Page 1

IMPORTANT INFORMATION

IMPORTANT INFORMATION

IMPORTANT INFORMATION IMPORTANT INFORMATION

KEEP FOR OPERATOR

KEEP FOR OPERATOR

KEEP FOR OPERATORKEEP FOR OPERATOR

IMPORTANT INFORMATION

IMPORTANT INFORMATION

IMPORTANT INFORMATIONIMPORTANT INFORMATION

OPERATOR MANUAL OM-TDB

Models: TDB and TDBC

Steam Jacketed Kettle

Self-Contained

Electrically heated

Table top mounted

Tilting

CITSEMODA veR 575731 rebmuN traP

Model TDB

Model TDBC

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE.

READ, UNDERSTAND AND FOLLOW THE INSTRUCTIONS AND

WARNINGS CONTAINED IN THIS MANUAL.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPORS AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER

APPLIANCE.

Information contained in this document is

known to be current and accurate at the time

of printing/creation. Unified Brands recommends referencing our product line websites,

unifiedbrands.net, for the most updated

product information and specifications.

Page 2

OM-TDB

IMPORTANT — READ FIRST — IMPORTANT

CAUTION: BE SURE ALL OPERATORS READ, UNDERSTAND AND FOLLOW THE OPERATING

INSTRUCTIONS,

MANUAL.

WA RNING: THIS UNIT IS INTENDED FO R USE IN THE CO MMERCIAL HE ATING, COOKING AND

HOLDING O F WATER AND F O O D PRODUCTS, PE R THE INSTRUCTIO NS

CONTAINED IN THIS MANUAL. ANY OTHER US E COULD RESUL T IN SERIOUS

PERSONAL INJURY OR DAMAGE TO THE EQUIPMENT AND WILL VOID

WARRANTY.

WA RNING: KETTLE MUS T BE INSTALLE D BY P ERSONNEL QUAL IFIED TO WORK WITH

ELECTRICITY. IMPROPER INSTALLATION CAN RESULT IN INJURY TO

PERSONNEL AND/OR DAMAGE TO EQUIPMENT.

DA NG ER: ELECTRI CAL LY GROUND THE UNIT AT THE TERM INAL PRO VIDED. FAIL URE TO

GROUND UNIT COULD RESULT IN ELECTROCUTION AND DEATH.

WA RNING: A VOID ALL DIRECT CONTACT WITH HOT EQUIPMENT SURFACES . DIRE CT SKIN

CONTACT COULD RESULT IN SEVERE BURNS.

WA RNING: A VOID ALL DIRECT CONTACT WITH HOT FOOD OR WATER IN THE KETTLE.

DIRECT CONTACT COULD RESULT IN SEVERE BURNS.

CA UTION: DO NOT OVER FILL THE KETTLE WHE N CO OKING, HO L DING OR CLE ANING.

KEEP LIQUIDS A MI NI MUM OF 2-3” (5-8 cm) BELOW THE KETTLE BODY RIM TO

A L L O W CL EARANCE FOR STIRRING, BOILING AND SAF E PRODUCT TRANSFER.

WARNING: TAKE SPECIAL CARE TO AVOID CONTACT WITH HOT KETTLE BODY OR HOT

PRODUCT WHEN ADDI NG INGREDIENTS, STIRRING OR TRA NSFERRING

PRODUCT TO A NO THE R CONTAINER.

WA RNING: DO NOT STA ND O N O R AP PLY UNNECESSARY WEIGHT OR PRESSURE ON THE

KETTLE FRONT OR POURING LIP. THI S COULD RESUL T IN OVERL O AD AND

FAILURE OF THE TILT MECHANI SM, AND POSSIBLE SERIOUS INJURY AND

BURNS TO THE OPERATOR AND OTHERS.

WA RNING: WHEN TILTING KETTLE FOR P RO DUCT TRANSFE R:

1) WEAR PROTECTIVE OVEN MITT AND PROTECTIVE APRON.

2) USE CONTAINER DEEP ENOUGH TO CONTAI N AND MINIMIZE PRODUCT

SPLASHING.

3) PLACE CONTA INER ON S TABLE , FLAT SURFACE, AS CLOSE TO KETTLE AS

POSSIBLE.

4) STAND TO LEF T OR RIGHT SI DE OF KETTLE (DEP ENDING ON TILTING

HA NDL E PLACEMENT) WHIL E POURING . DO NOT STAND DI RECTLY IN POUR

PATH OF HOT CONTENTS.

