Grundig RRCD-2420-MP-3 Service manual

Service Document

Exchange Set

RRCD 2420 MP3

Service

Manual

Sicherheit

Safety

Materialnr./Part No.

720108000001

Dieses Service Dokument ist nur in Datenform verfügbar

This Service Document is only available as data

Änderungen vorbehalten/Subject to alteration

Made by GRUNDIG in Germany • HS-41 0305

http://www.grundig.com

Es gelten die Vorschriften und Sicherheitshinweise

gemäß dem Service Manual "Sicherheit", Material-

S

nummer 720108000001, sowie zusätzlich die eventuell abweichenden, landesspezifischen Vorschriften!

The regulations and safety instructions shall be

valid as provided by the "Safety" Service Manual,

S

part number 720108000001, as well as the

respective national deviations.

ǵ

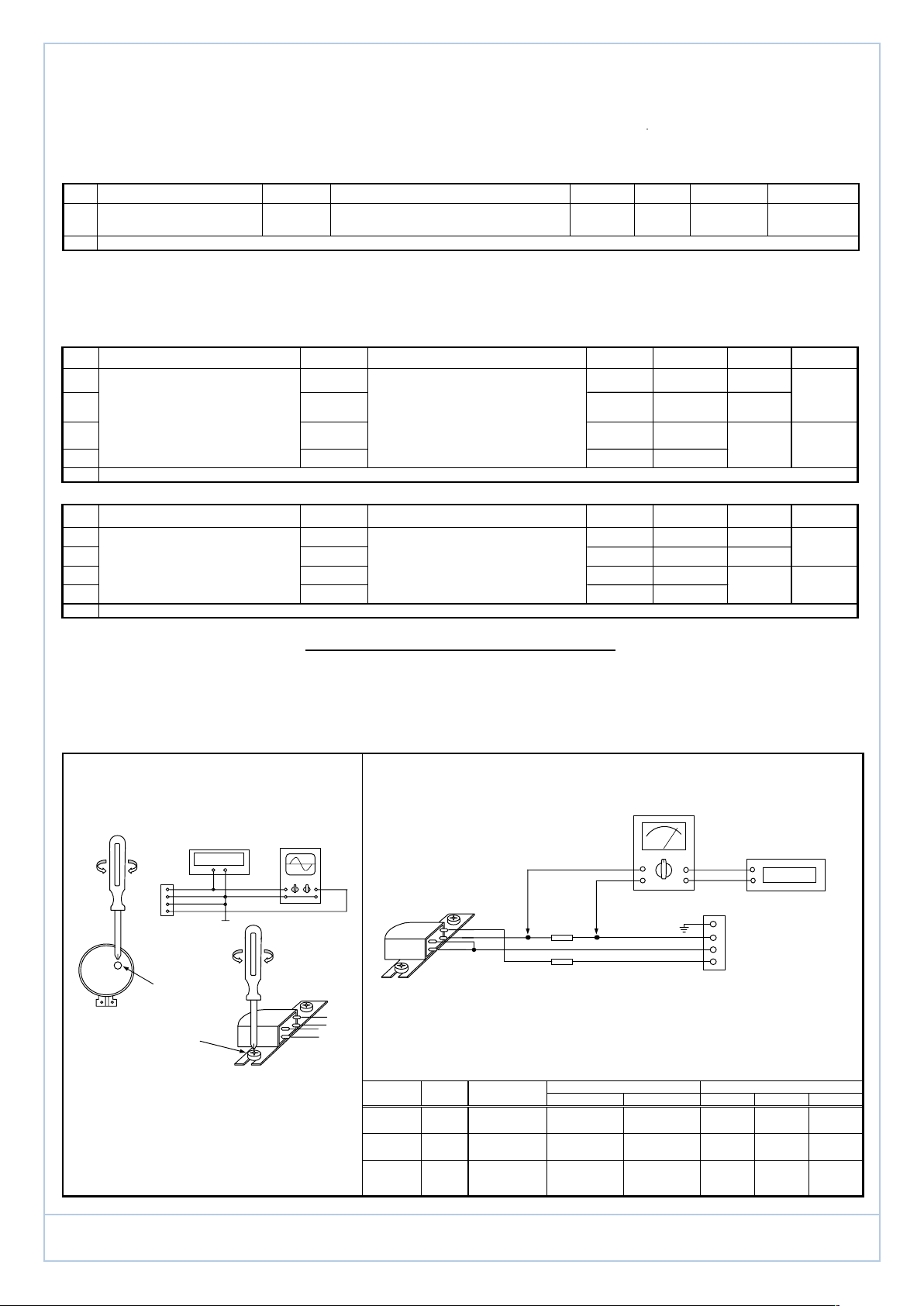

A L I G N M E N T P R O C E D U R E

(

INSTRUMENTS REQUIRED GENERAL PREPARATION

1. Signal Generator 1. Check source voltage, DC or AC according to specificaions

2. FM Signal Generator 2. Set function switch to band being aligned

3. FM/AM IF Sweep Generator (10.7 MHz for FM) 3. Signal input should be kept as low as possible to avoid AGC and AFC function

4. VTVM 4. Standard modulation :

5. Oscilloscope

6. Frequency counter

7. Regulated DC power supply

AM IF ALIGNMENT

SIGNAL SOURCE (AM RF Gen.)

STEP

1 loop and ground (TP4) Point T601 Maximum min. position

2 Repeat step 1 for max. output

FM IF ALIGNMENT

