Page 1

®

3. SAFETY INSTRUCTIONS

5. OPERATION

SOLDERING POT

Instruction Manual

Thank your for purchasing the HAKKO FX-301 soldering pot.

Please read this manual before operating the HAKKO FX-301.

Keep this manual readily accessible for reference.

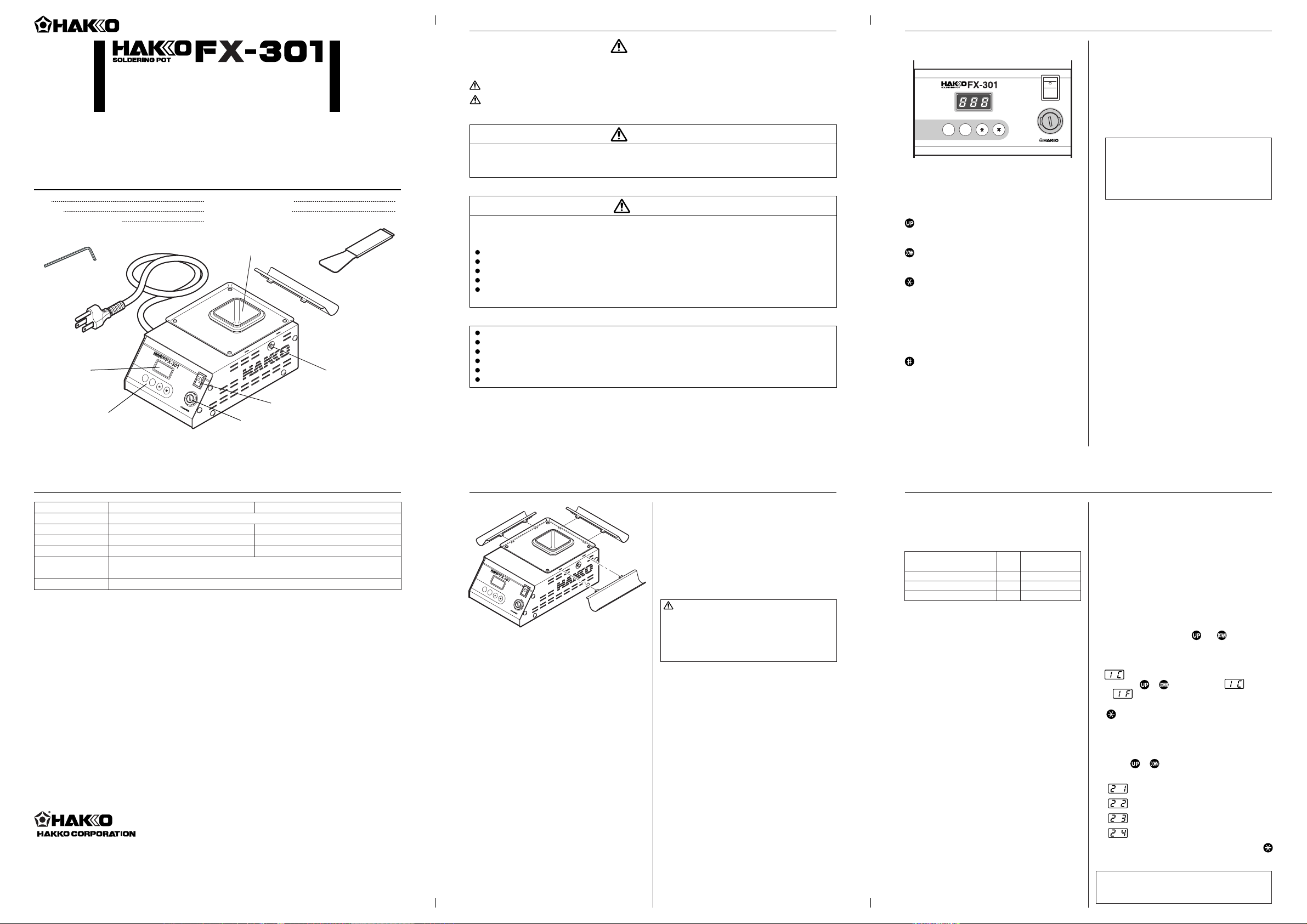

1. PACKING LIST AND PART NAMES

Unit 1

Spatula 1

J-shaped waste collector 1

Hexagon wrench

Power cord

Display

U

P

DO

WN

Control buttons

Hexagon wrench 1

Instruction manual 1

Solder pot

Fuse

Please check to make sure that all items listed

below are included in the package.

