Page 1

P1500 / P3000

PROFESSIONAL POWER AMPL

Installation & Operation

®

®

trans

MADE

IN THE

USA

nova

PROFESSIONAL POWER AMPLIFIER

Page 2

Declaration of Conformity

Application of Council Directive: 73 / 23 / EEC (Low Voltage Directive)

89 / 336 / EEC (EMC Directive)

Standard(s) to which Conformity is Declared: EN55103-1

EN55103-2

EN60065

Manufacturer’s Name: Hafler

Manufacturer’s Address: 546 South Rockford Drive, Tempe, Arizona 85281

Importer’s Name:

Importer’s Address:

Type of Equipment: 2-channel Audio Power Amplifier/Speaker

Model No.: P1000CE P1500CE P3000CE P4000CE 9505CE

TRM6CE TRM8CE TRM10sCE TRM12sCE

Year of Manufacturing: 1999 2000 2001 2002 2003

Serial Number:

I, the undersigned, hereby declare that the equipment specified above conforms

to the above Directive(s) and Standard(s)

Place: Hafler

Date: 09/01/1999

James C. Strickland, VP Engineering

Page 3

P ERFORMANCE SPECIFICATIONS

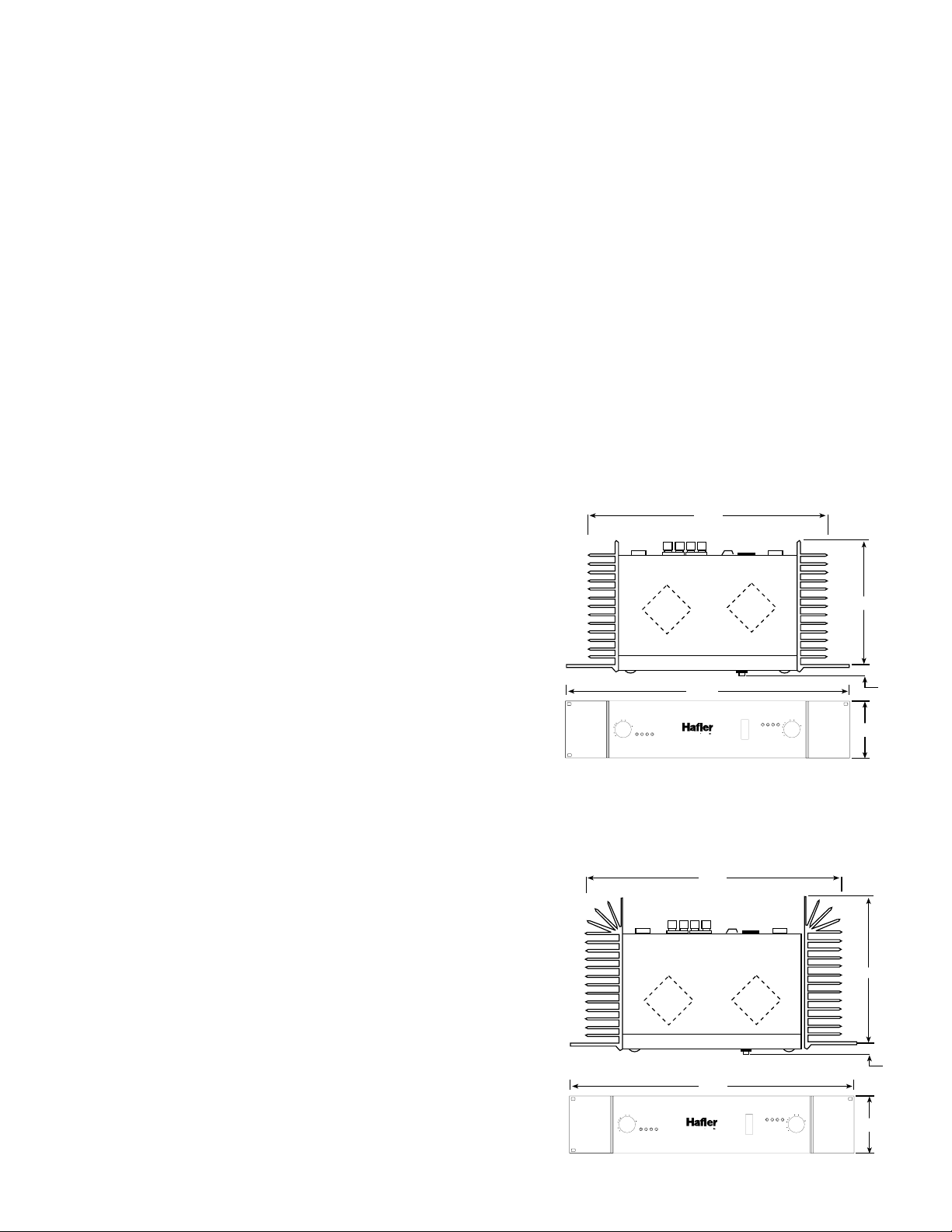

16.00

19.00

.717

sh

ort

th

erm

al

clip

p

ing

signal

channel 1

–15

–1

0dB

–10

–6

–3

channel 2

–15

–1

0dB

–10

–6

–3

nova

nova

trans

P1500

signal

clippin

g

therm

al

sh

o

rt

3.470

8.410

P1500/P3000

Frequency Response: 20Hz to 20kHz, ±0.1dB

0.15Hz to 300kHz, +0/–3dB

Signal-to-Noise: >100dB “A” Weighted

Distortion: <0.2% 20-20kHz, typically .01% at 1kHz @ rated power into 8Ω

Slew Rate: 100 V/µs

CMRR: 75dB at 1kHz

Input Impedance: 47k ohms per phase

Gain: +14dB min.

+29dB max.

P1500

Power Rating: 75 wpc @8 Ω, 85 wpc @ 4Ω, 170 Watts mono @ 8Ω

Damping Factor: 350 (to 1kHz); 150 (to 10kHz); 18 (to 100kHz)

Input Sensitivity Range: 870mV - 4.8V (for 75 W @ 8Ω)

650mV - 3.7V (for 85 W @ 4Ω)

Power Consumption: 60W / 500mA @ 120 VAC (Idle Power)

230W / 1.9A @ 120 VAC (1/8 Power – 8Ω)

325W / 2.70A @ 120 VAC (Max. Power – 8Ω)

Dimensions: 19"W x 8-1⁄2"D x 3-1⁄2"H (2-rack spaces)

(48.26cm x 21.59cm x 8.89cm)

Net Weight: 22 lbs. (9.98kg)

P3000

Power Rating: 150 wpc @8 Ω, 200 wpc @ 4Ω, 400 Watts mono @ 8Ω

Damping Factor: 400 (to 1kHz); 200 (to 10kHz); 18 (to 100kHz)

Input Sensitivity Range: 1.2V - 6.9V (for 150 W @ 8Ω)

1.0V - 5.6V (for 200 W @ 4Ω)

Power Consumption: 120W / 1.00A @ 120 VAC (Idle Power)

P1500

17.00

9.860

350W / 2.9A @ 120 VAC (1/8 Power – 8Ω)

600W / 5.00A @ 120 VAC (Max. Power – 8Ω)

Dimensions: 19"W x 9-7⁄8"D x 3-1⁄2"H (2-rack spaces)

(48.26cm x 25.08cm x 8.89cm)

Net Weight: 23 lbs. (10.43kg)

– i –

.717

19.00

–6

–3

l

g

a

n

l

i

t

a

m

r

p

r

n

o

p

–10

e

i

g

h

l

i

h

–1

s

s

t

c

0dB

–15

channel 1

nova

nova

trans

P1500

–6

–3

t

–10

l

g

l

r

a

n

a

o

i

–1

n

h

m

p

g

r

s

i

p

e

i

s

l

h

t

c

0dB

–15

channel 2

3.470

P3000

Page 4

NOTICE - IMPORTANT SAFETY INFORMATION

The lightning flash with arrowhead symbol within an equilateral triangle is

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

!

intended to alert the user to the presence of uninsulated "dangerous voltage"

within the product's enclosure, that may be of sufficient magnitude to

constitute a risk of electric shock to persons.

WARNING: TO PREVENT FIRE OR SHOCK

HAZARD, DO NOT EXPOSE THIS

EQUIPMENT TO RAIN OR MOISTURE.

