Page 1

THE

DH-110

PREAMPLIFIER

INSTRUCTIONS

for ASSEMBLY

and OPERATION

LM132

$3.00

THE DAVID HAFLER COMPANY

5910 Crescent Boulevard, Pennsauken, New Jersey 08109

DH-110

Please

number in all communications

refer to this serial

regarding this equipment.

Page 2

SPECIFICATIONS

The numbers in parentheses refer to the paragraph in the IHF specifications manual which defines the test procedure.

PHONO PREAMP SECTION

Rated Output: 3

Maximum Output (3.5): 12

Total Harmonic Distortion: Less than 0.0006%

Frequency Response (3.13): +0, -0.25 dB, 20 Hz-20 kHz

RIAA Equalization Accuracy: +0, -0.1 dB, 30 Hz-15 kHz

Full Power Bandwidth: -6 dB, 4 Hz-210 kHz

Sensitivity (3.7): 12.5 millivolts

Maximum Input Signal

Gain: 34

Input Impedance: 47,000 ohms in parallel with 30 pF; user adjustable.

Signal to Noise, weighted (3.12): 87

Slew Rate: 12 volts per microsecond

LINE AMPLIFIER SECTION

Rated Output: 3

Maximum Output (3.5): 14

Total

Frequency Response (3.13):

Full Power Bandwidth: -6

Sensitivity (3.7): 50 millivolts

Maximum Input Signal

Gain: 20 dB ± 1

Input Impedance: Greater than 25,000 ohms

Signal to Noise, weighted (3.12): 90

Slew Rate: 12 volts per microsecond

Rise Time: 2.5 microseconds maximum, Phono in

Crosstalk (3.14): down 72 dB, any input to any output

Separation (4.2): greater than 82

Gain

Maximum Output Noise: less than 350 microvolts,

Bass Control: 217 dB @ 20 Hz, moving inflection, variable turnover

Treble

Filter Response: -3

Filter Cutoff (3.13.2.2.1; 3.13.2.2.2): 25 Hz; -12

GENERAL SPECIFICATIONS

Semiconductors:

Inputs: 2 Phono, Tuner, Compact Disc or Video, 2 Tape recorders, EPL

Outputs: 2 Tape (buffered), 2

Controls:

Intermodulation Distortion: Both

AC Supply Voltage: 100-130 and 200-260 VAC,

Power Consumption:

AC Convenience Outlets: 3 switched, 5 amp continuous, 72 amp surge

Size: 17” wide x 3” high x

Shipping Weight: 12.5

Net Weight: 10

dB @ 1

Harmonic Distortion (3.4):

Tracking

Control: ±17 dB @ 20 kHz, shelving @ 5 kHz, fixed turnover

levels from phono input to line output are below the

residual of currently available instrumentation

19” rack mounting accessories included

Wms,

8 Hz-105 kHz

Vrms,

20 Hz-20 kHz at recording output

@

1 kHz, 3

@

1

kHz

(3.8): 300 millivolts; [3 V @ 20

kHz

Plug-in capacitors are installed to increase this

to 150

pF

on Phono 1; 250 pF on Phono 2

dB

Vrms,

4 Hz-210 kHz

Vrms,

20 Hz-20 kHz

Less

than

0.001%,

+0,

-0.1 dB, 20 Hz-20 kHz

dB,

2 Hz-420 kHz

@

1

kHz

(3.8): 14

dB

1 kHz square wave; load is 10,000 ohms in parallel with 10

dB @

Error (4.4): less than 0.5

less than 95 microvolts, ‘A’ weighted

[with 1 Kohm input termination, volume full

dB @

25 Hz; -6 dB @ 15 Hz; -12 dB @ 8.2 Hz; -25 dB @ 3 Hz

30 transistors, 3 ICs, 12 diodes, 2 LEDs

Line, EPL, Headphone Jack

Volume,

Monitor Selector, Mono-Stereo, Filter, External Processor Loop,

Tone Control Engage, Power

Balance, Bass,

3.5 watts

lbs.

lbs.

1

unswitched,

8½”

deep

Treble,

SMPTE

Vrms;

volume control @ -20

dB

/

Line out, 10 Vp-p,

1 kHz; greater than 52 dB @ 20 kHz

dB

dB/octave

Input Selector, Phono l/2 Selector,

and CCIF IMD at operating

50/60

5 amp continuous

Vrms

kHz]

20 Hz-20 kHz

dB

nF

wideband

CW]

Hz

2

©

Copyright 1985. All rights reserved.

Page 3

INTRODUCTION

Your preamplifier is the control center of your music

system, acting as an interface between the sound

sources-record players, tape recorders, FM and Video

tuners-and the power amplifier which drives the

loudspeakers. As the focal point of your system, it should

be attractive and easy to use, versatile and yet functionally

unobtrusive. It should contribute a minimum of noise or

distortion while providing signal amplification, control of

the signal level, and applicable modification of the frequency response.

The DH-110 achieves all these objectives with great

versatility, providing for two record players with magnetic

cartridges, two tape recorders, a tuner, and an additional stereo

input for a compact (digital audio) disc player or video audio. It

also includes inputs and outputs for an external signal processor

such as a graphic equalizer, time delay device, or noise

reduction unit. The performance of the DH-110 is exemplary,

and its assembly from an array of discrete components of

exceptional quality should ensure reliability and longevity of its

capabilities.

Exceedingly low noise and distortion is a hallmark of the

DH-110. Noise is essentially inaudible in the absence of a

signal, and distortion of all types, both steady state and

transient, is at or below the threshold of the finest mea-

surement capabilities. These excellent characteristics are

maintained far outside the customary 20 Hz to 20

kHz

band, and signals well beyond that are handled without the

need to restrict bandwidth.

Precise interchannel balance at all frequencies is maintained with close tolerance components, and RIAA phono

equalization is engineered to very narrow limits, maintain-

ing accurate phase relationships and correct spatial

perspectives, as well as exceptional unit-to-unit consistency. The tone controls, which can provide contouring of

response for individual needs when switched in, are normally isolated from the circuit for ruler-flat response.

The components in the DH-110 have been selected for

their superb audio performance as well as for their reliabil-

ity. They have been incorporated in the unique Hafler fully

complementary symmetry push-pull circuit in a carefully

designed circuit board layout which reduces crosstalk and

maintains separation for a synergistic audio result that

defies comparison, regardless of cost.

Those who have chosen to build the kit will find that its

step by step instructions will ensure a properly working

unit even for the novice builder. A substantial amount of

preassembly has enabled us to check out each kit in nearly

every aspect of performance, and makes the DH-110 a particularly fast, easy and enjoyable construction project,

which you will likely complete in one evening.

We suggest that you read the installation and operation

sections of this manual carefully, even though much may

be familiar to you. There are some subtle and significant

points which may be new, and their proper appreciation

will enable maximum satisfaction with your DH-110. We

wish you to have the very best in sound.

Installation

Operation

Assembly Instructions. ................... .7

Building the Kit

PC-14 Diagrams

If a Problem Arises

Overseas AC Line Connections

..........................

............................... .5

.......................... .9

........................ .12

...................... .15

..........

Page 4

.15

CONTENTS

Additional Information .................. .16

Functional Block Diagram

Component Values

Schematic Diagram

Kit Parts List

Service and Warranty

Pictorial Diagram

..................... .20

........................... .22

.....................

............... .16

.....................

................... .23

.19

Insert

3

Page 4

The DH-110 is provided with accessory Rack Mount end

caps in addition to the standard end caps installed on the

unit. These accessory caps extend the width of the front

panel to that of a standard 19” rack, with appropriate

mounting holes. Installation instructions are detailed later

in this manual under Additional Information.

POWER CONNECTIONS

As assembled, units are normally wired for 120 VAC,

50-60 Hz, as in the USA, unless they are specially identified on the carton. In the Additional Information section

you will find diagrams of alternate wiring of the power

transformer to conform to other line voltages.

The power regulation of the DH-110 will provide full per-

formance with line voltages which may vary substantially

from the standard. Units wired for 120 volts, for instance,

will work properly with line voltages between 95 and 130

volts.

Accessory AC outlets are provided on the back panel for

other equipment. One unswitched outlet is provided for a

turntable or tape recorder whose mechanical system may

require disengagement through its own power switch.

Most units, including power amplifiers, tuners, and many

tape recorders and record players, may be connected to

the switched outlets for convenient remote switching from

the preamp’s front panel. The DH-110 power switch has

been tested to provide adequate capacity for any Hafler

power amplifier and typical related equipment. You should

heed the maximum power rating printed on the back panel

of the unit.

