Page 1

HI 21/HI 22 SeriesHI 21/HI 22 Series

HI 21/HI 22 Series

HI 21/HI 22 SeriesHI 21/HI 22 Series

Wall-mounted,

Microprocessor-based

Process pH/mV Meters

Instruction Manual

Page 2

Dear Customer,

Thank you for choosing a Hanna Product.

Please read this instruction manual carefully before using the

instrument. It will provide you with the necessary information

for the correct use of the instrument, as well as a precise idea

of its versatility.

If you need additional technical information, do not hesitate

to e-mail us at

These instruments are in compliance with the

tech@hannainst.comtech@hannainst.com

tech@hannainst.com.

tech@hannainst.comtech@hannainst.com

directives.

TABLE OF CONTENTS

PRELIMINARY EXAMINATION . . . . . . . . . . . . . . . . . . 4

GENERAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . 4

FUNCTIONAL DESCRIPTION . . . . . . . . . . . . . . . . . . 6

MECHANICAL DIMENSIONS . . . . . . . . . . . . . . . . . . 7

SPECIFICATIONS HI 21 & HI 22 . . . . . . . . . . . . . . . 8

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

MODELS

The models HI 21XYZ are pH controllers, while the models

HI 22XYZ are ORP controllers.

HI 21111 pH Controller with single setpoint, ON/OFF

control, analog output

HI 21211 pH Controller with dual setpoint, ON/OFF

control, analog output

HI 21221 pH Controller with dual setpoint, proportional

and ON/OFF control, analog output

HI 21222 pH Controller with dual setpoint, proportional

and ON/OFF control, RS485 output

HI 21523 pH Controller with control through analog

output, PID control, analog and RS485 output

HI 22111 ORP Controller with single setpoint, ON/OFF

control, analog output

HI 22122 ORP Controller with single setpoint, propor-

tional and ON/OFF control, RS485 output

SETUP MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

CONTROL MODE . . . . . . . . . . . . . . . . . . . . . . . . . 17

IDLE MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

ANALOG OUTPUT . . . . . . . . . . . . . . . . . . . . . . . . 26

RS485 COMMUNICATION & DATA LOGGING . . . . 28

CALIBRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

LAST CALIBRATION DATA . . . . . . . . . . . . . . . . . . . . 48

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

FAULT CONDITIONS AND SELFTEST PROCEDURES . . 52

pH VALUES AT VARIOUS TEMPERATURES . . . . . . . . . 56

ELECTRODE CONDITIONING AND MAINTENANCE . . 57

TAKING REDOX MEASUREMENTS. . . . . . . . . . . . . . 61

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

CE DECLARATION OF CONFORMITY. . . . . . . . . . . 70

© 2002 Hanna Instruments

All rights are reserved. Reproduction in whole or in part is prohibited without the

written consent of the copyright owner, Hanna Instruments Inc., 584 Park East Drive,

Woonsocket, Rhode Island, 02895 , USA.

32

Page 3

PRELIMINARY EXAMINATION

Remove the instrument from the packing material and examine it carefully to make sure that no damage has occurred

during shipping. If there is any noticeable damage, notify

your Dealer or the nearest Hanna Customer Service Center

immediately.

Note Save all packing materials until you are sure that the instru-

ment functions correctly. Any damaged or defective items must

be returned in their original packing materials together with

the supplied accessories.

GENERAL DESCRIPTION

The product is a real time microprocessor-based pH/ORP

controller. It provides accurate measurements, flexible

ON/OFF, proportional or PID control capabilities and dual

alarm signals.

The system is composed of a case inside which the signal

conversion circuitry, the microprocessor circuitry and the

output power drivers are contained.

MAIN FEATURES OF DIFFERENT MODELS

• Display: large LCD with 4 ½ 13 mm digits and 3 ½ 7.7

mm digits.

• LEDs: three (HI 22) or four (HI 21) LEDs are provided for

signaling the energizing of relay 1 (a yellow LED), relay 2

(a yellow LED in HI 21 Series only) and alarm relays (a

green and a red LED).

• Relays: Electromechanical type, working through NO,

COM and NC contacts; 1 or 2 output relays for acid or

base dosage; 1 output relay for alarm condition.

• RS485 isolated communication link.

• Calibration and Setup procedures allowed only through

an unlock password.

• Calibration: for HI 21 Series in 1, 2 or 3 points with buffers 4.01, 7.01 and 10.01 pH (25 °C); for HI 22 Series in

1 or 2 points at 0, 350 and 1900 mV.

• Temperature compensation of the HANNA standard buffers (for HI 21 Series only).

• Temperature compensation of the pH reading (for HI 21

Series only).

• Manual temperature setting when the temperature probe is

not inserted or temperature exceeds the upper range.

• Internally recorded last calibration data (non-volatile EEPROM memory): calibration date and time, pH offset, pH

slopes, number of calibration points and correspondent

pH values (for HI 21 Series only) or calibration date and

time and the mV calibration points used (for HI 22 Series

only).

• Input: pH electrode with BNC connector.

• ±5 VDC output for amplified electrodes (max 10 mA).

• Output:

- isolated 0-1 mA, 10 KW maximum load (optional);

- isolated 0-20 mA, 750 W maximum load (optional);

- isolated 4-20 mA, 750 W maximum load (optional);

- isolated 0-5 VDC, 1 KW minimum load (optional);

- isolated 1-5 VDC, 1 KW minimum load (optional);

- isolated 0-10 VDC, 1 KW minimum load (optional).

• Real time clock.

54

Page 4

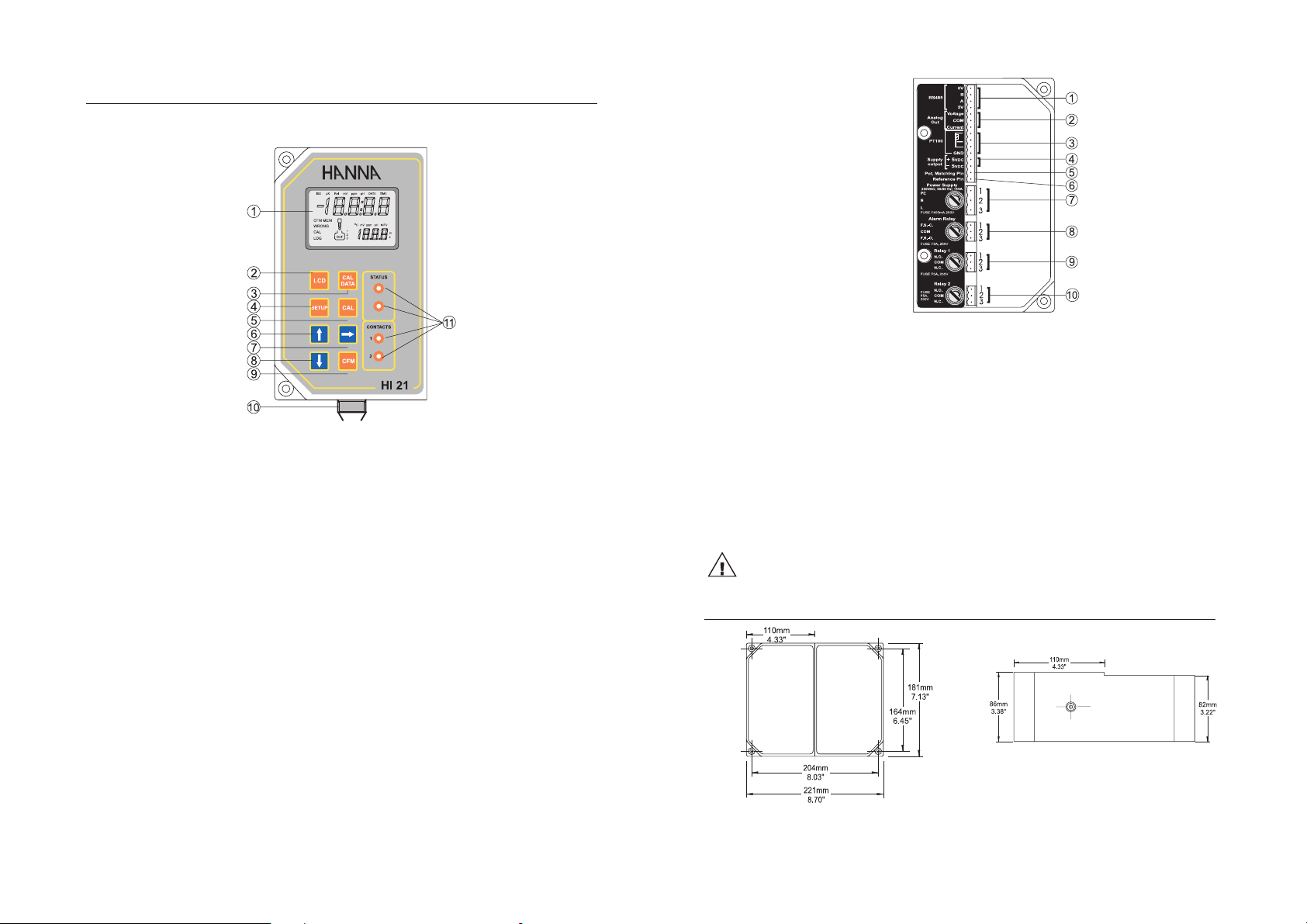

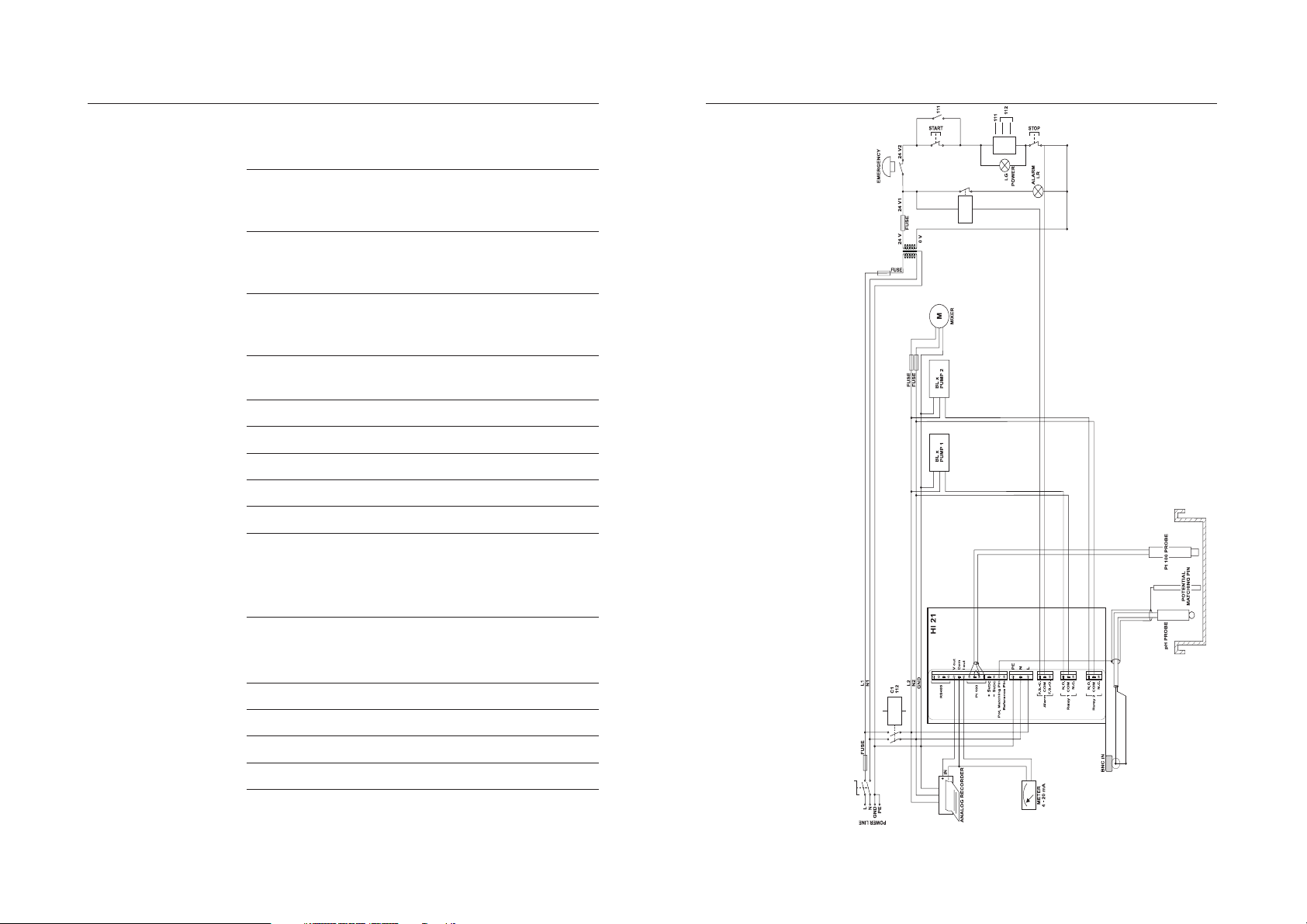

FUNCTIONAL DESCRIPTION

FRONT PANEL

1. Liquid Crystal Display

2. LCD key exits from setup and calibration modes and reverts back to

normal mode (in idle or control phases with the measurement on the display). In HI 21 series, during pH calibration,

alternately displays pH buffer value or current temperature

3. CAL DATA key last calibration data viewing (enters and exits)

4. SETUP key enters setup mode

5. CAL key initiates and exits calibration mode

6. ñ key increases the blinking digit/letter by one when selecting a

parameter. Advances forward while in last calibration data

viewing mode. Increases the temperature setting when

temperature probe is not inserted

7. ð key moves to the next digit/letter (circular buffer) when selecting a parameter. Same as ñ key during last calibration

data viewing mode

8. ò key decreases the blinking digit/letter by one when selecting a

parameter. Reverts backward while in last calibration data

viewing mode. Decreases the temperature setting when

temperature probe is not inserted

9. CFM key confirms current choice (and skips to the next item)

10. BNC Socket

11. LEDs

CONNECTIONS PANEL

1. 4-pin RS485 terminal (not for HI 21XY1 and HI 22XY1)

