Page 1

FR-1012B Operation and Maintenance Manual

American Hakko Products, Inc.

28920 Avenue Williams

Valencia, California 91355

Tel: (661)294.0090

Fax: (661)294.0096

Toll Free: 1-800-88-HAKKO (42556)

Page 2

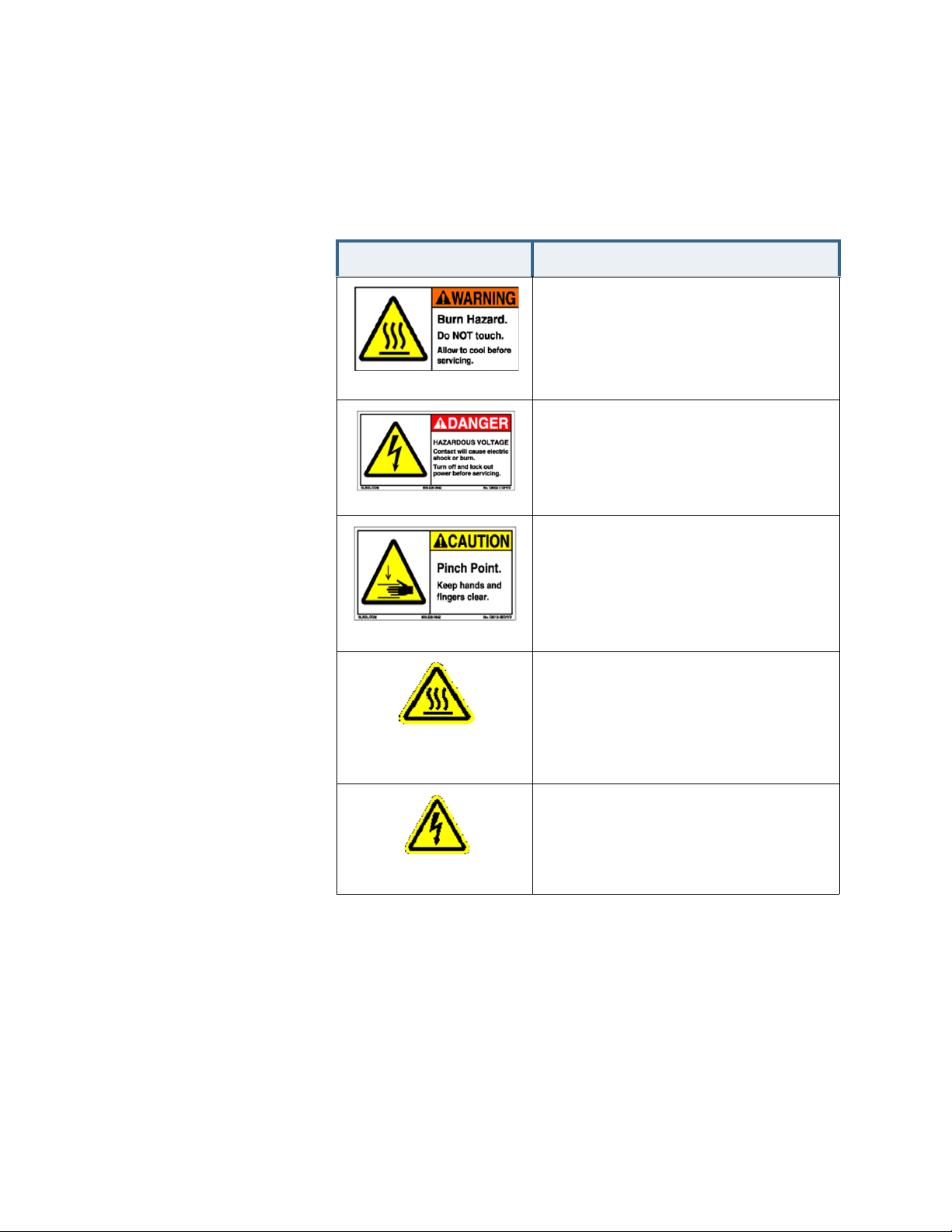

Safety Labels

Safety labels are located throughout the machine, indicating certifications of conformity and personal

safety warnings such as pinch points, burn hazards, or electrical hazards.

