Page 1

Instruction Manual

HI 8819 - HI 8820

Bench Conductivity

Meters

HI 8819

O

N

S

tandard C

O

F

F

onductivity at 25

S

ta

ndard

C

O

N

H

D

I 7033

°C

C

TEM

P

onductivity

H

I 7031

H

90µS

I 7030

H

I 7034

12,880µS

80,000µS

199.9

1413µS

µS

1999

µS

19.99

mS

99.9

mS

TEM

PERA

TURE

HI 8820

O

N

S

tandard C

O

FF

o

nductivity at 25

S

tandard

H

I 70

°C

C

ondu

33

ctivity

H

I 7

031

9

0µS

H

I 7030

H

I 7

034

80,000µS

12,880µS

1

9

9

14

.

9

13

µS

µS

1

µS

1

9

.

9

9

m

S

9

9

.9

m

S

C

http://www.hannainst.com

9

9

9

1

1

.5

0

.5

2

0

2

.5

TE

M

P

E

R

A

O

T

U

E

R

FF

E

IC

IE

N

T

Compliance with the CE Directives

These Instruments are in

Page 2

Dear Customer,

Thank you for choosing a Hanna Instruments Product.

Please read this instruction manual carefully before using the instru-

ment.

This manual will provide you with all the necessary information for the

correct use of the instrument, as well as a precise idea of its versatility

in a wide range of applications.

These instruments are in compliance with CSA, UL and (EN

50081-1 and EN 50082-1) directives.

TABLE OF CONTENTSTABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

PRELIMINARY EXAMINATION ................................................................ 3

GENERAL DESCRIPTION ........................................................................ 3

KEYBOARD AND REAR PANEL ............................................................... 4

SPECIFICATIONS .................................................................................. 5

CONDUCTIVITY MEASUREMENTS ........................................................... 6

CALIBRATION ....................................................................................... 8

CONDUCTIVITY VS. TEMPERATURE CHART ........................................... 12

TEMPERATURE COMPENSATION .......................................................... 13

DETERMINATION OF THE TEMPERATURE

COEFFICIENT OF A SOLUTION (FOR HI8820 ONLY) .............................. 14

PROBE MAINTENANCE ....................................................................... 15

ACCESSORIES .................................................................................... 16

WARRANTY ........................................................................................ 18

CE DECLARATION OF CONFORMITY...................................................... 19

ISO 9000 Certified

Company since 1992

2

Page 3

PRELIMINARY EXAMINATIONPRELIMINARY EXAMINATION

PRELIMINARY EXAMINATION

PRELIMINARY EXAMINATIONPRELIMINARY EXAMINATION

Remove the instrument from the packing material and examine it to

make sure that no damage has occurred during shipping. If there is

any damage, notify your Dealer.

Each meter comes supplied with a conductivity probe (HI7685 for

HI8819 or HI7687 for HI8820), a voltage adapter, a dust cover and

an instruction manual.

::

Note

: Save all packing material until you are sure that the instrument

::

functions correctly. All defective items must be returned in the

original packing with the supplied accessories.

GENERAL DESCRIPTIONGENERAL DESCRIPTION

GENERAL DESCRIPTION

GENERAL DESCRIPTIONGENERAL DESCRIPTION

HI8819 and HI8820 are digital bench-top multirange conductivity

meters designed for simplicity of use in measuring electrical conductivity in liquids. Four ranges of conductivity measurements are provided

to cover every application from deionized water to brine. The conductivity probe does not require changing or re-calibration when switching

from one range to another.

The probe is made of glass with 4 platinum rings that are corrosion

resistant. It is also suitable for measuring conductivity of liquids in

small sample sizes, and comes with a 1 m (3.3') cable.

The temperature effect can be compensated through a knob on the

front panel of HI8819.

With HI8820, the 4-ring probe has a built-in temperature sensor that

automatically compensates for temperature changes in the liquid

tested. The temperature coefficient can be adjusted from 0 to 2.5%.

3

Page 4

KEYBOARD & REAR PANELKEYBOARD & REAR PANEL

KEYBOARD & REAR PANEL

KEYBOARD & REAR PANELKEYBOARD & REAR PANEL

KEYBOARD:

ON/OFF To switch the instrument ON or OFF

COND/TEMP To select the display of conductivity readings or tem-

perature settings for compensation (for HI8819 only)

199.9 µS To select the range 0.0 to 199.9µS/cm

1999 µS To select the range 0 to 1999µS/cm

19.99 mS To select the range 0.00 to 19.99 mS/cm

99.9 mS To select the range 0.0 to 99.9mS/cm

TEMPERATURE Knob: To manually set to the temperature compen-

sation of the reading (for HI8819 only)

TEMPERATURE COEFFICIENT knob: To set the temperature coeffi-

cient from 0% to 2.5% per °C (for HI8820 only).

