Page 1

Instruction Manual

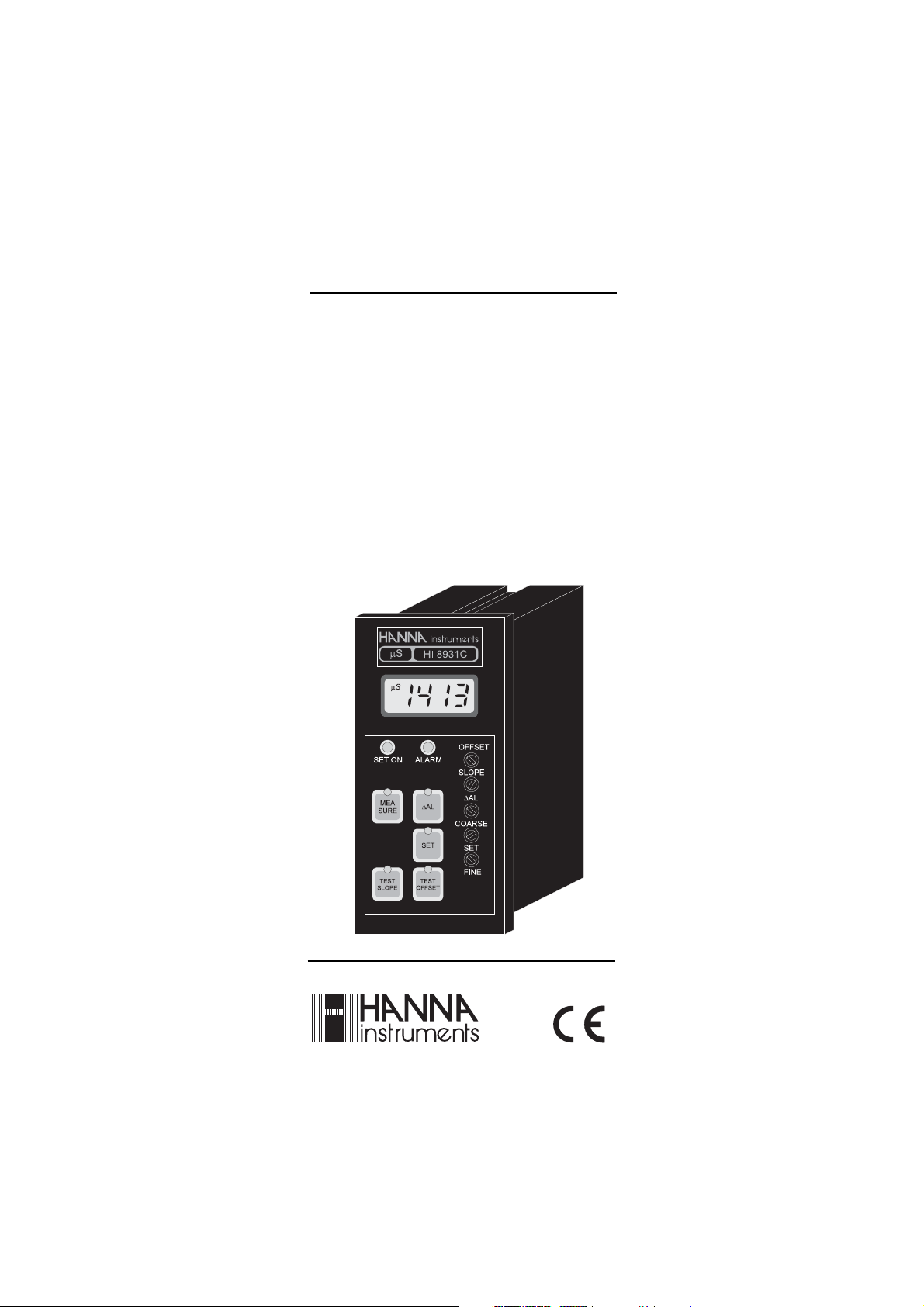

HI 8931A/B/C/D

HI 8936A/B/C/D

HI 8936AL/BL/CL/DL

HI 943500A/B/C/D

Conductivity

Process Instrumentation

These Instruments are in Compliance with the CE Directives

Page 2

Dear Customer,

Thank you for choosing a Hanna Instruments Product.

Please read this instruction manual carefully before using the

instrument.

This manual will provide you with all the necessary information for

correct use of the instruments, as well as a precise idea of thier

versatility in a wide range of applications.

These instruments are in compliance with the directives.

TABLE OF CONTENTS

Preliminary Examination ............................................................ 3

General Description .................................................................... 3

Functional Description HI8931/HI943500 ................................... 5

Functional Description HI8936 .................................................... 9

Conductivity Probes .................................................................. 12

Specifications HI8931 & HI943500 .......................................... 14

Specifications HI8936 .............................................................. 15

Connections .............................................................................. 16

Operational Guide ................................................................... 24

Calibration Procedure of

HI8931 & HI8936 with HI7635.............................................. 30

Calibration Procedure of

HI8931 & HI8936 with HI7638.............................................. 34

Calibration Procedure of

HI943500 with HI7638 .......................................................... 38

Conductivity Versus

Temperature Chart................................................................... 41

Diagnostic Tests ........................................................................ 42

Installation Examples ............................................................... 44

Probe Maintenance and Cleaning ............................................ 46

Accessories ................................................................................ 47

Warranty................................................................................. 50

CE Declaration of Conformity ..................................................... 51

2

Page 3

PRELIMINARY EXAMINATION

Remove the instrument from the packing material and examine it

carefully to make sure that no damage has occurred during shipping.

If there is any noticeable damage, notify your Dealer.

Note: Save all packing materials until you are sure that the

instrument functions correctly. All defective items must be

returned in the original packing materials together with

the supplied accessories.

GENERAL DESCRIPTION

The HI 8931 and HI 943500 are panel mounted conductivity meters

and controllers designed for simplicity of use in a wide range of

industrial process applications.

The instruments are designed with a standard DIN panel mount with

membrane keypads on the front, a large LCD and with autodiagnostic functions.

Probes, power supply, contacts and recorders are connected on the

rear panel through screw terminals.

Using HI 8931 in conjunction with a 4-20 mA output transmitter

HI 8936 series (or HI 8936L series, with LCD display) will assure you

of a strong, interference-free signal at distances up to 300 meters

(1000').

For in-line applications the probe should be HI 7635 and for tanks

HI 7638 with external threads. These probes with built-in NTC sensor,

provide temperature compensated conductivity measurements. The

probe cable length is 3 meters (10').

HI 943500 features a direct connection up to 20 m (67'), without

intermediate amplifiers, to the conductivity probe HI 7638 with 7-pin

DIN connector and automatic temperature compensation.

3

Page 4

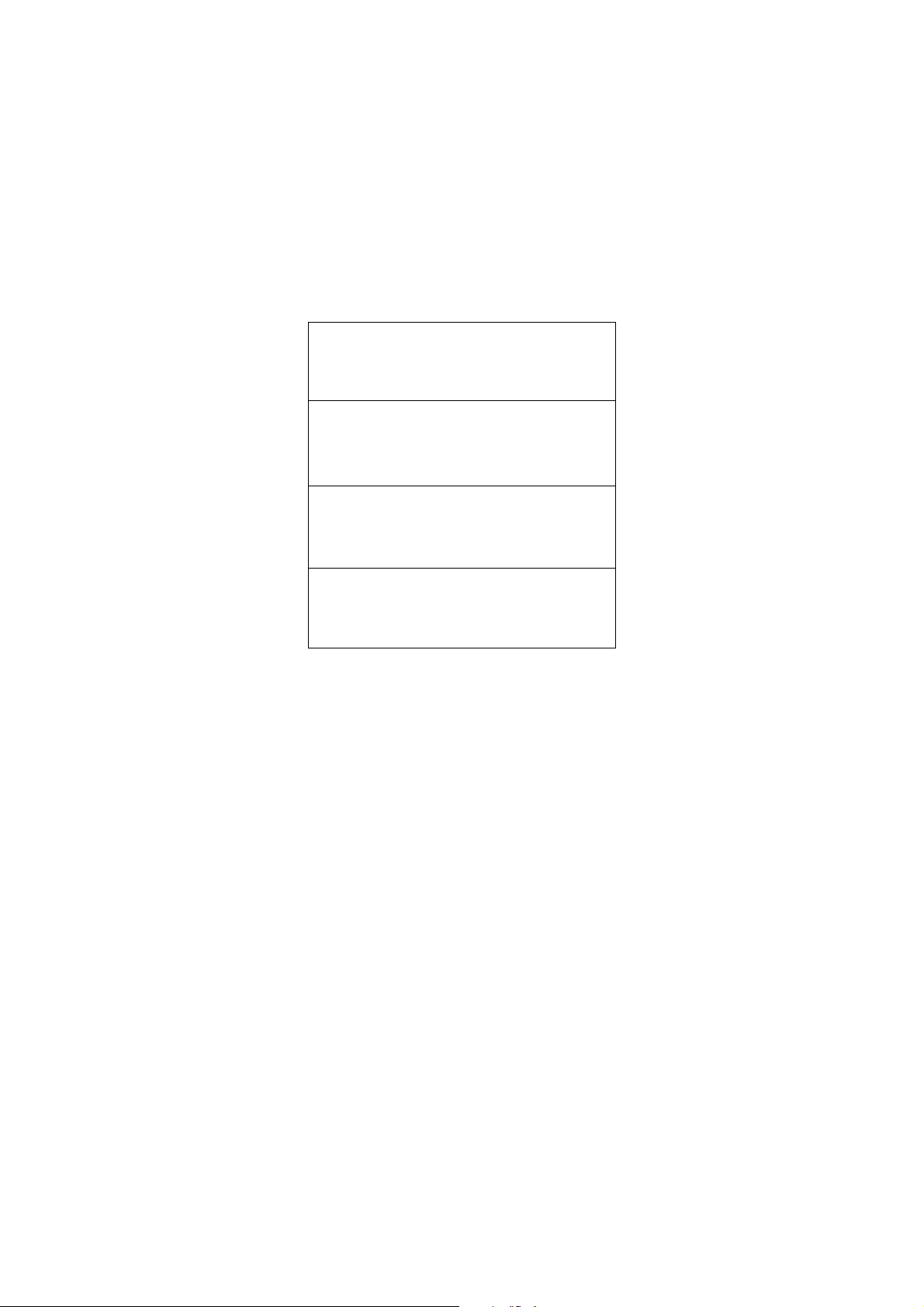

Four models with different measurement ranges are available to suit

individual applications:

HI8931A / HI 943500A

HI8936A / HI 8936AL

from 0.0 to 199.9 mS/cm

HI8931B / HI 943500B

HI8936B / HI 8936BL

from 0.00 to 19.99 mS/cm

HI 8931C / HI 943500C

HI8936C / HI 8936CL

from 0 to 1999 µS/cm

HI 8931D / HI 943500D

HI8936D / HI 8936DL

from 0.0 to 199.9 µS/cm

Other features include: recorder output in 0 to 20 mA or 4 to 20 mA

configuration; LED indicators (for HI 8931 and HI 943500) which

identify whether the controller is in operation mode or selection mode.

