Page 1

Page 2

Disclaimer

Hand Held Products, Inc. d/b/a HHP (“HHP”) reserves the right to make

changes in specifications and other information contained in this

document without prior notice, and the reader should, in all cases, consult

HHP to determine whether any such changes have been made. The

information in this publication does not represent a commitment on the

part of HHP.

HHP shall not be liable for technical or editorial errors or commissions

contained herein; not for incidental or consequential damages resulting

from the furnishing, performance, or use of this material.

This document contains proprietary information that is protected by

copyright. All rights are reserved. No part of this document may be

photocopied, reproduced, or translated into another language without the

prior written consent of HHP.

© 2001-2002 Hand Held Products, Inc. All rights reserved.

Web address: www.hhp.com

Page 3

Statement of Agency Compliance

Canadian Notice

This device complies with part 15 of the FCC Rules. Operation is

subject to the following two conditions: (1) this device may not cause

harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

FCC Class A Compliance Statement

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications. Operation of

this equipment in a residential area is likely to cause harmful interference,

in which case the user will be required to correct the interference at his

own expense.

Caution: Any changes or modifications made to this

device that are not expressly approved by Hand Held

Products, Inc. may void the user’s authority to operate the

equipment.

Note: To maintain compliance with FCC Rules and Regulations, cables

connected to this device must be shielded cables, in which the cable

shield wire(s) have been grounded (tied) to the connector shell.

This equipment does not exceed the Class A limits for radio noise

emissions as described in the Radio Interference Regulations of the

Canadian Department of Communications.

Le present appareil numerique n’emet pas de bruits radioelectriques

depassant les limites applicables aux appareils numeriques de la classe A

prescrites dans le Reglement sur le brouillage radioelectrique edicte par le

ministere des Communications du Canada.

The CE mark on the product indicates that the system has been

tested to and conforms with the provisions noted within the 89/336/ EEC

Electromagnetic Compatibility Directive, EN55022:1998 Class A.

For further information please contact:

Hand Held Products, Inc.

Nijverheidsweg 9

5627 BT Eindhoven

The Netherlands

i

Page 4

ii

Page 5

Table of Contents

Chapter 1 Getting Started

About This Manual 1-1

Chapter 2 Terminal Interfaces

Keyboard Wedge Interface 2-1

RS-232 Serial Interface 2-2

USB Keyboard Interface 2-4

Chapter 3 Programming the Scanner

HHP SET™ 3-1

Data Editor 3-3

Bar Code Programming Menu 3-5

Programming Procedures 3-6

Host Interface Selection 3-9

Symbology Programming 3-11

Keyboard Interface Control 3-21

Serial Interface Control 3-24

Wand Emulation Control 3-26

Operating Control 3-27

Chapter 4 Customer Service

Main Office 4-1

United Kingdom Office 4-1

Asia Pacific Office 4-2

Japan Office 4-2

Latin America Office 4-2

Application Support 4-2

Chapter 5 Limited Warranty

Appendix A

Interface Cable Converters A-1

Beeping Indications A-4

Keyboard Function Code Table A-5

ASCII Input Shortcut A-6

Bar Code Command Menu A-7

Sample Bar Codes A-8

Bar Code System Command A-9

Condensed Editor 3-32

iii

Page 6

iv

Page 7

Getting Started

1. Getting Started

The IMAGETEAM™ 3220 Mid-Range Linear Imager

replaces traditional laser bar code scanners with a high speed

scanner at a lower cost. Equipped with a new generation light

intensifier and optical design, the IT3220 has a high intensity

aiming line and captures bar codes from as far away as 8

inches (20.3 cm). The unique decoding engine gives the

IT3220 exceptionally fast and accurate scanning capabilities.

Since the built-in flash memory makes the IT3220

field-upgradeable, the scanner’s programming is always

up-to-date.

The VALUETEAM™ 3060B and 3080B CCD scanners are

ideal entry level bar code readers. They offer excellent

reading performance with the most often used terminals and

PCs for point-of-sale or general purpose applications. Both

the VT3060B and VT3080B have Flash Memory, are compact

in size, are comfortable to use, and have been designed to take

the punishment of daily use.

About This Manual

This User’s Guide provides installation and programming

instructions for both the IT3220 and the VT3060B/3080B.

Customer support and warranty information is also included.

HHP's scanners are factory programmed for the most common

terminal and communications settings. If you need to change

these settings, programming is accomplished by either

scanning the bar codes in this user’s guide or by using HHP

SET™, a Windows

perform on-screen configurations and software upgrades.

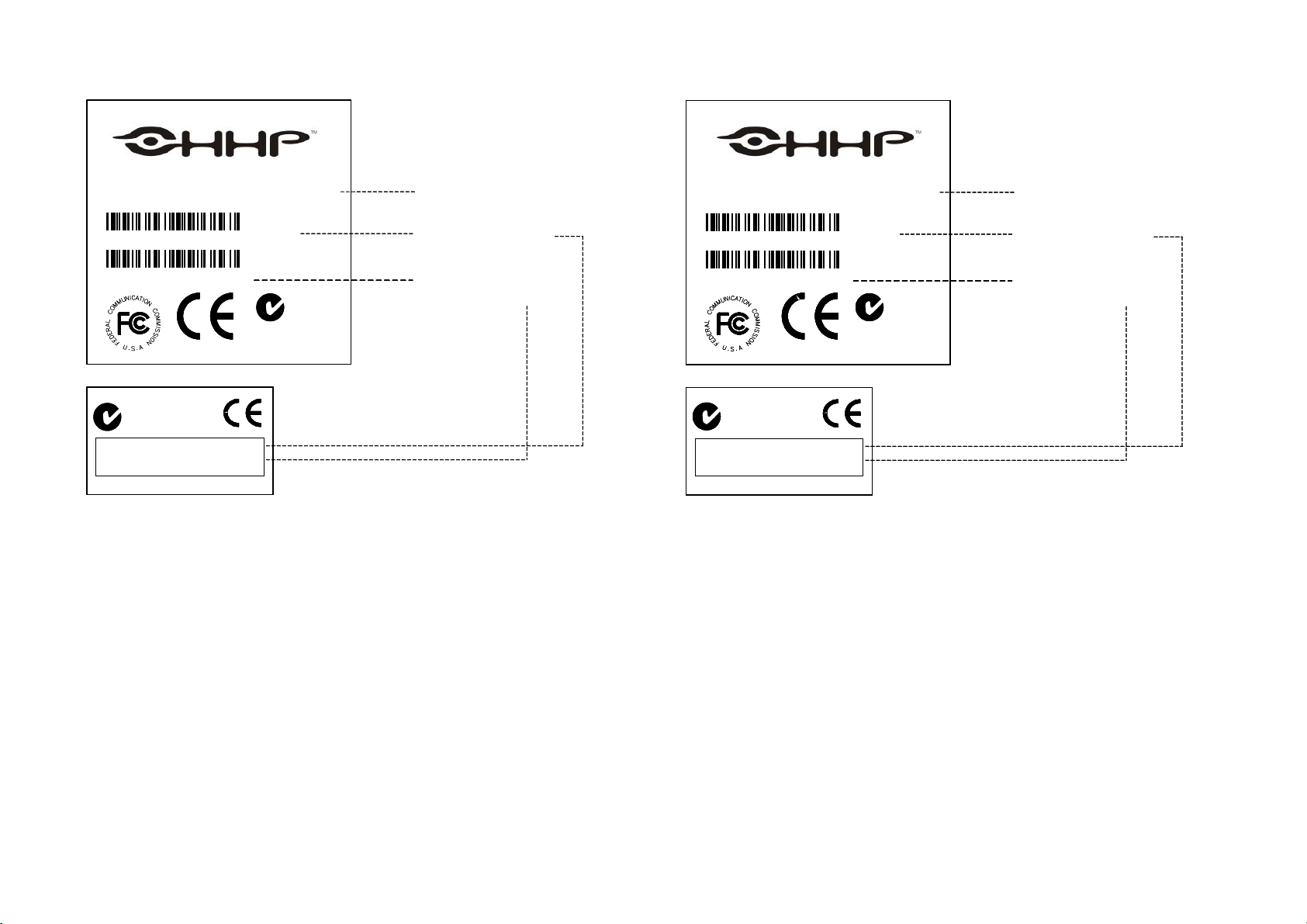

Please verify the information displayed on the product label

matches the information on the outer box label. If any

difference is found, please contact your vendor immediately.

®

-based utility that allows the user to

1-1

Page 8

IMAGETEAM MID - RANGE LINEAR

IMAGETEAM MID - RANGE LINEAR

IMAGER , UNIVERSAL I/F(US/EUR)

IMAGER , UNIVERSAL I/F(US/EUR)

P/N : 3220-12

P/N : 3220-12

S/N : A1210001

S/N : A1210001

Hand Held Products, Inc.

Hand Held Products, Inc.

Hand Held Products, Inc.

www.hhp.com

www.hhp.com

www.hhp.com

N344

N344

P/N:3220-12

P/N:3220-12

S/N:A1210001

S/N:A1210001

Complies with FCC Part 15 and Canadian ICES-003

Complies with FCC Part 15 and Canadian ICES-003

Emission requirements. See User’s Manual for details

Emission requirements. See User’s Manual for details

Made in Taiwan

Made in Taiwan

N344

N344

Made in Taiwan

Made in Taiwan

Product Label

Product Label

Outer Box Label

Outer Box Label

Description

Description

Model Number

Model Number

Serial Number

Serial Number

Getting Started

IMAGETEAM MID - RANGE LINEAR

IMAGETEAM MID - RANGE LINEAR

IMAGETEAM MID - RANGE LINEAR

IMAGER , PS/2 KB WEDGE KIT

IMAGER , PS/2 KB WEDGE KIT

IMAGER , PS/2 KB WEDGE KIT

P/N : 3220-12MDKIT

P/N : 3220-12MDKIT

P/N : 3220-12MDKIT

S/N : A1210001

S/N : A1210001

S/N : A1210001

N344

N344

N344

Made in Taiwan

Made in Taiwan

Made in Taiwan

Hand Held Products, Inc.

Hand Held Products, Inc.

Hand Held Products, Inc.

