Page 1

Instruction Manual

HI 88713

ISO Turbidity Meter

www.hannainst.com

1

Page 2

Dear Customer,

Thank you for choosing a Hanna Instruments product. This manual will provide you with the

necessary information for correct use of the instrument.

Please read this instruction manual carefully before using the instrument.

If you need additional technical information, do not hesitate to e-mail us at tech@hannainst.com

or see the back side of this manual for our worldwide sales and technical service contacts.

This instrument is in compliance with

TABLE OF CONTENTSTABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

PRELIMINARY EXAMINATION ................................................................................................................... 3

GENERAL DESCRIPTION ........................................................................................................................... 3

ABBREVIATIONS ..................................................................................................................................... 4

PRINCIPLE OF OPERATION ...................................................................................................................... 4

FUNCTIONAL DESCRIPTION ..................................................................................................................... 6

SPECIFICATIONS ..................................................................................................................................... 8

GENERAL TIPS FOR AN ACCURATE MEASUREMENT .................................................................................... 9

START UP ............................................................................................................................................ 15

RANGE SELECTION ................................................................................................................................ 16

TUTORIAL MODE .................................................................................................................................. 16

HELP MODE .......................................................................................................................................... 17

MEASUREMENT PROCEDURE .................................................................................................................. 17

CALIBRATION PROCEDURE ..................................................................................................................... 20

GOOD LABORATORY PRACTICE (GLP) ...................................................................................................... 26

RESTORE FACTORY CALIBRATION ........................................................................................................... 26

LOG & LOG RECALL ............................................................................................................................... 27

SETUP ................................................................................................................................................. 28

PC INTERFACE ....................................................................................................................................... 30

ACCESSORIES ....................................................................................................................................... 31

WARRANTY ........................................................................................................................................... 31

RECOMMENDATIONS FOR USERS .......................................................................................................... 31

directives.

PRELIMINARY EXAMINATIONPRELIMINARY EXAMINATION

PRELIMINARY EXAMINATION

PRELIMINARY EXAMINATIONPRELIMINARY EXAMINATION

Please examine this Product carefully. Make sure the instrument is not damaged. If any damage has

occurred during the shipment, please notify your dealer.

This HI 88713 Turbidity bench meter is supplied complete with:

• Six Sample Cuvettes and Caps

• Calibration Cuvettes

• Silicone Oil

• Cloth for wiping the cuvettes

• AC/DC power adapter

• Instruction Manual

• Instrument Quality Certificate

Note:Save all packing material until you are sure that the instrument works correctly. Any

defective item must be returned in the original packing with the supplied accessories.

GENERAL DESCRIPTION

GENERAL DESCRIPTIONGENERAL DESCRIPTION

GENERAL DESCRIPTION

GENERAL DESCRIPTIONGENERAL DESCRIPTION

The HI 88713 Turbidity bench meter is a high accuracy, meter that benefits from Hanna’s years of

experience as manufacturer of analytical instruments.

The HI 88713 Turbidity bench meter meets and exceeds the requirements of ISO 7027 standard.

The instrument is based on a state-of-the-art optical system which guarantees accurate results,

assures long term stability and minimizes stray light and color interferences. It also compensates for

variations in intensity of the LED, making no need for frequent calibration.

The 25 mm round cuvettes made from special optical glass guaranties reproductibility and consistency

of the measurements.

Turbidity measurements

can be made in four modes: FNU (Formazin Nephelometric Units) ratio

mode FAU (Formazin Attenuation Units) NTU (Nephelometric Turbidity Units) NTU non-ratio mode.

Alternative EBC (European Brewery Comitee) measuring units are available wen measuring in NTU modes.

Normal measurement, continuous measurement or signal averaging measurement can be selected,

depending on the sample and desired accuracy.

A two, three, four or five-point calibration can be performed by using the supplied (<0.1, 15, 100,

750 FNU and 2000 NTU) standards, user prepared formar in standards can also be used in all

modes. Calibration points can be modified when they are used.

2 3

Page 3

The HI 88713 Turbidity bench meter features G.L.P. (Good Laboratory Practice) functions that allow

traceability of the calibration conditions. The last calibration points as well as time and date

The HI 88713 Turbidity bench meter has a user-friendly interface with an easy to understand,

graphical LCD. Comprehensive contextual help is available at a simple key press. All messages and

help screens are available in several languages. Furthermore, a tutorial mode guides the user step by

step through the analysis process.

HI 88713HI 88713

The

HI 88713 features a logging function that can hold up to 200 measurements in the internal

HI 88713HI 88713

memory. Data can be viewed directly on the screen or it can be downloaded to a PC for further

analysis using the HI9200 Windows

NTU Nephelometric Turbidity Units

FAU Formazin Attenuation Units

FNU Formazin Nephelometric Units

ISO International Organization for

Standardization

®

compatible software.

ABBREVIATIONSABBREVIATIONS

ABBREVIATIONS

ABBREVIATIONSABBREVIATIONS

LCD Liquid Crystal Display

RTC Real Time Clock

RH Relative Humidity

ID Identification

EBC European Brewery Comitee

PRINCIPLE OF OPERATIONPRINCIPLE OF OPERATION

PRINCIPLE OF OPERATION

PRINCIPLE OF OPERATIONPRINCIPLE OF OPERATION

Turbidity is the optical property that causes light to be scattered and absorbed, rather than transmitted.

The scattering of the light as it passes through a liquid is caused by the suspended solids. The higher the

turbidity, the greater the amount of scattered light. The molecules in a very pure fluid scatter light to a

certain degree, no solution will have zero turbidity.

The ISO 7027 Method specifies the key parameters for the optical system and the method to

measure the turbidity of water.

The HI 88713 Turbidity bench meter is designed to meet or exceed the criteria specified by the ISO

7027, DIN 38404 and NF EN 27027.

The light beam that passes through the sample is scattered in all directions. The intensity and pattern

of the scattered light is affected by many variables including the wavelenght of the incident light,

particle size and shape, refractive index and color.