This model requires no FM IF alignment as the IF is fixed by ceramic filter and discriminator CF502 or CF503 & CF505. Please take note that correct type and same color dot of ceramic filter is used

in servicing, diff color dot of ceramic filter may cause worse IF 'S' curve characteristic and distortion.

Connect IF genescope output terminal to TP3 & TP4 (GND) in series with a 1000Pf capacitor, connect scope input terminal to TP1 & TP2 (GND), then the IF characteristic curve can be observed.

CONNECT TO

A standard radiation 450KHz Detector output terminal Quiet Volume control at

SET SIGNALTOALIGNMENT INDICATOR (Oscilloscope, VTVM)

CONNECT TO

TP3

AM 1 KHz 30% mod

FM 1 KHz 22.5 KHz dev

SET RADIO

DIAL TO

ADJUST ADJUST FOR REMARKS

FM RF ALIGNMENT

STEP

SIGNAL SOURCE (FM Signal Gen.)

1

2

3 88 MHz

4 (modulated) 106 MHz (RF trimmer)

Repeat steps 3 and 4 as necessary to minimize tracking error and also steps 1 and 2 if necessary

5

CONNECT TO

TP1 & TP2 108 MHz Terminals 108 MHz

through matching network (modulated) across speaker (Highest end) squeeze

if necessary voice coil L601 (RF coil)

SET SIGNALTOALIGNMENT INDICATOR (Oscilloscope, VTVM)

87.5 MHz 87.5 MHz NA

(modulated) (Lowest end) Volt meter is

(modulated) squeeze Maximum control at

106 MHz TC 601

CONNECT TO

SET RADIO

DIAL TO

88 MHz stretch or Volume

ADJUST ADJUST FOR REMARKS

NA

L604 (Osc. Coil)

stretch or DC 8V ±0.3V

Connected to

TP 5 and grg

max. position

AM RF ALIGNMENT

STEP

SIGNAL SOURCE (AM Signal Gen.)