2. Analog output (not for HI 21XY2 and HI 22XY2)

3. Connections for Pt 100 temperature sensor

4. ±5V power supply output

5. Connection for Potential Matching Pin

6. Connection for electrode reference

7. Power supply input (1 Potential Earth, 2 Neutral, 3 Line)

8. Alarm terminal (1 F.S. Closed, 2 COM, 3 F.S. Open)

9. Relay 1 - first dosing terminal (not for HI 21523) - (1 Normally Open, 2 COM,

3 Normally Closed)

10. Relay 2 - second dosing terminal (HI 212XY models only) - (1 Normally Open,

2 COM, 3 Normally Closed)

Unplug the meter before starting any electrical connections.

MECHANICAL DIMENSIONS

FRONT VIEW BOTTOM VIEW

76

Page 5

SPECIFICATIONS HI 21 & HI 22

INSTALLATION

Range 0.00 to 14.00 pH (HI 21 Series only)

±2000 mV (HI 22 Series only)

-9.9 to 120.0 °C

Resolution 0.01 pH (HI 21 Series only)

1 mV (HI 22 Series only)

0.1 °C

Accuracy ±0.02 pH (HI 21 Series only)

(@20°C/68°F) ±2 mV (HI 22 Series only)

±0.5 °C

Typical EMC Deviation ±0.05 pH (HI 21 Series only)

±4 mV (HI 22 Series only)

±1.0 °C

Analog Output 0 to 1 mA, 0 to 20 mA, 4 to 20 mA

0 to 5 VDC, 1 to 5 VDC, 0 to 10 VDC

Digital Output RS485

Power Supply Input ±5V (for amplified electrodes)

Power Supply 230 ±10% VAC or 115 ±10% VAC, 50/60 Hz

Power Consumption 15 VA

Over Current Protection 400 mA, 250V, FAST FUSE

Relays 1 and 2 Electromechanical relay SPDT contact outputs,

5A-250 VAC, 5A - 30 VDC (resistive load)

(HI 211YZ, HI 212YZ and HI 221YZ)

Fuse protected: 5A, 250V FAST FUSE

Alarm Relay Electromechanical relay SPDT contact output,

5A - 250 VAC, 5A - 30 VDC (resistive load)

Fuse protected: 5A, 250V FAST FUSE

HI 21 and HI 22 offer

a multitude of possibilities, from single and

dual setpoints to ON/

OFF, proportional or

PID dosage, isolated

outputs with user-selectable zoom,

bidirectional RS485, recorder outputs in

mAmps and Volts.

In addition, HI 21 and

HI 22 are both

equipped with the exclusive differential

input.

In a system with poor

grounding, it is possible

to have a ground current flowing through

the reference junction.

This can cause a rapid

degradation of the electrode. The Hanna

differential input reduces the likelihood of

ground loops.

See the diagram for a

recommended installation.

Environment 0-50 °C; max 85% RH not condensing

Protection IP 54

Dimensions 221 x 181 x 86 mm (8.7 x 7.1 x 3.4’’)

Weight approximately 1.4 Kg (3.1 lb.)

98

Page 6

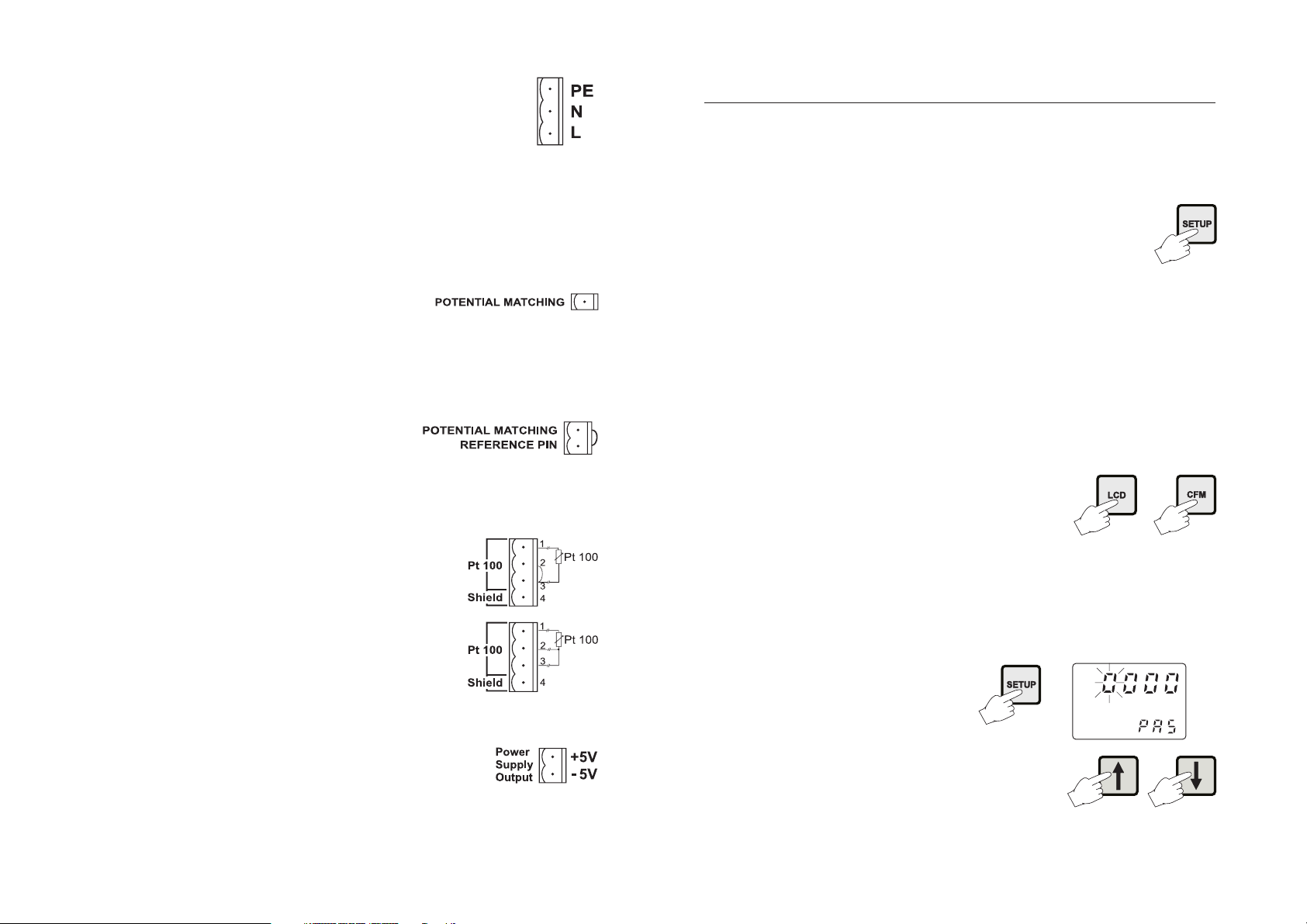

••

• Power Supply: Connect a 3-wire power cable

••

to the terminal strip, while paying attention to

the correct line (L), earth (PE) and neutral (N)

terminal connections.

Power: 115VAC - 100 mA / 230VAC - 50 mA.

Line Contact: fused inside 400 mA.

PE must be connected to ground; leakage current 1

mA.

••

• Electrode: Connect the pH or ORP electrode to the BNC

••

socket (#10 at page 6).

To benefit from the differential input, connect the proper

electrode wire (if available)

or a cable with a potential

matching pin (grounding bar) to the relevant terminal (#5

at page 7).

Note When it is not possible to immerse the Potential Matching Pin

together with the pH electrode in the solution, disable the

differential input by connecting the Connection for Potential

Matching Pin (#5 page 7)

with the Connection for Electrode Reference (#6 on

page 7) with a jumper wire.

••

• Pt 100 Terminals: these contacts (#3 at page 7) connect

••

the Pt 100 temperature sensor for automatic temperature

compensation of pH measurement. In the case of shielded wire,

connect the shield to pin 4.

In the case of a 2-wire sensor connect the Pt 100 to pins 1 and 3,

and short pins 2 and 3 with a

jumper wire.

If the Pt 100 has more than 2

wires, connect the two wires of one

end to pins 2 and 3 (pin 2 is an

auxiliary input to compensate for the cable resistance) and

one wire from the other end to pin 1.

Leave the fourth wire unconnected, if

present.

••

• Power Supply Output: these terminals provide +5V and -

••

5V DC (max current: 10 mA) signals to supply power to

amplified electrodes.

Note All cables connected to the panel should end with cable lugs.

SETUP MODE

HI 21 and HI 22 offer a multitude of possibilities from ON/

OFF, proportional or PID dosage to analog recorder output

and from alarm to selftest features.

The Setup Mode allows the user to set all needed characteristics of the meter.

The setup mode is entered by pressing SETUP

and entering the password when the device

is in idle or control mode.

Generally speaking, if the password is not inserted the user

can only view the setup parameters (except for password)

without modifying them (and the device remains in control

mode). An exception is certain setup items, or flags, which

can activate special tasks when set and confirmed.

Each setup parameter (or setup item) is assigned a twodigit setup code which is entered and displayed on the

secondary LCD.

The setup codes can be selected after password and CFM

are pressed. When CFM is pressed, the current setup item is

saved on EEPROM and the following item is displayed.

Whenever LCD is pressed, the device reverts back to control mode.

The same is true when CFM is

pressed on the last setup item.

The possible transitions in setup mode are the following:

ENTERING THE PASSWORD

• Press SETUP to enter the setup mode. The LCD will display

“0000” on the upper part and “PAS” on the lower. The first

digit of the upper part of the LCD will blink.

• Enter the first digit of the password by the ñ or ò keys.