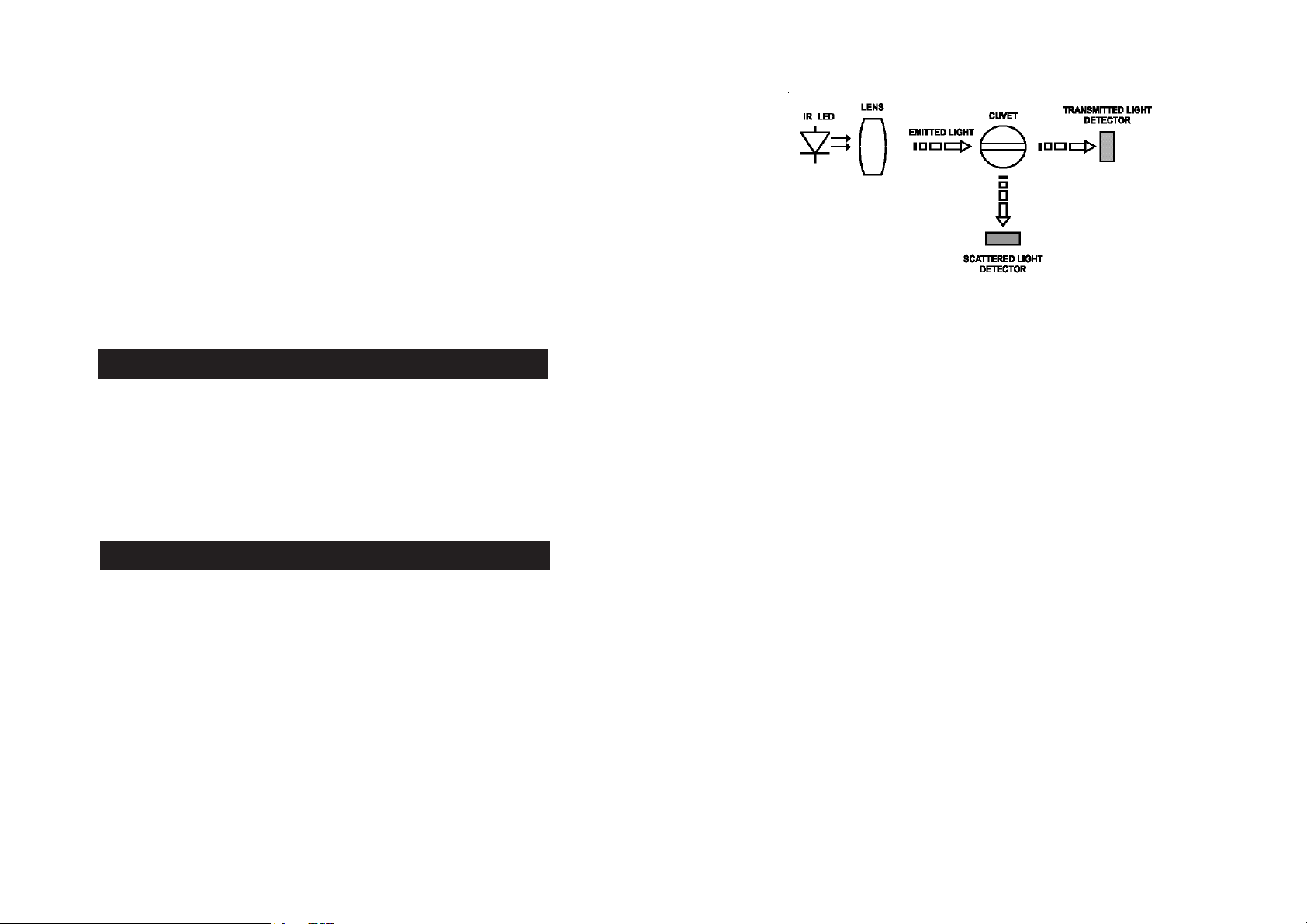

The optical system of the HI 88713 turbidity bench meter uses an IR LED, a scattered light detector

0

(90

) and a transmitted light detector (1800).

For the ratio turbidity mode, the microprocessor of the instrument calculates the NTU value, from the

signals that reaches the two detectors, by using an effective algorithm. The optical system and

measuring technique compensate the color interference and also the LED intensity fluctuations,

minimizing the need of frequent calibration.

For the FNU and NTU non ratio modes the turbidity is calculated from the signal that reaches the

scattered light detector (90°).

In FAU mode the turbidity is calculated from the signal that reaches the direct light detector, while

in NTU ratio mode the turbidity is obtained from signal ratio on scatter and transmitted light

detectors. The non ratio methods are more sensitive to the LED intensity fluctuations.

The lower detection limit of a turbidimeter is determined by the “stray light”. Stray light is the light that

reaches the detectors and is not caused by light scattering from suspended particles.

The optical system of HI 88713 instrument is designed to have very low stray light, providing accurate

results for low turbidity samples. However, special care must be taken when measuring low turbidities (see

page 9 “General Tips for an Accurate Measurement” for sample preparation and measuring techniques).

MEASUREMENT UNITS

The meter is using specific units according to the selected measurement mode. For NTU modes the

EBC unit option is available 1 EBC=0.245 NTU. When measuring in NTU modes a conversion to

EBC units is also available 0.245 NTU=1 EBC.

4 5

Page 4

FUNCTIONAL DESCRIPTIONFUNCTIONAL DESCRIPTION

FUNCTIONAL DESCRIPTION

FUNCTIONAL DESCRIPTIONFUNCTIONAL DESCRIPTION

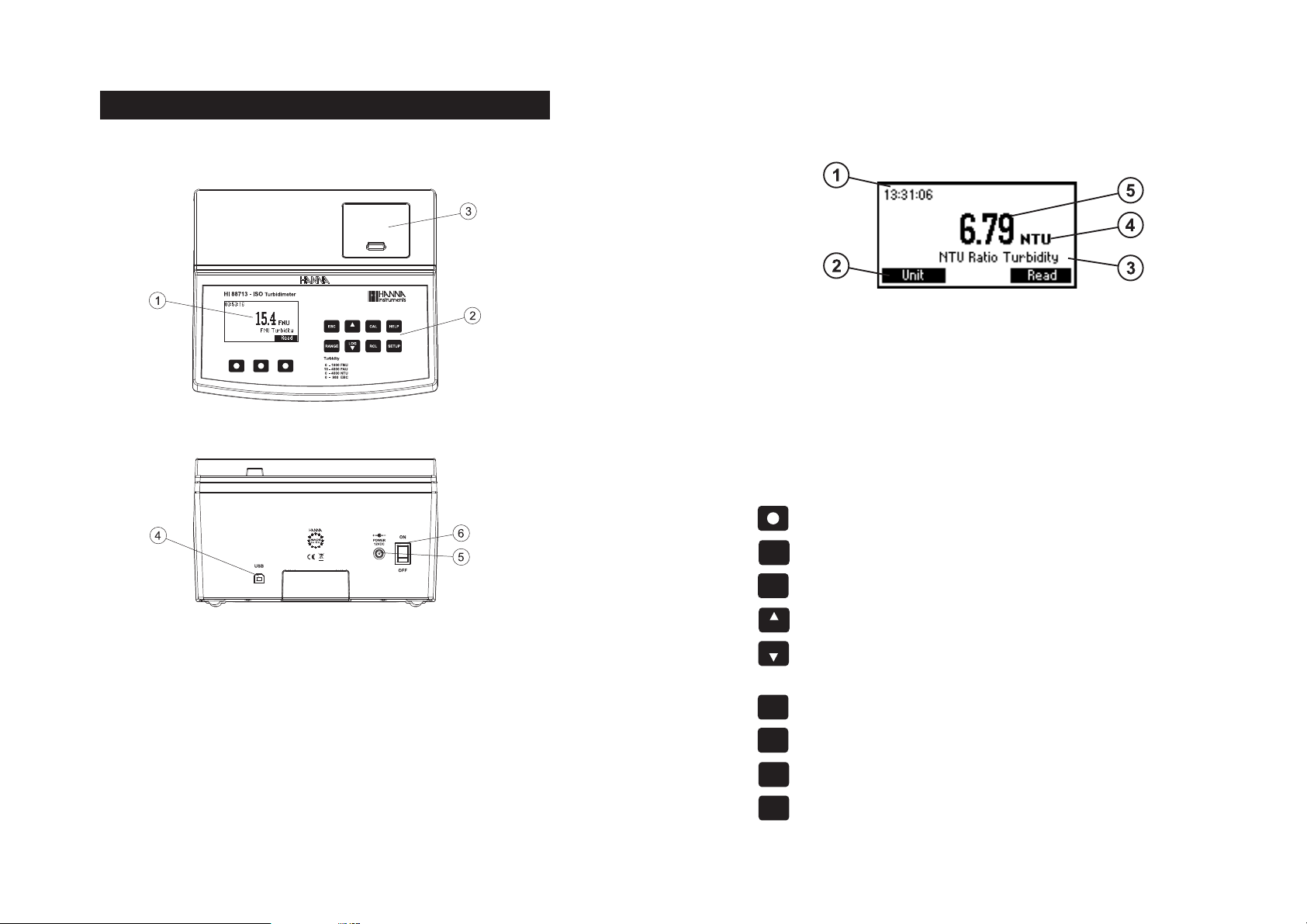

INSTRUMENT DESCRIPTION

DISPLAY DESCRIPTION

The display contains the following fields:

1) Current time

2) Functional keys

3) Selected mode

4) Measuring units

5) Measured value

KEYPAD DESCRIPTION

The keypad contains 8 direct keys and 3 functional keys with the following functions:

Press to perform the function displayed above it. The function are screen releated.

1) Liquid Crystal Display (LCD). The LCD has backlight for better visibility in dark environments.

2) Keypad. Splash proof resistant.

3) Cuvette Lid.

4) USB connector

5) 12 Vdc power input

6) ON/OFF switch

6 7

ESC

RANGE

LOG

CAL

RCL

HELP

SETUP

Press to exit the current screen.

Press to access measurement modes.

Press to scroll up in a menu and help or to increment a set value.

Press to scroll down in a menu and help or to decrement a set value. Press

to log the current reading.

Press to access calibration menu.

Press to recall the log.

Press to display the help screen.

Press to access the setup menu.

Page 5

SPECIFICATIONSSPECIFICATIONS

SPECIFICATIONS

SPECIFICATIONSSPECIFICATIONS

GENERAL TIPS FOR AN ACCURATE MEASUREMENTGENERAL TIPS FOR AN ACCURATE MEASUREMENT

GENERAL TIPS FOR AN ACCURATE MEASUREMENT

GENERAL TIPS FOR AN ACCURATE MEASUREMENTGENERAL TIPS FOR AN ACCURATE MEASUREMENT

FNU mode

Range 0.00 to 9.99; 10.0 to 99.9; 100 to 1000 FNU

Resolution 0.01; 0.1; 1 FNU

Accuracy ±2% of reading plus straylight

FAU mode

Range 10.0 to 99.9; 100 to 4000 FAU

Resolution 0.1; 1 FAU

Accuracy ±10% of reading

NTU ratio mode

Range 0.00 to 9.99; 10.0 to 99.9; 100 to 4000 NTU

0.00 to 9.99; 10.0 to 99.9; 100 to 980 EBC

Resolution 0.01; 0.1; 1 NTU

0.01; 0.1; 1 EBC

Accuracy ±2% of reading plus straylight

±5% of reading above 1000 NTU

NTU non ratio mode

Range 0.00 to 9.99; 10.0 to 99.9; 100 to 1000 NTU

0.00 to 9.99; 10.0 to 99.9; 100 to 245 EBC

Resolution 0.01; 0.1; 1 NTU

0.01; 0.1; 1 EBC

Accuracy ±2% of reading plus straylight

Range selection Automatic

Repeatibility ±1% of reading or straylight, whichever is greater

Stray Light < 0.1 NTU (0.05 EBC)

Light Detector Silicon Photocell

Method ISO 7027 Method

Measuring mode Normal, Average, Continuous.

