Page 1

Instruction Manual

HI 8614 - HI 8614L

HI8615 - HI8615L

pH and ORP

Transmitters

pH

HI8614L

pH INDICATOR

& TRANSMITTER

These Instruments are in Compliance with the CE Directives

http://www.hannainst.com

1

Page 2

Dear Customer,

Thank you for choosing a Hanna Instruments

Product.

Please read this instruction manual carefully

before using the instrument.

This manual will provide you with all the neces-

sary information for the correct use of the

instrument, as well as a precise idea of its

versatility in a wide range of applications.

These instruments are in compliance with the

directives.

TABLE OF CONTENTS

Preliminary Examination............................ 3

General Description ................................... 3

Specifications of HI8614 & HI 8614L ........ 5

Specifications of HI 8615 & HI8615L ........ 6

Terminal Board Connections ..................... 7

pH Calibration with Automatic Temperature

Compensation (HI8614 & HI8614L) .......... 9

pH Calibration with Manual Temperature

Compensation (HI8614 & HI8614L)....... 13

ORP Calibration (HI8615 & HI8615L) .... 14

Electrode Conditioning and Maintenance . . 19

Temperature-Resistance Correlation for

HANNA pH Sensitive Glass .................... 23

Installation Procedure and Examples ...... 25

Accessories .............................................. 28

Warranty .................................................. 34

CE Declaration of Conformity ................. 35

2

Page 3

PRELIMINARY EXAMINATION

Remove the instrument from the packing

material and examine it carefully to make

sure that no damage has occurred during

shipping. If there is any noticeable damage,

notify your Dealer.

Note: Save all packing material until you

are sure that the instrument functions

correctly. All defective items must be

returned in the original packing material together with the supplied accessories.

GENERAL DESCRIPTION

HI 8614 - HI 8614L (pH) and HI 8615 HI 8615L (ORP) are 2-wire water-resistant

transmitters designed specially for long distance measurement of pH or ORP for use in

industrial applications.

Two versions are available: the standard

HI8614 or HI8615 and HI8614L or HI8615L

with an LCD.

The LCD versions allow easy verification

and monitoring of measured values and are

easier to calibrate and maintain.

The pH or ORP signal is transmitted in a 2wire current loop in the range of 4 to 20 mA.

HI8614 and HI8614L can be connected to

Hanna process instruments HI 8510T,

HI8710T or HI 8711T, recorders, computers

or any data monitoring device that accepts

4 to 20 mA input.

HI8615 and HI8615L can be connected to

Hanna meters HI8512T, HI8720T or any

recorders, computers or data monitor that

accepts 4 to 20 mA input.

3

Page 4

The transmitters use a universal BNC socket

for quick and secure connection to any electrode with a BNC connector.

For HI8614 - HI8614L: temperature compensation is performed by the transmitter's

ATC circuitry when measurements are taken

with the temperature probe attached

(HI76608, optional); it is also possible to

substitute the temperature probe with a fixed

resistor if ATC is not required.

The input is isolated from the current loop

to eliminate problems related to ground loop,

low insulation cables, multiple electrode connections, and a common mode voltage of

up to 100V ensures true differential readings.

A terminal board in the transmitter provides

for connection of power supply, pH or ORP

electrodes (and temperature probe for

HI8614 & HI 8614L).

The unit is enclosed in a protective casing

conforming to IP65 standards.

4

Page 5

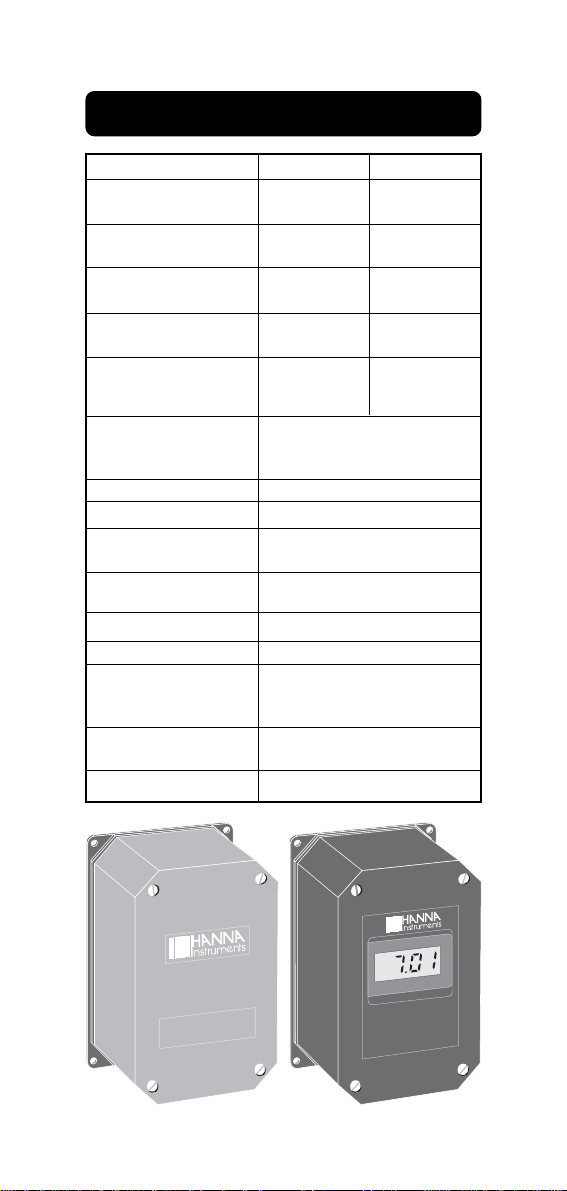

SPECIFICATIONS OF HI 8614 & HI 8614L

RANGE pH

mA

RESOLUTION pH

mA

ACCURACY pH

@20°C/68°F mA

TYPICAL EMC pH

DEVIATION mA

CALIBRATION Offset:

Slope:

TEMPERATURE

COMPENSATION

INPUT IMPEDANCE

OUTPUT

INSTALLATION

CATEGORY

POWER

LOAD

PROTECTION

ENVIRONMENT

TEMP.