1110

Page 7

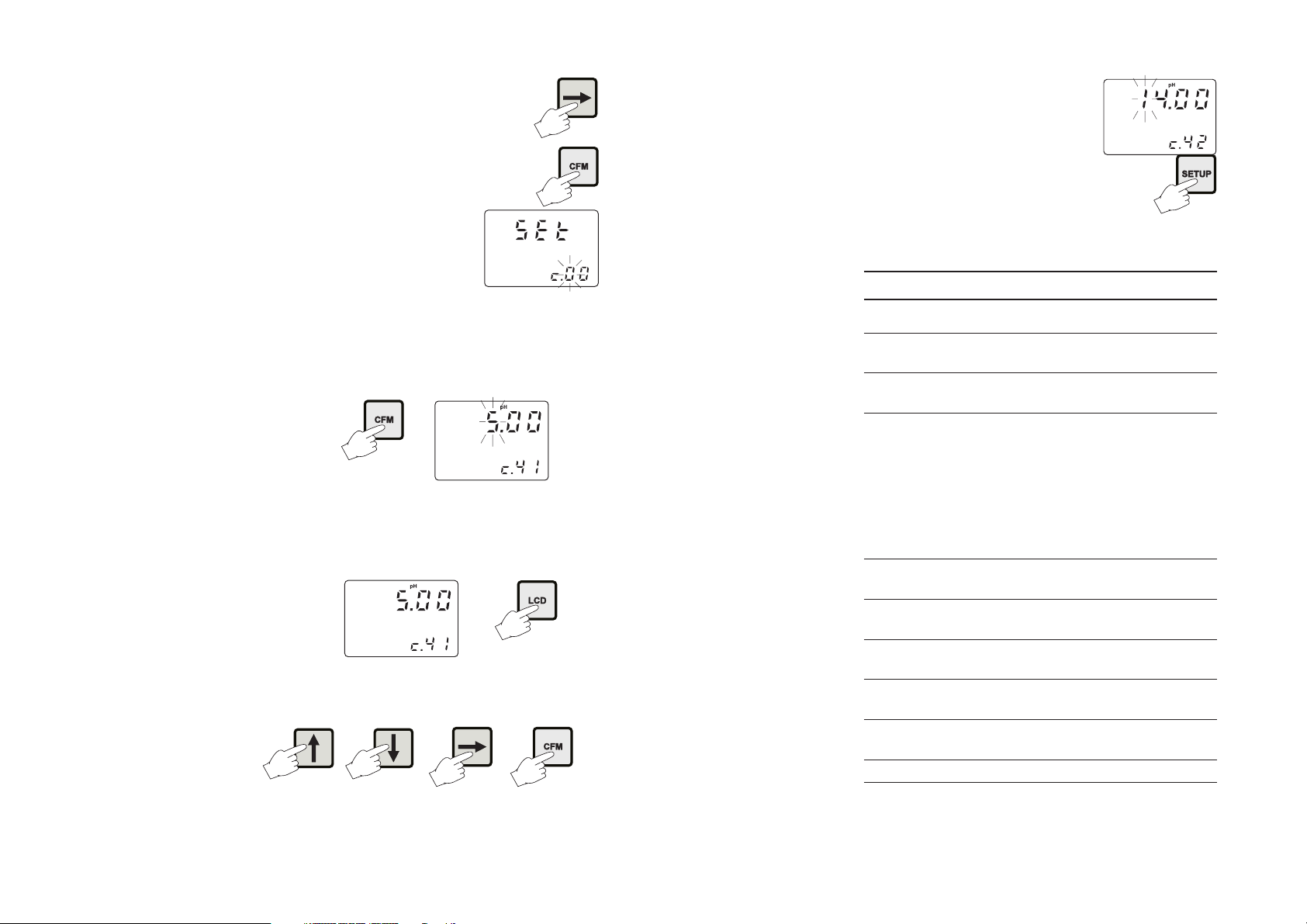

• Then confirm the displayed digit with

ð and move to the next one.

• When the whole password has been

inserted, press CFM to confirm it.

Note The default password is set at “0000”.

• The LCD will display “SET” on the

upper part and “c.00” on the lower,

allowing the user to edit setup parameters (see table below).

• Enter the code of the parameter you want to set, using the

arrow keys as per the password procedure above (e.g. 41).

• Confirm the code by pressing CFM and the default or the

previously memorized value will be displayed with the first

digit blinking.

Note When the password is not inserted or a wrong password is

confirmed, the display will only show the previously memorized value, without blinking (read only mode). In this case,

the value cannot be set. Press LCD and start again.

• Enter the desired value using the arrow keys and then press

CFM.

• After confirmation, the selected parameter is displayed. The user can scroll

through the parameters by pressing CFM.

In order to directly set another parameter, press SETUP again and enter the

code or scroll to it by pressing CFM.

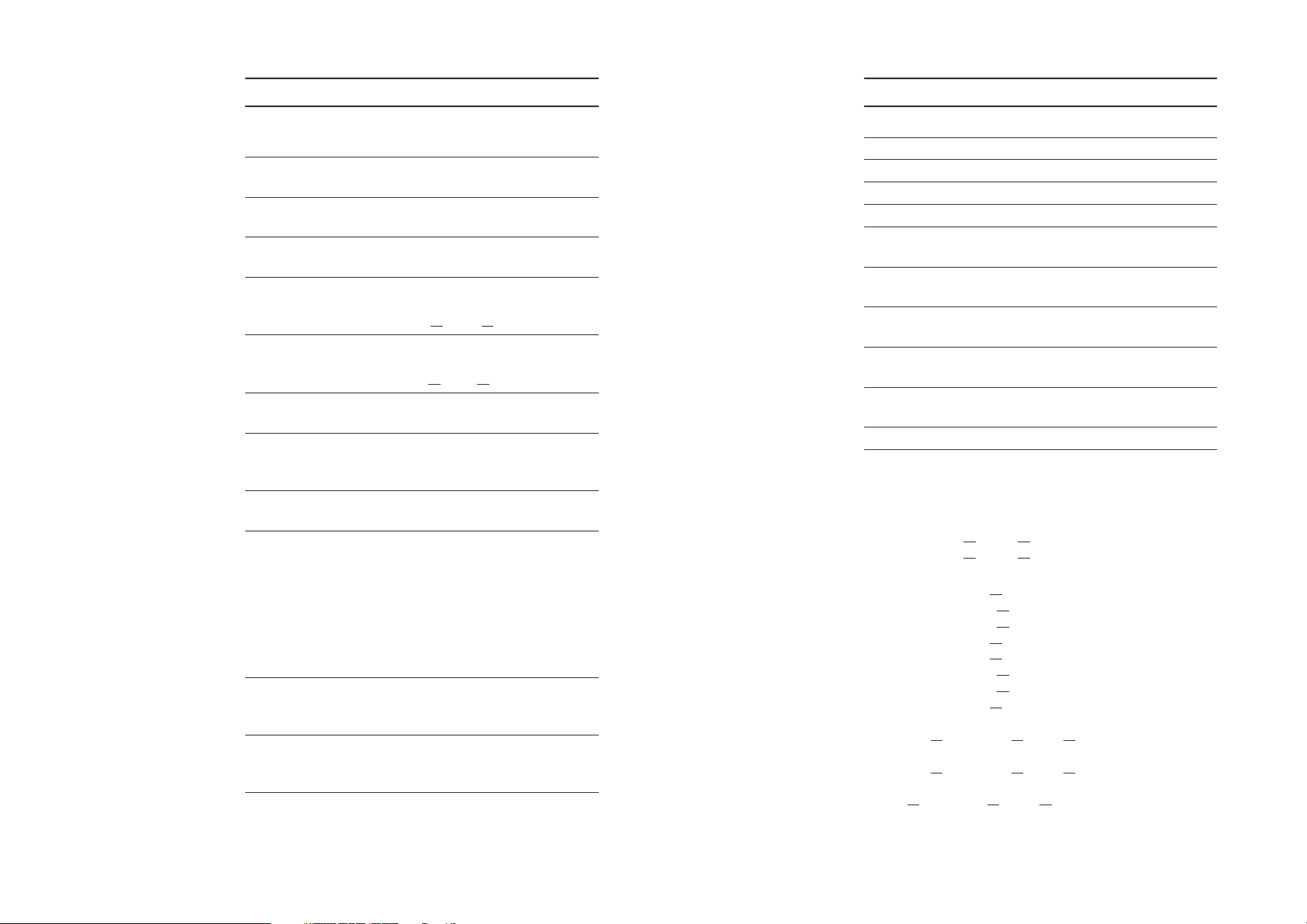

The following table lists the setup codes along with the description of the specific setup items, their valid values and whether

password is required to view that item (“PW” column):

Code Valid Values Default PW

00 Factory ID 0 to 9999 0000 no

01 Process ID 0 to 9999 (models w/o RS485) 0000 no

0 t o 99 (models with RS4 85) 00 no

02 Control enable/disable 0: C.M. disabled 0 no

1: C.M. enabled

11 Relay 1 mode 0: disabled 0 no

(M1) 1: ON-OFF high setpoint

2: ON-OFF low setpoint

3: PID, high setpoint

4: PID, low setpoint

for HI 21523 only : 0: disabled

1: PID, high setpoint

2: PID, low setpoint

12 Relay 1 setpoint 0.00 to 14.00 pH 8.00 pH no

(S1) -2000 to 2000 mV 500 mV

13 Relay 1 hysteresis 0.00 to 14.00 pH 1 pH no

(H1) 0 to 4000 mV 50 mV

14 Relay 1 deviation 0.50 to 14.00 pH 1 pH no

(D1) 25 to 4000 mV 50 mV

15 Relay 1 reset time 0.1 to 999.9 minutes 999.9 mins no

(HI 21523 only)

16 Relay 1 rate time 0.0 to 999.9 minutes 0.0 mins no

(HI 21523 only)

21* Relay 2 mode (M2) same as relay 1 0 no

22* Relay 2 setpoint (S2) 0.00 to 14.00 pH 6.00 pH no

-2000 to 2000 mV -500 mV

* Available only in models with two relays

1312

Page 8

Code Valid Values Default PW

Code Valid Values Default PW

23* Relay 2 hysteresis (H2) 0.00 to 14.00 pH 1 pH no

0 to 4000 mV 50 mV

24* Relay 2 deviation (D2) 0.50 to 14.00 pH 1 pH no

25 to 4000 mV 50 mV

25* Relay 2 reset time 0.1 to 999.9 minutes 999.9 mins no

(HI 21523 only)

26* Relay 2 rate time 0.0 to 999.9 minutes 0.0 mins no

(HI 21523 only)

30 Relay 3 high alarm (HA) 0.00 to 14.00 pH 9.00 pH no

-2000 to 2000 mV 600 mV

HA>LA, HA>S1 or HA>S2

31 Relay 3 low alarm (LA) 0.00 to 14.00 pH 5.00 pH no

-2000 to 2000 mV -600 mV

LA<HA, LA<S1 or LA<S2

32 Proportional control 1 to 30 min (

not for HI 21523) 5 min no

mode period 5 s to 30 min (HI 21523 only) 30 s no

33 Maximum relay ON time 1 to 60 min (

10 to 999 min (

HI 21523 only) 60 no

not for HI 21523) 60 no

(after which an alarm mode is entered)

34 Alarm mask time 00:00 to 30:00 00:00 no

(HI 21523 only)

40 Analog output selection 0: 0-1mA 2 no

1: 0-20 mA

2: 4-20 mA

3: 0-5 VDC

4: 1-5 VDC

5: 0-10 VDC

Note: this parameter refer to internal hardware configuration of the instrument. To

change it from the factory setting, see page 26.

41 Analog output 0.00 to 13.00 pH 0.00 pH no

lower limit -2000 to 2000 mV -2000 mV

(O_VARMIN) (O_VARMIN < O_VARMAX-(1.00pH or 50mV))

42 Analog output 1.00 to 14.00 pH 14.00 pH no

upper limit -2000 to 2000 mV 2000 mV

(O_VARMAX) (O_VARMIN < O_VARMAX- (1.00pH or 50mV))

60 Current day 01 to 31 from RTC no

61 Current month 01 to 12 from RTC no

62 Current year 1997 to 9999 from RTC no

63 Current time 00:00 to 23:59 from RTC no

71 Baud rate 1200, 2400, 4800, 9600 9600 (RS485) no

90 Display selftest 0: off 0 yes

1: on

91 Keyboard selftest 0: off 0 yes

1: on

92 EEPROM selftest 0: off 0 yes

1: on

93 Relays and LEDs selftest 0: off 0 yes

1: on

94 Watchdog selftest 0: off 0 yes

1: on

99 Unlock password 0000 to 9999 0000 yes

Note The process controller automatically checks to ensure that

the entered data matches other related variables. If a wrong

configuration is entered, “WRONG” blinks on the LCD to

prompt the user. The correct configurations are the following:

If M1=/ 0 then S1

If M2=/ 0 then S2

For models other than HI 21523:

If M1= 1 then S1-H1

If M1= 2 then S1+H1

If M1= 3 then S1+D1

If M1= 4 then S1-D1

If M2= 1 then S2-H2

If M2= 2 then S2+H2

If M2= 3 then S2+D2

If M2= 4 then S2-D2

If M1= 1 and M2 = 2

then S1-H1

If M1 = 2 and M2 = 1

then S2-H2

If M1 = 3 and M2 = 2

>S2+H2, S2>LA, HA>S1+D1;

then S1

<HA, S1>LA;

<HA, S2>LA;

>LA;

<HA;

<HA;

>LA;

>LA;

<HA;

<HA;

>LA;

>S2+H2, S2>LA, HA>S1;

>S1+H1, S1>LA, HA>S2;

1514

Page 9

If M1 = 2 and M2 = 3

then S1+H1

If M1 = 4 and M2 = 1

then S1

If M1 = 1 and M2 = 4

then S1–H1

If M1 = 3 and M2 = 4

then S1

If M1 = 4 and M2 = 3

then S2

For HI 21523 only:

If M1 = 1 then S1+D1

If M1 = 2 then S1–D1

where the minimum deviation (D1 or D2) is 0.5 pH (for HI

21) or 25 mV (for HI 22).