Hand Held Products, Inc.

www.hhp.com

www.hhp.com

www.hhp.com

www.hhp.com

N344

N344

N344

P/N:3220-12

P/N:3220-12

P/N:3220-12

S/N:A1210001

S/N:A1210001

S/N:A1210001

Complies with FCC Part 15 and Canadian ICES-003

Complies with FCC Part 15 and Canadian ICES-003

Complies with FCC Part 15 and Canadian ICES-003

Emission requirements. See User’s Manual for details

Emission requirements. See User’s Manual for details

Emission requirements. See User’s Manual for details

Made in Taiwan

Made in Taiwan

Made in Taiwan

Product Label

Product Label

Product Label

Outer Box Label

Outer Box Label

Outer Box Label

Description

Description

Description

Model Number

Model Number

Model Number

Serial Number

Serial Number

Serial Number

1-2

Page 9

Getting Started

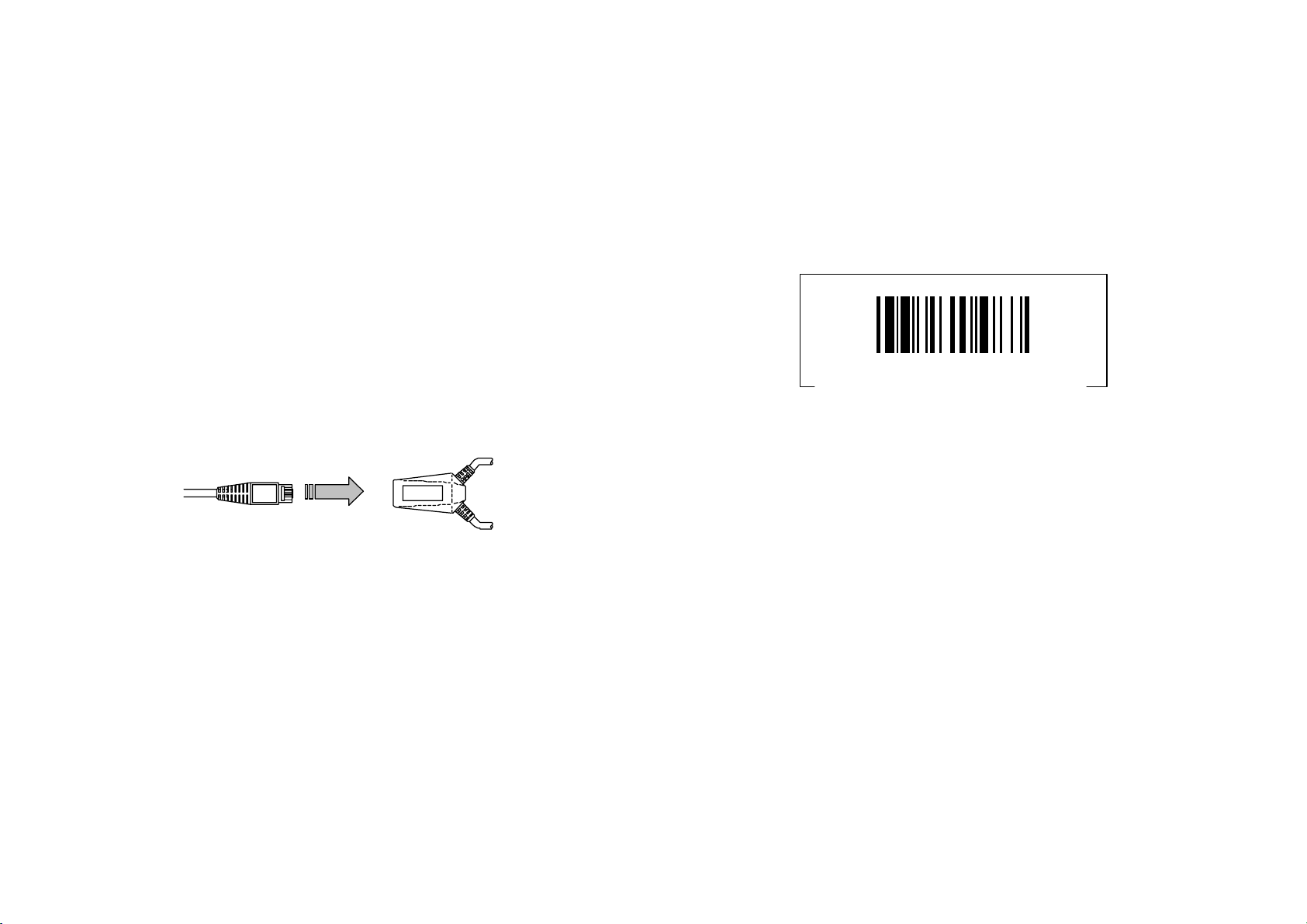

The IT3220 and VT3060B/3080B models come with a main

cable equipped with a RJ-45 phone plug, which can provide

multiple host interface connections when combined with a host

adapter cable. Please note that a separated cable adapter is

needed to complete the cable connection for product

installation.

HHP SET™

HHP SET is a unique software utility that has been designed to

operate under Microsoft

Windows

®

2000, and provides the following functions:

®

Windows® 95/98, Windows NT®, and

To use the HHP SET with the IT3220, the user must have a

serial adapter cable and a power supply. Please refer to Chapter

3 “Programming the Scanner” to understand all details of HHP

SET. You will find HHP SET has totally changed the

traditional ways of managing your bar code reading device.

User friendly on-screen configuration

Configuration download and upload

Program (Firmware) field upgrade

Check software revision

Full feature data editor

1-3

Page 10

Getting Started

1-4

Page 11

Terminal Interfaces

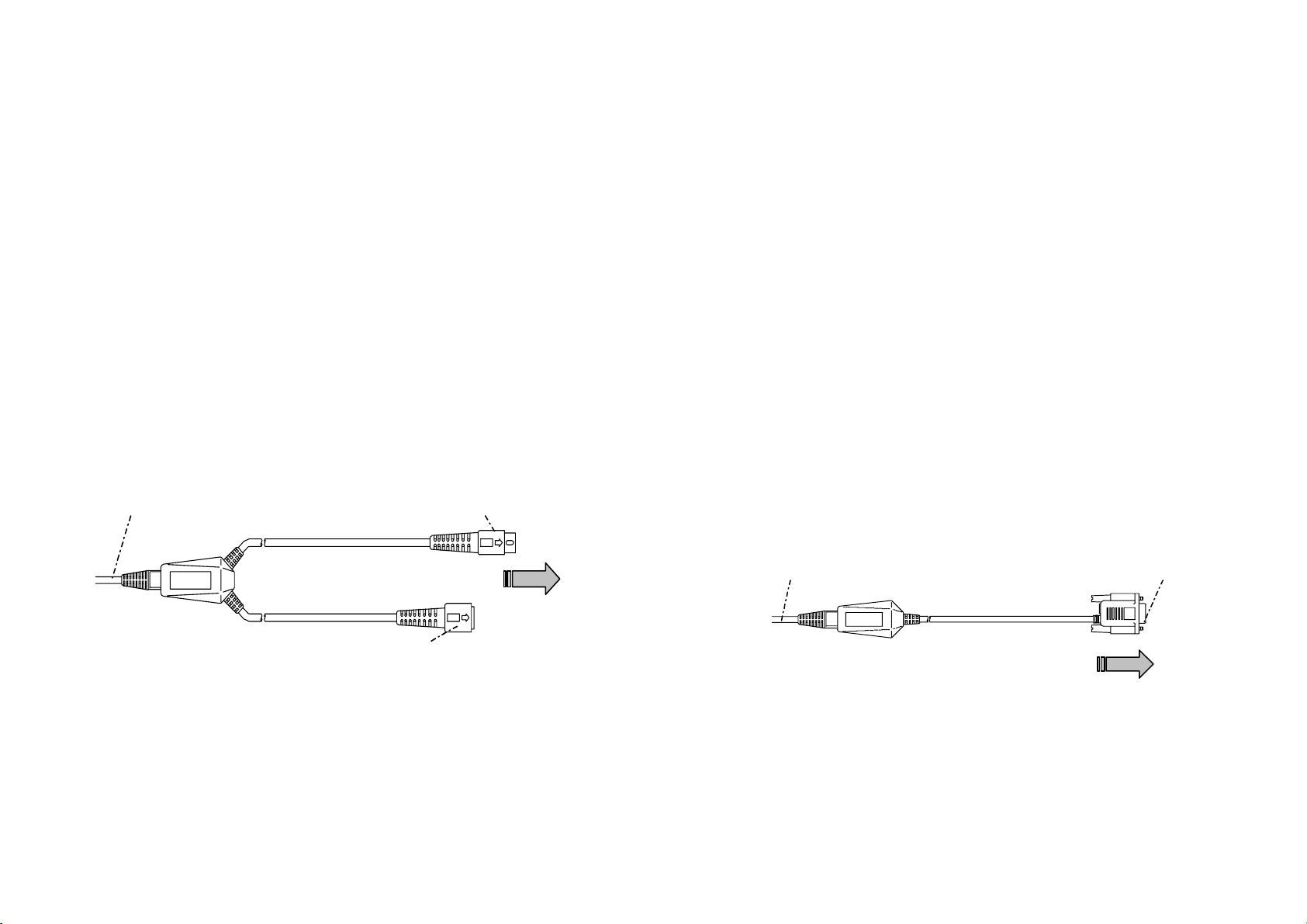

2. Terminal Interfaces

The IT3220 and VT3060B/3080B scanners are easily

configured to work with a variety of interfaces by installing the

desired cable adapter and by programming the selected

terminal interface. After identifying the communication

interface you will use and obtaining the suitable interface

adapter cable, plug the RJ45 Phone Plug of the IT3220 or

VT3060B/3080B main cable into the connector of the selected

interface cable adapter. Please make sure the connector clicks

into place securely.

3220 Main Cable

Interface Cable Adapter

Keyboard Wedge Interface

The keyboard wedge interface allows data transmission from

the scanner to the host through the existing keyboard port as

traditional keyboard input.

PC/AT, PS/2 Keyboard Wedge

For the keyboard wedge solution, the scanner must work with

the existing keyboard concurrently. If you want to link the

scanner to a computer keyboard port without a PC/AT or PS/2

keyboard, please select “Emulate External Keyboard.”

This selection instructs the scanner to perform the power-on

handshaking and routine reply between computer and

All scanners have been preset to the “IBM PC/AT, PS/2

Keyboard Wedge” interface. If you need to change the host

interface, please refer to the “Host Interface Selection”

described in Chapter 3 to find your desired interface. The

following paragraphs provide the installation of the most

popular host interfaces.

keyboard.

2-1

Page 12

Terminal Interfaces

t

Keyboard Wedge Installation

Turn off your computer system and unplug the keyboard.

Plug the RJ45 phone plug of scanner’s main cable into the

PC/AT or PS/2 cable converter.

Plug the male connector of the cable converter into the keyboard

port of your computer.

Plug the male connector of keyboard into the female connector

of the cable converter.

Turn on your computer system. Open a text program, such as

Notepad or Microsoft Word, and scan a bar code sample with the

scanner and verify that correct data is displaying on the screen.

Scanner Main Cable

To Computer Keyboard Port

PS/2 Keyboard Wedge Connection

Plug the 5P DIN female connector of the slave cable into the 5P DIN male

connector of the main cable of the scanner. Then connect the rest of the

connectors to the computer keyboard port and PS/2 keyboard.

PC/AT Keyboard Wedge Connection

Plug the 6P Mini DIN male connector of slave cable into 6P Mini DIN female

connector of the main cable of the scanner. Then connect the rest of the

connectors to the computer keyboard port and PC/AT keyboard.