INPUTS-Magnetic Phono

There are two pairs of phono inputs, identified as Phono

1

and Phono 2. These are independent, and thus they may

have different capacitive termination for differing cartridge requirements. As assembled, Phono 1 is provided

with a compensation capacitor of 120 picofarads, and

Phono 2 is provided with 220 picofarads. One of these values will accommodate most ‘Moving magnet’ cartridges.

These have output levels intended for normal phono inputs (0.5 millivolts per centimeter or higher) and are the

most popular. Some high output ‘moving coil’ design cartridges are not sensitive to capacitive loading, so they may

be used with either input.

Though some phono cartridges are comparatively free

of loading sensitivity, if the cartridge manufacturer

specifies the proper load capacitance (which is the sum of

the preamp’s internal capacitance, and the cables you use,

as well as the above described capacitor), the most accurate sound will be obtained by following that recommendation. If you have chosen the DH-110 for its sonic attributes,

you will be more likely than most to be aware of these differences, and will want proper cartridge termination.

The Additional Information section of this manual de-

tails the determination of the loading capacitor for a

specified cartridge load. It also describes how the resistive

load of the phono inputs may be changed, if needed, from

the standard 47K ohms.

Moving coil design cartridges often require an auxiliary

step-up transformer or pre-preamplifier (head amplifier)

because of their low output signal. The DH-110 has provi-

sion for internal addition of an accessory Hafler prepreamplifer which you or your dealer can install at any

time. This enables the Phono 1 input to accommodate such

cartridges directly. The Additional Information describes

its installation.

Adjacent to the Phono 1 input sockets are two Ground

terminals on the back panel. These thumbscrews provide

for connection of separate ground wires often provided on

turntables, or as part of their audio cables. This ‘chassis

ground’ may sometimes reduce the hum level of a system

when it is connected to an earth ground, such as a cold

water pipe, or the ground wire of 3-wire house wiring.

However, the need for such connection varies with indi-

vidual situations. After the system is operative, using a

phono source, experiment with and without an earth

ground to determine which provides the lowest hum, and

use that.

IMPUTS-Tuner, CD/Video

These are high level (line-50 millivolts or more) signals

from FM, AM or TV tuners, or compact digital audio disc,

video disc, or VCR players. These inputs are grounded at the

selector switch when they are not chosen for listening. The input

impedance is approximately 33K ohms.

INPUTS-Tape

1, Tape 2

These are at line level and impedance. They connect to

Tape Play outputs on the tape deck. They are not grounded

when unused, since they can be connected by either the

main selector switch or the Tape Monitor switch. They are

terminated with 1 megohm resistors to avoid a possible

switching transient.

RECORDING OUTPUTS

These connect to the Line Inputs of tape decks. The two

pairs of outputs are wired in parallel. Thus two tape recorders receive identical signals. These outputs

are

buffered

with a series resistor, and have an output impedance of

1.5K

ohms. To provide full specification performance, the

total tape recorder load should not be lower than

10K

ohms

(i.e. two 20k ohm recorder inputs on each channel).

Because it is possible that a preamplifier’s overall per-

formance may be adversely affected by rectification

ef-

4

Page 5

fects

that can result from unpowered electronic circuits in

the tape decks when they are connected to the Recording

Outputs, it is recommended that tape recorders be

switched on when the preamplifier is in use. This is a

which is otherwise a possibility. We recommend that you

turn off power amplifiers before connecting headphones,

or that they be plugged in before the system is switched on,

as a precaution.

commonly overlooked cause of less-than-ideal

preamplifier performance.

The Direct outputs provide conventional signal levels

independent of the headphone circuit. If headphones are

Signals at these outputs are at line input level (phono

signals are first amplified and equalized). These outputs

are unaffected by external processing circuits, or by the

DH-110’s Mono, Filter, Tone or Volume controls. Only signals indicated by the Selector switch are available, including the other tape input, so tape copying is provided using

either recorder as a source.

LINE OUTPUTS

Two pairs of outputs are provided for your power

amplifier connection. The set

labelled

‘Via Phones’ is

plugged in, the level of the Direct output will be greatly

reduced. These outputs should not be used when headphone use is anticipated.

The performance specifications will be met so long as

the input impedance of the power amplifier is

higher, and the cable capacitance is less than

10K

1Onf.

ohms or

This is

no problem with typical interconnecting cables up to 10

feet. If you

are

planning to use very long cables between

preamp and power amplifier, special low capacitance cable

can be obtained.

EXTERNAL PROCESSING LOOP

suggested for those who regularly listen through head- ‘Send’ is an output at line level for the purpose of driving

phones as an alternative. These are wired so that when

headphones

are

plugged in, the signal is disconnected from

the power amplifier. Two purposes are thus served. Since

many headphones require fairly high volume control

set-

tings, you avoid inadvertent high signal levels to your

speakers. And a power amplifier which is turned off

not degrade the quality of signal to the

headphones-

can-

an external signal processor such as an equalizer, time

delay, or noise reduction unit. Like the recording outputs,

the load impedance should not be less than

10K

ohms. The

EPL ‘Return’ input impedance is 33K ohms, and should

also be at line level. The EPL Return can also function as

an additional high level input, switched from the front

panel.

OPERATION

When you turn on the DH-110, power is also applied to

the switched AC outlets on the back panel. One of the red

duplicated by selecting the playback tape recorder on the

Selector switch, and recording on the second machine.

LEDs on the front panel will light, indicating that the

preamp is functioning. Typically, it will be the left-most

PHONO AMPLIFIER

LED, indicating that the Selector switch is determining

the signal source. At turn-off, it is normal for the LED to

fade slowly as the operating voltages decline.

either Phono 1 (in the OUT position) or Phono 2. The

switch may be operated to compare two cartridges while

music is playing, but if them is no cartridge connected to

DELAYED TURN-ON

An internal muting circuit prevents the voltage transients which may occur at turn-on or turn-off from causing

annoying noises, blown fuses or damaged loudspeakers.

At turn-on, the Line Outputs (but not the Recording

Outputs or EPL Send output) will be held near ground po-

tential for a few seconds until the internal voltages have

stabilized, and the unit is ready for operation. Only a faint

output can be heard during this time.

At turn-off, whether by operating the preamp’s power

switch, or as a result of external AC failure (a ‘brown-out’,

pulled plug, or blown house fuse), the line output will be

instantaneously lowered. Following power interruption,

the muting circuit will initiate a few seconds delay before

allowing full signal at the line outputs.

SIGNAL SELECTION

Your choice of signal sources is usually indicated by the

Selector Switch, identified by the adjacent lighted LED.

one input, noise or RF interference may cause a small au-

dible transient. The phono signal is accurately RIAA

equalized and amplified 34dB (at 1kHz), then passed to the

Selector switch at line level.

MONITOR SWITCH

vide an independent monitoring facility, the DH-110 provides this second selection function. When it is OFF, the

regular Selector switch determines what signals are heard.

When the Monitor switch is turned to either Tape 1 or Tape

2, the line amplifier is quietly disconnected from the signal

being recorded, and is connected to the tape playback in-

stead. This enables direct comparison of the signal source

with the taped replica, without affecting the recording pro-

cess. Tape decks which do not provide separate record and

playback heads are not able to utilize this comparison.

Selector is also set to Tape 1. Likewise avoid simultaneous

Tape 2 settings on both switches. Feedback will occur, and

there is a possibility of damage.

This switch passes line level signals direct to the Recording Outputs and to the EPL Send output as well as to the

Mono switch and subsequent line amp controls. Either or

both tape recorders may record this source. Tapes may be

LED at the Monitor switch will light, in place of the Selec-

tor LED, reminding you that tape playback has been

selected.

The button in the lower left of the front panel selects

To facilitate tape recording with tape decks which pro-

Note: Do not turn the Monitor switch to Tape 1 if the

When the Monitor switch is not in the OFF position, the

5

Page 6

The following controls affect all signals which are

heard through speakers or headphones. They have

no effect on the signals to the recording outputs.

MONO SWITCH

When this button is IN, left and right channel information is combined, and the composite signal is fed to both

left and right outputs. In this mode the sound image should

appear to be centrally located between the loudspeakers.

Critical listeners sometimes choose the mono mode for

system evaluation, for it enables you to isolate system response from the complexity of stereo effects. This switch

is also useful when listening to monophonic program material. It cancels the unwanted vertical phonograph modulations which are heard as noise from monaural records.