Standard Conductivity at 25°C

ON

Standard

OFF

COND

TEMP

HI 7033

HI 7031

HI 7030

HI 7034

Keyboard of HI 8819

Conductivity

84 µS

1413 µS

12,880 µS

80,000 µS

199.9

19.99

1999

µS

µS

99.9

TEMPERATURE

mS

mS

ON

OFF

Standard Conductivity at 25°C

Conductivity

Standard

HI 7033

HI 7031

HI 7030

HI 7034

84 µS

1413 µS

12,880 µS

80,000 µS

199.9

19.99

mS

1999

µS

µS

99.9

mS

1.5

1

0.5

0

TEMPERATURE

COEFFICIENT

Keyboard of HI 8820

REAR PANEL:

1) Probe Connection

Connect the conductivity probe to the DIN socket.

2) Calibration Trimmer

3) DC Power Socket

CONDUCTIVITY

ELECTRODE

123

Power connection

Plug the 12VDC adapter (HI710005 or HI710006) into the DC socket.

Note: Make sure the main line is protected by a fuse.

CAL. DC POWER

12V to 20V

4

+

2

2.5

Page 5

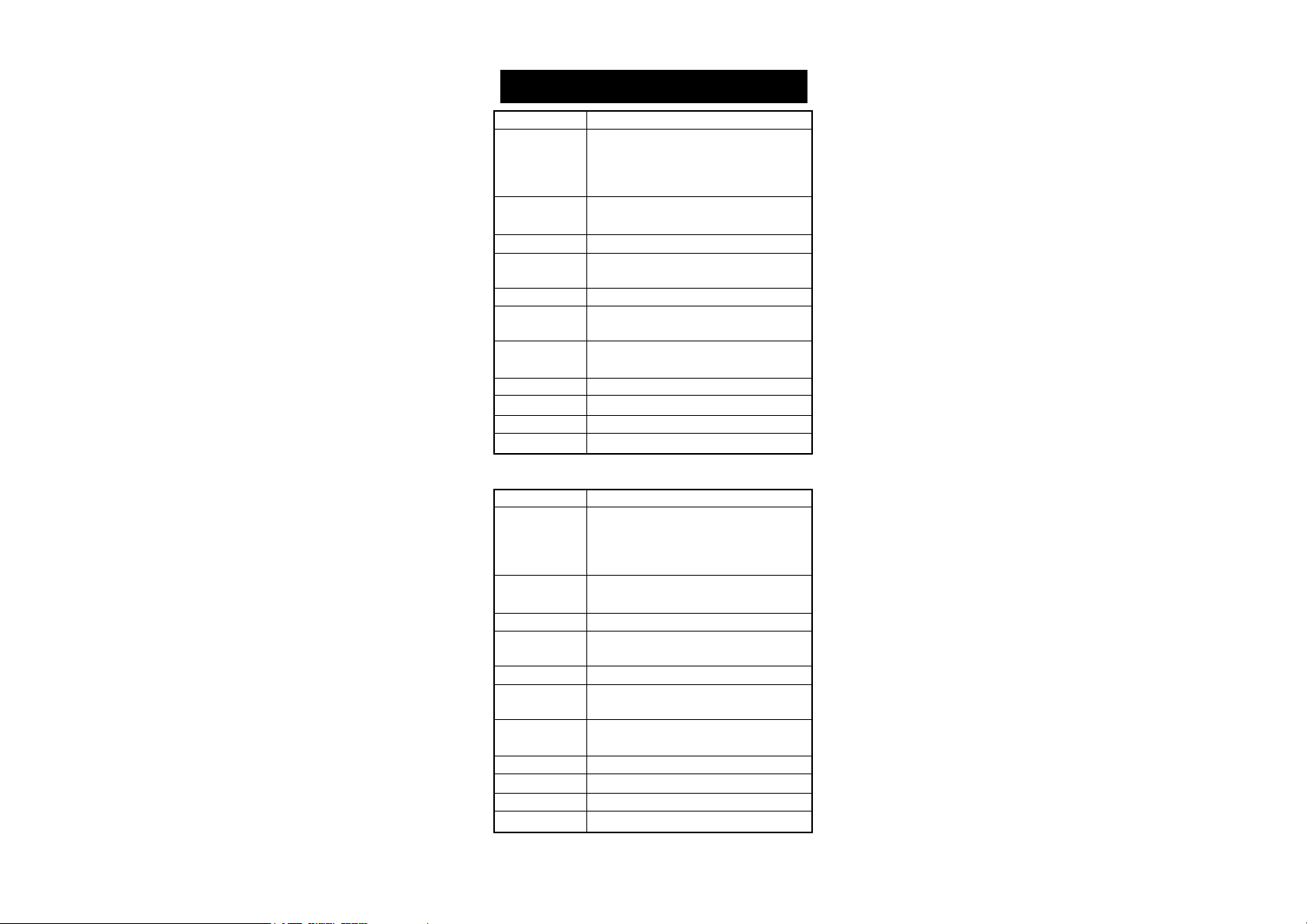

SPECIFICATIONSSPECIFICATIONS

SPECIFICATIONS

SPECIFICATIONSSPECIFICATIONS

HI8819

Range 0.0 to 199.9 µS/cm

0 to 1999 µS/cm

0.00 to 19.99 mS/cm

0.0 to 99.9 mS/cm

Resolution 0.1 µS/cm; 1 µS/cm

0.01 mS/cm; 0.1 mS/cm

Accuracy ±1% Full Scale excluding probe error

Typical EMC ±1% Full Scale

Deviation

Calibration Manual single point through trimmer

Temperature Manual from 0 to 50°C (32to 122°F)

Compensation with ß at 2%/°C

Probe HI 7685 platinum 4-ring conductivity probe

with 1 m (3.3') cable (included)

Power Supply 12VDC through HI710005 or HI710006 (included)

Environment 0 to 50°C (32 to 122°F); 95% RH

Dimensions 230x 170x 70mm (9.1 x 6.7 x 2.7")

Weight 1 Kg (2.2 lbs)

HI8820

Range 0.0 to 199.9 µS/cm

0 to 1999 µS/cm

0.00 to 19.99 mS/cm

0.0 to 99.9 mS/cm

Resolution 0.1 µS/cm; 1 µS/cm

0.01 mS/cm; 0.1 mS/cm

Accuracy ±1% Full Scale excluding probe error

Typical EMC ±2% Full Scale

Deviation

Calibration Manual single point through trimmer

Temperature Automatic from 0 to 50°C (32to 122°F)

Compensation with a variable ß from 0 to 2.5%/°C

Probe HI 7687 platinum 4-ring conductivity probe

with 1 m (3.3') cable (included)

Power Supply 12VDC through HI710005 or HI710006 (included)

Environment 0 to 50°C (32 to 122°F); 95% RH

Dimensions 230x 170x 70mm (9.1 x 6.7 x 2.7")

Weight 1 Kg (2.2 lbs)