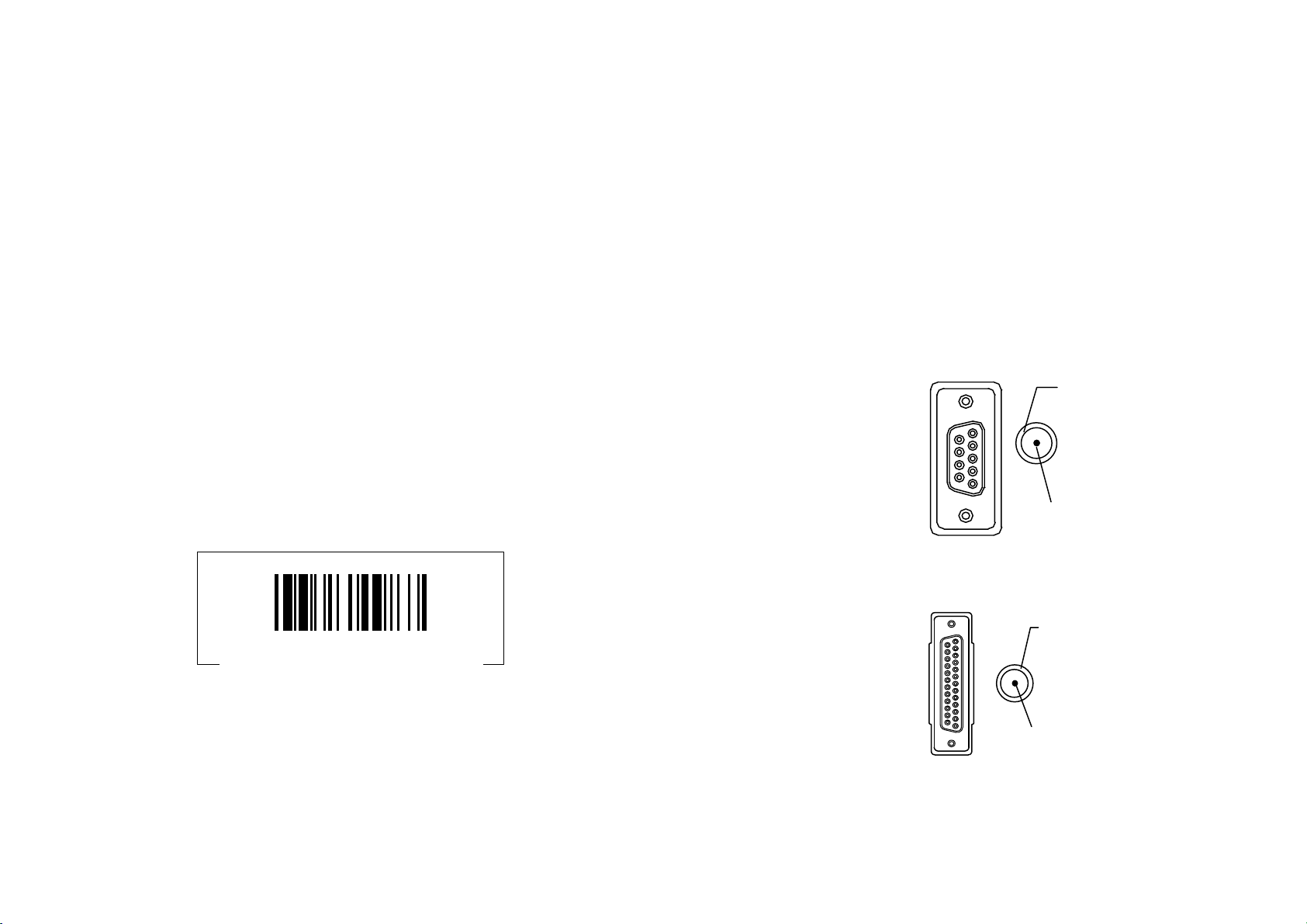

RS-232 Serial Interface

RS-232 Serial interface is among one of the most popular

applications of bar code scanners. Before connecting your

scanner to the RS-232 communication port of the host machine,

please follow the procedures illustrated below.

Scanner Main Cable To RS-232 Por

To Computer Keyboard

PC/AT Keyboard Wedge Connection

RS-232 Serial Interface Connection

2-2

Page 13

Terminal Interfaces

)

RS-232 Interface Installation

Verify the RS-232 port (COM1 or COM2) available on your

computer system.

Plug the RJ45 phone plug of the main cable into the RS-232

cable adapter.

Plug the 9-pin or 25-pin D-sub connector of the cable converter

into the desired serial port on your system.

Attach the power outlet plug of the optional AC power adapter to

the side power jack of the D-sub connector. You will hear the

power-on beep twice to signal that the scanner is ready for bar

code reading. Scan the “RS-232 Serial Interface” bar code to

configure the scanner to perform the RS-232 serial interface

operation.

Scanning the RS-232 interface bar code above configures the

scanner’s serial parameters to 9600 Baud, 8 data bits, no parity,

and 1 stop bit, no handshaking.

Please note that the RS-232 settings of the host system must

match the scanner’s RS-232 settings.

If you are in the Windows

Term inal

” to test.

®

environment, you may use the “Hyper

Standard RS-232 Pinouts

PIN-1: VCC (5V

PIN-2: TD

PIN-3: RD

PIN-4: NC

PIN-5: GND

PIN-6: NC

PIN-7: CTS

PIN-8: RTS

PIN-9: VCC (5V)

( - )

( + )

9 Pin D-sub RS-232 Female Connector

RS-232 Serial Interface

PIN-2: RD

PIN-3: TD

PIN-4: CTS

PIN-5: RTS

PIN-6: NC

PIN-7: GND

PIN-16: VCC (5V)

PIN-25: VCC (5V)

( - )

( + )

25 Pin D-sub RS-232 Female Connector

2-3

Page 14

Terminal Interfaces

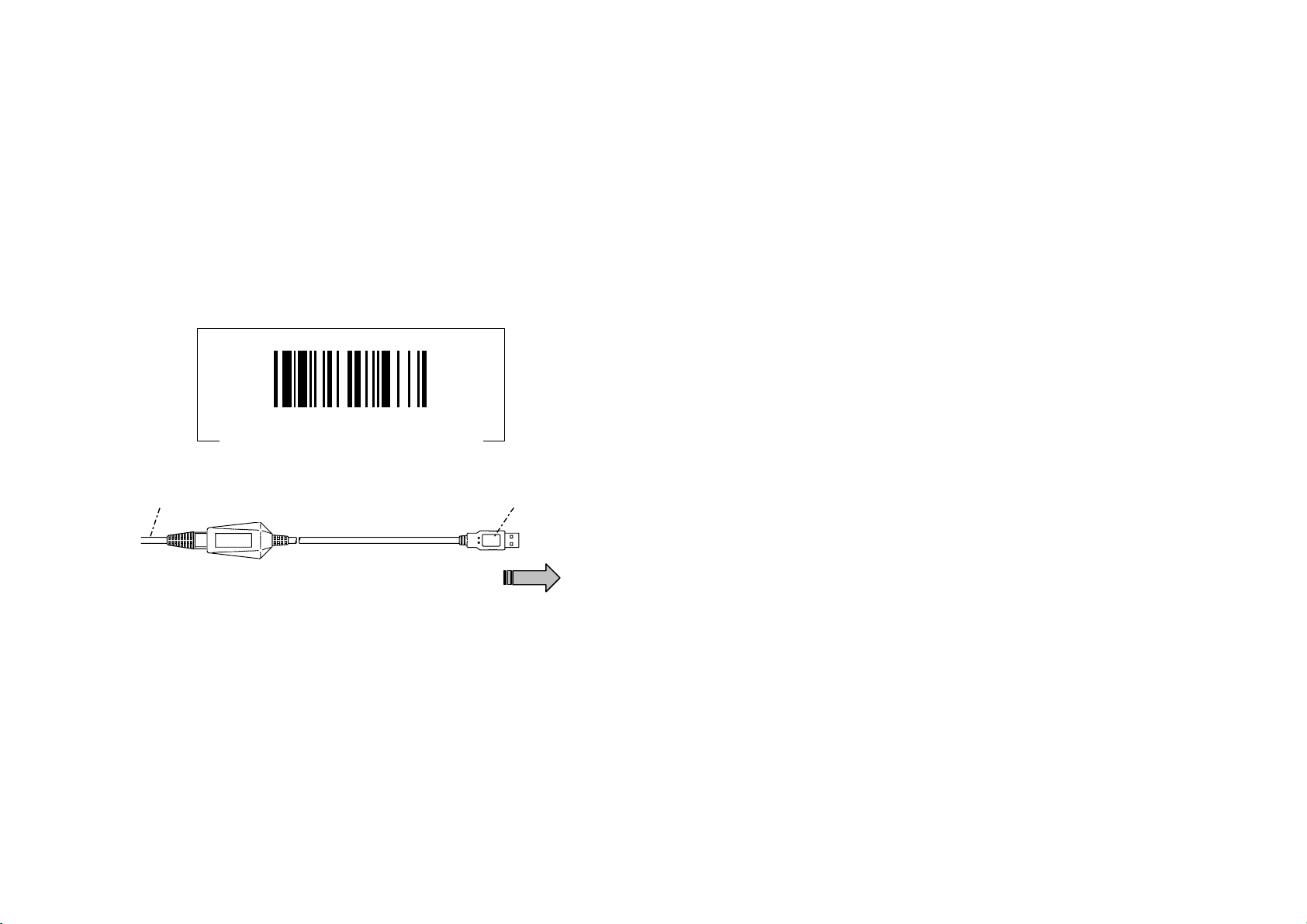

USB Keyboard Interface

The USB interface is one of the common standard peripheral

interfaces for today’s computer system working under

Windows

Scanning the following bar code will program for the USB

interface.

®

98 and Windows® 2000 or above.

USB Keyboard Interface

Main Cable To Computer USB Port

Make sure your computer has a USB port and the operating

system is Windows® 98, Windows NT® 5.0, and Windows® 2000

or above.

Plug the RJ45 phone plug of the scanner main cable into the

USB keyboard cable converter.

Plug the 4-pin USB Type A connector into the desired USB port

of your computer. You will hear the power-on beep twice to signal

that the power-on routine of the scanner is completed.

Whenever the scanner’s USB interface scanner is connected to

any computer system for the first time, a string of “USB

Manufacturer ID” messages will display to register the scanner

into the operating system.

Please scan the “USB Keyboard Interface” bar code to

configure the scanner into USB keyboard interface mode. The

USB Keyboard Interface Connection

scanner is now ready to use.

2-4

Page 15

3. Programming the Scanner

Programming the Scanner

Check Software Revision

There are two ways to configure the IT3220 or the

VT3060/3080 – either using HHP SET

™

or the programming

bar codes in this user’s guide.