Table 1: Safety Labels

Safety Label Hazard Description

The Burn Hazard tag shows the location

of very hot equipment. Contact may

cause burns as a result of contact with

the designated source.

The Electrical Danger tag shows the

location of hazardous electrical

equipment. Contacting dangerous

electrical equipment may cause

electrical shock or burn.

A Pinch Point Hazard represents

locations where machine movements

are dangerous to fingers and hands.

Keep hands and fingers clear of all

designated points.

This tag represents a hot surface or heat

source that may cause personal injury

due to burns. Caution should be

exercised to avoid hot surfaces.

Protective personal equipment should

be readily available to individuals using

this equipment.

Electrical tag represents the location of

an Electrical Hazard. Caution should be

exercised around electrical equipment to

avoid injury due to burns or shock.

Information in this manual is subject to change without notice. The information in this manual is offered in

good faith as representing typical values and not as a product specification. No warranty, either expressed

or implied, is made.

The suggested handling procedures detailed in this document are believed to be generally acceptable.

However, each user should review these recommendations in the specific context of the intended use, and

for agreement with company safety policies and governmental regulations in effect at the plant or facility

where they are being used.

9007-6845-03 2 March, 2009

Page 3

Contents

Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.0 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

FR-1012B Board Heater Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.0 Safety and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Layout of the Heater Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Rear View - Layout of the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Layout of the Unit - Operator Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operating the Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Power Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

T/C Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Programming Timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Setup Timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Save Timeout setting & exit Setup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.0 Maintenance and Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Changing a Heater Bulb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Layout of Bottom Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

9007-6845-03 3 March, 2009

Page 4

1.0 Introduction

The FR-1012 is a bench-top board heater designed to elevate the temperature of printed circuit

board assemblies so the components on them can be soldered or de-soldered easily. This is

particularly useful on medium to high-mass board assemblies, which can “heat-sink” a significant

amount of energy supplied by a soldering iron tip, or handheld hot-air tool.

CAUTION: As with all heating devices, exercise extreme care when using and

handling this unit. The circuit board, fixture, and other surfaces may get

very hot, especially during prolonged use at higher power or temperature

settings

Table 2: FR-1012 Board Heater Specifications

Board Capacity

Heated Area

Heater Watts

Heater Type

Thermocouple Inputs

Controller

Operating Modes

Power Requirements

Size

Weight

12 x 15 Inches 305 x 380 mm

10 x 12 Inches 250 x 305 mm

1,200 W

Low Mass Quartz I/R

(1) Type K

Industrial Microprocessor

Power Mode, or T/C Mode

100 - 120V / 12A Standard

200 – 240V / 6A Optional

14” W x 18” D x 5” T 360 x 460 x 130 mm

16 Lbs. 7 Kg

9007-6845-03 4 March, 2009

Page 5

2.0 Safety and Operation

CAUTION: As with all heating devices, exercise extreme care when using and

handling this unit. The circuit board, fixture, and other surfaces may get

very hot, especially during prolonged use at higher power or temperature

settings.

CAUTION: Unplug the unit before removing the top cover, or otherwise

attempting to service the unit. There are live, high voltage electrical

components underneath the cover even when the power switch is in the OFF

position.

