Page 1

HP-2999

COLOUR TELEVISION

Service Manual

MODEL :

HP-2999

THAILAND

Features

218 programs present

Multiple picture & volume modes

On/off timer

Child-lock

Slide curtain power on/off display

DVD component input

Program scan

Haier Group

Manual code: M-AS-TH-HP-2999-9363 Edition: 2003.0222

0

Page 2

Contents

1.Contents

1.Contents……………………………………………………………………… ..1

2. Product code illumination and series introduction………….…. …..2

3. Features…………………………………………………………….…..… ..2

Specifications…………………………………………………………..……3

4

5 Safety Precaution……………………………………………………….….4

6

Warning and cautions………………………………………………….….5

7

Net Dimension …………………………………………………………….11

8 Parts and Functions………………………………………………………12

9

Remote controller Functions……………………….…………………..13

10

Program Diagram…………………………………………………………14

11. Maintenance Service and Trouble Shooting…………………..……22

12. Circuit Diagram……………………………………………………….….27

13. Circuit Explanation…………………………………………..………….30

14. Adjustment…………………………………………………………..……40

15. Exploded View…………………………………………………….……..43

16. List of Parts…………………………………………………….…………45

17. Damageable Parts List…………………………………………….……62

18. Information of Resistors and Capacitors…………………….……..63

1

Page 3

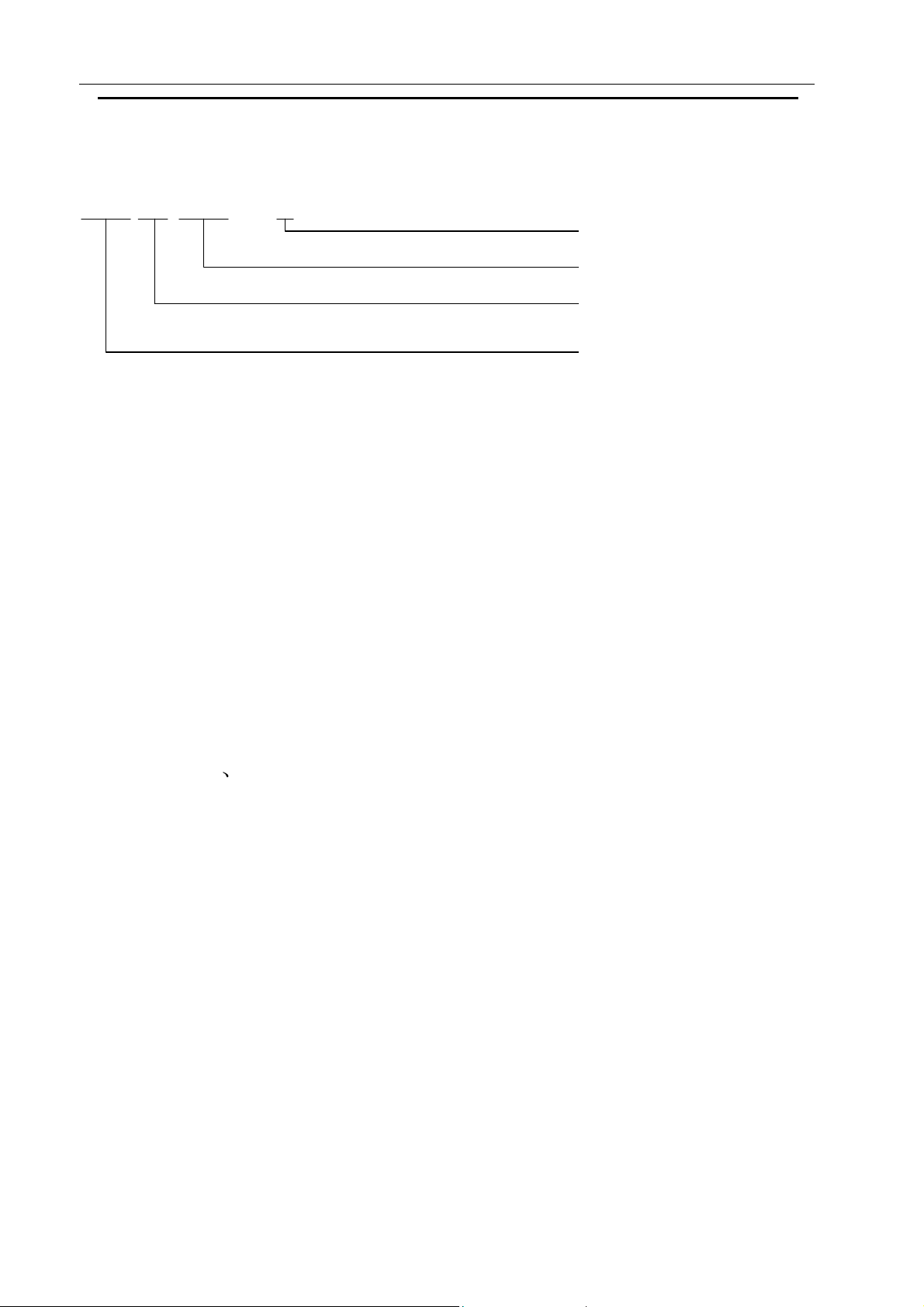

Product code illumination and series introduction

2. Product code illumination and series introduction

H P 29 99

Appearance serial

CMOS chip type

CRT catercorner 29 inch

HAIER

3.Features

1) 218 programs present

2) Multiple picture & volume modes

3) On/off timer

4) Child-lock

Program scan

5) Slide curtain power on/off display

6) DVD component input

2

Page 4

4. Specifications

Specificatio

NO. FUNCTION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

Main IC

CRT

Color system

PIC

Audio system

NO.of channels

OSD language

Multi-picture modes

AV stereo

Super woofer

Surrounding sound

Treble/bass boost

AUDIO

Left/right balancer

NICAM

Multi-audio modes

Tone adjuster

MTS/SAP

Auto-volume leveling

AV input

AV output

JIC

DVD terminal

S-video jack

Headphone socket

SCART socket

Digital curtain

Slow fading on & off

Semitransparent menu

Non-flshing channel changing

ZOOM

SOFTWARE

16:9 mode

Games

Calendar

Child-lock

Multi-functional lock

No-picture listening

Background light

Auto-timer on

CCD

V-CHIP

TDA9373

SF

PAL SECAM

B/G

218

ENG/THA

YES

YES

YES

YES

YES

YES

YES

YES

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

NO. FUNCTION

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

APPROVAL

NO. of built-in speakers

Audio output power(W)

Total power input

Voltage range

PARAMETER

Power frequency

Time of sleep timer(MINS)

Net weight(KG)

Gross weight(KG)

Net dimension(MM)

Packaged dimension(MM)

Quantity for 20' container

Quantity for 40' container

Quantiry for 40' high container

Acquired certificate

Suitable market

W

V

Hz

5

5W+5W+8W

140

150-250V

50HZ

42Kg

46Kg

810*530*600

3

Page 5

SAFETY PRECAUTIONS

5. SAFETY PRECAUTIONS

INPORTANT SAFETY NOTICE

These parts are identified by many electrical and mechanical parts in this chassis have

special safety-related characteristics.

It is essential that these special safety parts should be replaced with the same

components as recommended in this manual to prevent X-RADIATION, Shock, Fire, or

other Hazards.

Do not modify the original design without permission of the manufacturer.

General Guidance

An Isolation Transformer should always be used during the servicing of a receiver whose

chassis is not isolated from the AC power line. Use a transformer of adequate power

rating as this protects the technician from accidents that might result in personal injury

caused by electrical shocks.

It will also protect the receiver and it’s components from being damaged by accidental

shorts of the circuitry that might be inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown, replace it with a specified

one.

When replacing a high wattage resistor (Oxide Metal Film Resistor, over 1W), keep the

resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to the high vacuum and large surface area of the picture tube, extreme care should

be taken in handling the Picture Tube. Do not lift the Picture Tube by its Neck.

X-RAY Radiation

Warning:

The source of X-RAY RADIATION in this TV receiver is the High Voltage Section and the

Picture Tube.

For continued X-RAY RADIATION protection, the replacement tube must be of the same

type as specified in the Replacement Parts List.

Before returning the receiver to the customer,

Always perform an AC leakage current check on the exposed metallic parts of the

cabinet, such as antennas, terminals, etc., to make sure that the set is safe to operate

without any danger of electrical shock.

4

Page 6

Warning and Cautions

6 Warning and Cautions

1. When you clean the TV set, please pull

out the power plug from AC outlet. Don't

clean the cabinet and the screen with

benzene, petrol and other chemicals.

2.

In order to prolong the using life of the

TV set, please place it on a ventilated

place.

4. To prevent the TV set from firing and

electric shock, don't

make the TV set rain

or moisture.

5. Don't open the back cover, otherwise it is

possible to damage the components in the

TV set and harm you.

3.

Don't place the

TV set in the

sunshine or near

heat source.

6. When the TV set isn't going to be used

for long time or it is in thunder and

lightening, please pull out the plug from AC

outlet and the antenna plug from the cover

of the TV set.

5

Page 7

Warning and Cautions

Explanation on the display tube

Generally, it is not needed to clean the tube surface. However, if necessary, its surface

can be cleaned with a dry cotton cloth after cutting off the power. Don’t use any cleanser.

If using hard cloth, the tube surface will be damaged.

CAUTION: Before servicing receivers covered by this service manual and its

supplements and addenda, read and follow the SAFETY PRECAUTIONS.

NOTE: If unforeseen circumstances create conflict between the following servicing

precautions and any of the safety precautions, always follow the safety precautions.

