Page 1

Instruction Manual

HI 9142

Portable Waterproof

Dissolved Oxygen Meter

www.hannainst.com

Page 2

Dear Customer,

Thank you for choosing a Hanna Instruments

Product.

Please read this instruction manual carefully

before using the instrument.

This manual will provide you with all the neces-

sary information for the correct use of the

instrument.

If you need additional technical information, do

not hesitate to e-mail us at

tech@hannainst.com

This instrument is in compliance with the CE

directives.

PRELIMINARY EXAMINATION

Remove the instrument from the packing material

and examine it to make sure that no damage

has occurred during shipping. If there is any

damage, notify your Dealer.

The meter is supplied complete with:

• HI 76407/4 DO probe with 4 m cable

• 2 spare membranes with O-rings

• HI 7041S electrolyte solution (30 mL)

• Calibration screwdriver

• Batteries (4 x 1.5V AA)

• Instruction manual

• Rugged carrying case

Note: Save all packing material until you are sure

that the instrument functions correctly. All

defective items must be returned to us in the

original packaging with the supplied

accessories.

TABLE OF CONTENTS

Preliminary Examination ............................. 3

General Description..................................... 3

Probe Functional Description ...................... 4

Meter Functional Description....................... 5

Specifications ............................................. 6

Probe Initial Preparation .............................. 7

Calibration Procedure .................................. 8

Taking Measurements............................... 10

Altitude and Salinity Compensation........... 1 1

Probe & Membrane Maintenance .............. 13

Battery Replacement ................................ 15

Accessories.............................................. 16

Warranty ................................................... 17

CE Declaration of Conformity .................... 18

2

GENERAL DESCRIPTION

HI 9142 is a rugged, waterproof meter that

solves the common problems of field use, such

as cold, rain, snow and dust, that can damage

a meter, rapidly deteriorating its performance

and life.

It is very simple to use: calibration is performed

with HI 7040 zero oxygen solution, while 100%

calibration is done in air.

The polarographic probe (HI 76407/4) is pro-

vided with a membrane covering the sensors

and a built-in thermistor for temperature measurement and compensation. The thin permeable membrane isolates the sensor elements

from the testing solution, but allows oxygen to

enter. When a voltage is applied across the

sensor, oxygen that has passed through the

membrane reacts causing current to flow, allowing the determination of oxygen.

3

Page 3

The probe included with the meter is supplied

with a 4 m (13') cable that allows measurements

to be taken even in even hard to reach

places. For applications that require longer

probe cables, the HI 76407/10 and HI 76407/20

probes with a 10 m (33') or 20 m (67') cable are

available.