Turbidity Standards <0.1, 15, 100, 750 FNU and 2000 NTU

Calibration Two, three, four or five-point calibration

Light Source IR LED

Lamp life Instrument life

Display 40 x 70mm graphic LCD (64x128 pixels) with backlight

LOG Memory 200 records

Serial Interface USB

Environment 0°C (32°F) to 50°C (122°F); max 95% RH non-condensing

Power supply 12 Vdc power input

Dimensions 230 x 200 x 145 mm (9 x 7.9 x 5.7”) L x W x H

Weight 2.5 Kg (88 oz.)

The HI 88713 is a highly accurate bench too turbidity meter. Special care must be taken during

calibration and sample preparation to optimize the instrument performance and to fully benefit from

its features. Is very important for the analyst to use proper measurement techniques for accurate,

precise and repeatable readings. The instructions listed below should be carefully followed during

calibration and measurement to ensure optimum accuracy.

GENERAL RULES

• Always put the instrument on a flat, rugged surface when taking measurements.

• Do not operate in direct sunlight.

• Keep the lid of the instrument closed when it is not used to prevent dust or dirt entering inside.

• Always close the cuvette lid during measurement.

• Always use cuvettes without scratches or cracks because they can cause inaccurate readings.

• Always cap the cuvettes to prevent the sample from spilling

• To prevent contamination of the optical system, do not use to much oil.

• When using multiple cuvettes, they should be indexed and matched, when possible.

CUVETTE

The cuvette is part of the optical system in all measurements. The light reaches the sample by

passing through the cuvette glass. As a result, the measurement can be affected by the glass

imperfections, dirt, dust, scratches, or fingerprints present on the cuvette surface. Special care

must be taken in preparing and handling the cuvette.

Note: If you are using multiple cuvettes, always match the cuvettes.

CUVETTE HANDLING

The cuvettes should be free of scratches or cracks. Any cuvette with visible scratches should be

discarded. The cuvettes should be periodically washed with acid. After washing, the cuvettes

should be rinsed well with distilled or deionized water, multiple times. Allow cuvettes to air-dry

and store them for long periods of time with theire caps, to avoid dirt entering inside. Always

handle the cuvette by touching only the cap or its top side (over the horizontal line).

Always store the cuvettes in separate boxes or with separators between them to avoid scratches

on the surface.

CUVETTE PREPARATION

Whenever a cuvette is used, it must be clean inside and outside. When it is placed into the

instrument, it must be dry outside, completely free of fingerprints or dirt.

8 9

Page 6

CUVETTE PREPARATION

Whenever a cuvette is used, it must be clean inside and outside. When it is placed into the

instrument, it must be dry outside, completely free of fingerprints or dirt.

To further reduce the effect of glass imperfections, the cuvette can be indexed and use this new index as the position mark.

For indexing one cuvette or matching multiple cuvettes, the continuous reading mode is suggested.

In this mode multiple successive readings are taken without turning off the lamp. The turbidity is

immediately displayed, reducing considerably the measurement time.

Note: The instrument can not perform continuous readings if the average mode is on.

In order to index a cuvette follow the next steps:

• Fill the cuvette with high quality water (<0.1

FNU) up to the 10 mL mark.

If the cuvette is not indexed, use the factory marking to align the cuvette with the marking on the

cuvette holder.

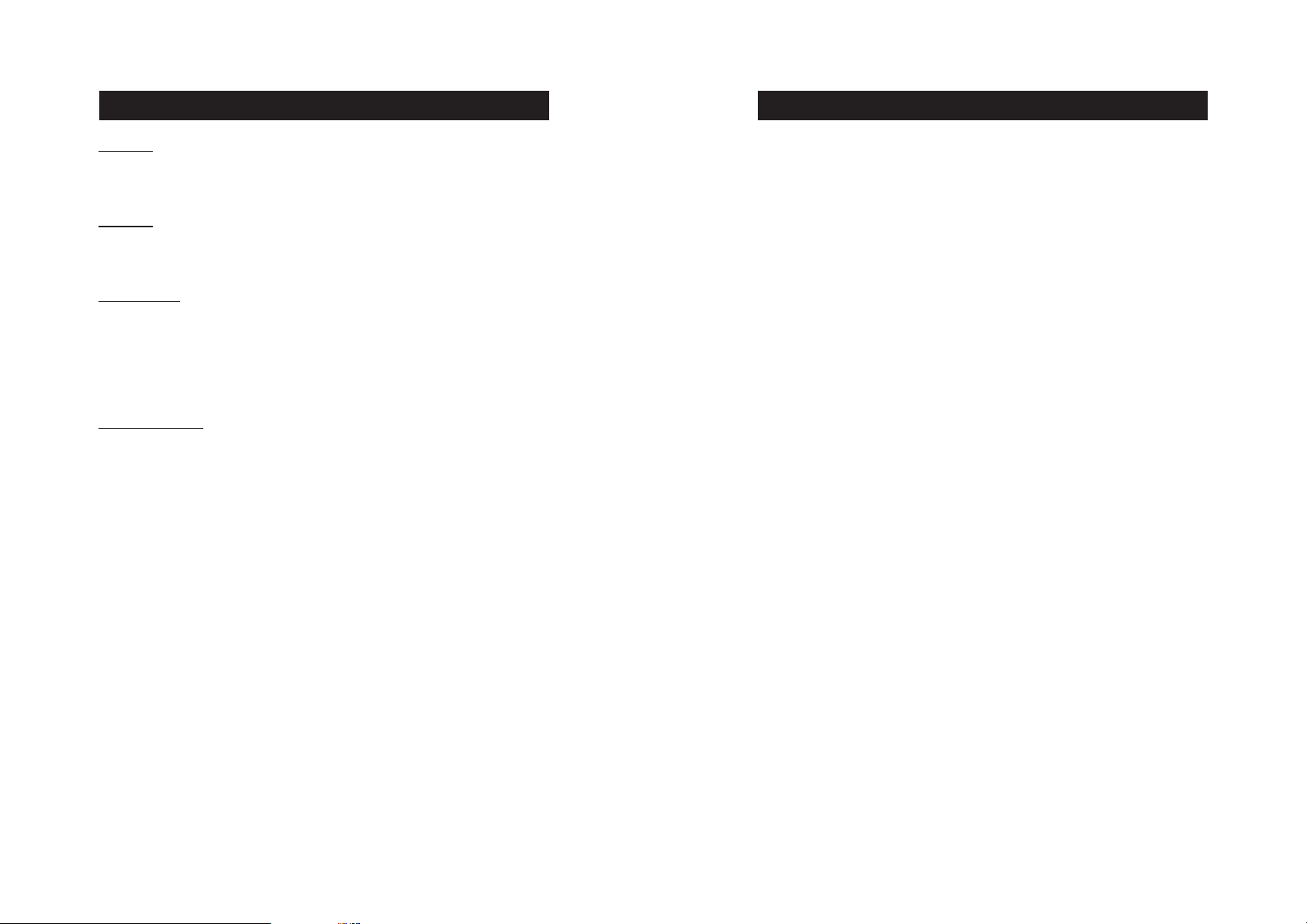

CUVETTE OILING

To hide minor imperfections and scratches, the cuvettes should be oiled outside with the supplied silicone

oil. This is very important, especially for low turbidity samples (< 1 FNU), otherwise scratches can

contribute and alter turbidity readings.

The silicone oil has the same refractive index as the glass and will not alter the turbidity readings. It is

important to apply only a thin layer of silicone oil.

Warning: Do not apply silicone oil in excess because it may retain dirt or contaminate the cuvette

holder of the instrument, altering the turbidity readings.