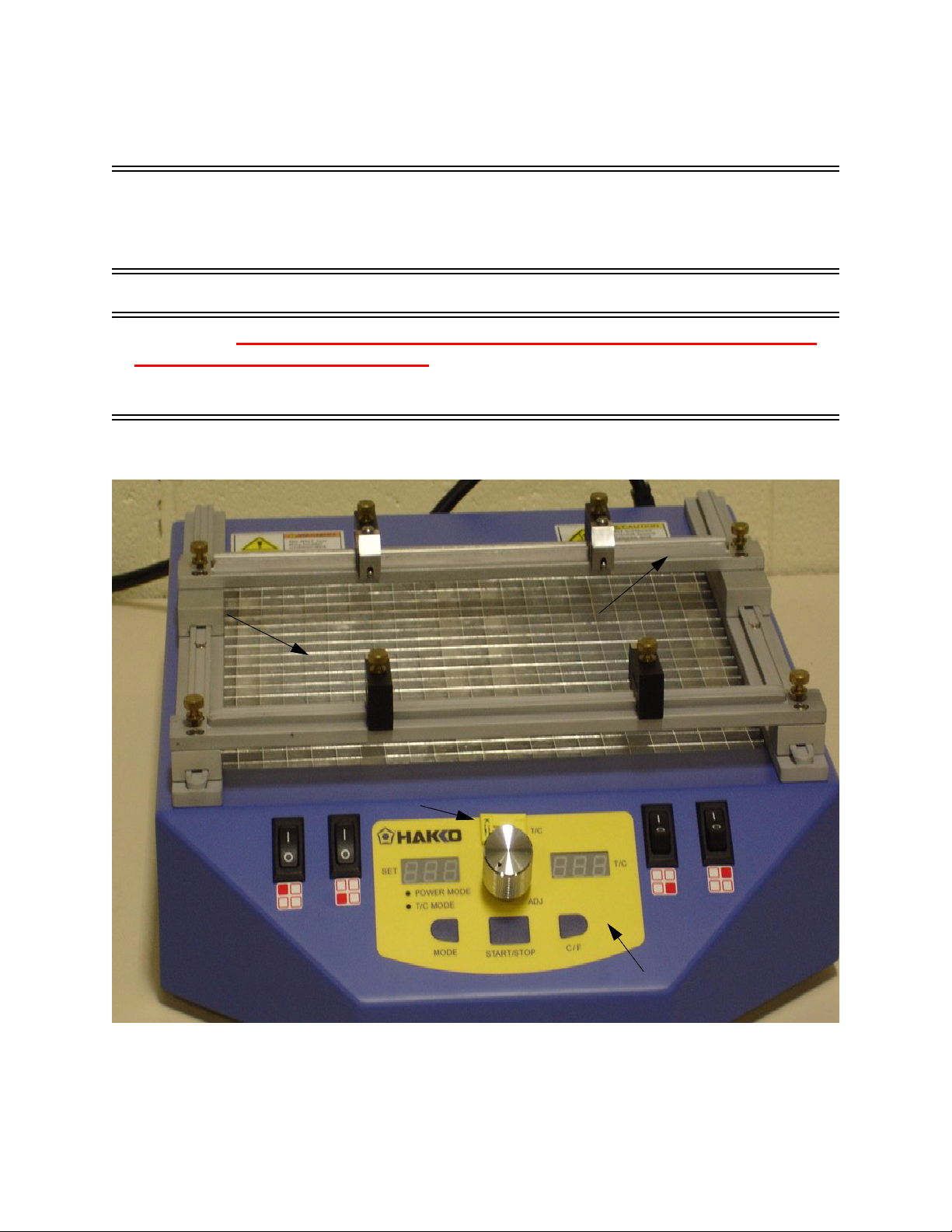

Figure 1: Layout of the Heater Unit

4 Zone IR Heater

Type K Thermocouple Input

Adjustable Board Fixture

Operator Interface

9007-6845-03 5 March, 2009

Page 6

Figure 2: Rear View - Layout of the Unit

Power Switch

Figure 3: Layout of the Unit - Operator Interface

Process setting Display

Mode Indicator

Zone Switches

Mode Select

Process Adjustment

Temperature Display

Zone Switches

Celsius Fahrenheit select

Start Stop

9007-6845-03 6 March, 2009

Page 7

Setup

To set up the heater, follow the steps below.