Each instrument is supplied with a plastic front cover and two

mounting brackets. Power cables are excluded.

Transmitters and conductivity probes are supplied separately.

4

Page 5

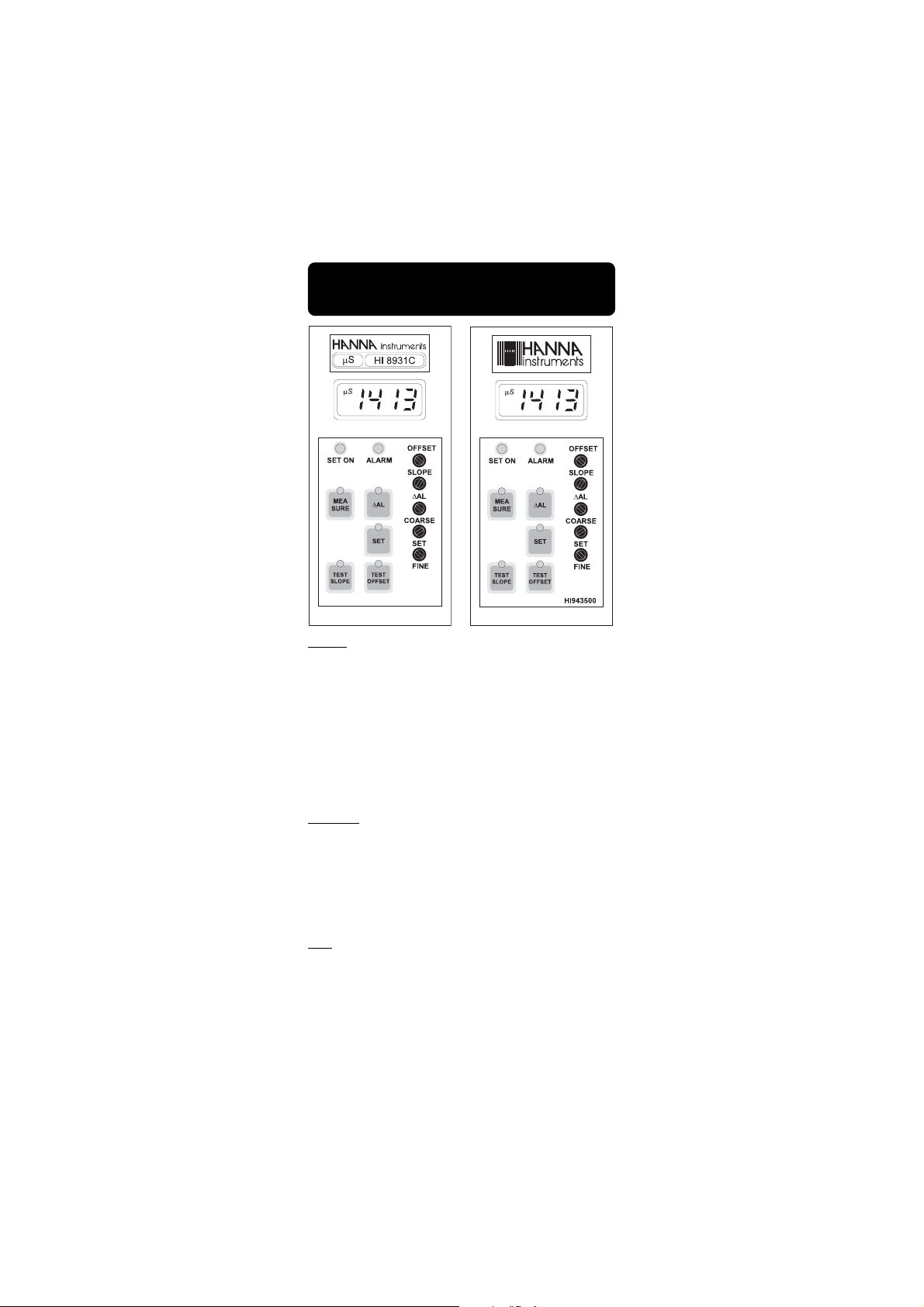

FUNCTIONAL DESCRIPTION

HI 8931 & HI 943500

KEYPAD

MEASURE To read the measurement values and to enable the

diagnostic tests

∆AL To display the set tolerance of the alarm

SET To set the working point

TEST SLOPE Diagnostic function

TEST OFFSET Diagnostic function

When each key is pressed the LED is lighted indicating to the user that the

function is in operation.

TRIMMERS

OFFSET For offset calibration

SLOPE For slope calibration

∆AL To set the alarm tolerance

COARSE To coarsely adjust the set point

SET FINE To finely adjust the set point

LEDS

SET ON To show that the dosage is active

ALARM To show that the controller is in alarm mode.

5

Page 6

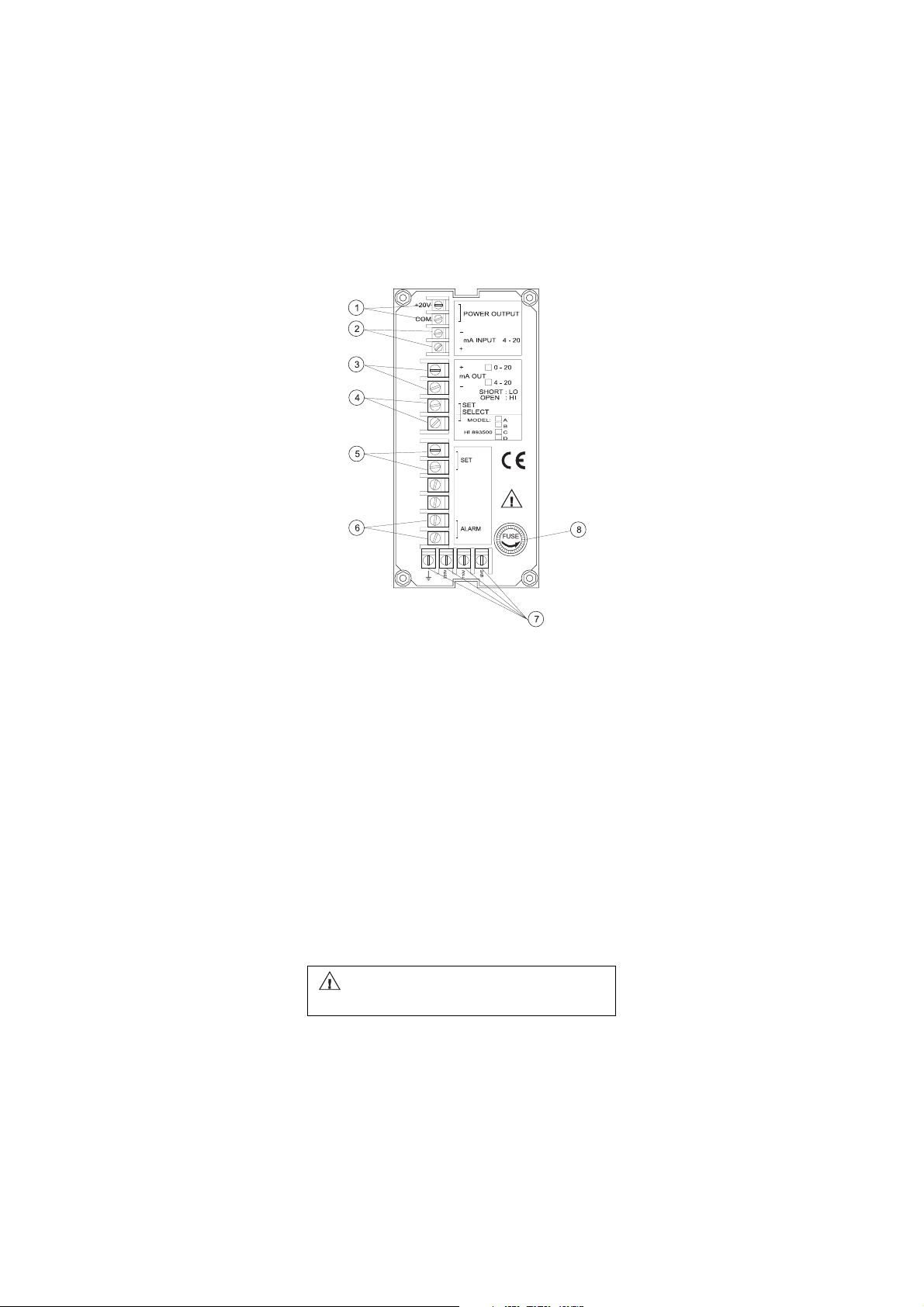

THE REAR PANEL OF HI 8931A/B/C/D

1. Power OUTPUT Terminals (+20V and COM) for connection

to a conductivity transmitter HI8936

2. mA INPUT from a conductivity transmitter

3. mA OUTPUT Terminals for connection to a recorder

4. SET SELECT Terminals for reverse control operation

5. SET Terminals for connection to a dosing pump

6. ALARM Terminals for connection to an external alarm device

7. Power Supply

8. Fuse Holder.

Unplug the instrument from power supply before

the replacement of the fuse.