RH

DIMENSIONS

WEIGHT

HI8614

----

4 to 20

----

0.01

----

±0.02

----

±0.25

±2.2 mA

±0.5 mA

HI8614L

0.00 to 14.00

4 to 20

0.01

0.01

±0.02

±0.02

±0.2

±0.25

±2.2 mA/±2 pH

±0.5 mA

86 to 116%

Fixed/automatic 0 to 100°C

(32 to 212°F) with HI76608

temp. probe (optional)

1012 ohm

4 to 20 mA isolated

II

without LCD: 18 to 30VDC

with LCD 20 to 36VDC

Max. 500 ohms

IP 65

0 to 50°C (32 to 122°F)

0-95% (non-condensing)

165 x 110 x 90 mm (L x W x H)

(6.5 x 4.3 x 3.5")

1 Kg (2.2 lb.)

HI8614

pH TRANSMITTER

pH

HI8614 L

pH INDICATOR

& TRANSMITTER

5

Page 6

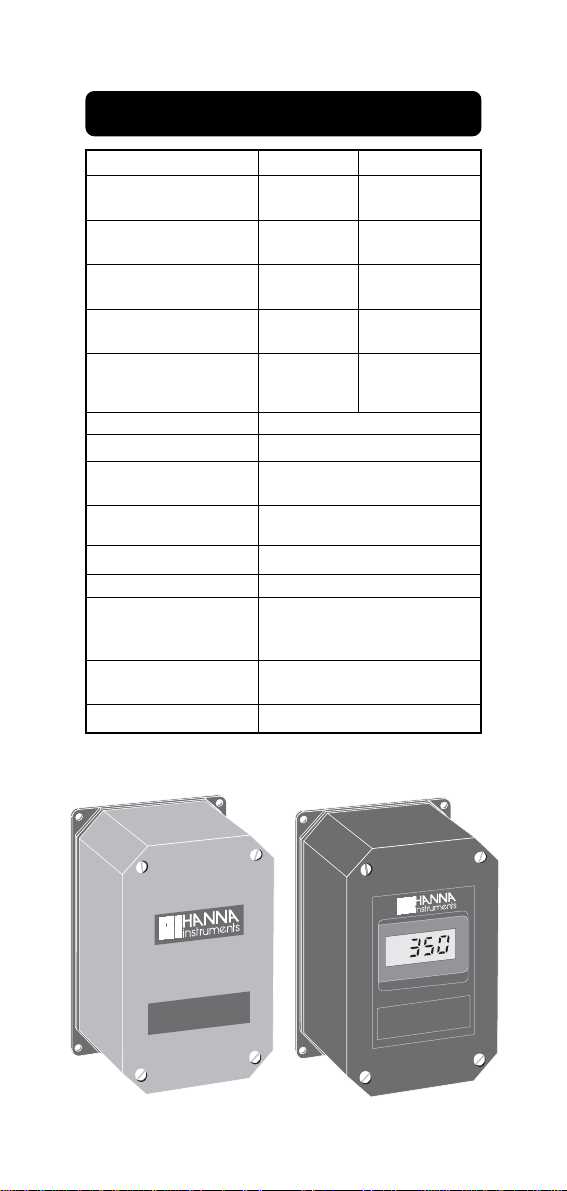

SPECIFICATIONS OF HI8615 & HI8615L

RANGE mV

mA

RESOLUTION mV

mA

ACCURACY mV

@20°C/68°F mA

TYPICAL EMC mV

DEVIATION mA

CALIBRATION Offset:

Slope:

INPUT IMPEDANCE

OUTPUT

INSTALLATION

CATEGORY

POWER

LOAD

PROTECTION

ENVIRONMENT

TEMP.

RH

DIMENSIONS

WEIGHT

HI8615

----

4 to 20

----

0.01

----

±0.02

----

±0.25

±0.8 mA

±0.8 mA

HI8615L

0 to ±1000

4 to 20

1

0.01

±5

±0.02

±15

±0.25

±0.8 mA/±100mV

±0.8 mA

90 to 110%

1012 ohm

4 to 20 mA isolated

II

without LCD: 18 to 30VDC

with LCD 20 to 36VDC

Max. 500 ohms

IP 65

0 to 50°C (32 to 122°F)

0-95% (non-condensing)

165 x 110 x 90 mm (L x W x H)

(6.5 x 4.3 x 3.5")