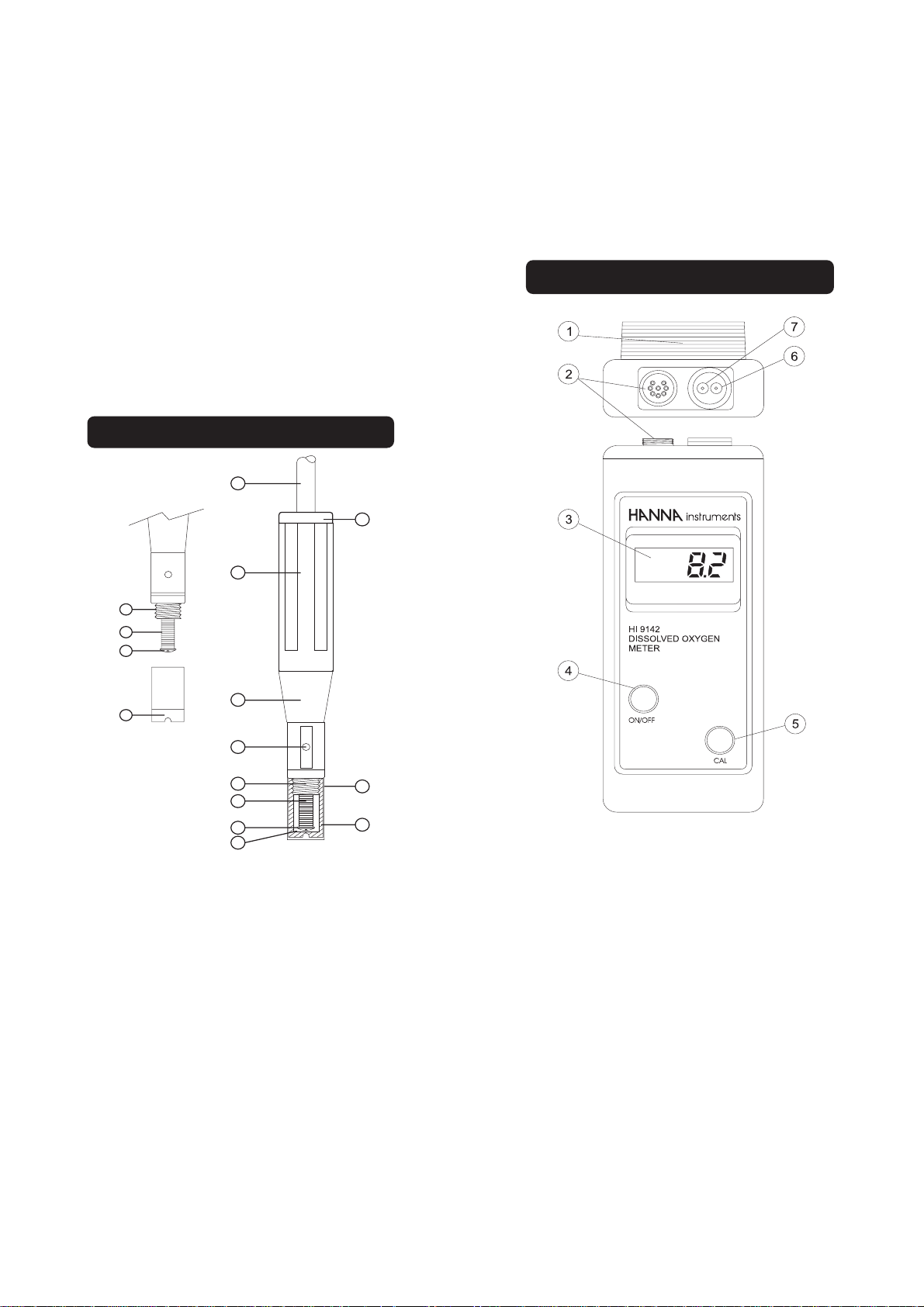

PROBE FUNCTIONAL DESCRIPTION

3

1

4

6

7

8

METER FUNCTIONAL DESCRIPTION

9

4

5

6

7

8

9

1. D.O. probe

2. Protective cap

3. Shielded cable

4. Polypropylene probe body

5. Temperature sensor

6. O-Ring seal

7. Silver chloride (AgCl) anode

8. Platinum cathode (sensor)

9. Oxygen permeable membrane

10.Membrane cap

4

2

10

1. Battery compartment

2. Probe connector

3. Liquid Crystal Display

4. ON/OFF button

5. Calibration button

6. Slope calibration trimmer

7. Zero oxygen calibration trimmer

5

Page 4

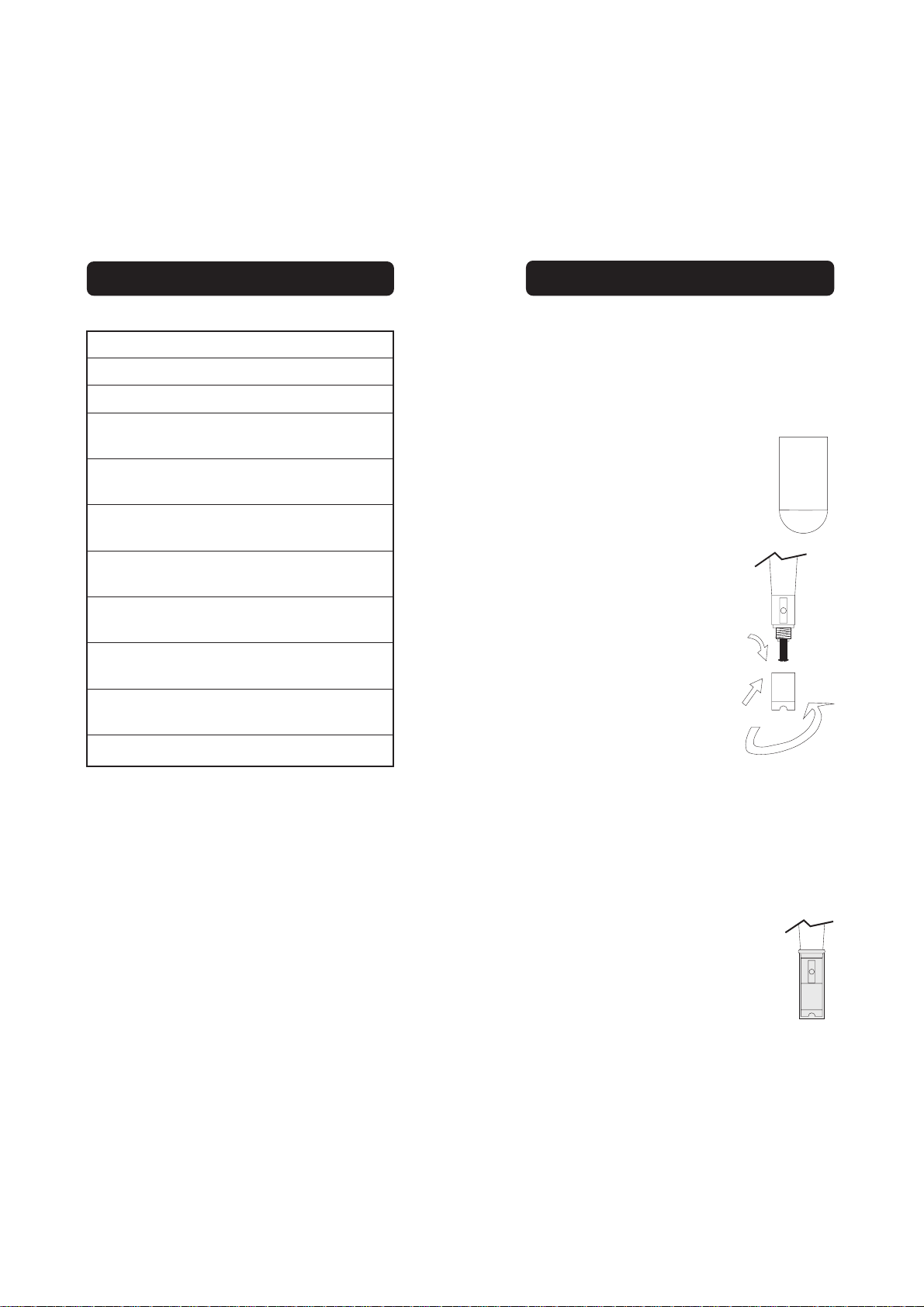

SPECIFICATIONS

Range 0.0 to 19.9 mg/L (ppm)

Resolution 0.1 mg/L

Accuracy ±1.5% FS

Typical EMC ±0.8 mg/L

Deviation with 4 m cable probe

Calibration Manual, 1 or 2 point

(zero and slope)

Temperature Automatic, 0 to 30°C

Compensation (32 to 86°F)

Probe HI 76407/4, polarographic,

with 4 m (13') cable (included)

Battery Type 4 x 1.5V AA

Life approx. 500 hours of use

Environment 0 to 50°C (32 to 122°F);

RH max 100%

Dimensions 196 x 80 x 60 mm

(7.7 x 3.1 x 2.4")

Weight 500 g (1.1 lb.)

PROBE INITIAL PREPARATION

Probe Preparation

All D.O. probes from Hanna Instrument are

shipped dry. To hydrate the probe and prepare it for use, connect it to the meter and

proceed as follows.

1. Remove the red & black plastic

cap. This cap is used for ship-

Shipping

cap

ping purposes only and can be

thrown away.

2. Wet the sensor by soaking the

black

bottom (2.5 cm/1") of the probe

in HI 7041S electrolyte solution

red

for 5 minutes.

3. Rinse the membrane

(HI 76407A supplied

with the meter) with

some electrolyte

while shaking it gently. Refill with clean

electrolyte.

4. Gently tap the sides

FILL FIRST

THEN TAP

of the membrane

with your finger to

ensure that no air

bubbles remain

trapped inside.

THEN SCREW

BACK ON

To avoid damaging the membrane, do not

tap the membrane directly on the bottom.

5. Place the rubber O-Ring properly inside

the membrane cap.

6. With the sensor facing down, screw the

cap clockwise. Some electrolyte will overflow.

When not in use and during polarization, protect the membrane with

the supplied cap.

6

7

Page 5

CALIBRATION PROCEDURE

PROBE POLARIZATION

The probe is under polarization with a fixed

voltage of approximately 800 mV.