FILTER SWITCH

This is a low frequency cutoff to remove much of the

signal below 25 Hz, such as noise, turntable rumble, or

loudspeaker-turntable feedback. Even in cases where the

speakers may have little response at these frequencies,

this filter can be useful. Very low frequencies can modulate

audible midband signals, so eliminating this interference

can improve overall clarity.

Note: The Filter button should be OUT when the DH-110

is turned ON to avoid a switching transient during the first

minute of operation. If it is IN at turn-on, wait one minute

before releasing it.

EPL SWITCH

This is the External Processor Loop. Engaging this

switch enables a signal processing device to be inserted in

the preamplifier signal path. Such devices include equaliz-

ers, time delays or ambience simulators, expanders, compressors, and noise reduction systems. Since the switch

permits bypassing the processor loop, an unpowered device in the EPL circuit will not deteriorate the DH-110 performance, as might be the case with switched-off tape

decks in the Record Outputs. The EPL switch can also

function as an additional input selection.

will be heard with the control fully counterclockwise, and

only the Right signal at the other extreme.

The ideal situation would find symmetry in room acoustics and in the electronics, but this realization is rare.

Stereo reproduction is, at best, a splendid illusion, and the

function of the Balance control is to optimize this illusion

in the listening space. Sound wave reflections from walls,

furniture and people can unbalance the stereo ‘stage’. With

judicious application of the balance control, much of the

attendant distortion of stereo imaging can be overcome.

With the preamplifier in the Mono mode, it will be easier to

use the Balance control to centrally position the apparent

sound source. This mono setting can then serve as a useful

reference point, though the appropriate balance setting

may vary from recording to recording in the stereo mode.

Our point is that Balance and Tone controls are intended

to facilitate the most satisfying sound to the listener; it is

appropriate that they be used to this end.

BASS and TREBLE CONTROLS

The Tone Switch must be IN for these controls to be effective. At full rotation, each control provides about 17

of boost (clockwise), or cut (counterclockwise) at the frequency extremes from the center ‘flat’ (detent) position.

The Bass control has a variable inflection, or ‘hinge’

point so that only the very low frequencies are

small amounts of rotation either side of center. This facilitates low frequency corrections without noticeably altering the musical balance, but speakers with diminished low

frequency response will not reflect small angular move-

ments from the detent. As the control is turned further,

frequencies closer to 500 Hz are affected, so the effect is

more apparent.

The Treble control has a fixed ‘hinge’ point at 1kHz and

has a ‘shelving’ action above 5kHz. This affords proper

correction without irritation from excessive boost at the

extreme.

affected

dB

by

TONE SWITCH

Until this button is depressed, all tone control circuitry

is completely removed from the signal path. Activating

this button may cause a slight change in the tonal balance

even when both Bass and

dian (detent) position. Potentiometer tolerances preclude

coincident mechanical and electrical centering. The tone

control circuitry limits, to an extent, the total bandpass of

the DH-110.

Operation of the Tone button will be silent if it is depressed

in a natural, deliberate manner. Rapid switching may generate small transient pulses.

BALANCE CONTROL

This adjusts the proportion of left and right channel sig-

nals to the Line outputs. In its detented center position the

channels will be matched to

Treble

controls are in their me-

±0.1

dB. Only the Left signal

VOLUME CONTROL

This step action control was selected for its very accurate tracking between channels, and for its low contact distortion. Clockwise from the 12 o’clock position it increases

in increments of roughly 1

terclockwise it progresses in increasing increments to full

attenuation.

HEADPHONE JACK

A 3-circuit shorting jack is connected so that the tip is

the left channel, in series with one set of line outputs, so

that the power amplifier is automatically disconnected

when the headphones are plugged in. We recommend that

you turn off the power amplifier before you connect head-

phones, or that they be plugged in before the preamplifier

is turned on, to guard against needless transients. Be sure

the volume is turned down before headphones are discon-

nected.

dB.

From 12 o’clock coun-

Page 7

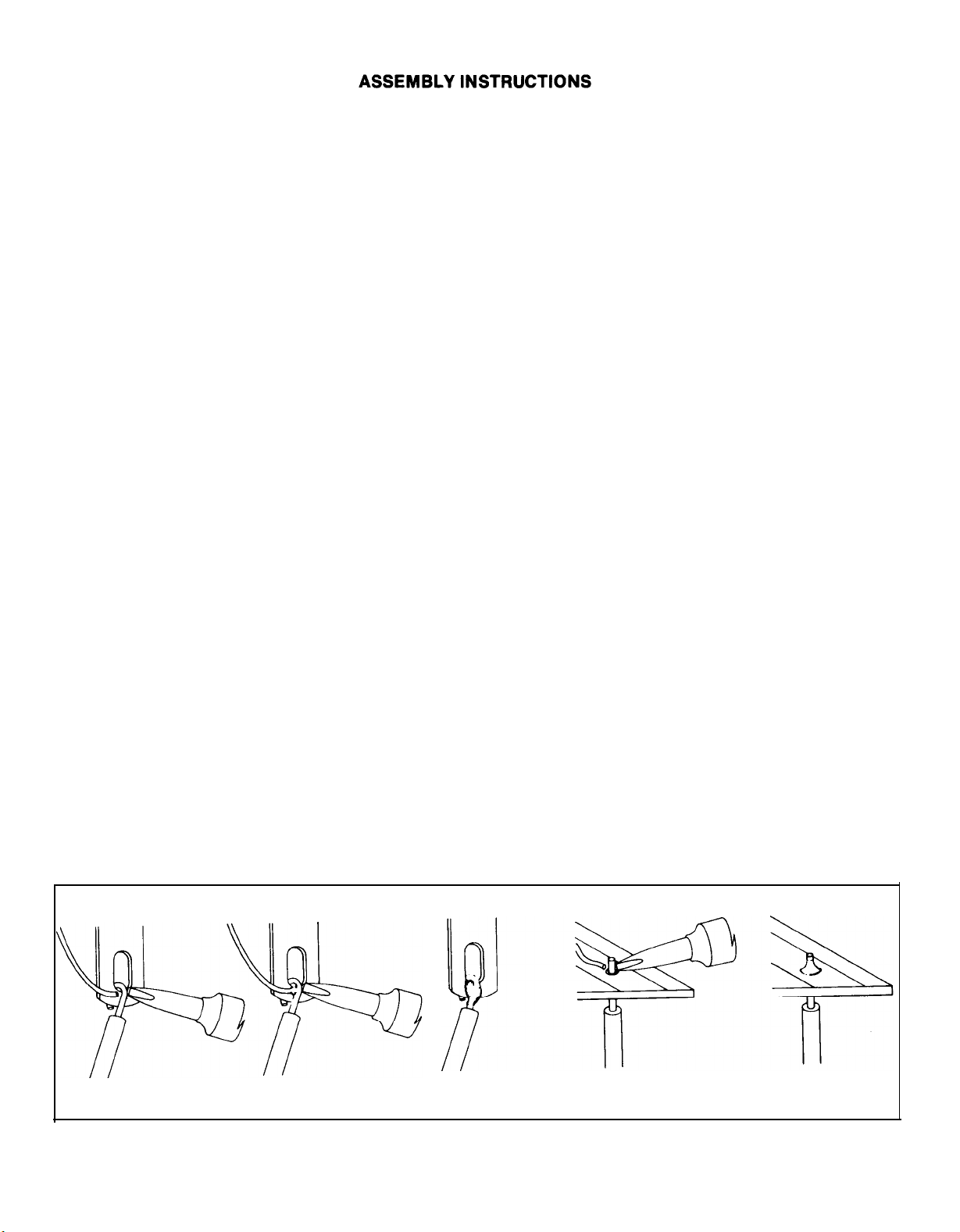

There are three basic rules for success in electronic kit

building:

1: Read the instructions carefully, and follow them in or-

der.

2. Make secure solder connections which are bright and

smooth.

3. Check your work carefully after each step.

The DH-110 preamplifier is a versatile component with

sophisticated circuitry which has been made remarkably

easy to build by individuals with many years of experience

in the design and engineering of the finest performing

audio kits, and in the preparation of their manuals.

Kit building should be fun, and we am certain you will

find this to be so. Fatigue increases the risk of error, so

take a break rather than push to early completion. There

are relatively few separate components in this design, to

make it easy to pack everything away, if need be.

