Hatco GRAN-51 Installation Manual

Installation & Operating Manual

for McDONALD’S

PREP LINE OVERHEAD WARMER

MOUNTING TO 7½ " (19.0 cm)

CONDIMENT STATION

GLO-RAY® Model GRAN-51

(Left Hand Unit GRAN.00007)

(Right Hand Unit GRAN.00008)

CONTENTS

Introduction

1

4

Safety Instructions

Model Descriptions

Installation Instructions

Electrical Specifications

Electrical Rating Chart

Plug Configurations

1

2

2

4

4

4

Operation

Cleaning

Replacement Parts List. 5

Warranty

Authorized Part Distributors

IMPORTANT OWNER INFORMATION

Record the model number, serial number, voltage BUSINESS HOURS: 8:00 a.m. to 5:00 p.m.

(located on the specification plate) and purchase date of Central Standard Time

your Prep Line Overhead Warmer in the spaces below. (Summer Hours: June to September Please have this information available when calling 8:00 a.m. to 5:00 p.m. C.S.T.

Hatco for service assistance. Monday through Thursday

Model No. ___________________________ 8:00 a.m. to 3:30 p.m. C.S.T. Friday)

Serial No. ____________________________ TELEPHONE: (800) 558-0607

Voltage______________________________ PARTS & SERVICE FAX : (800) 690-2966

Date of Purchase ______________________

4

6

Back Cover

INTRODUCTION

This manual provides the installation and operating instructions

for the Prep Line Overhead Warmer. We recommend all

installation, operating and safety instructions appearing in this

manual be read prior to installation or operation of your Prep

Line Overhead Warmer. Safety instructions that appear in this

manual after a warning symbol and the words

WARNING or CAUTION printed in bold face are important.

Warning means there is the possibility of personal injury to

yourself or others. Caution means there is the possibility of

damage to the unit.

IMPORTANT SAFETY INSTRUCTIONS WARNING

1. Plug warmer into an electrical outlet of the

correct voltage, size and plug configuration. If the plug

and receptacle do not match, contact a qualified

electri cian to determine the proper voltage and size and

install the proper electrical outlet.

2. To prevent electric shock, always unplug the unit before

performing cleaning, maintenance or repair.

3. Some exterior surfaces on the foodwarmer will get hot

Use caution when touching these areas to avoid injury.

4. For safe and proper operation, the foodwarmer must be

located a reasonable distance from combustible walls and

materials. If safe distances are not maintained,

discoloration or combustion could occur.

1

Warmer Dimensions: 51"L x 3"W x 2.5"H (129.5 x 7.6 x 6.4

2

cm).

MODEL DESCRIPTIONS

(1) Stainless Steel Reflector/Tray Stop, Part No.

04.08.411.00.

This model includes:

(1) GRAN-51 Prep Line Overhead Warmer with on/off toggle

switch, and 6' (182.9 cm) cord and plug attached.

Tools needed to complete installation (to be supplied by installer):

(1) Marking pen or pencil

(1) Center punch

(1) Hammer

(1) Electric hand drill

(1) 9/32" drill bit for stainless steel

(1) Tape measure

To install the Glo-Ray model GRAN-51 Prep Line Overhead

Warmer to the 7'/2" (19 cm) Condiment Station:

NOTE: Identify the holes being used to attach the stainless

steel reflector/tray stop to warmer.