Spatula

J-shaped waste collector

Solder pot mounting

screws (both sides)

Power switch

WARNING

Warnings, cautions and notes are placed at critical points in this manual to direct the operator’s

attention to significant items. They are defined as follows:

WARNING: Failure to comply with a WARNING may result in serious injury or death.

CAUTION : Failure to comply with a CAUTION may result in injury to the operator, or damage to the

items involved. Two examples are given below.

WARNING

When the power is ON, the temperature of the melted solder in the solder pot is approximately

450°C/842°F. Before changing the solder pot, be sure to unplug the power cord and let the solder

and the unit cool to room temperature.

Observe the following precautions to ensure safety.

CAUTION

The molten solder in the solder pot is dangerous since it reaches about 450°C/842°F. The pot cover also

becomes a high temperature when the power is ON. Wrong handling may cause burns or fire. Be sure to

observe the following precautions.

Use this product on highly stable metal workbench. Never use it near paper or other flammable materials.

Inform others in the area that the product is hot and should not be touched.

Never put water in the solder pot as this will cause solder to spatter out of the solder pot.

Turn the power off when not in use, or left unattended.

Before changing parts or storing the unit, be sure to turn the power off and allow the unit to cool to room

temperature.

Observe the following precautions to prevent accidents or damage to the unit.

Do not use the HAKKO FX-301 for applications other than soldering.

Do not modify the HAKKO FX-301.

Use only genuine HAKKO replacement parts.

Do not allow the HAKKO FX-301 to become wet, or use it with wet hands.

Be sure the work area is well ventilated. Soldering produces smoke.

Do not do anything else that might be dangerous.

Display and operation

UP

DOWN

● Display

The front panel of the HAKKO FX-301 soldering pot

has the following controls:

- Increases the value in the appropriate display

window.

- decreases the value in the appropriate display

window.

- Holding down the button for one second or

more will enter into the temperature setting

mode. If the button is otherwise pressed for

only less than one second, the current set

temperature will remain displayed. In the input

mode, establish the entered value and exist

the data input mode.

- Holding down the button for one second or

more will enter into the offset input mode. If

the button is otherwise pressed for only less

than one second, the current offset value will

remain displayed.

Operation

1. Turn the power switch ON.

2. The temperature set at factory is displayed.

*The temperature was set to 350°C at factory.

3. The temperature control is started, causing the

temperature to increase.

NOTE:

The display blinks when the power is turned

ON or when settings are changed. This blinking occurs because the temperature control is

in progress. The current temperature will be

displayed in a short time.

2. SPECIFICATIONS

Power consumption

Temperature range

Solder pot dimensions

Molten solder capacity

Weight

(w/o solder and cord)

Outer dimensions

* Only a 50 × 50 square solder pot is included in this product.

* The 75 × 75 square solder pot is an optinal part.

* Specifications and design are subject to change without notice.

HEAD OFFICE

TEL:+81-6-6561-3225 FAX:+81-6-6561-8466

http://www.hakko.com E-mail:sales@hakko.com

Please access to the following address for the other Sales affiliates.

100V - 200W, 110V - 260W, 120V - 310W, 220V - 240W, 230V - 260W, 240V - 280W

200 - 450°C (400 ~ 840°F)

50 (W) × 50 (D) × 42 (H) mm (2.0 × 2.0 × 1.7 in.)

0.85 kg (1.87 lb.)

1.7 kg (3.74 lb.)

143 (W) × 100 (H) × 220 (D) mm (5.6 × 4.0 × 6.7 in.)

http://www.hakko.com/address

Copyright © 2005 HAKKO Corporation. All Rights Reserved.

50 × 50 Square

75 × 75 Square

200 - 380°C (400 ~ 720°F)

75 (W) × 75 (D) × 55 (H) mm (3.0 × 3.0 × 2.2 in.)

1.2 kg (2.64 lb.)

MA01375JZ050202

2005.2

4. INTIAL SETUP

U

P

D

OW

N

1. Install the J-shaped waste collector to the unit.

(Three-way installation is possible to meet your

operating needs.)

2. Cut the solder sticks into small pieces and put

them in the solder pot.

3. Plug the power cord into a grounded wall socket.

CAUTION

Make sure the power switch is off before plugging

in the power plug.

This product is protected against electrostatic discharge.

Make sure this product is grounded before using.

6. PARAMETER SETTINGS

Before changing the setting temperature

The HAKKO FX-301 comes from the factory with

the following values preset:

°C or °F temperature display

selection

Setting a solder type

Setting the solder pot type

Setting the timer

● Entering the parameters

1. °C or °F temperature display selection

2. Setting a solder type

Once a solder type close to the applicable one

as shown in the right side, the temperature control will be performed for that solder type.