Your work area should have good lighting and the proper

tools. The tools should include:

1.

A 40 to 60 watt pencil soldering iron with a 3/16" or smaller tip which reaches

2.

60/40

(60% tin) ROSIN CORE solder, l/16” diameter or

smaller.

3. A damp sponge or cloth to wipe the hot tip of the iron.

4. A wire stripping tool for removing insulation. This can

be a single-edge razor blade, but inexpensive stripping

tools are safer, faster and easier.

5. A medium-blade screwdriver (about l/4” wide).

6. Needle-nose pliers (a long, narrow tip).

7. Diagonal or side-cutting small pliers.

8. Large “gas” or “slip-joint” pliers.

9. A

l/4”

“Spin-tite” nut driver may be helpful, but is not

necessary.

A soldering “gun” is not recommended. The unfamiliar

user is more likely to damage the etched circuit boards

with its higher heat potential and unbalanced weight. Also,

700°F

because he may not wait long enough for it to reach operat-

ing temperature each time it is switched on, poor solder

connections are

and easier to use, and there is no waiting time when solder

connections follow in sequence, as in kit building. Make

sure

you have a holder for it, though, and always unplug it

when you take a break.

Proper Soldering

There are four steps to make a good solder connection:

1.

Make a good mechanical connection to hold the wire in

position while heat and solder is applied.

2.

Heat the junction of the wire and lug, or eyelet, with the

bright, shiny tip of the iron.

3. After heating for a couple of seconds, apply solder to

the junction. It should melt immediately and flow

smoothly around both surfaces.

4. Allow the connection to cool undisturbed.

Remember that the connection is made by the solder,

not by mechanically attaching the wire to the terminal.

Usually the wire is looped through the lug and crimped in

place, but some prefer to just place it through the hole and

rely on the stiffness of the wire to hold it while soldering.

Eyelet connections, of course, are handled this way.

Good solder connections are essential for trouble-free,

noise-free operation. A good solder joint does not require

much solder around the conductors. Never “butter” partially melted solder on the joint, as it is useless. A good

connection looks smooth and bright because the solder

flows into every crevice when the parts am hot enough.

The iron must have a bright, shiny tip to transfer heat eas-

ily to the junction. That’s why the damp sponge should be

used frequently to wipe the tip, and occasionally you must

add a small amount of solder to the tip, too. If a connection

is difficult to heat, “wet” the tip with a small blob of solder

to provide a bigger contact surface to the joint. Once the

solder flows around the conductors, any movement must

be avoided for a few seconds to allow a good bond. When

cool, check the connection by wiggling the wire. If in

doubt, or if the connection is not shiny, m-heat the joint.

more

likely. Pencil irons

are

much lighter

Page 8

Excess solder may be removed from a connection by heating it and allowing the solder to flow onto the iron, which is

then wiped on the sponge.

pictorial diagram should quickly identify them. Or, the

quantities, and the process of elimination as you check the

ALL SOLDER USED MUST BE ROSIN CORE

Never use acid core solder or any separate flux in elec-

tronic work. Silver solder is also not suitable. If in doubt

about unmarked solder, always obtain a fresh supply of

parts list, will help. The pictorial diagram is necessarily

distorted to some extent for clarity, so that you can trace

every wire in a single overall view for verification as you

work.

rosin core solder. We recommend 60/40 for easiest use. Do

not confuse it with

40/60,

which is harder to melt.

from the length of that color, and strip about

The general procedure is to use a hot iron for a short time

to heat a connection, then add solder with the iron still in

contact. Remove the solderonce it flows, and then remove

the iron. A cooler iron applied for a longer time is more

likely to damage components, or lift the copper circuit pattern from the boards. A break in the etched circuit can be

mended by simply soldering a small piece of wire across it.

Do not allow much build-up of solder on the tip of the iron,

tion from each end. The wire supplied in the kit is

#22, so you can set adjustable wire-strippers accordingly.

The transformer leads are

careful that you do not nick the wire when you strip it (that

can happen more easily if you do not use wire strippers) for

that weakens it. The wire supplied in this kit is “bonded

stranded,” which provides exceptional flexibility with re-

sistance to breakage for easier use.

or it may fall onto adjacent circuitry and cause a short circuit.

tions will so state, or indicate by the symbol (S). If more

When soldering to an eyelet or hole on the board, insert

the wire from the components side, and apply the iron to

the bottom, leaving some bare wire exposed so that you

can see that the eyelet is then filled with solder for a secure

bond. A round wooden toothpick is suggested so that you

can heat and clear an eyelet of solder if it hinders your in-

serting the wire. Some builders prefer to clear every eyelet

first with a touch of the iron and toothpick. Others connect

than one wire is to be soldered to the same point, they will

be indicated by (S-2), (S-3), etc. If soldering is not called

for, other connections have yet to be made to that terminal. They would be more difficult if the connection was already soldered. Every connection in the kit will be soldered when it is complete. After soldering a connection, it

is best to clip off any excess lead length to minimize the

possibility of a short circuit, and for neatness.

the lead by bringing it up to the center of the eyelet on top

of the board, applying the iron from the bottom of the

board, and pushing the lead in as the solder in the eyelet

terminals or the chassis metalwork.

melts. If the wire has first been “tinned,” usually no additional solder is necessary, but it is a good practice to push

the wire through, and then back it up a bit, to be sure solder

fills the eyelet. On the bottom of the board, make certain a

bright, shiny flow is evident from the wire onto the circuit

pattern on the board.

wires together, the length of wire indicated anticipates a

fairly tight, uniform twist by hand, of three full turns every

two inches. If you find the wires too short, loosening the

twist will gain some needed length.

Wiring the Kit

If any components are unfamiliar to you, checking the

To “prepare” a wire means to cut the designated length

l/4”

of insula-

#18

and

#18,

and the line cord is

#16.

Be

Whenever a connection is to be soldered, the instruc-

Be sure that uninsulated wires cannot touch adjacent

When the instructions call for twisting two or three

“Tinning” refers to the process of applying a light coat-

ing of solder to the bared wire end. This keeps all the

strands secured, and also makes a good connection easier.

Simply touch the wire with the iron for a couple seconds,

and apply solder. Allow the excess to flow away onto the

iron. When properly done, the wire is uniformly bright,

and no larger than before. The hookup wire supplied with

this kit does not normally need tinning, for it is pre-tinned.

Take the time to be accurate and neat, and you can be

sure that your completed preamplifier will meet the performance of a factory assembled unit, and can continue to

perform properly for years to come. Check your work, and

make sure the entire step has been completed before placing a check mark in the space provided, and continuing on

to the next step.

Page 9

BUILDING THE KIT

Partial mechanical assembly of the kit provides protec-

6 0 Select the power switch and two #4 screws. Install

tion for major components during shipment. Most of the

hardware thus used is included in the quantities listed in

the parts list. The exception is that used to install the rear

mounting bracket on the PC-14, as this is considered an integral assembly. Only the two screws securing the bracket

7

to the side pieces need be removed, along with the

hardware securing the front sub-panel. Dismount the

power transformer and remove the side pieces.

A “set” of hardware includes a screw and a KEP nut

with attached lockwasher. Always install the lockwasher

side first. Screws

are

always inserted from the outside of

the chassis unless otherwise specified. #4 hardware is

smaller in diameter than #6. To separate #4 nuts from the

#6s,

use a long #4 screw to test.

We suggest you check off the parts as you unpack the

kit, and separate them in an egg carton for convenience.

0

The flanges of the front sub-panel bend towards the

1

8

inside of the preamp. Select the U-shaped head-

phone jack mounting bracket and 2 sets of

#4

hardware. Install the mounting bracket on the out-

side of the front panel, in front of the rectangular

hole in the lower right comer.

2

0 Select

Install it through the front panel with the single lug at

the bottom. The washer goes outside the bracket,

secured by the nut.

3

0

Prepare a 2” black wire. Connect one end to the

lower forward lug of the headphone jack.

the headphone jack, its washer and nut.

(S).

Place

The front of the board marks the component locations, and “J”

designations. Most components mount on

install them tight against the board, and solder each lead on the

back (circuit) side. Then cut off all excess leads.

9 0 Select the two 22,100 ohm resistors (red, red,

this wire through the panel.

