Programmable DC Power Supply

GPP-1326/GPP-2323/GPP-3323/GPP-4323

User Manual

GW INSTEK PART NO. 82PP343230ED1

ISO-9001 CERTIFIED MANUFACTURER

Copyright Statement

This manual contains proprietary information, which is protected by

copyright. All rights are reserved. No part of this manual may be

photocopied, reproduced or translated to another language without

prior written consent of Good Will company.

The information in this manual was correct at the time of printing.

However, Good Will continues to improve products and reserves the

rights to change specification, equipment, and maintenance

procedures at any time without notice.

Good Will Instrument Co., Ltd.

No. 7-1, Jhongsing Rd., Tucheng Dist., New Taipei City 236, Taiwan.

Table of Contents

Table of Contents

SAFETY INSTRUCTIONS .................................................. 6

Safety Symbols ........................................................... 6

Safety Guidelines ....................................................... 7

Power cord for the United Kingdom ......................... 10

OVERVIEW .................................................................... 11

Introduction ............................................................. 12

Key Features ............................................................ 15

Front Panel .............................................................. 17

Rear Panel................................................................ 24

Constant Voltage/Constant Current Crossover

Characteristics ......................................................... 26

GETTING STARTED ........................................................ 27

Start Up ................................................................... 28

Load Connection ...................................................... 29

Turning the Output On/Off ...................................... 31

BASIC OPERATION ........................................................ 32

Display Change ........................................................ 33

Source Function ....................................................... 36

Independent Output Mode ..................................... 41

Tracking Series and Tracking Parallel Modes ......... 42

Load Function .......................................................... 46

Sequence Function ................................................... 50

Set Sequence Output ............................................... 50

Set Group Parameter ............................................... 52

Construct Templet ................................................... 54

Menu Tree ................................................................ 57

Save and Recall ........................................................ 59

3

GPP Series User Manual

Delay Function ......................................................... 62

Set Delay Output ..................................................... 62

Set Group Parameter ............................................... 65

Menu Tree ................................................................ 68

Save and Recall ........................................................ 70

Monitor Function ..................................................... 72

Set Monitor .............................................................. 73

Recorder Function .................................................... 75

Set Recorder ............................................................. 76

Enternal I/O Control ................................................ 79

Key Function Description ........................................ 81

FILE OPERATION ........................................................... 83

Save/Recall .............................................................. 84

Restore Factory Default Settings .............................. 87

SYSTEM SETTINGS ........................................................ 88

System Information ................................................. 89

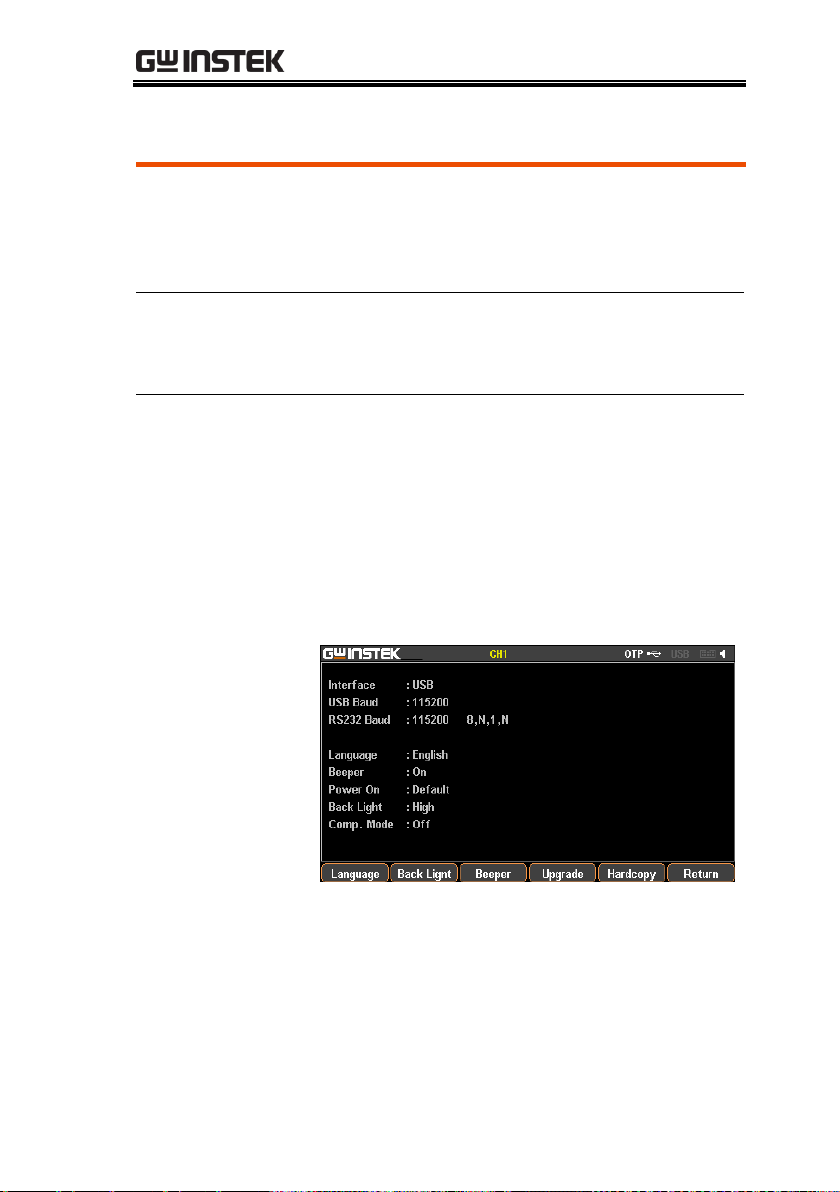

System Settings ....................................................... 90

Firmware Upgrading ................................................ 92

Description of Using Flash Drive ............................. 93

REMOTE CONTROL ....................................................... 95

Connection Usage .................................................... 97

RS-232 ...................................................................... 98

USB .......................................................................... 99

GPIB ......................................................................... 101

LAN .......................................................................... 102

Command Syntax ................................................... 108

Command List ....................................................... 112

Measurement Instructions ...................................... 112

Display Functions .................................................... 112

4

Table of Contents

Output Commands ................................................. 112

Source and Load Commands .................................. 113

Status Commands ................................................... 118

System Commands ................................................. 119

System Related Commands .................................... 120

IEEE488.2 Common Commands ............................ 120

Command Details .................................................. 121

Measurement Commands ...................................... 121

Display Commands ................................................. 123

Output Commands ................................................. 125

Source and Load Commands ............................... 129

Status Commands ................................................... 170

System Commands ................................................. 176

System Related Commands .................................... 185

SCPI Status Registers SCPI .................................... 186

Event Registers ........................................................ 188

Enable Registers ...................................................... 188

Status Byte Register ................................................. 188

Standard Event Register .......................................... 190

Status Byte Register Commands............................. 191

Standard Event Register Commands ...................... 192

Other Status Register Commands .......................... 194

Errors ..................................................................... 195

Error Message .......................................................... 195

Command Errors ..................................................... 195

APPENDIX .................................................................... 199

Replacing the Fuse ................................................. 199

Specifications ........................................................ 200

Optional Accessories ............................................. 203

Declaration of Conformity ...................................... 204

5

GPP Series User Manual

WARNING

Warning: Identifies conditions or practices that

could result in injury or loss of life.

CAUTION

Caution: Identifies conditions or practices that

could result in damage to the GPP or to other

properties.

DANGER High Voltage

Attention Refer to the Manual

Protective Conductor Terminal

Earth (ground) Terminal

Do not dispose electronic equipment as

unsorted municipal waste. Please use a

separate collection facility or contact the

supplier from which this instrument was

purchased.

SAFETY INSTRUCTIONS

This chapter contains important safety

instructions that you must follow during

operation and storage. Read the following before

any operation to insure your safety and to keep

the instrument in the best possible condition.

Safety Symbols

These symbols may appear in the manual or on the instrument.

6

SAFETY INSTRUCTIONS

General

Guideline

CAUTION

Do not place any heavy object on the unit.

Avoid severe impact or rough handling that

leads to damaging the unit.

Do not discharge static electricity to the unit.

Do not block the cooling fan opening.

Do not perform measurements on circuits that

are directly connected to mains power.

Do not disassemble the GPP unless you are

qualified.

(Measurement categories) EN 61010-1:2010

specifies the measurement categories and their

requirements as follows. The GPP Series falls

under category I.

Measurement category IV is for measurement

performed at the source of low-voltage

installation.

Measurement category III is for measurement

performed in the building installation.

Measurement category II is for measurement

performed on the circuits directly connected to

the low voltage installation.

Measurement category I is for measurements

performed on circuits not directly connected to

Mains.

Power Supply

WARNING

AC Input voltage range:

100V/120V/220V/230V ±10%

Frequency: 50Hz/60Hz

To avoid electrical shock connect the protective

grounding conductor of the AC power cord to

an earth ground.

Safety Guidelines

7

GPP Series User Manual

Fuse

WARNING

Fuse type: 100V/120V:T6.3A/250V,

220V/230V:T3.15A/250V

To prevent fire, replace the fuse only with the

specified type and rating.

Disconnect the power cord before replacing the

fuse.

Make sure the cause of fuse blowout is fixed

before replacing the fuse.

Cleaning the

power supply

Disconnect the power cord before cleaning the

oscilloscope.

Use a soft cloth dampened in a solution of mild

detergent and water. Do not spray any liquid

into the oscilloscope.

Do not use chemicals containing harsh products

such as benzene, toluene, xylene, and acetone.

Operation

Environment

Location: Indoor, no direct sunlight, dust free,

almost non-conductive pollution (Note below)

Relative Humidity: < 80%

Altitude: < 2000m

Temperature: 0°C to 40°C

8

SAFETY INSTRUCTIONS

(Pollution Degree) EN 61010-1:2010 specifies

pollution degrees and their requirements as

follows. The GPP Series falls under degree 2.

Pollution refers to “addition of foreign matter,

solid, liquid, or gaseous (ionized gases), that

may produce a reduction of dielectric strength

or surface resistivity”.

Pollution degree 1: No pollution or only dry,

non-conductive pollution occurs. The pollution

has no influence.

Pollution degree 2: Normally only non-

conductive pollution occurs. Occasionally,

however, a temporary conductivity caused by

condensation must be expected.

Pollution degree 3: Conductive pollution

occurs, or dry, non-conductive pollution occurs

which becomes conductive due to condensation

which is expected. In such conditions,

equipment is normally protected against

exposure to direct sunlight, precipitation, and

full wind pressure, but neither temperature nor

humidity is controlled.

Storage

environment

Location: Indoor

Relative Humidity: < 70%

Temperature: -10°C to 70°C

9

GPP Series User Manual

Green/ Yellow:

Earth

Blue:

Neutral

Brown:

Live (Phase)

Power cord for the United Kingdom

When using the power supply in the United Kingdom, make sure

the power cord meets the following safety instructions.