6

Page 7

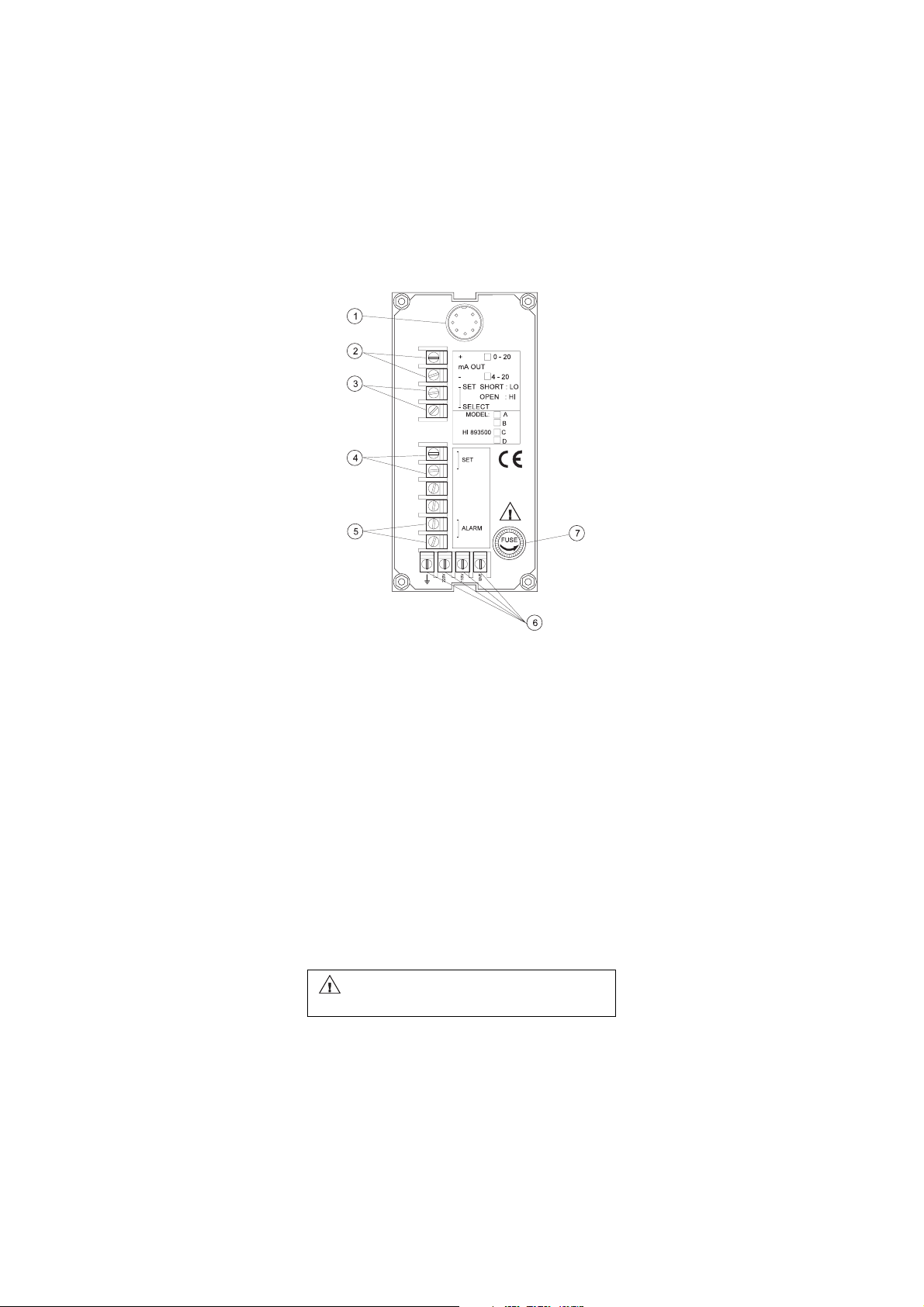

THE REAR PANEL OF HI 943500A/B/C/D

1. Conductivity Probe Connector (7-pin DIN)

2. mA OUTPUT Terminals for connection to a recorder

3. SET SELECT Terminals for reverse control operation

4. SET Terminals for connection to a dosing pump

5. ALARM Terminals for connection to an external alarm device

6. Power Supply

7. Fuse Holder.

Unplug the instrument from power supply before

the replacement of the fuse.

7

Page 8

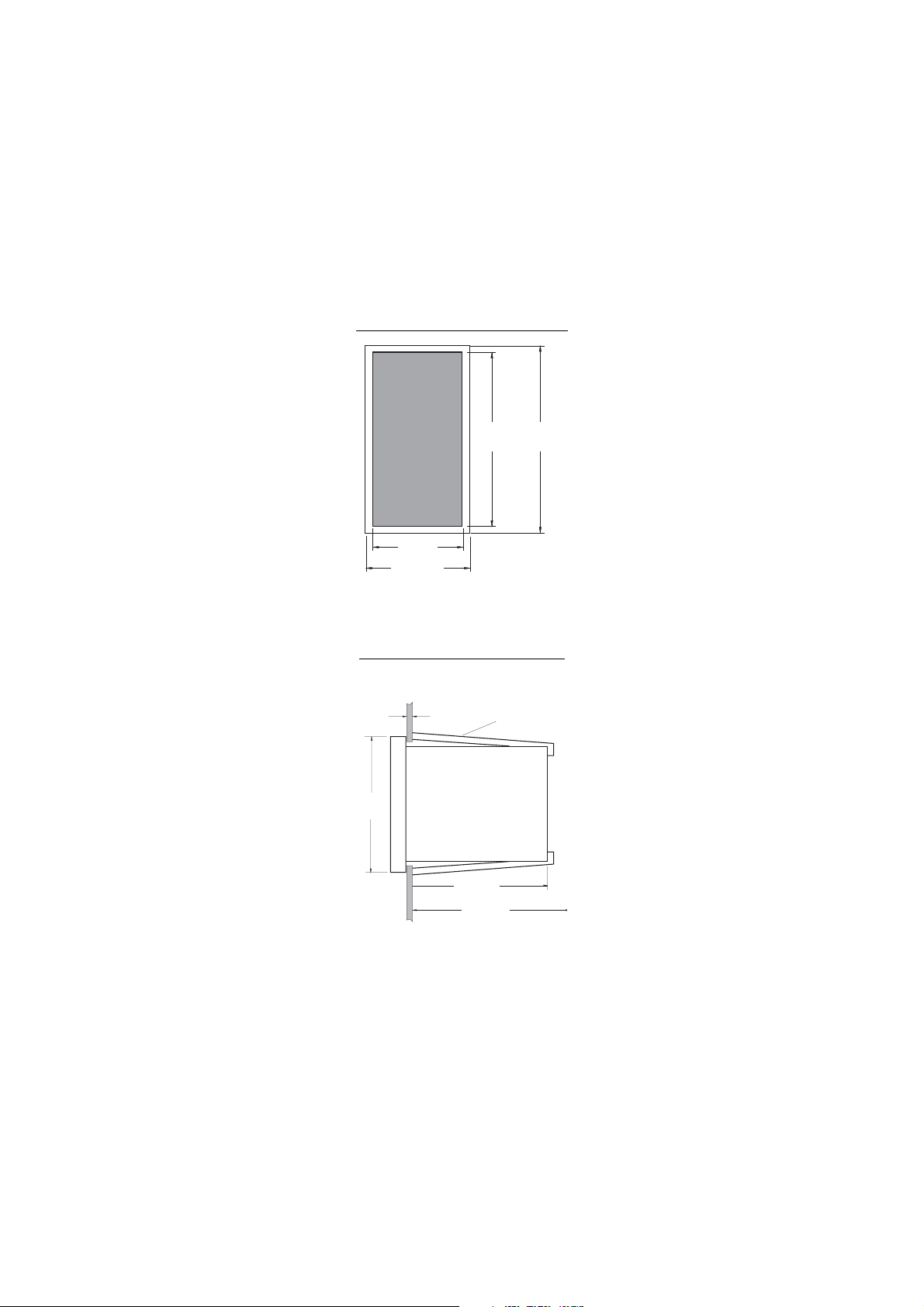

MECHANICAL DIMENSIONS

OF HI 8931 AND HI 943500

Front view of the panel-mounted unit

69mm

2.71"

72mm

2.83"

141mm

5.55"

144mm

5.67"

These dimensions show the cutout size for the installation.

Side view of the panel-mounted unit

144mm

5.67"

0.25/4mm

0.01/0.160"

ADJUSTABLE

LOCATION

BRACKET

135mm

5.31"

190mm MIN

7.50"

Adjustable location brackets (supplied with the meter) allow the indicator

to slide into the cutout and will hold the unit securely in place. 190 mm

(7.50") is the minimum amount of room required to install the indicator

with the cables connected.