1 (modulated) (Lowest end) NA

2

3 (modulated) 603 KHz (ant. coil) Maximum control at

4 (modulated) 1404 KHz (ant. trimmer)

Repeat steps 3 and 4 as necessary to minimize tracking error and also steps 1 and 2 if necessary

5

CONNECT TO

A standard radiation (modulated) Across speaker (Highest end) (Osc.Coil) DC 8V ±0.3V

loop ant. 603 KHz voice coil L 603 Volume

SET SIGNALTOALIGNMENT INDICATOR (Oscilloscope, VTVM)

522 KHz 522 KHz Digital DC

1620 KHz 1620 KHz L 605

1404 KHz TC 603

CONNECT TO

SET RADIO

DIAL TO

ADJUST ADJUST FOR REMARKS

Volt meter is

NA

Connected to

TP 5 and grg

max. position

ALIGNMENT PROCEDURE FOR CD SECTION

Applicable unit :

1 This model is using CD drive unit No. SANYO DA11B3V

2 The alignment for CD section is fully automatic and no adjustment is reguired

GENERAL PREPARATION -

A ) MEASURING INSTRUMENTS REQUIRED FOR TAPE B ) EQUIPMENTS REQUESTED FOR AC BIAS FREQUENCY / CURRENT ADJUSTMENT :

SPEED AND HEAD AZIMUTH ADJUSTMENT.

( 1 ) TAPE SPEED ADJUST

MTT-111 (3000 Hz) TEST

SPEAKER

TERMINALS

MOTOR

TAPE IS REQUIRED

1 ) Check source voltage, DC or AC according to specifications . 2 ) Set function switch to Tape being aligned .

°

FREQUENCY

COUNTER

3000 Hz

R/P HEAD

OSCILLOSCOPE

CH. 1

FIG.1

CH. 2

FIG.2

INPUT

R/P HEAD

Ra

10 ohm

Rb

10 ohm

VTVM

OUTPUT

4

1

FREQUENCY

COUNTER

60KHz

==> TO CASS PCB

CN401

Digital DC

AZIMUTH ADJ. SCREW

AC BIAS FREQUENCY ALIGNMENT :

Note :The test unit should be keep in recording mode and added two resistors Ra & Rb as shown in the

Fig. 2 before alignment. be sure to delete the both resistors Ra & Rb after alignment completed.

( 2 ) HEAD AZIMUTH ADJUSTMENT . Test Point Adjust Frequency Frequency Observe at Observe

2.1 - Connect the equipments as shown in the Fig. 1. at Beat 0 Beat 1 Beat 2 Beat 0 Beat 1 Beat 2

(The Both Speakers loading Are Required) Resistor

2.2 - Insert a test tape

2.3 - Press PLAY and set VOLUME at reference output.

10 KHz : MTT-114 ) into deck.

Ra or Rb L401 60KHz ± 0.3KHz 54KHz ± 2KHz

2.4 - Adjust the azimuth adjustment screw for the max.

& balance ch. output on both ch. of oscilloscope.

2.5 - Secure above screw with glue after adj. completed.