1 Kg (2.2 lb.)

HI 8615

ORP TRANSMITTER

mV

HI 8615

ORP TRANSMITTER

6

Page 7

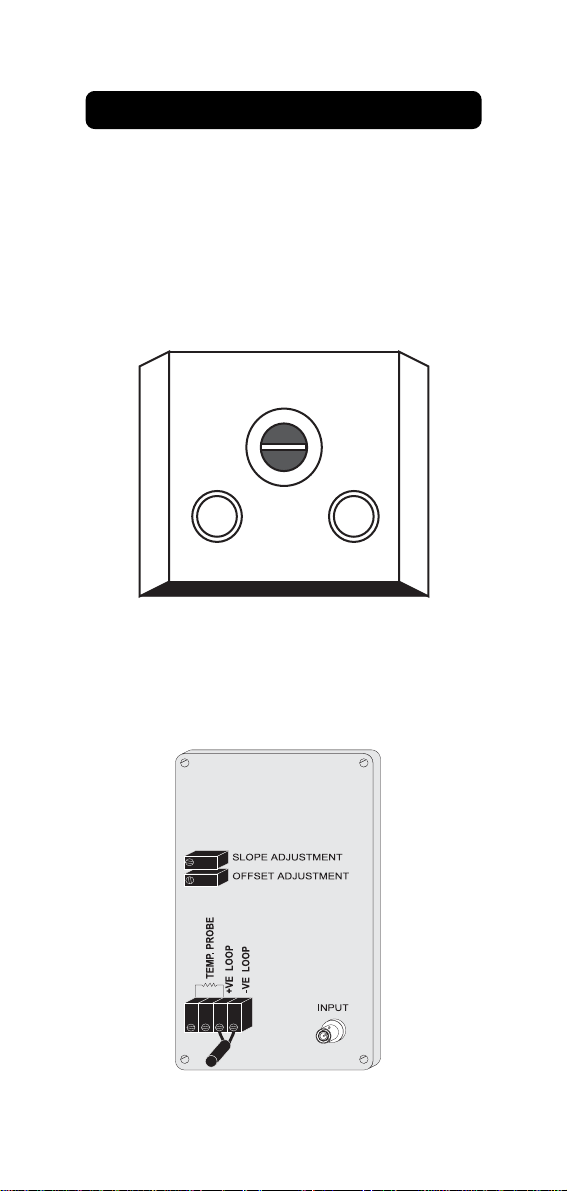

TERMINAL BOARD CONNECTIONS

Remove the 4 screws and take the top cover

off.

There are three cable glands on the cover of

the transmitter: two smaller ones and a large

one. The large cable gland with the split in the

rubber is for the electrode.

ELECTRODE

CABLE GLAND

WIRE CABLE GLANDS

Connect the positive supply to the strip terminal "+VE LOOP" and the negative supply to

the terminal "-VE LOOP" of the transmitter

terminal block.

7

Page 8

The wire between the transmitter and the

recorder/indicator/controller should be a PVC

insulated two wire with a wire diameter of at

least 0.7 mm. This wire is fed through one

of the smaller cable glands. The maximum

distance between the power supply and the

amplifier is 300 m (1000'). It is not necessary to use shielded cable. The transmitter

is protected against inversion of supply voltage.

Electrode connection: connect the BNC of the cable to the

BNC socket on the transmitter.

For HI 8614 & HI 8614L only:

for automatic temperature

compensation, connect the 2

terminals of the temperature

probe (HI76608, optional) to

"TEMP. PROBE" terminals.

If automatic temperature compensation is not required, short

the "TEMP. PROBE" terminals

with a resistance according to

the external temperature:

Temperature (°C) Resistance (Ohms)

0 1634

10 1774

20 1922

30 2078

40 2242

50 2412

60 2590

A 2 kohm resistor is factory mounted for 25°C

temperature compensation.

8

Page 9

pH CALIBRATION WITH AUTOMATIC

SLOPE ADJUSTMENT

OFFSET ADJUSTMENT

TEMPERATURE COMPENSATION

(HI 8614 & HI 8614L)

Initial preparation:

• Connect the pH electrode

to the BNC socket.

• Connect the temperature

probe to the transmitter.

Pour small quantities of pH 7.01 and pH 4.01

solution into two clean beakers.

4

0

0

I 7

H

HI 7004 HI 7007

For accurate calibration use two beakers for

each buffer solution, the first one for rinsing

the electrode, the second one for calibration. In this way contamination of the buffers is minimized.

To get accurate readings, use pH7.01 and

pH 4.01 if you are going to measure acid

samples or pH 7.01 and pH 10.01 for alkaline measurements.

RINSE

HI 7007

Note: with HI8614L the instru-

ments display can be

used during calibration

without the need to connect the ammeter and the

reading is directly expressed in pH units.

9

CALIBRATION

HI 7007

Page 10

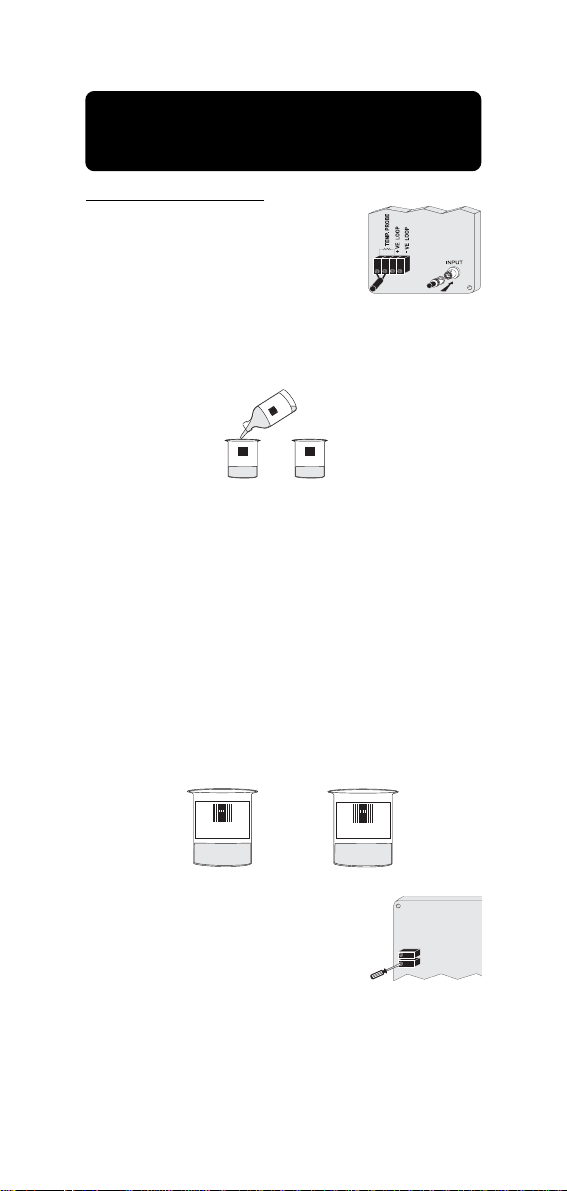

Procedure:

• Disconnect the +ve supply cable from

"+VE LOOP" terminal and connect a

20mA f.s. ammeter between the +ve

cable and "+VE LOOP" terminal.

