Page 1

TABLE TOP KETTLES

PROJECT NAME:

LOCATION:

ITEM NO:

TILTING DIRECT STEAM MODEL TDC/3

Kettle shall be a Groen Model TDC/3 (specify 3,6,10 or 20 quart) stainless steel 2/3 steam jacketed unit

operating from direct steam.

AVAILABLE MODELS:

TDC/3-3 (3 QUART)

TDC/3-6 (6 QUART)

TDC/3-10 (10 QUART)

TDC/3-20 (20 QUART)

CONSTRUCTION: Kettle interior shall be of 304

stainless steel, solid, one-piece welded construction.

Support arms are heavy stainless steel tubing. Rim shall

be heavy reinforced with a welded “Butterfly” shaped

pouring lip for pouring control and durability. Kettle shall

have two operating handle lugs so that the handle can

be attached on right or left side.

FINISH: Interior of kettle shall be polished to a 180

emery grit finish. Exterior of kettle shall be finished to

a bright high buff finish, ensuring maximum ease in

cleaning and maintaining brilliant appearance.

ASME CODE: Unit shall be ASME shop inspected,

stamped and registered with the National Board for

operation up to a maximum working pressure of 55 PSI.

SANITATION: Unit shall be designed and

constructed to meet NSF requirements and be NSF

listed.

STEAM PRESSURE: Kettle shall operate

dependably at any steam pressure between 5 and 55

PSI. Higher working pressure available.

PERFORMANCE/FEATURES: Pouring height

shall be such that kettle can be emptied into an 8” high

pan on a flat table. Design shall make it possible for

one person to tilt kettle, even when kettle is filled to

capacity. All sizes, including 3 and 6 quart models,

have full bottom hemisphere steam jacket, for rapid

product heating.

MOUNTING: Kettle shall be mounted on sturdy

tubular stainless steel arms. The steam supply

shall enter through the left kettle support arm into

the jacket at the rotary joint. Condensate shall be

removed through the right rotary joint, down through

the support arm. No exposed steam piping shall be

on the kettle body. Multiple kettles can be table or

back bar mounted for display cooking. Minimum table

space required: 14” for 3-10 quart and 16” for 20

quart.

INSTALLATION: Steam trap assembly is

required and not provided unless ordered as an

option. 3/8” IPS steam inlet and condensate outlet

required. Safety valve and remote steam source

required.

ORIGIN OF MANUFACTURE: Designed and

manufactured in the United States.

QTY:

MODEL NO:

AIA NO:

SIS NO:

Stainless steel 2/3 steam jacketed

kettle, table top mounted, tilting,

direct steam heated, 3, 6, 10 and

20-quart capacity.

OPTIONS/ACCESSORIES:

Etch marks, gallons

Etch marks, liters

316 s/s liner

Basket insert

Nylon basket liner

Liner retaining ring

Lift off cover

Cover strainer

Stand

Steam trap assembly

Pressure relief valve

Globe valve

Steam pressure regulator

Cabinet base

Table top stand

Table Top Kettles

141045 RevC

Revised 04/12

Page 2

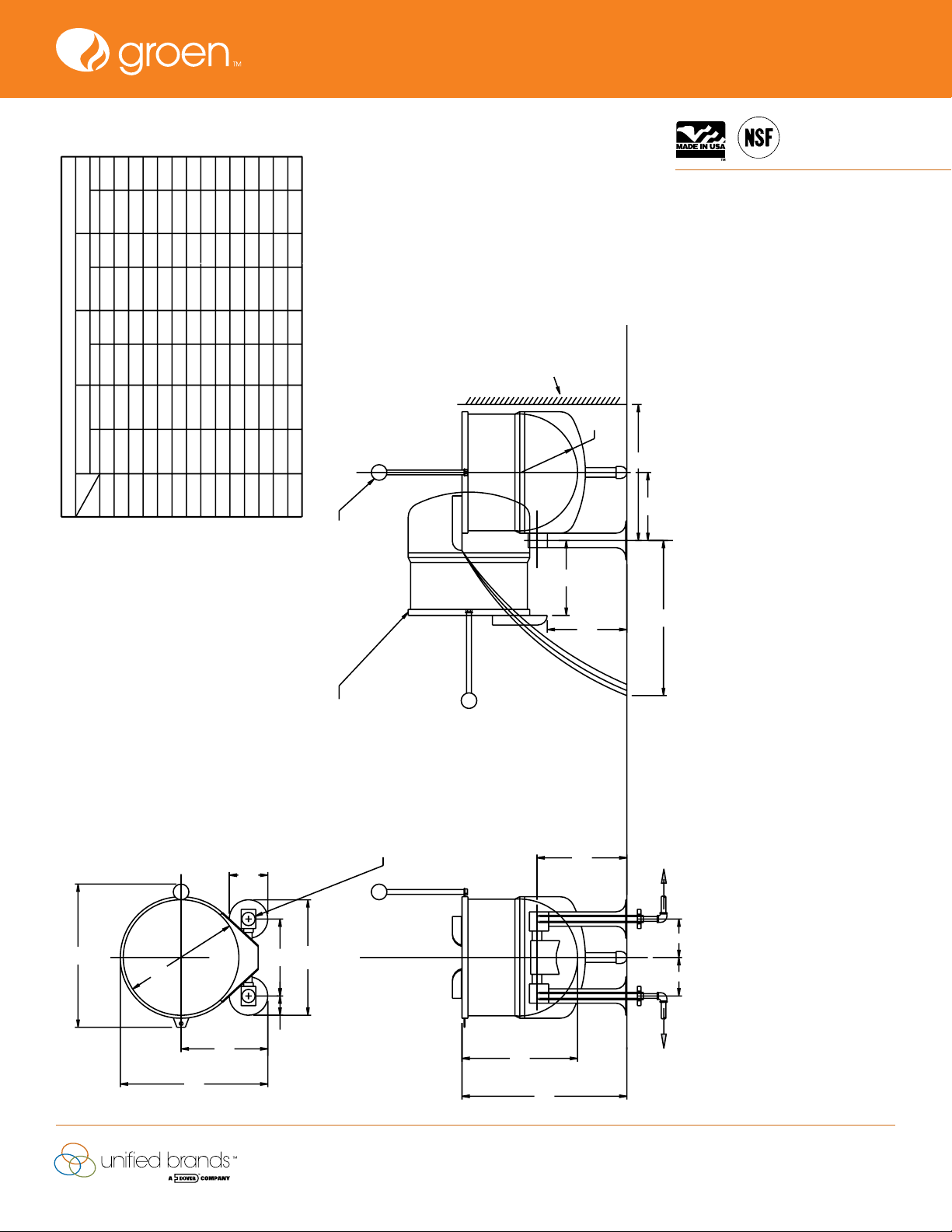

P/N 146528 REV E

8

(203)

J

K

C

HANDLE CAN BE

MOUNTED ON EITHER

SIDE OFKETTLE

L

M

P

H

G

F

E

B

D

12

(305)

2

(51)

4" DIA.

(101)

44

(101)(101)

A

(2) 1 3/8 DIA. HOLESREQ.

FOR MOUNTING

KETTLE IN

TILTED POSITION

3/8" I.P. S.

CONDENSATE

OUTLET

(5.7 L)

MM

TA BLE OF DIMENSIONS

G

F

E

D

C

B

DIM.

6 QT.

CAP.

A

IN.

1210

225

305

387

378

225

409

254

203

336

327

8 7/8

16 1/8

10

8

13 1/4

12 7/8

438

229

(18.9 L)

304

MM

(9.5 L)

254

MM

10 QT.

IN. IN.

20 QT

3/8" I.P.S.

STEAM

INLET

5

15

8 3/4

6 1/8

12 1/8

25 1/2

6

IN.MM

3 QT.(2.8 L)

HJKLMNP

152

307

155

222

381

648

127

7

14 1/8

7 1/8

8 1/2

16 1/8

26 1/2

6

9

12

8 7/8

15 1/4

17 1/8

14 7/8

152

409

216

181

359

673

178

NOTES:

1. SEE DWG.C-7059-2 FOR PIPING INSTALLATION DETAILS.

2. EXTENDED STEM. GLOBE VALVE & COLLARED SLEEVE

FURNISHED AT EXTRA COST. SEE DWG.C-7059-2

3. DIMENSIONS IN BRACKETS ( ) ARE MM.

12 1/8 14 1/8307359

5127 6

152

12 1/8

307

13 1/8 333

21 1/2 54622 1/2571

10 25412304

8 203 9229

6152 7178

12 7/8 327 14 7/8378

15 1/4387 13 1/4 336

4 7/8 124

8 7/8 8 7/8225225

11

8 1/2

2 7/8

6 7/8

12 1/8

3 7/8

8 1/4

279

215

73

308

209

98

177

WALL

TDC/3

P/N B-7059-030 REV B

© 2012 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of Dover Corporation.

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

Loading...

Loading...