<S2, S1>LA, HA>S2+D2;

<S2–H2, S1–D1>LA, HA>S2;

>S2, S2–D2>LA, HA>S1;

>S2, S2–D2>LA, HA>S1+D1;

>S1, S1–D1>LA, HA>S2+D2;

<HA;

>LA;

Note The password cannot be viewed when SETUP is pressed with-

out entering the original password first. The default password

is set at “0000”. In the event that the user forgets the password, this can be reset to “0000” by pressing and holding

CFM and then pressing LCD and CAL DATA at the same time

when the pH controller is in normal operating mode (idle or

control with measurement displaying).

CONTROL MODE

The control mode is the normal operational mode for these

meters. During control mode HI 21 and HI 22 fulfill the

following main tasks:

• convert information from pH/ORP and temperature inputs

• control relays and generate the analog outputs as deter-

• RS485 management (if the feature is included).

In addition, HI 21 and HI 22 can log working data through

RS485 connection. This data includes:

• pH, mV and

• last calibration data;

• setup configuration (also from PC).

The status of the meter is shown by the LED’s on the right

to digital values;

mined by the setup configuration, display alarm condition;

o

C measured values;

STATUS LEDs

Control Alarm Alarm LED (green) Relay LED (yellow) Red LED

OF F ---- O N O FF O N

ON OFF ON ON or OFF OFF

ON ON OFF ON or OFF Blinking

Note When a wrong setup value is con-

firmed, the pH controller does not skip

to the next setup item but remains in

the current item displaying a flashing

“WRONG” indicator until the parameter value is changed by the user (the same is also true for

the setup code selection). In some circumstances, the user

cannot succeed in setting a parameter to a desired value if

the related parameters are not changed beforehand; e.g. to

set a pH high setpoint to 10.00 the high alarm must be set to

a value greater than pH 10.00 first.

Note For code numbers 40, 41, 42, the output is related to pH or mV units

depending on the model (pH process meters or mV process meters).

Items 41 and 42 are not available in HI 215YZ .

Meter exits control mode by pressing SETUP or CAL and confirming the password. Note that this command generates a

temporary exit. To deactivate the

control mode definitively, set

CONTROL ENABLE to “0” (item

# 02).

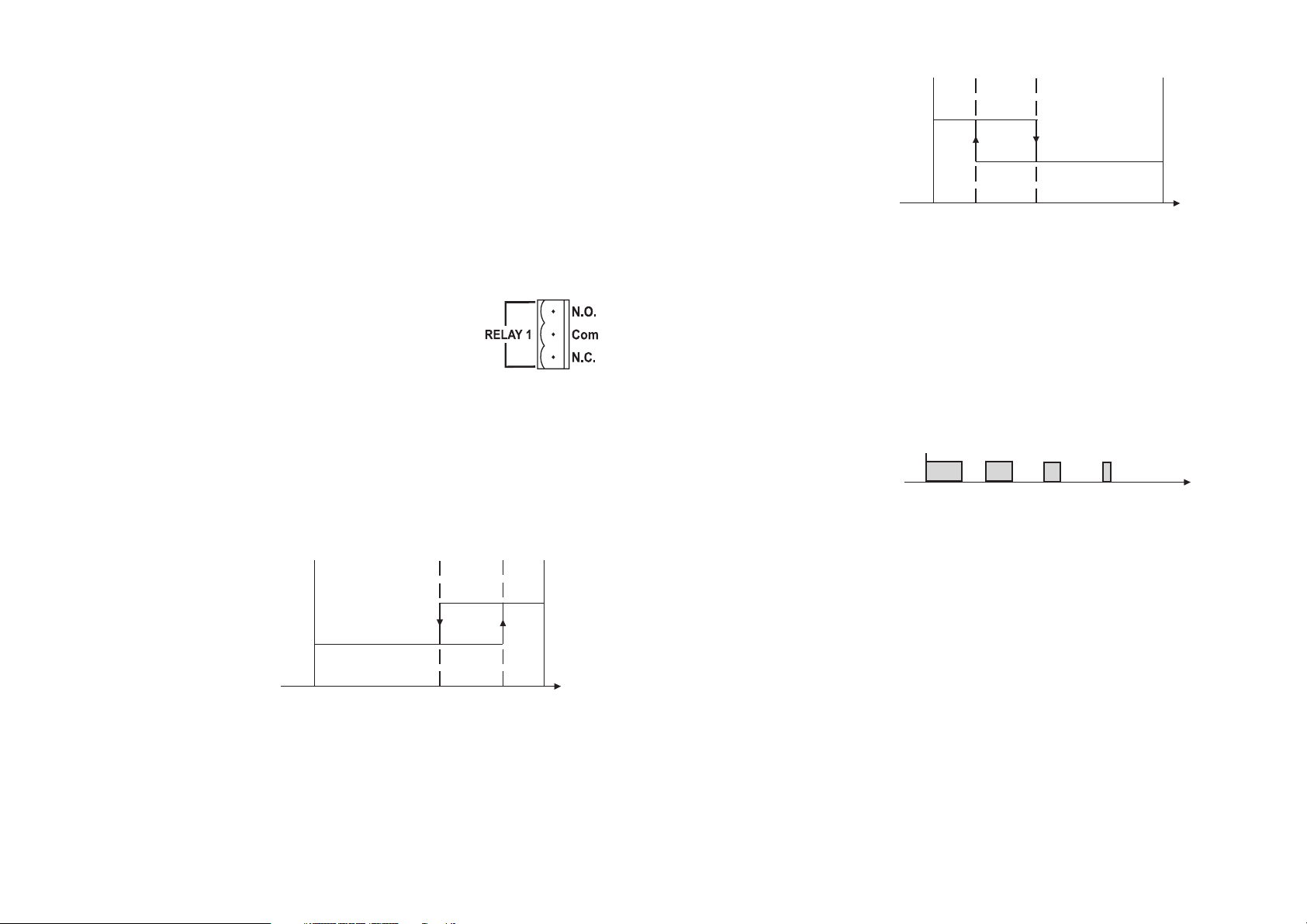

RELAY MODES

Once enabled, the relays 1 and 2 can be used in four different modes:

1) ON/OFF, high setpoint (acid dosage) (not for HI 21523);

2) ON/OFF, low setpoint (base dosage) (not for HI 21523);

3) Proportional or PID (HI 21523 only), low setpoint (base

dosage, if available);

4) Proportional or PID (HI 21523 only), high setpoint (acid

1716

Page 10

An upper boundary is imposed for acid/base dosage time

when relays are energized continuously, i.e. when relay works

in ON/OFF mode or in PID mode but in the latter case only

if the relay is always ON. This parameter can be set through

setup procedure. When the maximum boundary is reached,

an alarm is generated; device stays in alarm condition until

relay is de-energized.

ON/OFF CONTROL MODE

Either for mode 1 or 2 (base or acid dosage) the user has to

define the following values through setup:

• relay setpoint (pH/mV value);

• relay hysteresis (pH/mV value).

Connect your device to the COM and

NO (Normally Open) or NC (Normally

Closed) terminals.

The ON relay state occurs when relay is energized (NO and

COM connected, NC and COM disconnected).

The OFF relay state occurs when relay is de-energized (NO

and COM disconnected, NC and COM connected).

The following graphs show relay states along with pH measured value (similar graph can be derived for mV control).

As shown below, a high setpoint relay is activated when the

measured pH exceeds the setpoint and is deactivated when it

is below the setpoint value minus hysteresis.

Such a behavior is suitable to control an acid dosing pump.

A low setpoint relay as can be seen from the following graphs

is energized when the pH value is below the setpoint and is

de-energized when the pH value is above the sum of setpoint

and the hysteresis. The low setpoint relay may be used to

control an alkaline dosing pump.

dosage, if available).

ON

OFF

Setpoint –

Hysteresis

Setpoint

14

ON

OFF

Setpoint

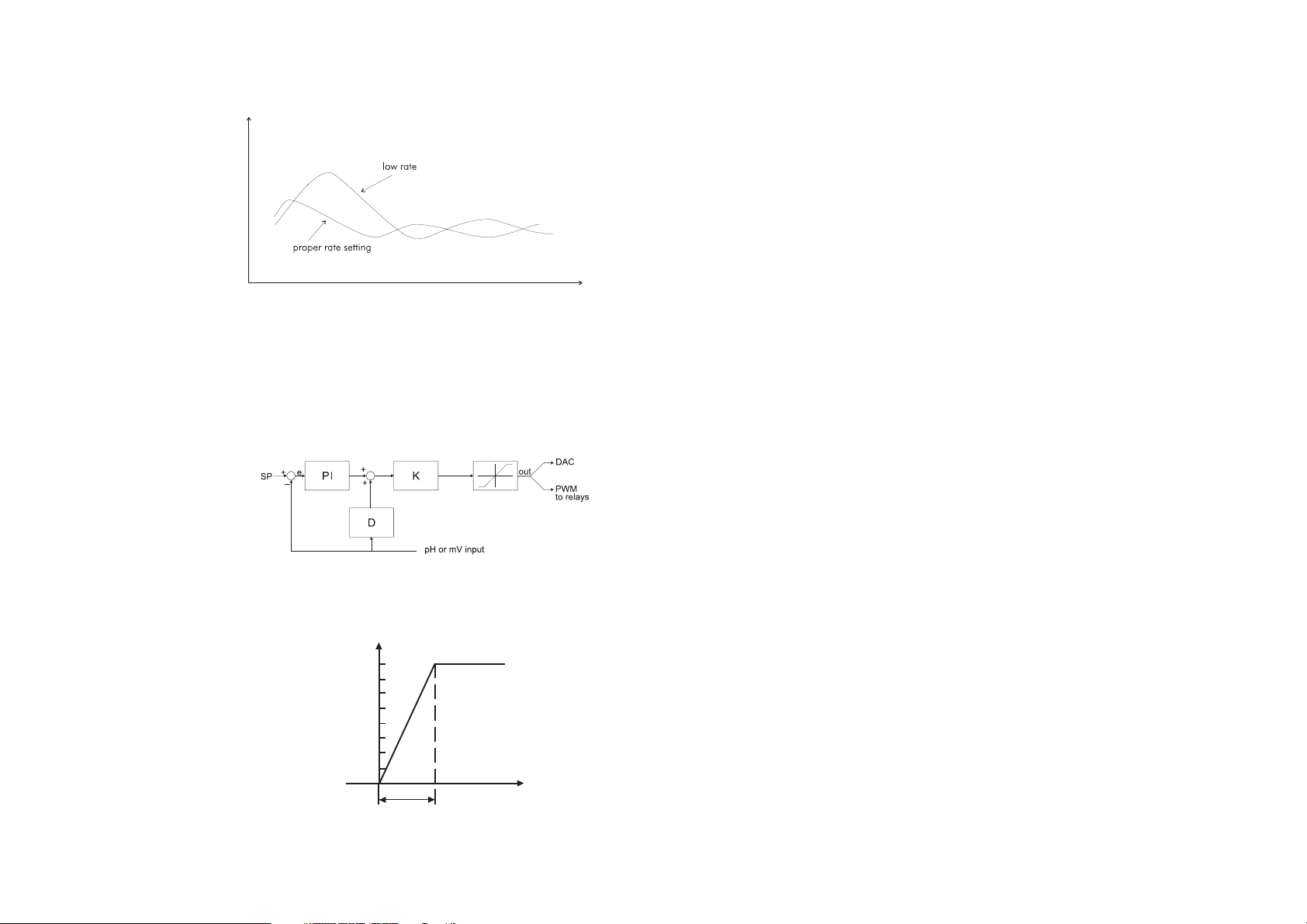

P.I.D. CONTROL MODE (HI 21523 ONLY)

PID control is designed to eliminate the cycling associated

with ON/OFF control in a rapid and steady way by means of

the combination of the proportional, integral and derivative

control methods.

With the proportional function, the duration of the activated

control is proportional to the error value (Duty Cycle Control

Mode): as the measurement approaches setpoint, the ON

period diminishes.

The following graph describes the pH process controller behavior. Similar graph may apply to the mV controller.

t

0

During proportional control the process controller calculates

the relay activation time at certain moments t

etc. The ON interval (the shaded areas) is then dependent to

the error amplitude.

With the integral function (reset), the controller will reach a

more stable output around the setpoint providing a more

accurate control than with the ON/OFF or proportional action only.

The derivative function (rate action) compensates for rapid

changes in the system reducing undershoot and overshoot of

the pH value.

During PID control, the ON interval is dependent not only to

the error amplitude but even to the previous measurements.

Definitely PID control provides more accurate and stable control than ON/OFF controllers and it is best suitable in system

with a fast response, quickly reacting to changes due to addition of acid or base solution.

t0+T

Setpoint +

Hysteresis

c

t0+2T

14

t0+3T

c

c

, t0+Tc, t0+2T

0

c

1918

Page 11

An example of how the response overshoot can be improved with

a proper rate action setting is depicted in the following graphic.

pH

RATE ACTION COMPENSATES FOR RAPID CHANGES t

PID TRANSFER FUNCTION

The transfer function of a PID control is as follows:

with Ti = Kp/Ki, Td = Kd/Kp,

where the first term represents the proportional action, the

second is the integrative action and the third is the derivative

action.