1. READ INSTRUCTIONS

All the safety and operating instructions of your Hafler equipment

should be read before power is applied to the equipment.

2. RETAIN OWNER'S MANUAL

These safety and operating instructions should be retained for

future reference.

3. HEED WARNINGS

All warnings on the equipment and in the operating instructions

are important and should be followed.

4. FOLLOW INSTRUCTIONS

All operating and use instructions are important and should be

followed.

5. HEAT

The equipment should be kept away from areas of high temperature, i.e., heater vents, radiators, stoves/ovens, fireplaces, etc.

6. VENTILATION

The equipment should be used in an area suitable for proper

ventilation. Care should be taken not to impede airflow in and

around the cabinet. Do not mount on a carpeted shelf or in a

sealed enclosure. Allow for proper clearance above the equipment.

7. WATER AND MOISTURE

The equipment should not be used in or around water, such as a

bathtub, sink, or swimming area. Also, the equipment should not

be used in areas prone to flooding, such as a basement.

The exclamation point within an equilateral triangle is intended to alert the

!

user of the presence of important operating and maintenance (servicing)

instructions in the literature accompanying the appliance.

the same three wire grounded connection. It is important that the

blades of the equipment’s plug be able to fully insert into the mating

receptacle. Never remove the round grounding pin on the plug in

an attempt to mate to a two wire ungrounded receptacle: use a

grounding adaptor with the grounding tab or wire suitably connected to earth ground.

11. NON-USE PERIODS

During periods of extended non-use, the power cord should be

unplugged from the power source.

12. CLEANING

The equipment should be cleaned only as detailed in the operating

instructions.

13. OBJECT AND LIQUID ENTRY

Care should be taken so that objects and/or liquids, such as

cleaning fluids or beverages, are not spilled into the enclosure of

the equipment.

14. DAMAGE REQUIRING SERVICE

Hafler equipment should be serviced by qualified service personnel when:

A. The power supply cord or plug has been damaged, or

B. Objects have fallen, or liquid has been spilled into the

equipment, or

C. The equipment has been exposed to rain, or

8. POWER SOURCES

The equipment should be connected only to a power source of

the same voltage and frequency as that listed on the rear panel

above the power cord entry point.

9. POWER CORD PROTECTION

Power cords should be arranged so they do not interfere with the

movement of objects in the room: people, fan blades, utility carts,

etc. Also, care should be taken that the cord is not pinched or cut,

and placed so it is not in danger of being pinched or cut, as in

under a rug, around a tight corner, etc.

10. POWER CORD GROUNDING

The power supply cord is of a three wire grounded type, designed

to reduce the risk of electric shock sustained from a live cabinet.

It is assumed to be of suitable length for most uses of the

equipment. The use of extension cords and power strips is

discouraged unless they are of suitable rating to deliver the

required total current for safe operation of all connected equipment. Furthermore, extension cords or power strips must provide

D. The equipment does not appear to operate normally or

exhibits a marked change in performance, or

E. The equipment has been dropped, or the enclosure has

been damaged.

15. SERVICING

The user should not attempt to service the equipment beyond that

which is described in the operating instructions. All other service

should be referred to qualified service personnel.

16. CARTS AND STANDS

The equipment should be used with carts or stands only of sufficient

strength and stability for the use intended.

An equipment and cart combination should be moved with care.

Quick stops and starts, excessive force, and uneven surfaces may

cause the equipment and cart combination to topple.

– ii –

Page 5

ADVERTENCIA – INFORMACION DE SEGURIDAD IMPORTANTE

El símbolo de flecha relámpago dentro de un triángulo equilátero, es para

alertar al usario de la presencia de “voltajes peligrosos” no aislados en el

interior del aparato, los cuales pueden ser de suficiente magnitud para

constituir un riesgo de choque eléctrico a las personas.

El símbolo de exclamación dentro de un triángulo equilátero, es para alertar

al usuario de la presencia de instrucciones importantes de operación y

mantenimiento (servicio) en la documentación que acompaña al equipo.

SPAÑOL

E

PELIGRO

RIESGO DE DESCARGA

ELÉCTRICA NO ABRÍR.

PRECAUCÍON:

Para Prevenir el incendio o la descarga electrica, no

exponer este equipo a la lluvia o a la humedad.

!

1. LEA LAS INSTRUCCIONES

Todas las instrucciones de seguidad y operación de su equipo

Hafler, deben ser leídas antes de que el equipo sea conectado

dléctricamente.

2. CONSERVE EL MANUAL DEL PROPIETARIO

Estas instrucciones de seguridad y operación, deben ser conservadas

para futuras referencias.

3. CUADROS DE ADVERTENCIAS

Todas las advertencias en el equipo y en las instrucciones de

operación, son importantes y deben ser seguidas.

4. SIGA LAS INSTRUCCIONES

Todas las instrucciones de uso y operación son importantes y deben

ser seguidas.

5. CALOR

El equipo debe ser mantenido lejos de areas de alta temperatura,

como por ejemplo: ventilaciones de calentadores, radiadores,

estufas/hornos, hogueras, etc.

6. VENTILACION

El equip debe ser usado en áreas con ventilación adecuada. Deben

er tornadas las precauciones necesarias para no impedir el flujo de

aire dentro y alrededor del aparato.

poder suministrar la corrioente requerida pra la operación segura

de todo el equipo conectado. Aun más, las extensiones deben

proveer de la misma conección aterrada de tres hiles. Es importante

que el enchufe se pueda introducir completamente en el receptáculo.

Nunca remeva el pin de aterramiento en un intento por conectar el

cable en un receptáculo de dos hilos no aterrado: use un adaptador

de aterramiento que esté adecuadamente conectado a un punto de

tierra.

11. PERIODOS SIN USO

Durante períodos prolongados sin uso del equipo, el cable de

corriente debe ser desconectado de la fuente de electrixidad.

12. LIMPIEZA

El equip debe ser limpiado solo en la forma que se detalla en las

instrucciones de operación.

13. INTRODUCCIÓN DE OBJETOS Y LIQUIDO

Deben ser tornadas precauciones con el fin de que objetos y/ó

líquidos, tales como fluidos de limpieza y gaseosas, no sean

derramados dentro del chassis del aparato.

14. DAÑOS QUE REQUIEREN DE SERVICIO

Los equipos Hafler deben ser llevados a servicio por personal

calificado cuando:

7. AGUA Y HUMEDAD

El equipo no debe ser usado en el agua ó alrededor de ésta, tales

como en una bañera, tanque o áreas de nado. También, el equipo

no debe ser usado en áreas propensas a inundaciones, tales como

en un sótano.

8. FUENTES DE PODER

El equipo debe ser conectado a una fuente de poder del mismo

voltaje y frecuencia que el indicado en el panel trasero sobre el

punto de entrada del cable de corriente.

9. PROTECCION DEL CABLE DE CORRIENTE

Los cables de corriente deben ser dispuestos de forma tal que no

interfieran con el movimiento de objetos en la sala: personas, aspas

de ventilación, carretillas, etc. También, es necesario tener cuidado

de que el cable no esté punzado o cortado, y debe estar ubicado de

forma tal que esto no ocurra, como podría suceder debajo de una

alfombra o al pasar el cable por una esquina aguda, etc.

10. ATERRAMIENTO DEL CABLE DE CORRIENTE

El cable de corriente es del tipo aterrado de tres hilos, diseñado para

reducir el riesgo de una descarga eléctrica procendent de un chasis

energizado. Se asume que su longitud es suficiente para la mayoría

de usos del equipo. El uso de extensiones y multienchufes no es

recomendado, a menos que tengan el amperaje adecuado para

A. El cable de corriente ó el enchufe haya sido dañado, ó

B. Objetos ó líquido hayan sido introducidos ó derramado en

el equipo, ó

C. El equipo haya sido expuesto a lluvia, ó

D. El equipo aparenta no operar normalmente ó exhibe un

marcado cambio en su desempeño, ó

E. El equipo se ha caído, o el chassis ha sido golpeado.

15. SERVICIO

El usuario no deberá intentar darle servicio al equipo más allá de lo

que está descrito en el instructivo de operación. Todo lo demás,

deberá ser referido a servicio por personal calificado.

16. CARRETILLAS Y SOPORTES

El equipo podrá ser usado con carretillas y soportes que tengan la

fortaleza y estabilidad suficiente para el uso previsto.

La combinación equipo/carretilla deberá ser movida con cuidado.