ǵ

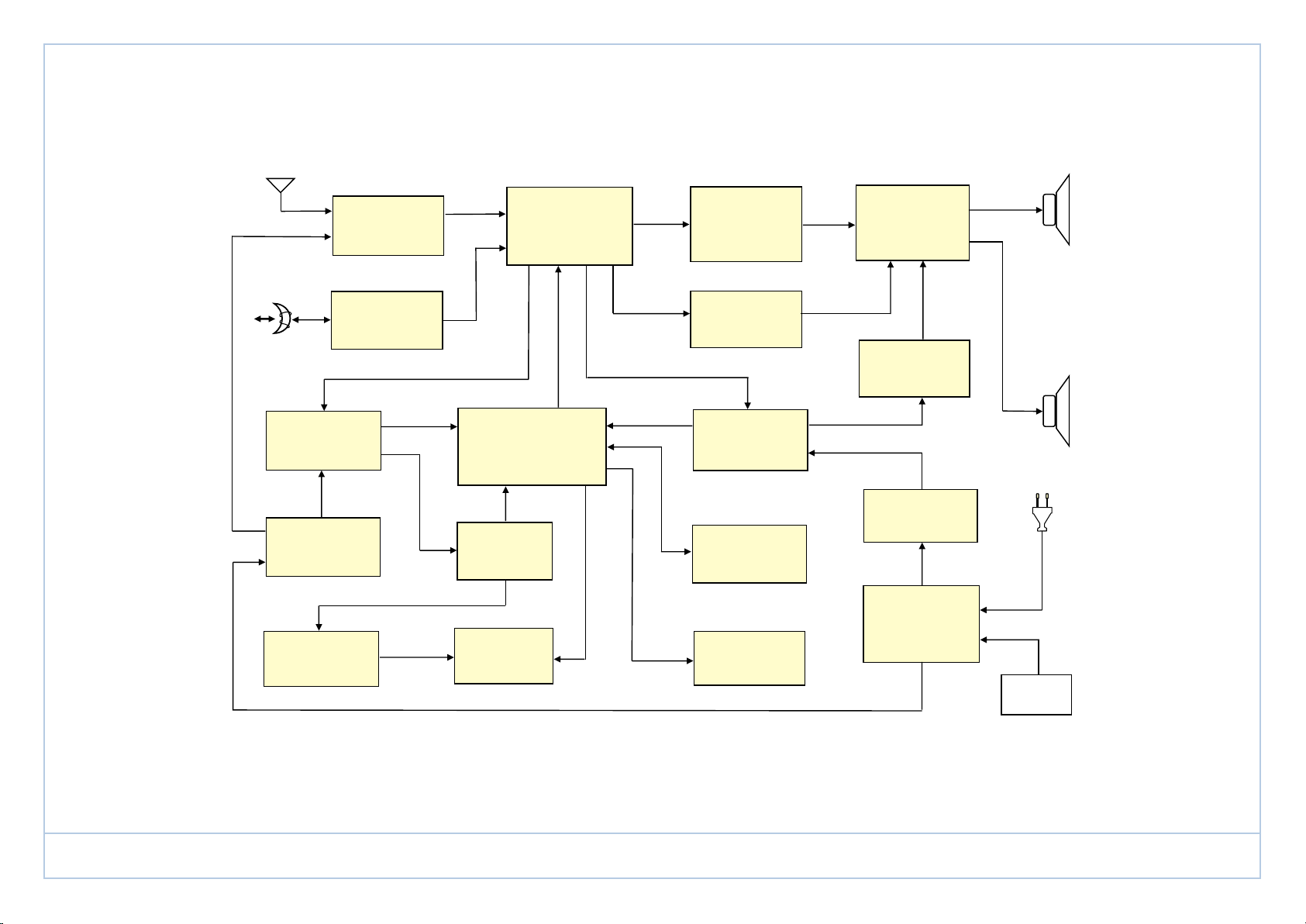

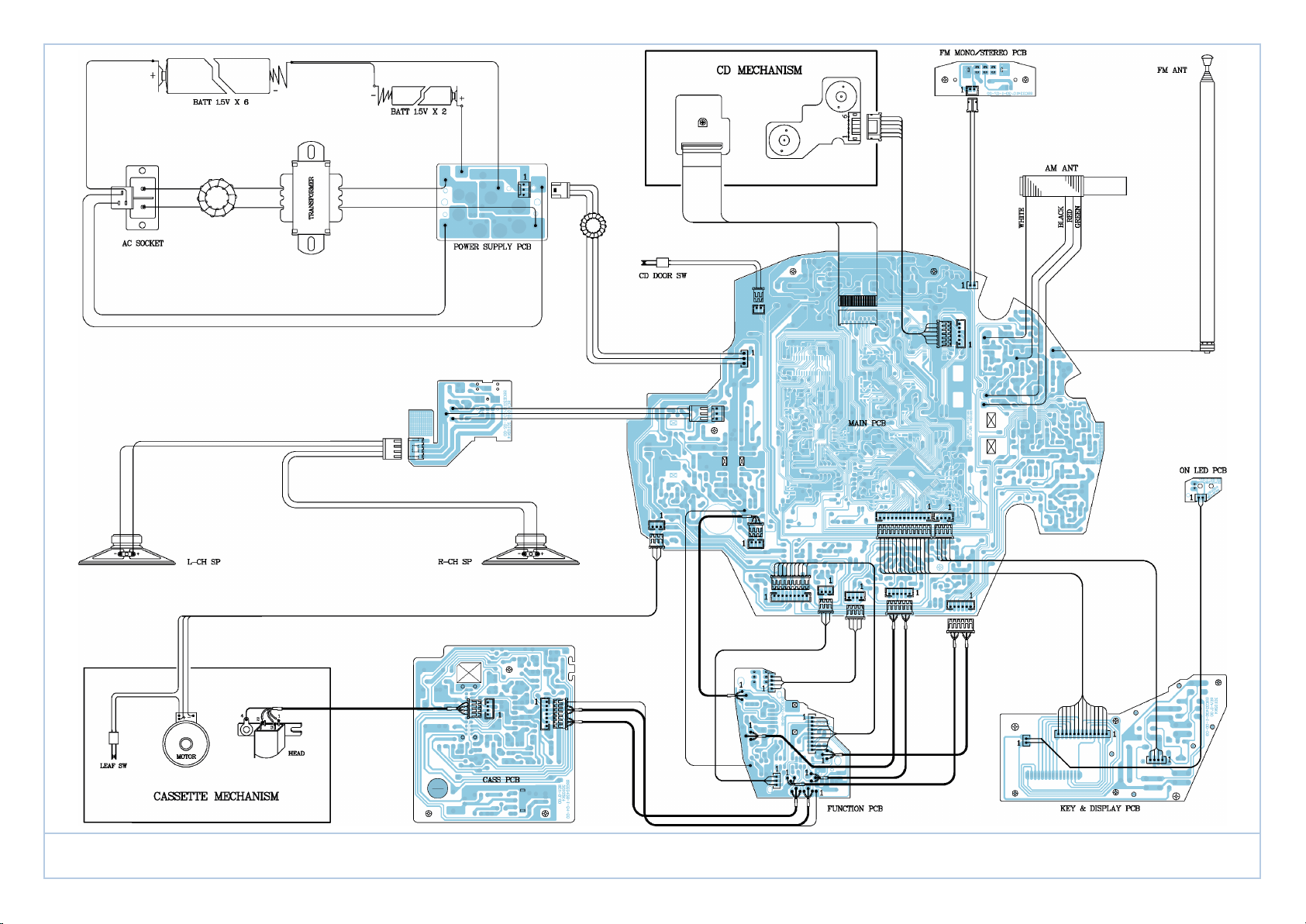

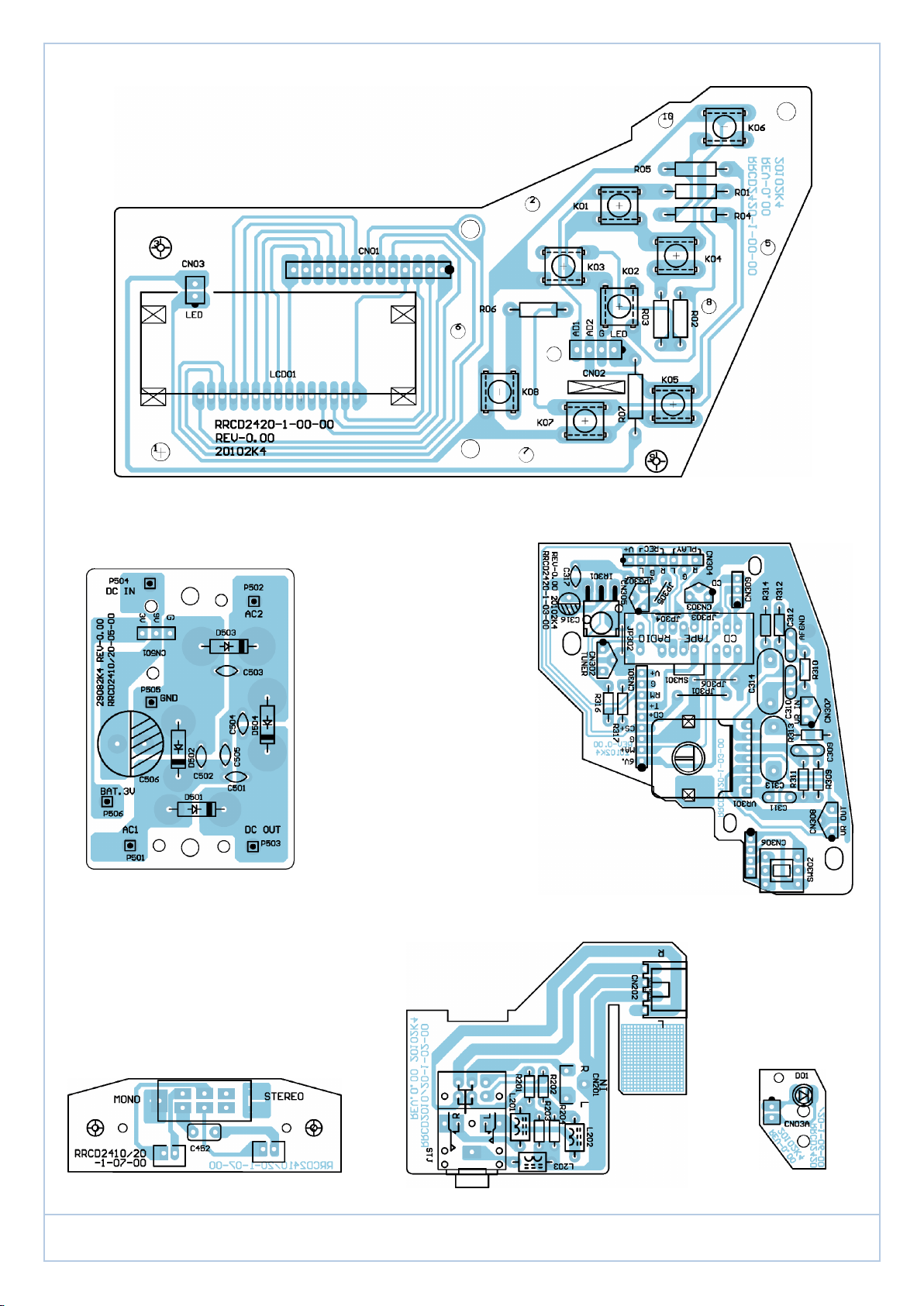

RRCD 2420 MP3

FM ANT.

R/P HEAD

TUNER

IC601 TB2132FN

TAPE R/P

IC401 LS22241

FUNCTION

SELECTOR

SW 301

AUDIO

CONTROL

VR301

Q301 Q302

POWER

SWITCH

Q105

POWER

AMPLIFIER

IC101 DV3287B

MUTING

CIRCUIT

Q207 Q208

R-CH

SPEAKER

5.7Ω

L-CH

ǵ

CD POWER

SUPPLY SW.

Q701 Q702 Q705

6.5V REG

Q105~Q109

3.3V REG

U708 B1117N

CD SERVO SYSTEM

U702 TC94A02F

U703 TA2153FN

U706 MM1469PH

5V REG

U709 7805

IM SRAM

U705

MCU

U701

TC94A09E-209

5V REG

Q111 ~ Q113

CD

MECHANISM

DA11B3V

MAIN POWER

SUPPLY

D501 ~ D504

DISPLAY

BATT

1.5V X 6

RRCD 2420 MP3

ǵ

RRCD 2420 MP3

ǵ

RRCD 2420 MP3

Loading...

Loading...