Probe polarization is essential for stable measurements with the same recurring degree of

accuracy.

With the probe properly polarized, oxygen is

continually "consumed" by passing through the

sensitive diaphragm and dissolving in the electrolyte solution contained in the probe.

If this operation is interrupted, the electrolyte

solution continues to be enriched with oxygen

until it reaches an equilibrium with the surrounding solution.

Whenever measurements are taken with a nonpolarized probe, the oxygen level revealed is

both that of the tested solution as well as that

present in the electrolyte solution. This reading

is incorrect

The calibration is very simple and fast.

• Make sure the probe is ready for measurements (see initial preparation at page 7), i.e.

the membrane is filled with electrolyte and the

probe is connected to the meter.

• Switch the meter on by

pressing the ON/OFF key

ON/OFF

• For an accurate calibration,

it is recommended that you

wait at least 15 minutes to

ensure precise conditioning of the probe.

• Remove the protective cap

from the D.O. probe.

8

ZERO CALIBRATION

• Dip the probe into HI 7040 zero

oxygen solution and stir gently for 2-3 minutes.

• Allow 2 minutes for the LCD

readout to stabilize.

• Adjust the zero D.O. calibration trimmer until the display

reads "0.0".

Note The zero calibration screw

is located close to the probe

connector.

SLOPE CALIBRATION

It is suggested to perform the slope calibration

in satured air.

• Rinse the probe in a large amount of clean

water to remove any residual zero oxygen

solution.

• Dry the probe tip and allow a few minutes for

the LCD readout to stabilize.

• Press and hold the CAL key.

• Adjust the slope trimmer on

CAL

the top of the meter to read

"100%" on the LCD (while still

holding the CAL button).

Note The slope calibration screw

is located farthest from the

probe connection.

• Release the CAL key and the

LCD will display the value in

%

ppm of oxygen.

The zero calibration of the HI 9142 is very

stable, therefore this procedure needs only to

be performed whenever the probe is re-

placed.

However, because the slope calibration is

more critical, it is recommended to perform

this procedure every week.

9

Page 6

TAKING MEASUREMENTS

ALTITUDE & SALINITY COMPENSATION

Make sure the meter has been

calibrated and the protective

cap has been removed. Immerse the tip of the probe in the

sample to be tested.

Make sure the temperature sensor is also

immersed.

For accurate dissolved oxygen measurements

a water movement of 0.3 m/sec is required at a

minimum. This is to ensure that the oxygendepleted membrane surface is constantly replenished. A moving stream will provide adequate circulation. To quickly check if the water

speed is sufficient, wait for the reading to stabilize and then move the D.O. probe. If the reading

is still stable, the measurement conditions are

right, while if the reading increases the water

movement is not adequate.

During field measurements, this condition may

be met by manually agitating the probe. Accurate readings are not possible while the liquid is

at rest.

During laboratory measurements, the use of a

magnetic stirrer to ensure a certain velocity in

the fluid is recommended. In this way, errors

due to the diffusion of the oxygen present in the

air in the solution are reduced to a minimum.

At all times, time necessary for thermal equilibrium to occur between the probe and the sample

must be allowed (a few minutes for temperature

difference of several degrees).

If the sample contains salts or if you are

performing the measurements at a different

altitude than sea level, the readout values must

be corrected, taking into account the lower

degree of oxygen solubility.

ALTITUDE COMPENSATION

All the readouts are referred at sea level, thus

the displayed measurements are higher than

the actual values. In fact, altitude affects D.O.

concentration decreasing its value. The following table reports the oxygen solubility at various

temperatures and altitudes, based on sea level

barometric pressure of 760 mm Hg.