1 C

2 1

3 1

4 0

°C

Sn-Pb (Tin an lead)

50 × 50 square

OFF or disabled

The HAKKO FX-301 has the following four parameters:

1) °C or °F temperature display selection

2) Setting a solder type

3) Setting the solder pot type

4) Setting the timer

Once you enter the parameter setting mode, the

setting sequence will start in the following order. After all the parameters have been set, the displayed

temperature setting starts blinking and the temperature of the solder pot starts rising.

1. Turn the power switch OFF.

2. Press and hold down the and buttons simultaneously, and then turn the power switch

ON.

3. When you enter the parameter setting mode,

is displayed.

4. Press the or button to select for °C

or for °F.

After checking the displayed selection, press the

button.

After establishing the temperature unit to use,

enter the solder type selection mode.

Press the or button to select the number corresponding to your solder type as follows:

Sn-Pb (Tin an lead)

Sn-Ag-Cu (Tin, silver, and copper)

Sn-Cu (Tin and copper)

Sn (Tin)

After checking the displayed selection, press the

button.

NOTE:

The solder types are listed for only rough classification. Select the closest one to your solder type.

Page 2

6. PARAMETER SETTINGS

8. IN CASE THE DISPLAY AND THE ACTUAL TEMPERATURE IS DEFFERENT

11. TROUBLE SHOOTING GUIDE

3. Setting the solder pot type

In the HAKKO FX-301 package, the size of the

solder pot is 50 × 50 square. The 75 × 75 square

solder pot is available to order for the requirement of your work.

Set the size of the solder pot that you will use.

50 × 50 Square: Setting range of temper-

atures 200 - 450°C/400 - 840°F

75 × 75 Square: Setting range of temper-

atures 200 - 380°C /400 - 720°F

Press the or to select the number corresponding to your solder pot size as shown above.

After checking the displayed selection, press the

button.

4. Setting the timer

It will be able to check the present addition time

by pressing the button.

for OFF or disabled

for a value between 10 and 9990 hours

Select the displayed and then press the

button. You will proceed to enter the time to set.

Enter a desired time value.

Time can be set in units of 10 hours in a range between and (10 and 9,990 hours). After

entering the time value, press the button.

NOTE:

After the set time has passed, will be displayed, the alarm will start sounding, and then the

heater for the solder pot will be turned OFF. To

reset the alarm and others, turn OFF the power

switch and then immediately turn it ON again.

The timer will be reset to the above time setting.After the set time has passed, the heater for

the solder pot will be turned OFF.

● How to change and reset

Changing the time Enter the value between

001~999.

Resetting the time In case of resetting the time

(in the middle of setting the

time.), please change to the

different value once, and enter the desired value.

7. CHANGING THE TEMPERATURE SETTING

● Changing the temperature setting

The HAKKO FX-301 is preset at 350°C at the factory.

Example: 350°C to 400°C

1. Check that the displayed value is 350°C.

Press the button for one second or more. The

hundreds digit will start blinking, indicating the

unit is in the temperature setting mode.

2. Entering the hundreds digit

Press the or button to set the desired figure. When the desired figure is displayed, press

the button to enter. The tens digit will begin to

blink.

3. Entering the tens digit

Press the or button to set the desired figure. When the desired figure is displayed, press

the button to enter. The unit's digit will begin

to blink.

4. Entering the unit's digit

Press the or button to set the desired figure. When the desired figure is displayed, press

the button to enter. Now the setting has been

completed.

After the setting has been completed, the displayed

temperature starts blinking and the temperature in

the solder pot starts rising. The current temperature

will be displayed in a short time.

NOTE:

For the 50 × 50 square pot, the setting range of

temperatures is between 200 - 450°C/400 - 840°F.

For the 75 × 75 square pot, the setting range of

temperatures is between 200 - 380°C/400 - 720°F.

Press the button and

hold for one second.

Press the or button.

Press the button once.

Press the or button.

Press the button once.

Press the button once.

● Entering offset value

The offset value was set to 0°C at factory.

Range of values:

°C... -70 to +70°C

Press the button and

hold for one second.

Press the button

°F ... -158 to +158°F

Example:

When the set temperature is 400°C and the ac-

Press the or button.

tual solder temperature in the solder pot is

350°C; The difference between the two is

+50°C . Therefore, enter 050 instead of the cur-

Press the button

rent offset value.

Once you can check the display and the measured

temperature, all the settings are finished.

Press the button

When the temperature of solder reaches the set

value, the buzzer sounds. About 5 to 10 minutes

later, measure the temperature of solder. If the

measured value is different from the displayed temperature, match them with each other by entering

an offset.