4 0 Prepare a 14½” green wire, but strip

from one end. Prepare a 14½” red wire. Prepare a 14½”

black wire. Start with the red wire ¼” longer than the

longer bare end of the green wire, and the black wire ½”

shorter than the green wire. Twist these 3 wires together

uniformly throughout their length. Make about 3 com-

plete twists every two inches. On the rear of the phone

jack 8 numbered positions identify the 6 lugs in a counterclockwise rotation, with the #2 lug at the bottom (in line

3/8”

of insulation

10

11

12

with the front lug), and the #6 lug at the top. Insert the

longer bared end of the green wire through the #8 lug and

connect it to lug #7. Solder both lugs. Connect the red

wire to lug #6. (S).

5 @ Prepare another 14%” green wire with 3/8”

one end. Prepare one end of a

strip the other end. Prepare another

with the longer green wire end

14½”

¼”

longer than the red

wire, and the bare end of the black wire ½” shorter than

the red wire.

longer end of the green wire through lug #3 of the phone

jack and connect it to lug #4. Solder both lugs. Connect

the red wire to lug #2. (S).

Twist these together as before. Insert the

stripped from

black wire. Do not

14½”

red wire. Start

13

the switch above the headphone jack so that the

body of the switch is offset to the outer edge of the

panel.

0

Select the main PC-14 circuit board assembly, with

the fuse in place, and the rear bracket installed, and

a rubber grommet in the bracket. Select the 6 larger

nuts and washers for securing the controls to the

front sub-panel. The two largest sets are used for the

selector switches; the volume control is the smallest

size, next to the power switch; the 3 other sets go on

the 3 central control shafts. Be sure all the locating

lugs on the controls engage the holes in the panel before securing the hardware. The wires from the

phone jack go under the board. Push the ends of the

wires through the grommet.

0

Select the small circuit board assembly PC-13 and

two #4 screws. With the circuit board uppermost,

position the assembly at the top of the large front

panel opening so that the sockets on the board align

with the pins from below, and plug the board downward onto the pins. Make sure each pin is properly

engaged. Secure the assembly with screws through

the panel.

Set the front panel aside, and select the PC-12 circuit board.

the front. Always

brown, red) and install them at locations R50 and

R150.

0

Select the two 1,100 ohm resistors (brown, brown,

black, brown) and install them at R21 and R121.

0

Install the four 1 megohm resistors (brown, black,

black, yellow) at locations R22, R23, R122 and

R123.

0

Select the two 4-pin molded sockets. These are to be

installed at locations J26 and 5126 on the front of the

board, with the pins through the upper row of holes

(arrow) at each location. The lower row of holes

provides access from the rear of the board for plug-in

capacitors. lb assure correct alignment of the socket, insert a capacitor lead from the rear into holes E,

F, G and H to engage the sockets while you solder

the pins, and then remove the capacitors. Be sure

solder flows freely around each mounting pin for a

good connection. Sometimes these pins do not accept solder easily.

0

The proper way to install the 24 phono input sockets

is to first insert a phono plug (on the end of one of the

audio connecting cables supplied in the kit) so that

the center contact will not be deformed in the

mounting process. Adjacent to the center hole for

9

Page 10

each socket, the board is marked to indicate the side of

the hole on which the center mounting tab should be

positioned, so that it will be soldered to the widest part of

the circuitry on the back side. Leave the phono plug in the

socket while bending and soldering is completed. If you

do not bend the center tab quite flat against the board, it is

easier for solder to flow under the tab for a good connec-

tion. Solder both outer socket lugs first (they need not be

bent over), and then the center tab on each socket. At J9

be careful that a solder bridge is not made between the

center contact and the adjacent circuit track. Be sure

holes Q and S are not filled with solder when installing

sockets J

them open.

0

Select the two right angle

14

11

and J 1 1 1. A wooden toothpick will keep

15-pin

plugs, and install

their shorter pins at locations J22 and J24 at the top

of the board, so that the bent pins point toward the

upper edge. Be sure these sockets are tight against

the board, and make certain that every pin connection is properly soldered. Examine each connection

closely to make sure there are no solder bridges

between the tracks.

15 0

Prepare a 1” piece of green wire, and form it into a ½”

wide “U”. This wire connects on the back of the

board between holes A and B. Allow this wire to sit a

bit above the board, as it is a jumper which you may

wish to remove at some future date, if you install a

pre-preamplifier for a moving coil cartridge. After

soldering be sure you cut off any excess wire on the

front, so it cannot short to the input socket.

Then grip the larger portion of the strain relief with

the tips of the pliers, squeeze it tightly, and insert the

end of the cord and the strain relief through the panel

hole from the outside. Note that the hole has a flat on

one side, and the strain relief is installed so that the

cord is horizontal.

This is the most difficult step in the kit. Patience, and

a friend’s help, if available, will make this job easier.

Safety requirements dictate that this be a tight fit.

Some persons might find it helpful to bolt on a side

piece (with the flanges out) to add rigidity to the

back panel, as well as a support to press against the

back panel while you squeeze the strain relief and

pull the line cord through. The fixture snaps into pos-

ition when it is

fully

inserted. Remove the side piece

if you attached it.

20

0

Select the power transformer and 2 sets of #6

hardware. Install the transformer next to the line

cord so that the leads are in the lower comer below

the strain relief.

0

Select the 4 AC sockets. Snap these into the back

21

panel holes from the outside.

22

0

Select the PC-12 circuit board assembly and the 2 flat

cable interconnecting assemblies. Plug one end of

each cable onto the pin connectors at the top of the

board so the cables extend past the back of the

board. The marked edge of the cable is not significant. Now check socket J1 to make sure it does not

contact the stub of wire at hole A.

16

0

Prepare a 1” piece of red wire, and form it into a

“U”

as before. Connect it in like manner to holes C and D

on the back of the board.

17 0 Select the two 10,000 pF capacitors and install them

on the front of the board at locations C1 and C101.

18

0

Select the 2 long bright screws, the 2 lockwashers,

and two of the spacers. Place a lockwasher over

each screw first, and insert the screw from the back

(circuit side) of the board into one of the mounting

holes next to the rear jumpers. Add a spacer on the

components side, and tighten it. Set the completed

board assembly aside.

19

0

Select the back panel, the AC line cord, and the plas-

tic strain relief. Separate the two conductors at the

end of the cord for 2”. Cut 3/4" off of one conductor.

Strip both ends the usual ¼", and tin the strands to

secure

them. Six inches from the longer end make a

sharp V in the cord by bending it back on itself.

Install the strain relief as shown in the drawing. The

small end of the strain relief is nearest the stripped

ends. Crimp the two halves of the strain relief

together around the cord with heavy pliers to partially form it before insertion into the back panel.

10

Page 11

23 [7 Select the 6 black 5/8" screws, the 6 spacers, and 6

small nuts. Insert the screws from the outside of the

back panel at the locations nearer the center of the

panel (not in the end holes marked “Grounds”).

Install a spacer on each screw and tighten them.

Place the PC-12 assembly in position

screws pass through the end holes. Install the nuts

on the black screws, and tighten them.

24 0

Select the 2 small nuts and the 2 knurled thumb nuts.

Install a nut on each of the Ground screws, making

sure the lockwasher surface is tight against the

panel. It must cut through the painted surface to

make a chassis ground connection . Then add the

thumb nuts.

25

0

With a pair of pliers, carefully twist the 8 lugs on the

AC outlets counter-clockwise l/6 turn, or about

This will enable a wire to be passed horizontally

through these lugs.

26

0

Cut a

through lug #2 of AC outlet B and connect it to lug

#l and to lug #3. Solder lugs 1 and 2.

27

0

Cut a 3%” length of bare wire. Slide it through AC

outlet lugs #6 and #7, and connect it to lug #5 and to

lug #8. Solder lugs 5,6 and 7.

28

0

Prepare a 13” length of white wire. Connect one end

to AC outlet C, lug

top of the transformer.

2¼”

piece of the bare buss wire. Slide it

#3.

(S-2). Place this wire over the

so that its two

60º.

34

0

Plug the two flat wire assemblies onto the pin con-

nectors on PC-14.

35 IJ Prepare a 1%” piece of white wire. Connect one end

to the rear lug of the power switch. (S). Connect the

other end to eyelet Y of PC-14, nearest the fuse. (S).

All eyelet connections should be soldered on the

bottom of the board for secure connections.

36

q

Select the white wire from the tear grommet. Con-

nect it to eyelet W on PC-14. (S).

37 0 Select the blue wire

the side lug of the power switch. (S).

38 0 Select the yellow wire. Connect it to eyelet T on

PC-14. (S).