• Remove the protective cap

from the electrode, rinse it

with some pH 7.01 solution

or immerse it in the pH 7

rinse solution, then immerse the pH electrode and

HI 7007

temperature probe into

pH 7.01 calibration buffer

solution; shake briefly and

wait for the reading to stabilize.

Note: the tip of the elec-

trode should be submerged approximately 4 cm (1½")

into the solution. The

4 cm

1½"

temperature probe

should be located as

close to the pH electrode as possible.

• Adjust the offset trimmer until the am-

meter reads 12mA or the display shows

"7.01" (HI 8614L only) if the temperature

of the buffer is at 25°C.

SLOPE ADJUSTMENT

OFFSET ADJUSTMENT

mA

10

Page 11

For other buffer temperatures, refer to

page 11 for the appropriate mA / pH

reading.

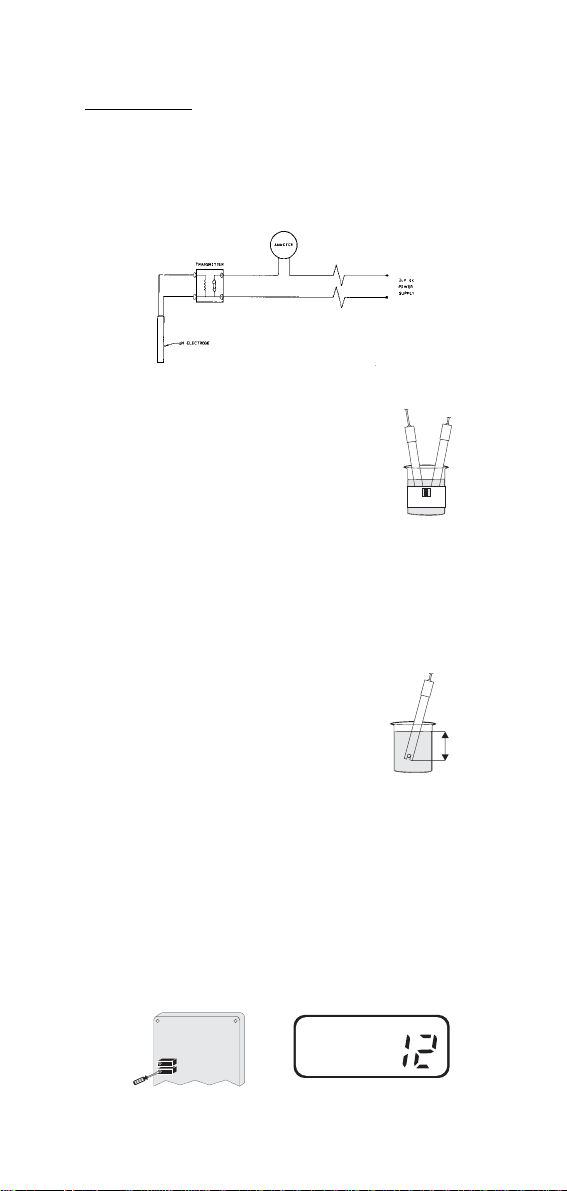

• Rinse the electrode with

tap water or distilled water

and a small amount of

pH 4.01 or 10.01 buffer solution or immerse it in the

pH4 rinse solution (2nd

calibration point). Dip the

electrode and the tempera-

HI 7004

ture probe into pH 4.01 (or

10.01) calibration buffer solution, shake briefly and

wait for a few minutes for

reading to stabilize.

• Adjust the slope trimmer until the amme-

ter reads 8.58 mA or the display shows

"4.01" at 25°C. For other buffer temperatures, refer to page 11 for the appropriate mA / pH reading (HI 8614L).

SLOPE ADJUSTMENT

OFFSET ADJUSTMENT

mA

If you are using pH 10.01

buffer solution adjust the

slope trimmer until the am-

mA

meter read 15.43mA at

25°C (77°F) or the value

indicated at page 11.

FOR HI8614L ONLY:

The Display Module is factory calibrated, so

that the LCD display results are referred to

the 4-20 mA loop current (e.g. LCD displays

0.00 pH when loop current is 4.00 mA and

displays 14.00 pH when current is 20.00mA).

11

Page 12

Under normal application, adjustment on this

module may not be necessary.

If routine check is required, the following

procedures shall be performed.

• Follow the procedure at page 7 to per-

form calibration on the transmitter module (using a ammeter).

• Simulate a 4.00 mA loop current for the

transmitter (i.e. pH 0.00 as Electrode input) and check for display reading.

• Simulate a 20.00 mA loop current for the

transmitter (i.e. pH 14.00 as Electrode

input) and check for display reading.

Note: when the instrument is used in con-

junction with the Hanna indicator

HI 8510T or controllers HI 8710T,

HI 8711T, the calibration can also be

performed on the indicator/controller.

In this case slight calibration adjustment can be made on the indicator/

controller even if the whole system

calibration is advised, always starting

from the transmitter.

12

Page 13

pH CALIBRATION WITH FIXED

TEMPERATURE COMPENSATION

(HI 8614 & HI 8614L only)

• Take the temperature of the

°C

buffer solutions using a

Checktemp or a thermometer with a resolution of at

least 1°.

• Connect the appropriate re-

sistor to the "TEMP.

PROBE" terminals (see

page6) depending on the

temperature of the calibration solution.

• Follow the procedure as outlined in the

calibration with automatic temperature

compensation and use the thermometer

reading to adjust the trimmer until the

ammeter reads the value according to

the following table.

