Page 1

Page 2

TABLE OF CONTENTS

Introduction

.....................................................

Page

1

Features ..........................................................

Page

1

Installation and Setup..

....................................

Page 2

Special System Configurations

.......................

Page 4

Rear Panel ......................................................

Page8

Operation ........................................................

Page 9

LED Displays ...................................................

Page 9

Care ................................................................

Page

10

Troubleshooting

..............................................

Page

10

Specifications

..................................................

Page

12

Warranty

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 13

Page 3

INTRODUCTION

The JF2000 is the first amplifier in the signature series line

of Hafler audio components. In the Hafler tradition, it is hand-

made in America. The signature series embodies Hafler's

philosophy of supplying the same quality music reproduc-

tion of higher priced audio components for less.

FEATURES

Output Section

High Current

Capability

Wide Load

Range

SOA Protection

(Safe

Operating

Area)

Thermal

Protection

The

JF2000

uses 32 MOSFET output devices - 16 per

channel - to source the high current and power required.

Each device is rated at 4.0 Amperes continuous drain

current at 100 degrees Celsius.

Each channel can safely produce peak transient output

currents exceeding 50 Amperes. This ensures that mo-

mentary speaker impedance dips and surge current requirements are easily supplied.

The JF2000 is fully rated for loads of 4 and 8 Ohms. It is

stable to 2 Ohms. (This means it will operate safely, cleanly

and stably into 2 Ohms, but very high power dissipation may

lead to frequent thermal shutdown.)

The 16 output devices per channel assure operation well

within the MOSFET Safe Operating Area with low imped-

ances and/or reactive loads.

The output devices of the JF2000 are protected by a so-

phisticated analog computing system. The device instantaneous temperature is continuously calculated by the com-

puter and compared to a maximum limit. If the limit is

reached, the computer cuts back thte power and lights the

channel’s distortion (red) front panel LED.

A pair of thermistors, one mounted on each heatsink, measure temperature of the output system. They control fan

speed and provide thermal shutdown in case temperatures

become too high for safe operation. (Thermal shutdown

turns the power lamp red.)

Page 4

Toroidal

Transformer

Energy Storage

Great Flexibility

Display

Fan Cooling

The fan cooling system is a key to the

JF2000’s

perfor-

mance. The fan is of a very quiet design, with continuous

variable speed control. When the amp is cool, the fan is

off

As the amp is driven harder, the fan gradually turns on and

speeds up only to the extent needed to sustain the power

dissipation needed for the conditions.

The power supply for the JF2000 is based on a 1000 Volt-

Ampere toroidal (donut-shaped) line transformer. We use

the toroid core (which is more expensive than a conventional

square transformer) for its higher efficiency, lower weight,

smaller size, and freedom from stray magnetic fields. The

1000 Volt-Ampere rating indicates that the transformer can

supply power to a load of 1000 Watts continuously.

Energy storage for the power supply consists of two 42,000

Microfarad capacitors. This large energy storage capability

provides a low-impedance source of extremely high current

for surges, musical transients, variations in speaker impedance, and very low frequencies.

Individual channel gain controls match the JF2000 to a wide

range of installations.

Four Output Modes are available to fit almost any require-

ment: Normal Stereo, Stereo plus Bridged Mono, Bridged

Mono, and Dual Mono.

Simple three-LED multicolor display shows amplifier status

including power, signal level, distortion, and thermal condi-

tion.

INSTALLATION AND SETUP

Amplifier

Placement

The JF2000 is designed to be placed on a shelf or other

substantial support. (A rack-mount front panel is available.)

Take care to ensure unimpeded airflow behind the amplifier,

as the intake and exhaust vents are located at the rear. If the

amp is to be placed in an enclosed wall unit or cabinet, it

would be a good idea to allow for fresh air intake and hot air

exhaust venting in the back of the cabinet, especially for

continuous high-output operation.

2

Page 5

Power

Connection

Speaker

Connection

Normal Stereo

Connections

The

JF2000 is designed to operate on 120 Volts AC, 60 Hertz

standard U.S. line output) only. Connection is via a standard

3-prong grounded AC plug. If a

3-prong (grounded) outlet is

rot available, the third (ground) wire MUST be grounded to

a

satisfactory electrical ground using adapters available at

nost hardware stores.

If an extension cord must be used, it will rob power from the

amplifier. Use only the highest qualtiy 3-wire (grounded)

extension

cords, with large wire

(14-Gauge

or larger) to

educe

losses.