8

Page 9

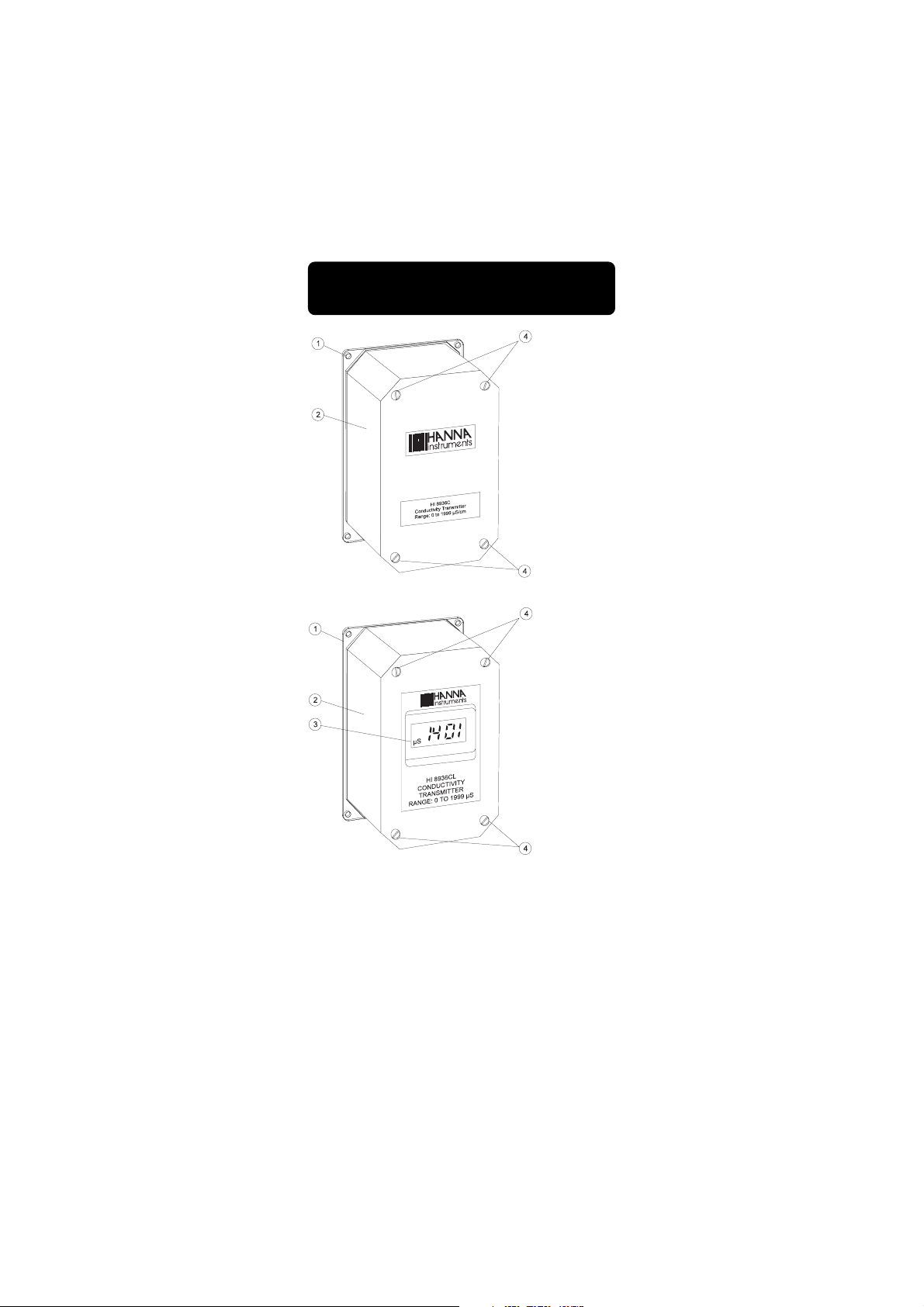

FUNCTIONAL DESCRIPTION

HI 8936

HI8936A

HI8936B

HI8936C

HI8936D

HI8936AL

HI8936BL

HI8936CL

HI8936DL

1. Back Cover

2. Top Plastic Cover

3. LCD Display (for HI8936AL, HI 8936BL, HI8936CL, HI 8936DL

only)