Temperature 4.01 pH Buffer 7.01 pH Buffer 10.01 pH Buffer

°C

°F pH mA pH mA pH mA

0

32

4.01

8.576

7.13

12.137

10.32

10

15

20

25

30

35

40

45

50

55

60

5

41

4.00

8.565

7.10

50

59

68

77

86

95

104

113

122

131

140

4.00

4.00

4.00

4.01

4.02

4.03

4.04

4.05

4.06

4.07

4.09

8.565

8.565

8.565

8.576

8.587

8.599

8.610

8.622

8.633

8.645

8.667

7.07

7.04

7.03

7.01

7.00

6.99

6.98

6.98

6.98

6.98

6.98

12.103

12.069

12.034

12.023

12.000

11.989

11.977

11.966

11.966

11.966

11.966

11.966

10.24

10.18

10.12

10.06

10.01

9.96

9.92

9.88

9.85

9.82

9.79

9.77

15.789

15.697

15.629

15.560

15.491

15.434

15.377

15.331

15.285

15.251

15.217

15.182

15.159

13

Page 14

ORP CALIBRATION (HI8615 & HI8615L)

mA

Initial preparation:

Disconnect the +ve supply cable from the

"+VE LOOP" terminal and connect a 20 mA

f.s. ammeter between the +ve cable and the

"+VE LOOP" terminal. With HI 8615L the

instrument display can be used during calibration without the need to connect the ammeter. In this case the values are directly

expressed in mV units.

Pour a small quantity of

HI 7020

HI7020 ORP solution into a

beaker.

Procedure:

• Connect the shorting BNC

connector to the ORP transmitter.

• Adjust the OFFSET ADJUSTMENT trimmer on the module for a display of 12 mA

on the ammeter or 0 mV on the instrument display (HI 8615L only). This sets

the zero point for the transmitter.

SLOPE ADJUSTMENT

OFFSET ADJUSTMENT

• Connect the ORP electrode to the transmitter and immerse the tip of the electrode into a beaker of HI 7020 ORP calibration solution, and check that the ammeter reading lies between 13.6 and

14.2 mA or the instrument reading is between 200 and 275 mV at 25°C (HI8615L).

HI 7020

14

mA

Page 15

• If the reading lies outside

mA

this range, adjust the slope

adjustment trimmer on the

SLOPE ADJUSTMENT

OFFSET ADJUSTMENT

transmitter for a reading just

within this range.

The unit is now calibrated.

A complete calibration of the transmitter

module is advised periodically.

This calibration procedure requires the

HI 8427 or the HI 931001 pH and ORP simulator to simulate the ORP electrode.

HI 8427 or HI 931001 produce a known signal into the system so that the faults of the

system can be isolated.

• Connect the ORP transmitter to the simulator.

• Set the simulator to 0 mV and adjust the

offset trimmer to read 12 mA on the

ammeter or 0 mV on the HI 8615L display (HI 8615L only).

SLOPE ADJUSTMENT

OFFSET ADJUSTMENT

15

Page 16

• Set the simulator to 350 mV and adjust

the slope trimmer to read 14.8 mA on

the ammeter or 350 mV on the HI 8615L

display (HI 8615L only).

SLOPE ADJUSTMENT

OFFSET ADJUSTMENT

mA

• Connect the ORP electrode to the module and immerse the tip of the electrode

into the beaker of HI 7020 ORP solution

and check that the ammeter reading lies

between 13.6 and 14.2 mA or the instrument reading is between 200 and 275mV

at 25°C (HI 8615L only).

HI 7020

mA

• Only if the reading lies outside this range, adjust the

slope adjustment trimmer

on the transmitter to reflect

SLOPE ADJUSTMENT

OFFSET ADJUSTMENT

a reading within this range.

16

Page 17

FOR HI8615L ONLY:

The HI 8615L is factory calibrated, and the

displayed values are referenced to the 4-20

mA loop current (e.g. LCD displays -1000

mV when loop current is 4.00 mA and displays +1000 mV when current is 20.00mA).

Under normal application, adjustment on this

module may not be necessary. If routine

check is required, the following procedures

shall be performed.

• Follow the above procedure for HI 8615

(see page 12).

• Simulate a 12.00 mA loop current for the

transmitter (i.e. 0 mV at Electrode input)

and check display reading.

• Simulate a 20.00 mA loop current for the

transmitter (e.g. +1000 mV at Electrode

input) and check display reading.

17

Page 18

Please note:

-1000 mV = 4 mA

0 mV = 12 mA

1000 mV = 20 mA

350 mV = 14.8 mA

200 mV = 13.6 mA

275 mV = 14.2 mA

1 mV = 12.008 mA

Note: when the meter is used in conjunction

with the Hanna indicator HI 8512T, or

the controller HI 8720T, the calibration can also be performed on the

indicator/controller. In this case slight

adjustment can be made on the indicator/controller even if the whole system calibration is advised, always starting from the transmitter.

18

Page 19

ELECTRODE CONDITIONING

AND MAINTENANCE

Reference

Filling Hole

Reference

Filling Hole

Sensitive

Wire

Reference

Wire

Reference

Junction

Glass

Bulb

Reference

Wire

Reference

Junction

Platinum or

Gold tip

Plastic Body

pH Electrode

Reference

Plastic Body

ORP Electrode

Glass Body

pH Electrode

Wire

Glass Body

ORP Electrode

Reference

Wire

Sensitive

Wire

Reference

Junction

Glass

Bulb

Reference

Junction

Platinum or

Gold tip

PREPARATION

Remove the protective cap.

DO NOT BE ALARMED IF ANY SALT DE-

POSITS ARE PRESENT.

This is normal with electrodes and they will

disappear when rinsed with water.

During transport tiny bubbles of air may have

formed inside the glass bulb. The electrode

cannot function properly under these conditions. These bubbles can be removed by

"shaking down" the electrode as you would

19

Page 20

do with a glass thermometer.