Via HHP SET

HHP SET is a unique software utility designed to operate

under Microsoft

®

Windows® 95, 98, NT or above. HHP SET

offers a convenient and user-friendly way to program the

scanner.

Via Bar Code Programming Menu

The bar code programming menu is designed for field

programming convenience. Before you use the bar code

programming menu, please take the time to review the

command structure and various programming procedures.

HHP SET

The innovative HHP SET utility provides the following

features:

User Friendly On-screen Configuration

Configuration Download and Upload

Program (Firmware) Field Upgrade (Flash)

Full-featured Data Editor

These beneficial features are accomplished through

outstanding software design and on-board advanced flash

memory ASIC.

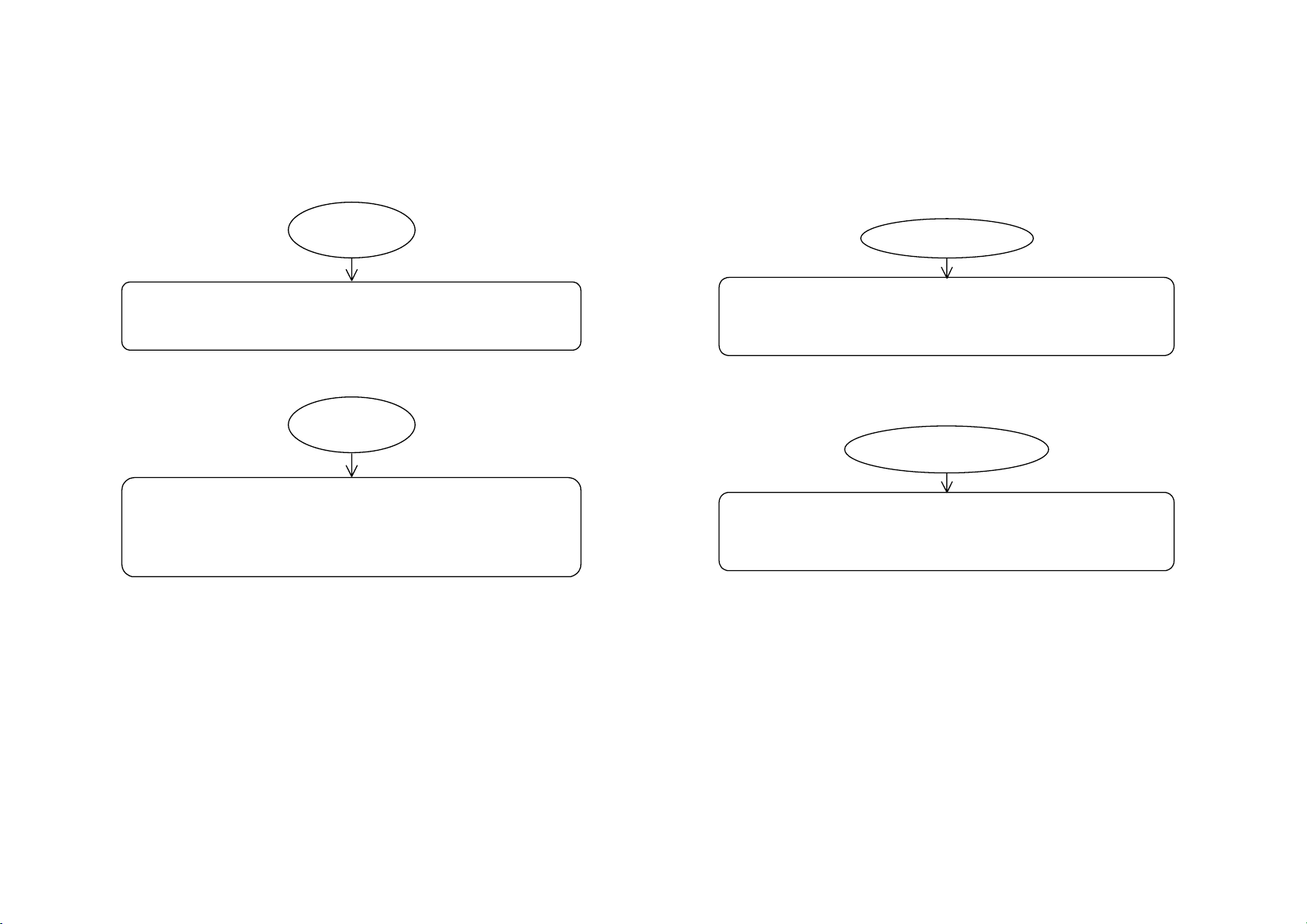

HHP SET at a Glance

HHP SET Main Screen Host Interface Screen

Data Editor Screen Bar Code Screen

3-1

Page 16

Programming the Scanner

While you are asking HHP SET to do the “Download,”

“Upload,” and “Diagnostic” with the scanner, HHP SET will

ask you to use the scanner to scan the Host Link Command

for initial handshaking with HHP SET and then perform your

desired action.

HHP SET Host Link

Software Installation

You may download HHP SET from the IT3220 or

VT3060B/3080B product pages from our web site at

www.hhp.com

Configuration Download and Upload

You can retrieve (Upload) the configurations from the scanner

or send (Download) new configurations to the scanner. Of

course, duplicating preset configurations is as easy as 1-2-3.

Program Field Upgrade

Internal program (firmware) change or modification is only

one step away via the Field Upgrade feature of the utility.

Check Software Revision

You can use the Check Revision feature to check the

software revision number, to verify if the communication

between your scanner and host system is good, and to check

the operation of the beeper and the indicator light.

On-screen Configuration

Compared with the traditional configurations done via bar code

menus, HHP SET provides a GUI interface that allows the user

to easily configure the scanner. The Save feature allows the

configuration to be saved as a file. The Convert feature

consolidates all programmable parameters for a certain

application and prints the configuration list.

3-2

Page 17

Programming the Scanner

Data Editor

Data Editor is an Artificial Intelligence-based expert system

used to format the scanned data before it is transmitted to the

host system. The Data Editor condensed version has been

embedded in the scanner. You gain access to desired Data

Editor’s functions via scanning the menu’s bar code. The

full-feature Data Editor is only available through HHP SET,

which gives you the freedom of modifying the scanned data

anyway you like, and allows you to integrate the scanner into

any existing application.

Data Format Editor

The ultra powerful data editing functions provided by the Data

Editor are controlled by user-defined rules. Through

General Transmission Control

The available parameters include “Preamble,” “Postamble,”

“Suffix,” “Symbol ID and Data Length Transmission,” and

“Transmission Time Control.”

Advanced Data Verification

The user can base the specific data format on the desired Bar

Code Symbologies to select “Valid ASCII Domain,” “Valid

Data Length Domain,” and “Matched Data Value” to establish

any desired filtering algorithm. This feature not only provides

an on-scanner data filter without application software

modification, but also reduces the error reading rate and

improves data capture reliability.

Field Oriented Data Formatter

independent rules, users can easily get the following

functionality:

The Field Oriented Data Formatter allows the user to flexibly

divide scanned data by “Delimiter” or “Length.” When used

with “Added Field” and “Transmission Sequence

Arrangement” features, you can implement “Insert,”

“Delete,” “Replace,” “Re-organize,” and other data

editing capabilities beyond your imagination.

3-3

Page 18

Programming the Scanner

Application Example

The bar code label is a 16-digit Code 39 that contains a 6-digit

date code, a 6-digit serial number, and a 4-digit unit price (in

that order). The scanner can do the following for you without

software modification:

Check the bar code to see if it is Code 39 or not. Reject any

codes that are not Code 39.

Check the bar code content to see if it is numeric or not. Reject

any codes that are not all numeric as invalid.

Check the first two digits to see if they match “99.” Reject any

codes that do not match.

Output each of the three fields followed by a “TAB.”

The date code output should skip “99” and replace it with “AA.”

The serial number output should be led with “S/N:.”

The first 2 digits (98) of unit price output should be skipped.

The output sequence should be unit price (76), date code (1025),

and serial number (123456).

Actual Bar Code label: 9 9 1 0 2 5 1 2 3 4 5 6 9 8 7 6

Desired Output: 76[TAB]AA1025[TAB]S/N:123456[TAB]

Please use HHP SET to configure the full-feature Data Editor, and

follow the procedures listed below.

Configuration Procedure

Disable “Data Editor Pass Control” (no check in box = Disable)

Select “Using 1 Rule.”

Set “Applied Bar Code” to “Code 39.”

Set “Valid ASCII Range” to “Numeric.”

Select “Using Match 1.”

Set “Matched Data “ to “99,” and set “Start Position” to “1.”

Set “Original Field” to “Divide scanned data into 4 fields.”

Set “Field Divided By” of F1 to “Fixed Length” of “2.”

Set “Field Divided By” of F2 to “Fixed Length” of “4.”

Set “Field Divided By” of F3 to “Fixed Length” of “6.”

Set “Field Divided By” of F4 to “Fixed Length” of “2.”

Then the Data Editor assigns the remaining 2 digits as “Last

Field (LF)” automatically. Please note that if the Code 39 bar

code label is printed with “Check Digit,” the last field will have 3

3-4

digits.

Page 19

Programming the Scanner

Set ”Added Field” to “Insert 3 Added Fields.”

Set “AF1” (Added Field 1) to “AA.”

Set “AF2” to “S/N:.”

Set “AF3” to “TAB (Hex 09).”

Set ”Transmission Sequence” user defined transmission

sequence to “LF,” “AF3,” “AF1,” “F2,” “AF3,” “AF2,” “F3,” and

“AF3.”

3-5

Page 20

Programming the Scanner

Bar Code Programming Menu

The bar code commands are specially designed Proprietary

bar code labels that allow you to set the scanner’s internal

programming parameters. The three main programming bar

code types are referred to as System Command, Family

Code, and Option Code. With the exception of the Option

Code bar codes, which are found on the foldout section in the

back of the book, each programmable family is contained on

one page, and each page includes all of the bar codes needed to

program the scanner. Refer to the flow chart on page 3-8 for

further clarification.

System Command

The System Command is the highest level bar code command

that directs the scanner to perform immediate operations, such

as entering programming mode (PROGRAM), exiting

programming mode (EXIT), listing system information

(SYSLIST), recovering to factory preset configurations

(M_DEFAULT), and so on. Please note that all system

Family Code

The Family Code is scanned to select the user desired

programming family. More than one hundred programming

families have been provided to meet any specific requirements.

Option Code

The Option Codes is a set of bar code commands represented

by “0–9,” “A–F,” and finishing selection (FIN). For most

settings, you must select at least one option code following the

family code selection to set the desired parameter for the

selected programming family.

Programming Procedures

As you scan the bar code command to select the desired

parameters, the information is stored in the scanner’s internal

Flash Memory ASIC or non-volatile memory. If you turn off

the unit, the Flash Memory ASIC or non-volatile memory

retains all programmed settings.

commands will take a few seconds to complete the operations.

The user must wait for the completion beeps before scanning

another bar code.