Rápidas paradas y arranques, excesiva fuerza y superficies imparejas,

pueden causar el volcamiento del conjunto de carretilla/equipo.

– iii –

Page 6

ATTENTION: INFORMATIONS IMPORTANTES DE SÉCURITÉ

La lumière clignotante du symbole de la flêche à l'intérieur d'un triangle

équilatéral, à pour objet d'alerter l'utilisateur de la présence “d'un voltage

dangereux” non-isolé à l'intérieur du produit, qui pourrait être de magnitude

suffisante au risque d'éléctrocution.

RANÇAIS

F

ATTENTION

RISQUE DE CHOC

ÉLECTRIQUE NE PAS OUVRIR

!

AVERTISSEMENT:

Afin de prévenir les risques de feu ou de choc, ne pas

exposer cet appareil à la pluie ou à l'humidité.

1. LIRE LES INSTRUCTIONS

Le mode d'emploi et les mesures de sécurité de votre équipement

Hafler devraient être consultés avant sa mise en marche.

2. CONSERVER LE GUIDE DE L'UTILISATEUR

Le mode e'emploi et les mesures de sécurité devraient être

conservés pour des références futures.

3. CONSIDÉRATIONS DE MISE EN GARDE

Le mode d'emploi et les mises en garde concernant cet équipement

sont de grande importance et devraient être suivis.

4. SUIVRE LE MODE E'EMPLOI

Le mode d'emploi et les conseils d'utilisation sont importants et

devraient être suivis.

5. CHALEUR

Le matériel devrait être préservé loin de toute source de chaleur:

radiateurs, cuisinière/fours, cheminées,…etc.

6. VENTILATION

Le matériel devrait être utilisé dans un endroit à bonne ventilation. Il reste nécessaire de respecter la circulation de flux d'air à

l'intérier et autour du meuble.

Le point d'exclamation, à l'intériur d'un triangle équilatéral, à pour objet de

prévenir l'utilisateur de l'importance des instructions de fonctionement et de

maintenance, jointes à l'appareil.

11. PÉRIODES DE NON-UTILISATON

Durant les périodes de non-utilisation, la prise de courant ne

devrait pas être branchée à une source d'energie.

12. NETTOYAGE

Le matériel devrait être nettoyé en respectant les instructions

indiquées.

13. PENETRATION DES LIQUIDES

Un attention particulière est éxigée quant à la dispersion de

liquides tels que les produits de nettoyage et boissons, de façcon

à éviter toute pénetration dans l'enceinte du matériel.

14. DÉGÂT NÉCESSITANT UNE RÉVISION

Le matériel Hafler devrait être révisé par des personnes qualifées

de service après-vente, lorsque:

A. Les fiches ou la prise de courant ont été endommagé, ou:

B. De objets sont tombés sur le matériel, ou des liquides s'y sont

dispersés, ou:

C. Le matériel a été exposé à la pluie, ou:

7. EAU ET HUMIDITÉ

Le matériel ne devrait pas être utilisé près d'une source d'eau,

telle qu'une baignoire, un évier, ou une aire de baignade. De

plus, le matériel ne devrait pas être utilisé dans des lieux sujets

aux innondations, tels que les sous-sols.

8. SOURCES D'ÉNERGIE

Le matériel devrait seulement être relié à une source d'énergie de

même voltage et fréquence que celle indiquée sur le tableau

arrière, au dessus de la fiche d'entrée de la prise de courant.

9. PROTECTION DE LA PRISE DE COURANT

La prise de courant devrait être arrangée de façon à ne pas

interférer avec le déplacement d'objets (chariots, pales de

ventillateurs…etc.) ou de personnes à l'intérieur de la pièce.

D'autre part, il faudrait faire tres attention à ce que la prise ne soit

pas percée ou coupée, ou disposée de façon à risquer de l'être,

comme sous un tapis, autour d'un angle pointu…etc.

10. PRISE DE COURANT ÀTROIS FICHES

La prise de courant est composée de trois fiches, désignées à

réduire le risque de décharge électrique de l'appareil.

Elle devrait être de longueur suffisante pour la plupart des

utilisations de ce matériel. L'utilisation de rallonge t d'adaptateur

est déconsellée à moins dêtre en mesure de fournir la charge

électrique requise à un fonctionement sans risque, de tout

matériel relié.

D. Le matériel ne semble pas fonctioner correctement, ou

affiche un changement de performance, ou:

E. Le matériel a été renversé à terre, ou l'enceinte a été

endommagée.

15. REVISION

L'utilisateur ne devrait pas essayer de réviser le matériel en allant

plus loin que ce qui a été décrit dans le mode d'emploi. Toute

autre réviion devrait être confiée à un personnel qualifié.

16. CHARRIOTS ET MEUBLES

Le matériel devriat être utilisé avec des charriots et meubles de

qualité et stabilité suffisante à son utilisation préconçue.

L'ensemble du matériel et du charriot devrait être déplacé avec

précaution. Des mises en marche et arrêts brusques, des collisions excessives ainsi que des surfaces inégales peuvent renverser

l'ensemble du matériel et du charriot.

– iv –

Page 7

ACHTUNG – WICHTIGE SICHERHEITS – INFORMATIONEN

EUTSCH

D

Um die gefahr eines elektroschocks oder feuer zu

vermeiden, setzen sie das gerät keinem regen oder

1. INSTSRUKTIONEN LESEN

Alle Sicherheits- und Operationshinweise Ihres Hafler Equipments

sollten vor der Inbetriebnahme gelesen werden.

2. BETRIEBSANLEITUNG AUFBEWAHREN

Bewahren Sie die Bedienungsanleitung sorgfältig auf, damit Sie in

dieser auch in Zukunft nachschlagen können.

3. WARNUNGEN BEACHTEN

Alle Warnungen des Gerätes und der Bedienungsanleitung sind

extrem wichtig und müssen befolgt werden.

4. INSTRUKTIONEN BEACHTEN

Alle Operations- und Gebrauchshinweise sind extrem wichtig and

müssen beachtet werden.

5. HITZE

Das Equipment sollte fern von Hitze ausstrahlenden Geräten

aufgestellt werden, wie z.B. Heizungen, Öfen etc.

6. VENTILATION

Das Equipment sollte so aufgestellt werden, daβ eine ausreichende

Ventialition gewährt wird.

7. WASSER UND FEUCHTIGKEIT

Das Equipment sollte nicht im oder in der Nähe von Wasser benutzt

werden, wie z.B. in Schwimmbädem, Saunen etc. Es sollte ebenfalls

nicht in Überschwämmungsgefährdeten Gebieten aufgestellt werden,

wie z.B. Kellerräumen.

8. STROMANSCHLUβ

Das Equipment darf nur an eine Stromversorgung angeschlossen

werden, die die gleichen Parameter aufweist, welche auf der

Rückseite, über em Anschluβterminal des Gerätes, aufgelistet sind.

ACHTUNG

GEFAHR EINES

ELEKTRISCHEN SCHLAGS

NICHT ÖFFNEN

WARNUNG:

extremer feuchtigkeitaus.

!

Der Blitz mit dem Pfeil, in einem gleihschenkligen Dreieck, soll den benutzer

vor unisolierter “gefährlicher Spannung” innerhalb des Gerätes warnen.

Das Ausrufezeichen, in einem gleichschenkligen Dreieck, soll den Benutzer

darauf aufmerksam machen, daβ dem Gerät wichtige Operations - und Service

- Informationen beigefügt sind.

11. ZEITRÄUME IN DENE DAS GERÄT NICHT GENUTZT WIRD

Wird das Gerät über einen längeren Zeitraum nicht genutzt (z.B.

Urlaub), ziehen Sie bitten den Netzstecker aus der Steckdose.

12. REINIGEN

Reinigen Sie das Gerät nur, wie in der Bedienungsanleitung detailliert

beschrieben.

13. EINDRINGEN VON FREMDKÖRPERN

Achten Sie darauf, daβ weder Fremdkörper, noch Flüssigkeiten in

das Gerät eindringen.