5) POUR SLOWLY, MAINTAIN CONTROL OF KETTLE BODY HANDLE AT ALL

TIMES, AND RETURN KE TTLE BODY TO UP RIGHT POS ITION AF TE R

CONTAINER IS FILLED OR TRANS F ER IS CO MPLE TE .

6) DO NOT OVER FILL CONTA INER. AVOID DIRECT SKIN CONTA CT WITH HOT

CONTAINER AND ITS CONTENTS.

CAUTIONS, AND SAFETY INSTRUCTIONS CONTAINED IN THIS

CAUTION: KEEP

WA RNING: FAILURE TO CHECK PRES SURE RELIEF VAL VE OPE RATION PERIODI CAL L Y

WARNING: WHEN TESTING, AVOID ANY EXPOSURE TO THE STEAM BLOWING OUT OF THE

WA RNING: TO AVOID INJURY, READ AND FOL L O W ALL PRECAUTIO NS STATE D ON THE

WARNING: BEFORE REPLACING ANY PARTS, DISCONNECT THE UNIT FROM THE ELECTRIC

FLOORS IN FRONT OF KETTLE WORK AREA CLEAN AND DRY. IF SPILLS

OCCUR,

COULD RESULT IN PERS O NAL INJURY AND/OR DAMAGE TO EQUIPM ENT.

PRESSURE RELIEF VA LVE. DIRECT CONTACT COULD RESULT IN SEVERE

BURNS.

LABEL OF THE WATER TREATMENT COMP O UND.

POWER SUPPLY.

CLEAN IMMEDIATELY, TO AVOID SLIPS OR FALLS.

2

Page 3

OM-TDB

IMPORTANT — READ FIRST — IMPORTANT

WARNING: KEEP WATER AND SOLUTIONS OUT OF CONTROLS AND ELECTRICA L

EQUIPMENT. NEVER USE A HIGH PRESSURE HOSE TO CLEAN KETTLE

SURFACES.

CA UTION: MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES, MUCO US MEMBRANES

A ND CL O THING. PRECA UTIONS SHO UL D BE TAKEN. WEAR RUBBER GLOVES,

GOGGLES OR FA CE S HIELD AND PROTECTIVE CLOTHING. CAREFULLY READ

THE WA RNINGS AND F OL L O W THE DIRECTIONS ON THE LABEL O F THE

CLEANER TO BE US ED.

CAUTION: USE

IMPORTANT: SERVICE PERFORMED BY OTHER THAN FACTORY AUTHORIZED PERSONNEL

OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY GROEN

OR

THEIR AUTHORIZED DISTRIBUTORS CAN CAUSE OPERATOR INJURY AND

DAMAGE TO THE EQUIPMENT, AND WILL VOID ALL WARRANTIES.

WILL VOID WARRANTI ES.

3

Page 4

OM-TDB

Table of Contents

IMPORTANT OPERATOR WARNINGS ..................................................... 2

EQUIPMENT DESCRIPTION.............................................................. 5

INSPECTION & UNPACKING ............................................................. 6

INSTALLATION......................................................................... 7

INITIAL START-UP ...................................................................... 9

OPERATION .......................................................................... 10

SEQUENCE OF OPERATION ............................................................ 12

MAINTENANCE ....................................................................... 13

COMPONENT REPLACEMENT .......................................................... 16

CLEANING............................................................................ 18

TROUBLESHOOTING .................................................................. 20

PARTS LISTS ......................................................................... 21

SCHEMATICS ......................................................................... 30

SERVICE LOG ........................................................................ 32

REFERENCES ........................................................................ 33

WARRANTY .......................................................................... 34

4

Page 5

Equipment Description

OM-TDB

The Groen TDB and TDBC are table top, tilting,

steam jacketed kettles with a thermostatically

controlled, self-contained, electrically-heat ed

steam supply and appropriate controls, mounted

on a sturdy base. Models TDB and TDBC are

avai lable in 20 or 40 - quart capacity.

The body of the TDB and TDBC Kettle is

constructed of stainless steel, w elded i nto one

solid piece. The kettle is furnished with a

reinforced rim and a butterfly shaped pouring lip.

It has a steam jacket rated for a design pressure

of 50 PSIG. K ettle finis h is 180 emery gri t on the

inside and bright s emi-deluxe on the outs ide. A

tilt handle on the TDB kettle and a handwheel

crank on the TDBC kettle allows the operator to

manually tilt the kettle body in a controlled

manner. Pouring height accepts pans up to four

inches hi gh on a table top.