5

Page 6

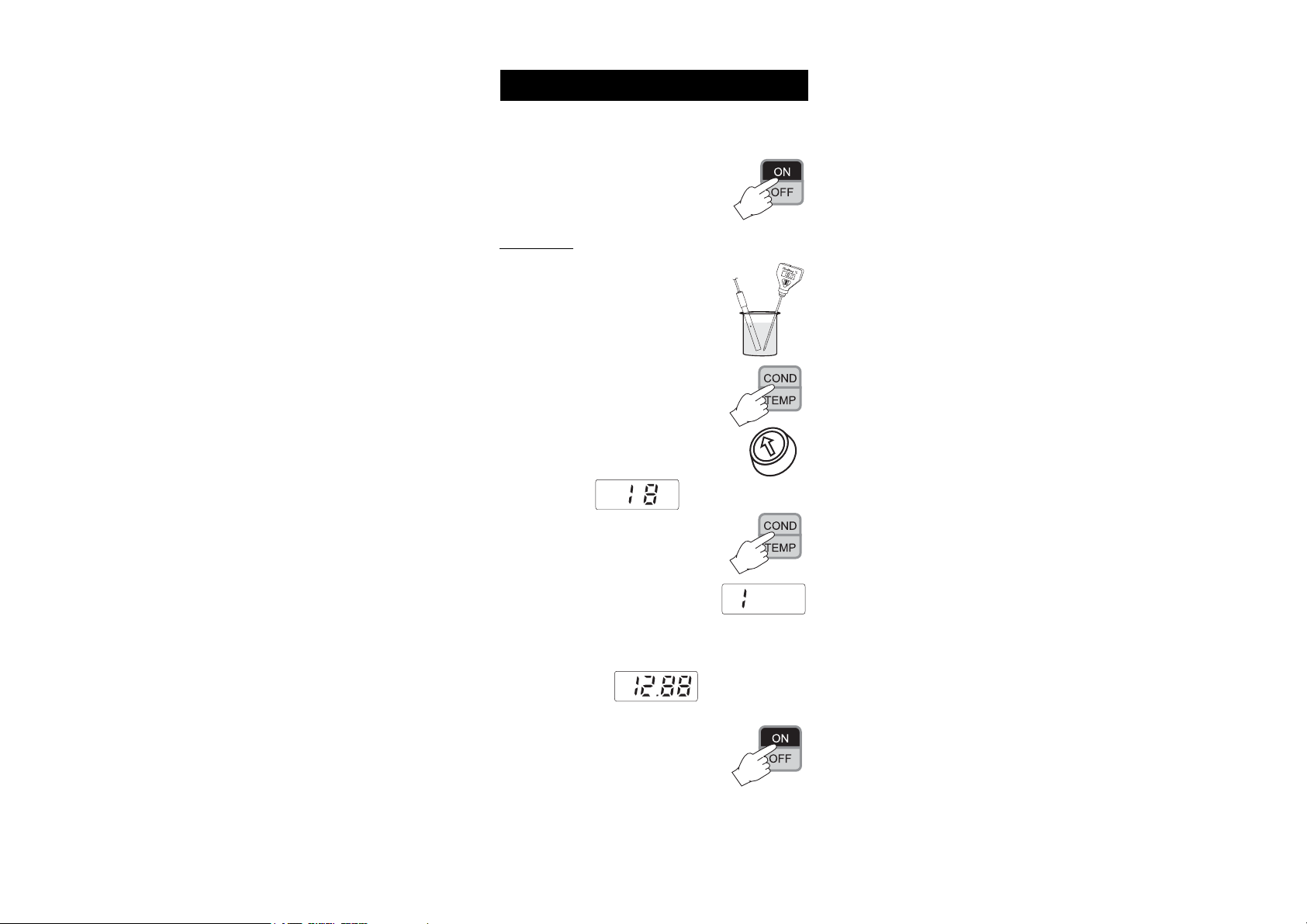

CONDUCTIVITY MEASUREMENTSCONDUCTIVITY MEASUREMENTS

CONDUCTIVITY MEASUREMENTS

CONDUCTIVITY MEASUREMENTSCONDUCTIVITY MEASUREMENTS

Make sure that the instrument has been calibrated before taking

conductivity measurements (see page 8 for calibration procedure).

Connect the probe to the back of the meter and

switch the instrument on by pressing the ON/OFF

key. If possible, to minimize any EMC interferences, use plastic beakers for the solutions.

FOR HI8819:

••

• Immerse the probe in the solution submerging

••

the holes of the sleeve (0.5 cm below). Tap

the probe lightly on the bottom of the recipient to remove any air bubbles which may

have being trapped inside the sleeve.

••

• Take the temperature of the solution with a

••

CHECKTEMP or a glass thermometer.

••

• Press the COND/TEMP key to select tempera-

••

ture mode.

••

• Adjust the TEMPERATURE knob until the LCD

••

displays the temperature of the solution.

°C

••

• Press the COND/TEMP key to select the con-

••

TEMPERATURE

ductivity measurement range.

••

• If the display shows only a "1", there is an

••

over-range condition. Select the next higher

range.

••

• The conductivity reading displayed has been manually compen-

••

sated for temperature variations.

mS

••

• After the measurement is completed, the in-

••

strument should be switched off by pressing

the ON/OFF key and the probe should be

cleaned (see page 15 for cleaning procedure).

6

Page 7

FOR HI8820:

••

• Immerse the probe in the solution submerging