Speaker

connectors are heavy-duty

gold-plated “5-way”

binding posts, spaced for standard banana jack connectors.

They will accept bare stranded wire up to approximately

12-

Gauge. Banana connectors may be more convenient.

For

normal stereo operation leave ALL REAR PANEL

SWITCHES IN. The amplifier’s left channel red binding post

connects to the left positive (+) speaker terminal and the left

black

post goes to the left negative (-) speaker terminal. Wire

the right channel the same. (Refer to Figure 1)

Figure 1

Left

positive (+) terminal (red) to Left Speaker positive (+)

Left

negative (-) terminal (black) to Left Speaker negative (-)

Right

positive (+) terminal (red) to Right Speaker positive (+)

Right

negative (-) terminal

(black) to Right Speaker negative (-)

3

Page 6

Speaker

Polarity Note

Be sure to observe speaker polarity (+ and - leads) through-

out your system. Getting them wrong can result in missing

bass, massive distortion, or blown speakers!

SPECIAL SYSTEM CONFIGURATIONS

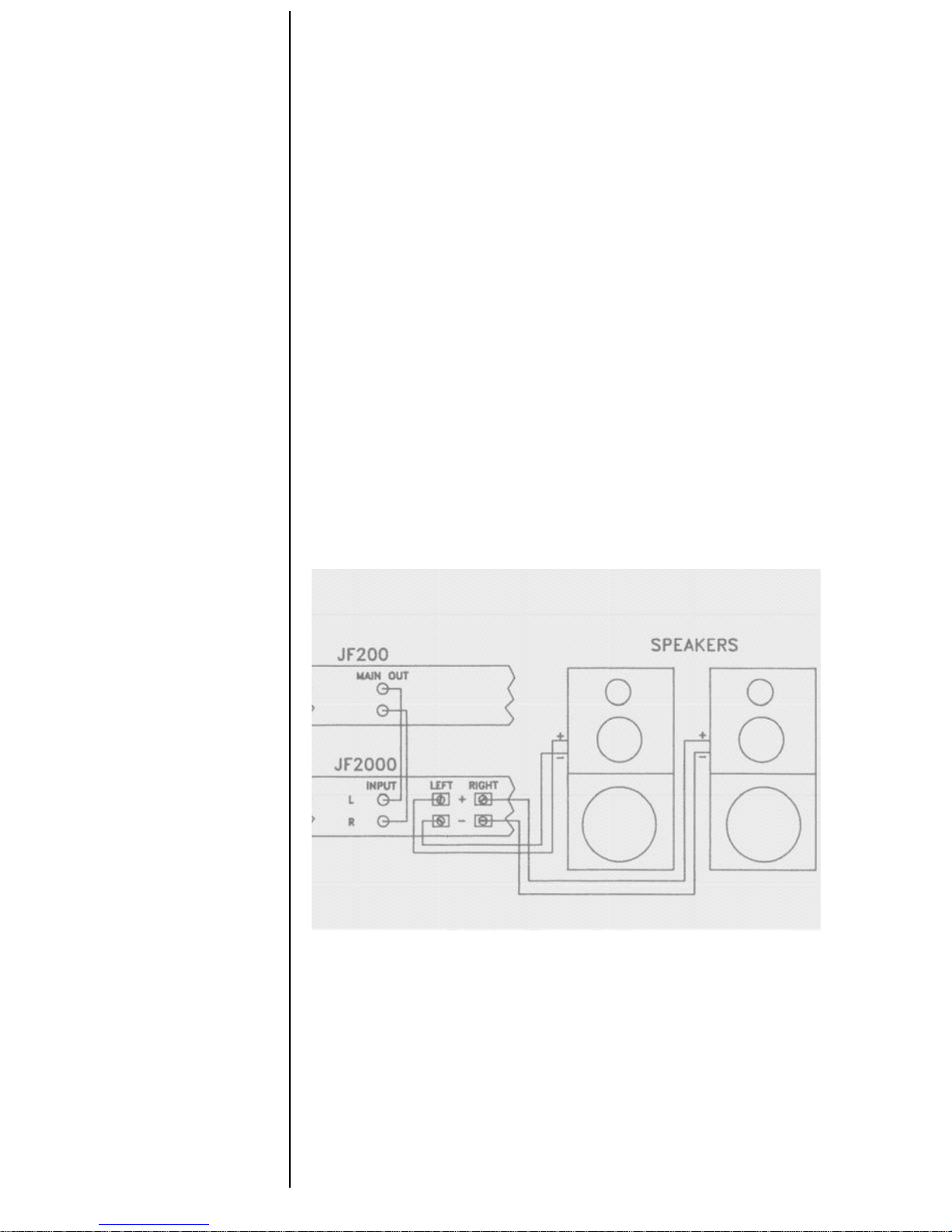

Biamplification

Dual Monaural

(Mona)