Altitude, Meters above Sea Level

°C

0 m

300 m

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

600 m

0

14.6

14.1

2

13.8

4

13.1

6

12.4

8

11.8

11.3

10.8

10.3

9.9

9.5

9.1

8.7

8.4

8.1

7.8

7.5

7.3

7.1

6.8

6.6

6.4

13.3

12.7

12.0

11.4

10.9

10.4

9.9

9.7

9.2

8.8

8.4

8.1

7.8

7.5

7.2

7.1

6.9

6.6

6.4

6.2

13.6

12.9

12.2

11.6

11.0

10.5

10.1

9.6

9.2

8.7

8.5

8.1

7.8

7.5

7.3

7.0

6.8

6.6

6.3

6.2

6.0

6.4

6.1

5.9

5.8

900 m

13.2

12.4

11.9

11.2

10.6

10.2

9.7

9.3

8.9

8.6

8.2

7.8

7.5

7.3

7.0

6.8

6.6

1200 m

12.7

12.0

11.4

10.8

10.3

9.8

9.4

9.0

8.6

8.3

7.9

7.7

7.3

7.0

6.8

6.5

6.4

6.2

5.9

5.7

5.6

1500m

12.3

11.6

11.0

10.4

9.9

9.5

9.1

8.7

8.3

8.0

7.7

7.3

7.1

6.8

6.6

6.3

6.1

6.0

5.7

5.6

5.4

1800m

11.8

11.2

10.6

10.1

9.6

9.2

8.8

8.3

8.0

7.7

7.4

7.1

6.8

6.6

6.3

6.1

5.9

5.8

5.5

5.4

5.2

°F

32.0

35.6

39.2

42.8

46.4

50.0

53.6

57.2

60.8

64.4

68.0

71.6

75.2

78.8

82.4

86.0

89.6

93.2

96.8

100.4

104.4

10

This gives an idea of the error that can be

introduced at different altitudes and allows you

to calculate the quantity to be subtracted to

correct your reading.

11

Page 7

SALINITY COMPENSATION

The table below shows the influence of salt in

the measurement of oxygen.

In HI 9142 all the readouts are referred to 0 g/l

of salinity value. In fact, salinity affects D.O.

concentration decreasing its value.

For your reference the table below reports the

oxygen solubility at various temperatures and

salinity. From the table you can calculate the

quantity to be subtracted to correct your reading.

Salinity (g/l) at Sea Level

°C

10

12

14

16

18

20

22

24

26

28

0 g/l

11.3

10.8

10.3

9.9

9.5

9.1

8.7

8.4

8.1

7.8

10 g/l

10.6

10.1

9.7

9.3

8.9

8.5

8.2

7.9

7.6

7.4

20 g/l

9.9

9.5

9.1

8.7

8.4

8.0

7.8

7.5

7.2

7.0

30 g/l

9.3

8.9

8.6

8.2

7.9

7.6

7.3

7.1

6.8

6.6

35 g/l

9.0

8.6

8.3

8.0

7.6

7.4

7.1

6.9

6.6

6.4

°F

50.0

53.6

57.2

60.8

64.4

68.0

71.6

75.2

78.8

82.4

PROBE & MEMBRANE MAINTENANCE

The oxygen probe body is made of reinforced

plastic for maximum durability.

A thermistor temperature sensor provides temperature measurement and compensation. When

not in use, it is always recommended to protect

the probe against damage and dirt using the

supplied cap.

To replace the membrane or refill with electrolyte, proceed as follows:

• Remove the protective cap

by gently twisting and pulling it off (see fig. 1).

• Unscrew the membrane

by turning it counterclock-wise (see fig. 2)

TWIST

AND

PULL

• Wet the sensor by soak-

ing the bottom (2.5 cm) of

fig. 1

the probe in HI 7041S

electrolyte solution for 5

minutes.

• Rinse the new membrane

(HI 76407A supplied with

the meter) with some electrolyte while shaking it

gently. Refill with clean

electrolyte.

• Gently tap the sides of

the membrane with your

finger to ensure that no air

bubbles remain trapped

inside. Do no directly tap

the bottom as this will

damage the membrane.

• Make sure that the rubber

O-ring is seated properly

UNSCREW

inside the membrane cap.

fig. 2

12

13

Page 8

• With the sensor facing down, screw the

membrane cap clock-wise. Some electrolyte will overflow.

The Platinum cathode (#8 in the Functional

Description at page 4) should always be bright

and untarnished. If it is tarnished or stained,

which could be due to contact with certain

gases or extended use with a loose or damaged

membrane, the cathode should be cleaned.

Use a lint-free cardboard or cloth and rub the

cathode very gently side to side 4-5 times. This

will be enough to polish and remove any stains

without damaging the platinum tip. Afterwards,

rinse the probe with deionized or distilled water

and install a new membrane cap using fresh

electrolyte. Recalibrate the instrument.