Remember : Safety First.

General Servicing Precautions

1. Always unplug the receiver AC power cord from the AC power source before:

a. Removing or reinstalling any component, circuit board module or any other

assembly of the receiver.

b. Disconnecting or reconnecting any receiver electrical plug or other electrical

connection.

c. Connecting a test substitute in parallel with an electrolytic capacitor in the

receiver.

CAUTION: A wrong substitution part or incorrect installation polarity of

electrolytic capacitors may result in an explosion hazard.

d. Discharging the picture tube anode.

2. Test high voltage only by measuring it with an appropriate high voltage meter or other

voltage-measuring device (DVM, FETVOM, etc.) equipped with a suitable high

voltage probe. Do not test high voltage by “drawing an arc”.

3. Discharge the picture tube anode only by (a) first connecting one end of an insulated

clip lead to the degaussing or kine aquadag grounding system shield at the point

where the picture tube socket ground lead is connected, and then (b) touch the other

end of the insulated clip lead to the picture tube anode button, using an insulating

handle to avoid personal contact with high voltage.

4. Do not spray chemicals on or near this receiver or any of its assemblies.

5. Unless specified otherwise in this service manual, clean electrical contacts only by

applying the following mixture to the contacts with a pipe cleaner, cotton-tipped stick

or comparable nonabrasive applicator; 10% (by volume) Acetone and 90% (by

volume) isopropyl alcohol (90%-99% strength)

CAUTION: This is a flammable mixture.

Unless specified otherwise in this service manual, lubrication of contacts is not

required.

6. Do not defeat any plug / socket B+ voltage interlocks with which receivers covered

6

Page 8

Warning and Cautions

by this service manual might be equipped.

7. Do not apply AC power to this instrument and/or any of its electrical assemblies

unless all solid-state device heat sinks are correctly installed.

8. Always connect the test receiver ground lead to the receiver chassis ground before

connecting the test receiver positive lead.

Always remove the test receiver ground lead last.

9. Use with this receiver only the test fixtures specified in this service manual.

CAUTION: Do not connect the test fixture ground strap to any heat sink in this

receiver.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity.

Such components are usually called Electrostatically Sensitive (ES) Devices. Examples

of typical ES devices are integrated circuits and some field effect transistors and

semiconductor “chip” components. The following techniques should be used to help

reduce the incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductorequipped assembly, drain off any electrostatic charge on your body by touching a

known earth ground. Alternatively, obtain and wear a commercially available

discharging wrist strap device, which should be removed to prevent potential shock

prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the

assembly on a conductive surface such as aluminum foil, to prevent electrostatic

charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static type folder removal device. Some solder removal devices not

classified as “anti-static” can generate electrical charges sufficient to damage ES

devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges

sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until

immediately before you are ready to install it. (Most replacement ES devices are

packaged with leads electrically shorted together by conductive foam, aluminum foil

or comparable conductive material).

7. Immediately before removing the protective material from the leads of a

replacement ES device, touch the protective material to the chassis or circuit

assembly into which the device will be installed.

CAUTION: Be sure no power is applied to the chassis or circuit, and observe all other

safety precautions.

7

Page 9

Warning and Cautions

8. Minimize bodily motions when handling unpackaged replacement ES devices.

(Otherwise even some normally harmless motions such as mutual brushing of your

clothes’ fabric or lifting of your foot from a carpeted floor might generate static

electricity sufficient to damage an ES device.)

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and appropriate tip size and shape

that will maintain tip temperature within the range of 500 oF to 600 oF.

2. Use an appropriate gauge of RMA resin-core solder composed of 60 parts tin/40

parts lead.

3. Keep the soldering iron tip clean and well tinned.

4. Thoroughly clean the surfaces to be soldered. Use a mall wire bristle (0.5 inch, or

1.25cm) brush with a metal handle. Do not use freon-propelled spay-on cleaners.

5. Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal temperature.(500 o F to 600o F)

b. Heating the component lead until the solder melts.

c. Quickly draw the melted solder with an anti-static, suction-type solder removal

device with solder braid.

CAUTION: Work quickly to avoid overheating the circuit board printed foil.

6. Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal temperature.(500 o F to 600o F )

b. First, hold the soldering iron tip and solder the strand against the component lead

until the solder melts.

c. Quickly move the soldering iron tip to the junction of the component lead and the

printed circuit foil, and hold it there only until the solder flows onto and around

both the component lead and the foil.

CAUTION: Work quickly to avoid overheating the circuit board printed foil.

d. Closely inspect the solder area and remove any excess or splashed solder with a

small wire-bristle brush.

Remove /Replacement

Some chassis circuit boards have slotted holes (oblong) through which the IC leads are

inserted and then bent flat against the circuit foil. When holes are of slotted type, the

following technique should be used to remove and replace the IC. When working with

boards using the familiar round hole, use the standard technique as outlined .

Removal

Desolder and straighten each IC lead in one operation by gently prying up on the lead

with the soldering iron tip as the solder melts.

8

Page 10

Warning and Cautions

Draw away the melted solder with an anti-static suction-type solder removal device (or

with solder braid) before removing the IC.

Replacement

Carefully insert the replacement IC in the circuit board.

Carefully bend each IC lead against the circuit foil pad and solder it.

Clean the soldered areas with a small wire-bristle brush.(It is not necessary to reapply

acrylic coating to the areas).

“Small-Signal” Discrete Transistor

Removal/Replacement

Remove the defective transistor by clipping its leads as close as possible to the

component body.

Bend into a “U” shape the end of each of three leads remaining on the circuit board.

Bend into a “U” shape the replacement transistor leads.

Connect the replacement transistor leads to the corresponding leads extending from the

circuit board and crimp the “U” with long nose pliers to insure metal to metal contact then

solder each connection.

Power Output, Transistor Device

Removal/Replacement

Heat and remove all solder from around the transistor leads.

Remove the heat sink mounting screw (if so equipped).

Carefully remove the transistor from the heat sink of the circuit board.

Insert new transistor in the circuit board.

Solder each transistor lead, and clip off excess lead.

Replace heat sink.

Diode Removal/Replacement

Remove defective diode by clipping its leads as close as possible to diode body.

Bend the two remaining leads perpendicularly to the circuit board.

Observing diode polarity, wrap each lead of the new diode round the corresponding lead

on the circuit board.

Securely crimp each connection and solder it.

Inspect (on the circuit board copper side) the solder joints of the two “original” leads. If

they are not shiny, reheat them and if necessary, apply additional solder.

Fuse and Conventional Resistor

Removal/Replacement

9

Page 11

Warning and Cautions

1. Clip each fuse or resistor lead at top of the circuit board hollow stake.

2. Securely crimp the leads of replacement component around notch at stake top.

3. Solder the connections

CAUTION: Maintain original spacing between the replaced component and adjacent

components and the circuit board to prevent excessive component temperatures.

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed circuit board will weaken the

adhesive that bonds foil to the circuit board causing the foil to separate from or “lift-off”

the board. The following guidelines and procedures should be followed whenever this

condition is encountered.

At IC Connections

To repair a defective copper pattern at IC connections use the following procedure to

install a jumper wire on the copper pattern side of the circuit board.(Use this technique

only on IC connections).

1. Carefully remove the damaged copper pattern with a sharp knife. (Remove only as

much copper as absolutely necessary).

2. Carefully scratch away the solder resist and acrylic coating (if used) from the end of

the remaining copper pattern.

3. Bend a small “U” in one end of a small gauge jumper wire and carefully crimp it

around the IC pin. Solder the IC connection.

4. Route the jumper wire along the path of the out-away copper pattern and let it

overlap the previously scraped end of the good copper pattern. Solder the

overlapped area and clip off any excess jumper wire.

At other connections

Use the following technique to repair the defective copper pattern at connections other

than IC Pins. This technique involves the installation of a jumper wire on the component

side of the circuit board.

1. Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to insure that a hazardous condition will not exist

if the jumper wire opens.

2. Trace along the copper pattern from both sides of the pattern break and locate the

nearest component that is directly connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the lead of the nearest component on

one side of the pattern break to the lead of the nearest component on the other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is dressed so that it does not touch

components or sharp edges.