What

‘PLEASE NOTE:

The minimum nominal load impedance for

each

channel of the amplifier is 4 ohms. In bridged mode,

each

channel of the amplifier uses half of the nominal load

impedance. Therefore, in bridged/mono mode the minimum

equired load impedance is 8 ohms.

If the speaker system in use is capable of having separate

inputs for the woofer and midrange or tweeters, or if the

system

has a woofer in a separate box and satellite midrange

and

tweeters, then the final sound from the system could be

improved by biamplifying. This means using two amplifers in

normal

stereo mode, each being driven by a dedicated signal

high or low frequency

-

and loaded by a dedicated driver

-

high

or low frequency. This allows different power levels to

be

applied to the high and low frequency drivers of a speaker

system.

(Refer to Figure 2 for proper hook-up.)

Figure 2

Both

channels are driven by the same signal. (In the JF-

!

2000,

the common signal input is the Left channel input.) In

his mode, both amplifiers are controlled by the left input gain

control

and put out exactly the same kind of signal and

power.

4

Page 7

Why

How

Bridged Mono

What is Bridging?

may wish to drive biamplified pairs of speakers with

identical signals if the speakers have internal crossovers.

‘You may wish to drive multiple speakers which would be too

low in impedance if driven together (under 4 Ohms).

Set the INPUT switch to MONO (out). This feeds the right

and left channel power amplifier section from the left input

signal jack. Connect the speakers the same as you would for

standard stereo. Leave all other switches in the standard

position (IN) unless you have other reasons for using them.

(Refer to Figure 3)

Figure 3

Left positive (+) terminal (red) to Left Speaker

positive (+)

Left

negative (-) terminal (black) to Left Speaker negative (-)

Right

positive (+) terminal (red) to Right Speaker positive (+)

Right

negative (-) terminal (black) to Right Speaker negative

(-)

“Bridging” an amplifier means using two amplifier channels

to drive a single speaker. Normally, one terminal of the

speaker is driven by an amplifier section, and the other

terminal is grounded (that is, current is returned to the driving

amplifier). When a speaker load is driven by a bridged

amplifier pair, each terminal of the speaker is driven by a

separate amplifier section.

5

Page 8

Bridging applies much more power to the speaker load than

either amplifier channel would alone. For an 8-Ohm speaker,

the JF2000

is rated for a minimum output of 200 Watts for a

single channel. For both channels bridged into the same

speaker,

the minimum output would be 600 Watts.

When the application calls for higher power levels than you

can get from the

JF2000 in normal stereo, you can use the

bridged mono mode.

USE CAUTION! Most speakers cannot handle the power of

the JF2000 in bridged mono mode.

Typical applications include: driving large (mono) subwoofers,

large power hungry speaker systems, or bi-amp applications

where large amounts of power are required.

In order to use both channels of input to sum the signal to

drive a mono speaker, set the input switch to stereo (IN) and

the output switch to mono (OUT). The amplifier’s left channel

red binding post connect to the positive (+) speaker terminal

and the right channel red binding post connects to the

negative (-) speaker terminal. (Refer to Figure 4)

I

Figure 4

6

Page 9

Bridged Mona

Stereo Plus Stereo satellites can be driven at the same time as a bridged

mono subwoofer or bridged center channel speaker (with

one

JF2000).

If you have satellites designed specifically for midrange and

treble, with a single mono subwoofer designed for bassonly:

Set output switch to MONO (OUT). All other switches IN.