A built-in steam generator, sized for the kettle

capacity and heated by electricity , delivers steam

into the jacket. “A irless” operation of the steam

jacket permits uniform, efficient heat ing at

temperatures as low as 150°F and as high as

295°F. I n additi on t o the adjustable thermostat

for operating control, the unit has a tilt cut-off

switch, low water cut-off, pressure relief valve,

and high-limit pres sure switch as safety features.

A heating indicator li ght, pressure gauge, and

sight glass are provided for monitoring kett le

operation.

A single electrical connecti on is requi red for

installation. The unit may be ordered for use

with 208/ 240 or 480 volt power. All kettles are

wired for 208 volt, three-phase operat ion. For

240 volt, t hree-phase OR single-phase

conversion, see the wiri ng diagrams and

installation inst ructions i n this manual.

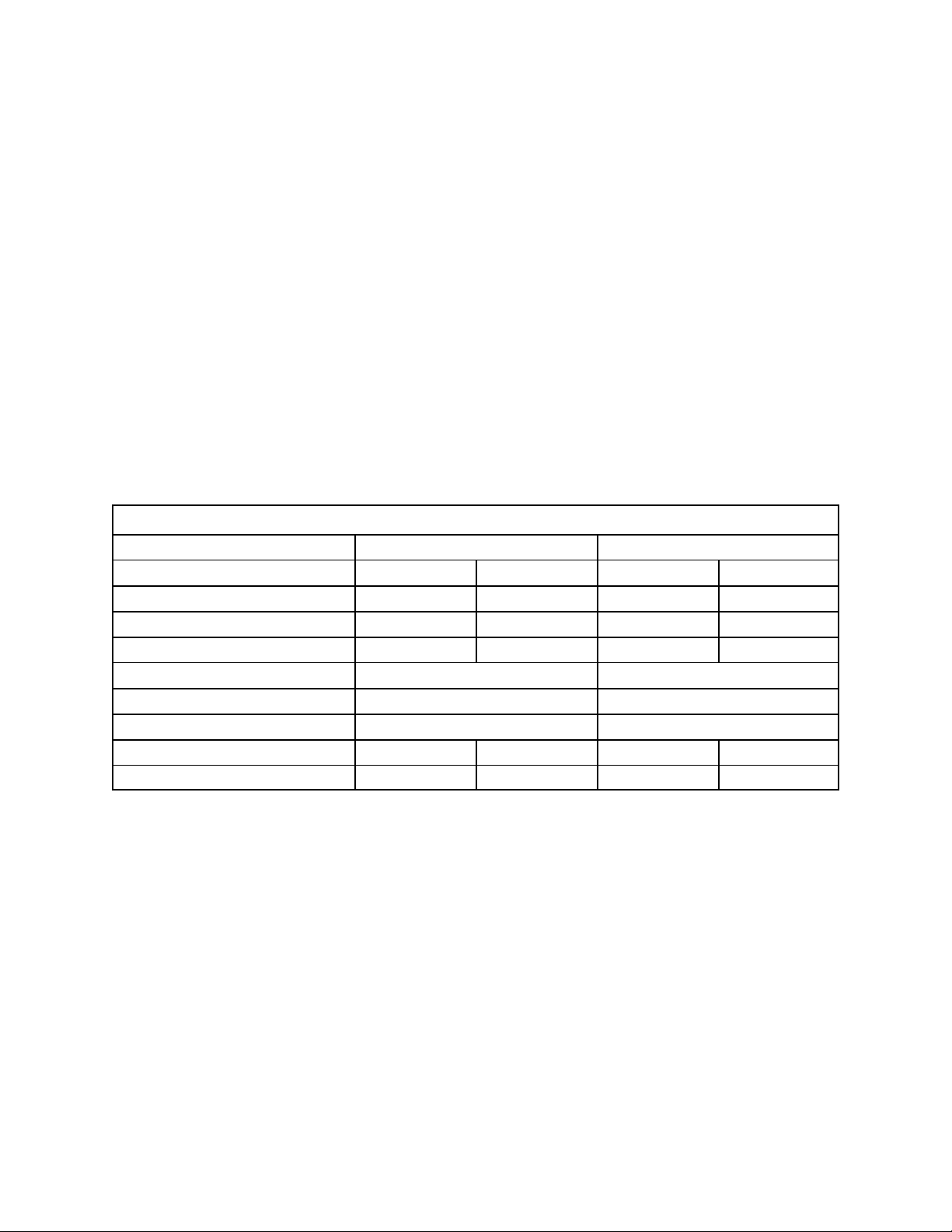

KETTLE CHARACTERISTICS

TDB-20 and TDBC-20 TDB-40 and TDBC-40

Kettle Capacit y 20 qts. 18.8 liters 40 qts . 37.6 liters

Jacket Capacity 7 qt s . 6.6 liters 9 qts. 8.5 liters

Diameter 14” 36 cm 16-1/2” 42 cm

Depth 11” 28 cm 14-1/4” 36 cm

K.W. at 208 V 6.3 10.8

K.W. at 240 V 8.4 14.4

K.W. at 480 V 6.3 12.0

Base Width 24” 60 cm 28” 60 cm

Base Depth 16” 41 cm 16” 41 cm

Options available include:

1. Kit, cover and holder (P/N 139805, 20 quart - P/N 139806, 40 quart).

2. One-piece, lift-off cover (P/N 128003, 20 quart - P/N 128002, 40 quart).

3. Holder for Lift-off cover (P/ N 133837).

4. Basket i nsert (P/N 001159, 20 quart - P/N 001161, 40 quart).

5. Rice Strainer (P/N 005187, 20 quart - P/N 005186, 40 quart).

6. Stand that s upports the uni t and holds a pan in position for filling (Model TS-9).

7. Water fill swing faucet.

8. 316 stainless steel int erior (must be ordered wi th origi nal equipment order).

9. Agitators wi th motor drives (must be ordered wit h original equi pment order).

5

Page 6

OM-TDB

Inspection & Unpacking

The unit will arrive in a heavy shi pping carton

and will be attached to a s kid. Immediately upon

receipt, inspect the cart on carefully for exterior

damage.

CAUTION

SHIPPING STRAPS ARE UNDER TENSION

AND CAN SNAP BACK WHEN CUT. TAKE

CARE TO AVOID PERSONAL INJURY OR

DAMAGE TO THE UNIT BY STAPLES LEFT

IN TH E WAL LS O F THE C ARTON.

Carefully cut the polyes t er straps around the

carton and detach the sides of the box from the

skid. P ull the carton up off the unit.

Thoroughly inspect the unit for concealed

damage. Report any shipping damage or

incorrect shipments to the delivery agent .

Write down the model number, serial number,

and installation date, and retain this information

for future reference. Space for these entries is

provi ded at the top of the Service Log at t he

back of this manual. Keep this manual on file

and avai lable for operators t o use.

For TDB units, attach the tilt handle (normally

shipped inside t he ket t le) by carefully threading it

into the socket on the trunnion support. Be

careful to avoid cross-threading the fine threads

on the trunnion.

CAUTION

THIS UNIT WEIGHS 140 TO 163 LB. (64 TO

74 KG). INSTALLER SHOULD OBTAIN

HELP AS NEEDED TO LIFT THIS WEIGHT

SAFELY.

When installation is to begi n, carefully cut the

straps w hich hold the unit on t he s kid. Lift the

unit straight up off the skid. Examine packing

materials to be sure loose parts are not

discarded with the materials.

NOTE: After handle installation on the ri ght hand

side, retain the hardw are supplied wi th the unit

for left hand installation.

6

Page 7

Installation

OM-TDB

The Groen Kettle is provided with complete

internal wiring. It is ready for

immediate connection. A wiri ng

diagram is provided i n this

manual and on the inside of the

control housing service panel.

Any mechanical or electrical

changes must be approved i n by

Groen’s Food Service Engineering Department.

WARNING

INSTALLATION OF THE KETTLE MUST BE

DONE BY A CERTIFIED ELECTRICIAN OR

GROEN AUTHORIZED REPRESENTATIVE

QU ALIFIED TO WO RK WIT H E LEC TR ICIT Y .

IMPROPER INSTALLATION CAN RESULT

IN INJURY TO PERSONNEL AND/OR

DAMAGE TO EQUIPMENT.

The completed unit has been operated at the

factory to t est all controls and heater elements.

1. Set the kettle in place and level it. The

base should be securely fast ened to a

table or work surface. Four 3/8”-16 N.C.

threaded couplings are provided i n the

base of unit. Installation under a ventilation

hood is recommended.

2. Once the unit is anchored to a mounting

surface, apply a small bead of silicone

caulk around the perimeter of the kettle

base and seal the joint.

3. Provide electrical power as s pecified on

the electrical information plate attached t o

the equipment. Observe local codes

and/or The National Electrical Code i n

accordance with ANSI/NFPA 70 - (current

edition).