If the bulb and/or junction are dry, soak the

electrode in HI70300 or HI80300 Storage

Solution for at least one hour.

For refillable electrodes:

If the fill solution (electrolyte) is more than

1cm (½") below the fill hole, add HI 7082 or

HI 8082 3,5M KCl Electrolyte Solution for

double junction or HI 7071 or HI 8071 3,5M

KCl+AgCl Electrolyte Solution for single

junction electrodes. For a faster response

unscrew the fill hole screw during measurements.

For AmpHel electrodes:

If the electrode does not respond to pH

changes, the battery is run down and the

electrode should be replaced.

MEASUREMENT

Rinse the electrode tip with distilled water.

Immerse the tip (4 cm / 1½") in the sample

and stir gently for approx. 30 seconds.

For a faster response and to avoid cross

contamination of the samples, rinse the electrode tip with a few drops of the solution to

be tested, before taking measurements.

STORAGE

To minimize clogging and assuring a quick

response time, the glass bulb and the junction should be kept moist and not allowed to

dry out. Replace the solution in the protective cap with a few drops of HI70300 or

HI80300 Storage Solution or, in its absence, Filling Solution (HI 7071 or HI 8071

for single junction or HI 7082 or HI 8082 for

double junction electrodes). Follow the Preparation Procedure above before taking measurements.

Note: NEVER STORE THE ELECTRODE

IN DISTILLED WATER OR DRY.

20

Page 21

PERIODIC MAINTENANCE

Inspect the electrode and the cable. The

cable used for connection to the meter must

be intact and there must be no points of

broken insulation on the cable or cracks on

the electrode stem or bulb. Connectors must

be perfectly clean and dry. If any scratches

or cracks are present on the electrode body,

replace the electrode. Rinse off any salt deposits with water.

For refillable electrodes:

Refill it with fresh electrolyte (HI7071 or

HI8071 for single junction or HI7082 or

HI8082 for double junction electrodes). Al-

low the electrode to stand upright for 1 hour.

Follow the Storage Procedure above.

CLEANING PROCEDURE

General Soak in Hanna HI7061 or

HI 8061 General Cleaning Solution for approximately 1 hour.

Removal of films, dirt or deposits on the

membrane/junction:

Protein Soak in Hanna HI7073 or

HI8073 Protein Cleaning Solution for 15 minutes.

Inorganic Soak in Hanna HI7074 or

HI8074 Inorganic Cleaning

Solution for 15 minutes.

Oil/grease Rinse with Hanna HI7077 or

HI 8077 Oil and Fat Cleaning

Solution.

IMPORTANT: After performing any of the

cleaning procedures rinse the electrode thoroughly with distilled water, drain and refill

the reference chamber with fresh electrolyte, (not necessary for GEL filled electrodes)

and soak the electrode in HI70300 or

HI80300 Storage Solution for at least 1

hour before taking measurements.

21

Page 22

TROUBLESHOOTING

Evaluate your electrode performance based

on the following.

• Noise (Readings fluctuate up and down)

could be due to:

- Clogged/Dirty Junction: Refer to the

Cleaning Procedure above.

- Loss of shielding due to low electro-

lyte level (in refillable electrodes only):

HI7071 or HI8071 for single junction or

HI7082 or HI8082 for double junction

electrodes.

• Dry Membrane/Junction: Soak in Storage Solution HI70300 or HI80300 for at

least 1 hour.

• Drifting: Soak the electrode tip in warm

Hanna Solution HI7082 or HI8082 for

one hour and rinse the tip with distilled

water. Refill with fresh HI7071 or HI8071

for single junction electrodes and HI7082

or HI8082 for double junction electrodes.

• Low Slope: Refer to the cleaning proce-

dure above.

• No Slope: Check the electrode for cracks

in glass stem or bulb and replace the

electrode.

• Slow Response/Excessive Drift: Soak

the tip in Hanna Solution HI7061 or

HI8061 for 30 minutes, rinse thoroughly

in distilled water and then follow the

Cleaning Procedure above.

22

Page 23

TEMPERATURE-RESISTANCE

0

0+10+20+30+40+50+60+70+80+90

C

CORRELATION FOR HANNA

pH SENSITIVE GLASS

The resistance of glass electrodes partially

depends on the temperature. The lower the

temperature, the higher the resistance. It

takes longer time for the reading to stabilize

if the resistance is higher. In addition, the

response time will suffer to a greater degree

at temperatures below 10°C.

Ω

9

2x10

-10

9

1x10

-10

8

-10

2x10

8

1x10

-10

7

2x10

-10

-10

7

1x10

-10

-20-2

°

Since the resistance of the pH electrode is

in the range of 200 Mohm, the current across

the membrane is in the pico Ampere range.

Large currents can disturb the calibration of

the electrode for many hours.

For these reasons high humidity environ-

ments, short circuits and static discharges are detrimental for a stable pH

reading.

The pH electrode's life also depends on the

temperature. If constantly used at high temperatures, the electrode life is drastically

reduced.

23

Page 24

Typical Electrode Life

Ambient Temperature 1- 3 years

90 °C Less than 4 months

120°C Less than 1 month

High concentrations of sodium ions interfere

with readings in alkaline solutions; the pH at

which the interference starts to be significant depends upon the composition of the

glass. This interference is the alkaline error

and causes the pH to be underestimated.

Hanna's glass formulations have the indicated characteristics.

Alkaline Error

Sodium Ion Correction for the Glass

at 20-25°C

Concentration pH Error

0.1 Mol L-1 Na

1.0 Mol L-1 Na

+

13.00

13.50

14.00

+

12.50

13.00

13.50

14.00

0.10

0.14

0.20

0.10

0.18

0.29

0.40

24

Page 25

INSTALLATION PROCEDURE

AND EXAMPLES

The HI8614, HI8614L, HI8615 and HI 8615L

transmitters may be wall mounted in any convenient location near the measurement point.