••

the holes of the sleeve (0.5 cm below). Tap

the probe lightly on the bottom of the recipient

to remove any air bubbles which may have

being trapped inside the sleeve.

••

• If the display shows only a "1", there is an

••

over-range condition. Select the next higher

range.

••

• Adjust the "TEMPERATURE COEFFICIENT" knob

••

to the value of the solution. See page 15 for

the procedure to select the correct coefficient

value.

••

• Before taking any measurement allow a few minutes for the

••

reading to stabilize. As soon as the thermal equilibrium is reached

(3 or 4 minutes) the reading stops drifting.

• The conductivity reading displayed has been automatically com-

pensated for temperature variations (after 2 or 3 minutes).

••

• After the measurement is completed, the in-

••

strument should be switched off by pressing

the ON/OFF key and the probe should be

cleaned (see page 15 for cleaning procedure).

0

2

0.5

1.51

TEMPERATURE COEFFICIENT

7

Page 8

CALIBRATIONCALIBRATION

CALIBRATION

CALIBRATIONCALIBRATION

INITIAL PREPARATION

If you are measuring in the mS ranges, calibrate the meter using

HI7030 (or HI8030) conductivity solution (12.88 mS @ 25°C) or

HI7034 (or HI8034) conductivity solution (80 mS @ 25°C). Choose

a solution with a conductivity value close to the solution to be

measured. For the µS ranges, use HI7031 (or HI8031) conductivity

solution (1413 µS @25°C) when calibrating in the range from 0 to

1999 µS or HI7033 (or HI8033) conductivity solution (84 µS @

25°C) when calibrating in the range from 0 to 199.9 µS.