Proportional action can be set by means of the Proportional

Band (PB). Proportional Band is expressed in percentage of the

input range and is related to Kp according to the following:

Kp = 100/PB.

Kp + Ki/s + s Kd = Kp (1 + 1/(s Ti) +s Td)

100%

Controller

output

In HI 21 and HI 22 the proportional action is set directly as

“Deviation” in pH and mV units respectively. Relation between Deviation (D) and PB is:

D = Range * PB/100

Each setpoint has a selectable proportional band: PB1 for

setpoint1 and PB2 for setpoint2. Two further parameters must

be provided for both setpoints:

Ti = Kp/Ki, reset time, measured in minutes

Td = Kd/Kp, rate time, measured in minutes.

Ti1 and Td1 will be the reset time and rate time for setpoint1,

while Ti2 and Td2 will be the reset time and the rate time for

setpoint2.

TUNING A PID CONTROLLER

The proportional, integrative, derivative terms must be tuned,

i.e. adjusted to a particular process. Since usually the process variables are not completely known, a “trial and error”

tuning procedure must be applied to get the best possible

control for the particular process. The target is to achieve a

fast response time and a small overshoot.

Many tuning procedures are available and can be applied

to HI 21. A simple and profitable procedure is reported in

this manual and can be used in almost all applications.

The user can vary five different parameters, i.e. the setpoint

(S1 or S2), the deviation (D1 or D2), the reset time, the rate

time and the proportional control mode period T

30 minutes).

Note User can disable the derivative and/or integrative action (for

P or PI controllers) by setting Td = 0 and/or Ti = MAX (Ti)

respectively through the setup procedure.

SIMPLE TUNING PROCEDURE

The following procedure uses a graphical technique of analyzing a process response curve to a step input.

Note Connecting an external device (chart recorder or PC) to the

controller, the procedure is easier and doesn’t need the use

of hand plotting the process variable (pH or mV).

(from 1 to

c

0

Proportional Band

Error

2120

Page 12

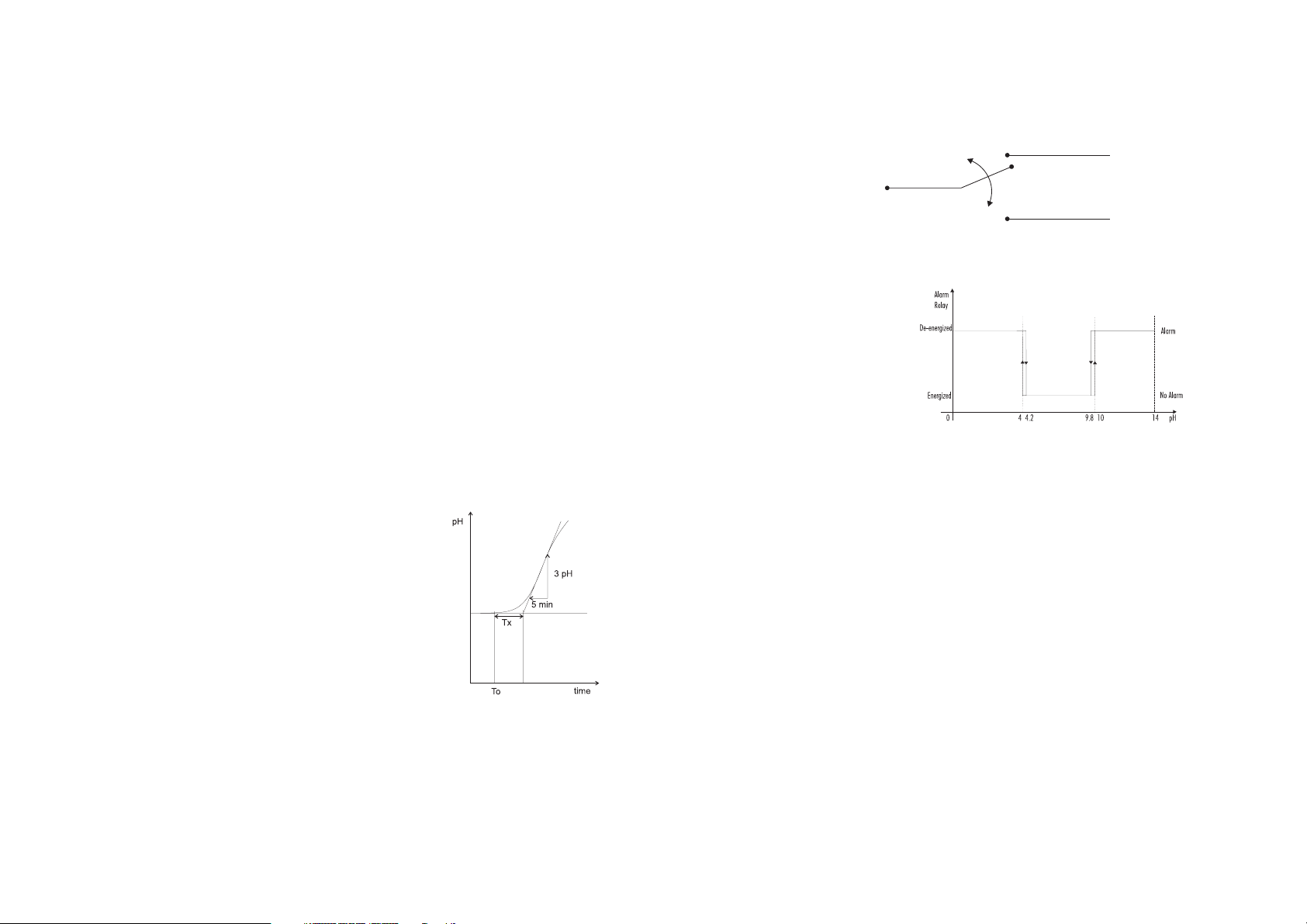

1. Starting from a solution with a pH or mV value different

from the dosed liquid (at least a 3 pH or 150 mV difference) turn on the dosing device at its maximum capacity

without the controller in the loop (open loop process). Note

the starting time.

2. After some delay the pH or mV starts to vary. After more

delay, the pH or mV will reach a maximum rate of change

(slope). Note the time that this maximum slope occurs and

the pH or mV value at which it occurs. Note the maximum

slope in pH or mV per minute. Turn the system power off.

3. On the chart draw a tangent to the maximum slope point until

intersection with the horizontal line corresponding to the initial

pH or mV value. Read the system time delay Tx on the time axis.

4. The deviation, Ti and Td can be calculated from the following:

• Deviation = Tx * max. slope (pH or mV)

• Ti = Tx / 0.4 (minutes)

• Td = Tx * 0.4 (minutes).

5. Set the above parameters and restart the system with the

controller in the loop. If the response has too much overshoot or is oscillating, then the system can be fine-tuned

slightly increasing or decreasing the PID parameters one

at a time.

Example:

the chart recording in the figure

aside was obtained continuously

dosing an alkaline solution to a

weak acid solution in a tank. The

initial settings will be:

Max. slope = 3 pH/5 mins = 0.6

pH/min

Time delay = Tx = approx. 7 mins

Deviation = Tx * 0.6 = 4.2 pH

Ti = Tx / 0.4 = 17.5 mins

Td = Tx * 0.4 = 2.8 mins

ALARM RELAY The alarm relay functions in the following manner:

During alarm condition, the relay is de-energized. When not

in alarm condition, the relay is energized.

FS•C = NO (Normally Open)

Energized Relay

COM

FS•O = NC (Normally Closed)

De-energized Relay

Example: High alarm set at 10 pH

Low alarm set at 4 pH

An hysteresis will eliminate the possibility of continuous sequences ‘energizing/de-energizing’ of the alarm relay when

the measured value is close to the alarm setpoint. The hysteresis amplitude is 0.2 pH in HI 21 and 30 mV in HI 22.

Moreover the alarm signal is generated only after a user selectable time period (alarm mask) has elapsed since the

controlled value has overtaken one alarm threshold. This

additional feature will avoid fake or temporary alarm conditions.

Note If the power supply is interrupted, the relay is de-energized as

if in alarm condition to alert the operator.

In addition to the user-selectable alarm relays, all HI 21 and

HI 22 models are equipped with the Fail Safe alarm fea-

ture.

The Fail Safe feature protects the process against critical

errors arising from power interruptions, surges and human

errors. This sophisticated yet easy-to-use system resolves these

predicaments on two fronts: hardware and software. To eliminate problems of blackout and line failure, the alarm function

operates in a “Normally Closed” state and hence alarm is

triggered if the wires are tripped, or when the power is down.

2322

Page 13

This is an important feature since with most meters the alarm

terminals close only when an abnormal situation arises, however, due to line interruption, no alarm is

sounded, causing extensive damage. On

the other hand, software is employed to

set off the alarm in abnormal circumstances, for example, if the dosing terminals

are closed for too long a period. In both

cases, the red LED’s will also provide a

visual warning signal.

The Fail Safe mode is accomplished by connecting the external alarm circuit between the FS•O (Normally Open) and

the COM terminals. This way, an alarm will warn the user

when pH goes over the alarm thresholds, the power breaks

down and in case of a broken wire between the process meter

and the external alarm circuit.

IDLE MODE

During idle mode the device performs the same tasks as when

it is in control mode except for the relays. The alarm relay is

activated (no alarm condition), the acid and base relays are

not activated while the analog output remains activated.

When the instrument is in idle mode the red and green status

LEDs are on.

Idle mode is useful to disable control actions when the external devices are not installed or when the user detects unusual

circumstances.

Control actions are stopped as soon

as the user presses SETUP and enters

the password.

Note In order to have the Fail Safe feature activated, an external

power supply has to be connected to the alarm device.

CONTROL THROUGH ANALOG OUTPUT

Model HI 21523 has a proportional output signal (selectable among 0-1 mA, 0-20 mA, 4-20 mA, 0-5 VDC, 1-5

VDC and 0-10 VDC) at the analog output terminals. With

this output, the actual output level amplitude is varied, rather

than the proportion of ON and OFF times (duty cycle control). A device with analog input (e.g. a pump with a 4-20

mA input) can be connected to these terminals.

Note Models with this feature don’t have the output relay for a duty

cycle control.

In order to reactivate the control mode, use code 02 of setup

(see “Setup” section). Otherwise, the meter remains in idle

mode.

2524

Page 14

ANALOG OUTPUT

All models HI 21XY1, HI 21XY3 and HI 22XY1 are provided

with the analog output feature.

The output is isolated and can be a voltage or a current.

With the recorder, simply connect the common port to the

ground output and the second port to the current output or

voltage output (depending on

which parameter is being used)

as depicted aside.

The type (voltage or current)

and the range of the output

analog signal is selectable through the jumpers on the power

board.

Configurations of the jumpers are as follows:

Output Jumper 1 Jumper 2 Jumper 3 Jumper 4

0-5 VDC, 1-5 VDC OFF ON – – – –

0-10 VDC ON OFF – – – –

0-20 mA, 4-20 mA – – – – ON – –

0-1 mA – – – – OFF – –

These values can be changed by the user to have the analog

output matching a different pH range, for example, 4 mA =

3.00 pH and 20 mA = 5.00 pH.

To change the default values, the setup mode must be en-

tered. Setup codes for changing the analog output minimum

and maximum are 41 or 42, respectively. For the exact

procedure, refer to the setup mode section in the manual.

Note The difference between maximum and minimum values for

the analog output must be at least 1.00 pH or 50 mV.

Note The analog output is factory calibrated through software. The

user may also perform these calibration procedures following

the procedure at page 46. It is recommended to perform the

output calibration at least once a year.

Choice between different ranges with the same configuration

(for example 0-20 mA and 4-20 mA) is achieved via software by entering the setup mode and selecting code 40 (see

Setup Mode section for exact procedure).

Factory default is jumpers 1 and 3 closed (ON) and jumpers

2 and 4 open (OFF), i.e. 0-20 mA, 4-20 mA and 0-10

VDC.

In any case, contact the nearest Hanna Customer Service

Center for changing of the default configuration.

By default the minimum and maximum values of analog

output correspond to the minimum and maximum of the

range of the meter. For example, for the HI 21 series with a

selected analog output of 4-20 mA, the default values are

0.00 and 14.00 pH corresponding to 4 and 20 mA, respectively.

2726

Page 15

RS485 COMMUNICATION

HI 21XY2, HI 21XY3 and HI 22XY2 are provided with an

RS485 port.