10

Page 12

Net Dimension

7 Net Dimension

790mm

525mm

590mm

11

Figure 1

Page 13

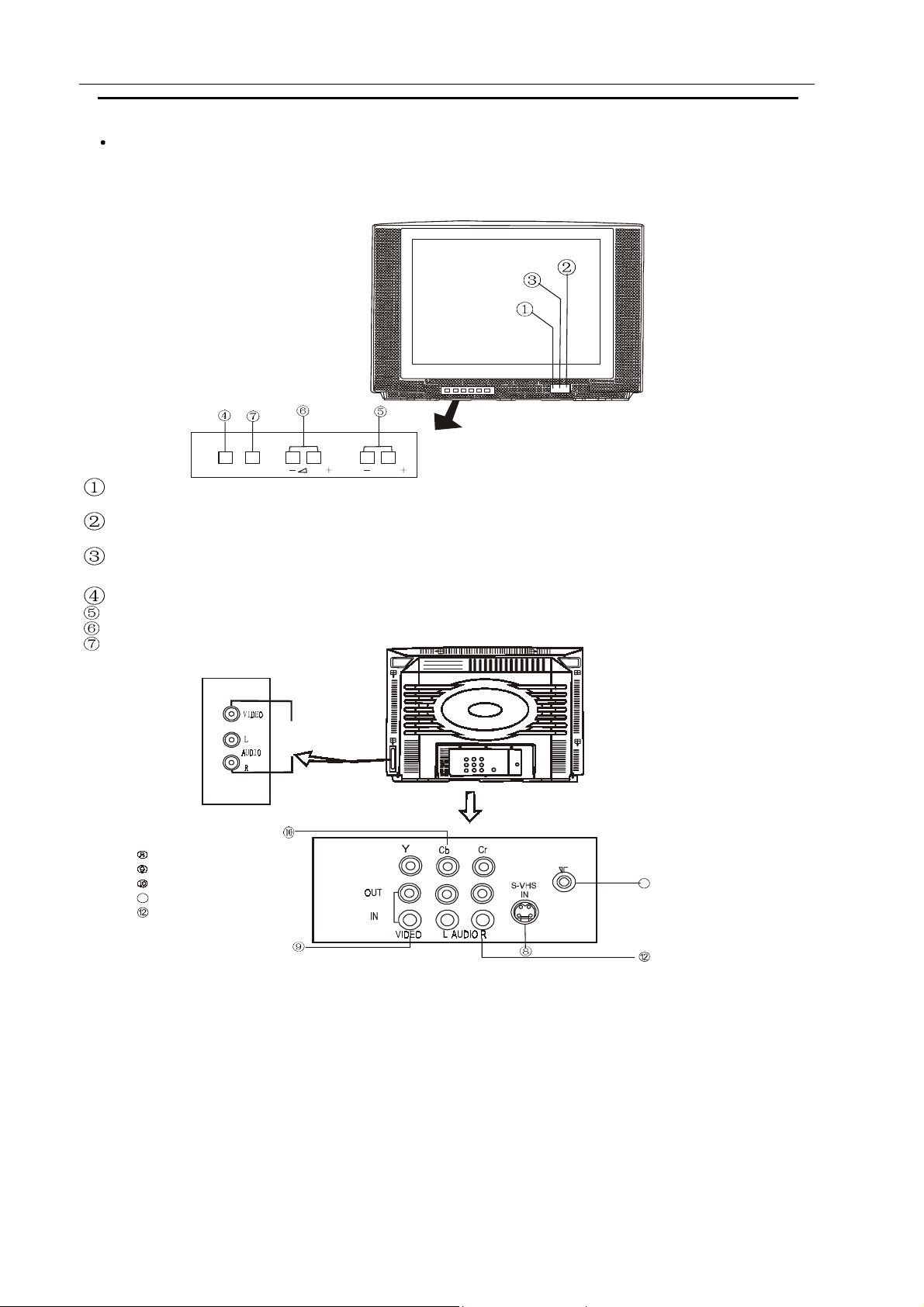

8 Parts and Funcitions

Front and side panel of the TV set

1 .Fro n t Pa n e l

MENUP TV/AV

Remot e sensor:let The remo te controller aim he re the set can rece ive remote

control signal.

Power switch:Press the button to turn on the TV set . press the button again to turn

off the TV set.

Power indicator: the indicator lights in standby status ,the indicator lights in sleep

status . The indicato r glin ts when you use remote contro ller

Menu butto n

Progr am up/do w n button

Vo lu me up/down button

TV/AV

2.Rear Panel

And Side Board

.

Parts and Funcitions

VIDEO input

Left audio input

Right audio input

S-VHS input

VIDEO input/output

DVD component input

11

Antenna input

Audio input/output

A V IN 1

When using S terminal, please pull out video 1 input terminal

Figure 2

11

12

Page 14

9. Remote Controller Functions

Remote Controller Functions

MARK

FUNCTION DESCRIPTION

Program scan

Standby

SWAP

Mute

1

2

3

TV/AV

-VOL+

-CH+

TV/VIDEO SELECTION

VOLUME CONTROL

CHANNEL NUMBER UP/DOWN

PICTURE MENU

P

.

P

C

P

I

T

R

U

E

S

W

P

A

SOUND

TIME

FUNCTION

0-9

SOUND MENU

TIME MENU

FUNCTION MENU

ONE DIGIT SELECTION

-/--

MENU

MENU DISPLA Y

EXIT MENU DISPLAY

STEREO/NOMO SOUND SE LECT I ON

PICTURE MODE SELECTION

SOUND MODE SEL ECTION

TUNE MENU SELECTION

CHILDLOCK

Figure 3

13

Page 15

Program Diagram

10.ProgramDiagram

OPERATION MENU

OCT

TUNE

COLOR SYSTEM AU T O

SOUND SYSTEM B/G

BAND VHFL

SKIP OFF

PROG NO 19

SEARCH

FINE TUNE

AUTO SEARCH

6.Selecting color syste m

Usually this should be set in the Auto position. However if the colours displayed on

the scree n are incorrect you can manually select the correct co lour sy stem. When

you have f inished remember to turn it back to auto ag ain so that other pro g rams

will still work correctly. Use the CH+/- buttons to select COLOR SYSTEM then the

VOL+/- buttons to select a color system you need.. Press the EXIT button to save

the setting.

14

Page 16

Program Diagram

OPERATI ON M ENU

7.Program skip

The Program ski p featur e enables you to sk ip /h id e program s th at you do n o t w ish to

be displayed w hen usi ng th e C H + /- buttons. T h e se c h an n e ls w ill st i l l be di spl ayed by

di rect l y usi ng t he channel num ber but t ons on t he rem ote c o n tro l. th e

T o sk ip , press

CH+/- but t ons t o se lec t th e SKIP m enu, Pr ess the V O L+/ - but t ons t o t une t he skip

f eat ure on/ off. Pr ess the EX IT but t on t o save the setting .

8. Pr ogr am Number

The program num ber i s th e rem o te control channel num ber . Y ou can change th e

program num ber to see w hich channels are st ored w i t hout ex itin g th is m a in

menu. Pr ess t he CH +/ - but ton to se le c t PROG NO, Pr ess t he VOL+/- t o change

t he program num ber t hat you are adjusting.

9. Ba nd Sw itching (note: Thi s is a new item )

If you already know w hat band t he channel is on, t uning can speed up by

se lecting the correct band before going in to th e search menu. This feat u re

should only be used i f you underst and th e channels in your lo cal area.

Picture Adjustments

1 Contrast ( A dds dept h t o t he pictur e)

Pr ess t he CH+/- but t ons t o sel ect Contrast, th en

press th e V O L + /- b u tto n s to adjust t he Contrast l evel .

2 Bri ght ness (A dds sparkle and shine to the picture)

PIC T UR E

CONTRAST 89

BRIG HTNESS 66

COLO UR 50

SHA RPN ESS 50

TILT 08

IIIIIIIIIIIIIIIIIIIIIIIII..........

OCT

Pr ess t he CH+/- but t ons t o sel ect Brightness, then

press th e V O L + /- b u tto n s to adjust t he brightness

lev el.

3 Col our (A dds col our dept h)

Pr ess t he CH+/- but t ons t o sel ect Colour, then press t he V O L + /- but t ons t o

adjust th e C olour l evel .

4 Sharpness (A dds fine detail)

Pr ess t he CH+/- but t ons t o sel ect Sharpness, then press t he VOL+/- but tons t o

adjust th e Sharpness le v el.

Note: D o n o t tu rn th e sharpness up to high if th e rec e p tio n is poor or has l ots of

noi se as it w ill enhance t he fine g rain details.

15

Page 17

OPERATION M ENU

Sound Adjustments

Press th e m e n u b u tto n tw ice or press the Sound button on th e rem o te con trol,

to display th e Sound setting m enu.

1 Volum e (A djust the l oudness l evel )

SOUND

VOLUME 50

BASS 50

TR EBL E 50

BALANCE 0

SURROUND OFF

WOOFER ON

WOOFER VOL 50

IIIIIIIIIIIIIIIIIIIIIIIII..........

OCT

Pr ess t he C H + /- b u tto n s to sele ct Volum e,

th en pr ess the VOL+/- but tons to adjust th e

v o lu m e lev el.

2 Ba s s (Add lo w frequency depth)

Pr ess t he C H + /- b u tto n s to sele ct B ass, th en

press th e V O L + /- b u tto n s to adjust t he

v o lu m e lev el.

3 Tr eble ( Add hi gh f requency clarity)

Pr ess t he C H + /- b u tto n s to sele ct Treble, th en

press th e V O L + /- b u tto n s to adjust t he treb le

lev el.

4 Balance (S elects betw een the left and righ t

stereo channel l evels)

Pr ess t he C H + /- b u tto n s to sele ct Balance,

th en pr ess the VOL+/- but tons to adjust th e

balance lev el.

5 S urrou n d (E nh ances the stereo effect by

m aki ng t he sound appear w ider)

Pr ess t he C H + /- b u tto n s to sele ct

SURROUND, th e n press t he V O L+/- but t ons

to tu rn th is fea tu re on/off.

6.W oofer on/off

Press the CH+/- buttons to select

SURROUND, then press the VOL+/buttons to turn this woofer on/off.

7.Woofer volume adjustment

Press the CH+/- buttons to select

WOOFER VOL, then press the VOL+/buttons to adjust woofer volume.

16

Page 18

OPERATION MENU

Function Menu

1.B ackground (If th e sig n a l is very poor or t here is no

in pu t signal th e picture w ill m ute to black)

Pr ess t he C H + /- but t ons t o sel ect Background,

th en pr ess the VOL+/- b u tto n s to tu rn th is feat u re

on/off.

FUNCTION

BACKGROUND ON

BLACK STR ETCH ON

NOISE REDUCE OFF

FA D E ON

CHILDLOCK OFF

AV L OFF

SO FT CHANGE OFF

OCT

2.N oise R educe (P icture Noise & G rain reduction c irc u it.)