14. ERFORDERLICHER REPARATURSERVICE

Hafler Equipment sollte nur von qualifizierten Service-Technikern

instand gesetzt werden, wenn:

A. Das Stromversorgungskabel beschädigt wurde

B. Eine Flüssigkeit in das Gerät eingedrimgem ist

C. Das Gerät Regen ausgesetzt wurde

D. Das Gerät nicht mehr ordnungsgemäβ funktioniert, ggf. nicht

mehr die volle Leistung abgibt

E. Das Gerät runtergefallen ist oder das Gehäuse beschädigt

wurde

15. SERVICE

Der Benutzer sollte nur den Service ausführen, der in der

Bedienungsanleitung für den Benutzer freigegeben wird. Den

weiterführenden Service sollte nur von qualifizierten Tevhnikern

durchgeführt werden.

9. SCHUTZ DER ZULEITUNG

Die Zuletungen sollten so verlegt werden, daβ diese nicht in den

Bewegungsbereich anderer Möbelstücke oder Personen hereinragen.

Achten Sie darauf, das das Kabel nicht gequestscht oder

durchschnittren wird, wie z.B. unter Schränken oder an scharfen

Kanten etc.

10. MASSEANSCHLUβ

Das dreiadrige Anschlubkabel ist mit einem Erdungsleiter ausgestattet,

welcher die Risiken eines Elektroschocks verringert. Das Kabel hat

eine Länge, welche für die meisten Anwendungen völlig ausreicht.

Wenn Sie Verlängerungskabel benutzen, achten Sie darauf, das dies

die erforderlichen Ströme bertragen können. Benutzen Sie immer

dreiadrige Verlängerungskable.

16. AUFSTELLUNG

Das Equipment sollte so aufgestellt werden, daβ der gewählte

Untergrund die erforderliche Stabilität aufweist, so daβ eine

gefahrlose Bnutzong gewährleistet wird.

Das Equipment und der Untergrund sollte mit äuberster Vorsicht

bewegt werden. Bei schnellen Bewegungen oder starkem

Abbremsen, kann es zum Umkippen des Equipments kommen.

– v –

Page 8

NOTARE – IMPORTANTI INFORMAZIONI SULLA SICUREZZA

Il simbolo del fulmine in un triangolo equilatero vuole avvertire della presenza

TALIANO

I

Per prevenire incendio scariche elettriche, non esporre

ATTENZIONE

RISCHIO DI SCARICHE

ELETTRICHE NON APRIRE

ATTENZIONE:

questo apparato a pioggia o umiditá.

!

di tensioni elevate non isolate e di valore sufficiente per costituire rischio di

shock elettrico alle persone.

Il punto esclamativo contentuto in un triangolo equilatero vuole avvertire

l'utente della presenza di parti di servizio e di manutenzione che sono

dettagliate nel manuale di istruzioni.

1. LEGGETE LE ISTRUZIONI

Tutte le istruzioni riguardanti la sicurezza ed il funzionamento

devono essere lette prima di applicare tensione all'apparato.

2. CONSERVATE IL MANUALE

Queste istruzioni riguardanti la sicurezza ed il funzionamento

devono essere conservate come riferimento futuro.

3. AVVERTENZE

Tutte le avvertenze poste sull'apparato e sul libretto di istruzioni

sono importanti e devono essere seguite.

4. SEGUIRE LE ISTRUZIONI

Tuttle le istruzioni operative e di funzionamento devono essere

seguite.

5. TEMPERATURA

L'apparato deve essere mantenuto lontano da tuttle le zone ad alta

temperature, termosifoni, termoconvettori, stufe e forni, caminetti

ed altro.

6. VENTILAZIONE

L'apparato deve essere posizionato in aree convenienti per una

corretta ventilazione. Prestare attenzione che sia consentita

circolazione d'aria attorno e dentro il cabinet.

7. ACQUA E POLVERE

L'apparato deve essere posizionato lontano da zone contenenti

acqua, come vasche a bagno, acquari e piscine. Inoltre non deve

essere impiegato in aree soggette ad allagamento, come le cantine.

8. REQUISITI DI ALIMENTAZIONE

L'apparato deve essere connesso solo ad un'alimentazione della

stessa tensione e frequenza di quanto scritto sulla parte posteriore

del telaio.

9. PROTEZIONE DEL CAVO DI ALIMENTAZIONE

Il cavo di alimentazione deve essere posizionato in modo di non

interferire con il movimento di oggetti nella stanza: persone,

ventilatori, carrelli, ecc…prestate attenzione anche che il cavo non

sia tagliato o spellato e che non possa tagliarsi e spellarsi.

11. PERIODI DI NON UTILIZZO

Durante lunghi periodi di non utilizzo, staccare il cavo di

alimentazione.

12. PULIZIA

L'apparato deve essere pulito solo come indicato dalle istruzioni.

13. INGRESSO DI OGGETTI E LIQUIDI

Si deve prestar attenzione che oggetti e liquidi, come fluidi detergenti

e bibite, non vengano versati all'interno dell'apparato.

14. RIPARAZIONI

Gli apparati Hafler devono essere riparati da personale qualificato

quando:

A. Il cavo di alimentazione o la spina sono danneggiati

B. Oggetti sono caduti all'interno del telaio o quando del

liquido è entrato

C. Quando l'apparato è stato esposto a pioggia

D. Quando l'apparato non sempra funzionare normalmente o

quando esibisce un cambiamento di prestazioni o

E. Quando è caduto o il telaio è stato danneggiato

15. ASSISTENZA

L'utente non deve tentare di prestare assistenza all'apparato, se non

per quanto esposto nelle istruzioni. Tutti gli altri interventi devono

essere effettuati da un tecnico specializzato.

16. CARRELLI E STAND

L'apparato deve essere impiegato su carrelli o stand solo se questi

sono sufficientemente solidi e stabili per la funzione a cui si vuole

dedicarli.

La combinazione di carrello ed apparato deve essere mossa con

cautela. Fermate e partenze improvvise, forze eccessiva e superfici

irregolari, possono ribaltare la cominzione carrello e apparato.

10. MESSA A TERRA

Il cavo di alimentazione è del tipo a tre fili con terra ed è progettato

pr ridurre il rischio di shock elettrici. Si presume che sia della

lunghezza sufficiente per la maggior parte degli impieghi. L'impiego

di prolunghe e adattatori è sconsigliato se questi non garantiscono

la potenza sufficiente per i corretto fuinzionamento degli apparati

connessi. E altersì importante che vengano sempre impiegate

prolunghe con la configurazaione a tre fili con terra.

– vi –

Page 9

T ABLE OF CONTENTS

PERFORMANCE SPECIFICATIONS ...............................................................................................................................i

SAFETY PRECAUTIONS ............................................................................................................................................... ii

INTRODUCTION ........................................................................................................................................................1

FRONT & REAR PANEL VIEW ..................................................................................................................................... 2

INSTALLATION

Location ................................................................................................................................................................ 3

AC Line ................................................................................................................................................................. 3

Input......................................................................................................................................................................4

PC Board Layout .............................................................................................................Removable Center Spread

Output Connections .............................................................................................................................................. 7

Monophonic Use...................................................................................................................................................7

OPERATION

Power Switch ........................................................................................................................................................ 7

Level Controls ....................................................................................................................................................... 7

Mono Switch .........................................................................................................................................................7

Short Circuit Protection ......................................................................................................................................... 8

LED Indicators .......................................................................................................................................................8

Warm Up .............................................................................................................................................................. 8

Cleaning and Maintenance .................................................................................................................................... 8

PC BOARD LAYOUT ...................................................................................................................................................9

PARTS LIST ................................................................................................................................................................10

TECHNICAL REFERENCE

Field Service Considerations ................................................................................................................................ 12

Theory and Operation of trans•

Circuit Operation ................................................................................................................................................ 13

trans•

nova

Implementation .................................................................................................................................13

Output Short Protection ....................................................................................................................................... 14

Thermal Protection ..............................................................................................................................................14

Clipping Indicator................................................................................................................................................15

Signal Present Indicator ....................................................................................................................................... 15

Calibration .......................................................................................................................................................... 15

Bias ..................................................................................................................................................................... 15

Common Mode Rejection....................................................................................................................................15

Module Replacement .......................................................................................................................................... 16

nova ...................................................................................................................

12

Page 10

I NTRODUCTION

The Hafler P1500 and P3000 are two channel professional power amplifiers. Passive cooling with large heatsinks

is used for low mechanical noise. Our patented trans•nova circuit topology and MOSFET output stage ensures

trouble free, long term operation and is backed by our five year warranty.