NOTE: This lead/appliance must only be wired by competent persons

WARNING: THIS APPLIANCE MUST BE EARTHED

IMPORTANT: The wires in this lead are coloured in accordance with the

following code:

As the colours of the wires in main leads may not correspond with

the coloured marking identified in your plug/appliance, proceed as

follows:

The wire which is coloured Green & Yellow must be connected to

the Earth terminal marked with either the letter E, the earth symbol

or coloured Green/Green & Yellow.

The wire which is coloured Blue must be connected to the terminal

which is marked with the letter N or coloured Blue or Black.

The wire which is coloured Brown must be connected to the

terminal marked with the letter L or P or coloured Brown or Red.

If in doubt, consult the instructions provided with the equipment or

contact the supplier.

This cable/appliance should be protected by a suitably rated and

approved HBC mains fuse: refer to the rating information on the

equipment and/or user instructions for details. As a guide, a cable

of 0.75mm2 should be protected by a 3A or 5A fuse. Larger

conductors would normally require 13A types, depending on the

connection method used.

Any exposed wiring from a cable, plug or connection that is

engaged in a live socket is extremely hazardous. If a cable or plug is

deemed hazardous, turn off the mains power and remove the cable,

any fuses and fuse assemblies. All hazardous wiring must be

immediately destroyed and replaced in accordance to the above

standard.

10

OVERVIEW

OVERVIEW

This chapter contains a brief introduction to GPP

series including the main features and an

overview of the front and rear panel. Use the

Getting Started chapter on page 27 to start up

instructions and how to setup the appropriate

operation environment.

Introduction ............................................................. 12

Key Features ............................................................ 15

Front Panel .............................................................. 17

Rear Panel................................................................ 24

Constant Voltage/Constant Current Crossover

Characteristics ......................................................... 26

11

GPP Series User Manual

Overview

The GPP series regulated DC power supply

series are light weight, adjustable,

multifunctional work stations. The GPP-1326

has a 1 independent adjustable voltage outputs

with sense.The GPP-2323 has a 2 independent

adjustable voltage outputs. The GPP-3323 three

independent outputs: two with adjustable

voltage levels and one with fixed level

selectable from 1.8V, 2.5V, 3.3V and 5V. The

GPP-4323 has four independent voltage

outputs that are all fully adjustable.

The GPP series can be used for logic circuits

where various output voltage or current are

needed, and for tracking mode definition

systems where plus and minus voltages with

insignificant error are required.

Independent /

Tracking Series /

Tracking Parallel

The three output modes of GPP series,

independent, tracking series, and tracking

parallel, can be selected through pressing the

TRACKING key on the front panel. In the

independent mode, the output voltage and

current of each channel are controlled

separately. The isolation degree, from output

terminal to chassis or from output terminal to

output terminal, is 500V.

In the tracking modes, both the CH1 and CH2

outputs are automatically connected in series

or parallel; no need to connect output leads. In

the series mode, the output voltage is doubled;

in the parallel mode, the output current is

doubled.

Introduction

12

OVERVIEW

Load Mode

The GPP series models have additional Load

function on both CH1 & CH2 with 3 modes:

CV (Constanct Voltage), CC (Constant Current)

and CR (Constant Resistance), all of which can

be selected through the function keys on the

front panel. Voltage, current and resistance can

be well regulated in each mode, respectively.

Constant Voltage/

Constant Current

Each output channel is completely

transistorized and well-regulated, and works in

constant voltage (CV) or constant current (CC)

mode. Even at the maximum output current, a

fully rated, continuously adjustable output

voltage is provided. For a big load, the power

supply can be used as a CV source; while for a

small load, a CC source. When in the CV mode

(independent or tracking mode), output

current (overload or short circuit) can be

controlled via the front panel. When in the CC

mode (independent mode only), the maximum

(ceiling) output voltage can be controlled via

the front panel. The power supply will

automatically cross over from CV to CC

operation when the output current reaches the

target value. The power supply will

automatically cross over from CC to CV when

the output voltage reaches the target value. For

more details about CV/CC mode operation,

see page 26.

Automatic

tracking mode

The front panel display (CH1, CH2) shows the

output voltage or current. When operating in

the tracking mode, the power supply will

automatically connect to the auto- tracking

mode.

13

GPP Series User Manual

Display Change

Function

The GPP series provides up to 7 display types,

each of which can be well selected via setting.

For details, see page 32.

Output Waveform

Function

Under Source mode of the GPP series, user can

customize a certain V/I sequential waveform

output. Under Load mode, it is programmable

for dynamic load (below 1Hz). For details, see

page 50.

Remote Control

To meet the various needs of customers, the

GPP is designed for USB, GPIB and LAN

remote control. For details, see page 95.

Additional

Function

Control signal of external switch is reserved for

user. For details, see page 79.

14

OVERVIEW

Features

Multiple Outputs:

GPP-1326:32V/6A x 1

GPP-2323:32V/3A x 2 (CH1/CH2)

GPP-3323:32V/3A x 2 (CH1/CH2)

1.8V/2.5V/3.3V/5V/5A x 1 (CH3)

USB Port Output:3A

GPP-4323:32V/3A x 2 (CH1/CH2)

5V/1A x 1 (CH3),15V/1A x 1 (CH4)

Constant voltage and constant current operation

(CV/CC).

Low noise, thermostatically controlled fan.

Compact, lightweight, standard rack mount

comformity 3U, half Rack.

4.3 inch TFT display.

Key Features

15

GPP Series User Manual

Operation

Digital panel control.

Output on/off control (ON/OFF), and each

channel can be controlled separately.

Digital voltage and current settings. (Key &

Encode)

10 groups of save/recall settings and 2 groups of

power-on settings.

10 groups of save/recall Sequence.

10 groups of save/recall Delay.

10 groups of save/recall Record.

CH1/CH2 workable in Load Mode

7 types display modes available with 5 contents

and 2 waveforms respectively

Input/Output terminal (Control I/O)

Alarm buzzer (BEEP).

Key lock function (LOCK).

Multiple remote control interfaces (standard:

RS232, USB; optional: GPIB, LAN)

Protection

Features

Overvoltage and overcurrent protection (OVP/

OCP)

Overtemperature protection (OTP).

Polarity Reverse Protection

Overload Protection (OPP in Load mode)

Interface

Remote Control RS-232 (standard)

USB remote control. (standard)

Control I/O (standard)

LAN remote control (optional)

GPIB & LAN remote control (optional)

16

OVERVIEW

LCD

Number

pad

Scroll wheel/

Arrow keys

Function

keys

USB host

Front panel

output terminals

Power button

Display

Display

Interface

(Take GPP-4323 model as example)

Front Panel

*The panel above is the example of GPP-4323. For other models,

refer to page 23.

17

GPP Series User Manual

Channel

distribution

Channel number and distribution vary by

models with different colors identifications:

CH1: Yellow CH2: Blue CH3: Pink CH4:

Green CH1 is master and CH2 becomes yellow

under tracking series and tracking parallel

modes.

Single channel

display

Channel/

Status

Power

display

V/I

setting

Voltage

display

Current

display

OVP/OCP

setting area

Channel no.

Color of channel remains the origanl when

not in the state of setting.

Color of channel blinks between the original and

orange when being set.

Channel status

Display active channel state

Power supply: CH1/CH2/CH3/CH4: green

or red

Load Mode: CH1/CH2: orange

Voltmeter

Indicators

Displays the output voltage with up to 6 digits

of resolution. The default units are Volts (V).

18

OVERVIEW

CH1:

CH2:

CH3: (GPP-4323)

(GPP-3323)

CH4:

Ammeter

Indicator

Displays the output current with up to 5 digits

of resolution. The default units are ampere (A).

CH1:

CH2:

CH3: (GPP-4323)

CH4:

Setting Display

Displays the voltage and current settings.

CH1/CH2/CH3/CH4:

CH3(GPP-3323) displays setting of voltage only

Display OVP/OCP settings

CH1/CH2/CH3/CH4:

The CH3 OVP of GPP-3323 is a fixed value

(approx. 5.5V), non-configurable and with only

on or off switch available for user. OCP is

available only for USB output port (approx.

3.1A)

19

GPP Series User Manual

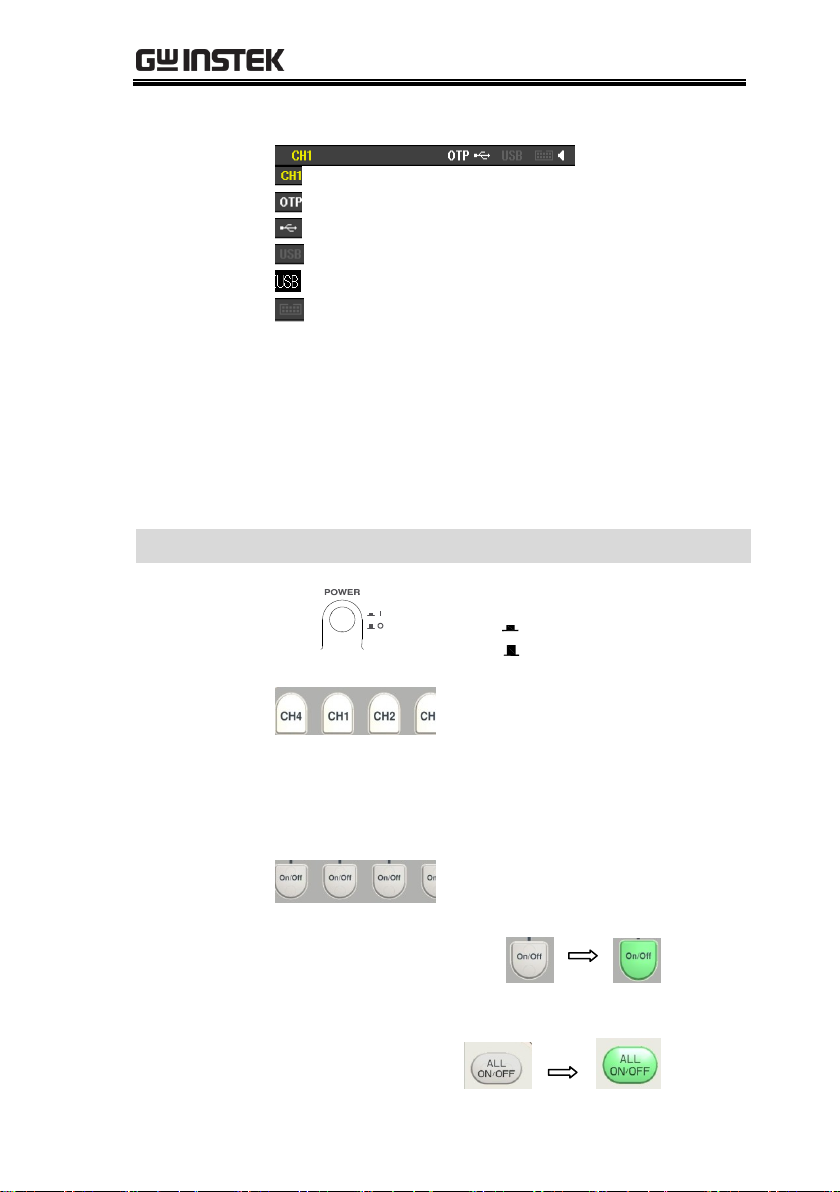

Status

Indicator

Display the set function/remote control interface

: The active channel under setting status

: The status of OTP protection mode

: The status of USB flash drive connected

: USB remotely disconnected

: USB remotely connected

: The status of control I/O connected

Others: when operating in the series/parallel

tracking mode, the corresponding SER/PAR icons

appear on the display.

when Sequence/Delay/Monitor/Recorder is

activated, the corresponding SEQ/DLY/MON/

REC icons appear on the display.