4. Standard equipment is shipped ready for

208V, 3-phase or 480V, 3-phase

operation. Refer t o the wiring diagram

located on the inside cover of the control

box and the inst ruct ions below for

conversion to si ngle-phase operation. A

jumper wire and “conversion” label are

included wit h the unit. They can be found

in a plastic bag attached to the trunnion

assembly ins ide the control box.

CAUTION

BEFORE ANY ELECTRICAL CONVERSION,

VERIFY THA T THE BRANCH CIRCUIT

WIRING IS ADEQUATE TO HANDLE ANY

INCREASE AMPERAGE REQUIRE MENTS.

REFER TO THE ELECTRICAL

SPECIFICATIONS LISTED BELOW.

a. For conversion from 208V, 3-phase to

208V or 240V 1-phase OR 480V,

3-phase to 480V, 1-phase:

i. Verify that the branch circuit w iring is

adequate for any increased

amperage requirements (see table

on page 8).

ii. For 240V 1-phase only, enlarge

electrical inlet opening for 1" condui t

fitting. Use a 1" sealtite conduit

fitting.

iii. 1-phase requires tw o jumper wires.

One jumper wire exists on t he

terminal block for 3-phase input.

The second jumper wire is located in

a plastic bag i nside the control box.

iv. Attach jumper wire to terminal block

as per wi ring diagram for 1-phase

supply.

v. For 240V 1-phase only

from 208V tab on control

transformer and insert on 240V tab

(See Photo #1).

vi . Complete “conversion label”

(supplied in bag) and adhere it to t he

control box near t he UL dat aplate.

b. For conversion from 208V, 3-phase to

240V, 3-phase:

i. Verify that the branch circuit w iring is

adequate for any increased

amperage requirements (see table

on page 8).

ii. Pull lead from 208V tab on control

transformer and insert on 240V tab.

(See Photo #1)

iii. Complete “conversion label”

(supplied in bag and adhere it to t he

control box near t he UL dataplate).

, pull lead

7

Page 8

OM-TDB

c. For conversi on from 480V, 3-phase t o

460V, 3-phase:

i. Verify that the branch circuit w iring is

adequate for any increase

amperage requirements (see table

on page 8).

ii. Complete “conversion label”

(supplied in bag and adhere it to t he

control box near t he UL dataplate).

5. Bring incoming electrical service through

the conduit fitting (for 240V 1-phase, a

new one inch condui t fitti ng is requi red) at

the rear of the support hous ing, making a

watertight connection w ith the incoming

lines. A BX style connection is not

recommended.