3-6

Page 21

Programming the Scanner

Program & End

Scanner enters programming mode,

and inhibits all non-programming functions.

Scanner exits programming mode, and stores all

parameters in Flash Memory ASIC or non-volatile memory,

then issues the completion beep (

Scan

“

PROGRAM”

Scan

“

”

END

3 short beeps

).

System List & Master Default

Scan “

Scanner lists the product information and

revision number to host via selected host interface,

then issues the completion beep (

Scan “

Scanner returns all programmable

parameters to factory preset configurations,

then issues the completion beep (

SYSLIST

M_DEFAULT

”

3 short beeps

”

3 short beeps

).

).

Please note that the scanner will take 3-4 seconds to store

parameters in internal Flash Memory ASIC or non-volatile

memory after you scan the “END.” Please do not turn off

the power before the completion beep. It may destroy all

configured parameters.

3-7

Page 22

Programming the Scanner

Selection Flow Diagrams

EXAMPLE 1

Scan

Codes

Codes

FIN

No

”

”

“PROGRAM”

Scan

One of

Family

Scan

One of

Option

Scan “

If indicated

Yes

Repeat

Selection

Scan

“

END

Enter programming mode.

Select one of desired

programming families.

Select one or several

option codes.

Finish cycling selection.

(If necessary)

Want to select another

programming family?

Exit programming mode.

EXAMPLE 2

Scan

Enter programming mode.

Select one of desired

programming families.

Select several option codes

of desired parameters.

1. Select one or several

option codes.

2. If it’s necessary, scan

“FIN” to terminate

option code selection.

Want to select another

programming family?

Exit programming mode.

Yes

“

PROGRAM”

One of

(

Several

(

2nd

Several

Selection

Scan

Family

1st

Option

Codes

) Scan

Codes

) Scan One or

Option

Codes

Repeat

No

Scan

“

END”

3-8

Page 23

Programming the Scanner

Host Interface Selection

♦ TERMINAL ID ♦

PROGRAM END(Exit)

Family Code Selection Parameter Selection Option Code

Host Interface Selection

US/EUROPEAN VERSION

Host Interface Selection

JAPANESE VERSION

Standard/TTL RS-232 serial interface

IBM PC/XT, 286/XT keyboard wedge interface (Full Size Din)

IBM PS/2, 25-30 series keyboard wedge interface (Mini Din)

IBM PC/AT, PS/1, PS/VP series keyboard wedge interface (Mini Din)

PC/AT, PS/2 keyboard replacement interface (without external keyboard)

General Notebook PC keyboard wedge interface (PC/AT, PS/2 Compatibles)

General Notebook PC keyboard direct-link interface (without external keyboard)

APPLE ADB keyboard wedge interface

Standard TTL RS-232 serial wedge interface

Wand emulation interface

USB keyboard interface (for Microsoft

DOS/V keyboard wedge interface*

DOS/V keyboard wedge interface (direct connect)*

NEC PC-98xx keyboard wedge interface*

IBM ThinkPad 950 keyboard direct-link interface (without external keyboard)*

®

Windows® 98, 2000 and Apple iMac)

00

01

02

03

10

03

14

49

50

61

C4

A2

B8

A3

A6

FACTORY DEFAULT

For Notebook computer user, we suggest that the user try ID=10 first, then ID=14.

USB keyboard interface is only supported by Windows 98, Windows 2000 or above and Apple iMac system.

*Supported by Japanese Version only. All other interfaces are supported by both the US/European and Japanese units.

3-9

Page 24

Programming the Scanner

User Defined Code ID

This section allows the user to define and program a Code ID

that is different from the Code ID default.

To specify a one-character Code ID, scan in the 2-digit hex

value for that character. Then scan “END.” The hex value can

be determined by referring to the HEX/ASCII Reference Table

on page A-6.

To specify a two-character Code ID, scan the 2-digit hex

values for each of the desired characters. Then scan “END.”

If you only want to assign a one-character Code ID for UPC-E

or EAN-8, scan the two-digit hex code for the desired

character. Then Scan “FIN” and “END” bar codes.

Note: To transmit the Code ID, you have to enable Code ID

transmission on page 3-12.

3-10

Page 25

Programming the Scanner

Symbology Programming

♦ User Defined Code ID ♦

PROGRAM END(Exit)

Family Code Selection Parameter Selection Option Code Option Code

Symbol ID : 1 character

Symbol ID : 2 character

Code 128 (default=B)

UCC/EAN-128 (default=C)

UPC-A (default=A)

EAN/JAN/CAN-13 (default=F)

Codabar/NW-7 (default=D)

Code 39/Code 32 (default=G)

Code 93 (default=H)

Standard/Industrial 2 of 5 (default=I)

Interleaved 2 of 5 (default=J)

Matrix 2 of 5 (default=K)

China Postal Code (default=L)

German Postal Code (default=M)

IATA (default=O)

Code 11 (default=P)

MSI/Plessey (default=R)

UK/Plessey (default=S)

Telepen (default=T)

UPC-E (default=E0)

EAN-8 (default=FF)

00

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

00

01

Scan hex value (2 digits)

Scan hex value (2 digits)

Scan hex value (2 digits)

Scan hex value (2 digits)

Scan hex value (2 digits)

Scan hex value (2 digits)

Scan hex value (2 digits)

Scan hex value (2 digits)

Scan hex value (2 digits)

Scan hex value (2 digits)

Scan hex value (2 digits)

Scan hex value (2 digits)

Scan hex value (2 digits)

Scan hex value (2 digits)

Scan hex value (2 digits)

Scan hex value (2 digits)

Scan hex value (2 digits)

Scan hex value

(2 or 4 digits) [FIN]

Scan hex value

[2 or 4 digits] [FIN]

To determine the hex value for the “

Character

,” refer to the

HEX/ASCII Table

found on page A-6.

3-11

Page 26

Programming the Scanner

Symbology Programming

♦ Code ID Transmission and Symbology Enable ♦

PROGRAM END(Exit)

Family Code Selection Parameter Selection Option Code

Code ID Transmission

Symbology Enable

Remember to scan

this selection. But if you select the

“Automatic discrimination”

will terminate this selection

automatically

“FIN”

to terminate

, scanner

.

Disable symbology ID transmission

Enable prefix symbology ID transmission

Enable suffix symbology ID transmission

Enable both prefix and suffix symbology ID transmission

Automatic discrimination

Code 128, UCC/EAN-128

UPC-A

UPC-E

EAN/CAN/JAN-13

EAN/CAN/JAN-8

Codabar/NW-7

Code 39/Code 32, HIBC

Code 2 of 5 Family, IATA

Code 93

Code 11

MSI/Plessey

UK/Plessey

Telepen

0

1

2

3

00

01

02

03

04

05

06

07

08

09

10

11

12

13

FACTORY DEFAULT

If your application is reading known, limited bar code symbologies, you may increase the reading speed and decrease the reading error possibility by enabling

those known symbologies only. Furthermore, to add the “

ID. For example, to enable UPC-A and Code 39, only scan the following bar codes: “PROGRAM,” “Symbology Enable,” “0,” “2,” “0,” “7,” “FIN” and “END.”

To further ensure fast, accurate readings, you can complete more complex configurations via full-feature the

Editor, you must use the

HHP SET

, a Windows

Symbology ID

®

95/98/NT based software utility specially designed for the scanner.

” into the transmitted data is also helpful for applications to identify the specific symbology

Data Editor

. To configure the full-feature the Data

3-12

Page 27

Programming the Scanner

Symbology Programming

♦ Code 39/Code 32 Settings♦

PROGRAM END(Exit)

Family Code Selection Parameter Selection Option Code

Code 39 Family Settings

Code 39 Min. Length

Select Standard Code 39

Select Full ASCII Code 39*

Select Code 32 (Italian Pharmaceutical)

Disable start/stop symbol transmission

Enable start/stop symbol transmission

Disable Code 32 leading A transmission

Enable Code 32 leading A transmission

Disable MOD 43 check digit verification

Enable MOD 43 check digit verification

Disable check digit transmission

Enable check digit transmission

Default (04)

Minimum length

Scan 2 digits from the option code chart in the Appendix.

0

1

2

3

4

5

6

7

8

9

A

(2 digits)

Code 39 Max. Length

FACTORY DEFAULT

* Selecting Full ASCII Code 39 disables Code 32 (both options may not be enabled at the same time). Code 39 and full ASCII may be enabled at the same time, and

Code 32 and Code 39 standard my be enabled at the same time.

Default (99)

Maximum length

Scan 2 digits from the option code chart in the Appendix.

(2 digits)

3-13

Page 28

Programming the Scanner

Symbology Programming

♦ Codabar/NW-7 Setting ♦

PROGRAM END(Exit)

Family Code Selection Parameter Selection Option Code

Codabar Settings

Select Codabar standard format

Select Codabar ABC format

Select Codabar CLSI format

Select Codabar CX format

Disable start/stop symbol transmission

Enable ABCD/ABCD start/stop symbol transmission

Enable abcd/abcd start/stop symbol transmission

Enable ABCD/TN*E start/stop symbol transmission

Enable abcd/tn*e start/stop symbol transmission

Disable check digit verification

Enable check digit verification

Disable check digit transmission

Enable check digit transmission

0

1

2

3

4

5

6

7

8

9

A

B

C

Codabar Min. Length

Codabar Max. Length

FACTORY DEFAULT

Default (04)

Minimum length

Scan 2 digits from the option code chart in the Appendix.

Default (99)

Maximum length

Scan 2 digits from the option code chart in the Appendix.

(2 digits)

(2 digits)

3-14

Page 29

Programming the Scanner

Symbology Programming

♦ UPC-A & UPC-E Setting ♦

PROGRAM END(Exit)

Family Code Selection Parameter Selection Option Code

UPC Family Settings

Select UPC without supplement digits

Select UPC with only 2 supplement digits

Select UPC with only 5 supplement digits

Select UPC with 2/5 supplement digits

Disable UPC-E ex-pansion

Enable UPC-E expansion

Disable UPC standardization

Enable UPC standardization

Disable UPC numeric system

Enable UPC numeric system

Disable UPC-A check digit transmission

Enable UPC-A check digit transmission

Disable UPC-E check digit transmission

Enable UPC-E check digit transmission

Disable UPC “leading 1” portion

Enable UPC “leading 1” portion

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

UPC-E & EAN-8 Expansion :

UPC-A/E Standardization :

UPC Lead 1 Numeric System :

WPC Selection

(UPC/EAN/JAN/CAN)

UPC-A 12 - 1 - 1 + 2 + 5 + 1 0

UPC-E 7 - 1 - 1 + 2 + 5 + 1 + 5

EAN/JAN/CAN-13 13 - 1 NC + 2 + 5 NC 0

EAN/JAN/CAN-8 8 - 1 NC + 2 + 5 NC + 5

Expand the 7-digit UPC-E and 8-digit EAN to 12-digit UPC-A and 13-digit EAN-13.