Function Keys

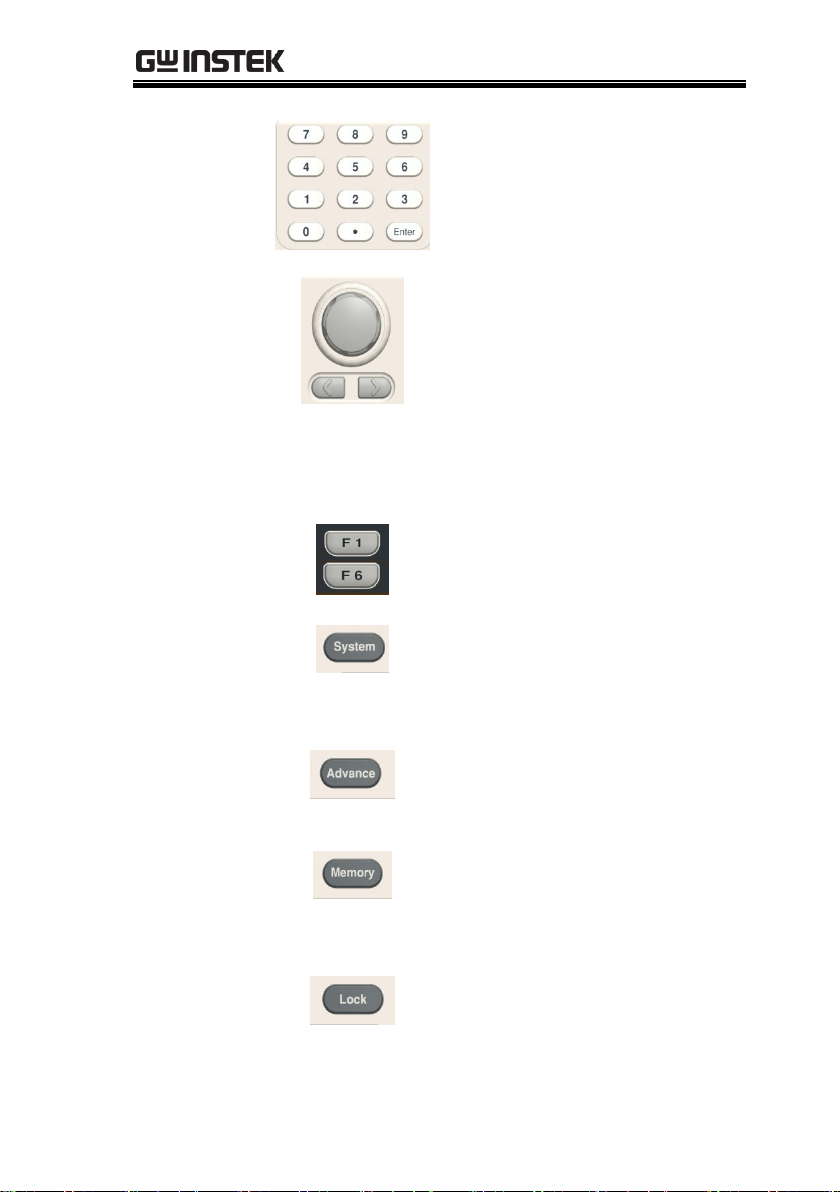

Power Button

Turns the power on or off.

On:

Off:

Channel select

buttons

Each channel has its own

button and promptly

switchable among CH1-CH4

setting.

Output buttons

Individual

output

The ON/OFF button is

operational individually by

each channel. The Output key

will light up when the output is

on.

ON:

Output all

All ON:

20

OVERVIEW

Number pad

For parameter value setting

Scroll wheel &

Arrow keys

Scroll wheel is used to set each

parameter value, whilst arrow

keys are used for parameter,

menu selection and

voltage/current fine

adjustment. It is used to switch

or operate the displayed

waveforms under diagram

display mode.

Function keys

The 6 function keys (F1-F6)

display varied functions per

different opertations.

System key

It is used to set functions

including Interface, Beep,

Backlight, etc. For details, refer

to page 90.

Advance key

It is used for certain advanced

functions like Sequence, Delay,

Monitor, Recorder, etc.

Memory key

It is used to operate several

functions including save and

recall, etc., for set parameters.

For details, refer to page 83.

Lock key

It is used to disable all the

panel keys except for the

Output key.

21

GPP Series User Manual

Unlock

Press the F6 button to unlock,

which can disable remote

control and return to panel

operation.

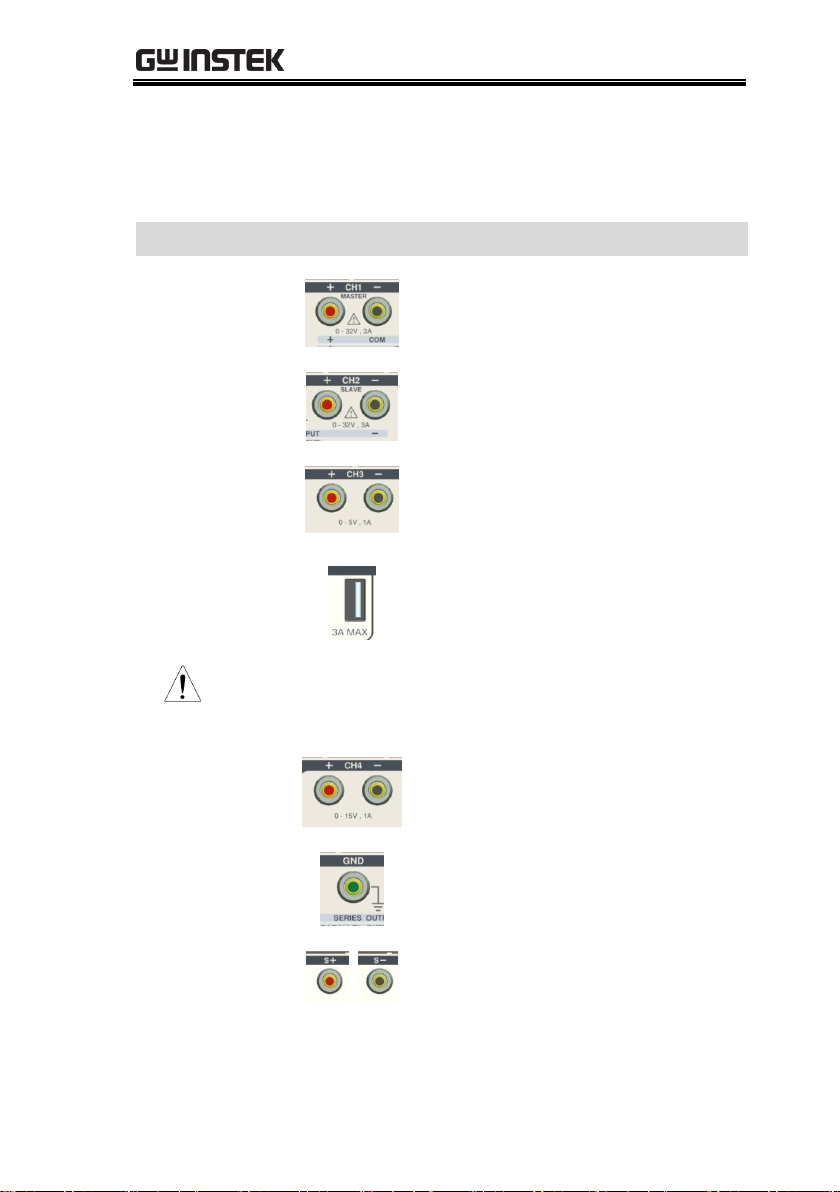

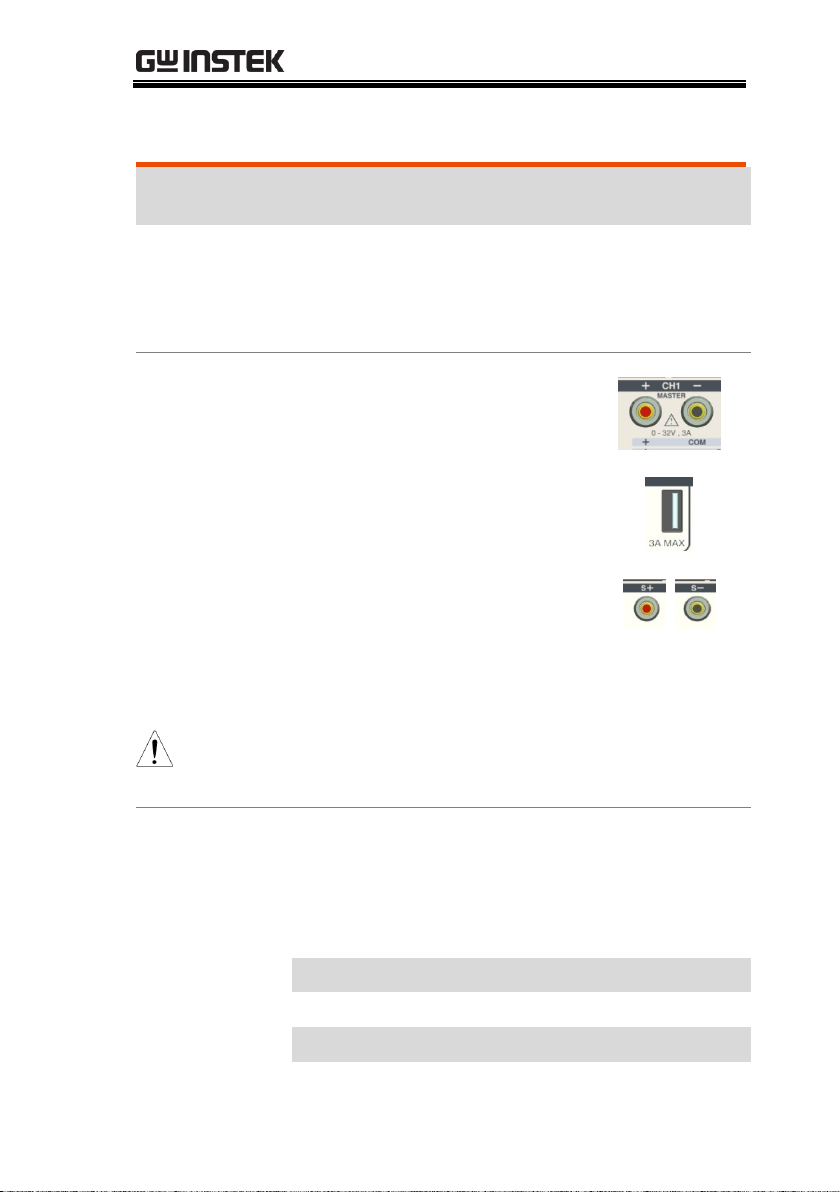

Terminals

CH1 terminal

Power output terminal or load

input terminal

CH2 terminal

Power output terminal or load

input terminal

CH3 terminal

Power output terminal

Power output terminal (GPP-

3323 only)

Warning: The output current from the 2 terminals should

Not exceed 5A for GPP-3323.