1. Carefully unpack the unit and place it on a level bench or table.

2. Connect the power cord to the socket at the rear of the unit.

3. Check the serial number label for the correct power supply requirements and plug the unit into

the supply.

4. The unit is now ready to run.

Operation

To use the heater, follow the steps below.

(Use the Figure “Operating the Heater” on page 8 for reference.)

1. Mount a printed circuit board assembly (PCBA) on the fixture.( See Figure 4 “Operating the Heater”

on page 8.) A variety of board fixture clips and supports are available as options for boards that are

odd-shaped or difficult to hold.

2. Attach a Type-K thermocouple (T/C) to an ungrounded area of the PCBA to monitor the board’s

temperature, or operate in the closed-loop T/C Mode.

NOTE: An erroneous T/C reading may result if the T/C is electrically

connected to the unit’s ground though the board fixture.

All of the buttons on the control panel work as toggles. Press and release the buttons to operate. Do not

hold the buttons in or you may inadverntly toggle several time unexpectedly.

3. Select a control mode, by pressing the Mode Select button to toggle between Power Mode and

T/C Mode.

4. Select degrees C or F for temperature readouts by toggling the C/F Button.

5. Press and release the Start/Stop button once to start operation in either mode.

6. Adjust the Set Value or Percent Power while the unit is running by turning the Adj Knob.

7. You may turn on individual zones by toggling the appropriate zone on / off switch.

9007-6845-03 7 March, 2009

Page 8

Figure 4: Operating the Heater

Power Mode

Power Mode allows the Output of the unit to be set manually. The Output is set by rotating the

Process Adjust Knob to the desired percentage of output power, which displays on the left-hand

L.E.D. readout. When running in this mode, the unit will output the set percentage of power,

regardless of the T/C actual value. A thermocouple is not required in this mode, but may be used to

monitor the actual board temperature.

Power Mode output is measured in percent of Power ( 0 - 100%). Though Power Mode does not

operate at a temperature setpoint parameter, a thermocouple can be used to monitor actual board

temperature. The actual temperature depends on a number of variables such as board size,

thickness, composition andcomponent types.

T/C Mode

NOTE: A Type-K thermocouple must be secured to the PCBA and plugged

into the unit’s T/C jack for T/C Mode to work correctly.

9007-6845-03 8 March, 2009

Page 9

TC Mode allows the desired temperature to be set for the PCBA for closed-loop control of the

temperature using the T/C Input. The desired temperature from 50 to 180

by rotating the Process Adjust Knob to the desired temperature for closed-loop control, which

displays on the left side of the L.E.D. readout.

°C (122 to 356°F) is set

When running in T/C Mode, the unit will apply 100% power until the board reaches 10

set temperature. The unit will then start PID Control to regulate the power output of the heater to

hold the PCBA at the set temperature.

°C below the

CAUTION: Unplug the T/C whenever it is not securely attached to a PCBA

mounted on the board fixture. An open (unplugged or broken) T/C will read

999 on the right-hand display, and prevent accidental operation in T/C Mode

which will apply 100% power until the T/C approaches set temperature.

If a T/C is plugged in, and not securely mounted to a PCBA in the fixture so

that it can read the board’s temperature, the unit will continue to apply 100%

power indefinitely, possibly damaging the PCBA.

Programming Timeout

The FR-1012 Heater can be programmed for Timeout, which represents the amount of time the

heater stays on before it automatically turns off. This is a safety feature which prevents operators

from leaving the heater on for an extended period of time. Timeout is accessed in Setup Mode. The

Timeout parameter is prefixed by a “C” and there are 5 possible settings from 0 to 60 minutes.

To program Timeout, follow the steps below.

1. Enter Set Up Mode by pressing both the MODE and START/STOP buttons simultaneously. A letter

“C” appears in the right display as shown in Figure 5 below.