Important: In order to have accurate and stable

measurements, it is important that the surface

of the membrane is in perfect condition. This

semi-permeable membrane isolates the sensor

elements from the environment but allows oxygen to enter. If any dirt is observed on the

membrane, rinse carefully with distilled or deionized water. If any imperfection still exists, or any

damage is evident (such as wrinkles or tears),

the membrane should be replaced. Make sure

that the O-Ring is properly seated in the membrane cap.

BATTERY REPLACEMENT

When the battery level is low,

"V" is displayed on the LCD

V

to warn the user that the battery needs to be replaced.

The meter will still work for approximately 4

hours, then the display will be shut-off to avoid

erroneous readings.

Battery replacement must only take place in a

safe area and using alkaline 1.5V AA type

batteries.

In order to replace the batteries, simply remove

the two screws on the rear cover of the instrument and replace all four batteries with new

ones, while paying attention to the correct

polarity.

14

15

Page 9

ACCESSORIES

WARRANTY

HI 7040M Zero oxygen solution, 230 mL

HI 7040L Zero oxygen solution, 500 mL

HI 7041S Refilling electrolyte solution,

30 mL

HI 76407/4 D.O. probe with 4 m (13')

cable

HI 76407/10 D.O. probe with 10 m (33')

cable

HI 76407/20 D.O. probe with 20 m (66')

cable

HI 76407A/P D.O. membrane (5 pcs)

All Hanna Instruments meters are warranted

for two years against defects in workmanship

and materials when used for their intended

purpose and maintained according to the instructions. The probes are warranted for a

period of six months.

Damages due to accidents, misuse, tampering

or lack of prescribed maintenance are not covered. This warranty is limited to repair or replacement free of charge.

If service is required, contact the dealer from

whom you purchased the instrument. If under

warranty, report the model number, date of

purchase, serial number and the nature of the

failure. If the repair is not covered by the warranty, you will be notified of the charge for repair

or replacement. If the instrument is to be returned to Hanna Instruments, obtain a Return

Goods Authorization from the Customer Service Department first and then send it with

shipment cost prepaid. When shipping any

instrument, make sure it is properly packaged

for complete protection.

16

All rights are reserved. Reproduction in whole or

in part is prohibited without the written consent

of the copyright owner.

Hanna Instruments reserves the right to

modify the design, construction and appearance of its products without advance notice.

17

Page 10

CE DECLARATION OF CONFORMITY

Recommendations for Users

Before using this product, make sure that it is entirely suitable for the environment in

which it is used.

Operation of this instrument in residential area could cause unacceptable interferences to radio and TV equipments, requiring the operator to take all necessary steps

to correct interferences.

Any variation introduced by the user to the supplied equipment may degrade the

instrument's EMC performance.

To avoid electrical shock, do not use this instrument when voltages at the measurement surface exceed 24 Vac or 60 Vdc.

To avoid damages or burns, do not perform any measurement in microwave ovens.

In particular cases the meter could turn off. In these cases it can be turned on by

pressing the ON/OFF key.

18

19

Page 11

SALES & TECHNICAL SERVICE CONTACTS

Australia:

Tel. (03) 9769.0666 • Fax (03) 9769.0699

China:

Tel. (10) 88570068 • Fax (10) 88570060

Egypt:

Tel. & Fax (02) 2758.683

Germany:

Tel. (07851) 9129-0 • Fax (07851) 9129-99

Greece:

Tel. (210) 823.5192 • Fax (210) 884.0210

Indonesia:

Tel. (21) 4584.2941 • Fax (21) 4584.2942

Japan:

Tel. (03) 3258.9565 • Fax (03) 3258.9567

Korea:

Tel. (02) 2278.5147 • Fax (02) 2264.1729

Malaysia:

Tel. (603) 5638.9940 • Fax (603) 5638.9829

Singapore:

Tel. 6296.7118 • Fax 6291.6906

South Africa:

Tel. (011) 615.6076 • Fax (011) 615.8582

Taiwan:

Tel. 886.2.2739.3014 • Fax 886.2.2739.2983

Thailand:

Tel. 66.2619.0708 • Fax 66.2619.0061

United Kingdom:

Tel. (01525) 850.855 • Fax (01525) 853.668

USA:

Tel. (401) 765.7500 • Fax (401) 765.7575

For e-mail contacts and complete list of Sales and

Technical offices, please see www.hannainst.com

MAN9142R2 08/05

Loading...

Loading...