CH4 terminal

Power output terminal

GND terminal

Ground terminal

Voltage

feedback

terminal

(SENSE)

Sense terminal of power

output (1326 only)

22

OVERVIEW

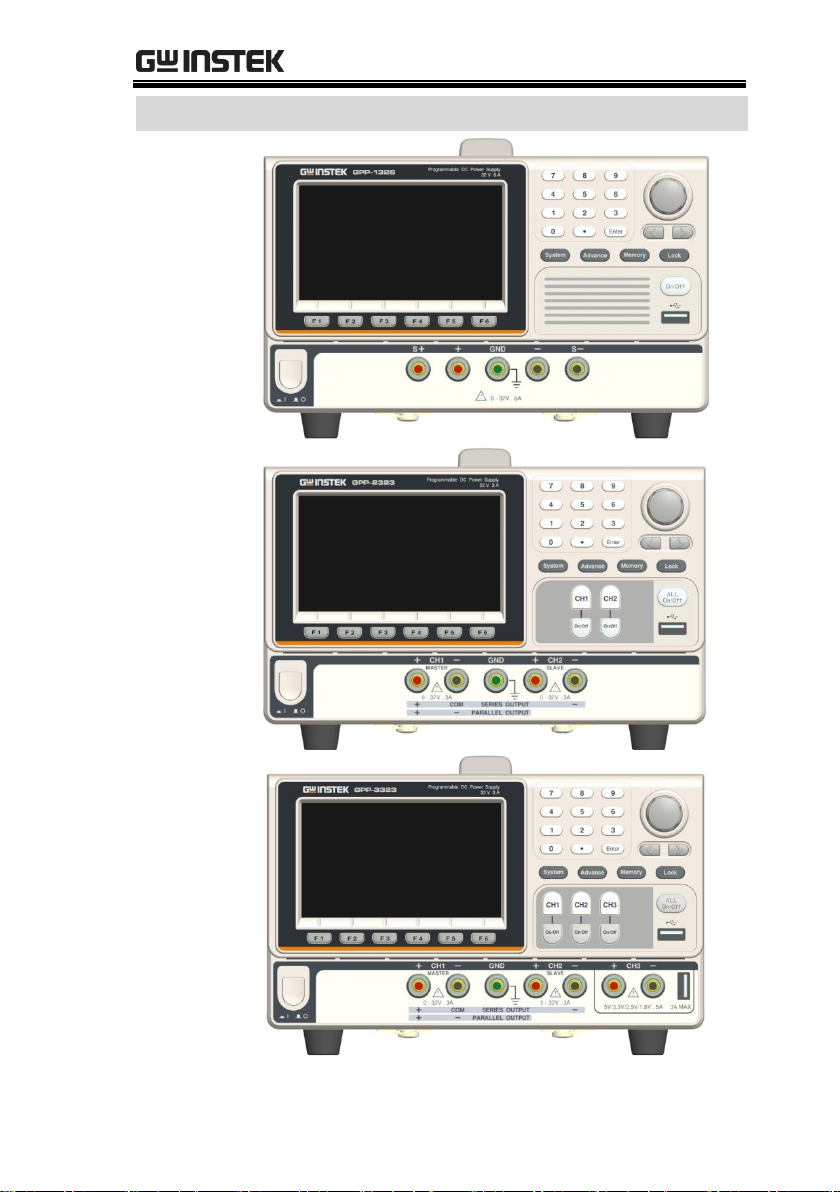

Panels of other models:

GPP-1326

GPP-2323

GPP-3323

23

GPP Series User Manual

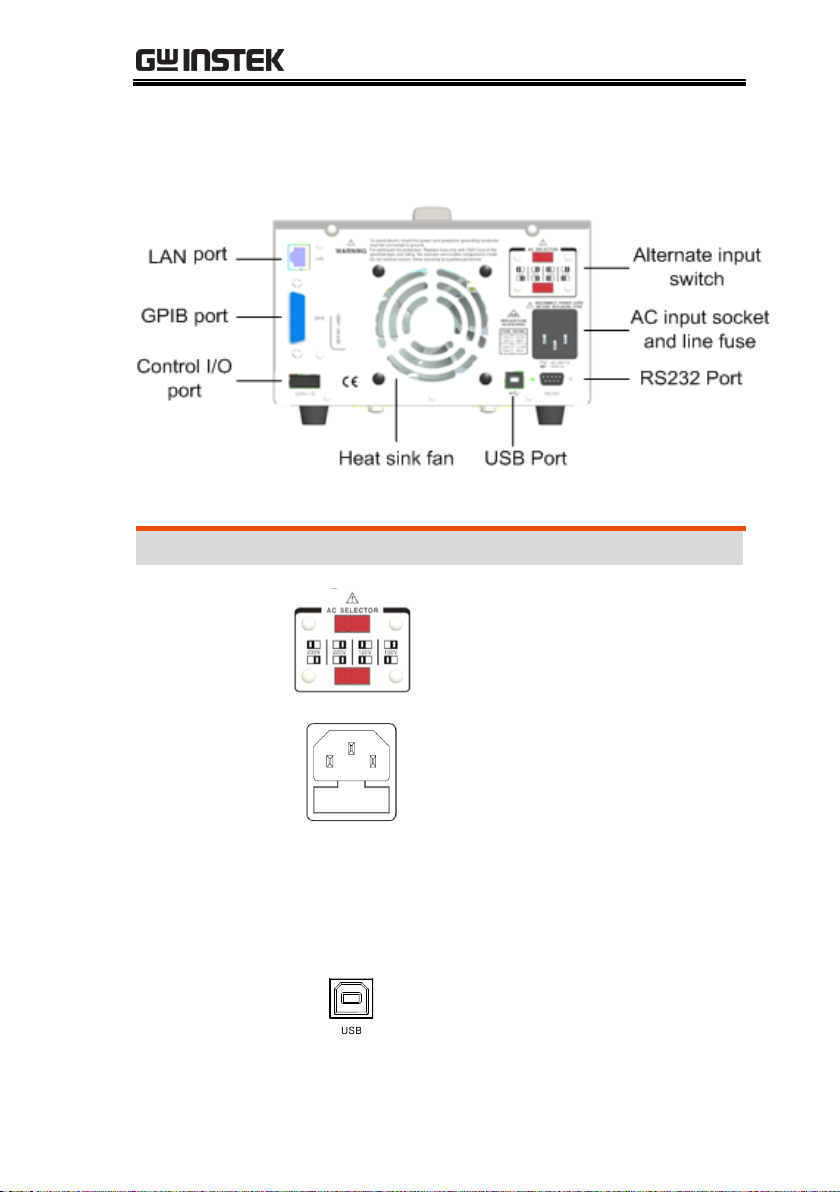

Terminals

Alternate

input switch

AC voltage selection:

100V/120V/220V/230V

±10%, frequency 50/60Hz

AC input

socket and

line fuse

The AC input accepts

100V/120V/220V/230V

AC. The frequency is

50Hz/60Hz.

Fuse:

100V/120V: T6.3A/250V,

220V/230V :T3.15A/250V,

slow-blow type, See page

199 for details.

USB port

USB device port for remote

control. See page 95 for

details.

Rear Panel

24

OVERVIEW

GPIB port

GPIB slave port for remote

control. Abides to

IEEE488.2 (SCPI) protocol.

See page 101 for details.

LAN port

LAN port for remote

control. See page 102 for

LAN setting and operation

details.

RS 232 port

RS232 port for remote

control. See page 98 for

details.

Heat sink

fan

Control I/O

port

5 ports in all for

input/output control. See

page 79 for details of

configuration.

25

GPP Series User Manual

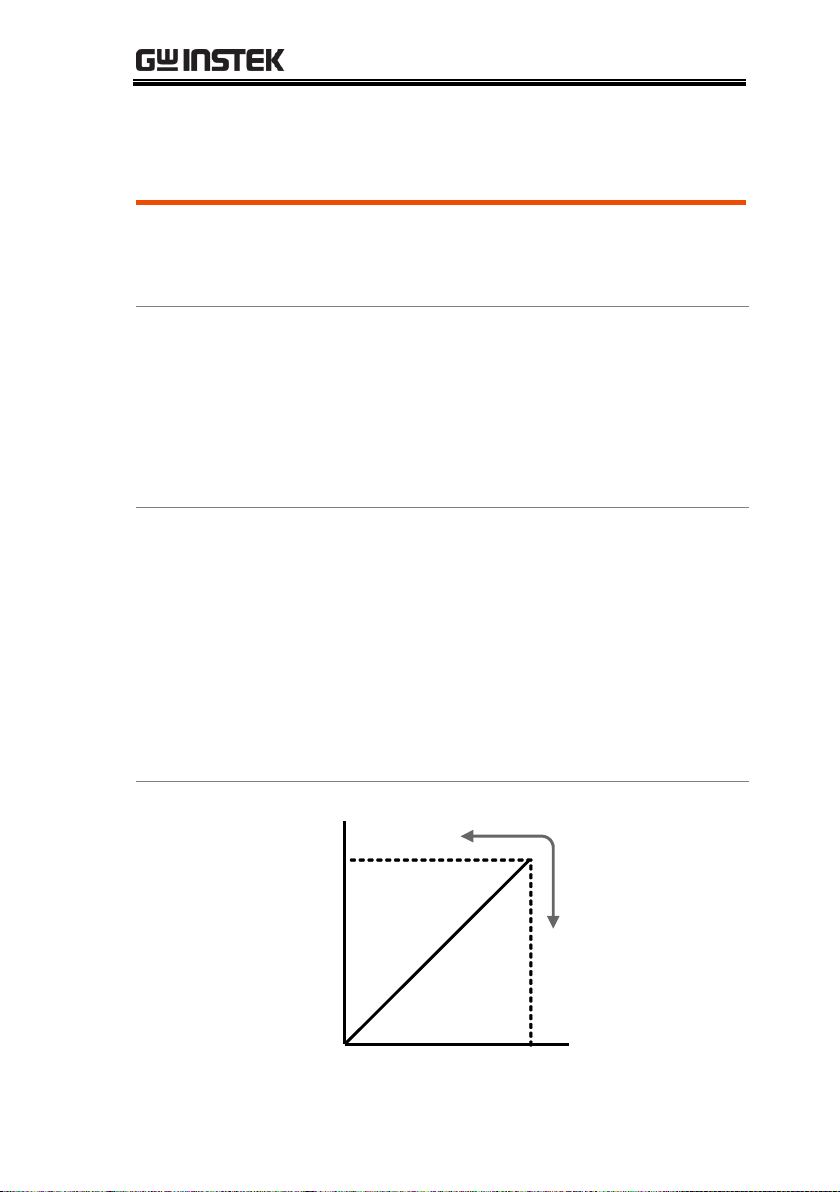

Background

The unit will switch automatically between

constant voltage and constant current

according to changes in the load.