Pr ess t he C H + /- but t ons t o sel ect Noise Reduce, th en press t he VOL+/but t ons t o t ur n th is feature on/off.

4. Chi ld Lock (Enables th e TV front cont rol but t ons t o be lo ck ed )

Pr ess t he C H + /- b u tto n s to se lec t C h ild L o ck , t hen press th e VOL+/ but t ons t o t ur n t hi s feature on/off.

5. AV L (A ut om at i c Volum e Li mit control reduces effect of l arge vol um e

changes such as w hen the ads com e on) Press th e C H + /- b u tton s to select

AVL, th en p re ss th e VOL+/- buttons to tu rn th is featu re on/off.

6. B lack Stretch (A dds D eeper B l acks and i ncreases the contrast range)

Pr ess t he C H + /- but t ons t o sel ect Black Stretch, th e n press t he VOL+/- buttons

to tu rn th is fea tu re on/off.

Calender Menu

E n ter C a len d e r m e n u , press th e P+/P- to sel ect year, month, dat e, press th e VOL+/to cha n ge calender set up.

SOLA R 2008 1 20

LU N A R 2002 12 18

S M T W T F S

1 2 3 4

5 6 7 8 9 10 11

12 13 14 15 16 17 18

19 20 21 22 23 24 25

26 27 28 29 30 31

17

Page 19

MULT I FUNCT ION TIM ER

Multi Function Tim er

The TV set has in built a c om p reh en siv e tim er

th at has Five basic funct i ons

1.Clock

2 .O n tim er so th a t the TV set can be pr ogram m ed

to tu rn o n at a certain t im e

3.O ff tim e r that allow th e TV set to tu rn off at a

preset tim e

4.Sleep t im er to allow t he T V se t to tu rn o ff after

TIM E

CLOCK --:-ON TIM E --: -ON-PROG 1

OFF TIM E --:-SLEEP TI MER --: -REM IND TIM E --:-REM IND PRO G 1

COUN T 00001:22

OCT

10 ~ 180 minutes

5. Program r em ind t i m er , that displays an onscreen rem inder prom pt, when a program on a

di fferent channel i s due to star t.

Note: The clock w ill o nly wo rk if th e T V set if le ft tu rn e d on or in standby.

W hen the set is disconnect from th e p ow er supply or i s turned of f by t he

main pow er sw itch o n th e fro nt panel, th e clock lo o ses pow er and w il l

need to be re se t w h e n th e pow er is reconnected.

18

Page 20

MULTI FU NCTIO N TIM ER

to a d ju st th e am ount of t im e before th e TV se t w ill a u to m atic ally

tu rn o ff. Each tim e th e V O L+ but t on i s pressed the sleep tim e will in c re ases by 10

minutes. The m axi m um sl eep tim e i s 180 m i nut es.

5. Remind Tim e

Press th e C H + /- buttons to select R E M IN D TIM E, then press the VOL+/- but t ons t o

adjust th e H ours

Press th e C H - Button to sele ct min utes an d th e VOL + /- to a d ju st th e minutes.

Press th e C H - Button to sele ct REM IND-PROG and the VOL +/- to select the TV

channel th a t the T V set w ill au to m atically rem ind you to t ur n t o w hi l e wat ching

another channel.

6.C ount

The funct i on i s used for di splay t he TV s et used for all tim e.

OCT

Program Number E xchange

This fe ature enables TV program s that m ay

be on a wrong TV channel num ber to be

sw apped/exchanged. This feature is very

EX CH A N G E

P ROGRAM 1 1

P ROGRAM 2 1

EX CH A N G E

usef ul w hen A utom atic Search Tuni ng has

been used, to re allo c a te t he found program s

to th e co rrect channel num ber s.

Pr ess t he Menu butt on 6 tim es unt i l t he exchange m enu i s displayed.

Pr ess t he CH+/- until program 1 is selected. Use th e VOL+/- buttons to

select the channel num ber to be sw apped. (I. E if you wi sh to exchange

Cha nnel 2 and 4 PR O G RA M 1 shoul d = 2)

Pr ess t he CH+/- until program 2 i s selected. Use the V O L+/ - but tons to

select the channel num ber to be sw apped. (I. E if you wi sh to exchange

Cha nnel 2 And 4 PRO G RA M 2 shoul d = 4)

Pr ess t he CH+/- until EXCHANGE is sel ected. Pr ess th e VOL+ button to

enable t he exchange.

19

Page 21

GENERAL OPERATION

1.C hannel Changi ng (218 possibl e channels)

Use either th e C H + /- buttons on th e rem o te o r th e f ront of t he TV s et to change t he

channels.

Or

D irect ly ent er t he channel num ber w i t h t he num eri c keypad on th e rem o te co n tro l.

To sel ect channel num ber s from 10 ~ 99 press [-/--] button an d enter th e tw o digit

channel num ber. To sel ect channel num ber s from 100 ~ 218 pr ess [-/ --] button

tw ice and enter the 3 digit channel num ber.

2.Volume Adjustment

Press th e V O L + /- b u tto n s on th e re m o te o r th e fro n t of th e TV se t to ad ju st th e

vol um e le v el. The range i s 0~99. W hen the Vol um e but t ons are pressed the volum e

l evel i s di spl ayed autom atically on th e TV scr een.

3.Standby

U sin g th e rem ote cont rol t he TV s et can be pl aced i nt o standby mode. Standby

m ode m ust be used fo r th e Tim er features to operate correctly. A re d standby lig h t

w ill g low on th e TV front panel when th e T V set is p la ce d into standby. To tu rn

th e TV set back on agai n pr ess st andby but t on on t he rem o te control again. It will

take a few seconds before a picture w ill be displayed.

4.Mute

Press th e m u te button on th e re m o te co n tro l to mute th e TV set s sound. Pressing

th e M ute again w ill tu rn th e sound back on again.

5.Preset Picture M odes

Our engineers have desi gned i n 5 com m onl y used pi ct ure set ti ngs to allow fast

pi ct ure lev el selectio n depending on w h a t ty p e o f TV program is show ing. Each

m ode i s se lec te d in tu rn by pressi ng t he "P STD " button on th e rem o te co n tro l.

The 5 modes are

Listen- This is a new feature th at blacks out th e TV screen when listening to

music onl y channel s

Soft - D esigned for night tim e l ow l i ght vi ew i ng

Standard - D esi gned f or room s th at have good all round l i ght i ng

Rich - D esigned fo r room s w i th hi gh am bi ent l i ght i ng such as daytim e sport .

User- A s pare setting th at can b e ad ju sted t o personal tastes

U sin g th e PICT URE adj ust m ent di splay m enu all 5 m odes can independently

adjus ted.

20

Page 22

GENERAL OPERATION

6.Pr es et Sound Modes

Ou r engi neer s have designed in 4 com m only used sound mo des to allo w th e

best possi bl e sound t o be selected quickl y. Each m ode i s sel ected in tu rn b y

pressing t he "S STD" but ton on th e rem o te control.

The 4 m odes are

Speech- D esi gned to red u ce th e bass and tre b le w hi ch enhances th e voice fo r

Ne ws program s

Theatre- Enables extra bass and treble to enhance t he m ovie exp erience

M usi c- Adjust the sound to best suit m usic program s

U ser - A s pa r e settin g th at can be adj ust t o per sonal t astes

U sing th e SOUND adjustm ent display m enu all 4 m odes can independent l y adj ust ed

7. Recal l ( O n-screen Display)

The Call butt on on the rem ote control allow s the onscreen menu to be

displayed, show ing th e channel num bers and col our syst em .

8. Program Scan (A ut om at i call y in c rem en ts/scan s th e channels and displays

each channel fo r a sh ort tim e)T he SC A N butt on on t he rem o te control turns

on/off th e scan f eature.

9. Zoom (Changes th e p ictu re si ze form at)

Each tim e the ZOOM b u tto n is pressed th e p ictu re si ze w il l change. There

are th e foll o w ing size options.

Normal - Used fo r st andard 4: 3 picture program s

E nlargem ent - Z o o m s th e p ictu re in to magnify sm aller im ages.

10.Sw ap (Toggles betw een the last channel view and the current channel)

Each tim e th e SW AP butt on i s pressed the last channel view i s di spl ayed.

11.AV input sel ect i on

Each tim e the TV/AV but t on i s press t he inp u ts selectio n will cycle betw een

TV- AV1- AV2- SVHS- DVD - TV.

No te s: I.AV1 & SV HS share the sam e AV 1 audio inputs.

.In AV m odes the RECALL stat us di spl ay will o n ly di spl ay t he colou r

system .

12.Lock

Pr ess t he LOCK b u tto n to sele ct Chi l dl ock on/ off.