This manual contains information on using the P1500 and P3000 amplifiers. It is organized into three main

sections. “Installation” covers the location and connection of the amplifier in the system. Like many precision

components careful attention to the initial setup can yield dividends in higher performance and trouble-free use.

“Operation” covers the controls and features of the amplifiers and how to use them to get the best effect. The

“Technical Reference” section contains field service information. In addition to the schematic and parts list there

are block diagrams and an explanation of circuit operation useful for technicians. We strongly urge reading over

the Installation and Operation portions of this manual before putting the amplifier into service.

The circuitry used in the P1500 and P3000 is the latest refinement of our trans•nova (

Voltage Amplifier, US Patent 4,467,288) circuit. It has been proven to offer sound quality to satisfy the most

analytic audiophile or the most demanding professional. The natural sound and realistic reproduction have made

trans•nova amplifiers preferred in many critical installations. Since our pioneering use of MOSFETs in the DH-

200 amplifier, they have proven extremely fault tolerant even in abusive situations. This sturdiness enables the

amplifier to drive reactive speaker loads without the performance and sound penalties imposed by elaborate

protection schemes.

Specialized circuits prevent damage to the amplifiers and speakers without affecting the audio signal. A soft start

circuit prevents sending potentially destructive turn-on and turn-off transients to the speakers. A thermal sensing

network monitors the heatsink temperature and shuts down the amplifier to protect from excessive operating

heat. The need for internal fuses has been eliminated; a sensing circuit monitors the output and shuts down

operation when it detects a short in the output load.

Each channel of these amplifiers is built as a self-contained module which only requires mounting the heatsink

and connection to the chassis-mounted transformer and binding posts to be fully functional. The circuit board

contains all the operational components. This modular arrangement simplifies construction and improves service

accessibility. The circuit board assembly makes extensive use of surface mount components in the low power

portion of the audio circuitry. Automated equipment is used to place and solder the components which yields

greater uniformity and reliability.

TRANSconductance NOdal

The front panel has controls for input level adjustment and the power switch. In addition, LED indicators give

a visual representation of the operating status of each channel. The THERMAL and SHORT indicators light to show

when these protection circuits have been activated. The CLIP indicator helps prevent damaging the speakers by

showing when the amplifier is overdriven. The SIGNAL indicator lights to show the presence of an audio signal.

– 1 –

Page 11

short

thermal

clipping

signal

channel 1

–15

–1

0dB

–10

–6

–3

channel 2

–15

–1

0dB

–10

–6

–3

nova

nova

trans

P3000

signal

clipping

thermal

short

• Use CH 1 Input ONLY

• Set CH 2 Gain to Max

• Set Output Level with

CH 1 Gain Control

A Division of Rockford Corp.

Tempe, AZ 85281 U.S.A.

Made in the U.S.A.

XLR Connections

3

21

+

–

Phone Connections

+

–

®

115V ~

60Hz

CH 1 (Mono)

CH 1

– +

4-8Ω

CH 2

– +

– +

Mono

P3000

250 V T4A

CAUTION: For continued

protection from risk of

fire, replace only with

same type and

rating of fuse.

CH 2

Audio Ground

Chass. Float

Mono 2-Ch

Mono Output:

8Ω 4-8Ω

WARNING: DO NOT REMOVE COVER

TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK

DO NOT EXPOSE THIS EQUIPMENT TO RAIN OR MOISTURE.

!

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

PUSH

PUSH

Front Panel View

Rear Panel View

– 2 –

Page 12

I NSTALLATION

LOCATION

The P1500 and P3000 power transformer can generate a substantial magnetic field, so caution should be exercised

in the placement of low level components such as a tape deck, mixer or mic preamp to avoid inducing noise in

the low level circuitry. The amplifiers can also produce considerable heat in normal operation so the primary

consideration when determining a location for the amplifiers is to allow for adequate ventilation. The large

heatsinks provide unrestricted airflow, but care must be taken to keep the slots in the bottom panel and top cover

clear. If the amplifier is mounted in an equipment rack, make sure adjacent equipment does not impede cool air

flow.

Rack systems should have two fans 4" to 5" in from the front of the amplifier blowing upward.

!

Inadequate ventilation can shorten component life, especially when other equipment raises the ambient air

temperature, so circulating fans should be considered in tight quarters.

4" to 5"

(from fan center)

(Bottom View)

Fan center approximately in line with edge of unit and starting of heat sink fins

• Fans placed 4" to 5" from front of unit

• Fans placed under the unit pointing upwards

• Recommended P1500 fan is 32 CFM x 2

• Recommended P3000 fan is 100 CFM x 2

AC LINE

The P1500U and P3000U operate from a 120 volt, 60Hz AC power line. The P1500CE and P3000CE operate from

a 230 volt, 50-60Hz AC power line. Connection is made by a 16 gauge, IEC Type 320, grounded line cord. For safety

considerations only a properly grounded (earthed) receptacle should be used. If a grounded circuit is not available

do not break off the ground pin; use the proper adapter plug for a two wire receptacle. Mounted on the rear panel

is the line fuse which interrupts the power to the amplifier. If this fuse blows replace it only with the same type

and rating fuse. The correct replacement fuse value is printed on the rear panel of the amplifier. If the new fuse

blows, this is an indication of a fault with the amplifier. Servicing should be performed only by a qualified

technician.

– 3 –

Page 13

INPUT

The input jacks located on the back of the amplifier are dual function connectors which accept 1/4" Phone (Tip

Ring Sleeve) or XLR plugs. The 1/4" Phone jack is connected according to conventional usage. The XLR jack is

connected according to the IEC and AES standard.

XLR Balanced Input

Check output of source unit for proper signal polarity

INPUT FROM

SOURCE

Pin 1 = GND

Pin 2 = (+)

Pin 3 = (–)

1

2

GND

–

3

+

Check output of source unit for proper signal polarity

Tip = (+)

Ring = (–)

Sleeve = GND

1/4" TRS Balanced Input

INPUT

+

–

SHIELD

FROM

SOURCE

Many popular mixers use unbalanced outputs and can be used with the Hafler amplifier. To minimize residual

ground noise, we recommend using twisted pair cable or short cable lengths in this type of configuration.

XLR Unbalanced Input

Connect (–) and GND (shield) terminals at

prevent unstable amplifier operation

INPUT FROM

both ends

of cable to

1/4" TRS Unbalanced Input

INPUT

FROM

SOURCE

SOURCE

Pin 1 = GND

Pin 2 = (+)

Pin 3 = GND

1

3

2

SHIELD

+

Tip = (+)

Sleeve = GND

+

SHIELD

– 4 –

Page 14

SCHEMATIC DIAGRAM

P3000 shown. Ground switch in Chassis position, Mono switch in 2-Channel position.

P1500 differences shown on parts list.

Removable Center Spread

Page 15

Removable Center Spread

Page 16

OUTPUT CONNECTIONS

The speaker output connectors are dual binding posts. These binding posts will directly accept 12 AWG wire

or banana plugs and are spaced on 3/4" centers to accept dual banana plugs.

MONOPHONIC USE

For systems with high power requirements, the amplifiers can be configured for single channel bridged mono

operation. To bridge the amplifier, set the rear panel Mono/2 Channel switch to the Mono position. The

Channel 1 input and level control is used and the Channel 2 level control must be set to its maximum gain

position. The speaker is connected to the RED output binding posts.

When the amplifier is bridged the output is floating. Any speaker which requires a common ground from

!

the amplifier output cannot be used in this application.

Since a bridged amplifier shares the load between the two channels, each channel will effectively drive

!

half of the load. Therefore, for bridged mono operation we recommend using an eight ohm load as the

minimum impedance.

O PERATION

POWER SWITCH

The POWER switch is located on the front panel of the amplifier. An internal lamp indicates when it is turned on.

Standard practice is to turn the amplifier on last and off first when switching components to prevent

!

sending damaging transients to the speakers.

It is possible to leave the power switch in the on position and switch the amplifier remotely through a power

distribution block or preamp switched outlet. When doing so make sure the switch is rated for the current

required by the amplifier.

LEVEL CONTROLS

The input sensitivity for each channel can be adjusted individually using the level controls on the front panel.

The gain control on an amplifier is usually fully advanced to its maximum (rated) sensitivity. In public systems

where it is necessary to match levels, the knobs can be removed and the controls adjusted with your fingers or

a flathead screwdriver. Cover the holes with the enclosed plugs to restrict access.