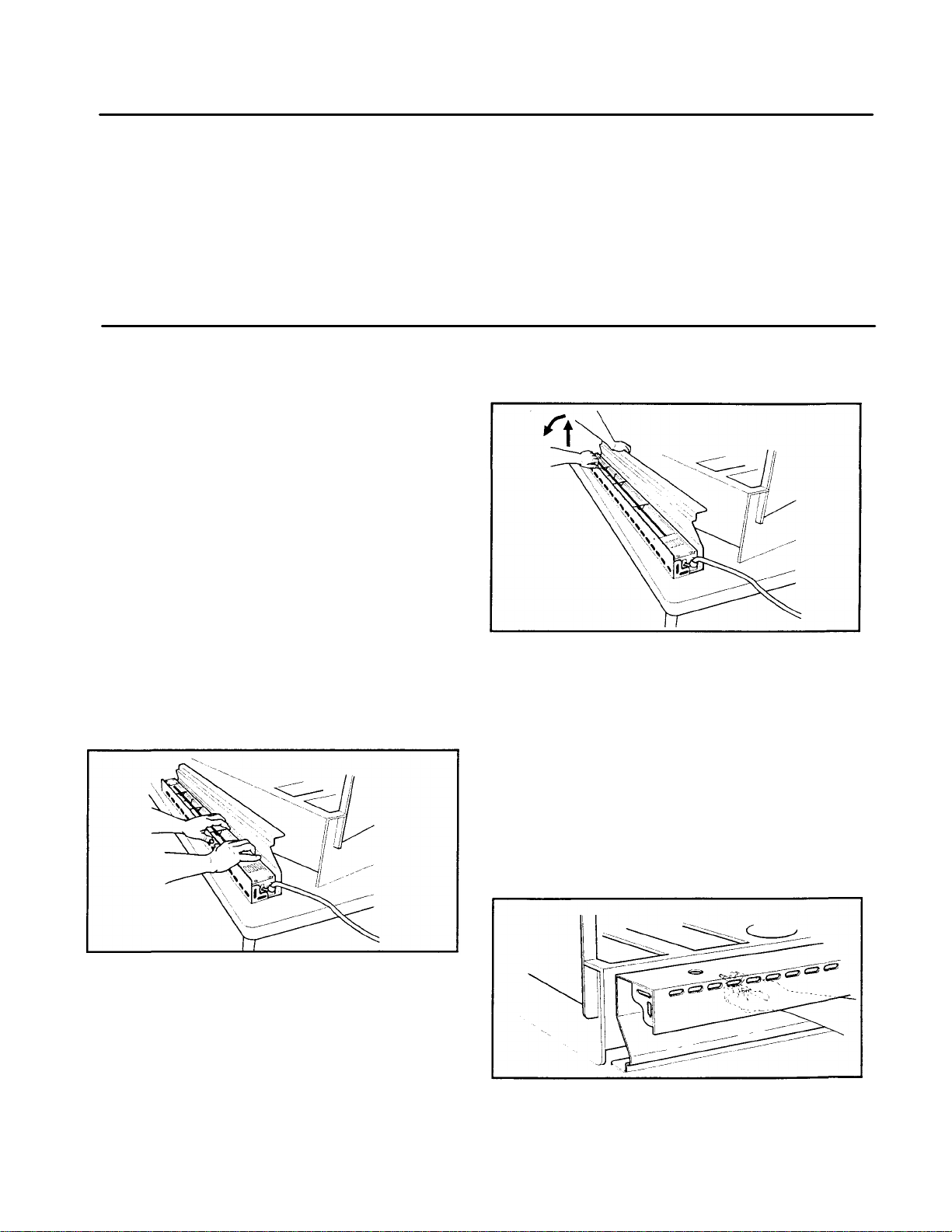

1. Loosen and remove the three (3) wing nuts from the back of the

unit. (Save wing nuts.)

2. Rest unit on a solid surface. Turn upside down. See Figure 1.

3. Squeeze food warmer against the front face until threaded posts

pop out of stainless steel reflector/tray stop holes.

(5) Wing nuts, Part No. 05.04.172.00 (Includes two extra).

(1) Polycarbonate Personnel Protector, Part No.

04.12.083.00.

INSTALLATION INSTRUCTIONS

4. Starting at the end opposite the switch, lift and turn warmer

until threaded posts come completely out of housing and you

are able to separate the two pieces. See Figure 2.

Figure 2. Removing Warmer From Tray Stop.

5. Position stainless steel reflector/tray stop onto prep table

surface making sure the six (6) pre-drilled mounting holes are

facing up and it is tight against the 7-1/2" condiment station.

NOTE: Tray stop has six (6) holes. Left end switch models

utilize the right hole in each pair. Right end switch models

utilize the left hole in each pair.

6. Mark the location of the three (3) holes with a pen or pencil

and remove tray stop. See Figure 3.

Figure 1. Removing Threaded Posts From Tray Stop.

Figure 3. Marking the Hole Locations.

Loading...

Loading...