The transformer leads may be shortened as desired for

neatness, but if there is any possibility that the transformer

may be connected for a different line voltage for use outside the USA, be sure to leave each lead long enough for

any alternative connection. We suggest that these leads be

made just long enough that they can be twisted together for

neatness, and placed outside the end piece where they can

be later secured with a wire tie.

39

0

Connect the Red-Yellow lead to eyelet A in the tear

comer of PC-14. (S).

40 0 Connect the two Red leads to eyelets B and C along

the rear edge of the board. Solder both.

from

the grommet. Connect it to

29 0 Prepare a 13” blue wire. Connect one end to outlet D

lug #4. Place this and the following wire over the

transformer.

30 0 Prepare a

end to outlet D lug #8.

31

0

Select the two side pieces, the rubber grommet, and

4 sets of #6 hardware. Install the grommet in the side

piece location adjacent to the power transformer

when the flanges bend towards the outside of the

unit. Before bolting this piece in position, pass the

line cord through the grommet from the outside, and

under the transformer. From the inside thread the 3

wires which come from the AC outlets and over the

top of the transformer out through the grommet.

Fasten both side pieces to the back panel.

32

0

Connect the shorter line cord conductor to outlet D

lug #8. (S-3). Connect the other conductor to lug

#4.

(S-2).

33 0 Join the front and rear halves of the preamp so that

the tabs on the main board rear bracket ate outside

the side pieces. Select 2 sheet metal screws and fasten the bracket tabs to the side pieces.

12½”

length of yellow wire. Connect one

For 120 volt wiring as in the USA, the following lead connections are to be used. Refer to the alternative line voltage diagrams in the manual for other line voltages.

41

0

Connect each lead as follows and solder:

Brown/White to eyelet D

Black/White to eyelet E

Brown/Red to eyelet F

Black/Red to eyelet M

Brown to eyelet R

Black to eyelet

42 0 Connect the short black wire from the forward lug of

the phone jack to eyelet G2. (S).

43

0

There are two groups of wires connected to the

phone jack under PC-14. The red and green wires

which connect to lugs 2 and 3 (these ate the lower

lugs, adjacent to the circuit board edge) are to be

connected to the upper (left channel) holes P and Q

on the back panel circuit board PC-12, adjacent to

the line outputs. Make certain you have the correct

group. The black

Instead, keep it twisted with the other wires until it

is close to the board, then wrapped tightly around

the red and green pair. Make

trudes from the black insulation. Connect the red

S

wire

is not connected to the board.

sure

no bare

wine

pro-

11

Page 12

IGHT

PHONO LEFT

PHON’

0

@

RIGHT

nn

i

1.6

02

13

03

IN

,

1 I

I! ot60” 04

r-

I

15-1

PHONO

SlA R

SELECTOR MONITOR TONE

I I

1 1

_EPL

M

t+

K

s3

FLAT

D13 D14

ROUND

15T1

I’

Page 13

HT

LINE-

-

LEFT LINE

-

No

n

E

-r

QlizJ

141-

aa

“;T

0109

0

0107

(J Q-&xo

I 1

-

-R44-

--R144-

--R45-

T c21 -

@oE

012

co “0 “0

Fl

v

0

I

E

011

0

Cl9

I

v

--R66-

-R65-

1

-R62-

-D7k

llll

8 6 g 3

K(TUK

III1

,-

-D5k

-Ml-

+D6-

c34

0

h

I

iD12-

--R59-

-R64-

C36

0

8

Ic38)

--R57-

C32

0

VOLUME

L

R

1

--R56-

527

(0

Do

EO

‘0

“6

R26

Page 14

wire to hole Q, which is between the center lugs of

Jll and 512. (S). The wire should not protrude significantly beyond the front surface of the board to

avoid coming in contact with a connector. To assure

a good solder connection, bare wire should be visible on the circuit side of the board.

Connect the

green wire to hole P in like manner. (S).

44

0

At the rear of the phone jack, connect the black wire

from the first group (lugs 2 and 3) to PC14 eyelet G3.

(S).

[7 Select the other group of three wires, and connect the

45

black wire to PC- 12 hole T. (S). Connect the red wire to

hole S between Jl 11 and J112. (S). Connect the green

wire

to hole R. (S). Make sure the wires do not protrude

significantly beyond the outside surface of the board.

0

Connect the black wire of the second group to PC14

46

eyelet G1. (S).

47

13 Select the 2 red LEDs. To install these with correct

polarity, observe the tiny ‘flat’ on the LED flange which

marks the cathode lead. This must he towards the near

end of the PC- 14 board, or Phono switch S 1, when the

LED is attached to the front, near the edge. When the

nipple of the LED is pointed toward you, with the flat on

the left, bend the leads (together, with long-nosed pliers)

upward at a right angle, so the bend will be 7/10” from the

back surface of the LED (about ¾”). Solder the LEDs to

the front holes on the under side of PC-14 with the bent

portion of the leads emerging on the top side. Each LED

protrudes through the front sub-panel hole. Solder both

leads on each LED.

48 0 Cut two ½” lengths of the black plastic shrink tubing.

Slide a piece of tubing over each LED from the front, so

only the nipple of the LED protrudes. Shrink the tubing

around the LED body by holding a lighted match near the

tubing. This will prevent back light from reflecting on the

sub-panel.

cap into the slots of the front panel. Select the 4 cap

screws and nuts, and secure the end caps with the

large Allen wrench.

53

0

Install the appropriate loading capacitors at the pairs

of holes identified E, F, G and H below the phono

input sockets on the back panel board. The correct

choice is discussed in the Additional Information

section of this manual. In lieu of more specific information, we suggest the 120 pF values at E and G

for Phono 1, and the 220 pF values at F and H for

Phono 2. Bend one lead around the capacitor so it is

parallel with the lead at the opposite end. The leads

should extend more than 1%” from the body, but must

not be longer than

%“, or they might touch the metal

back panel. Plug each into adjacent pairs of holes.

Now check to make sure that there are no strands of power

transformer leads, or the line cord, that are unsoldered. Where

the line cord passes under the transformer, make sure it is

clear of the screw hole in the back panel flange.

1/10

ampere

that the Red/Yellow transformer lead connects to the corner

eyelet A.

(lOOmA)

fuse is installed in the PC-14 clips, and

Check that a

54 q A wire tie can secure the transformer leads to the

side piece through the slot behind the PC-14 bracket.

These ties can be used only once, and lock securely

when the tail is pushed through the head end from

the flat side. Cut off the excess after pulling it tight.

55

0

The two groups of output leads from the phone jack

should be positioned at least 1” in from the side

piece, and straight to the rear of the PC-14 board;

then kept close to the bracket. A wire tie is

suggested at the rear comer. You may wish to use the

3rd tie on the wiring to the AC sockets, or on the

output leads near the back panel.

56

0

With 6 of the sheet metal screws, install the bottom plate.

The 2 large holes should he near the phono inputs at the

rear.

0

Select the two flat knobs, 2 set screws, and the smal-

49

ler L-shaped Allen wrench. Place a screw on the end

of the wrench and thread it into each knob. Install

these knobs on the switch shafts above the LEDs.

The set screw should engage the flat on each shaft.

50

0

In like fashion install the remaining set screws in the

4 round knobs, and fix them to the flatted shafts on

the other controls.

5 I

0

Taking care not to use excessive force, install the 6

black pushbuttons on the switches.

I Select a pair of end caps-either the standard ones,

52

c

or those for rack mounting-and the black front

panel extrusion. Place the front panel in position,

taking care to insert the LEDs into their holes, and

check for sufficient clearance around each knob. It

is possible to shift the phone jack bracket slightly, or

the mounting of an individual control (by resolder-

ing) if necessary for correct alignment. Slip each end

57

0

Place the 4 rubber feet in the corners of the bottom

plate. They are self adhesive when you remove the

paper backing.

58 0 Slide one piece of the U-shaped long plastic grommet

onto the top flange of the front sub-panel. The other piece

goes on the top flange of the back panel.

59

0

Check to make sure that the flat ribbon cable as-

semblies are up close to the top of the unit, away

from the circuit board, and slide the cover on from

the tear. Secure it with the 4 sheet metal screws.

60

17 Affix the self adhesive serial number label to the

center rear of the bottom.

You may wish to secure the smaller Allen wrench for the

knobs to the bottom of the unit with tape.

Page 15

IF A PROBLEM ARISES

If neither LED lights when you first turn on the power

switch, turn the unit off immediately. Check the fuse.