RS485 standard is a digital transmission method that allows

long lines connections. Its current-loop system makes this

standard suitable for data transmission in noisy environments.

Data transmission from the instrument to the PC is possible

with the HI 92500 Windows

ware offered by Hanna Instruments.

The user-friendly HI 92500 offers a variety of features such

as logging selected variables or plotting the recorded data. It

also has an on-line help feature to support you throughout

the operation.

HI 92500 makes it possible for you to use the powerful means

of the most diffused spreadsheet programs (Excel

©

etc.). Simply run your favorite spread sheet and open

1-2-3

the file downloaded by HI 92500. It is then possible to elaborate the data with your software (e.g. graphics, statistical

analysis).

To install HI 92500 you need a 3.5" drive and few minutes

to follow the instructions conveniently printed on the disk’s

label.

Contact your Hanna Dealer to request a copy.

SPECIFICATIONS

The RS485 standard is implemented in HI 21/HI 22 with the

following characteristics:

Data rate: up to 9600 bps

Communication: Bidirectional Half-Duplex

Line length: up to 1.2 Km typ. with 24AWG cable

Loads: up to 32 typ.

Internal termination: none

®

compatible application soft-

©

, Lotus

CONNECTIONS

The connections for the 4-pin RS485 terminal provided (#1

on page 7) are as follows:

The instrument has no internal line termination. To terminate

the line, an external resistor equal to the characteristic line

impedance (typically 120Ω) must be added at both ends of

the line.

Up to 32 units can be connected to the same RS485 line,

with a total line length of up to 1.2 Km using 24AWG cable.

To minimize electromagnetic interferences, use shielded or

twisted pair cable to connect the units.

Each HI 21/HI 22 unit is identified by its process ID number

(setup item “01”).

The HI 21/HI 22 controller acts as a “slave” device: it only

answers to commands received from a “master” device (e.g.

an industrial PC) connected to the line.

Excel© Copyright of “Microsoft Co.”

©

Copyright of “Lotus Co.”

Lotus 1-2-3

®

registered Trademark of “Microsoft Co.”

Windows

2928

Page 16

RS485 PROTOCOL

As additional feature, the controller is also

provided with two pins (5V and 0V) in order to apply the Fail Safe Open Line

protection method. To avoid erroneous

readings in Open-Line conditions, pullup and pull-down resistors should be

connected as shown.

The Fail-Safe resistors are connected only to one unit in the

line, and their value depends on the application and characteristic impedance of the connection cable.

The RS485 port is optoisolated from measuring circuit and

power line. If both analog output and RS485 port are present,

they have the same ground.

The commands sent to the controller must have the following

format:

• 2-digit process ID number

• 3-character command name

• Parameters (variable length, may be null)

• End of command (always the CR character, Hex 0D)

A maximum time interval of 20 ms is allowed between two

consecutive characters of a command.

It is possible to send commands to change the controller

settings or to simply ask information on the controller status.

Following is the complete list of commands available:

Command Parameter Description

CAR null Request calibration data

GET NN Request setup item NN

K01 null Same as CFM+ð+CAL keys

K02 null Same as LCD+CAL+SETUP keys

KCD null Same as CAL DATA key

KCF null Same as CFM key

KCL null Same as CAL key

KDS null Same as LCD key

KDW null Same as ò key

KRG null Same as ð key

KST null Same as SETUP key

KUP null Same as ñ key

MDR null Request firmware code

MVR null Request mV reading

(HI 22 only; available in

control or idle mode only)

PHR null Request pH reading

(HI 21 only; available in

control or idle mode only)

PWD NNNN Send the 4-digit password

SET NNPC1C2C3C4C

blank (the command is

not available if the controller is

in setup mode)

Set setup item NN to the

5

PC1C2C3C4C

P=+ if value is greater than 0

P=

-

C

can be 0 or 1 only

1

C2C3C4C

value

5

if value is less than 0

can be 0 to 9 or

5

3130

Page 17

TMR null Request temperature reading

Note If the controller is not in control or idle mode and the tem-

perature reading is requested through the TMR command,

the controller answers with the last acquired reading when it

was in control or idle mode.

Note After a recognized PWD command is received, the controller

allows a maximum of 1 minute without receiving data, after

which it locks again and a new PWD command is needed to

perform password protected operations.

Following are examples of commands for setup items:

1) “03 SET 22

This command sets the setup item 22 (relay 2 setpoint) of

a mV controller, identified by the process ID number 03,

to the -1200 mV value.

2) “01 SET 33+015

This command sets the setup item 33 (max. relay ON

time) of a controller, identified by the process ID number

01, to 15 minutes. The

Once the controller has received a command, it answers

with its 2-digit process ID number followed by:

• ACK (Hex 06)

• STX (Hex 02) , Data , ETX (Hex 03)

• NAK (Hex 15)

• CAN (Hex 18)

-

01200<CR>”

◊◊<CR>”

“◊” character means blank.

If the controller recognizes the received command

and performs the requested task;

If the received command is a request of data;

If the received command is not recognized (e.g. the

syntax is wrong);

If the controller cannot answer the request (e.g. the

password was not sent, the controller is in setup

mode, the setup item is not available in that model,

etc.)

Note The controller answers to the GET command with the same

data format explained in the SET command.

Following are examples of answers:

1) “03<STX>

The controller with process ID number 03 says that its

current setpoint is -1200 mV.

2) “01<STX>UHI2122210<ETX>”

The controller with process ID number 01 says that it is a

HI 21222 model with firmware release 1.0.

The time-out for the first character of the controller answer is

2 seconds (except answers to PHR, MVR and TMR as explained below).

The minimum delay between the last received character and

first character of the answer is 15 ms.

The time-out for the complete controller answer to the PHR,

MVR and TMR commands is:

30 ms at 9600 bps

40 ms at 4800 bps

60 ms at 2400 bps

90 ms at 1200 bps

When the controller answers to the PHR, MVR and TMR commands, the reading is sent as ASCII string followed by a

character (HI 21523 only) indicating the control and alarm

status of the controller. This character can assume the following values:

• “A”, control and alarm are ON;

• “C”, control is ON and alarm is OFF;

• “N”, control and alarm are OFF;

For example, a possible answer to the TMR command is:

-

01200<ETX>”

“03<STX>10.7C<ETX>”

3332

Page 18

meaning that the current temperature reading is 10.7°C, the

control action is active and no alarm condition is present.

If asking for last calibration data and the controller was never

calibrated, it answers with “0”; e.g. “01<STX>0<ETX>”.

If the controller was calibrated, it answers with “1” followed

by the calibration data. The Data field of the answer has the

following format:

HI 21:

1<Date><Time><Offset><Slope1><Slope2 ><Buf1><Buf2><Buf3>

• Date: DDMMYY (e.g. “170400” for April 17,2000)

• Time: HHMM (e.g. “1623” for 4:23 pm)

• Offset: ASCII string (e.g. “

-

0.2”)

• Slope 1: ASCII string (e.g. “62.5”)

• Slope 2: ASCII string (e.g. “60.4”)

• Buf 1: ASCII string (e.g. “7.01”)

• Buf 2: ASCII string (e.g. “4.01”)

• Buf 3: ASCII string (e.g. “10.01”)

HI 22: 1<Date><Time><Buf1><Buf2>

• Date: DDMMYY (e.g. “170400” for April 17,2000)

• Time: HHMM (e.g. “1623” for 4:23 pm)

• Buf 1: ASCII string (e.g. “7.01”)

• Buf 2: ASCII string (e.g. “4.01”)

The items in the Data field are separated by blanks.

If an item is not available (e.g. Buf 3 if only a two points

calibration was performed) it is replaced by the “N” character.

Note The “r485” message can appear on the LCD while the con-

troller is receiving or answering commands.

CALIBRATION

The controller is factory calibrated for mV and temperature

inputs as well as for the analog outputs.

The user should periodically calibrate the instrument. For greatest accuracy, it is recommended that the instrument is calibrated

frequently.

It is possible to standardize the electrode with only one buffer,

preferably close to the expected sample value (one-point calibration), but it is always good practice to calibrate in at least

2 points.

pH CALIBRATION (for HI 21 Series only)

The pH controller can be calibrated through a one-point,

two-point or three-point calibration. You do not need to enter the method chosen, simply exit the

calibration mode, by pressing CAL,

when the desired number of points has

been calibrated.

The calibration points for HI 21 are pH 4.01, pH 7.01 and

pH 10.01 (at 25°C). The sequence proposed by the controller is pH 7.01, pH 4.01, pH 10.01. However, the user can

change this sequence by means of the ñ and ò keys.

The electrode must be kept hydrated at all times and definitely prior to calibration. The temperature probe should also

be connected to the process meter. The meters are equipped

with a stability indicator. The user is also guided with indications on the display during the calibration procedure.

Initial Preparation

Pour small quantities of pH 7.01

(HI 7007) and pH 4.01 (HI 7004)

and/or pH 10.01 (HI 7010) solutions

into individual beakers. If possible, use

plastic beakers to minimize any EMC

interference.

HI 7004

HI 7004

HI 7007

SETTING THE BAUD RATE

The transmission speed (baud rate) of the meter and external

device must be the same.

The meter is factory set to 9600 bps. To change this value,

use setup item 71.

3534

Page 19

For accurate calibration, use two beakers for each buffer

solution, the first one for rinsing the electrode, the second

one for calibration. By doing this, contamination between

the buffers is minimized.

To obtain accurate readings, use pH 7.01 and pH 4.01 if

you measure acidic samples, or pH 7.01 and pH 10.01 for

alkaline measurements or perform a 3-point calibration for

the entire range.

One Point Calibration (Offset)

• To perform the pH calibration enter

the calibration mode, by pressing

CAL and entering the password.

• After the correct password is entered,

the control actions stop and the primary LCD will display the pH value

using the current offset and slope,

with the "CAL" and "

and the probe indicator "

ing. The value displayed on the

secondary LCD is the buffer value

at the actual temperature.

Note The actual pH value varies with temperature, thus the cali-

bration value displayed on the secondary LCD will vary around

pH 4.01, 7.01 and 10.01 with temperature changes: for example at 25

o

C it shows 4.00 - 7.03 - 10.06 (see page 57 for other val-

ues).

• pH 7.01 is the default value for

the 1

ferent value is needed, select it

on the secondary display by

pressing ñ or ò.

Note If the wrong password is entered the system reverts back and

restarts displaying the pH value.

RINSE

HI 7007

1

BUF

" indicators lit

CALIBRATION

HI 7007

" blink-

o

C the display shows 4.01 - 7.01 - 10.01, at 20

st

calibration buffer. If a dif-

• Remove the protective cap from the

pH electrode and immerse it into the

selected buffer solution (e.g. pH 7.01)

with the Potential Matching Pin and

temperature probe, then stir gently.

Note The electrode should be submerged ap-

proximately 4 cm (1½") in the solution.

The temperature probe should be located

as close as possible to the pH electrode.

Note When it is not possible to immerse the Potential Matching Pin

together with the pH electrode in the solution, disable the

differential input by connecting the Connection for Potential

Matching Pin (#5 page 7) with the Connection for Electrode

Reference (#6 on page 7) with a jumper wire.

• Only when the reading is stable the

probe indicator "

(after about 30 seconds) and the

"CFM" indicator will start blinking.

• Press CFM to confirm the calibration; if the reading is close to

the selected buffer (±1.5 pH), the meter stores the reading

and the secondary LCD will display the expected second buffer

value. Offset and slope calculation is made at the end by

pressing CAL to exit.

If the reading is not close to the selected

buffer, "WRONG

• If CAL is pressed, the calibration process ends by memorizing a new offset

value. The new offset value is stored

and a default value of 57.5 mV per

pH unit at 25°C is assigned as the

new slope value.

For best accuracy however, it is recommended that a twopoint calibration is performed.

" will stop flashing

BUF

" will blink.

3736

Page 20

Two-point Calibration

Note The meter will automatically skip the buffer that was used for

Note If you are not going to perform a three-point calibration, it is

Note The electrode should be submerged ap-

• Proceed as described above for one-point calibration, using pH 7.01 as the first point, but do

not quit calibration by pressing CAL at the end.

the first calibration to prevent errors.

• After the first calibration point is confirmed, immerse the pH electrode with

the Potential Matching Pin into the second buffer (e.g. pH 4.01) and stir gently

recommendable to use pH 4.01 buffer if you are going to measure acid samples, or use pH 10.01 buffer for alkaline samples.

proximately 4 cm (1½") in the solution.

The temperature probe should be located

as close as possible to the pH electrode.

• Select the 2

nd

buffer value on

the secondary display by pressing ñ or ò (e.g. pH 4.01).

• Only when the reading is stable

the probe indicator "

" will stop

flashing (after about 30 seconds) and

the "CFM" indicator will blink.