Expand the 7-digit UPC-E and 12-digit UPC-A to 8-digit UPC-8 to 13-digit EAN-13 with 1 zero insertion.

Enable to read UPC leading with the 1 numeric system, you must enable this option.

Basic

Length

Disable

Check Digit

Disable

Numeric System

With 2-digit

Addendum

With 5-digit

Addendum

Enable

Standardization

Enable

Expansion

3-15

Page 30

Programming the Scanner

Symbology Programming

♦ EAN/JAN/CAN & IATASetting ♦

PROGRAM END(Exit)

Family Code Selection Parameter Selection Option Code

EAN/CAN/JAN Settings

IATA Settings

Select EAN without supplement digits

Select EAN with only 2 supplement digits

Select EAN with only 5 supplement digits

Select EAN with 2/5 supplement digits

Disable EAN-8 expansion

Enable EAN-8 expansion

Disable EAN-13 check digit transmission

Enable EAN-13 check digit transmission

Disable EAN-8 check digit transmission

Enable EAN-8 check digit transmission

Disable ISBN/ISSN Conversion reading check

Enable ISBN/ISSN Conversion reading check

Select 15-digit fixed length IATA checking

Select variable length IATA

Disable check digit verification

Enable check digit automatic verification

Enable S/N checking digit verification only

Enable CPN checking digit verification only

Enable CPN, Airline and S/N check digit verification

Disable start/stop symbol transmission

Enable start/stop symbol transmission

Disable check digit transmission

Enable check digit transmission

0

1

2

3

4

5

6

7

8

9

A

B

0

1

2

3

4

5

6

7

8

9

A

FACTORY DEFAULT

3-16

Page 31

Programming the Scanner

Symbology Programming

♦ Code 2 of 5 Family & German Post Code Setting ♦

PROGRAM END(Exit)

Family Code Selection Parameter Selection Option Code

Code 2 of 5 Settings

Code 2 of 5 Min. Length

Select any Code 2 of 5

Select Standard/Industrial 2 of 5 only

Select Matrix 2 of 5 only

Select Interleaved 2 of 5 only

Select Interleaved 2 of 5 S Code only

Select IATA only

Select China Postal Code only

Disable check digit verification

Enable check digit verification

Disable check digit transmission

Enable check digit transmission

Default (06)

Minimum length

Scan 2 digits from the option code chart in the Appendix.

0

1

2

3

4

5

6

7

8

9

A

(2 digits)

Code 2 of 5 Max. Length

German Postal Setting

Default (99)

Maximum length

Scan 2 digits from the option code chart in the Appendix.

Disable

Enable

(2 digits)

0

1

FACTORY DEFAULT

The scanner can decode almost all Code 2 of 5 symbologies automatically. However, since the Code 2 of 5 encoding algorithm is not very robust, we recommend

that you select

only one

kind of Code 2 of 5 for reading, or set limited

maximum and minimum reading lengths

for reading.

3-17

Page 32

Programming the Scanner

Symbology Programming

♦ Code 11 & Code 93 Setting ♦

PROGRAM END(Exit)

Family Code Selection Parameter Selection Option Code

Code 11 Settings

Code 11 Min. Length

Code 11 Max. Length

Code 93 Settings

Select 1-check digit verification

Select 2-check digit verification

Disable check digit transmission

Enable 1-check digit transmission

Enable 2-check digit transmission

Default (04)

Minimum length

Scan 2 digits from the option code chart in the Appendix.

Default (99)

Maximum length

Scan 2 digits from the option code chart in the Appendix.

Disable check digit transmission

Enable check digit transmission

0

1

2

3

4

(2 digits)

(2 digits)

0

1

Code 93 Min. Length

Code 93 Max. Length

FACTORY DEFAULT

Default (03)

Minimum length

Scan 2 digits from the option code chart in the Appendix.

Default (99)

Maximum length

Scan 2 digits from the option code chart in the Appendix.

(2 digits)

(2 digits)

3-18

Page 33

Programming the Scanner

Symbology Programming

♦ MSI/Plessey, Code 128 & UCC/EAN 128 Setting ♦

PROGRAM END(Exit)

Family Code Selection Parameter Selection Option Code

MSI/Plessey Settings

MSI/Plessey Min. Length

MSI/Plessey Max. Length

Select MOD 10 check digit

Select MOD 10-10 check digit

Select MOD 11-10 check digit

Disable check digit transmission

Enable 1-check digit transmission

Enable 2-check digit transmission

Default (04)

Minimum length

Scan 2 digits from the option code chart in the Appendix.

Default (99)

Maximum length

Scan 2 digits from the option code chart in the Appendix.

0

1

2

3

4

5

(2 digits)

(2 digits)

Code 128/EAN-128 Settings

Code 128/EAN-128 Min. Length

Code 128/EAN-128 Max. Length

FACTORY DEFAULT

Disable function code conversion

Enable function code conversion

Default (04)

Minimum length

Scan 2 digits from the option code chart in the Appendix.

Default (99)

Maximum length

Scan 2 digits from the option code chart in the Appendix.

3-19

0

1

(2 digits)

(2 digits)

Page 34

Programming the Scanner

Symbology Programming

♦ UK/Plessey & Telepen Setting ♦

PROGRAM END(Exit)

Family Code Selection Parameter Selection Option Code

UK/Plessey Settings

UK/Plessey Min. Length

UK/Plessey Max. Length

Telepen Settings

Telepen Min. Length

Select UK/Plessey Standard Format

Select UK/Plessey CLSI Format

Disable Convert X to A-F

Enable Convert X to A-F

Disable check digit transmission

Enable check digit transmission

Default (04)

Minimum length

Scan 2 digits from the option code chart in the Appendix.

Default (99)

Maximum length

Scan 2 digits from the option code chart in the Appendix.

Select Telepen Numeric mode

Select Telepen Full ASCII mode

Disable check digit transmission

Enable check digit transmission

Default (04)

Minimum length

Scan 2 digits from the option code chart in the Appendix.

0

1

2

3

4

5

(2 digits)

(2 digits)

0

1

2

3

(2 digits)

Telepen Max. Length

FACTORY DEFAULT

Default (99)

Maximum length

Scan 2 digits from the option code chart in the Appendix.

(2 digits)

3-20

Page 35

Programming the Scanner

Keyboard Interface Control

♦ Keyboard Layout (Language) Setting ♦

PROGRAM END(Exit)

Family Code Selection Parameter Selection Option Code

Keyboard Layout

The

“Universal Selection”

PC/AT, PS/VP, PS/2 and IBM

compatibles in

environment that can perform unique

output

without

Style) concern. All transmitted data will

follow the original full ASCII form. You

also need not worry about the

upper/lower case control.

DOS

Caps Lock on/off (Output

is only for

or

Windows

USA (QWERTY)

France (AZERTY)

Germany (QWERTZ)

United Kingdom - UK (QWERTY)

Canadian French (QWERTY)

Spain (QWERTY)

Sweden/Finland (QWERTY)

Portugal (QWERTY)

Norway (QWERTY)

Latin America (QWERTY)

Italy (QWERTY)

Netherlands (QWERTY)

Denmark (QWERTY)

Belgium (AZERTY)

Switzerland-Germany (QWERTY)

Iceland (QWERTY)

Universal (only available for IBM PC/AT, PS/VP in MS DOS and Windows Mode)

00

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

99

FACTORY DEFAULT

Please refer to the

To set preamble or postamble as function key output, you must enable the

Keyboard Interface Message String :

Preamble Data Length Prefix Symbol ID

1-15 characters 2-3 digits 1 or 2 characters variable length 1 or 2 characters 1-15 characters 1 character

HEX/ASCII Table

listed in Appendix A to determine HEX codes for characters, symbols, and functions to be used as premble or postamble.

“Function Key Emulation”

Scanned Data

Suffix Symbol ID Postamble Record Suffix

3-21

feature as listed in page 3-23 first.

Page 36

Programming the Scanner

Keyboard Interface Control

♦ Record Suffix, Preamble, Postamble & Delay Setting ♦

PROGRAM END(Exit)

Family Code Selection Parameter Selection Option Code

Record Suffix

Preamble

None

RETURN

TAB

SPACE

ENTER (Numeric Key Pad)

User defined character (1 character)

None

1-15 characters

0

1

2

3

4

5, (00-7F)

FIN

[00-7F], [FIN]

Maximum 15-character input; scan “FIN” to terminate this selection.

Postamble

None

1-15 characters

FIN

[00-7F], [FIN]

Maximum 15-character input; scan “FIN” to terminate this selection.

Character Frame Control

Intermessage Delay

Intercharacter Delay

FACTORY DEFAULT

None

00-99 msec.

Scan 2 digits from the option code chart in the Appendix.

None

00-99 (x5) msec.

Scan 2 digits from the option code chart in the Appendix.

None

00-99 msec.

Scan 2 digits from the option code chart in the Appendix.

(2 digits)

(2 digits)

(2 digits)

3-22

Page 37

Programming the Scanner

Keyboard Interface Control

♦ Caps Lock Control & Emulation Setting ♦

PROGRAM END(Exit)

Family Code Selection Parameter Selection Option Code

Caps Lock Control

Function Key Emulation

“Caps Lock Off” State

“Caps Lock On” State

Auto Detect (PC/AT, PS/2, Keyboard Replacement and DOS/V Machines only)

Enable ASCII 00-31 code as keyboard function code output

Ctrl-Output

0

1

2

0

1

Refer to page A-5 – Keyboard Function Code Table for details.

Key Pad Emulation

Disable key pad emulation

Enable numeric output as key pad (

Num Lock On

) output

0

1

Upper/Lower Case

Normal case (neglect the upper/lower case control)

Inverse case (change all characters output to inverse case)

Upper case (force all characters output as upper case)

Lower case (force all characters output as lower case)

0

1

2

3

FACTORY DEFAULT

Character Frame Control is used to adjust the timing gap between bytes within one character data output by the scanner. Intercharacter Delay is a time delay

between data characters output by the scanner. These two parameters are used to synchronize data communication when : 1) the data transmission speed is too

fast, characters may be skipped; 2) multitasking operation system or host computers in a network may slow down the keyboard handling; 3) various notebook or

desktop PC systems require different timing parameter settings. Please always add one extra unit as a safety margin when adjusting these two parameters.

Intermessage Delay is a time delay between messages output by the scanner. Increasing this delay will help host applications process the incoming data on time.

The “Caps Lock Control” and “Key Pad Emulation” functions are only available for IBM PC/AT, PS/VP, PS/2 series personal computers and compatible machines.

If you select other host interfaces, these selections will not perform the above functions.

Please check the actual Caps Lock state in use while the software application is running. If the Caps Lock state is off, select the “Caps Lock Off” state, then the

scanner will perform normal data transmission. If the Caps Lock state is on, select the “Caps Lock On” state. If you select “Auto Detect,” the scanner performs

special transmission handshaking without changing the status of the Caps Lock switch.