Figure 5: Use Setup Mode to Program Timeout

9007-6845-03 9 March, 2009

Page 10

2. Press the START/STOP button to move through the Set Up Mode options to Timeout Setting.

The display on the right shows the letter “C”.

9007-6845-03 10 March, 2009

Page 11

Figure 6: Setup Timeout

The value shown following the letter “C”

indicates the timeout period. (C 15 parameter represents 15 minutes until Timeout.)

00 = Timeout Disabled. No Timeout is set.

05 = 5 Minutes until Timeout.

15 = 15 Minutes until Timeout.

30 = 30 Minutes until Timeout.

60 = 60 Minutes until Timeout.

3. The value shown following the letter “C” indicates the number of minutes until the Timeout period

begins and the heater turns off. For example, C 15 means that the heater will operate for 15 minutes and then turn off.

• 00 = Time out disabled. No Timeout is set.

• 05 = 5 Minutes

• 15 = 15 Minutes

• 30 = 30 Minutes

• 60 = 60 Minutes

4. Press the C/F button to change the time out setting.

5. Press both MODE and START/STOP buttons simultaneously to store the new setting and exit

Set Up Mode. (See “Save Timeout setting & exit Setup Mode”.)

9007-6845-03 11 March, 2009

Page 12

Figure 7: Save Timeout setting & exit Setup Mode

Figure 8: FR-1012 Front Panel

9007-6845-03 12 March, 2009

Page 13

3.0 Maintenance and Care

For best performance, observe the following:

• Use reasonable care to keep flux and debris from falling into the heater

• Do not pour liquid fluxes directly onto PCBA mounted on the machine.

• Periodically clean the board fixture rails. You may optionally unplug the unit, and apply a thin

layer of Teflon lubricant to the aluminum rails. Be careful not to pour or spray lubricant into the

heater panel.

• Do not touch the quartz-halogen bulbs with your fingers or hands. Oils from your hands will create hot-spots on the bulbs, leading to premature failure.

Changing a Heater Bulb

One defective bulb may cause three or more bulbs to not operate. A failed bulb can be identified by close

visual inspection for a broken filament, or discoloration. Before attempting to replace a defective bulb, turn

the heater off, and unplug the unit. Allow the heater to cool if necessary

To replace a defective bulb, follow the steps below. (Refer to “Layout of

Bottom Heater” on page 14 for reference.)

1. Turn the heater off and unplug the unit. Allow the heater to cool, if this is necessary.

2. Remove the (6) screws securing the board fixture to the unit base.

3. Lift the board fixture off as an assembly.

4. Carefully remove the Housing/Cover, lifting it straight up, and then to the Left. There is a ribbon

cable plugged into the Operator interface. It is not necessary to unplug this cable.

5. Remove the Honeycomb Grille.

NOTE: Do Not touch bulbs with bare hands. Use a clean towel or cotton glove

to handle the bulbs.

6. Use a clean towel or glove. Locate the defective bulb(s) and remove it by gently pushing to one

side, and then rotating the bulb up out of the bulb holder fixture.

7. Insert a new bulb into the fixture. Check that it is properly seated on the contact pins by rotating it

and gently rocking it side to side. You should feel the bulb being suspended by the contact spring,

and it should rotate a small amount freely on the contact pins.

9007-6845-03 13 March, 2009

Page 14

8. Clean any debris out of the heater panel reflectors.

9. Re-assemble the cover and board fixture, taking care by tucking the ribbon cable into the operator

interface inside the Housing/Cover on the left side of the unit, without pinching the cable.

10. Plug in the unit, turn on the power to test.

Figure 9: Layout of Bottom Heater

Ribbon cable under

housing on left side.

Board Fixture Mounting Screws

3 on each side

Honeycomb Grille

Bulbs under Grille

Housing Cover

9007-6845-03 14 March, 2009

Loading...

Loading...