Check the polarity of the LEDs. Check the power

transformer wiring for proper connections for your line

voltage. Look for a short caused by a stray strand of wire,

or for a solder splash on the circuit board. A print of the

circuit pattern in this manual enables you to check out a

doubtful connection which might include a solder bridge.

If there is no audio output, is the monitor switch OFF? Is

the EPL switch OUT? Is the wiring of the phone jack correct? Are the plugs seated properly on the flat ribbon

cables-not offset by one pin? Is the Phono pushbutton

switch in the correct position? Check the PC-12 for a solder

splash between the circuit paths. A sharp knife can correct

that.

AC LINE CONNECTIONS FOR OVERSEAS USE

The power transformer supplied with the DH-110 has

dual tapped primary windings. By arranging these two

windings in various series-parallel combinations, line voltages of

accommodated.

100,120,200,220

and 240 volt 50/60 Hz lines can be

If there is noticeable hum; turn off the unit and reverse

the line cord. Make

power amplifier (or that the turntable is not too close,

either). Check for a defective connecting cable, or turntable ground wire. Inside the preamp, the screws for the

thumb nut ground connections must be tight, both to the

PC-12 board, where the lockwasher under the screw head

contacts the circuit ground, and to the back panel, where

the lockwasher must break through the paint to the metal.

Also, the PC-14 rear bracket mounting screw near the

power transformer must be tight for a good ground con-

tact.

A spare 1/10 ampere slo-blo fuse is supplied with the kit.

A larger value fuse will not provide protection in the event

of a fault. If the replacement fuse blows, the unit should be

returned to the factory for competent service.

sure

the preamp is not too close to the

The diagrams below show the connections for altematives to the 120 volt connections shown on the pictorial

diagram. When connected for 200-240 volt lines, the line

fuse should be changed to

l/16

ampere (60 mA) slo-blo.

IOOVIOOV

Jo

KO

--//---K/W

ma

240V

d

BLACK

15

Page 16

ADDITIONAL INFORMATION

RACK MOUNT END CAP INSTALLATION

Every DH-110 is supplied with front panel accessory end

caps which adapt it to a standard 19” rack panel, and with a

5/32”

Allen wrench which fits the mounting screws.

Remove all power and signal connections from the DH-

110. On a protected surface such as a towel, remove the

two cover screws on each side of the bottom, and slide the

cover back. Remove the screws in each corner of the front

panel. Exchange the end caps-they slide outward. If you

are careful, you will not dislodge the LEDs

from

the panel.

Replace the cap screws and nuts only finger tight at first.

Check the alignment of the panel around the knobs before

tightening fully. Then replace and secure the cover.

PHONO CARTRIDGE CAPACITOR LOADING

The cartridge manufacturer usually specifies in their

instructions the optimum ‘load’ or termination for the cartridge. The needed capacitance is expressed in picofarads

(pF).

The DH-110 is supplied with pairs of two values of

capacitors plugged into the sockets behind the rear circuit

board at the Phono inputs (one for each channel). One of

these values is likely to accommodate the majority of

available cartridges with most high quality connecting cables within the accepted tolerance of

±5OpF

If no informa-

tion is available, we suggest first trying the 120pF which is

installed in the Phono 1 input.

If you require new capacitors, we suggest that you

purchase, if possible, either polypropylene or polystyrene

types. These premium grades have been selected for all

critical circuits in the DH-110 because of their superior

audio performance. Their leads should be formed like

those presently installed, and they must extend at least

but not more than

3/8”

beyond the capacitor body to avoid

¼",

a short circuit to the back panel.

Some fastidious users prefer to solder the compensation

capacitors in place once a final value has been determined,

to preclude any less-than-perfect socket contact as time

passes.

PHONO CARTRIDGE RESISTIVE LOADING

As supplied, the phono load resistance of the DH-110 is

46.55K ohms, which is accurate loading for most car-

tridges. This value may be changed if need be, by replacing

Rl and

RlOl

on the main circuit board. See the board dia-

gram in the center of the manual.

The input resistance is determined by the parallel com-

bination of Rl (101) and R2

(201),

each of which is

93.1K

ohms (white, orange, brown, red). A different value of Rl

(101) will change the desired load to the value RT in accordance with the formula:

The total capacitive load is the sum of three numbers:

Turntable cable capacitance (from its manufacturer)

+ Preamp input capacitance (DH-110 = 30 pF)

+ Compensation capacitor (value you desire)

= The specified load (from the cartridge manufacturer)

You need to know the cable capacitance, from either the

turntable maker, or the cable supplier, if they are separate.

Unfortunately, this is not always readily available, and it

can vary widely, but lower capacitance cables invariably

are more expensive. If you must guess, use 60pF per foot.

If your turntable accepts plug-in cables, you can usually

overlook its internal wiring capacitance, as it will likely be

within the 50pF tolerance. Short cables are desirable

because total cable capacitance can itself be higher than

the total specified load. The lowest you can go in compensation is to leave that capacitor out. It is why a good

preamp design has a low input capacitance.

As an example: Recommended cartridge load= 320 pF

The turntable has a three foot cable, and

they say it is 60pF/foot. Subtract 3

So far we still need

Subtract the DH-110 input capacitance

Compensation capacitor required

X

60 = -180

= -30

=110 pF

140

pF

-93.1

Rl =

1

-

93.1/RT

To simplify, the following standard 1% values of Rl will

provide desired loads

RT

as shown (all in Kohms):

Rl Value Kohms Desired Load Kohms

11.3 10

17.8

24.9

34.8

44.2

56.2 35

15

20

25

30

Metal film type resistors are recommended for lowest

noise.

This is close enough to the 120pF supplied that Phono 1 can

be used without change.

16

Page 17

MINIMIZING NOISE IN THE SYSTEM

Your choice of separate components is the right way to

secure the best performance from a music system, but the

wide-band

characteristics

and complexity of the best systems may also not conceal the introduction of ground

loops and noise pickup-especially

RFI

(radio frequency

interference). With exceedingly high quality equipment we

may become conscious of distractions that would be ignored on a lesser level. Careful interwiring practice will

greatly reduce the likelihood of such problems.

The DH-110 is a very quiet preformer. There can be occasions where even the finest equipment exhibits hum or

noise due to irregularities in its interconnection. The simple expedient of reversing line cord plugs will often reduce

hum. Listen to the hum level after each change, reversing

only one cord at a time.

CAUTION: Do not indiscriminately disconnect and

reconnect a power amplifier when other components

are

turned ON. Use the DH-110 muting circuit for protection

against loud noises. With the power amp connected to a

switched convenience outlet on the DH-110, turn the

preamp OFF, reverse the amplifier line cord, and then turn

the preamp ON.

Use connecting cables of high quality, and treat them

with care. Unplug cables by grasping the connector-not

the cord-to maintain good connections. We have no evidence that special connector platings are required, but the

surfaces should be

free

from grease, fingerprints, or any

contaminate that may prevent a firm and complete connection. Some audiophiles are convinced that a good contact

cleaner is an important adjunct to a high quality music system.

It does not usually reduce noise to connect each component to an ‘earth’ ground. This may even aggravate a

ground loop problem, for good ‘earth’ grounds are hard to

find, and unsatisfactory grounds are likely carriers of RFI.

The previous suggestions may also help reduce RFI. In

difficult cases,

RFI

filters can be purchased for insertion

between the line cord plug and the wall outlet, or a device

called a ferrite bead may be installed in the phono stage by

a competent technician. If you use a pre-preamplifier and

find that it is

RF1

sensitive, increasing the cartridge compensation capacitor may help (moving coil cartridges do

not require a specific value), or try connecting a 0.01 mfd

capacitor across the phono input jack that feeds the

preamplifier. Even for experienced engineers,

sents problems which often demand that they simply

RFI

pre-

pre-

‘try

and try again’.

17

Page 18

Tape 2

law

1

CD/Video

TONE

FILTER

PHONO

Phono 1

Phono 2

1

C

2

C

R

B

Tuner

Record Out

EPL Send

Roturn

EPL

FUNCTIONAL BLOCK DIAGRAM

EPL

0 0

1

SAL

VOL

v v,

To Right

Channel

Treble Bass

LINE

OUTPUTI

r-K

Switched

E

Direct

18

Page 19

COMPONENT VALUES

COMPONENT VALUES

All resistors are

RI

R2

R3

R4

R.5

R6

R7

R8

R9

RIO

RI1

RI2

RI3

RI4

Rl5

R16

RI7

RI8

RI9

R20

R2l

R22

R23

R24

R25

R26

R27

E

R30

R3l

R32

R33

R34

R35

R36

R37

R38

R39

R40

R41

R42

R43

R44

R45

R46

R47

R48

R49

R50

R5l

R52

R53

R54

R55

R56

E8’

R59

R60

R6l

R62

R63

R64

R65

ii:

R68

R69

::

s3

s4

S5

s6

147.000 ohms

147,000

147,800 ohms

100,000 ohms linear taper

147.000 ohms

4XWOOohms, ¼ w.