4. Screws for fastening the top cover.

9

Page 10

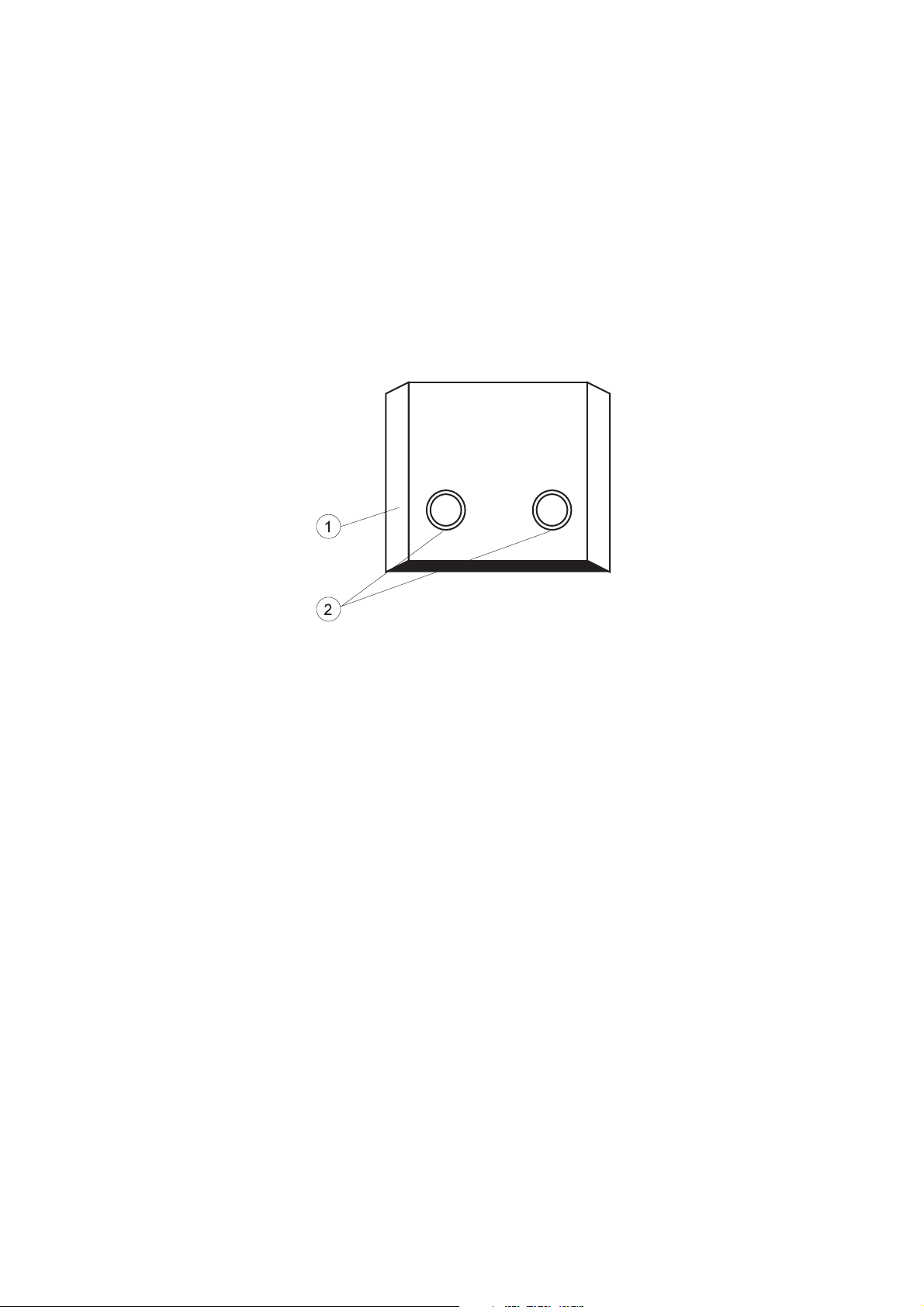

SIDE VIEW

HI 8936A HI8936B HI8936C HI8936D HI 8936AL

HI8936BL HI8936CL HI8936DL

1. Top Plastic Cover

2. Wire cable glands.

10

Page 11

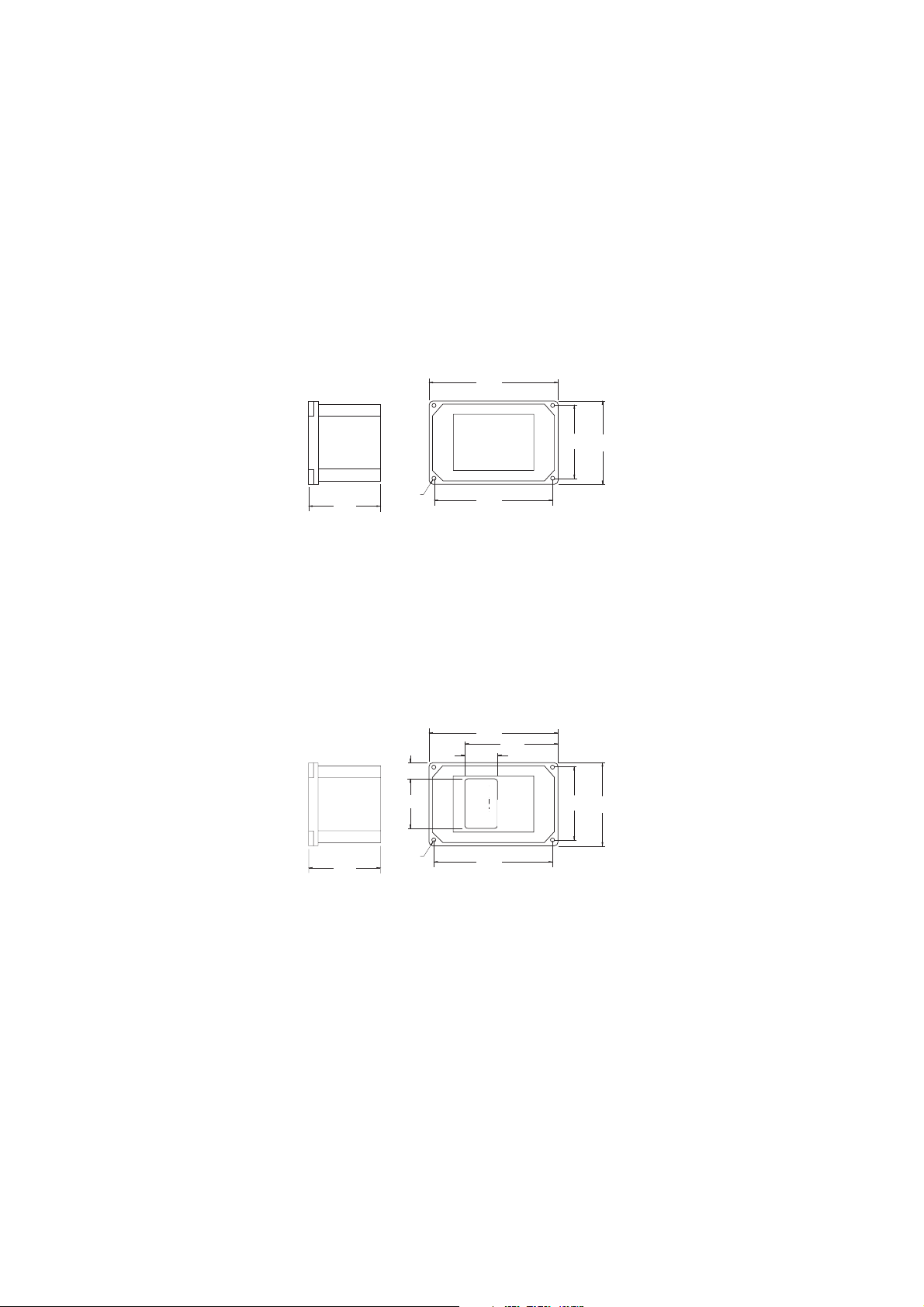

MECHANICAL DIMENSIONS

HI 8936A, HI8936B, HI8936C, HI 8936D

165mm

6.50"

100mm

3.94"

HI 8614

4 x 4.3mm

90mm

3.54"

4 x 0.17"

155mm

6.10"

MECHANICAL DIMENSIONS

HI 8936AL, HI8936BL, HI8936CL, HI 8936DL

110mm

4.33"

90mm

3.54"

24mm

0.94"

45mm

1.77"

4 x 4.3mm

4 x 0.17"

11

58mm

2.28"

165mm

6.50"

155mm

6.10"

126mm

5.00"

HI 8614L

100mm

3.94"

110mm

4.33"

Page 12

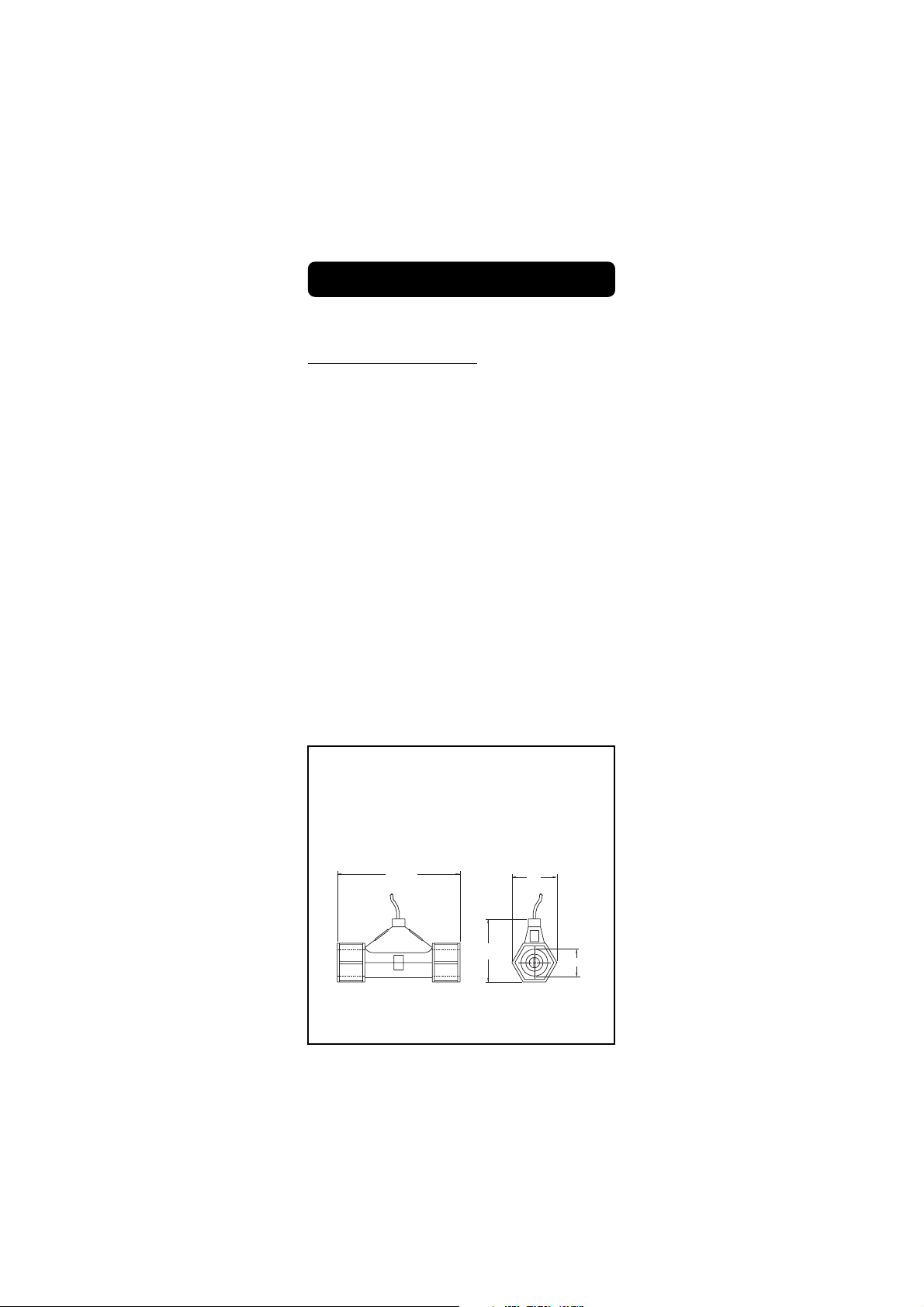

CONDUCTIVITY PROBES

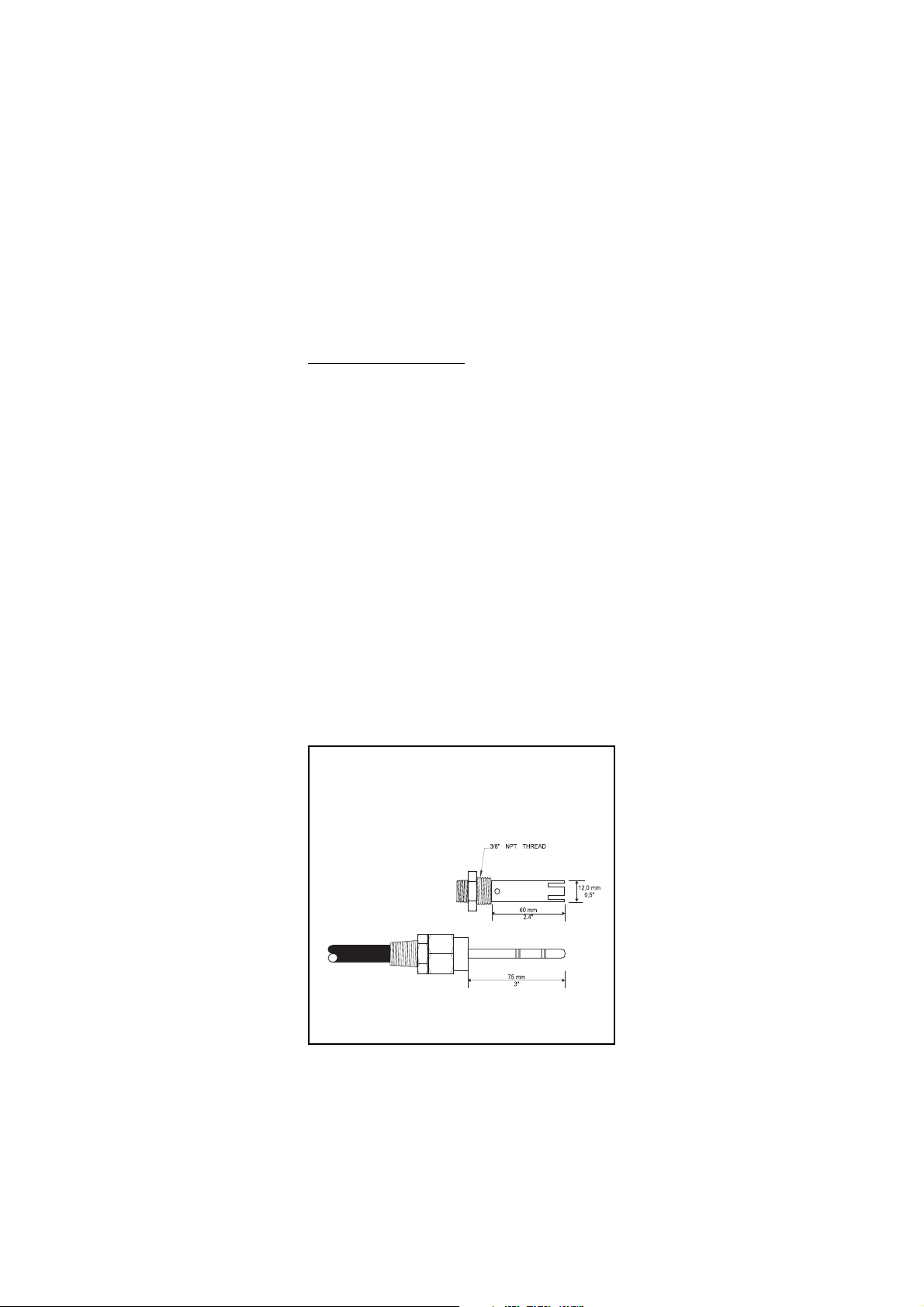

HI 7635 In-line Conductivity Probe

HI 7635 is a one piece, molded conductivity probe with pipe threads

(1" NPT) at both ends.