This inverts the right channel output, while leaving the input

stereo. You will connect the left speaker normally, but the

right speaker POS (+) and NEG (-) will be REVERSED from

normal stereo. The center (bridged mono) channel will be

connected between the two RED (MONO) amplifier termi-

nals. (Refer to Fig. 5)

Figure 5

Left Positive (+) terminal (red) to Left Speaker Positive (+)

Left Negative (-) terminal (black) to Left Speaker Negative (-)

Right Negative (-) terminal (black) to Right Speaker Positive (+)

Right Positive (+) terminal (red) to Right Speaker Negative (-)

Left Positive (+) terminal (red) to Mono Speaker Positive (+)

Right Positive (+) terminal (red) to Mono Speaker Negative (-)

7

Page 10

REAR PANEL

Switches

Balanced/

Unbalanced Input

Switch

Home Version

Input Switch

(Right Channel)

Output Switch

(Right Channel)

Ground Switch

Input

Connections

Level Adjust

Speaker Fuses

NOTE:

Normal stereo position for all rear panel switches is

IN. The only time any of the switches should be OUT is for

one of the special functions in this section.

Be sure to turn the amplifier OFF before changing rear panel

switch positions (to avoid possible pops and clicks).

The Balanced/Unbalanced Input Switch is disabled in the

JF2000. This function is used only with special professional

connectors (XLR and

1/4

inch phone plugs) available with

the PRO6000 professional back panel.

IN position: Stereo. Right input feeds Right channel.

OUT position: Mono. Left input feeds Right channel.

IN position: Stereo (normal). Right channnel is in phase with

Left.

OUT position: Mono. Right channel is reversed in phase

compared to Left.

IN position: Floating (normal). Chassis ground separate

from Output section ground.

OUT position: Chassis. Chassis ground connected to output

section ground.

This switch should be set for minimum system hum.

Input is via standard “RCA” style pin jacks.

Input sensitivity is adjustable with the level controls adjacent

to each input RCA jack. The overall gain ranges form zero

(fully counter-clockwise) to 36 dB (fully clockwise).

The JF2000 is equipped with AGC5-Ampere speaker pro-

tection fuses. These fuses are for speaker protection only.

Most speakers will not handle more than a 5-Ampere fuse (or

less). Refer to your speaker manufacturer’s recommendations for your fuse selection.

Page 11

OPERATION

Turning On

The Amp

First Time: Before turning on the power switch to the JF2000

forthefirst time, double-check all speaker and input connections and turn the input level controls all the way down (fully

counter-clockwise). Turn on your source equipment (preamp, CD player, etc.) Turn the power switch on and adjust

the input controls so that the left and right channel LEDs light

up green at a low preamp volume control position.

Normal Operation: As with any high-powered amplifier, it is

b

est to turn on the amplifier AFTER all other equipment is on,

and turn it off BEFORE any other equipement. This prevents

any turn-on or turn-off transients from other equipment

damaging your speakers.

LED DISPLAYS

Channel

Status

LEDs

From left to right the front panel LEDs indicate: Left Channel

Status, Right Channel Status, and Power Status.

The Channel Status LEDs indicate the condition of the Left

and Right channel outputs. They will turn on GREEN to

indicate a signal output of over about 200 Milliwatts. They will

switch to RED to indicate distortion over about 0.5% THD.

The Power Status LED will turn on GREEN to indicate power

on. In case of overheating, it will switch to RED and the

amplifier will turn off until it cools down.

The channel status LEDs can show three indications:

OFF indicates no signal or a signal level under about 200

Milliwatts (a very quiet level with most speakers).

GREEN indicates a signal over about 200 Milliwatts and very

low distortion (under 0.5% for most conditions); that is,

normal operation.

RED indicates distortion in the output signal for any reason:

blown speaker fuse, shorted speakers, excessive speaker

load, or any other reason.

Page 12

Power

Status

The Power Status LED can show three indications:

LEDs

OFF: The power switch is off, the amplifier is not plugged in,

or the main fuse is blown.

GREEN: Indicates normal power and operation.

RED: Indicates amplifier overheat. Leave the switch on and

the fan will cool the amplifier down to operating temperature

very quickly.

CARE

Do not allow speaker wires to touch each other, chassis

ground, or any metal object.

Protect your amplifier from moisture and dust.

Clean anodized finishes with soft, damp cloth.

Save the original carton and packing. It is the only safe way

to ship the amplifier. If you need to replace the carton and/or

packing, consult your authorized dealer or Hafler Customer

Service Department.

No user serviceable parts inside. Do not disassemble amplifier for any reason. Refer to an authorized Hafler warranty

station or to Hafler directly. See Warranty Statement.

TROUBLESHOOTING

LED Displays for

The LED displays show a lot of information about how the

Troubleshooting

amplifier is acting. They can provide direction and trouble-

shooting information for most system problems if they are

interpreted properly.

Power Status LED

The Power LED can show three indications:

(Rightmost LED)

OFF: No power is reaching the main amplifier board lowvoltage section.