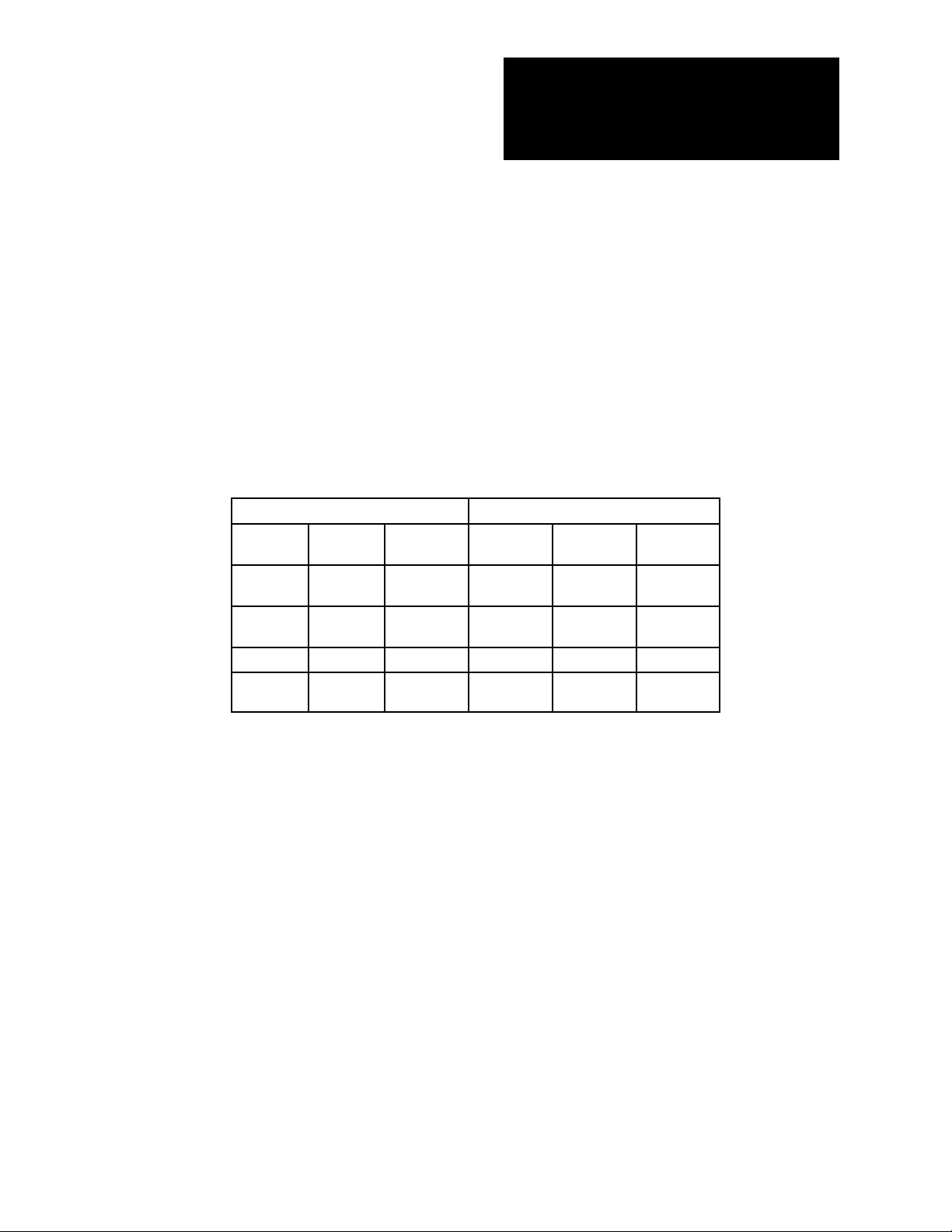

TDB / TDBC SUPPLY WIRE REQUIREMENTS

THWN (75°) / THHN (90°) COPPER ONLY

DANGER

ELECTRI CALLY GROUND THE UNIT A T

THE TERMINAL PROVIDED. FAILURE TO

GROUND UNIT COULD RESULT IN

ELECTROCUTI ON AND DEATH.

6. Confirm that the jacket wat er level is at or

just above mid point of sight glass (new

models). If the level is low, follow the

instruct ions under “Jacket Fi lli ng and

Water Treatment” in the “Mai ntenance”

section of the manual.

7. Ensure that the open end of the elbow on

the outlet of the press ure reli ef valve is

directed downward.

TDB-20, TDBC-20 TDB-40, TDBC-40

VOLTAGE AMPS

208V 1 PH

3 PH

240V 1 PH

3 PH

460V 3 PH 7.3 14 460V 3 PH 14 12

480V 1 PH

3 PH

31

18

35

20

14

8

SUPPLY

WIRE

8

12

8

12

14

14

VOLTAGE AMPS

208V 1 PH

3 PH

240V 1 PH

3 PH

480V 1 PH

3 PH

52

30

60

35

25

15

SUPPLY

WIRE

6

8

4

8

10

12

Photo #1

Pull lead fro m 208V tab and insert on 240V tab .

8

Page 9

OM-TDB

Initial Start-Up

IMPORTANT:

BE SURE ALL OPERATORS READ, UNDERSTAND AND FOLLOW THE OPERATING

INSTRUCTI O NS, CAUTIONS, AND SAFE TY INSTRUCTIONS CONTAINED IN THIS MANUAL.

Now that the ket t le has been installed, you

should test it to ensure that the unit is operating

correctly.

1. Remove all literature and packing

materials from inside and outs ide of the

unit.

2. Turn on the electrical service to the unit.

3. Pour 1-2 quarts of water int o t he ket tle.

4. Following “To St art Kettle” ins tructions in

the “Operation” section of this manual,

begin heating the water at t he highest

thermostat setting. The heati ng indicator

light should come on immediately, and

heating should continue until the w ater

boils.

5. To shut down t he unit, turn the thermostat

dial to “OFF”.

AVOID ALL DIRECT CONTACT WITH HOT

SURFACES. DIRECT SKIN CONTACT

COULD RESULT IN SEVERE BURNS.

AVOID ALL DIRECT CONTACT WITH HOT

FOOD OR WATER IN THE KETTLE.

DIRECT CONTACT COULD RESULT IN

SEVERE BURNS.

If the uni t functions as des cribed above, it is

ready for use. If the unit does not functi on as

intended, first recheck power supply connections

and, if necessary, contact your local Groen

Certifi ed Service Agency.

WARNING

A simple turn of the thermostat controls the Groen

TDB and TDBC kettle.

9

Page 10

OM-TDB

Model TDBC

Operation

The operator controls kettle heating with the

thermostat dial. The dial turns heating element

electric power on or off and sets the operating

temperature of the kettle.