3-23

Page 38

Programming the Scanner

Serial Interface Control

♦ Record Suffix, Handshaking & Time Out Setting ♦

PROGRAM END(Exit)

Family Code Selection Parameter Selection Option Code

STX/ETX Control

Record Suffix

Preamble

Disable STX/ETX transmission

Enable STX/ETX transmission

STX/ETX are two characters used to indicate the starting and ending of the total

data frame transmitted via serial interface.

None

CR (0DH)

LF (0AH)

CRLF (0D0AH)

TAB (09H)

SPACE (20H)

EOT (04H)

User defined character (1 character)

None

1-15 characters

0

1

0

1

2

3

4

5

6

7, (00-7F)

FIN

[00-7F],[FIN]

Maximum 15-character input; scan “FIN” to terminate this selection.

Postamble

None

1-15 characters

FIN

[00-7F],[FIN]

Maximum 15-character input; scan “FIN” to terminate this selection.

FACTORY DEFAULT

The record suffix and postamble differ in that the record suffix is always last and follows a postamble.

Serial Interface Message String :

STX Preamble Data Length Prefix Symbol ID

1 character 1-15 characters 2-3 digits 1 or 2 characters variable length 1 or 2 characters 1-15 characters 1 character 1 character

Scanned Data

Suffix Symbol ID Postamble ETX Record Suffix

3-24

Page 39

Programming the Scanner

Serial Interface Control

♦ Baud Rate & Data Frame Setting ♦

PROGRAM END(Exit)

Family Code Selection Parameter Selection Option Code

Handshaking Protocol

Baud Rate (BPS)

Data Frame

Time Out Control

None (free running mode)

RTS/CTS (hardware handshaking)

ACK/NAK (software handshaking)

Xon/Xoff (software handshaking)

38.4K BPS

19.2K BPS

9600 BPS

4800 BPS

8, None, 1

8, Odd, 1

8, Even, 1

8, Space, 1

8, Mark, 1

8, None, 2

7, Odd, 1

7, Even, 1

None

200 mseconds

500 mseconds

2400 BPS

1200 BPS

600 BPS

300 BPS

7, Space, 1

7, Mark, 1

7, None, 2

7, Odd, 2

7, Even, 2

7, Space, 2

7, Mark, 2

1 second

2 seconds

5 seconds

User defined value (seconds)

0

1

2

3

0

1

2

3

4

5

6

7

0

1

2

0

1

2

3

A

B

C

D

E

3

4

5

6, (2 digits)

4

5

6

7

8

9

FACTORY DEFAULT

When the

communication. This option is very helpful to ensure the reliability of data communication.

When the

after each data transmission. If the NAK is received, the scanner will re-send the data until receiving ACK.

The

RTS/CTS Hardware Handshaking

ACK/NAK Software Handshaking

Time Out Control

option is selected, the

option is selected, the scanner waits for an

is a pre-defined delay time for the scanner to wait for handshaking, acknowledgment, or non-acknowledgment from the host computer.

(request to send) and

RTS

CTS

(acknowledge) or

ACK

3-25

(clear to send) signals will be issued before normal data

(not acknowledge) from the host computer

NAK

Page 40

Programming the Scanner

END(Exit)

PROGRAM

Wand Emulation Control

♦ Output Polarity, Signal State, Margin/Module Time,

Narrow/Wide Ratio, Code 39 Emulation♦

Family Code Selection Parameter Selection Option Code

Output Polarity

High level (5Vdc) on Bar (low level on Space)

Low level (0Vdc) on Bar (high level on Space)

0

1

Determine the output voltage level for both bar and space.

Initial Signal State

High Level (5Vdc)

Low Level (0Vdc)

0

1

Determine the initial state of output voltage level.

Margin Time

Module Time

10 mseconds

15 mseconds

20 mseconds

25 mseconds

Extremely short

Short

Medium

30 mseconds

50 mseconds

100 mseconds

Delay time before data transmission

Long

Time base of minimum narrow bar

0

1

2

3

0

1

2

4

5

6

3

Narrow/Wide Ratio

Code 39 Emulation

FACTORY DEFAULT

[ Code 39 Skip ] :

read, they will be translated to upper case characters. Any other characters that are not available in Code 39 symbology set will be

[ Code 39 Replace] :

When this option is selected, all scanned data will be translated as Standard Code 39 wand emulation output. If any lowercase characters are

Any character not normally available in the standard Code 39 symbology set will be translated as

1:2

1:2.5

1:3

Disable standard Code 39 emulation

Enable standard Code 39 skip emulation

Enable standard Code 39 replace emulation

Space

3-26

.

skipped

0

1

2

0

1

2

.

Page 41

Programming the Scanner

Trigger Modes

This section allows the user to select the trigger mode that is

different from the Trigger Mode default. The operations of

each trigger mode are described as below.

Low Power Mode

When this operation mode is selected, the scanner goes into idle state after

scanning the bar code. You must press the trigger to wake up the scanner for

operation. While the scanner is in the idle state, there is only maximum 500uA

standby current for the entire reading device. It is very helpful for mobile data

collection and application, which are concerned with power savings, but

please keep a minimum of 120 milliseconds debounce time to stabilize the

power transition.

Manual Trigger Mode

When this operation mode is selected, you must press the trigger to turn on

the light source of the scanner before scanning the bar code. If you do not

press the trigger, the light source will be turned off immediately. Please note

that the scanner maintains standby current. You can adjust the debounce time

to obtain faster triggering reading.

Level Mode (Auto Power Off)

When this operation mode is selected, the scanner continues to turn on the

light source of the scanner before a good read or pre-defined auto power off

duration. If the scanner decodes a bar code successfully, it turns off the light

source immediately. After the scanner turns off the light source, you must

press the trigger to turn on the light source again. If there is no scanning

operation performed during the pre-defined auto power off time, the scanner

enters the idle state after the pre-defined auto power off duration.

Alternative Mode

When this operation mode is selected, the scanner keeps the light source of

the scanner turned on and disables the infrared sensor before the pre-defined

auto power off duration. Because you do not have to press the trigger

frequently, it is very convenient for multiple scanning. After each good read,

the auto power off timer counter is reset. After the scanner turns off the light

source, you must press the trigger to turn on the light source again. If there is

no scanning operation in pre-defined auto power off duration, the scanner

turns off the light source and enables the infrared sensor after the pre-defined

auto power off duration

Presentation Mode

When this operation mode is selected, the scanner flashes the light source of

the scanner without using the trigger. If the scanner detects an image similar

to a bar code, the scanner forces on the light source automatically and scans.

If the scanner cannot detect a bar code, it resets the light source immediately

to blinking. Adjusting the Pulse Driven Duty Cycle can change the frequency

of the blinking.

Auto Trigger Mode (Continued Power On)

When this operation mode is selected, the light source of the scanner is

forced on for continued operation without pressing the trigger switch. This

mode is convenient for high speed bar code reading.

Toggle Mode (Repeat Reading)

The toggle mode is very similar to the Alternative Mode without the

pre-defined auto power off duration concern. When this operation mode is

selected, you must press the trigger to turn on the light source of the scanner.

The scanner keeps the light source turned on until you press the trigger again.

3-27

Page 42

Programming the Scanner

Diagnostic Mode (Test Reading)

This operation mode is specifically designed for diagnostic purposes. When

this operation mode is selected, the light source of the scanner is forced on

without regard for other programmable parameters, such as double scan

verification, redundancy, and so forth.

Scanning Tolerance

(Printing Quality Control)

This parameter provides the user with a helpful tool to use

when the printing quality of the bar code is poor. This is a

programmable feature in IT3220 units with software revision

AXX, and 3060/80B with software revision CXX. Units using

later software revisions [IT3220 (revision BXX) and

VT3060/80B (DXX) scanners] perform this feature

automatically without any extra programming.

To reduce the error reading rate further, we also recommend

that you limit the number of enabled symbologies to only

those that you need to read, and to also limit the minimum and

maximum reading of each enabled bar code symbology.

3-28

Page 43

Programming the Scanner

Operation Control

♦ Trigger Mode, Buzzer Tone, Scanning Tolerance ♦

PROGRAM END(Exit)

Family Code Selection Parameter Selection Option Code

Operation Mode

Buzzer Tone Adjust

Low Power mode (Low Power triggering)

Manual trigger (External triggering)

Level mode (Auto power off)

Alternative mode (Periodic power off)

Presentation mode (Pulse driven reading)

Auto trigger mode (Continued power on)

Toggle mode (Repeat reading)

Diagnostic mode (Test reading)

Buzzer tone - mute

Buzzer tone - low

Buzzer tone - medium

Buzzer tone - high

Buzzer tone - extremely high

Good-read beep before data transmission

Good-read beep after data transmission

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

Scanning Tolerance

(Printing Quality Control)

FACTORY DEFAULT

Power-on beep

No power-on beep

Regular (standard) printing quality

Poor (critical) printing quality

Please read the Scanning Tolerance information on page 3-28 before attempting to

program this feature.

7

8

0

1

3-29

Page 44

Advanced Operation Control

Programming the Scanner

This section allows the user to program the following

parameters for advance operation control. The definitions of

each parameter are described below.

Reread Delay

This feature is designed to inhibit the scanner from reading the same bar code

within a certain period of time. The time period can be programmed for

immediate, short, medium, or long time out duration. Another selection, Force

Verification, does not allow reading of the same bar code twice even after a

very long duration. Also note that this feature is not available if you have

selected Low Power Mode, Manual Trigger Mode, Level Mode, or Diagnostic

Mode.

Scan Voting

Scan Voting is the number of times the same bar code is decoded before it is

transmitted. This feature is useful when the bar codes being read are of poor

quality. It should also be noted that this feature is not available if you have

selected Low Power Mode, Manual Trigger Mode, Level Mode, or Diagnostic

Mode.

Pulse Driven Duty

The Pulse Driven Duty is designed to control the flashing frequency of the

light source. For example, the 1/2 duty cycle means that the scanner turns on

the light source at a time equal to 1/2 the duty cycle. Generally speaking, the

higher scan rate will take the higher duty.

Auto Power Off Duration

The Auto Power Off Duration is a pre-defined power off time out counter for

Level Mode and Alternative Mode. You can adjust this parameter to meet your

own application requirement.

3-30

Page 45

Programming the Scanner

Operation Control

♦ Reread Delay, Scan Voting ♦

PROGRAM END(Exit)

Family Code Selection Parameter Selection Option Code

Reread Delay

Scan Voting

Auto Power Off Duration

Pulse Driven Duty

Dollar Sign Control

Disable

Immediate time out duration

Short time out duration

Medium time out duration

None

1 time

2 times

3 times

Short (around 2 seconds)

Medium (around 3-4 seconds)

Long (around 5-6 seconds)

Extremely long (around 7-8 seconds)

1/2 duty cycle

2/3 duty cycle

3/4 duty cycle

4/5 duty cycle

Dollar sign output as “$”

Dollar sign output as “Japanese Yen”

Long time out duration

Force Verification

4 times

5 times

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

4

5

4

5

FACTORY DEFAULT

The Debounce Time Control feature is available in the IT3220 (prior to software revision B) and in the VT3060/3080 (prior to software revision D). Units using later

software revisions perform this function automatically.