21

Page 23

Maintenance Service and Trouble Shooting

11. Maintenance Service and Trouble Shooting

a. TROUBLESHOOTING PROCESS

Grating off

Check +B

Abnormal Normal

Disconnect R214 to

check main voltage

Normal

Abnormal None

Check TDA9373

voltage

Check for short between

output voltage and ground

Check for 300V voltage

Check N801 for

peripheral circuit

Check R415, R505

and R526

Check V403, T401

Check V402

Check pin 33 of

N201 for output

Check lamp filament,

release and grating voltages

Check CRT

cathode voltage

Check N201 for

signal output

Check TDA6107Q

and peripheral circuit

R, G and B

22

Page 24

d

Maintenance Service and Trouble Shooting

Horizontal bright line

Check pin 21 and 22 of N201 for curve output

None Yes

Check R228 and C227

Abnormal Normal

Check N201

Check R413 and R408

Check T444

Check 16V and 47V

voltage

Check N301 an

peripheral circuit

Disabled remote control

Abnormal Normal

Check all pins of V801for voltage

Check receiver voltage

Check pin 61 of

N201 voltage

Check RR230 and C234

Check VD806 for

voltage output

Check receiver

Check N201

23

Page 25

Pincushion distortion

Maintenance Service and Trouble Shooting

Enter factory mode and adjust

5EWP to see if picture changes

None Yes

Check pin 20 of N201for voltage

and ground resistance

Check

V401 and DZ401

Check pin 12 N301 for voltage

and ground resistance

Check C416

Check and replace

N201 and N301

Check and replace

VD404A andVD404B

24

Page 26

Maintenance Service and Trouble Shooting

TV program sound off

Yes

Check pin 7 of N201 for

None Yes

Yes None

noise suppression

No

Check N201 44 for

sound signal output

Check and replace N201

Check N701 3 5

for sound signal output

Check N701 15 18

for sound signal output

None Yes

Check and

replace N701

Check N601 and peripheral

Press mute button, or check

and replace N201

Check V213, R243,

C246 and C706

circuit components

25

Page 27

Maintenance Service and Trouble Shooting

b. Troubleshooting guide

To assist in location possible faults use help guide below

BREAKDOWN PHENOMENON

PICTURE

Picture with snow Noise

Double or Triple Image

Disturb

No Picture No sound

SOUND

Normal

Noise

No soundNormal

The aerial direction and connection

This is called ghosting which can be minimized with

an outside aerial, and good quality cable and

terminations. Altering the aerial direction can also

minimize this effect.

Electrical interference which can be caused by cars,

motorbikes etc, Fluorescent lamps and dirty

insulators on overhead power cables.

Volume Sound mute

Ensure that the power supply is connected to

the TV set and turned on. Also ensure that the

TV set is not in "Listen Mode" or that the

brightness and contrast are not turned down.

CHECKING

.

Adjust colour control

No colour Normal volume

Adjust channel again

Scramble

Colour Spot

Note:

1.If the fault can not be repaired using the above guide consult with your local authorized service

center.

2.The TV set must only be repaired by a qualified registered service person. Never attempt to

remove the back cover as the TV set has dangerous voltages in side that may cause a fatally or fire.

3. The cabinet may produce the occasional "snapping sound" This is normal and caused by the

materials in the cabinet expanding with room temperature changes.

Normal or Weak Volume

Normal volume

Colour Purity fault which can be caused by moving the

TV set, placing magnets near the TV screen or turning

on/off house hold appliances such as vacuum cleaners

near the TV set. Turn the TV off with the mains power

switch for 15 minutes. When the power is turn on again

the TV set will automatically degauss the picture. In

server cases leave the TV set turned off over night.

26

Page 28

p

g

p

12. Circuit Diagram

Circuit Diagram

a. Pane hint picture

b.

+8V

RM201

remote

control

TU101

TUNER

SCL

E2PROM

Assistant

power supply

Switch

transforme

Microprocessor and signal processor

r

SF101

sound surface

filte

SDL

SDL SCL

+5.1V

+130V

+16V

+15V

r

Dark current

check-u

N201

The second SIF filter

The second SIF WAVE TRAP

V-SYNC

H-SYNC

pillow figure

emendation

N701

Sound processing and

lifyin

am

MUTE

peaker1

CRT

+46V

+16.5V

+200V

S

Speaker2

N610

Sound

amplifying

N501

Video frequency

amplifying

N301

field output

V403

line output

tube

T444

FBT

R

G

B

V

-DY

H-DY

FOCUS

SCREEN

Figure 4

27

Page 29

c

Circuit Diagram

Circuit Diagram

P+

P-

TV/AV

V-

V+

RB03

1.8K

TU101

ENV59D69F1Q

VT B U

AGC

C105

C107

C106

104

22U

0.33U

R110

51

L103

10uH

R261

12K

VD217

1N4148

R203

R202

10K

11K

C203

104

BL

BU

V204

KSR1010

C212

104

BH

CN801

TJC1-2Y

L801

LCL-207

CN802

TJC1-2Y

RP803

PTH

DEGUSS

VD810

D5SB60

1234

+

C804

222

~~

RP801

5

C805

222

MENU

TJC3-2Y

1

RB06

1.2K

C104

104

L102

10uh

9.1K

R262

R227

100

R260

9.1K

R204

10K

C204

104

C210

104

C213

104

C211

104

SW07

KDC-A10

C801

104

R801

3.3M

DV801

MYN15-471K

R803

33K

R802

33K

R804

470K

C806

330uF

R805

470K

RB09

CNB01

620

1K

470

TJC3-2Y

2

R219

R222

R220

R212

R223

A6-5V

3.3K

3.3K

3.3K

3.3K

AFT

NC

NC11IF

+BBH BL

GND

9

1083154672

C101

0.22U

M9911AN101

C103

104

C102

220U

R102

2.2K

R103

2.7K

R201

10K

V201

4A/250VF801

123456

DZ102

MTZJ5.1B

L101

R101

1.2uH

24

B4-12V

C109

DZ101

103

MTZJ9.1B

CD108

47U

C110

102

VD101

SF101

K2972M

BAW75

R105

56K

R104

560

V101

BC548

C201

C202

DZ201

10u

104

KA33V

A1-33V

R206

10K

KSC815

C205

152

C206

R205

151

10K

V202

KSR1010

V205

R225

KSC815

10K

R224

10K

V203

KSR1010

LD901

HTRYG9208

KA5Q1265RF-YDTU

N801C

L803

L807

4

VFB

F/B

F/B

1

C807

2

222

VCC

SYNC

35

R806

VD804

470

IN4148

R807

C811

600

392

VD803

VD802

ERB4304

B1206

C808

47u

N802

PCT817C

C809

473

3.3K

STANDBY

R209

100

SCL

C209

R210

100

SDA

A5-3.3V

R266

3.3K

R216

47

C259

3.3K

SYSTEM

R218

MUTE

10K

MAG

C215

104

C214

104

224

L201

0.47uH

C216

.

A7-8V

L202

C219

C220

10uH

104

100u

C217

224

C218

222

R226

C222

15K

1u

C221

472

C224

2.2u

222

C225

C226

222

R228

39K

C227

104

C228

L204

L205

L203

223

1uH

1uH

1uH

C229

332

C230

10u

R229

3.9K

C231

102

C232

331

C233

EW-DRI

C813

472

R808

4.7M

4

3

4.7

VD-NVD-P

N804 KA7630

A7-8V

A5-3.3V

R841

R840

1K

1K

1234

C829

C828

10U

R821

220U

R820

1

1

R843

2K

V801

KSC815

C812

472

DZ808

CD842

MTZJ3.9B

10u

R809

C814

4.7M

L805

561

5.1

VD805

L804

T801

D5L60

BCK-100-02

LB3.5*5

1

8

C817

561

15

4

10

11

VD806

TR5GU41

6

VD807

L806

L808

12

D6L20U

LB.6*6

LB3.5*6

13

7

C519

561

14

1

R813

R845

1.5K

68

C821

R814

104

1K

2

DZ805

KA431

VD815

1N4148

R846

10K

RLP1

LK1aF-12V

V802

KSC815

CNB02

RB07

RB08

SDA

A6-5V

R211

R215

3.3K

3.3K

TDA9384PS/N2/3

N201

1

64

STANDBY

INT.REM

2

63

SCL

AV/SVHS

56

3

62

SDA

AV1/AV2

C208

56

461

VT

VDDP

5

60

RESET

KEY

6

59

SYSTEM

XTAL.OUT

7

58

XTAL.IN

MUTE

8

57

OSC.GND

MAG

9

56

VDD.C

VSSC/P

10

55

VPE

BAND

11

54

VDD.A

BAND

53

12

VSSA

B.OUT

13

52

SEC.PLL

G.OUT

14

51

R.OUT

VP2

15

50

DECD/G

BLK.IN

16

49

PH2.LF

BCL.IN

17

48

PH1.LF

B2/U.IN

18

47

GND3

G2/Y.IN

C223

104

46

19

DEC.BG

R2/V.IN

20

INSS.W2(BL)

EWD

44

21

AUD.OUTV.DRB

43

22

CHROMA

V.BRA

23

42

CVBS/Y

IF.IN1

24

41

GND1

IF.IN2

25

40

CVPS.INT

I.REF

26

39

VP1

V.S.C.

