surface area to improve heat-up time and minimise the difference

between the block and solution temperature.

• Fluoropolymer coating gives added durability.

• Tests have shown that a 250ml flask of water can be boiled in under 9 minutes, 50% faster than the competition.

• All Heat-On blocks have a probe hole for use with separate temperature probe.

• Heat-On blocks can be used up to 200˚C without damage to the block. Temperatures up to 260˚C can be achieved

but some minor surface degradation may occur.

Page

2

Safety Information

The following symbols are intended to assist the

ser in the safe and efficient operation of Heat-On.

u

Heat-On Instructions

!

Warning

Applies when there is a possibility

f personal injury.

o

Important,Important,

Important, Important,

Important, Important,

mportant, Important,

I

mportant, Important,

I

mportant, Important,

I

mportant, Important,

I

Important Note

Alerts the user to important facts.

Important WARNINGS

1. Please read these instructions completely before using your Heat-On Block.

2. Operate only in a fume cupboard with protective safety sash.

3. During and after heating take care not to touch the Heat-On block.

4. Risk of burns from hot blocks

Like oil baths, Heat-On blocks remain hot for some considerable time after the heating source has been switched off. A temperature

probe or temperature sensitive label can be used to indicate when blocks are too hot to touch.

5. Flask selection process

Heat-On is designed so that over sized flasks cannot fit through the slightly narrower opening at the top of the block well. This means

that all suitable flasks should sit at the bottom of the block well, be a loose fit and as such spin freely in the Heat-On well.

When a flask is inserted into the well it is important to ensure that the flask touches the bottom of the well and does not ‘catch or stick’

on the sides of the block well. If the flask is ‘catching or sticking’ it may be deformed and may result in jamming and even cracking of

the flask when the Heat-On block is cooling.

There is a simple rule when using glassware with the Heat-on: “If it does not spin, then throw it in the bin”. If the flask does not

spin freely then it is unsuitable for use in the Heat-On and an alternative flask should be used.

6. Starting and stopping your reaction

In an ideal situation you should load your glassware into the block when the block is at ambient (room temperature).

However in certain situations this may not be practical. In such circumstances you should note:-

a. You can use cold water to cool the block down rapidly, but take care with blocks above 100˚C as steam is a potential hazard.

b. It is generally safe to insert flasks into blocks that are below 50˚C, but the flask should be removed before the block temperature

drops below the start temperature as there is a small risk that the contraction of the block could crush the glass flask.

c. In all eventualities flasks should be removed at or above the temperature they were originally inserted; i.e. in the case of a flask

that is inserted at 80˚C, it should be removed when or before the block cools to 80˚C.

7. Chemical resistance

Anodised Heat-On blocks are resistant to the majority of solvents and splash resistant to dilute acids and alkalis at room temperature.

The fluoropolymer coated Heat-On blocks offer superior resistant to the majority of solvents, acids and alkalis.

Extended exposure to acids or alkalis will attack the surface of the Heat-On blocks. The stronger the concentration and the longer the

exposure time the more chance and intensity of any attack. Heat will also speed up and intensify any attack. e.g. hot concentrated

sulphuric acid will damage the fluoropolymer coated Heat-On blocks over a period of time. It is important to clean off any residual

chemical spills immediately after they occur.

8. Temperature range

Heat-On blocks can be used up to 200˚C without damage to the block. Temperatures up to 260˚C can be achieved but some minor

surface degradation may occur.

Page

3

Loading...

Loading...