MONO SWITCH

Conventional two-channel stereo operation is obtained with the MONO/2 CH switch in the 2-Channel

position. For high powered single channel use, switch to MONO and use the Channel 1 input and connect the

speaker to the RED binding posts.

For thermal considerations we do not recommend using less than an eight ohm load on the amplifier

!

when running it in mono.

When the switch is set in the mono position, the Channel 1 (+) and (–) inputs are connected to the Channel

2 in reversed polarity, which inverts the Channel 2 output. The gain is controlled by the Channel 1 level

adjustment; set Channel 2 to maximum.

– 7 –

Page 17

SHORT CIRCUIT PROTECTION

Due to the self-protecting properties of the output power MOSFETs, there is no need for sonically degrading

voltage and current limiting circuits. To protect the amplifier from problems which may occur in the speaker

line there is an overload detection circuit.

In the event of a short in the speaker load or cables, the speaker detection circuit will shut down that

channel and light the front panel SHORT indicator. If this happens, correct the fault and turn the

!

amplifier off, then back on to reset.

LED INDICATORS

Amplifier operation is monitored internally and each channel has four status LEDs. These indicators can be used

for system troubleshooting in case of aberrant behavior.

Signal Monitors the amplifier output and lights when a signal is present. The SIGNAL indicator

is calibrated to activate at an equivalent input voltage of 30mV.

Clipping Monitors the DRIVE SIGNAL and lights when the drive signal voltage exceeds the

maximum for linear operation of the output MOSFETs.

Thermal Indicates when the thermal protection has shut down the amplifier. This occurs when

the heatsink temperature exceeds 90° C.

Short Indicates when the output overload monitor detects a potentially damaging short and

shuts down amplifier operation. After clearing the fault, restore normal function by

turning the amplifier off, then on again.

WARM UP

In order to achieve the best sonic performance from the amplifier, we recommend letting it warm up for 1 hour

before beginning any critical listening. The amplifier may not deliver its full potential sound quality before this

time has passed.

CLEANING AND MAINTENANCE

There is no requirement for regular maintenance on the electronic components of the amplifier. If the case

becomes soiled it can be cleaned using a soft cloth and a mild detergent, such as spray window or glass cleaner.

If the amplifier is located in a particularly dusty environment cleaning the inside with compressed air or

vacuuming every 18 to 24 months is sufficient.