27

38

IF.VO/SVO

AGC

28

37

PLL.IF

AV.DEEM

29

36

EHTO

DECS.DEM

30

35

AUO.EXT

GND2

31

34

F.B.L.SO

SND.PLL

324533

H.OUT

AVL

56 78910

VD810

C831

R822

10U

10K

IN4148

C830

DZ803

1U

5.6B

7.5KR811

C816

R817

100u

33K

C815

220u

C818

2200

C820

2200u

R815

R849

127K

10K

R824

39K

VD816

1N4148

R816

R848

R847

2.49K

6.2K

6.2K

DZ807

MTZJ5.1B

V206

KSC815

SCL

R208

A6-5V

N202

100

24C08

A6-5V

RM201

1

8

E0

VCC

C207

HS0038A

103

E1

WC

E2

SCL

R943

GND

SDA

OUT

GND

VCC

47

4

5

R230

100

C234

102

AV/SVHS

AV1/AV2

C236

22U

X201

12M

C242

104

R238

12K

R248

6.8K

C250

10u

BL

C246

10U

C247

474

C253

474

C255

100U

R244

390

C256

R276

27K

104

R245

100

R263

200

H-DRI

A6-5V

A7-8V

C832

100U

C833

47U

POWER

A5-3.3V

A3-15.8V

A1-33V

10KR810

A2-130V

A3-15.8V

A4-15V

A6-5V

V803

KSC815

R214

10K

C922

100U

A6-5V

L206

10uH

C237

104

C239

33

C240

33

L207

10uH

L208

10uH

C241

100uH

D-COIL

A5-3.3V

R235

100

R236

100

R237

100

VD201

R274

IN4148

22K

R273

33K

R277

100K

R264

470

R265

75

C248

VD202

104

IN4148

H-SYNC ABL

A7-8V

A7-8V

V213

KSC815

R262*

4.7K

R255

430

R250

47

V209

KSC815

V208

KSC815

DZ205

MTZ4.7B

R249

20K

R710*

4.7K

R242

1K

R243

1K

R256

470

L209

10UH

C254

223

R275

270K

R259

100K

R246

8.2K

C249

151

R247

3.3K

R213

10K

POWER

ST-BY

N702

HEF4053

9

8169

CN201

10

10

11

11

R740

R741

3.3K

3.3K

12

12

C744

13

13

1u

14

14

15

15

16

CVBS/Y

R742

10

AV1-AL

AV1-AR

R708

220

L708

10uH

C705

C725

224

224

BASS

32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17

N701

TDA9860

B-OUT

G-OUT

R-OUT

12 3 4 5 6 7 8 910111213141516

D-COIL

CUT-OFF

L709

10uH

21P-B

21P-G

21P-R

L211

10uH

C252

47u

Z203

4.5MHz

R254

180

Z204

5.5/6.0/6.5MHz

R253

L210

510

5.6U

Z201

R252

5.5MHz

100

Z202

R251

5.5/6.0/6.5MHz

200

TJC-2A

7

6

Y-SVHS

R719

100

AV1-VIN

5

4

R718

75

3

R715

2

75

Y

1

AV2-VIN

AV2-AL

AV2-AR

R707

R704

R703

220

220

220

L704

L707

L703

10uH

10uH

10uH

C721

C727

C723

C722

224

153

153

224

VI4P2VO2 CPS1 VI1 CPS2 VO5 MAD VO1 VI7 CBL1 CBL2 VO7 CTL VO3 SDA

HEADPHONE

CHANNEL

MULTIPLE

VOLUME

SOURCE

AND MODE

SELECTION

CROSS BAR

SWITCH

REFERENCE

VOLTAGE

CONTROL

VI3 P1 VI 5 CSMO

VP VO5 VO2 VI2

VI6

C707

100u

R751

C708

R752

SHORT

10K

10K

C710

C709

C706

100u

104

224

R-OUT

A-OUT

A-OUT

C-SVHS

Y-SVHS

A7-8V

V210

R257

KSR2010

47

C257

47u

V212

V-OUT

KSC815

R258*

R258

75

1K

V211

KSR1010

SYSTEM

A7-8V

AV1-VIN AV1-AL AV1-AR

CNS01

CT0175RT01

102

RT03

RT02

YC

75

100

CNT01

TJC3-10A

CN200

C-SVHS

YCbCr

R-OUT

L-OUT

V-OUT

AV2-VIN

AV2-AL

AV2-AR

L-OUT

R706

100

R731

R730

10K

1K

C720

10u

STEREO

SPATIAL

STEREO

PSEUDO

STEREO

FORCEO

VOLUME

MONC

GND

R726

C711

1K

10u

R727

10K

R705

100

SCL

SDA

HEATER

B1-180V

R602

0.18

A4-15V

V04

POWER

mute

V03

CN701

AV1-VIN

OUT

VIDEO

C718

333

C719

10u

BASS

TREBLE

CONTROL CONTROL

CBR1 CBR2 VO6 CTR VO4 SCL

C712

10u

C713

333

V05

CNS02

AV1-AR

AV1-AL

C001

10u

CN001

TJC3-4Y

C002

10u

C003

R001

R002

10u

120

120

R003

120

C717

562

IIC-BUS

CONTROL

HUE

VOLUME

BALANCE

C714

R728

R729

562

100

100

R610*

6.2K

R741

R740

R611*

100

100

6.2K

V04 V03

VD-P

VD-N

EW-DRI

H-SYNC

B4-12V

A3-15.8V

H-DRI

A2-130V

HEATER

B1-180V

ABL

C507

C508

391

391

CN501

CN503

R507

TJC-5

100

1

G-OUT

R508

100

B-OUT

2

R509

GND

CUT-OFF

CN502

TJC-3

HEATER

1

180V

2

3

INPUT INPUT

12345678910

2.3V 2.3V 8.5V 17.3V 8.4

R301

3.3K

V402

KSC2331-Y

100

3

4

5

R505

2.4

6

7

R526

68

8

C502

222

C506

10u

R527

33K

R601

0.18

DZ604

MTZJ30D

N301 TDA8350Q

VERTICAL

FEEDBACK

GND

VP

NC VFLYBACK OUTPUT

R302

1.5

C303

R303

68u

1.5

C302

C301

100u

474

DZ301

MTZJ22A

C306

104

VD301

1N4148

DZ304

MTZJ30D

DZ306

MTZJ30D

C421

100u

C422

104

VD403

IN4004

VD402

IN4004

R411

C412

110

T401

561

R410

270

C413

100u

C411

103

C509

391

MTZJ9.1B

DZ501

MTZJ9.1B

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

L601

10uH

R304

33K

N401

KA7812A

C426

100u

R415

0.39

DZ504

DZ503

MTZJ9.1B

VD502

ERB4304

N601

TDA7297

OUT2 VCC2 SVR

C607

1000u

DZ603

MTZJ30D

L603

10uH

EASTWEST AMPLIFIER

C304

104

DZ303

MTZJ15C

DZ302

MTZJ30D

DZ402

MTZJ5.1B

R408

10

B2-46V

L304

33uH

C410

68u

B3-18.5V

C420

224

V403

FJAF6810D

C427

R421

33

GT501 1P

GT502 1P

R503

1.8K

R501H

1.8K

R502H

1.8K

3.0

3.0

3.0

DZ502

MTZJ9.1B

6.0

180

R510

100

111

R512

100

116

R511

100

114

VD503

VD504

ERB4304

ERB4304

ST-BY IN2 MONO

IN-MUTE

C605

1u

C606

103

R606

3.3K

R607

6.2K

OUTPUT

INPUT

INPUT

12

13

11

0.7V47V 8.7V 13V

R403

5.6K

R401

52.6K

R402

100

V401

KSA614Y

DZ401

MTZJ30D

R407

3.9K

C409

471

C408

472

VD407

ER24-06

VD405

R414

R5GU41

10

C418

471

C419

470u

C414

VD404

FMP-3FU

472

102

C503

103

SC

FO

HV

N501B TDA6107Q

123

V1 V2 V3 VDD

1

GND

456789

2

3

PROBE3

PROBE2

PROBE1

GND

C604

DZ605

102

MTZJ5.6B

POWER

C402

103

L401

1mH

C403

22u

C407

681

R413

0.27

C415

752

R415

C416

0.47

153

CRT

73X707Y22-DC01

R504

10M

C504

4.7u

VD501

ERC24-06

IN1

MUTE1

VCC1 OUT1

SPEAKER2

CN602

TJC3-2Y

CN603

VD601

IN4148

C603

2.2u

R605

1K

VD602

IN4148

MUTE

L301

10uH

R305

R306

390

220

L302

10uH

C406

474

VD401

C405

TR5GU41

2.2u

18K

R406

R405

390

L402

AC0031TL

C404

102

T444

JF0101-85907

8

46

9

16.5

6

7

HEATER

1

H-OUT

4

5

VIDEO

3

B+

VD406

TVR10G

R417

91K

SPEAKER1

C601

TJC3-2Y

1u

R604

R603

6.2K

3.3K

C602

103

DZ601

DZ602

MTZJ30D

MTZJ30D

C305

104

V1

V2

CN401

TJC-4

H2

H1

TO CRT

HV

HV

FO

SC

FO

SC

TO CRT PCB SCREEN & FOCUS

10 11

C423

471

C424

C425

R419

22u

104

1K

R418

GT404

91K

NOTE:This diagram is only for reference and subject to

28

Page 30

Circuit Diagram

c.

PCB Diagram

Figure 6

29

Page 31

Circuit Explanation

13. Circuit Explanation

The UOC module comprised of Philip super advanced CMOS chip TDA9373 is used for model

34F9B-T color TV pictures and text. This product has I2C bus-mastering digital control system and

DVD component terminals (or SCART terminal) for auto sound identification, independent woofer

volume control, English and Russian picture texts, treble and bass tone increase, image and sound

mode for individual preference, picture size zooming and 218 channel storage.

I. Electrical circuits and integrated circuits of 34F9B-T TV receiver

1.1 Electrical circuits

Electric circuits of the 34F9B-T TV receiver are comprised of the following sections:

1.1.1 Microprocessor and signal processor: comprised of super single chip integrated circuit

N201(TDA9373), storage N202 (KS24C08).

1.1.2 Sound processing and amplifying: comprised of integrated circuit N701 (TDA9860) for

sound tone processing and integrated circuits N601 and N610 (TDA7297) for sound

amplifying.