470,OW

680,000 ohms, ¼ w, 5% carbon

Phono Input Selector, DPDT

Source Selector

Monitor Sckctor

EPL switch, 4PDT

Mono switch, 4PDT (assembly)

Tone

Filter switch, 4PDT (assembly)

Power switch

1/4

watt I% Metal Film unless otherwise noted.

93,lOOohms

93,1OO ohms

1,100

ohms

22,100 ohms

22,100 ohms

ohms

22,100 ohms

22,100

ohms

47,500 ohms

47,500 ohms

100

ohms, 1/2 w, 5% carbon film

100

ohms,

1/2 w,

11,000 ohms

301 ohms

100

ohms

II,000

ohms

499

ohms

I megohm

1,100

ohms

1

megohm

I

megohm

1,100

ohms

potentiometer (Balance)

50,000 ohms log taper

potentiometer (Volume)

17,400 ohms

17,400 ohms

82,500 ohms

82,500 ohms

47,500 ohms

47,500 ohms

100

ohms,

100

ohms,

316 ohms

100

ohms

ll,O00 ohms

100,000 ohms

potentiometer (Treble)

4990hms

1,100 ohms

11,000 0hms

100,000 ohms inverse log taper

potentiometer (bass)

316

ohms

1.100 Ohms

11,000ohms

11,000 ohms

1,lOOohms

I

megohm

22,100 ohms

270

ohms, ¼ w, 5% carbon film

1,800 ohms, ¼ w. 5% carbon film

270 ohms, ¼ w, 5% carbon film

1,800 ohms, ¼ w. 5% carbon film

4,708 ohms,

Ohms, ¼ w. 5% carbon film

39,OoOohms, ¼

10,000 ohms, ¼ w, 5% carbon film

2.2

megOhms, ¼ w,

27Oohms. ¼ w,

100,000

ohms, ¼ w, 5% carbon film

47,008 ohms, ¼ w. 5% carbon film

10,000

ohms. ¼ w. 5% carbon film

1,800

ohms; ¼ w; 5% carbon film

1,000 Ohms, ¼ w, 5% carbon film

1,000 ohms, ¼ w, 5% carbon film

4,640 ohms, ¼ w, 5% metal film

switch, 4PDT

5% carbon film

1/2

w, 5%

carbon film

1/2

w, 5% carbon film

inverse

log

taper

4c1 w,

5% carbon film

5% carbon film

w, 5% carbon film

5% carbon film

5% carbon film

film

RM045

RMO45

RM025

RM035

RM035

RMO43

RMO43

RM035

RM035

RMO36

RM036

RDl2l

RDl2l

RM024

RM0l4

RM0l2

RMO43

RM024

RM018

RM044

RM025

RMO44

RMO44

RM025

RPO2l

RPO29

RM043

RM027

RM027

RM046

RM046

RM036

RM036

RDl2l

RDl21

RM015

RM012

RM024

RP022

RM018

Ez

RP022

RM015

RM025

RM024

RM024

RMO25

RMO44

RM035

RCO29

RC023

RC029

RC023

RC042

RCO44

RCO44

RC038

RC0l6

RC028

RC046

RC029

RC017

RC043

RC0l6

RC023

RC015

RC0l5

RM034

SPI I2

SRl I2

SR111

SPI I3

SAI I6

SP111

SA1

16

SLll2

--

Rii channel corresponding values have designations above 100.

Cl

::

::

:5

ET0

Cl1

Cl2

Cl3

Cl4

Cl5

Cl6

Cl7

Cl8

Cl9

C20

c21

c22

C23

C24

C25

C26

C27

C28

C29

C30

C3l

C32

c33

C34

c35

CM

c37

C38

c39

C40

C4l

Dl

D2

D3

D4

D5

D6

D7

D8

D9

D10

Dll

D12

D13

D14

ICl

IC2

IC3

Fl

10 mF, polypropykne,

120 pF,

polypropylene,

220

pF,

polypropykne.

10nF

polypropylene,

22 mfd, NP ekctmlytic,

220 mfd, NP ekctmlytic,

220

mfd,

NP ekctrolytic,

I5 nF,

polycarbonate,

I5 nF,

polycarbonatc,

25 nF I%, poiypropykne,

6.8 nF, 1%. polypropylene,

1000 mfd,

NP ekctrolytic,

1.5 nF, polypropykne,

IO

nF,

polypropylene,

22 mfd, NP ekctrolytic,

470 mfd, low ESR electrolytic, 25v

470 mfd, low ESR electrolytic, 25v

470 nF, polypropylene,

68 pF, polypropylene, 50v CP144

10

nF,

polypropylene, 50v CPlll

22 mfd, NP electrolytic,

470 mfd, low ESR electrolytic, 25v

470 mfd, low ESR electrolytic, 25v

I .5

nF, polypropylene, 50v

I5

nF, polycarbonate,

47 nF, polycarbonate,

470 nF, polycarbonate,

4.7 mfd, NP ekctrolytic,

47 mfd, NP ekctrolytic.

100 nF,

polycarbonate.

1000

mfd, electrolytic,

1000

mfd, electrolytic,

22 mfd, ekctmlytic,

100 nF,

polycarbonate,

22 mfd, ekctrolytic, 50 v

100 nF.

polycarbonate,

47nF, polycarbonate,

4.7 mfd, NP ekctmlytic,

4.7 mfd, NP ekctrolytic.

22 mfd, electrolytic,

IN4003

IN4003

lN4003

IN4003

IN4003

IN4003

IN525lF

22v

IN4003

IN4003

IN525IF

22v

IN4003

IN524OB 10v

LED

LED

LM3l7T Positive Regulator

LM337T Negative Regulator

LM393 Dual Comparator

414C

Transistor

416C Transistor

416C Transistor

55OB

Transistor

556B Transistor

546B ‘Transistor

550C Transistor seketed

560C

Transistor seketed

550C Transistor seketed

560C

Transistor seketed

560B

Transistor

55OB

Transistor

56OB

Transistor

550B

Transistor

Jll2 FET

Transformer,

Fuse, 1/10A

Slo-Blo, AGC

5Ov

50v

50v CPl16

5Ov

5Ov

IOv

10v

5Ov

5Ov CC123

50v

5Ov

6v

50v

50v

50v

50v

5Ov

50v

5Ov

5Ov

25v CN118

l6v

50v

50v CL124

50v CL124

50v

50v

50v

50v

25v

25v

50v CL117

Zener, 1%

Zener, I%

Zener, 5%

Power

CP111

CPll2

CP11

CNll6

CNll2

CN112

CC123

CZ1

CZll5

CN111

CPll4

CPII

CNI

CL111

CL111

CPl18

CN116

CL111

CL111

CP1 14

CC123

CC1 14

CC115

CNll9

CC125

CL117

CC125

CL117

CC125

CC1

CNl18

CN118

QD1

QD115

QD115

QD1

QD115

QD115

QD113

QD1 I5

QDll5

QDll3

QDII5

QDlll

QD119

QDI

QBll3

QBll4

QBll6

QNll7

QPIl7

QP117

QNl18

QP124

QNl26

i$;:9’

i$l%

QPII8

QNll8

QPII8

QNII8

QNl3l

TAII8

I4

I

I6

14

15

15

19

19

Page 20

TUNER

TAPE 1

@j----o

PC12a

CABLE PIN NUMBERS

N

ISELECTOR]

”

R24

EPL SEND

DIRECT

OUTPUT

OUTPUT VIA

PHONE JACK

PHONO 1

PHONO 2

GROUND

pos1.s

PHONE

JACK

00

50 08

40

30 010 ~OOOOOOOOQOOO]

20

10

(0)“’

6

JlO

07

00

012

I

I

,T

e m-c

I

I

I

‘I I

-U+

I

Twisted

,a

I3 L

I4 I

b

1

b

I

8

7

6

. s2c

0

513

e,,

rbd

pm*”

-

_

‘R

black

123456162345

s2a