Rinse the probe thoroughly in distilled water. This is to minimize

contamination of the calibration solution and secure higher accuracy.

When possible, use plastic beakers to minimize any EMC interferences.

PROCEDURE FOR HI8819:

• Pour a small quantity of the conductivity so-

lution into a plastic beaker e.g. HI7030 or

HI8030 (12.88 mS/cm @ 25°C).

• Immerse the conductivity probe in the solu-

tion submerging the holes of the sleeve (0.5cm

below). Make sure that no air bubbles are

trapped inside the glass sleeve. Wait for 2 or

3 minutes for the thermal equilibrium.

• Use a CHECKTEMP or a glass thermometer

with resolution of 1° for measuring the

temperature of the solution (e.g. 18°C).

• Switch the instrument on by pressing the ON/

OFF key.

• Press COND/TEMP key to display temperature

settings.

• Adjust the TEMPERATURE knob to display

"25°C" if you are using 25°C (77°F) as reference temperature.

°C

HI 7030

TEMPERATURE

8

Page 9

• Press the COND/TEMP key to display conduc-

tivity readings and select the appropriate

conductivity range

e.g. "19.99 mS" for HI7030/HI8030,

"99.9 mS" for HI7034/HI8034,

"1999µS" for HI7031/HI8031,

"199.9 µS" for HI7033/HI8033.

• Using a small screwdriver adjust the trimmer on the rear panel

until the display shows the conductivity reading at the temperature of the solution noted earlier (see the

conductivity vs. temperature chart on page

mS

13) e.g. "11.19 mS".

CONDUCTIVITY

ELECTRODE

CAL DC POWER

12V to 20V

+

Calibration is now completed and the instrument is ready for use.

TO CHECK THE CALIBRATION

• Press the COND/TEMP key to display the tem-

perature.

• Adjust the TEMPERATURE knob to display the

temperature of the calibration solution, i.e.

the temperature noted with the CHECKTEMP

or glass thermometer.

9

TEMPERATURE

Page 10

• Press the COND/TEMP key to display conduc-

HI 7030

tivity.

• The display should read the conductivity of the

calibrating solution at the reference temperature.

E.g. using HI7030/HI8030 with a solution at 18°C, the reading will be

"12.88 mS".

PROCEDURE FOR HI8820:

• Pour a small quantity of the conductivity solu-

tion into a plastic beaker.

• Immerse the conductivity probe in the solution sub-

merging the holes of the sleeve (0.5 cm below).

Make sure that no air bubbles are trapped inside

the glass sleeve. Wait for 2 or 3 minutes for thermal

equilibrium.

• Switch the instrument on by pressing the ON/OFF

key.

• Select the appropriate conductivity range

e.g. "19.99 mS" for HI7030/HI8030,

"99.9 mS" for HI7034/HI8034,

"1999µS" for HI7031/HI8031,

"199.9 µS" for HI7033/HI8033.

• Set the temperature coefficient knob to

2%°C.

10

1.5

1

0.5

0

TEMPERATURE

COEFFICIENT

2

2.5

Page 11

• Using a small screwdriver adjust the trimmer on the rear panel

until the display shows the conductivity reading at 25°C (77°F),

e.g.: "12.88 mS" for HI7030/HI8030,

"80.00 mS" for HI7034/HI8034,

"1413 µS" for HI7031/HI8031,

"84 µS" for HI7033/HI8033.

CONDUCTIVITY

ELECTRODE

CAL DC POWER

12V to 20V

+

If you are using a different reference temperature, refer to the

conductivity vs temperature charts on page 12 for the appropriate

conductivity reading at the reference temperature.

E.g. If you prefer to standardize the temperature to 20°C (68°F)

rather than 25°C (77°F), using HI7030/HI8030, adjust the trimmer to read "11.67 mS" i.e.11670 µS (as indicated on the chart

on page 12). All subsequent measurements will be compensated

to 20° (68°F).

The calibration is now complete.

Note: The instrument should be calibrated weekly or every time the

probe has been changed.

11

Page 12

CONDUCTIVITY VERSUSCONDUCTIVITY VERSUS

CONDUCTIVITY VERSUS

CONDUCTIVITY VERSUSCONDUCTIVITY VERSUS

TEMPERATURE CHARTTEMPERATURE CHART

TEMPERATURE CHART

TEMPERATURE CHARTTEMPERATURE CHART

The conductivity of an aqueous solution is the measure of its ability to

carry an electrical current by means of ionic motion.

The conductivity invariably increases with increasing temperature.