It is very important to apply the silicone oil on a clean, dry cuvette. Apply a few drops of oil and wipe

the cuvette thoroughly with a lint-free cloth. Wipe off the excess oil till you obtain a thin, uniform

layer. If the procedure is correctly followed, the cuvette should appear nearly dry with no visible oil.

Note: The supplied cloth for oiling should be stored together with the silicone oil bottle and

cuvettes, taking care to avoid contamination with dirt. After a few oiling procedures, the cloth

will contain enough oil to wipe the bottle with it without adding more oil. From time to time

add some drops of oil on the cuvette to provide the necessary oil quantity in the cloth.

• Clean and oil the cuvette as described in the

previous section.

• Turn the instrument ON.

• Insert the cuvette into the instrument and press

“Read” functional key. Record the reading.

• Open the instrument lid, slightly rotate the cuvette and take a new reading.

INDEXING A CUVETTE

It is very important for low turbidity readings to always insert the cuvette into the instrument in the same position.

All cuvettes are factory indexed. The factory mark on the cuvette can be used to align the cuvette with

sign on the cuvette holder.

10 11

• Repeat the previous step until you read the lowest value.

• Alternatively, press and hold the “Read” key to make continuous readings. After the first value

is displayed, open the lid and start rotating the cuvette until the lowest value is displayed.

Page 7

• Mark this position on the white band at the top of

the cuvette with a water resistant pencil.

• Always use this position to align the cuvette

with the mark on the cuvette holder.

MATCHING MULTIPLE CUVETTES

Precise measurements require the use of a single cuvette. If it is not possible, cuvette selection

and matching must be performed before taking measurements.

In order to match multiple cuvettes follow the next

steps:

• Fill multiple cuvettes with high quality water

(<0.1FNU) up to the 10 mL mark.

• Clean and oil the cuvettes as described before.

• Turn the instrument ON.

• Insert the first cuvette into the instrument and

press “Read” functional key. Record the

reading.

• Open the instrument lid, slightly rotate the

cuvette and take a new reading.

• Insert the second cuvette into the instrument and

take a reading.

• Open the instrument lid, slightly rotate the

cuvette and take a new reading.

• Repeat the last step for the second cuvette until the reading is within 0.01 FNU of the value obtained for the first cuvette.

• Alternatively, press and hold the “Read” functional key, after the first value is displayed, open

the lid and start rotating the cuvette until the read value matches the first cuvette.

• Mark this position on the second cuvette with a water resistant pencil.

• Follow the same procedure for all the cuvettes you need.

Note: If the cuvette is indexed, use the index to position it in the instrument.

SAMPLING TECHNIQUE

When taking turbidity measurements it is very important to select a representative sample. For

consistent results, follow the next tips when sampling:

• Gently mix the water before taking the sample.

• If the sample is taken from a pipe, discard the first few liters.

• If measuring a non uniform source, collect samples from different places and mix them.

When measuring the collected sample, keep in mind the following:

• Samples should be analyzed immediately after collection because the turbidity can change in time.

• To avoid dilution of the sample it is better to rinse the cuvette with a quantity of sample and then

discard. Then you can fill the cuvette with sample.

• Pay attention that cold samples do not condense on the sample cell.

• Repeat the previous step until you read the

lowest value.

• Mark this position on the white band at the top

of the cuvette with a water resistant pencil.

12

REMOVING AIR BUBBLES

Any air bubbles present in the sample will cause high turbidity readings. To obtain accurate

measurements, remove the air bubbles using one of these methods:

• Application of a partial vacuum;

• Addition of a surfactant, such as Triton X-100;

13

Page 8

• Use of an ultrasonic bath;

• Heating the sample.

Sometimes it is necessary to combine two or more methods for efficient air bubble removal.

Note: Each method can alter the sample turbidity, if misused, so they have to be used with caution.

APPLICATION OF VACUUM

Vacuum works by decreasing the atmospheric pressure. The bubbles from the solution come out to

the surface. Application of vacuum is a very simple procedure andany vacuum can be used. The

simplest equipment is a syringe and a rubber stopper.

Notes: • Pay attention that the vacuum equipment be clean and oil-free.

• It is not recommended to apply vacuum to a viscous sample that contains volatile

components. The vacuum can disrupt the volatile components and increase the bubbles

in the sample.

ADDITION OF SURFACTANT

Surfactant changes the surface tension of the water. This causes the bubbles to be released from the

sample. This method is effective for samples that are supersaturated with air.

The procedure consists in the addition of a drop of surfactant in the cuvette before adding the sample

to be analyzed.

A common surfactant used for degassing is Triton X-100.

Warning: Changing the surface tension will cause a rapid settling of particles that cause turbidity.

To avoid this problem, analyze the sample as soon as possible.

Do not shake the sample vigorously because the surfactant may foam. Always rinse the cuvette before

adding a new sample to avoid surfactant accumulation.

Surfactant contribution to the turbidity readings is negligible.

Note: Surfactant addition should be used for degassing only when other methods are ineffective.

HEATING THE SAMPLE

This procedure can be very effective however it should be handled with care because it can alter the

turbidity of the sample. When heating a sample, the volatile components from the sample can

vaporize, the suspended components can dissolve or the sample characteristics can change.

The heating procedure should be used with extreme care.

Use a warm water bath and immerse the cuvette filled with sample into the bath. Heat the sample

only until the visible bubbles are removed.

Note: Always cool the heated sample to the original temperature before measurement.

The heating procedure can be used in combination with vacuum or ultrasonic waves application for

a more effective air bubble removal.

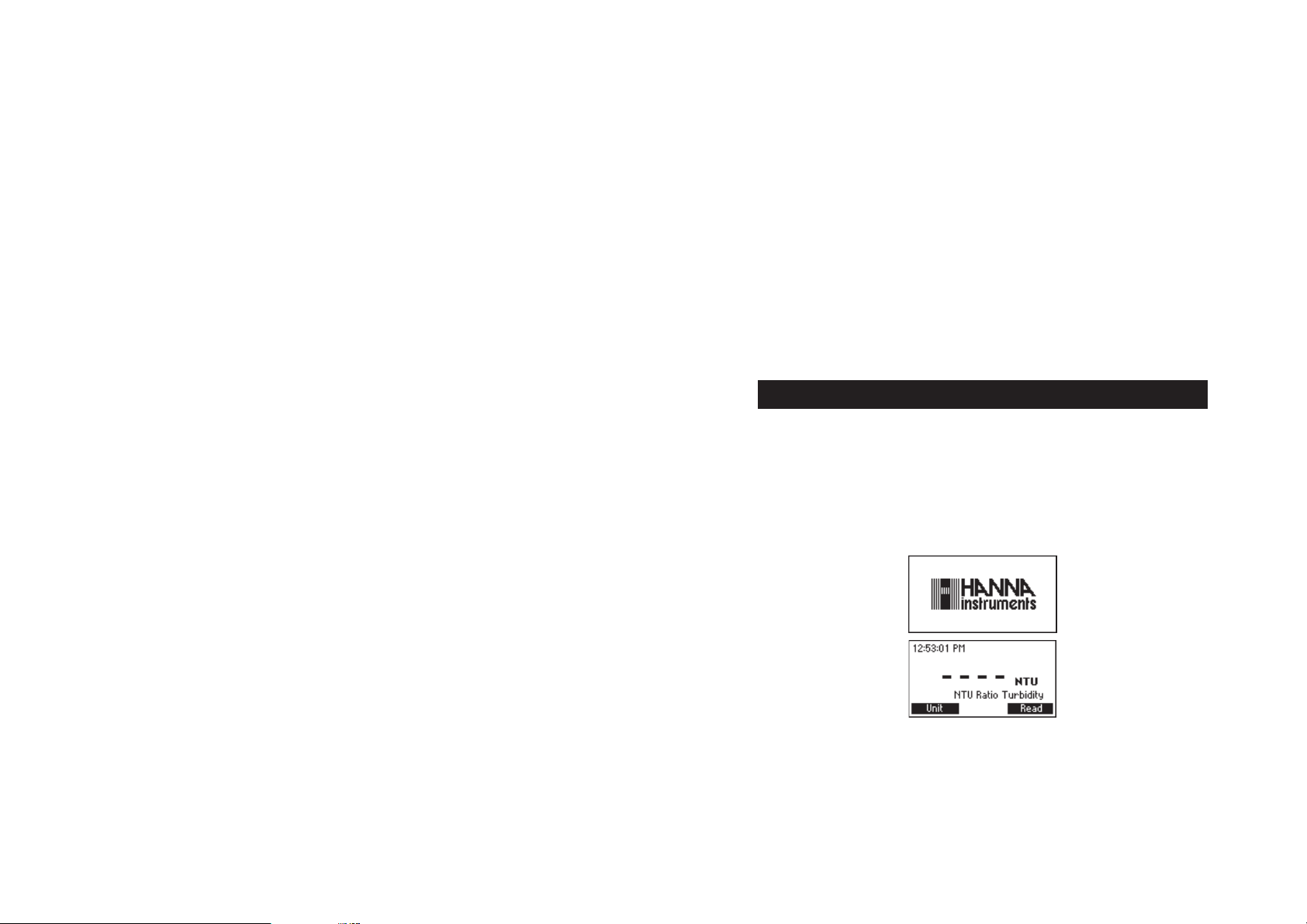

STARTUPSTARTUP

STARTUP

STARTUPSTARTUP

The HI 88713 Turbidity bench meter is supplied with all necessary accesories

Unpack the instrument and place it on a flat surface. Do not place the instrument in dirrect sunlight.