This allows the probe to attach to an in-line system, and to be used

in conjunction with the HI 8936 conductivity transmitter.

The HI 7635 uses a 4-ring potentiometric measuring method. This

method is highly accurate and requires very little maintenance.

The construction of the housing is rugged, fiber-reinforced polypropy-

lene.

The maximum working pressure of this unit is 5 BAR (72.5 psi).

Do not use in systems where the temperature exceeds 80°C (176°F).

142mm

5.60"

HI7635

12

73mm

2.87"

52mm

2.04"

1" NPT

Page 13

HI7638 Tank Conductivity Probe

HI7638 conductivity probe combines the proven 4-ring potentiometric

method of measuring conductivity with the platinum sensor and

stainless steel external thread.

This method incorporates a series of four platinum rings into the probe

shaft and is highly accurate requiring very little maintenance.

The removable cover is made of Ultem® which resists the harmful

effect of most chemicals and can be unscrewed for quick and simple

maintenance.

This probe can withstand temperatures of up to 120°C (248°F) and

pressure of up to 5 bar (72.5 psi).

This probe is supplied complete with a 7-pin DIN connector.

HI7638

13

Page 14

SPECIFICATIONS HI 8931 & HI 943500

Range

HI8931A - HI943500A

HI8931B - HI943500B

HI8931C - HI943500C

HI8931D - HI943500D

Accuracy

(@20°C/68°F)

Typical EMC

Deviation

4-20mA INPUT from

Transmitter

HI8931A

HI8931B

HI8931C

HI8931D

HI943500

Conductivity Probe

Calibration

Temp. Compensation

HI8931

HI943500

Readout

Recorder Output

1 Set Point Relay &

1 Alarm Relay

Power Supply

Panel Cutout

Environment

Weight

Enclosure

0.0 to 199.9 mS/cm

0.00 to 19.99 mS/cm

0 to 1999 µS/cm

0.0 to 199.9 µS/cm

±2% of Full Scale

excluding probe error

±2.5% of Full Scale

±0.4 mA

HI8936 A or AL (not included)

HI8936 B or BL (not included)

HI8936 C or CL (not included)

HI8936 D or DL (not included)

------

HI7635 for in-line applications or

HI7638 for tank (not included)

Manual 2-point through offset and

slope trimmers

See transmitter HI8936

Automatic from 0 to 60°C with ß=2%

4-digit LCD plus graphic symbols

4 to 20 mA (isolated)

Isolated, 2A, Max. 240V, resistive

load, 1,000,000 strokes

110/115V or 220/240V

(user selectable); 50/60 Hz

141 x 69 mm (5.6 x 2.7")

-10 to 50°C (14 to 122°F)

1 Kg (2.2 lb.)

DIN 43 700 144x72 mm (5.7x2.8") in

black anodized aluminum. Front and

back with shockproof ABS plastic and a

transparent cover.

14

Page 15

SPECIFICATIONS HI 8936 & HI 8936L

Range

HI8936A & AL

HI8936B & BL

HI8936C & CL

HI8936D & DL

Accuracy

(@20°C/68°F)

Typical EMC

Deviation

Conductivity Probe

Calibration

Temperature

Compensation

Output

Power Supply

HI8936A/B/C/D

HI8936AL/BL/CL/DL

Protection

Environment

Dimensions

Weight

0.0 to 199.9 mS/cm

0.00 to 19.99 mS/cm

0 to 1999 µS/cm

0.0 to 199.9 µS/cm

±2% of Full Scale

excluding probe error

±2% of Full Scale

±0.4 mA

HI7635 for in-line applications or

HI7638 for tank (not included)

Manual 2-point through Offset and

Slope trimmers

Fixed or automatic

from 0 to 50°C (32 to 122°F)

with ß=2%

4 to 20 mA not-isolated

Max. 500 ohm

12 to 30 VDC

17 to 36 VDC

0 to 50°C (32 to 122°F)

95% RH max

165 x 110 x 90 mm (LxWxH)

(6.5 x 4.3 x 3.5")

1 Kg (2.2 lb.)

IP 65

15

Page 16

CONNECTIONS

REAR CONNECTIONS FOR HI 8931

• Power Connection Terminals

4-screw-terminal-strip for connection

to a 3-wire power cable according to

the indicated voltage (115 or 230V).

• IN/OUT Transmitter

2 wires of the 4-core signal cable

from the conductivity transmitter

(HI8936) have to be connected to

the mA input terminals and the

other 2 wires to the "+20V" and

"COM" while paying careful attention to the polarity.

+20V supply is the regulated DC supply required for the

operation of the external Conductivity Transmitter HI8936.

• Set Contacts

Dosing pumps or other control equipment may be connected to the "SET"

(Max. 2A, 240V) terminals. These

contacts act only as a "dry" switch

allowing electrical continuity, not as

a power supply.

16

Page 17

• Set Select

These contacts permit the activation

of a Set Contact relay when the

measured value is lower (connected

terminals) or higher (open terminals) than the user's set value. See

also page 27.

• +4-20 mA

These are the output terminals for connection to a recorder or other

control equipment.

The output current varies from 4 to 20 mA and is proportional to

the measured conductivity value.

• Alarm Contacts

During normal operation these terminals remain closed.

If the measured conductivity level is

not within the tolerance of the set

value, the alarm contact is open.

These contacts act only as a switch.

See also page 28.

17

Page 18

TERMINAL BOARD CONNECTIONS FOR H8936

• Remove the 4 screws and the top cover of the HI 8936 conductivity

transmitter to obtain access to the terminal board connections.

• HI8936 used in conjunction with HI8931 controller

Use a PVC insulated 4-core cable to connect the transmitter to the

18

Page 19

HI8931 conductivity controller (see

also page 24).

The 4-core cable has to be connected to the transmitter according

to the label instructions on the 4terminal strip.

The regulated D.C. supply required for the proper operation of the

transmitter is "+20V", labeled "+20V" and "COM". The current

(mA) output terminals are labeled "4-20 mA" and "COM".

The transmitter is protected against inversion of supply voltage.

• HI8936 used in conjunction with

an external power supply

Use 2 PVC insulated 2-core cables.

Connect a +20V DC power supply

directly to the terminals labeled

"+20V" and "COM", paying careful attention to polarity (see also

page 24) or if necessary in series with the receiving device.

The regulated D.C. supply required for the proper functioning of

the circuit is marked "+20V" and "COM", and the transmitter

current output is indicated "4-20 mA" and "COM".

The transmitter is protected against inversion of supply voltage.

Max. current required: 40 mA.

• Use of an amplifier

The maximum permissible distance between the power supply unit

and the amplifier is 300 m (1000'). It is not necessary to use a

shielded cable.

19

Page 20

• Probe Connection

The conductivity probe is supplied

with a 3 m (10'), 6 core cable. The

cable is to be connected to the

terminals provided (see also page

23 for proper connection scheme of

HI 7635 and HI7638).

20

Page 21

REAR CONNECTIONS FOR HI 943500

• Power Connection Terminals

4-screw-terminal-strip for connection to a 3-wire power cable according to the indicated voltage

(115 or 230V).

• 7-pin DIN connector

socket

For connection to the

HI 7638 conductivity

probe.

• + mA output -

The first and the second

terminals are the output

terminals for connection to

a recorder or other control

equipment. The output current varies from 4 to 20

mA and is proportional to

the measured conductivity

value.

• Set Select

These contacts permit the activation of the Set Contact relay when

the measured value is lower (connected terminals) or higher (open

terminals) than the user's set value. See also page 27.

21

Page 22

• Set

Dosing pumps or other control equipment may be connected to the

"SET" (Max. 2A, 240V) terminals. These contacts act only as a

"dry" switch allowing electrical continuity, not as a power supply.

• Alarm Contacts

During normal operation these terminals remain closed.

If the measured conductivity level

is not within the tolerance of the

set value, the alarm contact is

open. These contacts act only as a

switch. See also page 28.

22

Page 23

CONDUCTIVITY PROBE CONNECTIONS

The connections for HI 7635

are color coded for easy installation and are as follows:

HI 7635 cable HI8936 transmitter

Black or Grey NTC

Red or Pink SENSOR

Brown or Orange probe pin 1

Blue probe pin 2

White probe pin 3

Green or Yellow probe pin 4

The connections for HI 7638 are

as follows:

HI 7638 HI8936 transmitter

#1 probe pin 1

#2 probe pin 2

#3 probe pin 3

#4 probe pin 4

#5 NTC

#6 SENSOR

Note: NTC and SENSOR are equivalent and are both labeled

SENSOR on the HI8936 conductivity transmitter.

23

connector

inside view

Page 24

OPERATIONAL GUIDE

INITIAL PREPARATION & INSTALLATION:

Material needed:

• a 3-wire power cable (for connection of HI 8931/HI943500 to

the mains)

• a PVC insulated 4-core cable (as connection cable between

HI8931 and HI8936)

• rubber seals and a pipe sealant (for installation of HI7635)

FOR HI 8931 AND HI8936 ONLY

• Remove the 4 screws and the top

of the HI8936 Process Conductivity

transmitter.

• Connect the 2 wires connected to

the 4-20 mA and COM terminals of the 4-core signal cable

from the conductivity transmitter

HI8936 to the terminals marked

mA input paying careful attention

to polarity. Connect the other 2

wires to the +20V and COM terminals while paying careful attention to polarity.

• Connect the 3-wire power cable to

the 4-screw terminal strip according to the voltage level as indicated and pay particular attention to the correct live, earth and

neutral terminal connections.

24

Page 25

• The HI 8936 transmitter may be wallmounted at any convenient location close

to the measurement site. To minimize

thermal drifts due to extreme temperature

fluctuations, particularly if the measurement is conducted outdoors, it is recommended that the transmitter is protected

in a casing.