CV mode

When the load current is less than the current

setting, the unit operates in constant voltage

mode, changing the current level according to

the load but maintaining the set voltage level

until the current reaches the set current level.

The status indicator will show CV on the LCD

when in CV mode.

Constant Current

Mode

When the output current reaches the set

current level, the unit switches operation to

constant current mode. The status indicator

will show CC on the LCD display. In CC mode,

the current level is maintained and the voltage

level is limited to less than the set voltage level

to limit the output power from an overload.

When the current drops below the set current

level, the unit will revert back to CV mode.

Diagram

Vmax

Imax

Constant

Voltage

Constant

Current

Vout

Iout

Constant Voltage/Constant Current

Crossover Characteristics

26

GETTING STARTED

GETTING STARTED

This chapter describes the start up procedures and

the preparation that is necessary before operating

the power supply.

Start Up ................................................................... 28

Load Connection ...................................................... 29

Turning the Output On/Off ...................................... 31

27

GPP Series User Manual

Checking the AC

Voltage

Before the power is turned

on, confirm that the input

power supply meets the

following conditions:

100V/120V/220V/230V

±10%,50/60Hz

Connecting the

AC power cord

The fuse is a slow-blow fuse.

3.15A(220V/230V)

6.30A(100V/120V),

Confirm that the fuse is of the

correct type and rating before

connecting the power cord.

Turning the

power on

Press the power button.

Turning the

power off

To turn the power off, press

the power button again.

Start Up

28

GETTING STARTED

Recommended

Cables

Model

Specification

Usage

GTL-

104A

10A

Front panel terminal

GTL-105A

3A

Sense(1326 only)

Front panel

wiring

Use the GTL-104A cables for

the front panel source

connections.

USB Type A only

(Greater than 4A)

Use the GTL-105A cables for

the GPP-1326 sense

connections. Or connect + to

S+, - to S- terminal with a

short bar.

Caution

For safety considerations, please keep in mind

that the wiring must be equivalent to the wiring

on the front terminals.

Wire Gauge

Load wires must have enough current capacity

to minimize cable loss and load line impedance.

Voltage drop across a wire should not excess

0.5V. The following list is the wire current

rating at 450A/cm2.

Wire Size(AWG)

Maximum Current (A)

20

2.5 18

4

Load Connection

29

GPP Series User Manual

16

6 14

10 12

16

30

GETTING STARTED

Panel Operation

Press the Output key of

each channel

individually to turn the

output on. The Output

key will light-up when

the output is on.

When the output is

turned on, pressing the

Output key again will

turn the output off.

Press ALL ON/OFF key

when it needs to output

or turn off all channels

simultaneously (GPP-

1326 does not have this

button) .

Command Set

Refer to page 112 for more details on remote

commands chapter.

Automatic

Output Shut

Down

Any of the following actions will cause the

output to be automatically shut down:

Toggle between power output and load mode

Independent/Tracking Series/Tracking Parallel

operation

Recall the saved setting

OVP/ OCP/OPP/OTP protection is tripped.

When Sequence/Delay/Monitor/Control IO

fits the set conditions.

Turning the Output On/Off

31

GPP Series User Manual

BASIC OPERATION

This chapter describes how to set various

functions.

Display Change ........................................................ 33

Source Function ....................................................... 36

Independent Output Mode ..................................... 41

Tracking Series and Tracking Parallel Modes ......... 42

Load Function .......................................................... 46

Sequence Function ................................................... 50

Set Sequence Output ............................................... 50

Set Group Parameter ............................................... 52

Construct Templet ................................................... 54

Menu Tree ................................................................ 57

Save and Recall ........................................................ 59

Delay Function ......................................................... 62

Set Delay Output ..................................................... 62

Set Group Parameter ............................................... 65

Menu Tree ................................................................ 68

Save and Recall ........................................................ 70

Monitor Function ..................................................... 72

Set Monitor .............................................................. 73

Recorder Function .................................................... 75

Set Recorder ............................................................. 76

Enternal I/O Control ................................................ 79

Key Function Description ........................................ 81

32

BASIC OPERATION

Channel/Status

Work status

area

Read back

status area

Parameter

setting area

Function keys

display area

Warning

:

1. Under the Source interface:

Each channel has its own setting area

(V/I/OVP/OCP) and read back status area (V/I/W).

2. Under the Load interface:

It is basically equivalent to Sourece interface with

additional Load and OPP status displays.

Diverse display screens

In order to offer diverse information display of each channel to

meet requirements from different users, the GPP series provide

several selections of different display screens as follows:

Display Change

Display Area

33

GPP Series User Manual

Type

GPP-1326

GPP-2323

GPP-3323

GPP-4323

Nomarl

Type1

×

Type2

×

Type3

× × ×

Type4

Type5

Waveform

Type6

Type7

*Only Type 1, Type 4 and Type 7 have setting value display

*Type's selection: Advance key ->F1(Display) key->F1(Normal) key

or F2(Waveform) key.

Default factory display screen

GPP-1326

GPP-2323

GPP-3323

GPP-4323

Type4

Type1

Type1

Type1

34

The introduction to Type 6 display

a represents the currently edited channel, which can be toggled through

the channel button on the panel.

b indicates the adjustable items of reference point for

voltage/current/power respectively in the active channel. The one with

a red triangular arrow is the active item to adjust, which can be toggled

through the directional button on the panel.

c stands for the vertical sensitivity for voltage/current/power

respectively in the active channel.

d stands for the horizontal sensitivity for time.

e represents the output state of active channel and the open state of

OVP/OCP.

f indicates the output curve for voltage/current/power respectively in

the active channel. The three curves have the identical color in

common with slight difference in brightness, which corresponds to the

brightness of b.

g stands for the output reference point for voltage/current/power

respectively in the active channel, which is adjustable ups and downs

via scroll wheel.

a b c

e

g

f

d

BASIC OPERATION

35

Source Function

Description

Each channel is equipped with basic power

functions and able to display both settings

and read back value of V/I as well as output

status

Parameter

description

Vset

Set output voltage of active channel.

The range is as the following:

CH1:0.000V-33.000V

CH2:0.000V-33.000V

CH3:0.000V-5.500V (GPP-4323)

CH4:0.000V-16.000V (GPP-4323)

Iset

Set limited current of active channel.

The range is as the following:

CH1:0.0000A-3.2000A

CH2:0.0000A-3.2000A

CH3:0.0000A-1.1000A (GPP-4323)

CH4:0.0000A-1.1000A (GPP-4323)

OVP

Set OVP. The range is as the

following:

CH1:0.5V-35.0V

CH2:0.5V-35.0V

CH3:0.5V-6.0V (GPP-4323)

CH4:0.5V-16.5V(GPP-4323)

GPP Series User Manual

36

OCP

Set OCP. The range is as the

following:

CH1:0.05A - 3.50A

CH2:0.05A - 3.50A

CH3:0.05A - 1.20A (GPP-4323)

CH4:0.05A - 1.20A (GPP-4323)

Parameter

Setting (CH1

for example)

Voltage

Press the F1 key

corresponding to

Voltage to activatate

voltage setting area on

LCD (red font color

with the underline

indicator).

(a) Input digit with number pad (09,.) and press unit key F1(V) or

F2(mV) to confirm:

Input 6.543V:

(b) Step input:

Press the left or right

arrow buttons to select

high and low level that

require fine-tune

(underline below the

corresponding number

value), and scroll the

scroll wheel to

increase or decrease

setting value.

Current

Press the F2 key

corresponding to

BASIC OPERATION

37

GPP Series User Manual

Current to activatate

current setting area on

LCD (red font color

with the underline

indicator).

(a) Input digit with number pad (09,.) and press unit key F1(A) or

F2(mA) to confirm:

Input 1.543V:

(b) Step input:

Press the left or right

arrow buttons to select

high and low level that

require fine tune

(underline below the

corresponding number

value), and scroll the

scroll wheel to increase

or decrease setting

value.

OVP

Press F3 key to enter the

Protect menu.

Press F3 key to open

OVP function. OVP

display will change

from gray to white font.

Press the F1 key to enter

OVP setting area on

LCD, which will be thus

38

BASIC OPERATION

activated (red font color

with the underline

indicator).

(a) Input digit with number pad (09,.) and press unit key F1(V) or

F2(mV) to confirm:

Input 6.5V:

(b) Step input:

Press the left or right

arrow buttons to

select high and low

level that require fine

tune (underline

below the

corresponding

number value), and

scroll the scroll

wheel to increase or

decrease setting

value.

OCP

Press F3 key to enter

the Protect menu.

Press F3 key to open

OCP function. OCP

display will change

from gray to white

font.

Press the F2 key to

enter OCP setting

area on LCD, which

will be thus activated

39

GPP Series User Manual

(red font color with

the underline

indicator).

(a) Input digit with number pad (09,.) and press unit key F1(A) or

F2(mA) to confirm:

Input 2.5A:

CAUTION:

There’s no proper sequence between turning

on OVP/OCP functions and setting

OVP/OCP value.

Either step input or number pad input is

applicable for setting parameter value.

Operation

ON/OFF

Output ON/OFF control.

Output is open when output

lights up; whilst output is off

when output lights out.

All ON/OFF

1. When the output state of all

channels is identical, press All

ON/OFF to perform the

opposite operation.

2. When the output of all

channels is inconsistent, press

All ON/OFF will close the

open channel of the output.

State

description

CV/CC

Constant

voltage displays

in green CV,

while constant

40

current displays

in red CC.

OVP/OCP

OVP/OCP displays in white

when OVP is not in activation.

OVP/OCP displays in red and

output is off when OVP is

activated.

OVP/OCP displays in gray when

OVP/OCP functions are off.

Independent Output Mode

Description

Each channel within the models GPP1326/2323/3323/4323 series is apart from one

another and capable of operations including

independent setting and individual output, etc.