Insert the 12 Vdc power plug into its input on the back of the instrument.

Switch on the instrument. On the LCD, the Hanna Logo will appear for a short time, followed by the

main screen for turbidity measurements.

USE OF AN ULTRASONIC BATH

The ultrasonic waves are very effective in removing air bubbles from samples. However, ultrasonic

waves should be used with care because they can alter the samples turbidity characteristics, by

modifying the shape and size of particles which cause turbidity. The ultrasonic waves can also break

the existing air bubbles, leading to a complication in the degassing process.

In order to avoid excess application of the ultrasonic waves use the ultrasonic bath until all visible air

bubbles are removed, and then measure the turbidity. This is the most used procedure for degassing.

If you are not sure that all air bubbles were removed, apply ultrasonic waves again for a short period

of time and then measure the turbidity. Repeat this procedure until the turbidity is increasing instead

of decreasing, sign that turbidity of the sample was altered.

In order to degas a sample, fill a clean cuvette with sample and immerse it (1/2 to 2/3 immersed)

in an ultrasonic bath. Follow the degassing procedure described above. Only after the degassing

procedure is finished the cuvette can be capped.

14 15

The instrument loads the selected language. If no language can be loaded the instrument will work

in the “safe mode”. In “safe mode” all the messages are displayed in English and

tutorial and help information are not available.

Page 9

RANGE SELECTIONRANGE SELECTION

RANGE SELECTION

RANGE SELECTIONRANGE SELECTION

HELP MODEHELP MODE

HELP MODE

HELP MODEHELP MODE

The HI 88713 bench-top Turbidity meter has four

measuring modes: FNU, FAU, NTU Ratio and NTU

Non Ratio. When the instrument is in the main

screen, the selected mode is displayed in the right

side of the LCD, on the message line.

To change the mode, press the RANGE key.

When the display shows the Change mode screen,

use the UP or DOWN key to select a new mode .

Press “CFM” key to select the new mode. The

instrument returns to the main screen.

TUTORIAL MODETUTORIAL MODE

TUTORIAL MODE

TUTORIAL MODETUTORIAL MODE

The HI 88713 bench-top Turbidity meter has a unique Tutorial Mode that provides additional

information to help the unexperienced user during the measurements. The instrument displays a screen,

with explanations and confirmation button, when a preparation or other operation has to be performed

by the operator. The instrument resumes the measuring sequence when the operator confirms that the

requested operation was done.

To disable this mode, when in the main screen,

press the SETUP key to enter the setup, and then

press DOWN key until the “Tutorial” line is

highlighted. Press the “Disable” key then press

ESC to return to the main screen.

The HI 88713 bench-top Turbidity meter offers an interactive contextual help that assists the user

at any moment.

To access help screens, just press HELP.

A screen with additional information will appear.

To read all available information, scroll down or

up text using the UP or DOWN key.

Press the “Support” key to access a list of the

Hanna support centers and their contact information.

Press the “Accessories” key to view a list of the

instruments accessoies.

To exit support or accessories screens, press ESC, and

the instrument will return to the previous help screen.

To exit help mode just press the HELP key again

and the meter will display the previous screen.

MEASUREMENT PROCEDUREMEASUREMENT PROCEDURE

MEASUREMENT PROCEDURE

MEASUREMENT PROCEDUREMEASUREMENT PROCEDURE

When taking turbidity measurements, several basic rules should be followed:

• Always use cuvettes without scratches or cracks because they can cause inaccurate readings.

• Always cap the cuvettes to prevent spillage of the sample from spilling the instrument.

• Always close the cuvette cover during measurement.

• To prevent contamination of the optical system, do not use too mush silicon oil.

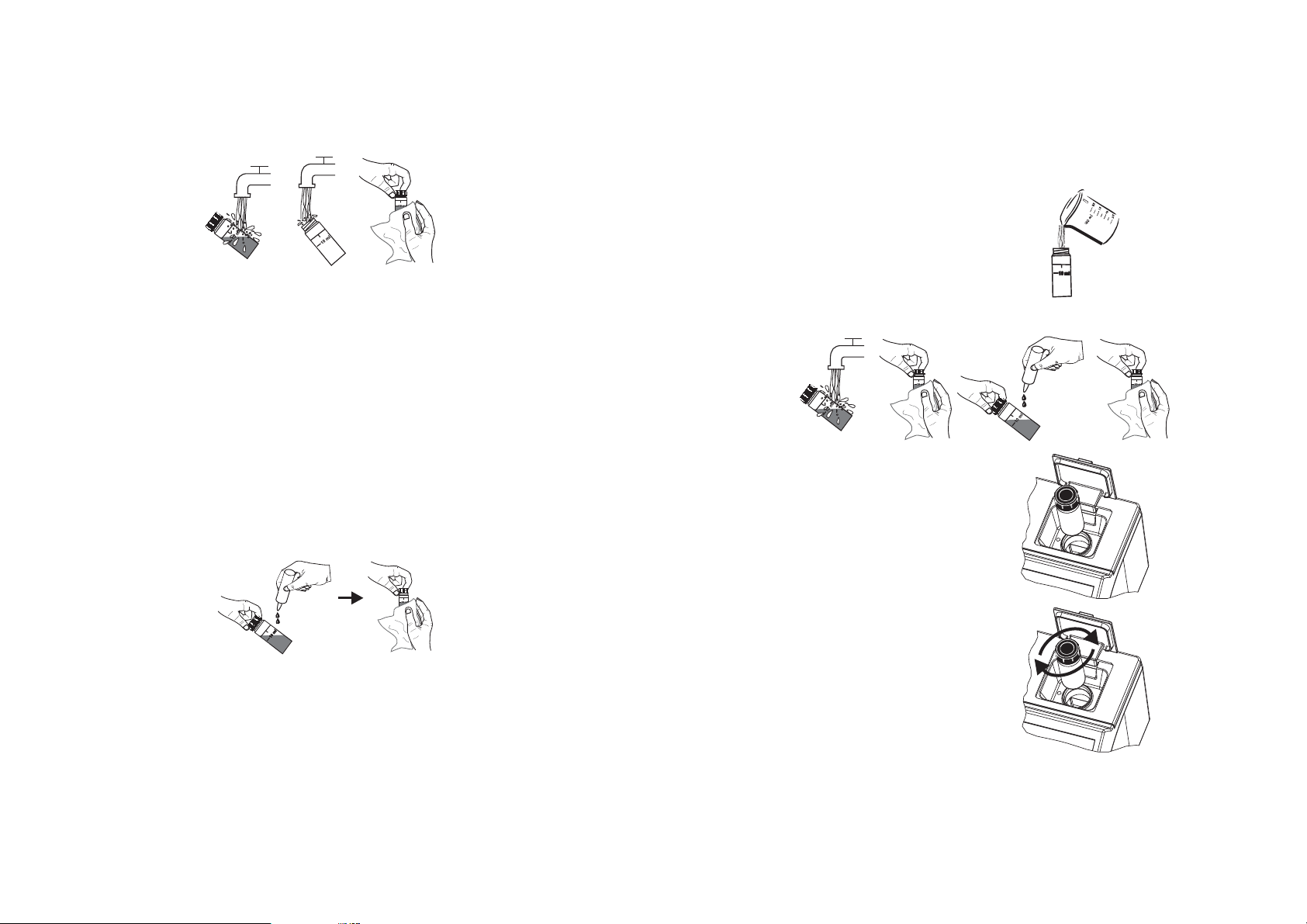

To take turbidity measurements:

• Turn the instrument ON by pressing ON/OFF.

When dashes are displayed on the LCD, the

instrument is ready. The current time appears in

the upper left corner of the display and the

mode name appears on the right side of the

LCD, in the message line.