NOTE:

When measure the temperature of the solder, be

sure to measure at the same position.

9. MAINTENANCE

WARNING

Unless otherwise directed, carry out these procedures after turning the power switch OFF,

unplugging the power plug and waiting for both the unit and the solder to sufficiently cool down.

Changing the solder pot

1. Using the hexagon wrench (provided with the

HAKKO FX-301) to loosen the screws on both

sides of the unit.

U

P

D

O

W

N

NOTE:

Removal is unnecessary.

2. Pull out the solder pot.

CAUTION

After changing the solder pot, measure the temperature again. If the measured value is different

3. Insert a new solder pot and then tighten the

screws on both sides.

from the displayed temperature, enter an offset.

CAUTION

WARNING

When the power is ON, the temperature of the

melted solder in the solder pot is approximately

Check that the solder pot has been locked

now. Otherwise, the temperature may not in-

crease properly.

450°C/842°F. Before changing the solder pot, be

sure to unplug the power cord and let the solder

and the unit cool to room temperature.

Replacing the heating element

1. Loosen the screws on both sides of the unit.

(Fig. 1)

NOTE:

U

P

D

O

W

N

Removal is unnecessary.

Fig. 1

2. Pull out the solder pot. (Fig. 2)

U

P

D

O

W

N

Fig. 2

U

P

D

O

W

N

3. Remove the setscrews (6 pieces) on the unit.

(Fig. 3)

Fig. 3

4.

Slide the front panel frontward, remove the connec-

U

P

D

O

W

N

Fig. 4

tor (Fig. 4) on the connector circuit board, and then

pull out the unit of the heating element (Fig. 5).

5. Insert a new heater unit and then install it by reversing the above steps.

U

P

D

O

W

N

After finishing the maintenance, measure the temperature of solder. If the measured value is different

Fig. 5

from the display temperature, enter an offset.

10. ERROR MESSAGES

● Sensor Error There is the possibility that a failure has occurred in

the sensor circuit. The power is shut down with the

buzzer sounding continuously.

WARNING

• Before checking the inside of the FX-301 or replacing parts, be sure to disconnect the power

plug.

l The unit does not operate when the

power switch is turned on.

CHECK : Is the power cord and/or the connection plug disconnected?

ACTION : Connect it.

CHECK : Is the fuse blown?

ACTION : Investigate why the fuse blew and then replace the fuse. If the

cause can not be determined, replace the fuse. If the fuse blows

again, send the unit in for repair.