Connection

+ - + - + - + -

CH3

Load

CH2

Load

CH1

Load

CH4

Load

BASIC OPERATION

41

GPP Series User Manual

Voltage/Cur

rent Rating

GPP-1326:32V/6A x 1

GPP-2323/3323/4323:

CH1/CH2: 32V/3A x 2

CH3:1.8V/2.5V/3.3V/5V/5A x 1 (GPP-3323)

USB Port Output:3A (GPP-3323)

5V/1A x 1 (GPP-4323)

CH4:15V/1A x 1

Setting

1. Press F4 or F5 button for operating the

corresponding Independent to enter the

Independent function.

2. For setting opertation of parameter, refer to

page 37.

Output

The independent button ON/OFF of each

channel is available, while All ON/OFF button

is available for all channels.

Tracking Series and Tracking Parallel Modes

Descri

ption

Tracking series operation doubles the Voltage

capacity of the GPP-2323/3323/4323 by internally

connecting CH1 (Master) and CH2 (Slave) in series

and combining the output to a single channel. CH1

(Master) controls the combined Voltage output level.

42

BASIC OPERATION

Tracking series without common terminal

Output

rating

rating 0 - 64V/0 - 3A

Setting

1. Press F4 or F5 button for operating the

corresponding Series to enter the tracking series

function. Yellow SER will be shown on the

status area.

2. Press CH1 button to proceed to CH1/CH2

voltage setting and CH1 limit current setting.

3. Press CH2 button to proceed to CH2 limit

current setting.

4. For setting operation of parameter, refer to

page 37.

Output

The button ON/OFF of CH1/CH2 is

individually available, while All ON/OFF

button is available for all channels.

Load

+ -

43

GPP Series User Manual

Tracking series with common terminal

Output

rating

0 - 32V/0 - 3A for CH1+ - COM

0 - 32V/0 - 3A for CH2- - COM

Operation

1. Press F4 or F5 button for operating the corresponding

Series to enter the tracking series function. Yellow SER

will be shown on the status area.

2. Press CH1 button to proceed to CH1/CH2 voltage

setting and CH1 limit current setting.

3. Press CH2 button to proceed to CH2 limit current

setting.

4. For setting operation of parameter, refer to page 37.

Output

The button ON/OFF of CH1/CH2 is individually

available, while All ON/OFF button is available

for all channels.

CAUTION: under Tracking series mode, CH1 is master, whilst CH2

is slave. Thus, output voltage setting is Not available for CH2.

Load

+ com -

44

BASIC OPERATION

CH1/CH2 Tracking Parallel Mode

Output rating Rating 0 - 32V/0 - 6A

Operation

1. Press F4 or F5 button for operating the

corresponding Parallel to enter the tracking

parallel function. Yellow PAR will be shown on

the status area.

2. Press CH1 button to proceed to CH1/CH2

voltage/current setting.

4. For setting operation of parameter, refer to page

37.

Output

The button ON/OFF of CH1/CH2 is individually

available, while All ON/OFF button is available

for all channels.

CAUTION: under tracking parallel mode, CH1 is master, whilst

CH2 is slave. Thus, output voltage/current setting is Not available for

CH2.

Load

+ -

45

GPP Series User Manual

Load Function

Description

CH1/CH2 of the GPP-1326/2323/3323/4323

series can be set to the Load Mode function,

under which both tracking series and tracking

parallel function are Not available.

Note

The voltage (≥1V) or --.--(<1V) pertaining to port

appears when Output is Off.

Parameter

Description

Load

Under PWR. mode, press F6 (Load

Mode) to enter the Load mode. LCD

will display the status .

Vset

Set rating range of voltage value

under Load mode of active channel:

CH1:1.50V-33.00V

CH2:1.50V-33.00V

Iset

Set rating range of current value

under Load mode of active channel

CH1:0.000A-3.200A

CH2:0.000A-3.200A

46

BASIC OPERATION

Rset

Set rating range of resistance value

under Load mode of active channel

CH1:1Ω-1000Ω

CH2:1Ω-1000Ω

Others

OPP: Fixed 50W of single

channel(GPP-1326:100W), nonrevisable

OVP/OCP: indentical to Source

Parameter

setting

Vset

Press F4 or F5 button for operating

the corresponding (CV) mode

followed by F1 button (Vset). The

voltage setting area on LCD will be

activated and appears

(red font color with the underline

indicator).

(a) number pad (0-9,.) input; press

unit button F1 (V) or F2 (mV) button

to confirm:

Input 6.54V:

(b) Step input: Press the

left or right arrow

buttons to select high and

low level that require

fine tune (underline

below the corresponding

number value), and scroll

the scroll wheel to

increase or decrease

setting value.

47

GPP Series User Manual

Iset

Press F4 or F5 button for operating

the corresponding (CC) mode

followed by F1 button (Iset). The

current setting area on LCD will be

activated and appears (red

font color with the underline

indicator).

(a) number pad (0-9,.) input; press

unit button F1 (A) or F2 (mA) button

to confirm:

Input 1.543A:

(b) Step input: Press the

left or right arrow

buttons to select high

and low level that

require fine tune

(underline below the

corresponding number

value), and scroll the

scroll wheel to increase

or decrease setting

value.

Rset

Press F4 or F5 button for operating

the corresponding (CR) mode

followed by F1 button (Rset). The

current setting area on LCD will be

activated and appears

(red font color with the underline

indicator).

(a) number pad (0-9,.) input; press

48

BASIC OPERATION

unit button F1 (OHM) to confirm:

Input 52Ω:

(b) Step input: Press

the left or right arrow

buttons to select high

and low level that

require fine tune

(underline below the

corresponding

number value), and

scroll the scroll wheel

to increase or

decrease setting

value.

OVP

OCP

The setting method is identical to

Source.

Operation

ON/OFF

The button ON/OFF of CH1/CH2 is

individually available, while All

ON/OFF button is available for all

channels.

Mode

CV CC

CR

Font color appears

in orange under

Load mode.

Note

In CR mode, the external power supply must provide the

current required for I = V / R, otherwise the output ports

V and I will fluctuate.

49

GPP Series User Manual

Sequence Function

Description

This function can be used for practical

applications when different voltage waveforms

are required to be output. Users can edit the

output waveform according to their needs. The

amplitude range of the output waveform is the

output voltage range of power supply. The

setting range for output waveform duration is 1s

(duration calculation: Time x Groups x Cycles)

and the resolution is 1s.

Caution: This feature is applicable to both

CH1 and CH2.

Set Sequence Output

Parameter

Description

Cycles

Cycle number, 1 represents a cycle of

single period, whilst 2 indicate a

cycle with 2 periods, and so on. The

range is from 1 to 9999 or Infinite.

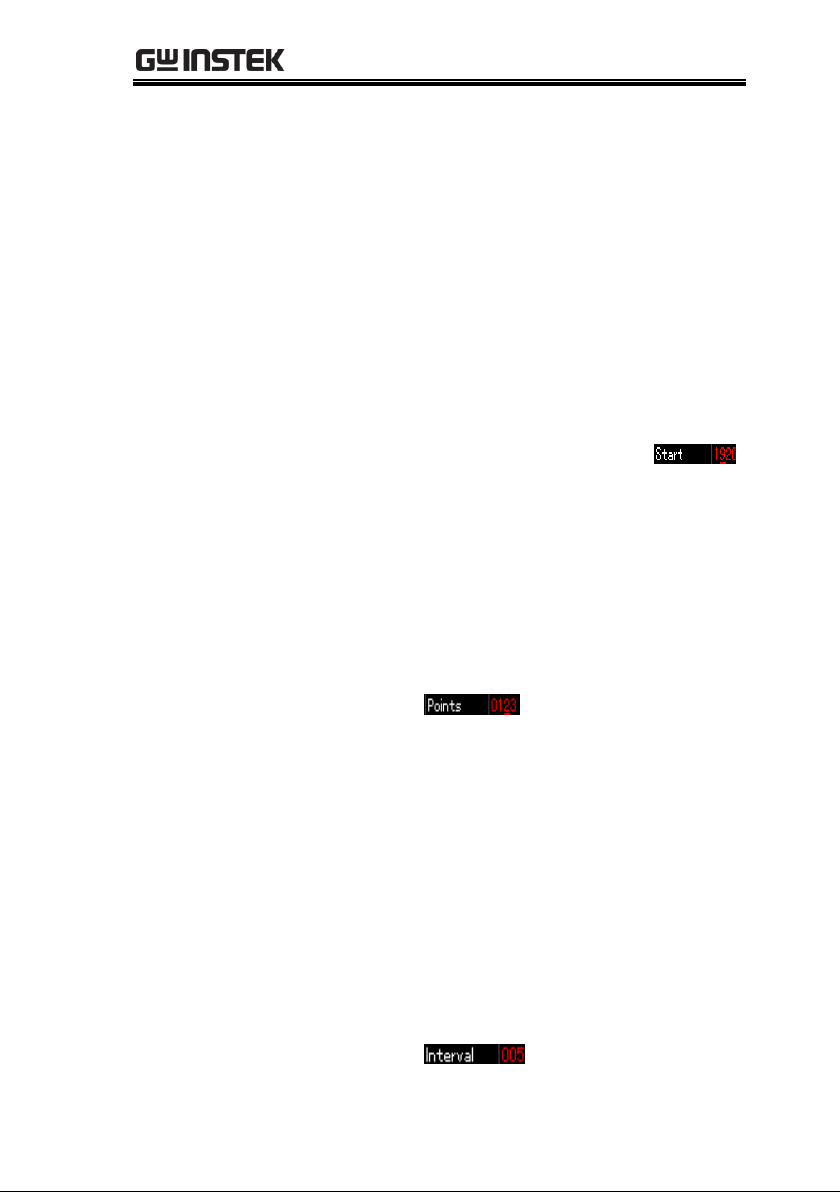

Start

The number to execute, 0 indicates

the execution starts from the group

0, while 1 indicates it begins from the

group 1, and so on. The range is

from 0 to 2047.

50

Groups

The number to be executed. It can

NOT exceed 2048 for Start+Groups.

End State

There’re 2 statuses after the

necessary Group and Cycle are

executed: output termination or

being hold with the last step.

Parameter

Setting

Cycles

Press the Advance key on control

panel. Select F2 (Sequence) function.

Press F1 (Set) button followed by

selecting F1 (Cycles). The setting on

LCD is activated and appears in red

font color . Use number

pad to set the parameters directly

and then press the F1 (Done) button

to confirm; or use arrow keys along

with scroll wheel to complete the

setting. Press and hold the F5

(Infinite) button if Infinite execution

is in need.

Start

Under the Sequence function, press

F1 (Set) button followed by selecting

F2 (Start). The setting on LCD is

activated and appears in red font

color . Use number pad to

set the parameters directly and then

press the F1 (Done) button to

confirm; or use arrow keys along

with scroll wheel to complete the

setting.

Groups

Under the Sequence function, press

F1 (Set) button followed by selecting

F3 (Groups). The setting on LCD is

activated and appears in red font

color . Use number pad

BASIC OPERATION

51

GPP Series User Manual

to set the parameters directly and

then press the F1 (Done) button to

confirm; or use arrow keys along

with scroll wheel to complete the

setting.