• Fill a clean, dry cuvette with 10 mL of sample up to

the mark, only handle the cuvette by the top.

16 17

Page 10

• Replace the cap.

• Wipe the cuvette thoroughly with a lint-free

cloth to remove any fingerprints, dirt or water

spots.

• Apply silicone oil on the cuvette and wipe with

a lint-free cloth to obtain an even film over the

entire surface of the cuvette.

Note: It is very important to oil the cuvette, espe-

cially for low turbidity values (< 1 FNU)

to hide the glass imperfections which can

influence the reading.

• Place the cuvette into the instrument. Align the

mark from the cuvette with the sign on the

instrument top

• Close the lid.

Note: If you have a cuvette with indexing mark,

place the cuvette into the instrument with

the indexing mark aligned with the sign on

the instrument top.

NORMAL MEASUREMENT

This type of measurement is best suited for regular readings, when the sample is stable and normal

accuracy is required. In normal mode, the measurement takes about 10 seconds and the lamp is ON

for a minimum period of time (about 7 seconds).

• Press “Read” functional key to take the

measurement.

The display will show “READ” in the left side

and blinking dashes. The dashes and light icon

will appear during different measurement

phases.

• The result is displayed in the selected units.

CONTINUOUS MEASUREMENT

This measurement mode is suitable when many measurements have to be taken in a short period of

time. The mode is useful to evaluate a very fast settling sample. This measurement mode is

recommended for indexing cuvettes.

• Press “Read” functional key and keep it pressed to take continuous readings.

The display will show “READ” in the left side and blinking dashes. The dashes and light icon will

appear during different measurement phases. The first value is displayed after 10 seconds and then

a new reading is displayed each second as long as the “Read” functional key is kept pressed. When

a new value is displayed, the measurement value will briefly blink.

The last value remains on the display after the “Read” functional key is released.

AVERAGED MEASUREMENT

This measurement mode is useful when samples that cause unstable readings are analyzed. By

averaging several readings, noise effect is reduced and accurate measurements can be taken.

This mode can also be selected when high accuracy measurements are needed. In the average mode

10 measurements are averaged in a short period of time (about 20 seconds).

To use the averaged reading mode first enter setup and enable the Average reading mode. The “AVG”

text will be displayed in the left side of the screen.

• Press “Read” functional key to take the

measurement.

The display will show “READ” in the left side and

blinking dashes. The dashes and light icon will

appear during different measurement phases. The

first value is displayed after 10 seconds and then a

new average of the available readings is displayed

each second. When a new value is displayed, the

measurement value will blink briefly. The last averaged

value remains on the display at the end of the

measurement.

The HI 88713 Turbidity bench meter automatically

selects the correct turbidity range to display the

results with the highest accuracy. In FNU and NTU

Non-Ratio Turbidity Modes, if the measured value

is higher than 1000 FAU, the display will show

the maximum value blinking and the message “Out

of range” on the message line. For FAU Turbidity

and NTU Ratio Turbidity modes, if the measured

value is higher than 4000 FNU/NTU (980 EBC),

the display will show the maximum value blinking

and the message “Out of range” on the message

line.

18 19

Page 11

UNITS CHANGE (only for NTU Ratio and NTU Non-Ratio modes)

To change the units for NTU Ratio and Non-Ratio modes, simply press the “Unit” functional key

when a measurement is available. The EBC value is obtained by multiply with 0.245 the NTU value.

CALIBRATION PROCEDURECALIBRATION PROCEDURE

CALIBRATION PROCEDURE

CALIBRATION PROCEDURECALIBRATION PROCEDURE

The HI 88713 Turbidity bench meter is supplied with 5 AMCO Hanna standards (<0.1 FNU, 15 FNU,

100 FNU, 750 FNU and 2000 NTU) that are specially designed for NTU ratio mode.

The calibration can be done using the supplied calibration solutions for NTU Ratio mode or

user prepared standards for all modes. Turbidity standards have a shelf life and should not be

used after the expiration date. Alternatively, formazin standards can be used. It is recommended

that the turbidity value of the prepared calibration solutions to be close to the default

calibration points.

The first calibration point should be near 0 FNU, the second point can be chosen between 10 and

20 FNU, the third point between 50 and 150 FNU, the fourth point between 600 and 900 FNU and

the fifth point between 1500 and 2500 NTU.

FORMAZIN PREPARATION

In order to prepare formazin 4000 NTU stock solution, follow the next procedure:

Solution I : Dissolve 1.000 gram of hydrazine sulfate, (NH

2)2 H2SO4, in distilled, deionized water

and dilute to 100 mL in a volumetric flask.

Warning: Handle hydrazine sulfate with care because it is a carcinogen reagent. Avoid inhalation,

ingestion, or skin contact. Formazin solution can also contain some hydrazine traces.

Solution II : Dissolve 10.000 grams of hexamethylenetetramine, (CH2)

6N4, in distilled, deionized

water and dilute to 100 mL in a volumetric flask.

Stock solution: Mix 10 mL Solution I and 10 mL Solution II in a flask. Let the stock solution stays

48 hours at 25±3°C (77±5°F). This will result in a 4000 NTU formazin suspension. It is very

important for the formation of the formazin polymer to maintain the same temperature.

The stock solution (4000 NTU) can be stored up to one year in proper conditions. Store formazin in

amber glass bottle or any UV-light blocking bottle.

To obtain a high quality formazin always use pure reagents and high-purity water.

To prepare the calibration standards, dilute the stock solution with the same high-purity water you

used for the preparation of the stock solution. The diluted formazin solutions are not stable. They

should be used immediately after preparation and discard immediately after use.

CALIBRATION

For best results, the measurement techniques must be followed during calibration. If formazin

standards are used, mix the cuvettes gently for about 1 minute and then allow the standard to settle

for 1 more minute before calibration.

Calibration can be performed in up to five points, independently, for each mode. The calibration

points are:

FNU mode: 0, 15, 100, 750 FNU

FAU mode: 15, 100, 750, 2000 FAU

NTU ratiometric mode: 0, 15, 100, 750, 2000 NTU

NTU non-ratiometric mode: 0, 15, 100, 750 NTU

Before making the calibration, assure that you are in the correct mode.

To enter calibration, press CAL key while in main screen. The first screen of GLP

information is displayed. Press “Cal” functional key to start calibration.

It is possible to interupt calibration procedure at any time by pressing CAL or ESC key.

FIRST POINT CALIBRATION

• The first calibration point is displayed on the LCD.

This point is used for FNU and NTU modes to check the quality of the water used for dilution and to

confirm that the optical system is not dirty. In this case, if the value of the first point is over 0.15 FNU

(NTU), a warning “Cal Point1 high !” is displayed when the calibration is saved and a warning “Out of

calibration range” is displayed when measurements under 10.0 FNU (NTU) are performed.

20 21

Page 12

Note: The reading of the first point could be skipped for FNU and NTU modes by pressing “Skip”

functional key. In this case, the 0.00 value will be used for calibration.

• Place the cuvette for first calibration point:

• <0.1 FNU (NTU) calibration cuvette for all

modes except FAU mode.

• 15 NTU formazin prepared standard for FAU

mode.

Note: For the FAU mode, if necessary, press UP

or DOWN key to edit the calibration point value

to match the exact value of the standard.

• Close the lid and press “Read” functional key. The display will show the value blinking and the

light icon during measurement.

Note: If the Average mode was previously selected, the measurement in calibration mode will be

done using the average.

• At the end of the measurement, the second proposed calibration point is displayed.

SECOND POINT CALIBRATION

• Remove the first calibration cuvette.

• Place the cuvette for second calibration point:

• 15 NTU (FNU) calibration cuvette for NTU

ratiometric mode.

• 15 NTU formazin prepared standard for NTU

non-rating and FNU modes.

• 100 NTU formazin prepared standard for FAU mode.

• If the calibration is terminated, the display will briefly

show “Store...” and the two point calibration is saved.

The instrument returns to the main screen.

THIRD CALIBRATION POINT

• Remove the second standard cuvette.

• Place the cuvette for third calibration point:

• 100 FNU (NTU) calibration cuvette for NTU

ratiometric mode.

• 100 NTU formazin prepared standard for NTU

non-ratio and FNU modes.

• 750 NTU formazin prepared standard for FAU mode.

If necessary, press UP or DOWN key to edit each

Note:

calibration point value to match the exact value of the

standard as measured with a reference turbidimeter.

• Close the lid and press “Read” functional key.

The display will show the value blinking and the light icon during

measurement.

• At the end of the measurement, the fourth proposed calibration point is displayed.