To minimize thermal drift due to extreme

temperature fluctuations during the measurement process, particularly if the measurement

is conducted outdoors, it is best to protect the

transmitter in an enclosed casing.

General Installation Procedure

For most industrial application involving long

term monitoring and control, it is also recommended to use tank electrode holders (HI6050

or HI6051) to protect the pH electrode and the

temperature probe from contamination by the

test solution.

Controlling the pH / ORP with a recorder

25

Page 26

Monitoring the pH/ORP with Panel Mounting

pH (HI8510)/ORP (HI8512) Indicator

Controlling the pH/ORP with

an Industrial Regulator

Monitoring and Controlling the pH/ORP

with Panel Mounting Indicator/Regulator

and Dosage Control of either Acid or Base

26

Page 27

Monitoring and Controlling the pH with

(HI 8711) Panel Mounting Indicator/

Regulator with Independent Dosage

Control for Acid and Base

27

Page 28

ACCESSORIES

pH CALIBRATION SOLUTIONS

HI7004M pH 4.01 Buffer Solution, 230 mL

HI7004L pH 4.01 Buffer Solution, 460 mL

HI7006M pH 6.86 Buffer Solution, 230 mL

HI7006L pH 6.86 Buffer Solution, 460 mL

HI7007M pH 7.01 Buffer Solution, 230 mL

HI7007L pH 7.01 Buffer Solution, 460 mL

HI7009M pH 9.18 Buffer Solution, 230 mL

HI7009L pH 9.18 Buffer Solution, 460 mL

HI7010M pH 10.01 Buffer Solution, 230mL

HI7010L pH 10.01 Buffer Solution, 460 mL

ORP SOLUTIONS

HI 7020M 200-275mV Buffer Solution, 230 mL

HI 7020L 200-275mV Buffer Solution, 460 mL

HI 7091M Pre-Treatment Reducing Solution,

230 mL

HI 7091L Pre-Treatment Reducing Solution,

460 mL

HI 7092M Pre-treatment Oxidizing Solution,

230 mL

HI 7092L Pre-Treatment Oxidizing Solution,

460 mL

ELECTRODE STORAGE SOLUTIONS

HI70300MStorage Solution, 230 mL

HI70300L Storage Solution, 460 mL

ELECTRODE CLEANING SOLUTIONS

HI7061M General Cleaning Sol., 230 mL

HI7061L General Cleaning Sol., 460 mL

HI7073M Protein Cleaning Sol., 230 mL

HI7073L Protein Cleaning Sol., 460 mL

HI7074M Inorganic Cleaning Sol., 230 mL

HI7074L Inorganic Cleaning Sol., 460 mL

HI7077M Oil & Fat Cleaning Sol., 230 mL

HI7077L Oil & Fat Cleaning Sol., 460 mL

REFILLING ELECTROLYTE SOLUTIONS

HI7071 3.5M KCl + AgCl Electrolyte,

4x50 mL, for single junction electrodes

HI7072 1M KNO3 Electrolyte, 4x50 mL

HI7082 3.5M KCl Electrolyte, 4x50 mL,

for double junction electrodes

28

Page 29

pH ELECTRODES

DIA 9.5mm

3/4 x 16 UNF

DIA 12mm

110mm

38.5mm

DIA 20.5mm

HI 1090T Screwcap PG13.5 connector,

double junction, glass-body

PG13.5 THREAD

φ 12mm φ 9.5mm

110mm30mm

HI 1110S Screw connector, single junction,

glass-body

HI 1130B/3 BNC connector, 3 m (9.9') cable,

single junction, glass-body

M13 x 1.5

DIA

16

mm

25

7

mm

mm

HI 1110S HI 1130B/3

HI 1110T Screwcap PG13.5 connector,

double junction, glass-body

PG13.5 THREAD

φ 12mm φ 9.5mm

HI 1114S Screw connector, double junc-

110mm30mm

tion plastic-body

HI 1134B/3 BNC connector, 3 m (9.9') cable,

double junction plastic-body

DIA

16

mm

3/4 x 16 UNF

DIA 20.5mm

38.5mm

M13 x 1.5

25

7

mm

mm

HI 1114S HI 1134B/3

DIA 12mm

110mm

HI 1115S Screw connector, single junction,

glass-body

HI 1135B/3 BNC connector, 3 m (9.9') cable,

single junction, glass-body

DIA 16.5mm

5mm

M13 x 1.5

DIA

16

mm

25

7

mm

mm

HI 1115S HI 1135B/3

DIA 7.6mm

25mm

29

DIA 12mm

150mm

Page 30

HI 1210T Screwcap PG13.5 connector,

DIA 20.5mm

DIA 9.5mm

3/4 x 16 UNF

DIA 12mm

110mm

38.5mm

double junction, plastic-body

PG13.5 THREAD

φ 12mm

110mm30mm

HI 1910B BNC connector, 1 m (3.3') cable,

double junction, plastic-body,

built-in amplifier

3/4 x 16 UNF

DIA 20.5mm

DIA 12mm

38.5mm

110mm

HI 1911B BNC connector, 1 m (3.3') cable,

double junction, plastic-body,

built-in amplifier

3/4 x 16 UNF

DIA 20.5mm

38.5mm

DIA 12mm

110mm

HI 1912B BNC connector, 1 m (3.3') cable,

double junction, plastic-body,

built-in amplifier

HI 1912B/5 BNC connector, 5 m (16.5') cable,

double junction, plastic-body,

built-in amplifier

HI 2114B/5 BNC connector, 5 m (16.5') cable,

double junction, plastic-body

3/4 x 16 UNF

DIA 20.5mm

DIA 12mm

38.5mm

110mm

30

Page 31

HI 2910B/5 BNC connector, 5 m (16.5') cable,

double junction, plastic-body,

built-in amplifier

3/4 x 16 UNF

DIA 20.5mm

DIA 12mm

38.5mm

110mm

ORP ELECTRODES

HI 2930B/5 BNC connector, 5 m (16.5') cable,

Pt, Ultem®-body, built-in amplifier

3/4 x 16 UNF

DIA 20.5mm

38.5mm

DIA 12mm

110mm

HI 3110S Screw-type connector, Pt, glass-

body

HI 3130B/3 BNC connector, 3 m (9.9') cable,