End State

Under the Sequence function, press

F1 (Set) button followed by selecting

F4 (End State), and 2 statuses

Last/Output off will appear in turn

on LCD . The one

displaying is what’s called the

current status.

Operation

ON/OFF

Press the F5 (SEQ.On) button. When

the output is on, the Output key will

light up. When the output is off, the

Output key will not be lit. SEQ will

appear in the status area (yellow for

CH1 only, blue for CH2 only, while

white for both on).

In Sequence ON, the F1 (Restart)

button appears, it means that start

from the first; in CH1/CH2 running

sequence, the F2 (Sync) button

appears, it means that two channels

start from the first at the same time.

CAUTION

If the channel has been in Output

ON before Sequence function, the

status remains unchanged until

SEQ.On so that Sequence starts to

output.

Set Group Parameter

52

Description

Each Group consists of Voltage, Current and

Time. Therefore, properly confirm parameter of

each group is correct before setting Sequence

output.

Parameter

Description

No.

Voltage

Current

Time

Group number. Maximum 2047

Voltage setting of each group.

Range: 0-33V

Current setting of each group.

Range: 0-3.2A

Execution duration of each group.

Range: 1S – 300S

Parameter

Setting

No.

Under the Sequence function, press

F2 (Edit) button followed by

selecting F1 (No.). The setting on

LCD is activated and appears in red

font color . Use number

pad to set the parameters directly

and then press the F1 (Done) button

to confirm; or use arrow keys along

with scroll wheel to complete the

setting. The F4 (Page Up)key and F5

(Page Down) key can jump directly

to the previous or next page,each 8

groups is a Page.

Voltage

Under the Sequence function, press

F2 (Edit) button followed by

selecting F3 (Voltage). The setting on

LCD is activated and appears in red

font color . Use

number pad to set the parameters

directly and then press the F1 (V) or

F2 (mV) button to confirm; or use

arrow keys along with scroll wheel

BASIC OPERATION

53

GPP Series User Manual

to complete the setting.

Current

Under the Sequence function, press

F2 (Edit) button followed by

selecting F4 (Current). The setting on

LCD is activated and appears in red

font color . Use

number pad to set the parameters

directly and then press the F1 (A) or

F2 (mA) button to confirm; or use

arrow keys along with scroll wheel

to complete the setting.

Time

Under the Sequence function, press

F2 (Edit) button followed by

selecting F2 (Time). The setting on

LCD is activated and appears in red

font color . Use

number pad to set the parameters

directly and then press the F1

(Second) button to confirm; or use

arrow keys along with scroll wheel

to complete the setting.

Construct Templet

Description

This function can be used for practical applications

when different voltage waveforms are required to be

output. Users can edit the output waveform according

to their needs. The built-in Sine, Pulse, Ramp, Stair Up,

Stair Dn, Stair UpDn, Exp Rise, Exp Fall waveforms are

practical per usage.

Parameter

Description

Object

To edit Voltage or Current

Type

Select the buit-in waveforms

including Sine, Pulse, Ramp, Stair

54

BASIC OPERATION

Up, Stair Dn, Stair UpDn, Exp Rise,

Exp Fall.

Max

Value

Set the max. value of waveform

voltage/current

Min

Value

Set the min. value of waveform

voltage/current

Start

Set the initial group number of

waveform. Maximum: 2037

Points

Select the required points. Range: 102047

Inverted

Invert the selected waveform

Parameter

Setting

Object

Press the F1 (Object) button to select

Voltage /Current

in turn. Simply stop at the

parameter which is in need of

setting.

Type

Afer pressing the F2 (Type) button,

select the button corresponding to

the applicable waveform. Up to 8

default waveforms are available for

selection.

Max

Value

Press the F3 (Max Value) button. The

setting on LCD will be activated and

appears in red front color

. Use number pad to set

the parameters directly and then

press the F1 (V/A) or the F2

(mV/mA) button to confirm; or use

arrow keys along with scroll wheel

to complete the setting.

55

GPP Series User Manual

Min

Value

Press the F4 (Min Value) button. The

setting on LCD will be activated and

appears in red front color. Use

number pad to set the parameters

directly and then press the F1 (V/A)

or the F2 (mV/mA) button to

confirm; or use arrow keys along

with scroll wheel to complete the

setting.

Start

Press the F5 (More) button and then

press the F1 (Start) button. The

setting on LCD will be activated and

appears in red front color .

Use number pad to set the

parameters directly and then press

the F1 (Done) to confirm; or use

arrow keys along with scroll wheel

to complete the setting.

Points

Press the F2 (Points) button. The

setting on LCD will be activated and

appears in red front color

. Use number pad to set

the parameters directly and then

press the F1 (Done) to confirm; or

use arrow keys along with scroll

wheel to complete the setting.

Interval

Setting the time interval of each

point of the current selected

template (i.e. the duration of output

of each set of timing parameters) ,it

can be set from 1s to 300s.

Press the F3 (Interval) button. The

setting on LCD will be activated and

appears in red front color

. Use number pad to set

56

BASIC OPERATION

the parameters directly and then

press the F1 (Done) to confirm; or

use arrow keys along with scroll

wheel to complete the setting.

Inverted

Press the F4 (Inverted) button. On

(inverted) and Off (noninverted) appear on LCD

in turn. Simply stop at the status

which is required.

Construct

Construct

Press the F5 (Construct) to complte

construction.

Menu Tree

Description

User is able to well understand the overall

functions of Sequence via menu tree, which

is put in proper order by tiers. The Return

key is used for back to the parent menu. See

the construction below:

Advance

Sequence

Level1------------

Level2------------

Level3------ ......

Level4----

Set

Edit

Level5-------

Level6---------(...)

Done

Return

Cycles No. ......

57

GPP Series User Manual

Done Done Type *.CSV

Return PageUp Sine *.SEQ

Sequence

Cycles No. Object Type Restart

Return Last (Stair Dn) Save Return

Done V V/A

Return mV mV/mA

PageDown Pulse

Return Ramp

Next (Stair UpDn)

Return (Exp Rise) Recall

Return V/A

Last Return

Next MinValue

Return Return Return

(Return) Select

mV/mA

Infinite Save Return

Return

Return Construct

(Exp Fall)

Start Time StairUp NewFile SEQ.Off

Done Second More

Groups Voltage MaxValue Return

Return

Endstate Current More

A Start (Done, Return)

mA Points (Done, Return)

Last Interval (Done, Return)

Next Inverted

Advance

Set Edit Templet Memory SEQ.On Return

Note: In the Memory menu, Type/*.CSV/*.SEQ/New

File/Select appear only when flash drive is plugged in.

58

BASIC OPERATION

Save and Recall

Description

GPP models can save and recall the Sequence

data from internal 10 groups or flash drive.

Parameter

Description

Type

New File

Avaialble for *.CSV or *.SEQ

file type

Avaialble for creating new

*.CSV or *.SEQ file type

*.CSV or *.SEQ file type

Save

Save the Sequence data to the

specified file.

Recall

Recall the data saved in the

specified file.

Select

Select the file folder in need.

Operation

Internal

storage

1. In the Sequence menu, press F4

(Memory) button to enter the page as

figure show below.

2. Press right arrow button to enter

the list of 10 groups.

59

GPP Series User Manual

Flash

drive

storage

3. Rotate the scroll wheel (Encode) to

select target file.

4. Press F3 (Save) button to save the

settings of Sequence into the

corresponding file.

Press the F4 (Recall) button to recall

the Sequence file of list to the current

sequence settings when necessary.

1. Plug flash drive in before rotating

the scroll wheel (Encode) to select

flash drive.

2. Press right arrow button to enter

the root directory of flash drive.

3. Press F1 (Type) button to select

required file type *.CSV or *.SEQ.

4. Rotate the scroll wheel (Encode) to

select target file.

60

BASIC OPERATION

5. Press F3 (Save) button to save the

settings of Sequence into the

corresponding file.

6. Press the F4 (Recall) button to recall

the Sequence file of list to the current

sequence settings when necessary.

61

GPP Series User Manual

Delay Function

Description

It is necessary to output a series of pulse in real

applications. This function is available when

voltage is constant. Output waveform can be

edited per user’s preference. The amplitude

range of the output waveform is the output

voltage range of power supply. The setting

range for output waveform duration is 1s ~

Infinite (duration calculation: Time x Groups x

Cycles) and the resolution is 1s.

Note: This feature is applicable to both CH1

& CH2.

Set Delay Output

Parameter

Description

Cycles

Cycle number, 1 represents a cycle of

single period. 2 represents a cycle

with 2 periods, and so on. The range

is from 1 to 9999 or Infinite.

Start

The number (No.) to start execute. 0

indicates the execution starts from

the group 0, while 1 indicates it

begins from the group 1, and so on.

The range is from 0 to 2047.

62

Groups

The number to be executed. It can

NOT exceed 2048 for Start+Groups.

End State

There’re 3 statuses after the

necessary Group and Cycle are

executed: output termination or

output on or being hold with the last

step.

Stop

Condition

Halt the current operation based on

the set condition of

Voltage/Current/Power.

Parameter

Setting

Cycles

Press the Advance key on control

panel. Select the F3 (Delay) function.

Press the F1 (Set) button followed by

selecting F1 (Cycles). The setting on

LCD is activated and appears in red

font color . Use number

pad to set the parameters directly

and then press the F1 (Done) button

to confirm; or use arrow keys along

with scroll wheel to complete the

setting. Press and hold the F5

(Infinite) button if Infinite execution

is in need.

Start

Under the Delay function, press the

F1 (Set) button followed by selecting

the F2 (Start). The setting on LCD is

activated and appears in red font

color . Use number pad to

set the parameters directly and then

press the F1 (Done) button to

confirm; or use arrow keys along

with scroll wheel to complete the

setting.

BASIC OPERATION

63

GPP Series User Manual

Groups

Under the Delay function, press the

F1 (Set) button followed by selecting

the F3 (Groups), the setting on LDC

will be activated and appears in red

font . Use number pad

for direct setting followed by

pressing F1 (Done) key to confirm; or

use arrow keys along with scroll

wheel to complete setting.

End State

Under the Delay function, press the

F1 (Set) button followed by selecting

the F3 (Groups), and 3 statuses

Last/Output on/ Output off will

appear in turn on LCD

. The one

displaying is what’s called the

current status.

Stop

Condition

Under the Delay function, a condition of

stopping operation can be set. When the

instrument monitors the condition, the

execution of delay function can be

terminated. press the F3 (Stop) button

and halt the operation by setting voltage

F2 (Voltage), current F3 (Current) and

power F4 (Power), or Stop infinitely by

F1 (None). The output state of the

instrument after stopping is determined

by the setting of "End State".

Operation

ON/OFF

Press the F5 (Delay On) button.