It is affected by the type and number of ions in the solution and by

the viscosity of the solution itself. Both parameters are temperature

dependent. The dependency of conductivity on temperature is expressed as a relative change per degree Celsius at a particular

temperature, commonly as percent per °C.

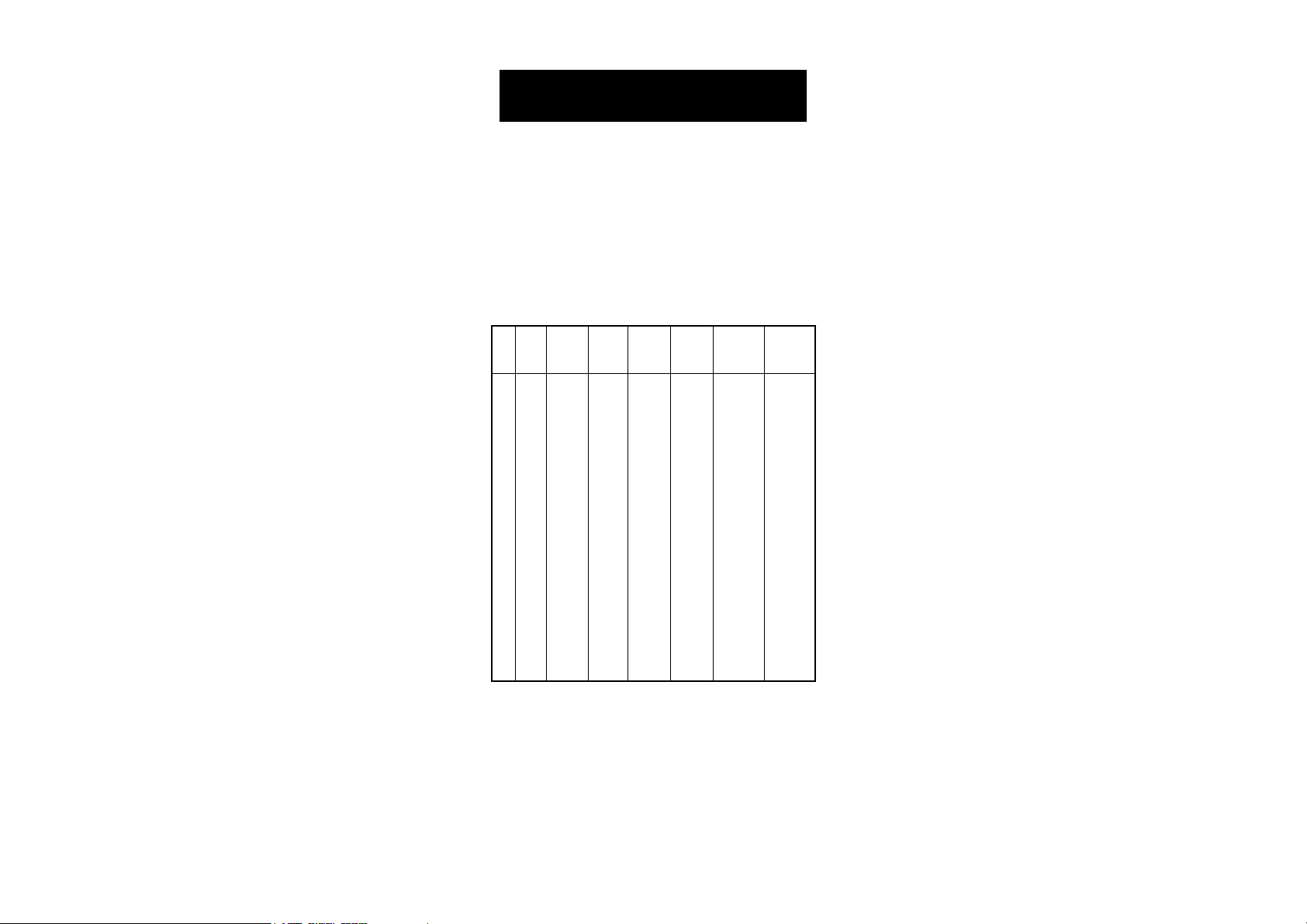

°C °F HI 7030 HI 7031 HI 7033 HI 7034 HI 7035 HI 7039

0 32 7150 776 64 48300 65400 2760

5 41 8220 896 65 53500 74100 3180

10 50 9330 1020 67 59600 83200 3615

15 59 10480 1147 68 65400 92500 4063

16 60.8 10720 1173 70 67200 94400 4155

17 62.6 10950 1199 71 68500 96300 4245

18 64.4 11190 1225 73 69800 98200 4337

19 66.2 11430 1251 74 71300 100200 4429

20 68 11670 1278 76 72400 102100 4523

21 69.8 11910 1305 78 74000 104000 4617

22 71.6 12150 1332 79 75200 105900 4711

23 73.4 12390 1359 81 76500 107900 4805

24 75.2 12640 1386 82 78300 109800 4902

25 77 12880 1413 84 80000 111800 5000

26 78.8 13130 1440 86 81300 113800 5096

27 80.6 13370 1467 87 83000 115700 5190

28 82.4 13620 1494 89 84900 117700 5286

29 84.2 13870 1521 90 86300 119700 5383

30 86 14120 1548 92 88200 121800 5479

31 87.8 14370 1575 94 90000 123900 5575

HI 8030 HI 8031 HI 8033 HI 8034 HI 8035 HI 8039

(µS/cm) (µS/cm) (µS/cm) (µS/cm) (µS/cm) (µS/cm)

E.g.: If you are calibrating HI8819 using HI7030/HI8030 (12880

mS/cm @ 25°C) as buffer solution and the solution temperature is 18°C, set the temperature reference to 25°C and turn the

trimmer to display "11.19 mS".

12

Page 13

TEMPERATURE COMPENSATIONTEMPERATURE COMPENSATION

TEMPERATURE COMPENSATION

TEMPERATURE COMPENSATIONTEMPERATURE COMPENSATION

The conductivity of an aqueous solution is the measure of its ability to

carry an electrical current by means of ionic motion. The conductivity

invariably increases with increasing temperature. It is affected by the

type and number of ions in the solution and by the viscosity of the

solution itself. Both parameters are temperature dependent. The dependency of conductivity on temperature is expressed as a relative

change per degree Celsius at a particular temperature, commonly as

percent/°C. Acids, alkalis and concentrated salt solutions have lower

values, typically 1.5%/°C. Since a small difference in temperature

causes a large change in conductivity readings particularly at high

and low temperatures, the readings are usually normalized at 25°C.

The HI8819 manually compensates for temperature differences with a

fixed ß at 2%.