1.1.3 Integrated circuit for line and field scan output: comprised of integrated circuit N301

(TDA8350Q) for field output, V403 (2SD1887YD) for line output tube and T444

(BSC29-0130D) line output transformer.

1.1.4 Video frequency amplifying: comprised of integrated circuit N501 (TDA6107Q)

1.1.5 Power supply control: comprised of switch transformer T801 (BCK-100-02), power

integrated circuit N801(KA5Q1265RF-YDTU) and secondary power integrated circuit N804

(KA7630).

1.2 Main integrated circuits:

1.2.1 TDA9373 Microprocessor / picture intermediate frequency / sound intermediate

frequency / video processing / line field scanning / color decoding / text

1.2.2 TDA9860 Multi- function TV stereo sound tone processing integrated circuit

1.2.3 TDA8350Q Field output integrated circuit

1.2.4 TDA6107Q Video amplifying integrated circuit

1.2.5 TDA7297 Sound amplifying integrated circuit

1.2.6 KA5Q1265RF-YDTU Power integrated circuit

30

Page 32

Circuit Explanation

1.2.7 KA7630 Secondary power integrated circuit

2 Electric circuit analyses

2.1 Super single chip integrated circuit TDA9373

As a super large-scale decoding and microprocessing integrated circuit, TDA9373 is comprised of a

microprocessor, picture image intermediate frequency amplification, sound intermediate frequency

amplification, line and field scanning, dwarf signal processing, color decoding, sound filtering and

auto identification, luminance separation, high voltage tracking and over voltage protection. It

functions for I

2

C bus-mastering and automatic adjustment for transmeridional correction and dark

balance.

Table 1 lists the pin function and test data of TDA9373 as the reference for maintenance.

The data is to be tested under the mode of 49.75MHz, PAL B/G and cylindrical color card muting,

using a model FLUKE 79

instrument.

Table 1

Resistance to Ground

Pin Function

Working

voltage

V

Forward Test Back Test

R

1. STANDBY 0 36K 29K

2. SCL 3.5 15K 15K

3. SDA 3.2 15K 15K

4. VT 3.0 20K 20K

5. KEY 3.4 36K 30K

6. SYSTEM 4.4 15K 15K

7. MUTE 5.1 15K 15K

8. GND.MAG 0 Infinity 2.9M

9. VSS C/P 0 0 0

10. BAND 3.3 14.5K 14K

11. BAND 0 14.5K 14K

12. VSSA 0 0 0

13. SEC.PLL 2.3 6.4M 4.3M

14. VP2 7.8 18K 18K

15. DECD/G 5.0 31.9K 32K

16. PH2.LF 2.9 6.4M 4.2M

17. PH1.LF 3.9 6.4M 4.2M

18. GND3 0 0 0

19. DEC.BG 4.0 39.8K 40K

20. EWD 0.7 63K 63K

21. V.DRB 2.4 6.0M 4.0M

22. V.BRA 2.4 6.0M 4.0M

23. IF.IN1 1.9 37.5K 38K

24. IF.IN2 1.9 37.5K 38K

25. I.REF 3.85 38.8K 38.8K

26. V.S.C. 3.8 6.3M 4.6M

27. TUNER.AGC 1.7 4.9K 4.9K

28. AU.DEEM 3.2 6.1M 3.6M

31

Page 33

Circuit Explanation

29. DECS.DEM 2.4 5.9M 3.6M

30. GND2 0 0 0

31. SND.PLL 2.4 6.3M 4.7M

32. AVL 0 6.2M 3.8M

33. H.OUT 0.6 21K 21K

34. F.B.L.SO 0.3 6.4M 4.4M

35. AUO.EXT 0 0 0

36. EHTO 1.7 21.8K 22K

37. PLL.IF 2.4 6.4M 4.6M

38. IF.VO/SVO 3.3 4.3M 4.6M

39. VP1 7.8 18K 18K

40. CVPS.INT 3.9 5.4M 4.1M

41. GND1 0 0 0

42. CVBS/Y 3.3 6.2M 4.0M

43. CHROMA 1.5 83K 83K

44. AUD.OUT 3.4 6.4M 4.8M

45.

INSS.W2

BL

2.1 0.86K 0.86K

46. R2/V.IN 2.5 6.3M 4.5M

47. G2/Y.IN 2.5 6.3M 4.5M

48. B2/U.IN 2.5 6.3M 4.5M

49. BCL.IN 1.5 216K 239K

50. BLK.IN 4.9 28K 28K

51. R.OUT 2.8 7.46K 7.5K

52. G.OUT 2.8 7.48K 7.5K

53. B.OUT 2.9 7.5K 7.5K

54. VDD.A 3.3 32K 26K

55. VPE 0 0 0

56. VDD.C 3.3 32K 26.5K

57. OSC.GND 0 14 13

58. XTAL.IN 1.8 3.0M 2.7M

59. XTAL.OUT 1.7 0.5M 0.54M

60. RESET 0 0 0

61. VDDP 3.4 32K 26.6K

62. AV1/AV2 5.1 15K 15K

63. AV/SVHS 5.1 15K 15K

64. INT.REM 5.0 41K 40.6K

2.3 Analysis of common passage circuits

Having been received by antenna or fed by cable TV into the antenna input terminal of HF tuner

TU101

TECC7949 , HF TV signals pass through tuning for station selection, HF amplification and

frequency mixing inside the HF tuner and then, a 38MHz IF picture signal and 31.5MHz IF sound

signal will be transmitted from the IF terminal of TU 101 and be fed directly into (1) of the pre-IF

amplification thick-film circuit N101 (M9911A), where the signals will be amplified to compensate for

the insertion loss of the sound surface filter.

The sound surface filter SF101

K6264K adopts single-terminal or double-terminal input according to

different system choices. The single-terminal or double-terminal input are controlled by the (6) of

N201 via V101

BC548C : D/K, B/G and I signals will be input in a single channel and M signals in

double channels. The sound surface filter K6264K is a wide range filter for single channel input,

suitable for D/K, B/G and I sound signal; and is a narrow range filter for double-channel input,

32

Page 34

Circuit Explanation

suitable for M sound signal. The IF signals which have passed through sound carrier deep trap by

sound surface filter will be sent to the (23) and (24) of N201

be sent out from the (27) of N201

TDA9373 under the control of I2C bus for the gain control of HF

TDA9373 . HF amplification AGC will

tuner.

2.4 Analysis of signal trap option switch circuit

Video color signals will be sent out from (38) of N201

TDA9373 and emit and followed by triodes

V208 and

V209, and then, divided into sub-flows which are fed into the wave traps Z201~Z204 respectively. All

TV signals will be selected and pass through V210 and V211, which are rejector triodesand serve the

function of switches here. When the 6 pins of N201(TDA9373) export high level with sound below

4.5M, V211 will break over and the signals will pass through the wave traps Z201~Z202; and when

the 6 pins send out low level with sound of 4.5M, V211 will stop and V210 break over, and the signals

will go through the wave traps Z203~Z204. Video signals will be produced after all TV signals are

trapped by the wave trap, and then, one sub-flow will go through R255

430 and R256 470

for signal adjustment amplitude and enter into (40) of N201 TDA9373 , and another sub-flow will,

after emit and followed by a triode V212, serve as AV output.

Both the video signal in AV signals and the Y signal in S terminal signals will be selected and passed

through by N702

signal of S terminal will be fed into the (43) of N201

and the Y signal of S terminal will be selected and passed through by N702

control of the (62) and (63) of N201

The DVD component terminal Y, U and V signals will be coupled by the capacitors C001

HEF4053BP , and will then be fed into the (42) of N201 TDA9373 ; and the C

TDA9373 . Both the AV1 and AV2 video signals

HEF4053BP under the

TDA9373 .

10u ,C006

10u and C005 10u and fed into the (47), (48) and (49) of N201 TDA9373 respectively.

2.5 Analysis of sound tone processing circuit

The sound tone processing circuit is comprised of an integrated circuit N701

TDA9860 and

peripheral components. TDA9860 is a multi-function TV sound tone processing integrated circuit of Hi-Fi

grade, inside which treble and bass frequency division processing, stereo processing and encircling

sound processing are made.

The audio signals sent out by the (44) of N201, after emit and followed by V213 and passing through

a coupling capacitor C706

N701

TDA9860 respectively. Meanwhile, the audio signals from the left and right channels of AV1

terminal will be put into the (1) and (32) of N701

224 , will be divided into two sub-flows which enter into the (3) and (5) of

TDA9860 . The audio signals of S terminal and AV1

share the same sub-flow. The audio signals from the left and right channels of AV2 terminal will be

put into the (28) and (30) of N701

TDA9860 . The audio signals of DVD component terminal and

AV2 share the same sub-flow.

As for TV or AV audio signals that have been selected and go through inside N701 (TDA9860) without

sound tone processing, the independent audio signal of left and right channels and exported directly

33

Page 35

Circuit Explanation

from (13) and (20) will be directly fed into the (12) of woofer amplification integrated circuit N610

(TDA7297); and, as for the audio signals that have gone through sound tone processing , the audio

signals exported from the (18) and (15) will be directly fed into the (12) and (4) of the sound

amplifying integrated circuit N601

TDA7297 . The external capacitors C717 562 and C714 562

of the (19) and (14) of N701 TDA9860 are used as the treble control capacitors for left and right

channels. The (31) of N701

TDA9860 is a woofer control switch.

Table 3 lists the pin function and test data of TDA9860 as the reference for maintenance. The data is

tested under the mode of 49.75MHz

PAL D/K and cylindrical color card, using a model FLUKE 79

instrument.