• At this moment it is possible to exit calibration by pressing “End” functional key.

• If the calibration is terminated, the display will briefly

show “Store...” and the three point calibration is saved.

The instrument returns in the main screen.

If necessary, press UP or DOWN key to edit

Note:

each calibration point value to match the exact value of

the standard as measured with a reference turbidimeter.

• Close the lid and press “Read” functional key.

The display will show the value blinking and the light icon during

measurement.

• At the end of the measurement, the third proposed calibration point is displayed.

• At this moment it is possible to exit calibration by pressing “End” functional key.

22 23

Page 13

FOUR-POINT CALIBRATION

• Remove the third standard cuvette.

• Place the cuvette for third calibration point:

• 750 FNU (NTU) calibration cuvette for NTU

ratio mode.

• 750 NTU formazin prepared standard for NTU

non-ratio and FNU modes.

• 2000 NTU formazin prepared standard for FAU

mode.

If necessary, press UP or DOWN key to edit each calibration point value to match the exact value

Note:

of the standard as measured with a reference turbidimeter.

• Close the lid and press “Read” functional key. The display will show the value blinking and the

light icon during

measurement.

• The “Store...” message is displayed for FAU, FNU and NTU non-ratio modes and the calibration

is saved. The instrument returns to the main screen.

• The fifth proposed calibration point, 2000 NTU for NTU Ratio mode, is displayed.

• At this moment it is possible to exit calibration by pressing “End” functional key.

• If the calibration is terminated, the display will

briefly show “Store...” and the four point calibration

is saved. The instrument returns in the main screen.

FIFTH CALIBRATION POINT (NTU Ratio Turbidity only)

• Remove the fourth standard cuvette.

• Place the 2000 NTU calibration cuvette (or the

fifth prepared formazin standard) into the holder,

with the cuvette mark aligned to the sign on the

instrument top.

Note:

If necessary, press UP or DOWN key to edit the calibration point value to match the exact value of

the standard as measured with a reference turbidimeter.

• Close the lid and press “Read” functional key. The display will show the value blinking and the

light icon during

measurement.

• At the end of the measurement, the calibration

is saved and the display will briefly show “Store...”.

The instrument returns in the main screen.

CALIBRATION ERROR MESSAGES

If the value of the standard read during the calibration is too far from the set value, the instrument

will display a standard low or a standard high message.

Check if the correct standard is used or prepare a fresh standard, if formazine is used, and repeat the

reading of the standard.

If the calculated calibration coefficients are outside a

certain range a calibration error message is displayed.

OUT CAL RANGE FUNCTION

The instrument has a mechanism to prevent taking

measurements in a range where the calibration

does not assure the best results. The message

“Out of Calibration Range” is displayed on the

message line in the following situations:

• When the first calibration point is over 0.15 FNU and the reading is under 10 FNU.

• When two point calibration was performed and the reading value is over 40 FNU.

• When a three point calibration was performed and the reading is over 150% of the the third point value.

• When a four point calibration was performed and the reading is over 200% of the the fourth point value.

24 25

Page 14

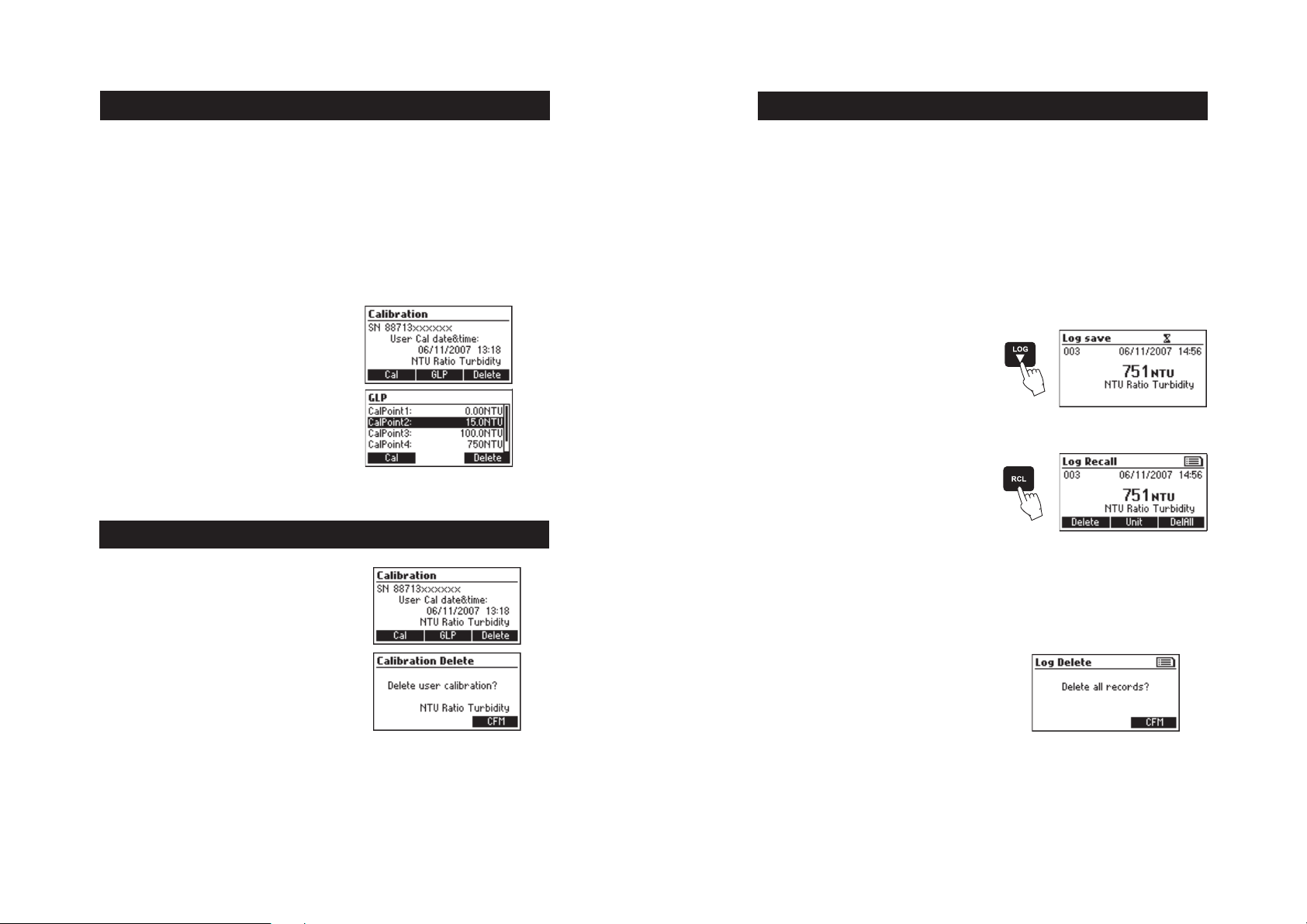

GOOD LABORATORY PRACTICE (GLP)GOOD LABORATORY PRACTICE (GLP)

GOOD LABORATORY PRACTICE (GLP)

GOOD LABORATORY PRACTICE (GLP)GOOD LABORATORY PRACTICE (GLP)

LOG AND LOG RECALLLOG AND LOG RECALL

LOG AND LOG RECALL

LOG AND LOG RECALLLOG AND LOG RECALL

The HI 88713 Turbidity bench meter has a built in complete GLP information. The calibration date

and the calibration points are displayed in a comprehensive mode for each range.

To display the GLP information, simply press CAL key. A screen with instrument serial number and

with information about the calibration is displayed. For further information, press the “GLP”

functional key.

The GLP contains:

• Instrument serial number

• The last user calibration date, in

selected format and time in hh.mm format. If no

calibration was performed, the “Not calibrated”

message is displayed and the meter uses only the

factory calibration.

• Parameter as NTU Ratio Turbidity, NTU

Non Ratio Turbidity, FAU Turbidity or FNU Turbidity.

• The value of each calibration point (up to

5 points for NTU ratio mode; 4 points for FNU, FAU

and NTU non-ratio modes). If the first calibration

point was skipped, the 0.00 value is displayed.

RESTORE FACTORY CALIBRATIONRESTORE FACTORY CALIBRATION

RESTORE FACTORY CALIBRATION

RESTORE FACTORY CALIBRATIONRESTORE FACTORY CALIBRATION

To restore the factory calibration for the currently

selected range, press CAL key when in the main

screen. The first screen for the GLP is displayed.

Press “Delete” functional key to initiate the

calibration delete procedure and then press “CFM”

functional key to delete the user calibration and

restore the Factory calibration.