Pt, glass-body

DIA

mm

16

3/4 x 16 UNF

DIA 20.5mm

38.5mm

DIA 12mm

110mm

M13 x 1.5

25

7

mm

mm

HI 3110S HI 3130B/3

HI 3110T Screwcap PG13.5 connector, Pt,

glass-body

PG13.5 THREAD

φ 12mm φ 1mm

110mm30mm

HI 3115S Screw-type connector, side-arm,

Pt, glass-body

HI 3135B/3 BNC connector, 3 m (9.9') cable,

side-arm, Pt, glass-body

DIA 16.5mm

5mm

M13 x 1.5

DIA

16

mm

25

7

mm

mm

HI 3115S HI 3135B/3

Ultem® is a registered Trademark of "General Electrics Company"

DIA 7.6mm

25mm

31

DIA 12mm

150mm

Page 32

HI 3210T Screwcap PG13.5 connector, Pt,

plastic-body

PG13.5 THREAD

φ 12mm

110mm30mm

HI 3410S Screw connector, Pt, plastic-body

HI 3430B/3 BNC connector, 3 m (9.9') cable,

Pt, plastic-body

DIA

16

mm

3/4 x 16 UNF

DIA 20.5mm

38.5mm

M13 x 1.5

25

7

mm

mm

HI 3410S HI 3430B/3

DIA 12mm

110mm

HI 3932B/5 BNC connector, 5 m (16.5') cable,

Pt, Ultem®-body, built-in amplifier

3/4 x 16 UNF

DIA 20.5mm

DIA 12mm

38.5mm

110mm

HI 4110S Screw-type connector, Au, glass-

body

HI 4130B/3 BNC connector, 3 m (9.9') cable,

Au, glass-body

DIA

16

mm

3/4 x 16 UNF

DIA 20.5mm

M13 x 1.5

25

7

mm

mm

HI 4110S HI 4130B/3

38.5mm

DIA 12mm

110mm

HI 4932B/5 BNC connector, 5 m (16.5') cable,

Au, Ultem®-body, built-in amplifier

3/4 x 16 UNF

DIA 20.5mm

38.5mm

Ultem® is a registered Trademark of "General Electrics Company"

32

DIA 12mm

110mm

Page 33

EXTENSION CABLES FOR SCREW-TYPE

ELECTRODES ONLY (SCREW TO BNC

CONNECTOR)

HI 7855 SERIES CABLE CONNECTORS

CONNECTOR AND 3.0 mm (0.12") CABLE WITH BNC

CONNECT TO

SCREW TYPE

ELECTRODES

CONNECT TO THE

BNC SOCKET

OF THE METER

HI7855/1 Extension cable 1m (3.3') long

HI7855/3 Extension cable 3m (9.9') long

HI7855/5 Extension cable 5m (16.5') long

HI7855/10 Extension cable 10m (33') long

HI7855/15 Extension cable 15m (49.5') long

OTHER ACCESSORIES

BL PUMPS Dosing Pumps with Flow Rate

from 1.5 to 20 LPH

ChecktempC Pocket-size thermometer with

penetration probe and 0.1°C

resolution (range -50.0 to

150.0°C)

HI6050 Submersible Electrode Holders

& HI 6051

HI 6054 Electrode Holders for In-Line

& HI 6057 Applications

HI76501/P Calibration Screwdriver (20 pcs)

HI 7871 Level Controllers

& HI 7873

HI8427 pH and ORP Electrode

Simulator with 1 m (3.3') Coaxial

Cable ending in Female BNC

Connectors (HI 7858/1)

HI931001 pH and ORP Electrode

Simulator with LCD Display and

1 m (3.3') Coaxial Cable ending

in Female BNC Connectors

(HI 7858/1)

MANPHTRR2 Instruction Manual

33

Page 34

WARRANTY

All Hanna Instruments meters are warranted

for two years against defects in workman-

ship and materials when used for their intended purpose and maintained according

to instructions.

The probes and the electrodes are warranted for a period of six months.

Damages due to accident, misuse, tampering or lack of prescribed maintenance are

not covered. This warranty is limited to repair or replacement free of charge.

If service is required, contact the dealer

from whom you purchased the instrument. If

under warranty, report the model number,

date of purchase, serial number and the

nature of the failure. Obtain a Returned

Goods Authorization from the Customer Service department first and then return the

instrument with the Authorization # included

along with shipment costs prepaid. If the

repair is not covered by the warranty, you

will be notified of the charge for repair or

replacement. When shipping any instrument,

make sure it is properly packaged for complete protection.

To validate your warranty, fill out and return

the enclosed warranty card within 14 days

from the date of purchase.

All rights are reserved. Reproduction in whole

or in part is prohibited without the written

consent of the copyright owner.

Hanna Instruments reserves the right to

modify the design, construction and appearance of its products without advance

notice.

34

Page 35

CE DECLARATION OF CONFORMITY

Recommendations for Users

Before using these products, make sure that they are entirely suitable for the environment

in which they are used.

Operation of these instruments in residential area could cause unacceptable interferences to radio and TV equipments, requiring the operator to take all necessary steps to

correct interferences.

Any variation introduced by the user to the supplied equipment may degrade the

instruments' EMC performance.

To avoid damages or burns, do not perform any measurement in microwave ovens.

35

Page 36

06/01

http://www.hannainst.com

36

MANPHTRR2

Loading...

Loading...