The HI8820 automatically compensates for temperature differences

with a built-in NTC sensor circuitry. A knob is also provided to adjust

the temperature coefficient manually from 0% (without compensation) to 2.5% per degree Celsius.

13

Page 14

DETERMINATIONDETERMINATION

DETERMINATION

DETERMINATIONDETERMINATION

COEFFICIENT OF A SOLUTIONCOEFFICIENT OF A SOLUTION

COEFFICIENT OF A SOLUTION

COEFFICIENT OF A SOLUTIONCOEFFICIENT OF A SOLUTION

(for HI8820 only)(for HI8820 only)

(for HI8820 only)

(for HI8820 only)(for HI8820 only)

Follow the procedure described below:

1) Immerse the probe into a sample of the solution and adjust the knob to 0% (i.e. no

compensation).

2) Condition the sample and probe at 25°C

and note the conductivity reading C25.

3) Condition the sample and probe to a temperature t°C which is approximately 5°C to

10°C different from 25°C and note the conductivity reading Ct.

4) The temperature coefficient ß of the solution is calculated with

the formula:

(Ct - C25)

ß = 100 x ---------------------------

(t - 25) x C25

The above procedure is suitable for determining the temperature

coefficient in the laboratory where the temperature of the solution

can be determined and controlled. If this is not possible e.g.

during on-site measurements, the following procedure should be

used:

a) Immerse the probe into the test solution and turn the temperature

coefficient knob to 0% (no compensation).

b) Allow the conductivity reading to stabilize (the reading should not

change by more than ±0.2 mS within 1 minute) and record the

value, C.

c) Repeat the procedure with the temperature of the solution changed

by more than 10°C. Wait for the conductivity reading to stabilize.

d) Adjust the temperature coefficient knob until the display reads the

value C as recorded earlier (point b).

e) The value indicated by the knob is the temperature coefficient of

the solution.

OFOF

OF

OFOF

THETHE

TEMPERATURETEMPERATURE

THE

TEMPERATURE

THETHE

TEMPERATURETEMPERATURE

0

2

0.5

1.51

TEMPERATURE COEFFICIENT

14

Page 15

PROBE MAINTENANCEPROBE MAINTENANCE

PROBE MAINTENANCE

PROBE MAINTENANCEPROBE MAINTENANCE

Rinse the probe with tap water after

every series of measurements. If a

more thorough cleaning is required,

remove the glass sleeve and clean

the probe with a cloth or a nonabrasive detergent.

After cleaning the probe, re-calibrate

the instrument.

The four ring platinum probe body

and sleeve are in glass. For this

reason great care while handling the

probe must be taken.