• For the installation of the HI 7635 conductivity probe, it is

necessary to use rubber seals between the probe and the pipe or

elbow joints. A pipe sealant is also recommended to ensure a leak

free joint. When screwing on the joints, take care not to overtighten as excessive pressures can cause the probe to be damaged.

• The conductivity probe HI 7635 is supplied with a 3m (10') length of cable.

The six core cable from the probe is

connected to the HI8936 process conductivity transmitter as shown. The

connections are color coded for an easy

installation. See page 23 for the proper

connection scheme.

25

Page 26

• It is recommended that the HI7635 is installed vertically. This is

to ensure that trapped air bubbles or turbulent flows cause

minimal interference to the measurement system. The maximum

working pressure of this unit is 5 BAR (72.5 psi).

CAUTION: do not use in systems where temperature exceeds 80°C

(176°F).

• The HI7638 process conductivity probe is also

supplied with a 3m (10') length cable. The

six core cable from this probe is connected to

the HI 8936 process conductivity transmitter

as shown.

The 7-pin DIN connector has to be removed when this probe is

used in conjunction with HI8936 transmitter. See page 23 for the

proper connection scheme.

FOR HI 943500 ONLY

Ensure that the HI7638 conductivity probe is connected to

the meter securely by aligning

the pins with the socket, pushing the plug in and tightening

the threaded ring.

26

Page 27

OPERATING INFORMATION

The various parameters are set through the front panel keys and

trimmers.

When each key is pressed the corresponding LED is lit, indicating that

the function is operational.

Make sure that the conductivity meter, transmitter and probe are

calibrated before using the instrument for measurements (see page

30 & 34 for HI8931 & HI8936 and page 38 for HI 943500).

SET POINT

To set the working point of the controller, press the SET key. The

display will indicate the set value.

Use a small screwdriver to adjust

the trimmers COARSE and FINE

until the desired set value is

displayed.

Above set-point control operation

Leave the SET SELECT/COM connectors open.

The set contacts relay will close if the measured value is higher than the set-point

value and the SET ON LED will be lit.

27

COM

SET

SELECT

Page 28

Below set-point control operation

Short the SET SELECT/COM connectors with

a jumper wire. The set contact relay will

close if the measured value is lower than

COM

SET

SELECT

the set-point value and the SET ON LED

will be lit.

ALARM

Press the ∆AL key and the display will show the set tolerance for the

alarm.

Use a small screwdriver to adjust

the trimmer ∆AL until the desired tolerance is displayed.

Example: If the set value is 200

µS/cm and a ∆Alarm of 50 µS/

cm is set, an alarm is activated

every time the measured value

is higher than 250 µS/cm or

lower than 150 µS/cm.

28

Page 29

When the alarm is active the ALARM LED is lit.

The alarm contacts of HI 8931 and HI 943500 remain closed during

normal operation. If the measured conductivity level is not within the

tolerance of the set value, the alarm contact will be open.

TAKING MEASUREMENTS WITH HI8931 AND HI 943500

After setting the working point and alarm value, press the MEASURE key.

The actual conductivity value of the test solution will be displayed.

TAKING MEASUREMENTS WITH HI8936AL, HI8936BL,

HI 8936CL, HI8936DL

The conductivity transmitters with LCD will

always display the measurement value

when connected to the HI8931 controllers

or a power supply.

29

Page 30

CALIBRATION PROCEDURE OF

HI8931 & HI8936 WITH HI7635

Material needed

• HI 7635 conductivity probe

• HI 8931 conductivity controller

• HI 8936 conductivity transmitter

• A 20 mA f.s. ammeter (for transmitters without LCD)

• A reference conductivity meter with automatic temperature compensation accurately calibrated (e.g. HI8733).

PROCEDURE

• Connect the HI7635 probe to the HI8936 transmitter (see page

23).

• Connect the HI8936 transmitter to the HI 8931 controller (see

page 24).

• Connect the HI8931 controller to the mains (see page 24).

Before proceeding with the calibration,

make sure that the meter is in measurement mode (MEASURE LED will be lit)

and not in set mode.

• Connect the ammeter to the HI8936 transmitter to monitor the

signal current (see the following picture).

MEA

SURE

30

Page 31

• Ensure that there is no solution inside the HI7635 conductivity

probe (dry probe).

• When the power is on, the ammeter should read "4.0 mA". The

HI8936L transmitter with LCD should display "0".

• If not, adjust the OFFSET trimmer

of the HI8936 transmitter to obtain "4 mA" or "0" on the

HI8936L.

• The HI 8931 controller should display "0" value.

• If not, adjust the OFFSET trimmer

of HI8931 to display a zero reading.

• Switch the flow on and allow the

sample solution to flow through

the HI 7635 conductivity probe.

Collect a sample of this solution in

a beaker.

• Measure the conductivity of the

solution with the HI8733 portable conductivity meter with ATC.

The value obtained will be used

for the transmitter and controller

calibration.

31

µS

°C

HI 8733

199.9

µS

19.99

mS

0

0.5

TEMPERATURE COEFFICIENT

s

ins

rum n

ON

OFF

1999

µS

199.9

mS

2.5

2

1.51

Page 32

• The reading will be converted to mA by the following formula:

mA = K (measured value x 16/2000) + 4

K = conversion factor depending on the model

Model Conversion factor K

HI 8936A & AL 10

HI 8936B & BL 100

HI8936C & CL 1

HI8936D & DL 10

For example, using a HI8936A, if the measured value is 123.4

mS, then

output current = 10 x (123.4 x 16/2000) + 4

= 13.9 mA

Adjust the SLOPE trimmer of the

HI8936 transmitter to read "13.9

mA" on the ammeter or the reading

displayed by the HI8733 conduc-

tivity meter on the HI8936L dis-

play. E.g. "123.4 mS".

• Adjust the SLOPE trimmer of the HI 8931 controller until the

controller reading is the same as the reading displayed by the

HI8733 conductivity meter. E.g. "123.4 mS".

32

Page 33

• The calibration is now complete and the instrument is ready for

use. All subsequent measurements will now be compensated to

25°C (77°F).

• If the instrument will not calibrate refer to the Probe Maintenance

and Cleaning section (see page 46).

• If the HI8936 transmitter is not used in conjunction with the

HI8931 controller, connect the transmitter to an external power

supply (see page 19). Connect the transmitter to the HI7635

conductivity probe (see page 23) and to an ammeter (see page

19).

The calibration of the transmitters with LCD (HI8936AL, HI 8936BL,

HI8936CL, HI 8936DL) does not require an ammeter.

Follow the above calibration procedure performing the operations

referred to the HI8936 transmitter only.

33

Page 34

CALIBRATION PROCEDURE OF

HI8931 & HI8936 WITH HI7638

Material needed

• HI 7638 conductivity probe

• HI 8931 conductivity controller

• HI 8936 conductivity transmitter

• An ammeter (for transmitters without LCD)

• Calibration solutions, according to the different models:

HI7034 80 mS/cm @25°C

for HI8931A, HI8936A & AL

HI7030 12.88 mS/cm @25°C

for HI8931B, HI8936B & BL

HI7031 1413 µS/cm @25°C

for HI8931C, HI 8936C & CL

HI7033 84 µS/cm @25°C

for HI8931D, HI8936D & DL

PROCEDURE

• Connect the HI 7638 to the HI8936 transmitter (see page 23).

• Connect the HI8936 transmitter to the HI 8931 controller (see

page 24).

• Connect the HI8931 controller to the mains (see page 24).

Before proceeding with the calibration,

make sure that the meter is in measurement mode (MEASURE LED will be lit)

and not in set mode.

• Connect the ammeter to the HI8936 transmitter to monitor the

signal current (see the following picture).

MEA

SURE

34

Page 35

• Leave the HI7638 conductivity probe

in air (dry probe).

• When the power is on, the ammeter should read "4.0 mA" or the

HI8936L transmitter with LCD should display "0".

• If not adjust the OFFSET trimmer

of the HI8936 transmitter to obtain "4 mA" or "0" on the HI8936L.

• The HI8931 controller should display "0" value.

• If not adjust the OFFSET trimmer of

HI8931 to display a zero reading.

35

Page 36

HI 7030

• Pour enough conductivity solution into a

plastic beaker to achieve at least 8 cm

(3¼

(3¼") of depth.

8 cm

")

• Immerse the probe into the beaker with the

conductivity solution. The holes on the sleeve

must be completely submerged in the solution.

• Tap the probe repeatedly on the bottom of the beaker and stir it

to ensure that no air bubbles are trapped inside the sleeve.

• If the temperature of the probe is close to that of the solution the

display of HI 8931 will stabilize quickly and provide a temperature

compensated conductivity measurement. However, allow a few

minutes if there is a temperature difference of 5°C (9°F) or more for

the ATC circuitry to compensate completely.

• For HI 8936

Adjust the SLOPE trimmer of the HI8936 transmitter to read on

the ammeter:

"10.4 mA" using HI7034 and HI8936A/AL

"14.304 mA" using HI7030 and HI8936B/BL

"15.304 mA" using HI7031 and HI8936C/CL

"10.72 mA" using HI7033 and HI8936D/DL

36

Page 37

• FOR HI 8931

When the reading stabilizes, turn the SLOPE trimmer on the front

of the HI8931 until the LCD reading is the same as the calibration

solution at 25°C (77°F), i.e.

"80.0 mS" using HI7034 with HI 8931A

"12.88 mS" using HI7030 with HI 8931B

"1413 µS" using HI7031 with HI 8931C

"84.0 µS" using HI7033 with HI 8931D

• The calibration is now complete and the instrument is ready for

use. All subsequent measurements will now be compensated to

25°C (77°F).

• If the instrument will not calibrate refer to the Probe Maintenance

and Cleaning section (see page 46).

• If the HI8936 transmitter is not used in conjunction with the

HI8931 controller, connect the transmitter to an external power

supply (see page 19). Connect the transmitter to the HI7638

conductivity probe (see page 23) and to an ammeter (see page

19).