• Press CFM to confirm the calibration; if the reading is close

to the selected buffer, the meter stores the reading, adjusting the slope point and the secondary LCD will display

the expected third buffer value.

Three-point Calibration

Note The meter will automatically skip the two buffers that were

Note The electrode should be submerged

• Proceed as described above but do

not quit calibration by pressing CAL.

used to prevent errors.

• After the second calibration point

is confirmed, immerse the pH electrode and the Potential Matching Pin

into the third buffer solution (e.g.

pH 10.01) and stir gently.

approximately 4 cm (1½") in the solution. The temperature probe should

be located as close as possible to the

pH electrode.

• Only when the reading is stable the

probe indicator "

" will stop flashing (after about 30 seconds) and the

"CFM" indicator will start blinking.

• Press CFM to confirm the calibration; if the reading is close

to the selected buffer, the meter stores the reading, adjusting the 2

with the offset and the 1

nd

slope point and the calibration process is ended

st

and 2nd slope of the meter cali-

brated.

If the reading is not close to the selected buffer, "WRONG

BUF

" will

blink.

If the reading is not close to the selected buffer, "WRONG

BUF

" will

blink.

• Press CAL and the calibration process is ended with the offset and the

st

slope of the meter calibrated.

1

Note During calibration, the secondary LCD displays the selected

buffer value. By pressing LCD the temperature can be displayed. This will allow you to check the buffer temperature

during calibration.

3938

Page 21

CALIBRATION WITH MANUAL TEMPERATURE COMPENSATION

• Enter the calibration procedure and press LCD to display

the temperature on the secondary LCD.

• Unplug any temperature probe that may

be attached to the meter. The "°C" symbol will flash.

• Note the temperature of the buffer solutions with a

ChecktempC or another accurate thermometer with a resolution of 0.1°C.

• Use ñ or ò to manually adjust the display reading to the

value of the reference thermometer (e.g. 20°C).

• Follow the calibration procedure above.

Note To toggle between the pH buffer and

the temperature press LCD.

PH BUFFER SELECTION (HI 21523 ONLY)

A one point pH calibration at a value different from standard

buffer is possible by directly entering the desired calibration

value.

• Pour a small quantity of the calibration solution in a beaker and then

press CAL to enter the calibration

mode.

• After the correct password is entered,

the control action stops and the primary LCD will display the pH value

using the current offset and slope,

with the "CAL" and "

lit and the probe indicator "

ing.

• Press SETUP and the pH value on

the secondary LCD will start blinking.

• By the ñ, ò and ð keys select the pH calibration value

of the buffer.

1

BUF

" indicators

" blink-

When a one-point calibration is carried out only the pH offset is computed and stored, while the pH slope is fixed

according to the theoretical values.

With a two-point calibration, offset and slope are computed

to fit the two calibration points. With a three-point calibration the offset and first slope values refers to pH 4.01 and

7.01 buffers, while the second slope refers to pH 7.01 and

10.01 buffers.

Note If the process meter has never been cali-

brated or an EEPROM reset has occurred,

the meter continues to perform measurement. However, the user is informed of a pH calibration

requirement by a blinking “CAL” (see “Start-up” section).

The device must be calibrated within the temperature range

of 0-95°C. Outside this range, the buffer pH values are not

reliable.

• Immerse the electrodes in the buffer solution.

• When the reading is stable press CFM to confirm the calibration.

Note During calibration with pH buffer solutions different from stan-

dard, the stability check function is not active. No “CAL” or

1

BUF

"

" indicators will blink, hence wait for the reading to stabilize after having immersed the electrode in the calibration

solution.

Note If the wrong password is entered the system reverts back and

restarts displaying the pH value.

Note Calibration can be aborted by pressing SETUP before CFM .

Calibration is restarted with no changes to calibration data.

4140

Page 22

OFFSET AND SLOPE DIRECT SELECTION (HI 21523 ONLY)

Whenever the pH electrode offset and slope parameters are

known, it is possible to directly calibrate the meter entering

the electrode parameters.

• Press the “CAL DATA” and then “SETUP”. The LCD will

show the default offset of -5.0 mV.

• Using the ñ, ò and ð enter the electrode offset param-

eter (the value must be between -100 and +100 mV).

• Confirm the value by pressing CFM.

If offset is invalid the “WRONG”

indicator will blink on the LCD.

• The LCD will then show the default

slope for Hanna electrodes: 57.5

mV/pH.

Note If CAL DATA or LCD are pressed before CFM, calibration is

aborted without changing the data of previous calibration.

• Using the ñ, ò and ð enter the electrode slope param-

eter (the value must be between +40 and +80 mV/pH).

• Confirm the value by pressing CFM. If

slope is invalid the “WRONG” indicator will blink on the LCD.

Note Press LCD or CAL DATA to exit cali-

bration. The slope will be set to the

default value (57.5 mV/pH).

Note Calibration data can be viewed pressing CAL DATA while in

normal mode but no pH buffer values will be displayed during the data scrolling on LCD.

mV INPUT CALIBRATION

The pH/mV controller is factory calibrated for the mV and

temperature inputs. However, the user may also perform a

mV calibration.

• Short the Connection for Potential Matching Pin (#5 on

page 7) and the Connection for the Electrode Reference

(#6 on page 7) with a jumper wire.

• Attach a HI 931001 (HI 21) or HI 8427 (HI 22) simulator

to the BNC socket.

• Press and hold first CFM and then

CAL to enter the mV Input Calibration mode.

• Execute the password procedure.

• With HI 21, the meter will ask for the calibration proce-

dure code number. The following table lists the possible

values of the input code and calibration points:

INPUT CODE POINTS CAL.VALUES INPUT RANGE

mV 0 2 0 & 350 or 0 & 1900* ±2000,

Temp. 1 2 0 & 25 or 0 & 50 -9.9 to 120.0 °C

* One of the points must be 0. 1900 mV calibration point is available

on HI 22 models only.

When calibrating the mV of HI 22 models, enter the calibration mode by pressing CAL and confirming the password

(as for pH calibration of HI 21). No code selection is required.

• Use ñ or ò to select code 0 for mV calibration and press

CFM to enter.

• CAL will blink on the LCD until the

meter confirms a steady reading.

4342

Page 23

• When the reading has stabilized at

a point near the first calibration

point, CAL will stop blinking and an

intermittent CFM icon will prompt the

user to confirm the first calibration.

• If the display stabilizes at a value

significantly different from the first

setpoint, an intermittent WRONG

icon will prompt the user to check

and adjust the simulator and start

again.

• After pressing CFM the unit will switch to the second calibration point at 350 mV.

• With HI 22 it is possible to select 1900 mV by pressing ñ

or ò. After that, proceed as described above.

Note A measure is considered stable when it varies little within a

sequence of acquisitions. The number of acquisitions is fixed

so that the waiting time for blinking “CFM” is about 20 seconds.

Calibration procedure may be interrupted by

pressing CAL. If the calibration procedure is interrupted this way, or if the controller is switched

off before the last step, no calibration data is

stored to EEPROM.

TEMPERATURE CALIBRATION

The pH/mV controller is factory calibrated for the mV and

temperature inputs. However, the user may also perform a

temperature calibration.

• Prepare a beaker containing ice

and water at 0°C/32°F and another one with hot water at 25°C/

77°F or 50°C/122°F.

0 °C

(32 °F)

• Use a Checktemp or another calibrated thermometer with

a resolution of 0.1° as a reference thermometer.

• Immerse the temperature probe in

°C

the beaker with ice and water as near

to the Checktemp as possible.

0 °C

(32 °F)

• Press and hold first CFM and then

CAL to enter the temperature calibration mode.

• Execute the password procedure.

• With HI 21, the meter will ask for the calibration procedure

code number. Use ñ or ò to select code 1 for the temperature calibration and press CFM to enter.

• CAL will blink on the LCD until the

meter confirms a steady reading.

• When the reading has stabilized at

a point near the first calibration

point, CAL will stop blinking and an

intermittent CFM will prompt the user

to confirm the first calibration.

• If the reading stabilizes at a reading

significantly variant from the first

setpoint, an intermittent WRONG

will prompt the user to check the

beaker or baths.

• After pressing CFM the unit will switch to the second calibration point.

°C

°C

• Select 25 or 50°C by pressing ñ or ò.

50 ºC

(122 ºF)

4544

Page 24

• Immerse the temperature probe in

the second beaker as near to the

Checktemp as possible and repeat

the above procedure.

Calibration procedure may be interrupted by pressing CAL

again at any time. If the calibration procedure is stopped this

way, or if the controller is switched off before the last step, no

calibration data is stored in non-volatile memory (EEPROM).

ANALOG OUTPUT CALIBRATION

In the meters where the analog output is available, this feature is factory calibrated through software. The user may also

perform these calibration procedures.

IMPORTANT It is recommended to perform the output calibration at least

once a year. Calibration should only be performed after a

few minutes from power up.

• With a multimeter or an HI

931002 connect the common

port to the ground output and

the second port to the current

or voltage output (depending

on which parameter is being

calibrated).

• Press and hold in sequence CFM first, then ð and then

CAL to enter the Analog Output Calibration mode.

• Execute the password procedure.

• The primary display will show the current selected parameter blinking. Use the ñ to select the code (0-5 see next

chart) for the desired parameter displayed on the secondary display (e.g. 4-20 mA).

50 °C

(122 °F)

°C

• Press CFM to confirm the parameter that stops blinking on

the primary display. The secondary display shows the multimeter or HI 931002 input value as the interval lower limit.

• Use ñ or ò to make the HI

931002 or multimeter output correspond with the value shown on

the secondary display (e.g. 4).

• Wait until the calibrator reading is stable (approx. 30 sec.).

• Press CFM to enter. The meter will switch to the second

calibration point. Repeat the above procedure.

• After the desired readings are obtained, press CFM and

the meter will skip back to normal operating mode.

Note When adjusting values using the ñ or ò it is important to

allow for sufficient response time (up to 30 seconds)

The table below lists the values of output codes along with

the calibration values (which are the analog output minimum and maximum) as indicated on the display.

The secondary display indicates the current calibration value,

while primary display indicates the current calibration type.

OUTPUT CALIBRATION CALIBRATION CALIBRATION

TYPE CODE POINT 1 POINT 2

0-1 mA 0 0 mA 1 mA

0-20 mA 1 0 mA 20 mA

4-20 mA 2 4 mA 20 mA

0-5 VDC 3 0 VDC 5 VDC

1-5 VDC 4 1 VDC 5 VDC

0-10 VDC 5 0 VDC 10 VDC

4746

Page 25

LAST CALIBRATION DATA

The meter stores the following information about last calibration in

the EEPROM:

• Date

• Time

• Offset in mV (for HI 21 only)

• Up to two slopes (for HI 21 only)

• Up to three buffers

While displaying this data, the pH controller remains in control mode.

The procedure below indicates the flow for a three-point calibration. The sequence will vary if fewer calibration points are

used (e.g. for a one-point calibration the following data will

be displayed: date, time, offset, first slope, buffer 1 value).

For the HI 22, last calibration data includes date and time

of calibration and the values of the 2 calibration points. Displaying of these items follows the above sequence.

• To begin the cycle press CAL DATA. The last calibration

date will appear on the main LCD display as DD.MM format, while the secondary display will show the year.

Note In any moment, by pressing LCD or CAL DATA the meter will

return to the regular operating display.

• Press ñ or ð to view the time of last calibration. The secondary display will show "HOU" to indicate hours.

• Press ñ or ð again to view the offset in mV at the time of

last calibration. The secondary display will show "OFF" to

indicate offset.

• Press ñ or ð again to view the first slope in mV at the time

of last calibration. The secondary display will show "SL1" to

indicate first slope.

If the meter has never been calibrated or an EEPROM reset

has occurred, no calibration data is shown when CAL DATA

is pressed. The “no CAL” message will blink for a few seconds, then the meter skips back to normal mode.

• Pressing ò will cycle through the following steps in reverse order, i.e. last

buffer.

• Press ñ or ð again to view the second slope in mV at the

time of last calibration. The secondary display will show

"SL2" to indicate second slope.

• Press ñ or ð again to view the first memorized buffer at

the time of last calibration. The secondary display will show

"BUF1" to indicate first buffer.

4948

Page 26

• Press ñ or ð again to view the second memorized buffer

at the time of last calibration. The secondary display will

show "BUF2" to indicate second buffer.

• Press ñ or ð again to view the third memorized buffer at

the time of last calibration. The secondary display will show

"BUF3" to indicate third buffer.

• Press ñ or ð again to return to the first CAL DATA display

(date) at the time of last calibration.