GREEN: Normal low-voltage power is available.

RED: Amplifier has shut down due to overheating (fan will

still run to cool the amplifier).

10

Page 13

No LED

Turns Red

(overheats)

Rapidly

Channel Status

LEDs

(Two Left

LEDs)

This is an indication that no power is reaching the amplifier.

Possible reasons include:

1) Amplifier not securely plugged in.

2) Power source (socket) failed (AC line fuse blown,

wiring open, etc.)

3) Internal amplifier fuse blown. Fuse replacement

should only be attempted by a qualified technician.

1) Rear cooling channels blocked. Clear the area behind

the amp.

2) No fresh air ventilation (rear air intake and output feeding

each other). Provide a source of fresh air (not heated air)

for the inlets at the sides.

3) Excessive loading. If the amplifier is run into less than a

4-Ohm speaker load per channel, or is bridged into less

than 8-Ohms, the amplifier may not be able to produce

continuous high output levels without overheating. Reduce the loading by increasing load impedance.

4) Fan is jammed or has failed. Clear the obstruction or

replace the fan.

5) There may have been an internal malfunction. Send amp

to the factory or a qualified technician for repair.

The channel status LEDs can show three indications:

OFF indicates no signal or a signal level under about 200

Milliwatts (a very quiet level with most speakers).

GREEN indicates a signal over about 200 Milliwatts and very

low distortion (under 0.5%) for most conditions); that is,

normal operation.

RED indicates distortion in the output amplifier sectionforany

reason: blown speaker fuse, shorted speakers, excessive

speaker load, or any other reason.

11

Page 14

SPECIFICATIONS

8-Ohm

POWER: Over 200 Watts per channel from 20 Hertz to

Performance

20,000 Hertz, both channels driven, at rated distortion.

4-Ohm

POWER: Over 300 Watts per channel from 20 Hertz to

Performance

20,000 Hertz, both channels driven, at rated distortion.

2-Ohm

Performance

S/N Ratio:

Peak Output

Current:

Frequency

Response:

Power Bandwidth:

Protection:

DISTORTION: Less than 0.05% Total Harmonic Distortion

plus Noise, 20 Hz to 20,000 Hz, both channels driven at full

power.

IM DISTORTION (IHF): Less than 0.01%

SLEW RATE: Exceeds 80 Volts per Microsecond.

DISTORTION: Less than 0.10% Total Harmonic Distortion

plus Noise, 20 Hz to 20,000 Hz, both channels driven at full

power.

IM DISTORTION (IHF): Less than 0.02%

Stable into two Ohms.

May overheat and shut down rapidy if driven hard at 2 Ohms.

Over 110 dB (unweighted) with respect to full power.

50 Amperes

20

Hz to 20,000 Hz: +0.l, -0.25 dB

5

Hz to 75,000 Hz: +0.l, -3.0 dB

5 Hz to 75,000 Hz

Capable of safe operation indefinitely into any load condi-

tion.

Sustained (over 1 second) hard clipping at ultrasonic fre-

quencies (over 20 KHz) will cause protection to activate, the

limit peak power. Please test ultrasonic behavior either with

signals that don’t cause clipping or with tone bursts.

12

Page 15

FACTORY SERVICE AND LIMITED WARRANTY

If you encounter any diff iculty or have any questions concern-

ing your

JF2000

preamplifier, please call our Customer

Service department weekdays, 8:00 am to 3:30 pm Mountain

Standard time, at 602-967-3565.

Before returning any unit to the factory for service, please call

us. All units being returned (regardless of warranty status)

must receive a Return Authorization (RA) Number. In addi-

tion, we can offer trouble-shooting assistance that may often

simplify or even eliminate the need for factory service.

The Hafler JF2000 is warranted for 3 years from date of

purchase, including parts, labor, and return shipping costs

from the factory to the owner within the Continental U.S.A.

It is the owner’s responsibility to pay shipping (preferably

UPS) to the factory: collect shipments will not be accepted.

Units under warranty should be accompanied by a copy of a

dated Bill of Sale. Use the original carton and all packing

material, and be sure to include a return address, and a brief

description of thedifficulty, including whether it is intermittent.

This warranty gives you specific legal rights. You may also

have other rights which vary from state to state.

13

Page 16

Hafler

A Division of Rockford Corporation

613 South Rockford Drive

Tempe, Arizona 85281 U.S.A.

602

-

967 - 3565

Loading...

Loading...