The calibration of the transmitters with LCD (HI8936AL, HI 8936BL,

HI8936CL, HI 8936DL) does not require any ammeter.

Follow the above calibration procedure performing the operations

referred to the HI8936 transmitter only.

37

Page 38

CALIBRATION PROCEDURE OF

HI943500 WITH HI7638

Material needed

• HI7638 conductivity probe

• HI943500 conductivity controller

• Calibration solutions, according to the different models:

HI7034 80mS/cm @25°C for HI943500A

HI7030 12.88mS/cm@25°C for HI943500B

HI7031 1413 µS/cm @25°C for HI943500C

HI7033 84 µS/cm @25°C for HI943500D

PROCEDURE

• Ensure that the probe is connected

to the meter securely by aligning the

pins with the socket, pushing the

plug in and tightening the threaded

ring.

• Insert the probe into the sleeve.

• With the conductivity probe in air,

press the MEASURE key to set the

meter to MEASURE mode.

38

Page 39

• Adjust the OFFSET trimmer if the LCD does not show the zero

reading.

HI 7030

• Pour enough conductivity solution into a

beaker to achieve at least 8 cm (3¼") of

depth.

(3¼

")

8 cm

• Immerse the probe into the beaker with the

conductivity solution. The holes on the sleeve

must be completely submerged in the solution.

• Tap the probe repeatedly on the bottom of the beaker and stir it

to ensure that no air bubbles are trapped inside the sleeve.

• If the temperature of the probe is close to that of the solution the

display will stabilize quickly and provide you with a temperature

compensated conductivity measurement.

However, allow a few minutes if there is a temperature difference

of 5°C (9°F) or more for the ATC circuitry to compensate completely.

• When the reading stabilizes, turn the SLOPE trimmer on the front

of the HI943500 until the LCD reading is the same of the

calibration solution at 25°C (77°F), i.e.:

80.0 mS using HI7034 with HI943500A

12.88 mS using HI7030 with HI943500B

1413 µS using HI7031 with HI943500C

84.0 µS using HI7033 with HI943500D

39

Page 40

• The calibration is now complete and the instrument is ready for

use. All subsequent measurements will now be compensated to

25°C (77°F).

• If the instrument will not calibrate refer to the Probe Maintenance

and Cleaning section (see page 46).

40

Page 41

CONDUCTIVITY VERSUS

TEMPERATURE CHART

°C °F HI7030 HI7031 HI 7033 HI7034 HI7035 HI7039

(mS/cm) (mS/cm) (mS/cm) (mS/cm) (mS/cm) (mS/cm)

0 32 7150 776 64 48300 65400 2760

5 41 8220 896 65 53500 74100 3180

10 50 9330 1020 67 59600 83200 3615

15 59 10480 1147 68 65400 92500 4063

16 60.8 10720 1173 70 67200 94400 4155

17 62.6 10950 1199 71 68500 96300 4245

18 64.4 11190 1225 73 69800 98200 4337

19 66.2 11430 1251 74 71300 100200 4429

20 68 11670 1278 76 72400 102100 4523

21 69.8 11910 1305 78 74000 104000 4517

22 71.6 12150 1332 79 75200 105900 4711

23 73.4 12390 1359 81 76500 107900 4805

24 75.2 12640 1386 82 78300 109800 4902

25 77 12880 1413 84 80000 111800 5000

26 78.8 13130 1440 86 81300 113800 5096

27 80.6 13370 1467 87 83000 115700 5190

28 82.4 13620 1494 89 84900 117700 5286

29 84.2 13870 1521 90 86300 119700 5383

30 86 14120 1548 92 88200 121800 5479

31 87.8 14370 1575 94 90000 123900 5575

If you are calibrating a HI8931A or HI 943500A using HI7030

(12.88 mS/cm @25°C) as buffer solution, turn the SLOPE trimmer

to display "12.88 mS", with a reference temperature of 25°C (77°F).

If you prefer a reference temperature of 20°C (68°F), turn the SLOPE

trimmer to display "11.67 mS".

41

Page 42

DIAGNOSTIC TESTS

The HI8931 and HI 943500 controllers are designed with built-in

diagnostic functions to enable the user to check and troubleshoot the

instrument. The checks performed are through the front panel keys and

can be used to isolate the cause of malfunction.

Press the MEASURE key before proceeding the following tests.

A) Test Offset

Press the TEST OFFSET key and the display should indicate the

following values:

HI8931/HI 943500A 0.0 mS ±1.0 mS

HI8931/HI 943500B 0.00 mS ±0.10 mS

HI8931/HI 943500C 000 µS ±100 µS

HI 8931/HI943500D 0.0 µS ±1.0 µS

42

Page 43

B) Test Slope

Press the TEST SLOPE key and the display should indicate the following

values:

HI8931/HI 943500A 100.0 mS ±35.0 mS

HI 8931/HI943500B 10.00 mS ±3.50 mS

HI 8931/HI943500C 1000 µS ±350 µS

HI 8931/HI943500D 100.0 µS ±35.0 µS

Note: The reading obtained by these functions will vary if the OFFSET

and the SLOPE trimmers on the front panel are adjusted.

43

Page 44

INSTALLATION EXAMPLES

Some typical installation setups are depicted in the following examples:

Example #1

Example #2

44

Page 45

Example #3

Example #4

Example #5

45

Page 46

PROBE MAINTENANCE & CLEANING

The probe can be compensated for normal contamination by a process of

re-calibration. However, it is recommended that the process conductivity

probe be removed from the system regularly for maintenance.

For HI7635 only: Deposits on the conductivity probe can be removed by

immersing the probe in 0.1 N Hydrochloric acid for about 30 minutes.

Heavier deposits may demand longer immersion periods. Clean the

electrode thoroughly with water prior to the reinstallation. On reinstalling,

check the seals carefully to ensure that a leak connection is obtained.

For HI 7638 only: Rinse the probe with tap water. If a more thorough

cleaning is desired, unscrew the Ultem sleeve and clean the sensors with

a nonabrasive cloth or alcohol.

After cleaning the probe, re-calibrate the instrument. However, if the

instrument will not re-calibrate with the clean probe, you must replace the

probe.

Note: Always re-calibrate the meter when attaching a new probe.

46

Page 47

ACCESSORIES

CONDUCTIVITY BUFFER SOLUTIONS

HI 7030L 12880 µS/cm (µmho/cm) @25°C (77°F), 460 mL

HI 7030M 12880 µS/cm (µmho/cm) @25°C (77°F), 230 mL

HI 7031L 1413 µS/cm (µmho/cm) @25°C (77°F), 460 mL

HI 7031M 1413 µS/cm (µmho/cm) @25°C (77°F), 230 mL

HI 7033L 84 µS/cm (µmho/cm) @25°C (77°F), 460 mL

HI 7033M 84 µS/cm (µmho/cm) @25°C (77°F), 230 mL

HI 7034L 80000 µS/cm (µmho/cm) @25°C (77°F), 460 mL

HI 7034M 80000 µS/cm (µmho/cm) @25°C (77°F), 230 mL

HI 7035L 111800 µS/cm (µmho/cm) @25°C (77°F), 460 mL

HI 7035M 111800 µS/cm (µmho/cm) @25°C (77°F), 230 mL

HI 7039L 5000 µS/cm (µmho/cm) @25°C (77°F), 460 mL

HI 7039M 5000 µS/cm (µmho/cm) @25°C (77°F), 230 mL

47

Page 48

CONDUCTIVITY PROBES

HI7635 In-line conductivity probe, 3 m (10') cable

(for HI 8936 only)

142mm

5.60"

73mm

2.87"

52mm

2.04"

1" NPT

HI7638 Tank conductivity probe, 3 m (10') cable

(for HI8936 or HI 943500)

48

Page 49

OTHER ACCESSORIES

HI 731326 Small calibration screwdrivers (20 pcs)

HI 779/P 6-wire cable (100 m/330' roll)

HI8733 Portable conductivity meter with automatic

temperature compensation

49

Page 50

WARRANTY

All Hanna Instruments meters are warranted for two years against

defects in workmanship and materials when used for their intended

purpose and maintained according to instructions.

The probes are warranted for a period of six months.

This warranty is limited to repair or replacement free of charge.

Damages due to accident, misuse, tampering or lack of prescribed

maintenance are not covered.

If service is required, contact the dealer from whom you purchased the

instrument. If under warranty, report the model number, date of

purchase, serial number and the nature of the failure. If the repair is not

covered by the warranty, you will be notified of the charges incurred. If

the instrument is to be returned to Hanna Instruments, first obtain a

Returned Goods Authorization Number from the Customer Service department and then send it with shipment costs prepaid. When shipping any

instrument, make sure it is properly packaged for complete protection.

All rights are reserved. Reproduction in whole or in part is prohibited

without the written consent of the copyright owner.

Hanna Instruments reserves the right to modify the design,

construction and appearance of its products without advance

notice.

50

Page 51

CE DECLARATION OF CONFORMITY

Recommendations for Users

Before using these products, make sure that they are entirely suitable for the

environment in which they are used.

Operation of these instruments in residential area could cause unacceptable interferences to radio and TV equipments, requiring the operator to take all necessary steps

to correct interferences.

The trimmers are sensitive to electrostatic discharges. It is recommended to use antistatic screwdrivers.

Unplug the instrument from the power supply before replacing the fuse. External cables

to be connected to the rear panel should end with cable lugs.

To maintain the EMC performance of this equipment, use the recommended cables

mentioned on this instruction manual.

Any variation introduced by the user to the supplied equipment may degrade the

instruments' EMC performance.

To avoid electrical shock, do not use these instruments when voltages at the

measurement surface exceed 24VAC or 60VDC.

To avoid damages or burns, do not perform any measurement in microwave ovens.

51

Page 52

05/03

www.hannainst.com

MANCDPRCR4

Loading...

Loading...