A. To Start Kettle

1. EVERY DAY make sure that t he jacke t

water level i s above the mid-point of the

round sight glass. If the l e vel is too low, see

“Jacket Filling” and “Water Treatment” on

page 14 of this manual.

2. Check the press ure gauge. If the gauge

does not show 20 to 30 inches of vacuum

(that is, a reading of 20 to 30 below 0), see

“Jacket Vacuum” on page 13 of this

manual.

3. Turn on the electrical power to the unit.

4. Turn the thermostat dial to the desired

setting. The heating indicator light indicates

that the kettle is heating, and cy cling of the

light on and off indicates that the kettle is

being h e ld at the set temperature. Once in

each cycle the contactors in the support

housing will make a clicking sound. This is

normal.

Model TDB

B. To Transfer Product or Empty Kettle:

TDB: The kettle is designed an d

manufactured to be tilted i n a controll e d

manner. Grasp the insulated plastic ball firmly.

Maintain a firm grip on handle when tilting,

while keeping kettle body i n a tilted pos ition

and when SLOWLY return ing the kettle body

to an upright position. DO NOT release kettle

hand le when kettle is partly tilted. It will

impact in either the upri ght or fully tilted

position and may cause burns.

TDBC: The kettle is tilted using its crank ti lt

hand wheel. Turning the crank clockwise t ilts

the kettle; counter-clockwise returns i t to an

upright positi on. The kett le will remain in any

cranked positi on.

WARNING

AVOID ALL DIRECT CONTACT WITH HOT

SURFACES. DIRECT SKIN CONTACT

COULD RESULT IN SEVERE BURNS.

AVOID ALL DIRECT CONTACT WITH HOT

FOOD OR W ATER IN THE KETTLE. DIRE CT

CONTACT COULD RESULT IN SEVERE

BURNS.

On TDB and TDBC units, the jacket water l evel is

shown in a sight gl ass on the kettle body.

TAKE SPECIAL CARE TO AVOID CONTACT

WITH HOT KETTLE BODY OR HOT

PRODUCT, WHEN ADDING INGREDIENTS,

STIRRING OR TRANSFERRING PRODUCT

TO ANOTHER CONTAINER.

10

Page 11

CAUTION

DO NOT OVERFILL THE KETTLE WHEN

COOKING, HOLDING OR CLEANING.

KEEP LIQUIDS AT LEAST 2-3” (5-8 cm)

BELOW THE KETTLE BODY RIM TO

A L L O W CL EARANCE FOR STIRRING,

BOILING PRODUCT AND SAFE

TRANSFER.

WARNING

WHEN TILTING KETTLE FOR PRODUCT

TRANSFER:

1) WEAR PROTECTIVE OVEN MITT AND

PROTECTIVE APRON.

2) USE DEEP CONTAINER TO CONTAIN

AND MINIMIZE PRODUCT SPLASHING.

3) PLACE CONTAINER ON STABLE, FLAT

SURFACE, AS CLOSE TO KETTLE AS

POSSIBLE.

4) S TAND TO LEFT OR RIGHT OF KE TTLE

(DEPENDING ON HANDLE PLACEMENT)

WHILE POURING — NOT DIRECTLY IN

POUR PATH OF HOT CONTENTS.

5) POUR SLOWLY, MAINTAIN CONTROL

OF KETTLE BODY HANDLE AT ALL

TIMES, AND RETURN KETTLE BODY TO

UPRIGHT POSITION AFTER CONTAINER

IS FILLED OR TRANSFER IS

COMPLETE.

6) DO NOT OVERFILL CON TAINER. AVOID

DIRECT SKIN CONTACT WITH HOT

CONTAINER AND ITS CONTENTS.

OM-TDB

Wear protectiv e oven mitts and a protective

apron.

When putting the cover on the kettle, positio n

it on top of kett le rim, with its flat edge facing

the pouring lip.

WARNING

AVOID ALL DIRECT CONTACT WITH HOT

SURFACES. DIRECT SKIN CONTACT

COULD RESULT IN SEVERE BURNS.

AVOID ALL DIRECT CONTACT WITH HOT

FOOD OR WATER IN THE KETTLE.

DIRECT CONTACT COULD RESULT IN

SEVERE BURNS.

When removing cover:

a) Firmly grasp plastic handle

b) Lift rear

2” (3-5 cm) to allow any steam and water

vapor to es cape t he cooking vessel.