Table 3

Resistance to Ground R

Forward Test

Back

Tes t

Pin Function

Working

Voltage

V

1 Pre-AV audio input of left channel 4.0 4.6M 3.1M

2 D-COIL 0.1 6.9M 4.9M

3 Interior audio input 4.0 4.7M 3.1M

4 Decoupling filter of power supply 7.9 9.1K 9.1K

5 Interior audio input 4.0 4.6M 3.1M

6 8V Power supply 8.0 2.8K 2.8K

7 AV audio output from right channel 4.0 6.5M 4.3M

8 Ground 0 0 0

9 Audio output from right channel 4.0 10.8K 10.8K

10 Audio input of right channel 4.0 4.6M 3.1M

11 Connecting terminal of bass control

4.0 4.6M 3.1M

capacitor

12 Connecting terminal of bass control

4.0 4.7M 3.1M

capacitor

13 Woofer frequency signal (L) 3.9 6.6M 3.9M~

14 Connecting terminal of treble control

4.0 6.2M 4.2M

capacitor

15 Audio output, right channel 4.0 8.8K 8.8K

16 Clock line of I2C bus 4.4 19K 17.9K

17 Data line of I2C bus 4.5 19K 18.0K

18 Audio output, left channel 4.0 8.9K 8.9K

19 Connecting terminal of treble control

4.0 6.2M 4.3M

capacitor

20 Woofer frequency signal (R) 3.9 6.5M 3.9M

21 Connecting terminal of bass control

4.0 4.6M 3.2M

capacitor

22 Connecting terminal of bass control

4.0 4.6M 3.2M

capacitor

23 Audio input of left channel 4.0 4.6M 3.2M

24 Audio output from left channel 4.0 10.8K 10.8K

25 Ground 0 0 0

26 AV audio output from left channel 4.0 6.5M 4.3M

27 Connecting terminal of analog. stereo

4.0 4.6M 3.2M

capacitor

28 Post- AV audio input of left channel 4.0 4.6M 3.2M

29 Connecting terminal of analog. stereo

4.0 4.6M 3.2M

capacitor

34

Page 36

30 Post-AV audio input of right channel 4.0 4.6M 3.2M

31 Woofer control 4.4 6.9M 4.8M

32 Pre-AV audio input of right channel 4.0 4.6M 3.2M

2.6 Analysis of sound amplifying circuit

The sound amplifying circuit is comprised of an integrated circuit TDA7297 and peripheral

components. TDA7297 is a double-channel stereo sound amplifying circuit featuring MUTE and

POWER functions, with power output 15+15W. TDA7297 has a BTL sound output manner with no

Circuit Explanation

coupling capacitor in its output circuit, which has a wide range of power supply

6V 18V and the

functions of short circuit protection and over-load protection.

(18) and (15) of the sound tone processing circuit N701 send out the sound signal for left and right

sound channels, which will be adjusted by R604, R603 and 607, R606 respectively , and then

coupled and fed into the (4) and (12) of the sound amplifying integrated circuit N601 via C601 and

C605, and , after being amplified, sent out from the (1), (2) and (14), (15) in positive and negative to

directly drive speakers for sound.

Woofer amplification is also comprised of the integrated circuit TDA7297 and peripheral components.

The sound signals from left and right channels that have not passed through sound tone processing,

will be coupled and fed into the (12) of N610 via C611, which, after being amplified, will be sent out

as positive and negative to directly drive speakers for sound.

Table 4 lists the pin functions and test data of TDA7297as the reference for maintenance. The data is

to be tested under the mode of 49.75MHz

79

instrument.

PAL D/K and cylindrical color card, using a model FLUKE

Table 4

Resistance to Ground R

Forward Test

Back

Tes t

Pin Function

Working

Voltage

V

1 Sound output from right channel 8.0 12.8K 12.7K

2 Sound output from right channel 8.0 12.8K 12.8K

3 15V Power supply 16.0 ~ 0.94M

4 Audio signal input of right channel 1.5 86.2K 86.6K

5 Blank pin 0 ~ ~

6 MUTE signal input 5.1 108.8K 107.6K

7 POWER signal input 5.1 5.6K 5.6K

8 Ground 0 0 0

9 Ground 0 0 0

10 Blank pin 0 ~ ~

11 Blank pin 0 ~ ~

12 Audio signal input of left channel 1.5 86.3K 86.5K

13 15V Power supply 16.0 ~ 0.94M

14 Sound output from left channel 8.2 12.7K 12.7K

15 Sound output from left channel 8.2 12.7K 12.7K

Table 5 lists the pin functions and test data of woofer TDA7297as the reference for maintenance.

35

Page 37

The data is to be tested under the mode of 49.75MHz PAL D/K and cylindrical color card, using a

Circuit Explanation

model FLUKE 79

instrument.

Table 5

Resistance to Ground R

Forward Test

Back

Tes t

Pin Function

Working

Voltage

V

1 Sound output from right channel 0 12.8K 12.7K

2 Sound output from right channel 0 12.8K 12.8K

3 15V Power supply 16.0 ~ 0.94M

4 Audio signal input of right channel 0 86.2K 86.6K

5 Blank pin 0 ~ ~

6 Bass signal input 4.4 108.8K 107.6K

7 POWER signal input 5.1 5.6K 5.6K

8 Ground 0 0 0

9 Ground 0 0 0

10 Blank pin 0 ~ ~

11 Blank pin 0 ~ ~

12 Audio signal input of left channel 0.7 86.3K 86.5K

13 15V Power supply 16.0 ~ 0.94M

14 Sound output from left channel 8.0 12.7K 12.7K

15 Sound output from left channel 8.0 12.7K 12.7K

2.7 Analysis of field output circuit

Field sync signals separated from the mixed sync signals trigger the field frequency division system.

Once a certain sum of field sync pulse signals have been detected, the field frequency division

system will start in action. Of the field sync pulse signals which are obtained from frequency division,

one sub-flow will be fed into a sample pulse generator to, together with line feedback signal, produce

sample pulses necessary for the circuit.

Another sub-flow will be sent to field saw-tooth wave generator. The field frequency saw-tooth wave

that has undergone geometric processing will be sent from the (21) and (22) of N201 to the (1) and (2)

of the field output N301. The external resistor R228

current to field saw-tooth wave generator , and the external capacitor C227

39K of the (25) of N201will supply reference

104 of the (26) serves

as the capacitor for field saw-tooth wave.

Field output integrated circuit N301 is a full bridge type current driving output circuit of with a bridge

type output manner, and field deflection coil is directly connected to the middle of output amplifier.

The positive and negative saw-tooth signals sent out from the (21) and (22) of N201will enter into the

(1) and (2) of N301 symmetrically, which, after being rectified and amplified by TDA8350Q, will be

sent out from the (9) and (5).

R301 (3K

produced when field scan current flows through a hunt resistor of R302(1.5

) will transform input current into voltage, which will be compared with the voltage

) and R303(1.5 ), and

the result thus obtained will be a feedback voltage for TDA8350Q, therefore, field output current size

can be changed by changing R301. TDA8350Q has double power supplies, and the line return stroke

pulses sent out by the line output transformer T444 will be rectified and filtered to supply power to

36

Page 38

Circuit Explanation

both the forward and return strokes of TDA8350Q , the two power supplies being +16.5V and +46V

respectively.

Table 6 lists the pin functions and test data of TDA8350Q as the reference for maintenance. The data

is to be tested under the mode of 49.75MHz

FLUKE 79

instrument.

PAL D/K and cylindrical color card, using a model

Table 6

Resistance to Ground R

Forward

Tes t

Back

Tes t

Pin Function

1 Field pumping signal input in positive

Working

Voltage

V

2.4 67.0K 67.3K

phase VDP

2 Field pumping signal input in negative

2.4 69.9K 70.3K

phase VDN

3 FEEDBACK 8.3 5.9K 5.9K

4 SUPPLY VOLTAGE 16.9 6.4M 2.4M

5 OUTPUT VOLTAGE B 8.2 6.4K 6.1K

6 Blank pin 0 ~ ~

7 Ground 0 0 0

8 FLYBACK SUPPLY VOLTAGE 48.8 32.5K 25.5K

9 OUTPUT VOLTAGE A 8.6 5.9K 6.1K

10 Blank pin 0.9 ~ 4.1M

11 Transmeridional correction signal

11.1 10.4K 10.1K

output

12 Transmeridional correction signal

0.73 62.5K 62.9K

input

13 Ground 0 0 0

2.8 Analysis of line sync and scan output circuit

As the line oscillation circuit is inside N201(TDA9373), no external line oscillation components is

needed and the oscillation frequency is under the control of PH-1 detector. A flow of luminance

signals including mixed syne signals is sent to a syne separation circuit therein, which separate line

and field syne pulse signals, among them, the line syne pulse signals are sent to PH-1 detector. The

PH-1 detector functions to synchronize the line oscillation frequency with the frequency of input

signals.

C221(472)

R226(15K ) and C222(1u) connected to N201(17) are PH-1phase-locked loop filters.

The line oscillation signals that have been corrected by PH-1 detector will be sent to PH-2 detector,

which functions to stabilize and control the phase of line drive pulse output for ensuring that the line

linearity and center remain unchanged.

The external capacitor C218(222) of (16) is a filter capacitor for PH-2 detector. Line pumping signals

are sent out by the (33) of N201 and fed into a line driving triode V402

being amplified by a triode V403

2SD1887 switch, drive line deflection coil to produce magnetic field

KSC2331 , and then, after

to control an electronic beam for horizontal scanning.

37

Page 39

Circuit Explanation