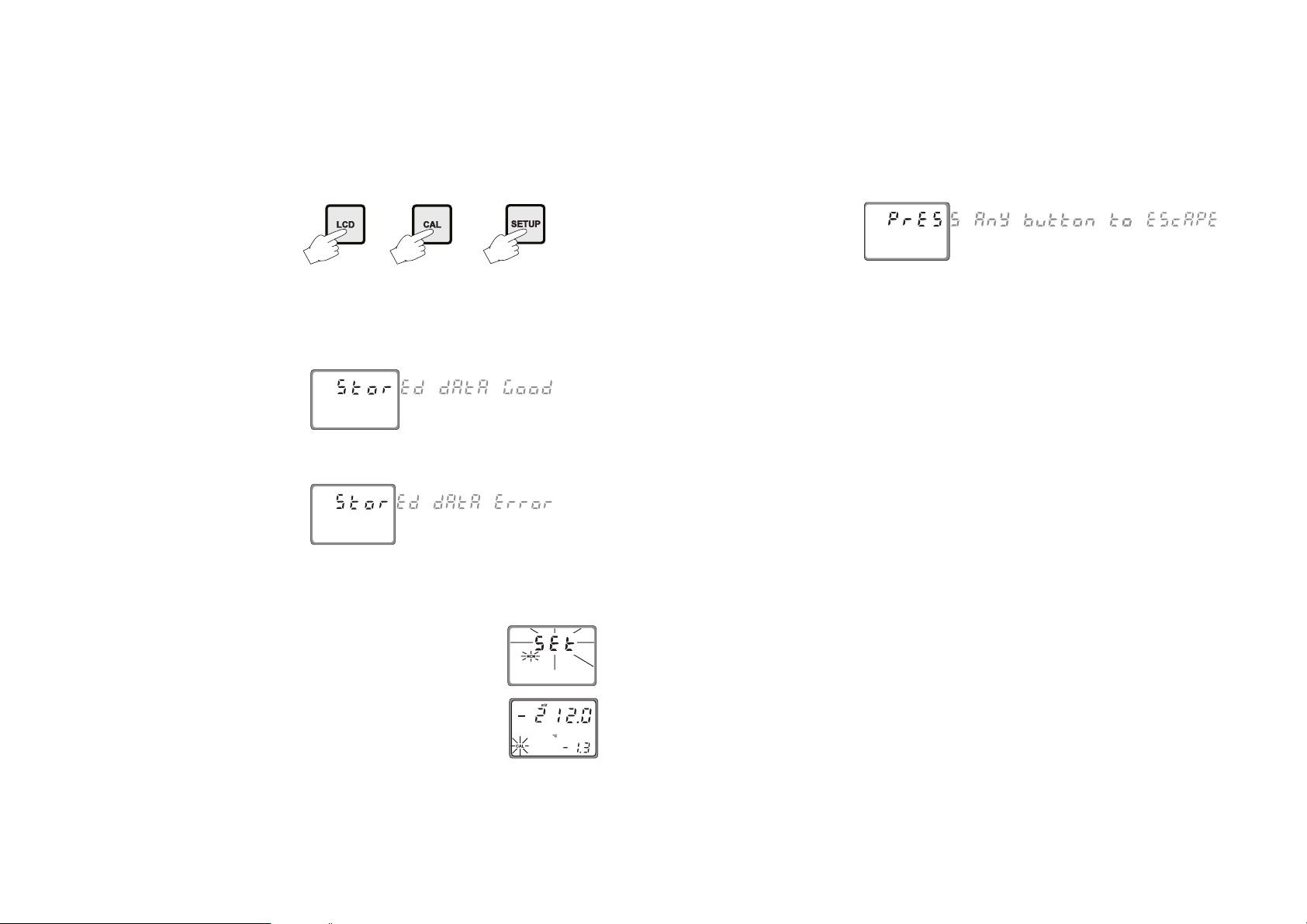

START-UP

At start-up the firmware release code scrolls through the LCD;

it is possible to escape from code scrolling pressing any key.

During the automatic start-up the Real Time Clock (RTC) is

checked to see if a reset occurred since last software initialization. In this case, the RTC is initialized with the default

date and time 01/01/1997 - 00:00. An EEPROM reset

does not affect the RTC settings.

The EEPROM is also checked to see if it is new. If this is the

case, the default values are copied from ROM and then

the device enters normal mode. Otherwise an EEPROM

checksum test is performed (the same is performed during

EEPROM selftest procedure).

If checksum is correct, normal mode is entered, otherwise

user is asked whether the EEPROM should be reset.

If EEPROM reset is requested, default values from ROM

are stored into EEPROM as would happen with a new

EEPROM.

Note that EEPROM data is composed of setup data and

calibration data. As for the setup data, the calibration data is

assigned default values when an EEPROM reset occurs. An

un-calibrated meter can perform measurement, though user is informed that

pH calibration (pH models) or mV calibration (mV models) is needed by

means a blinking “CAL” icon.

When the last calibration data is required, the “no CAL” message is

displayed if no calibration procedure

was performed.

Unlike pH and mV calibration, user has no information on

calibration need for other magnitudes, other than the awareness that EEPROM was reset.

After an EEPROM reset, all calibrations (input and output)

have to be performed in order to obtain correct measurements.

5150

Page 27

FAULT CONDITIONS AND SELFTEST PROCEDURES

The fault conditions below may be detected by the software:

• EEPROM data error;

• I2C internal bus failure;

• code dead loop.

EEPROM data error can be detected through EEPROM test

procedure at start-up or when explicitly requested using setup

menu.

When an EEPROM error is detected, user is given the option

to perform a reset of EEPROM. Thus the reset can be performed whenever needed. It may be useful to provide a means

to reset EEPROM directly (without a previous EEPROM error

detection). This is done by pressing CFM first and then SETUP,

ð and CAL DATA simultaneously.

The error detection for dead loops is performed by watchdog

(see below).

You can use special setup codes, perform selftest procedures

for LCD, keyboard, EEPROM, relays and LEDs, watchdog.

The operation of these functions is outlined in the setup section. The selftest procedures are described in detail in the

following subsections.

DISPLAY SELFTEST

The display selftest procedure consists of lighting up all of the

display segments together. The Display test is announced by a

scrolling "Display test" message.

The segments are lit for a few seconds and

then switched off before exiting the selftest

procedure.

KEYBOARD SELFTEST

The keyboard selftest procedure begins with the message “Button test, press LCD, CAL and SETUP together to escape”. The

LCD will then show only a colon.

Note When an EEPROM reset has been per-

formed calibration data are reset to

default. An intermittent CAL will blink

on the display to advise the user of

this status.

A I2C failure is detected when the I2C transmission is not

acknowledged or a bus fault occurs for more than a certain

number of attempts (this can be due, for example, to damage sustained by one of the ICs connected to I2C bus).

If so, the controller stops any tasks and displays a perpetual

sliding message “Serial bus error” (i.e. this is a fatal error).

As soon as one or more keys are pressed, the appropriate

segments out of 88:88 corresponding to the pressed keys,

will light up on the screen.

For example, if LCD and ñ are pressed together the LCD will

look like this:

5352

Page 28

The colon is a useful indicator for the correct position of

squares.

Note A maximum of two keys may be pressed simultaneously to be

properly recognized.

To exit the keyboard test procedure press LCD, CAL and SETUP

simultaneously.

RELAYS AND LEDS

Relays and LEDs selftests are executed as follows:

First all of the relays and LEDs are switched off, then they are

switched on one at a time for a few seconds and cyclically.

User can interrupt the otherwise endless cycle, as indicated

by the scrolling message, by pressing a key.

EEPROM SELFTEST

The EEPROM selftest procedure involves verifying the stored

EEPROM checksum. If the checksum is correct the “Stored

data good” message will be shown for a few seconds before

exiting selftest procedure.

If not, the instrument will display the message “Stored data

error - Press ñ to reset stored data or ð to ignore”.

If ð is pressed the EEPROM selftest procedure terminates

with no other action. Otherwise, EEPROM is reset with default values from ROM as when a device with a virgin

EEPROM is switched on.

During EEPROM reset a blinking message “Set MEM” is shown on the LCD.

At the end of this operation all the parameters are reset to their default

values. Calibration data is also reset.

For this reason the "CAL" flag blinks

until the pH calibration is performed.

Note Relays and LEDs test has to be carried out with the relay

contacts disconnected from external plant devices.

WATCHDOG

When a dead loop condition is detected a reset is automatically invoked.

The effectiveness of watchdog capability can be tested through

one of the special setup items. This test consists of executing

a dummy dead loop that causes watchdog reset signal to be

generated.

5554

Page 29

pH VALUES AT VARIOUS TEMPERATURES

Temperature has a significant effect on pH. The calibration

buffer solutions are effected by temperature changes to a lesser

degree than normal solutions.

For manual temperature calibration please refer to the following chart:

TEMP pH VALUES

°C °F 4.01 7.01 10.01

0 32 4.01 7.13 10.32

5 41 4.00 7.10 10.24

10 50 4.00 7.07 10.18

15 59 4.00 7.04 10.12

20 68 4.00 7.03 10.06

25 77 4.01 7.01 10.01

30 86 4.02 7.00 9.96

35 95 4.03 6.99 9.92

40 104 4.04 6.98 9.88

45 113 4.05 6.98 9.85

ELECTRODE CONDITIONING AND MAINTENANCE

50 122 4.06 6.98 9.82

55 131 4.07 6.98 9.79

60 140 4.09 6.98 9.77

65 149 4.11 6.99 9.76

70 158 4.12 6.99 9.75

For instance, if the buffer temperature is 25°C, the display

should show pH 4.01, 7.01 or 10.01 at pH 4, 7 or 10

buffers, respectively.

At 20°C, the display should show pH 4.00, 7.03 or 10.06.

The meter reading at 50°C will then be 4.06, 6.98 or 9.82.

PREPARATION

* Only available with refillable electrodes. For industrial applications, gel-filled electrodes are preferable

due to lesser maintenance requirements.

Remove the protective cap.

DO NOT BE ALARMED IF ANY SALT DEPOSITS ARE

PRESENT.

This is normal with electrodes and they will disappear when

rinsed with water.

During transport tiny bubbles of air may have formed inside

the glass bulb. The electrode cannot function properly under

these conditions. These bubbles can be removed by "shaking

down" the electrode as you would do with a glass thermometer.

5756

Page 30

If the bulb and/or junction are dry, soak the electrode in

HI 70300 Storage Solution for at least one hour.

For refillable electrodes**: If the refill solution (electrolyte) is more than 2½ cm (1")

below the fill hole, add HI 7082 3.5M KCl Electrolyte Solution for double junction or HI 7071 3.5M KCl+AgCl

Electrolyte Solution for single junction electrodes.

For AmpHel

®

electrodes: If the electrode does not respond to pH changes, the battery

is run down and the electrode should be replaced.

TEST MEASUREMENT

Rinse the electrode tip with distilled water.

Immerse the tip (bottom 4 cm / 1½") in the sample and stir

gently for approx. 30 seconds.

For a faster response and to avoid cross contamination of

the samples, rinse the electrode tip with the solution to be

tested, before taking your measurements.

STORAGE

To minimize clogging and assure a quick response time, the

glass bulb and the junction should be kept moist and not

allowed to dry out. This can be achieved by installing the

electrode in such a way that it is constantly in a well filled with

the sample (stream or tank).

When not in use, replace the solution in the protective cap

with a few drops of HI 70300 Storage Solution or, in its

absence, HI 7007 pH 7.01 Buffer Solution.

Follow the Preparation Procedure above before taking measurements.

Note NEVER STORE THE ELECTRODE IN DISTILLED OR DEION-

IZED WATER.

PERIODIC MAINTENANCE

Inspect the electrode and the cable. The cable used for the

connection to the controller must be intact and there must

be no points of broken insulation on the cable or cracks on

the electrode stem or bulb.

Connectors must be perfectly clean and dry. If any scratches

or cracks are present, replace the electrode. Rinse off any salt

deposits with water.

For refillable electrodes**: Refill the electrode with fresh electrolyte (HI 7071 for single

junction or HI 7082 for double junction electrodes). Allow

the electrode to stand upright for 1 hour. Follow the Storage Procedure above.

CLEANING PROCEDURE

General Soak in Hanna HI 7061 General Cleaning

Solution for approximately ½ hour.

Removal of films, dirt or deposits on the membrane/junction:

Protein Soak in Hanna HI 7073 Protein Cleaning

Solution for 15 minutes.

Inorganic Soak in Hanna HI 7074 Inorganic Cleaning

Solution for 15 minutes.

Oil/grease Rinse with Hanna HI 7077 Oil and Fat

Cleaning Solution.

IMPORTANT After performing any of the cleaning procedures rinse the

electrode thoroughly with distilled water, drain and refill the