Note: Only the user calibration for the current

selected range is deleted.

The HI 88713 Turbidity bench meter has a powerful log function that could store up to 200 records.

Each record contains:

the measuring mode,

•

•

the reading value,

•

the measuring unit,

•

the date and time of the measurement,

•

the current log number.

Notes: • The log can be saved only after a measurement is completed.

• A measurement can be saved only once.

LOG SAVE

To log a record, simply press LOG key after the

measurement is completed. A record number is

assigned to each logged measurement. Each

reading can be stored only once.

LOG RECALL

The log can be consulted at any time by simply

pressing RCL key.

To exit log consulting, press RCL key again.

The log content is displayed one record at a time,

starting with the most recent one.

The information

regarding one record is displayed in one screen.

To browse the log press the UP or DOWN key.

LOG DELETE

The last log or all logs can be deleted.

To delete the last log, simply press “Delete” functional key when the last log is displayed. The log

will be deleted and the next log is immediately displayed.

To delete all logs, press “DelAll” functional key. A

confirmation screen is displayed. Press “CFM”

functional key to confirm the action. The log will be

deleted and the instrument returns in the main screen.

Note: The records for all parameters are deleted

when this action is performed.

26 27

Page 15

SETUPSETUP

SETUP

SETUPSETUP

The instrument’s parameters can be changed in the Setup mode. Some parameters affect the measuring sequence

and others are general parameters that change the behaviour or appearence of the instrument.

The setup mode may be accessed from the main screen by pressing the SETUP key.

Press ESC or SETUP to return to the main screen.

A list of setup parameters will be displayed with currently

configured setting. Press HELP for aditional information.

Press the UP or DOWN key to select the parameter

and depending to the parameter type, select the

new value as follows.

Backlight

Values: 0 to 8.

Press “Modify” functional key to access the backlight value.

Use the “Right” or ”Left” functional key (alternatively,

the UP or DOWN key) to increase or decrease the

display backlight.

Press “Accept” functional key to confirm or ESC to return to

the setup menu without saving the new value.

Contrast

Values: 0 to 20.

This option is used to set the display’s contrast.

Press “Modify” functional key to change the display’s contrast.

Use the “Right” or ”Left” functional key (alternatively,

the UP or DOWN key) to increase or decrease the value.

Press “Accept“ functional key to confirm the value or ESC to

return to the setup menu without saving the new value.

Average

Option: Enabled or Disabled.

This option is used to enable/disable averaged measuring

mode. If enabled, the instrument takes 10 readings and

display the resulting average value

displayed during measurement.

Press the “Enable” functional key to enable or disable this

option.

. The partial average is

Date / Time

This option is used to set the instrument’s date and time.

Press “Modify” to change the date/time.

Press “Left” or ”Right” functional key to highlight the

value to be modified (year, month, day, hour, minute or

second). Use the UP or DOWN key to change the value.

Press “Accept” functional key to confirm the new value

or ESC to return to the setup without saving the new

time or date .

Time format

Option: AM/PM or 24 hours.

Press the “AM/PM” functional key to select the

new value.

Date format

Press “Modify” functional key to change the Date

Format.

Use the UP or DOWN key to select the desired format.

Press “Accept” functional key to confirm the value

or ESC to return to the setup menu without saving

the new format.

Language

Option: English, Italiano or Español

Press the corresponding function key to change the

option.

If the new selected language cannot be loaded,

the previously selected language will be reloaded.

Tutorial

Option: Enabled or Disabled.

This option is used to enable/disable tutorial mode.

If enabled this option will provide the user short

guides on the screen.

Press the “Enable” functional key to select this option.

28 29

Page 16

Beeper

Option: Enabled or Disabled.

This option is used to enable/disable the beeper.

Press the “Enable” functional key to enable or

disable this option.

When enabled, a short beep is heard every time a

key is pressed.

A long beep alert sounds when the pressed key is

not active or an error condition is detected.

Instrument ID

Option: 0 to 9999.

This option is used to set the instrument’s ID

(identification number). The instrument ID is used

while exchanging data with a PC.

Press “Modify” functional key to access the

instrument ID screen. Press the UP or DOWN key

in order to set the desired value. Press “Accept”

functional key to confirm the value or ESC to return

to the setup menu without saving the new value.

Meter information

Press “Select” functional key to view the Instrument

model, firmware version, language version and

instrument serial number.

Press ESC to return to the Setup mode.

ACCESSORIESACCESSORIES

ACCESSORIES

ACCESSORIESACCESSORIES

REAGENT SETS

HI 93703-58 Silicon oil (15 mL)

HI 88713-11 Calibration set for turbidimeter(<0.1, 15, 100 750 FNU and 2000 NTU)

OTHER ACCESSORIES

HI 731318 Tissue for wiping cuvetets (4 pcs.)

HI 731331 Glass cuvettes (4 pcs.)

HI 731335N Caps for cuvettes (4 pcs.)

HI 92000 Windows

HI 93703-50 Cuvettes cleaning solution (230 mL)

HI 88713 is warranted for two years against defects in workmanship and materials when used for

its intended purpose and maintained according to the instructions.

This warranty is limited to repair or replacement free of charge.

Damage due to accident, misuse, tampering or lack of prescribed maintenance is not covered.

If service is required, contact your dealer. If under warranty, report the model number, date of purchase,

serial number and the nature of the failure. If the repair is not covered by the warranty, you will be notified

of the charges incurred.

If the instrument is to be returned to Hanna Instruments, first obtain a Returned Goods Authorization

Number from the Customer Service Department and then send it with shipment costs prepaid. When

shipping any instrument, make sure it is properly packaged for complete protection.

To validate your warranty, fill out and return the enclosed warranty card within 14 days from the date of purchase.

®

compatible software

WARRANTYWARRANTY

WARRANTY

WARRANTYWARRANTY

PC INTERFACEPC INTERFACE

PC INTERFACE

PC INTERFACEPC INTERFACE

Log data download from the instrument to the PC can be done with the HI 92000 Windows compatible

software (optional). HI 92000 also offers graphing and on-line help features. Data can be exported to the

most popular spreadsheet programs for further analysis.

To connect your instrument to a PC, use a standard USB cable. Make sure that your instrument is switched

off. Plug one connector to the instrument’s USB socket and the other to the USB port of your PC.

Please reffer to the HI 92000 software to download the data from the instrument.

30 31

RECOMMENDATIONS FOR USERSRECOMMENDATIONS FOR USERS

RECOMMENDATIONS FOR USERS

RECOMMENDATIONS FOR USERSRECOMMENDATIONS FOR USERS

Before using this product, make sure that it is entirely suitable for your specific application and

for the environment in which it is used.

Operation of this instrument may cause unacceptable interferences to other electronic equipments,

requiring the user to follow all necessary steps to correct interferences.

Any variation introduced by the user to the supplied equipment may degrade the instrument’s

EMC performance.

To avoid damage or burns, do not put the instrument in microwave ovens. For your own and the

instrument safety do not use or store the instrument in hazardous environments.

Page 17

SALES AND TECHNICAL SERVICE CONTACTSSALES AND TECHNICAL SERVICE CONTACTS

SALES AND TECHNICAL SERVICE CONTACTS

SALES AND TECHNICAL SERVICE CONTACTSSALES AND TECHNICAL SERVICE CONTACTS

Australia:

Tel. (03) 9769.0666 • Fax (03) 9769.0699

China:

Tel. (10) 88570068 • Fax (10) 88570060

Egypt:

Tel. & Fax (02) 2758.683

Germany:

Tel. (07851) 9129-0 • Fax (07851) 9129-99

Greece:

Tel. (210) 823.5192 • Fax (210) 884.0210

Indonesia:

Tel. (210) 4584.2941 • Fax (210) 4584.2942

Japan:

Tel. (03) 3258.9565 • Fax (03) 3258.9567

Korea:

Tel. (02) 2278.5147 • Fax (02) 2264.1729

Malaysia:

Tel. (603) 5638.9940 • Fax (603) 5638.9829

Singapore:

Tel. 6296.7118 • Fax 6291.6906

South Africa:

Tel. (011) 615.6076 • Fax (011) 615.8582

Taiwan:

Tel. 886.2.2739.3014 • Fax 886.2.2739.2983

Thailand:

Tel. (662) 619.0708 • Fax (662) 619.0061

05/08

United Kingdom:

Tel. (01525) 850.855 • Fax (01525) 853.668

USA:

Tel. (401) 765.7500 • Fax (401) 765.7575

For e-mail contacts and a complete list of Sales and Technical offices, please see

www.hannainst.com

.

32

MAN88713

Loading...

Loading...