15

Page 16

ACCESSORIESACCESSORIES

ACCESSORIES

ACCESSORIESACCESSORIES

CONDUCTIVITY BUFFER SOLUTIONS:

HI 7030L 12880 µS/cm (µmho/cm), 460mL

HI 7030M 12880 µS/cm (µmho/cm), 230mL

HI 7031L 1413 µS/cm (µmho/cm), 460mL

HI 7031M 1413 µS/cm (µmho/cm), 230mL

HI 7033L 84 µS/cm (µmho/cm), 460 mL

HI 7033M 84 µS/cm (µmho/cm), 230 mL

HI 7034L 80000 µS/cm (µmho/cm), 460mL

HI 7034M 80000 µS/cm (µmho/cm), 230mL

HI 7035L 111800 µS/cm (µmho/cm), 460mL

HI 7035M 111800 µS/cm (µmho/cm), 230mL

HI 7039L 5000 µS/cm (µmho/cm), 460mL

HI 7039M 5000 µS/cm (µmho/cm), 230mL

CONDUCTIVITY BUFFER SOLUTIONS IN FDA APPROVED BOTTLES:

HI 8030L 12880 µS/cm (µmho/cm), 460 mL

HI 8031L 1413 µS/cm (µmho/cm), 460 mL

HI 8033L 84 µS/cm (µmho/cm), 460 mL

HI 8034L 80000 µS/cm (µmho/cm), 460 mL

HI 8035L 111800 µS/cm (µmho/cm), 460 mL

HI 8039L 5000 µS/cm (µmho/cm), 460 mL

CONDUCTIVITY PROBES:

HI 7685 This probe for HI8819 uses the 4-ring method

measure conductivity. The probe cable is 1m

(3.3') long.

HI 7687 This probe for HI 8820 uses the 4-ring method

and has a built-in temperature sensor for ATC.

The probe screened cable is 1m (3.3') long.

16

Page 17

OTHER ACCESSORIES:

CHECKTEMPC Electronic thermometer (range: -50.0 to 150.0°C)

HI710005 Voltage adapter from 115VAC to 12VDC

HI710006 Voltage adapter from 230VAC to 12VDC

HI 731326 Small screwdrivers, length 90 mm, for calibration

purposes (20 pcs)

HI 76405 Electrode holder

MANBNCONR2 Instruction Manual

17

Page 18

WARRANTYWARRANTY

WARRANTY

WARRANTYWARRANTY

All Hanna Instruments meters are guaranteed for two years against

defects in workmanship and materials when used for their intended

purpose and maintained according to instructions. The electrodes

and the probes are guaranteed for a period of six months. This

warranty is limited to repair or replacement free of charge.

Damage due to accident, misuse, tampering or lack of prescribed

maintenance are not covered.

If service is required, contact the dealer from whom you purchased the

instrument. If under warranty, report the model number, date of

purchase, serial number and the nature of the failure. If the repair is

not covered by the warranty, you will be notified of the charges

incurred. If the instrument is to be returned to Hanna Instruments, first

obtain a Returned Goods Authorization number from the Customer

Service department and then send it with shipping costs prepaid.

When shipping any instrument, make sure it is properly packaged for

complete protection.

To validate your warranty, fill out and return the enclosed warranty

card within 14 days from the date of purchase.

All rights are reserved. Reproduction in whole or in part is prohibited

without the written consent of the copyright owner,

Hanna Instruments Inc., 584 Park East Drive, Woonsocket, Rhode

Island, 02895 , USA.

Hanna Instruments reserves the right to modify the design, construction and appearance of its products without advance notice.

18

Page 19

CE DECLARATION OF CONFORMITYCE DECLARATION OF CONFORMITY

CE DECLARATION OF CONFORMITY

CE DECLARATION OF CONFORMITYCE DECLARATION OF CONFORMITY

Recommendations for Users

Before using these products, make sure that they are entirely suitable for the environment in which they are used.

Operation of these instruments in residential area could cause unacceptable interferences to radio and TV equipments, requiring the operator to take all necessary steps to

correct interferences.

The metal band at the end of the sensor is sensitive to electrostatic discharges. Avoid

touching this metal band at all times.

During calibration of instruments, ESD wrist straps should be worn to avoid possible

damage to the sensor by electrostatic discharge.

Any variation introduced by the user to the supplied equipment may degrade the

instruments' EMC performance.

To avoid electrical shock, do not use these instruments when voltages at the measurement surface exceed 24VAC or 60VDC.

Use plastic beakers to minimize any EMC interferences.

To avoid damages or burns, do not perform any measurement in microwave ovens.

19

Page 20

http://www.hannainst.com

PRINTED IN PORTUGAL

MANBNCONR2 01/99

Loading...

Loading...