– 8 –

Page 18

– 9 –

ROCKFORD CORP

PC-0812-H

M.ALBERS

R9R8R7 R6

J7

JW5

JW4

JW6

Q8

R53

CR4

R49

CR3

R50

CR2

R52

C30

CR1

C19

R54

R51

R55

R24

R26

R22

C121

P2P4

R165

U2

R11

C28

R57

R58

R25

C20

PC BOARD LAYOUT

C122

Z3Z1

Z2

J8

C22

C21

R61

R62

R59

U5

C9

C25

R23

R56

X5

C114

C112

J5

R127

R27

R134

C14

Q9

R132

R131

CR11

R139

R128

R12

Q3

R30

C2

AC4

P6P5

Q12 Q11Q10

R40

Q6

C29

F3

R129

Q7

CR8

CT2

Q104

R41

R31

F2

R133

CR12

Q105

C113

CR7

AC3

R60

R32

C115

R141

R124

Q103

R33

R14

R39

Q1

R28

R138

R130

R123

CR10

J4

R10

CR6 CR5

R5

R35

Q2

R29

C13

R13

R140

R136

C31

C8

CR13

C15

C36

C116

R21

R16

C16

R18

R47R46

C126

Q5

R17

C26

CR15

U4

R164

J2

C123

C1

R64

R19

R20

R1

R63

R48

CR14

R45R44

R42

R43

CR9

D1

D2

P3

P1

Q116 Q115

C10

C5

C4

JW7

TS1

Q4

AC1

R34

X4X3

C120

CT1

C119

AC2

C124

C33

C18

R37

SW2

R38

R3R2

R36

SW1

J6

J3

C35

R4

JW3

X2X1

R15

C7C6

CH 1

C17

C23

JW2

J1

U1

JW1

R159

C125

R135

C3

C24

ARTWORK COMPONENT SIDE

revised 12/12/96

Page 19

P ARTS LIST

P3000U 120VAC, 60Hz

DESIGNATOR VALUE PART #

ALL RESISTORS IN OHMS, 1/4W

DESIGNATOR VALUE PART #

R1 56.2k RMP/4-5622

R2 1k RM/4-102C

R3 47k RM/4-473C

R4 47k RM/4-473C

R5 4.7k RM/4-472C

R6 1.07k RM/4-1071C

R7 909 RM/4-9090C

R8 200, Trim Pot RVH-201

R9 1k RM/4-102C

R10 28k RMP/4-2802

R11 10M RMP/4-106C

R12 28k RM/4-2802C

R13 470k RM/4-474C

R14 16 RM/4-160C

R15 3.3M RM/4-335C

R16 4.7k RM/4-472C

R17 10k RM/4-103C

R18 100k RM/4-104C

R19 604k RM/4-6043C

R20 45.3k RM/4-4532C

R21 2.2M RM/4-225C

R22 100k RM/4-104C

R23 100k RM/4-104C

R24 10k Pot RV-0818

R25 820 RM/4-821C

R26 2.2M RM/4-225C

R27 316 RM/4-3160C

R28 316 RM/4-3160C

R29 3.92k RM/4-3921C

R30 3.92k RM/4-3921C

R31 100 RM/4-101C

R32 100 RM/4-101C

R33 16 RM/4-160C

R34 470 RM/4-471C

R35 220 RM/4-221C

R36 1k RM/4-102C

R37 1k RM/4-102C

R38 3.3M RM/4-335C

R39 1k RM/4-102C

R40 3k RM/4-302C

R41 6.8k RM/4-682C

R42 10k RM/4-103C

R43 15k RM/4-153C

R44 10k RM/4-103C

R45 15k RM/4-153C

R46 47k RM/4-473C

R47 47k RM/4-473C

R48 15k RM/4-153C

R49 10k RM/4-103C

R50 4.7k RM/4-472C

R51 4.7k RM/4-472C

R52 15k RM/4-153C

R53 2.2M RM/4-225C

R54 10k RM/4-103C

R55 100k RM/4-104C

R56 15k RM/4-153C

R57 10k RM/4-103C

R58 100k RM/4-104C

R59 10k RM/4-103C

R61 100k RM/4-104C

R62 2.2M RM/4-225C

R63 28k RM/4-2802C

R64 100k RM/4-104C

R123 2k RM/4-202C

R124 820 RM/4-821C

R127 1k RM/4-102C

R128 100 RM/4-101C

R129 100 RM/4-101C

R130 1k RM/4-102C

R131 3k RM/4-302C

R132 3k RM/4-302C

R133 3k RM/4-302C

R134 100 RM/4-101C

R135 1k RM/4-102C

R136 200, Trim Pot RVH-201

R138 100 RM/4-101C

R139 470 RM/4-471C

R140 1k RM/4-102C

R141 470 RM/4-471C

R159 470 RM/4-471C

R164 220 RM/4-221C

TS1 Thermistor SS-1519-A

SW1 DPDT Switch SW-0280

C1 680pF, 100V CDS-681DBAA

C2 0.22µF, 50V CYV-224

C3 6800µF, 80V CERS-688D

C4 0.22µF, 250V CY-224AC

C5 6800µF, 80V CERS-688D

C6 270pF, 50V CDS-271CAAA

C7 270pF, 50V CDS-271CAAA

C8 4.7pF, 100V CDS-047DBAA

C9 0.1µF, 50V CDS-104CCDB

C13 470µF, 50V CER-477C-024

C14 470µF, 50V CER-477C-024

C15 0.1µF, 50V CDS-104CCDB

C16 0.1µF, 50V CDS-104CCDB

C17 0.1µF, 50V CDS-104CCDB

C18 0.1µF, 50V CDS-104CCDB

C19 0.1µF, 50V CDS-104CCDB

C20 0.1µF, 50V CDS-104CCDB

– 10 –

Page 20

DESIGNATOR VALUE PART #

C21 10µF, 16V CER-106SM

C22 10µF, 16V CER-106SM

C23 0.47µF, 50V CYV-474

C24 0.47µF, 50V CYV-474

C25 0.1µF, 50V CDS-104CCDB

C26 1µF, 50V CER-105C-024

C28 47µF, 16V CER-476-024

C29 10µF, 50V CER-106C-024

C30 0.1µF, 50V CDS-104CCDB

C31 0.1µF, 50V CDS-104CABB

C33 0.1µF, 50V CDS-104CCDB

C35 47pF, 200V CM-470-024

C36 22pF, 200V CM-200-024

C112 100µF, 25V CER-107A-024

C113 100µF, 25V CER-107A-024

C114 100pF, 50V CDS-101CAAA

C115 100pF, 50V CDS-101CAAA

C116 0.047µF, 50V CYV-473

C119 0.1µF, 100V CY-104

C120 0.1µF, 100V CY-104

Q1 MMBT3904LT1 SS-0792

Q2 LM-317 SS-239

Q3 LM-337 SS-240

Q4 2SK1058 SSH-741T

Q5 2SJ162 SSH-740T

Q6 MMBT5088L SS-0114

Q7 MMBT5088L SS-0114

Q8 MMBT3904LT1 SSS-0792

Q9 MPS-A56 SS-101A

Q10 MPS-A56 SS-101A

Q11 MPS-A06 SS-102A

Q12 MPS-A06 SS-102A

Q103 MMBTA06L SS-102SM

Q104 MMBT3906LT1 SS-0791

Q105 MMBT3906LT1 SS-0791

Q115 2SK1058 SSH-741T

Q116 2SJ162 SSH-740T

CR1 Red LED SS-741

CR2 Red LED SS-741

CR3 Red LED SS-741

CR4 Green LED SS-740

CR5 MMBD914L Diode SS-803SM

CR6 MMBD914L Diode SS-803SM

CR7 MMBD914L Diode SS-803SM

CR8 MMBD914L Diode SS-803SM

CR9 Bridge Rectifier 15A SS-0801

CR10 Bridge Rectifier 1.5A SS-0800

CR11 BAV99L Dual Diode SS-260SM

CR12 BAV99L Dual Diode SS-260SM

CR13 MMBD914L Diode SS-803SM

DESIGNATOR VALUE PART #

CR14 BAV99L Dual Diode SS-260SM

CR15 BAV99L Dual Diode SS-260SM

U1 TL072CD Dual Opamp SS-143SM

U2 TL072CD Dual Opamp SS-143SM

U4 LM339 Comparator SS-730SM

U5 LM339 Comparator SS-730SM

Power Switch SWH-1009

IEC Connector CC-0852

IEC Line Cord FAH-146

Dual Binding Post CC-0867

P3000 Transformer TT-1531

F2 Fuse, 1A Fast FS-1592

F3 Fuse, 1A Fast PS-1592

Line Fuse Fuse, 5A Slo Blo FS-005SB

!

!

!

!

!

!

Parts List Modifications for P1500CE

European Linecord FA-1464

Fuseholder Cup 5x20mmFS-1125

1.25A Slo Blo 5x20mm FS-1474A

230V Transformer TT-1457B

!

!

!

!

Parts List Modifications for P3000CE

European Linecord FA-1464

Fuseholder Cup 5x20mmFS-1125

!

!

Parts List Modifications for P1500U 120VAC, 60Hz

Parts List Modifications for

C3 3300µF, 63V CERS-338E

P1500U 120VAC, 60Hz

C5 3300µF 63V CERS-338E

C35, 36 Not Used

CR9 Bridge Rectifier, 8A SS-0799

Q5, Q115 Not Used

Line Fuse Fuse, 4A Slo Blo FS-004SB

!

!

!

!

!

!

!

!

2.5A Slo Blo 5x20mm FS-1541A

230V Transformer TT-1532B

P1500 Transformer TT-1456

Components marked with this symbol are safety critical

and should only be replaced with identical components.

Los componentes marcados con el simbolo son

imprescindibles para la protección del equipo, por lo

cual que solo sean reemplazados por los mismos

componentes.

Les componsants marqués du symbole sont indispensables à la sécuritée et ne peuvent être remplacés

qu'avec des composants identiques.

Bauteile, die mit einem gekenzeichnet sind, sind

sehr wichtig und dürfen nur mit den orginal Ersatzteilen

ausgetauscht werden.

I componenti contrassegnati da sono critici per la

sicurezza e devono essere rimpiazzati solo con ricambi

di valore identico.

!

!

!

!

!

!

!

!

!

!

!

– 11 –

Page 21

T ECHNICAL REFERENCE

FIELD SERVICE CONSIDERATIONS

A primary focus during the design and development of the P1500 and P3000 was to ensure the dependability of the

amplifiers. The use of lateral MOSFET output transistors and the low voltage trans•

careful component selection for the circuit assembly made the reliability goals achievable. However, a parallel effort

was also underaken to make sure any down time caused by an amplifier fault was minimized by making the amplifiers

“technician friendly.” The modular construction allows for exchanging the entire operational portion of either channel

quickly and easily. This section of the manual also contains circuit descriptions and block diagrams to assist technicians

with component level repairs.

nova

input stage combined with

THEORY AND OPERATION OF trans•

The (TRANSconductance NOdal Voltage Amplifier) principle is based on our 1984 U.S. Patent 4,467,288. This patent

describes the advantages of audio power amplifiers in which a MOSFET output stage is connected in a grounded source

configuration. In this connection the output stage has its full voltage gain of typically 20dB (ten times), instead of the

usual 1dB loss of voltage follower designs.

It is an inevitable result of electrical physics that this output with gain inherently increases the power gain (for the same

bandwidth) of the output stage by typically ten times over the conventional follower connection, using exactly the same

MOSFET devices.

The output stage is thus now ten times less wasteful of its incoming drive power. The driver stage can now be of a low

voltage (±18 volts) nature and be designed along the same principles always used in high quality preamplifiers: Class

A operation, high linearity, and wide bandwidth. A topology utilizing an output stage with gain yields a much simpler,

shorter total signal path than that of the usual high voltage driver designs. The number of serial stages is reduced from

five or more, to only three.

But all of the above does not make an amplifier trans•

stage (current-to-voltage converter), to achieve extremely short loop (fast) negative feedback. The output stage is driven

cooperatively by a transconductance stage (voltage-to-current converter).

The P1500 and P3000 are the most affordable amplifiers we have yet developed utilizing the basic trans•

And, although the measured specifications are very good, the numbers do not describe the realistic sound of the

amplifiers.

nova

nova

. The output stage is further refined into a trans-impedance

nova

principle.

– 12 –

Page 22

CIRCUIT OPERATION

nova

trans•

Positive Input

Balanced Signal

Negative Input

Implementation:

Buffer

U1A

Buffer

U1B

Level

Adjust

R24 A, B

+18V

–18V

Positive Buffer, DC

Offset Integrator

U2A, R11, C21,

C22

Negative Buffer

U2B

Protection Switch,

Soft Start Delay

Q1, C29

CMRR

Adjust

R8

Current Mirror

Q104, Q105

Differential Amp

+ –

Q6, Q7

Current Source

Q103

Positive Driver

Cascode

Q9, Q10

Feedback

Network

Negative Driver

Cascode

Q11, Q12

Drive

Signal

Bias

Adjust

R136

Local

Feedback

Positive Output

Q4, Q115

Negative Output

Q5, Q116

B+

Output

B–

The transistor Q1 is configured to operate as a switch which controls the current source, Q103, of the input differential

amp, Q6 and Q7. When Q1 is off, the emitter voltage is low turning off Q103. Timing of the Soft Start function is

controlled by the charging time of C29. Operation of Q1 is controlled by the THERMAL and SHORT protection circuits.

U1A and U1B are buffer amps configured as unity gain followers which feed the resistive network comprised of R24A,

R24B and R6 which attenuates the differential input at U2A and U2B. The output of U2A and U2B is taken to the inputs

of the differential amp Q6 and Q7, U2A is also configured as a DC servo integrator to null the input offset currents.

Transistor Q6 is the non-inverting input of the differential amp, taking the signal from U2A, the output is taken through

the current mirror, Q105 and Q104 where the signal is inverted, then feeds the negative driver Q11 and Q12. Transistor

Q7 is the inverting input of the differential amp, taking the signal from U2B. This output feeds the positive driver Q9

and Q10. The positive drivers Q9 and Q10, and the negative drivers Q11 and Q12 are cascoded stages which supply

drive current and voltage to the output devices. Class AB bias current is controlled by R136. The network R1 and C1

form the short loop feedback for the output stage. Global feedback is supplied by the network R10 and C8.