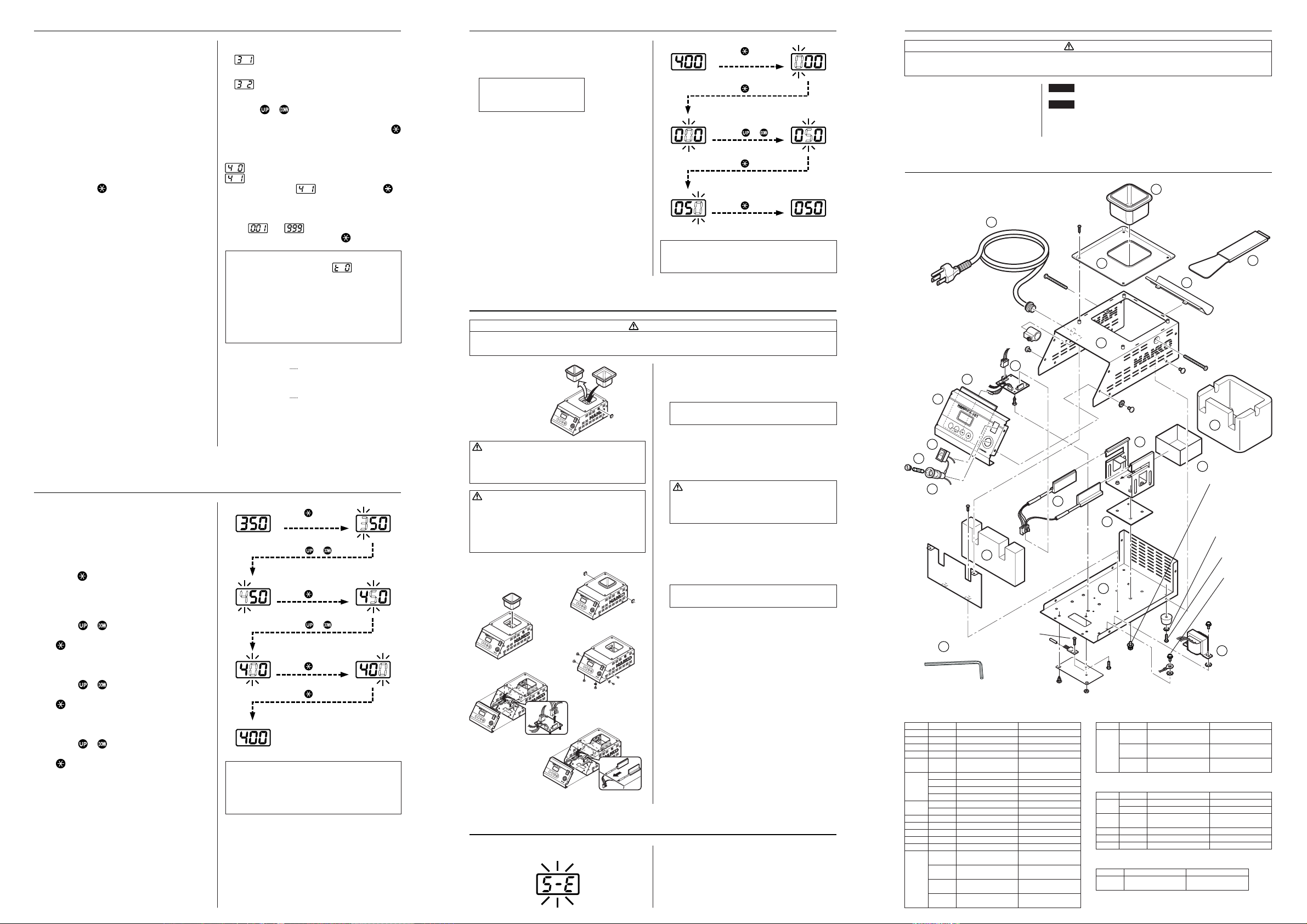

12. PARTS LIST

15

Truss screw

Button bolt

M4 × 35 (2)

14

Specifications

M3 × 8 (4)

2

1

Truss screw

M4 × 5 (12)

External tooth

lock washer

Nominal size 4 (2)

9

3

8

Part No.

Item No.

B1797

Power cord, 3 wired

cord & European plug

B1798

B3046

Part No.

A1515

A1516

A1517

B2919

B2932

B1417

Solder pot

Power cord, 3 wired

cord & Australian plug

Power cord, 3 wired

cord & BS plug

Heating element

Heating element

Solder pot

J-shaped waste collector

Spatula

Hexagon wrench

Part Name

⑬

● Replacement parts

Item No.

⑭

⑮

⑯

⑰

⑱

● Optional parts

Part No.

A1518

16

10

External tooth

lock washer

Nominal size 4 (1)

Part Name

Part Name

Specifications

75 × 75 × 55(mm)/2.95

× 2.95 × 2.17(in.)

3

Pan head screw with

spring, plain washer

M4 × 8 (4)

External tooth

lock washer

Nominal size 4 (1)

Plain washer

M3 (4)

Pan head screw

M3 × 10 (4)

Pan head screw

with spring washer

M4 × 6 (1)

Pan head screw

with spring, plain

washer

M3 × 6 (2)

7

External tooth

lock washer

Nominal size 3 (1)

Specifications

220V KTL, CE

240V

230V UK

Specifications

100 - 120V

220 - 240V

50 × 50 × 42(mm)/1.97

× 1.97 × 1.65(in.)

2.5mm

5

4

U

P

D

OW

N

11

6

12

Pan head screw

M3 × 4 (12)

18

● FX-301 Soldering pot

Part No.

Item No.

B2917

B2918

B2916

B2920

B2921

B2705

B2468

B2922

B3045

B2924

B2925

B2926

B2927

B2928

B1084

B1134

B1795

B1796

B2913

B2914

Cover

Overflow tray

Heat insulator

Front panel

P.W.B.

Fuse/125V-5A

Fuse/125V-5A

Fuse/250V-5A

Fuse/250V-5A

Transformer

Transformer

Chassis

Solder pot support

Solder pot tray

Power switch

Fuse holder

Power cord, 3 wired

cord & American plug

Power cord, 3 wired

cord but no plug

Power cord, 3 wired

cord & BS plug

Power cord, 3 wired

cord & Chinese plug

①

②

③

④

⑤

⑥

⑦

⑧

⑨

⑩

⑪

⑫

⑬

13

3

Part Name

5

Pan head screw

M3 × 8 (1)

With membrane sheet

For temperature

control, connector

100 - 110V

120V

220 - 240V

220 - 240V KTL, CE

100 - 120V

220 - 240V

With rubber feet

100 - 220V

230V

230V India

220V China

17

Loading...

Loading...