Output is open when output lights

up; whilst output is off when output

lights out. DLY appears on the status

bar (yellow for CH1, blue for CH2,

and white for both CH1 & CH2 on).

At this time, the F5 button will

become "Delay OFF", which can

64

BASIC OPERATION

perform the function of closing

Delay .

In Delay ON, the F1 (Restart) button

appears, it means that start from the

first; in CH1/CH2 running delay,

the F2 (Sync) button appears, it

means that two channels start from

the first at the same time.

Warning

If the channel has been in Output

ON before Delay function, the status

remains unchanged until Delay.On

so that the corresponding waveform

starts to output.

Set Group Parameter

Description

Each Group consists of Vltage, Current and Time.

Therefore, properly confirm parameter of each group is

correct before setting Delay output.

Parameter

Descriptiom

No.

Group number. Maximum 2047

State

Output status of each group: On,

Off

Time

Execution duration of each group.

Range: 1s – 300s

Patterm

Set the initial status of initial group.

01 Patt: start from Off; 10Patt: start

from On

Time set

It is used to generally set the pattern

of time change. Model is for the

changes covering fix (FixTime),

increase (Increase) and decline

65

GPP Series User Manual

(Decline). Base Time is for setting

time of initial Group. Step is for

setting time interval of neighboring

Group.

Parameter

Setting

No.

Under the Delay function, press the

F2 (Edit) button followed by

selecting the F1 (No.). The setting on

LCD is activated and appears in red

font color . Use number

pad to set the parameters directly

and then press the F1 (Done) button

to confirm; or use arrow keys along

with scroll wheel to complete the

setting. The F4 (Page Up)key and F5

(Page Down) key can jump directly

to the previous or next page,each 8

groups is a Page.

State

Under the Delay function, press the

F2 (Edit) button, and then the F2

(State) button followed by selecting

F1 (On), F2 (Off) or F3 (Inverted) to

set output On/Off status of each

group. Press the F4 (Last) key for

the previous one and the F5 (Next)

key for the next one

Time

Under the Delay function, press the

F2 (Edit) button followed by

selecting the F3 (Time). The setting

on LCD is activated. Use number

pad to set the parameters directly

and then press the F1 (Second)

button to confirm; or use arrow

keys along with scroll wheel to

complete the setting. Press the F4

(Last) key for the previous one and

the F5 (Next) key for the next one.

66

BASIC OPERATION

Patterm

Under the Delay function, press the

F2 (Edit) button followed by

selecting F4 (Pattern), and then set

up via F1 (01Patt) and F2 (10Patt).

The live setting result appears on

the LCD.

Time Set

Under the Delay function, press the

F2 (Edit) button followed by

selecting the F5 (Time Set), and then

set time change patterns of each

group, There are 3 types"Time Gen"

options:fix (FixTime), increase

(Increase) and decline (Decline) of

which are available) via F1 (Model).

The live setting result appears on

the LCD.

On Delay

Off Delay

When fix (FixTime) is set in Time

Set, it’s available to set the time

value of both F2 (On Delay) and F3

(Off Delay)at the same time.

Base

Time Step

When increase (Increase) or decline

(Decline) is set in Time Set, it’s

available to set the time value of F2

(Base Time) start time and F3

(Step)group change at the same

time.

67

GPP Series User Manual

Menu Tree

Description

User is able to well understand the overall

functions of Delay via menu tree, which is put in

proper order by layer. The Return key is used for

back to the parent menu. See the construction

below:

Level1------------ Advance

Level2------------ Delay

Level3------ ......

Level4----

Set

Edit

Level5-------

Done

Return

Cycle No. ......

68

BASIC OPERATION

Note: In the Memory menu, Type/*.CSV/*. DLY/New

File/Select appear only when flash drive is plugged in.

Delay

Cycles No. None Type Restart

Done Done Voltage *.CSV Sync

Return PageUp Define *.DLY

Return Off Current Save

Done Second Define Return

Return Last W

PageDown V Delay.Off

Return mV

Inverted Define

Last A Recall

Next mW

Return Return

Return Model

Return Return Select

Infinite Time Set

Return

Next mA

Start State Return NewFile Return

Done On

Groups Time Power

Endstate Patterm Return

01 Patt

10 Patt

Advance

Set Edit Stop Memory Delay On Return

On Delay

Off Delay

Return

69

GPP Series User Manual

Save and Recall

Description

GPP models can save and recall the Delay data from

internal 10 groups or flash drive.

Parameter

Description

Type

Avaialble for *.CSV or *.DLY file type

New File

Avaialble for creating new *.CSV or

*.DLY file type

Save

Save the delay data to the specified

file.

Recall

Recall the data saved in the specified

file.

Select

Select the file folder in need.

Operation

Internal

Storage

1. In the Delay menu, press F4

(Memory) button to enter the page as

figure show

below.

2. Press right arrow button to enter

the file list of 10 groups.

70

BASIC OPERATION

Flash

drive

storage

3. Rotate the scroll wheel (Encode) to

select target file.

4. Press F3 (Save) button to save the

settings of Delay into the

corresponding file.

5. Press the F4 (Recall) button to recall

the Delay file of list to the current

sequence settings when necessary.

1. Plug in flash drive before rotating

the scroll wheel (Encode) to select

flash drive.

2. Press right arrow button to enter

the root directory of flash drive.

3. Press F1 (Type) button to select

required file type *.CSV or *.DLY.

4. Rotate the scroll wheel (Encode) to

select target

file.

71

GPP Series User Manual

5. Press F3 (Save) button to save the

settings of Delay into the

corresponding file.

6. Press the F4 (Recall) button to recall

the Delay file of list to the current

sequence settings when necessary.

Monitor Function

Description

In order to have well understanding of the

channel under long-term output, the GPP series

has the additional live monitor function, which

helps guarantee load status of client via halting

operation based on certain preset conditions.

Warning: this feature is Not applicable to

CH3 of GPP-3323.

72

BASIC OPERATION

Set Monitor

Parameter

Description

Voltage

Set condition of monitor of voltage.

Current

Set condition of monitor of current.

Power

Set condition of monitor of power.

Stop

Type

Set status after halt. 3 types are

available, output disable, content

notice and audible alarm.

Select

To confirm if

voltage/current/power is selected as

monitor object. White font stands for

selected, while gray font represents

not selected.

Parameter

Setting

Voltage

Press the Advance key on control

panel. Select the F4 (Monitor)

function followed by pressing the F1

(Voltage) button to enter the voltage

setting.

1. Press the F1 (Set) button. The

setting on LCD is activated and

appears in red font color. Use

number pad to set the parameters

directly; or use arrow keys along

with scroll wheel to complete the

setting.

2. Press the F4 (Define) button to

define terminated condition.

3. Press the F5 (Logic) button to

define logical pattern of other

conditions.

73

GPP Series User Manual

Current

Press the Advance key on control

panel. Select the F4 (Monitor)

function followed by pressing the F2

(Current) button to enter the current

setting.

1. Press the F1 (Set) button. The

setting on LCD is activated and

appears in red font color. Use

number pad to set the parameters

directly; or use arrow keys along

with scroll wheel to complete the

setting.

2. Press the F4 (Define) button to

define terminated condition.

3. Press the F5 (Logic) button to

define logical pattern of other

conditions.

Power

Press the Advance key on control

panel. Select the F4 (Monitor)

function followed by pressing the F3

(Power) button to enter the power

setting.

1. Press the F1 (Set) button. The

setting on LCD is activated and

appears in red font color. Use

number pad to set the parameters

directly; or use arrow keys along

with scroll wheel to complete the

setting.

2. Press the F4 (Define) button to

define terminated condition.

74

BASIC OPERATION

3. Press the F5 (Logic) button to

define logical pattern of other

conditions.

Stop

Type

Press the Advance key on control

panel. Select the F4 (Monitor)

function followed by pressing the F4

(Outoff) button to set output disable;

select F2 (Alarm) to set content

notice; select F3 (Beeper) to set

audible alarm. Buzzer should be

turned on in system settings when

Beeper is enabled, refer to page 90.

Operation

ON/OFF

Press the F5 (MON. On) button to

enter live monitor. MON appears on

the status bar (the color of channel

remains the original when single

channel is enabled, whilst it turns to

white when multiple channels are

activated).

Recorder Function

Description

In order to have well understanding of the channel

under long-term output, the GPP series has the

additional live record function, which saves file via

media for further analysis later.

Warning: this feature is Not applicable to CH3 of

GPP-3323.

75

GPP Series User Manual

Set Recorder

Parameter

Description

Period

Set period of each recorded.

Groups

Set recorded group number.

Channel

Set recorded channel.

Memory

Set saving location of record.

Parameter

Setting

Period

Press the Advance key on control

panel. Select F5 (Recorder) function.

Press F1 (Period) button to enter

setting of recorded period. The

setting on LCD is activated and

appears in red font color. Use

number pad to set the parameters

directly and then press the F1 (s)

button to confirm; or use arrow keys

along with scroll wheel to complete

the setting.

Groups

Press the Advance key on control

panel. Select the F5 (Recorder)

function. Press the F2 (Groups)

button to enter setting of recorded

76

BASIC OPERATION

group number. The setting on LCD

is activated and appears in red font

color. Use number pad to set the

parameters directly and then press

the F1 (Done) button to confirm; or

use arrow keys along with scroll

wheel to complete the setting.

Channel

Press the Advance key on control

panel. Select the F5 (Recorder)

function. Press the F3 (Channel)

button to enter setting of recorded

channel. F1 (CH1), F2 (CH2), F3

(CH3), F4 (CH4) are available for

selection. The numbers of channel

may vary by models.

Memory

Press the Advance key on control

panel. Select the F5 (Recorder)

function followed by pressing F4

(Memory) button to setting of

recorded saving. Recorded data can

be stored in internal memory or

external USB Flash.

Internal

Storage

1. Press right arrow button to enter the

list of 10 groups. Rotate the scroll

wheel (Encode) to select target file.

Also rotate the scroll wheel (Encode)

to enter the flash drive when

necessary.

77

GPP Series User Manual

2. Press F3 (Save) button to save the

temporary data into the

corresponding file.

3. Press F4 (Recall) button to save the

record data of file into the

temporary storage for further saving

into flash drive later.

Flash

drive

operation

descriptio

n

Note:

Type/*.CSV/ *.REC/New

File/Select buttons appear when

flash drive is selected.

Type is used to select *.CSV and

*.REC file types.

New File is used to create new file.

Select is used to open the required

file folder.

Operation

ON/OFF

Press F5 (REC.On) button to enter

live record function. REC appears

on the status bar (the color of

channel remains the original when

single channel is enabled, whilst it

turns to white when multiple

channels are activated).

78

BASIC OPERATION

Enternal I/O Control

Description

The GPP series models

provides user with a

programmable external

trigger port, which is used

to dock certain functions

control.

Function

It can turn each Data Line

(D0,D1,D2,D3,D4) into input signal

respectively to have command of the