– 13 –

Page 23

Output Short Protection

Drive

Signal

Clip Detector

U3A

Clip Detector

U4A

Comparator

U3B

Short Latch

U4C, CR14

Shut Down

Switch

Q5, Q4

Short

Indicator

CR1

Output

Signal

Comparator

U4A

The Short detector monitors the Drive Signal and Output Signal levels and shuts down that channel when a shorted

output condition is detected. Recovering from the Short protection requires turning the amplifier off to reset. The

comparator U4B monitors the Drive Signal and goes low when the drive level is sufficient to clip the output stage. This

drive signal clip status is connected to the input of U4A on pin 7, the Output Signal is connected to the input of U4A

on pin 6. The output of U4A goes low when pin 7 is low and pin 6 is near zero. This condition, indicating high drive

voltage and low output voltage, occurs only when the output is shorted. If the output of U4A is low for the time sufficient

for C26 to charge, then U4C latches low activating the protection switch Q1 and lighting the indicator CR1. The output

of U4C is held low by CR14 and will reset only after the power is turned off.

Thermal Protection

Soft Start Switch

Q1

Tem p

TS1, R25

Comparator

U5B

THERMAL Indicator

CR2

The Thermal protection is activated, and shuts down audio operation when the amplifier heatsink reaches 90° C. The

voltage divider R22 and R23 establishes the reference voltage on pin 5 of U5B. The control voltage on pin 4 is established

by the voltage divider TS1 and R25. TS1 is a NTC (Negative Temperature Coefficient) thermistor mounted on the

heatsink. As TS1 warms and the resistance falls, the voltage on pin 4 rises. When the voltage on pin 4 exceeds the voltage

on pin 5, the output on pin 2 goes low activating the protection switch Q1 and lighting the THERMAL indicator.

– 14 –

Page 24

Clipping Indicator

Drive

Signal

Clipping

Detector

U5A

LED Driver

U5C

CLIP Indicator

CR3

The CLIP indicator is driven by the buffer U5C which is controlled by the comparator U5A. The voltage divider R56 and

R57 establishes the reference voltage for the Clipping detector at pin 7 of U5A. The reference voltage scales the output

of U5A to indicate when the Drive Signal at pin 6 demands in excess of the available voltage or current of the output

stage. The output of U5A is stretched by R55 and C30 to prevent the CLIP indicator CR3 from flickering. Hysteresis is

applied to the LED driver U5C by R53 to stabilize the output during input transitions.

Signal Present Indicator

Amplifier

Output

Signal

Detector

U5D

LED Driver

Q8

SIGNAL

Indicator

CR4

The SIGNAL indicator is controlled by the comparator U5D and the transistor Q8. The amplifier output is connected

to the input pin 9. The voltage divider R58 and R59 scales the output voltage to change the comparator output state at

an equivalent input voltage of 30mV, with the level controls set for full gain. The output at pin 14 controls the transistor

Q8 to shunt across and turn off the LED CR4.

CALIBRATION

WARNING: Only a competent technician should attempt the following procedure.

Bias:

The bias control establishes the quiescent Class AB output current of the amplifier. The bias should not need

readjustment from the factory setting; however, if the amplifier is repaired and output devices have been changed, or

if the two channels of the amplifier do not run at the same temperature, calibrating the bias is necessary. Disconnect

the power to the amplifier before removing the cover. To adjust the bias, disconnect the input and speakers and remove

the jumper JW7. Connect an amp meter across the exposed pins. Adjust R136 to get a current reading of 100 mA for

the P1500, 200 mA for the P3000.

WARNING: Only a competent technician should attempt the following procedure.

Common Mode Rejection:

The input common mode null is adjusted by the trim pot R8. The CMRR should be greater than 75dB below rated output.

If the CMRR requires adjustment, feed the amplifier input with a common mode signal and adjust R8. Disconnect the

power to the amplifier before removing the cover. Use a sinewave generator set to 1 volt output at 1kHz. Connect the

generator signal output to the tip and ring of a 1/4" plug and ground to the sleeve. Plug this into the amplifier input.

Connect an AC voltmeter to the amplifier output binding posts. Adjust R8 to give the lowest voltage output from the

– 15 –

Page 25

amplifier. For a temporary adjustment when a signal generator and voltmeter are not available, use an FM tuner and tune

it to an unused station as your signal source, and connect the output to the amplifier as described above. Connect the

amplifier output to a small full range speaker. Turn the amplifier level controls full down and turn the amplifier on. Turn

up the level control until you hear a signal through the speaker. Alternate adjusting R8 and the input control until you have

the level control full. There should be a very low output from the amplifier if any is detected at all.

MODULE REPLACEMENT

WARNING: Only a competent technician should attempt the following procedure.

The amplifier modules have been designed to eliminate the need for a special work place if a field exchange becomes

necessary. All wire connections are made by quick connect terminals. The following tools are needed:

Allen wrench, long reach 9/64

Allen wrench, long reach 7/64

Phillips screwdriver #1 tip

Thin nose pliers

Remove the Phillips head screws located on the rear panel, which secure the input jacks. Remove the two 9/64 Allen

screws located between the heatsink fins along the top edge on each side, which fasten the cover. Three more screws hold

the heatsink to the chassis; remove these screws and the level control knob. Unplug the gray cable which connects the

mono input signal to Channel 2. Tilt the rear of the heatsink up and disengage the assembly from the chassis. Pull the

heatsink away from the chassis to extend the wires. Disconnect the output wires from the binding posts and the power

wires from the module. Remove the module from the heatsink.

Install the new module on the heatsink. If it is Channel 1, set the Ground and Mono switches to the left (looking from the

rear of the module) and reattach the gray mono cable. To reduce the chance of assembly errors in high stress situations,

the main AC terminals are sized to accommodate only the correct wires. Reconnect the wires to the terminals as follows:

Wire Color Function Terminal/Size

Red Output Red Binding Post, 1/4"

Black Output Ground Black Binding Post, 1/4"

Orange (two) High Voltage AC AC1, AC2, 1/4"

White/Orange High Voltage Center Tap CT1, 1/4"

Blue (two) Low Voltage AC AC3, AC4, 1/8"

White/Blue Low Voltage Center Tap CT2, 1/8"

– 16 –

Page 26

SERVICE POLICY AND LIMITED WARRANTY

Rockford Corporation (Hafler Division) offers a limited warranty on Hafler products on the following terms:

• Length of Warranty

5 years on P1000, P1500, P3000, P4000

7 years on P9505 and P7000

90 days on all B-Stock (receipts are required)

• What is Covered

This warranty applies only to products sold to the original owner (non-transferable). This only applies to units sold in

the Continental United States. You are required to have a copy of the receipt stating the customer's name, dealer name,

product purchased and date of purchase.

• Products found to be defective during the warranty period will be repaired or replaced (with product deemed to be

equivalent) at Hafler's discretion.

• What is NOT Covered

1. Damage caused by accident, abuse, improper operations, water, theft

2. Service performed by anyone other than Hafler or an Authorized Hafler service center

3. Any product purchased outside the United States (please contact your local dealer)

4. Shipping charges to get the unit to Hafler

5. Any product which has had the serial number defaced, altered, or removed

• Limit on Implied Warranties

Any implied warranties including warranties of fitness for use and merchantability are limited in duration to the period

of the express warranty set forth above. Some states do not allow limitations on the length of an implied warranty, so

this limitation may not apply. No person is authorized to assume for Hafler any other liability in connection with the

sale of the product.

• How to obtain service or technical support

Please call 1-800-669-9899 for Rockford/Hafler support. You must obtain an RA # (return authorization number) to

return any products to Hafler. You are responsible for shipment of product to Hafler.

Rockford Corporation

Hafler Division

2055 E. 5th Street

Tempe, Arizona 85281

– 17 –

Page 27

NOTES

Page 28

®

HAFLER

A DIVISION OF

ROCKFORD CORPROATION

546 SOUTH ROCKFORD DRIVE

TEMPE, ARIZONA 85281 U.S.A.

480-967-3565 / 1-888-HAFLER1

WWW.HAFLER.COM

MAN-1461-C

4/99 E.W.R.

Loading...

Loading...