3-31

Page 46

Programming the Scanner

Condensed Data Editor

♦ Preamble, Postamble, Data Length & Symbol ID Trans. ♦

PROGRAM END(Exit)

Family Code Selection Parameter Selection Option Code

Preamble

None

1-15 characters (use hex value for each character)

FIN

[00-7F], [FIN]

Maximum 15-character input; scan “FIN” to terminate this selection.

Postamble

None

1-15 characters (use hex value for each character)

FIN

[00-7F], [FIN]

Maximum 15-character input; scan “FIN” to terminate this selection.

Data Length Transmission

Disable

Enable 2-digits data length transmission

0

1

If data length exceeds 99, 3-digit data length will be transmitted.

Code ID Transmission

Data Pass Control

Disable Code ID transmission

Enable prefix Code ID transmission

Enable suffix Code ID transmission

Enable both prefix and suffix Code ID transmission

Disable (format match required)

Enable (format match not required)

0

1

2

3

0

1

If data verifier is false, the original scanned bar code data will be transmitted.

The

Data Editor

Through the

and

Repeat Transmission

Due to the resources used by this system, the

done on-screen, under Windows

A

Condensed Version Data Editor

When Data Pass Control is disabled, all input data must conform to an edited format or the scanner does not transmit the input data to the host.

is a very powerful, Artificial-Intelligence based data editing expert system provided specifically for the 3060B/3080B/3220 bar code scanners.

Data Editor

, you can process the scanned data prior to transmitting in many ways, such as:

. It also allows you to arrange the transmission of scanned data to any specific format.

®

95/98/NT environment.

is provided here in the manual and is utilized by scanning the programming bar codes.

Full-feature Data Editor

is only supported by

HHP SET

. Through

Insert, Delete, Match, Verify, Replace, Reorganize

HHP SET

, all settings and configurations can be

3-32

,

Page 47

Programming the Scanner

Condensed Data Editor

♦ Data Formatter ♦

PROGRAM END(Exit)

Family Code Selection Parameter Selection Option Code 2nd Option Code

Formatter Control

1st Insertion

Disable

Select one bar code symbology

Select all bar code symbologies

Disable

Enable

FIN

(2 digits)

00

FIN

(2 digits)

automatic termination

automatic termination

Hex value for each

character, (FIN)

2nd Insertion

2-digits identified position; max. 3 insertion characters

Disable

Enable

position

FIN

(2 digits)

1-3 characters to insert

Hex value for each

character, (FIN)

3rd Insertion

2-digits identified position; max. 3 insertion characters

Disable

Enable

position

FIN

(2 digits)

1-3 characters to insert

Hex value for each

character, (FIN)

2-digits identified position; max. 3 insertion characters

position

1-3 characters to insert

4th Insertion

Disable

Enable

2-digits identified position; max. 3 insertion characters

FACTORY DEFAULT

The

Data Formatter

symbologies for formatter control, and provides

If the Data Formatter is enabled, it arranges only scanned data without

Record Suffix

Please refer to page 3-37 for information about the “

To determine the hex value for the “

Refer to page 3-12 for for the 2-digit symbology option code.

is used to edit the scanned raw data prior to transmitting the data to the host computer or terminal. It allows you to select desired bar code

Multiple Position Insertion

. All of the above programmable parameters perform the same function depending on your setting.

” and “

Character

Bar Code Selection

,” refer to the

HEX/ASCII Table

FIN

(2 digits)

position

and

Multiple Character Insertion

Preamble, Postamble, STX, ETX, Data Length, Prefix/Suffix Symbolology ID

Position Calculation

on page A-6

” of the data formatter.

(max three characters) in the identified position.

Hex value for each

character, (FIN)

1-3 characters to insert

3-33

or

Page 48

Programming the Scanner

Condensed Data Editor

♦ Data Verifier Settings ♦

PROGRAM END(Exit)

Family Code Selection Parameter Selection Option Code 2nd Option Code

Verifier Control

Identified Data Length

1st Identified Character

2nd Identified Character

Disable

Select one bar code symbology

Select all bar code symbologies

Disable

Enable

Determine the identified data length for verification.

Disable

Enable

2-digits checking position; 1 identified character

Disable

Enable

2-digits checking position; 1 identified character

FIN

(2 digits)

00

FIN

(2-digit decimal

value)

FIN

(2-digit HEX

value)

position

FIN

(2-digit HEX

value)

position

automatic termination

automatic termination

[00-7F]

[00-7F]

3rd Identified Character

Disable

Enable

2-digits checking position; 1 identified character

The

Data Verifier

All data must conform to the

Otherwise, the scanner will not transmit the data to the host computers, but will instead issue

The Data Verifier checks only scanned data without

Please refer to page 3-37 for information about the “

To determine the hex value for the “

Refer to page 3-12 for 2-digit symbology option code.

is used to provide advanced verification for error-free scanning and to work as an

Identified Bar Code Symbologies, Identified Data Length

Preamble, Postamble, STX, ETX, Data Length, Prefix/Suffix Symbology ID,

” and “

Position Calculation

on page A-6.

Character

Bar Code Selection

,” refer to the

HEX/ASCII Table

3-34

Embedded Data Transmitting Filter

, and one to three

3 long beeps

for verification error and

” of Data Verifier.

FIN

(2-digit HEX

value)

position

Identified Characters

skip

or

Record Suffix

[00-7F]

.

in the checking position.

the scanned data.

.

Page 49

Programming the Scanner

Condensed Data Editor

♦ Data Replacer Settings ♦

PROGRAM END(Exit)

Family Code Selection Parameter Selection Option Code 2nd Option Code

Replacer Control

1st Replacement

2nd Replacement

3rd Replacement

Disable

Select one bar code symbology

Select all bar code symbologies

Disable

Enable

2-digits identified position; 1 replacement character

Disable

Enable

2-digits identified position; 1 replacement character

Disable

Enable

2-digits identified position; 1 replacement character

FIN

(2 digits)

00

FIN

(2-digit decimal

value)

position

FIN

(2-digit decimal

value)

position

FIN

(2-digit decimal

value)

position

automatic termination

automatic termination

[ 00-7F ]

[ 00-7F ]

[ 00-7F ]

FACTORY DEFAULT

The

Data Replacer

symbologies for replacer control, and provides

All data must conform to the

enabled, it arranges only scanned data without

Please refer to page 3-37 for information about the “

To determine the hex value for the “

Refer to page 3-12 for 2-digit symbology option code.

is used to edit the scanned raw data prior to transmitting the data to the host computers or terminals. It allows you to select desired bar code

Multiple Position Replacement

Identified Bar Code Symbologies

Preamble, Postamble, STX, ETX, Data Length, Prefix/Suffix Symbology ID

Bar Code Selection

Character

,” refer to the

, and one to three

” and “

HEX/ASCII Table

in the identified position.

Identified Characters

Position Calculation

listed on page A-6.

3-35

in the identified position. While the Data Replacer is

” of Data Replacer.

, or

Record Suffix

.

Page 50

Programming the Scanner

Condensed Data Editor

♦ Data Organizer Settings ♦

PROGRAM END(Exit)

Family Code Selection Parameter Selection Option Code 2nd Option Code

Organizer Control

1st Organization

2nd Organization

Include/Exclude Control

Disable

Select one bar code symbology

Select all bar code symbologies

Disable

Enable

2-digits identified character position;

Transmit data before/after this position

Disable

Enable

2-digits identified position;

Transmit data before/after this position

Transmitted data excluding the data of identified position

Transmitted data including the data of identified position

FIN

(2 digits)

00

FIN

(2-digit decimal

value)

position

FIN

(2-digit decimal

value)

position

0

1

automatic termination

automatic termination

Direction :

0 (Before)

1 (After)

Direction :

0 (Before)

1 (After)

FACTORY DEFAULT

The

Data Organizer

symbologies for organizer control, and provides a maximum of two identified positions to send the data

data

including

While the Data Organizer is enabled, it arranges only scanned data without

Record Suffix

Please refer to the next page for information about the “

To determine the hex value for the “

Refer to page 3-12 for 2-digit symbology option code.

is used to edit the scanned raw data prior to transmitting the data to the host computers or terminals. It allows you to select desired bar code

or

excluding

.

the data of the identified position. Please refer to the application example on the next page for details.

Preamble, Postamble, STX, ETX, Data Length, Prefix/Suffix Symbology ID

” and “

Position Calculation

listed on page A-6.

Character

Bar Code Selection

,” refer to the

HEX/ASCII Table

3-36

or

before

” of Data Organizer.

. It also allows you to control the transmitted

after

, or

Page 51

Programming the Scanner

Select a Bar Code Symbology

You can use the Condensed Data Editor for an advanced

transmission arrangement with one or all bar code

symbologies. If you scan “00” to select all types, the scanner

arranges all incoming data to meet your pre-defined format. If

you want to select only one type of bar code, please select

one of the option codes listed below.

UPC-E :

UPC-A : 02

EAN/CAN/JAN-8 : 05

EAN/CAN/JAN-13 :

Code 32 : 07

03

Telepen : 13

Code 128 : 01

UCC/EAN 128 : 01

Code 39 : 07

04

Code 93 : 09

Codabar/NW-7 : 06

Code 25 Family : 08

Code 11 : 10

UK/Plessey : 12

MSI/Plessey : 11

Position Calculation

[Data Formatter]

If there is a 5-character input data string, refer to the following to

Application Example

The bar code label is an all-numeric 16-digit Interleaved 2 of 5,

which includes the information of 6-digit date code, 6-digit

serial number, and 4-digit unit price, in that order. The data

code always starts with a “9.” If a scanned bar code meets the

above criteria, the data will be separated into three fields. Each

field should end with a “TAB.” The first digit of the date code,

which is a “9,” should be replaced with an “A.” The serial

number should start with SN. The first 2 digits of the unit price

should be skipped.

Actual Bar Code read : 9 8 1 0 2 5 1 2 3 4 5 6 9 8 7 6

Desired Output : A81025[TAB]SN123456[TAB]76[TAB]

Programming Procedure

[Important Notice]

calculate the actual position for insertion:

X X X X X

00 01 02 03 04 05

[Data Verifier, Data Replacer, Data Organizer]

If there is an 11-character data string, please refer to the following

to calculate the actual position for identification.

X X X X X X X X X X X

00 01 02 03 04 05 06 07 08 09 10

Please note that the Condensed Data Editor will follow the preset

working flow as below:

Verifier Formatter Replacer Organizer

Consequently, when you set the identified position in the Data

Organizer, you must consider the inserted data that you have

already set via the Data Formatter.

3-37

Page 52