Wait 2-3 seconds.

c) Tilt cover to 45-60° angle and allow any

hot condensate or product to roll off

cover b ack into ke ttle.

edge (farthest from operator) 1-

CAUTION

KEEP FLOOR S IN FRONT OF T HE KET TLE

WORK AREA CLEAN AND DRY. IF SPILLS

OCCUR, CLEAN AT ONCE TO AVOID

SLIPS OR FALLS.

Common Accessories

1. Li ft Off Cover

As with stock pot cooki ng, an optional lift

off cover can speed up the heating of

water and food products. A cover helps

retain heat in the cooking vessel and

reduces the amount of heat and humidity

released into the kitchen. Use of a cover

can reduce some product cook times

and help maintain the temperature, color

and texture of products bei ng held or

simmered for extended peri ods.

Make sure the plast ic ball handle is

secure on the lift off cover before us ing.

ALWAYS use the plastic handle to place

or remove cover from the kettle.

Lift the rear of the l id first.

d) Remove cover, ensuri ng that any

remaining hot condensate or product

does not drip on operator, floor or work

surfaces.

e) Place cover on safe, flat, sani t ary, out-

of-the-way surface, or return to kett le

rim. Cover

may also

be placed

in the

optional

holder for

the cover

as shown

in the

photograph.

11

Page 12

OM-TDB

CAUTION

DO NOT TILT KETTLE BODY WITH COVER

IN PLACE. COVER MAY SLIDE OFF,

CA USING INJURY TO OPERATOR.

2. Basket Insert

An optional kettle bas ket insert can as s ist in

cooking water-boiled products including

eggs, potatoes , vegetables, shell fish, past a

and rice. The nylon mesh liner must be used

when cooking product smaller than the mesh

size of the basket , which i s approx imately

1/4” (6 mm). This includes rice and small

pasta shapes.

Tips For Use.

a) Allow for the water displacement of the

basket and product to be cooked. This

may mean only filling the kettle half full

of water. Test t he basket and product

displacement with the kettle OFF, and

with cold water in the kettle.

CAUTION

DO NOT OVERFILL THE KETTLE WHEN

COOKING, HOLDING OR CLEANING.

KEEP LIQUIDS A MINIMUM OF 2-3” (5-8

cm) BELOW THE KETTLE BODY RIM TO

ALLOW CLEARANCE FOR STIRRING,

BOILING AND SAFE PRODUCT

TRANSFER.

WARNING

AVOID ALL DIRECT CONTACT WITH HOT

FOOD OR WATER IN THE KETTLE.

DIRECT CONTACT COULD RESULT IN

SEVERE BURNS.

b) Load basket on a level, stable work

surface.

c) Lift the loaded basket w ith both hands .

Get help from another person if the

basket is too heavy for safe handling.

d) Slowly lower product int o ket t le.

e) When removing basket with cooked

product, lift basket straight up, ensuring

bottom of basket clears the rim and

pouring lip of the kett le. Wear protective

oven mitts and protective apron.

d) Allow hot water to fully drain from

product, before moving basket away

from the kettle. Do not rest kettle basket

on kettle rim or pouring lip. If basket is

too heavy for individual to lift and safely

move, get help from another person.

Remove product immediately from

basket int o another container, being sure

to avoid contact with hot product and hot

basket or. . .

e) Place basket with food on stable, flat

surface, setting it inside a solid steamer

or bake pan, to catch any remaining hot

water drai ning from product.

Sequence of Operation

The following “action-reacti on” outline is provided

to help the user understand how the equipment

works.

When the operator starts up the kettle by t urning

the operating t hermostat dial from “OFF” to a

desired setting, the thermostat switch closes.

This lights up the heating indicator light and

causes the contactors to close, allowing power t o

flow to the heating elements. When the

temperature of the steam jacket reaches the

value correspondi ng t o the dial setting, the

thermostat switch opens. Thi s turns off the

heating indicator light and caus es the contactors

to open, stopping the power t o t he heaters. As

soon as the thermostat s enses that t he ket t le is

cooling below the set point, the t hermostat

swi t ch closes , the heating indicator light comes

on, the contactors close, and t he heaters come

on again. On-off cycli ng continues, keeping the

kettle at the set t emperature. Thi s is w hy the

heating indicator light cycles on and off during

normal operation. Every ti me the kettle is ti lted,

the tilt cut -off sw itch interrupts the pow er supply

to the heaters, so that the heating elements will

not operate while not submerged in the jacket

water.

If steam pressure great er than 50 PSI is

generated in the jacket, the pressure relief valve

will open and reliev e the ex ces s pressure.

In the event that the jacket water level gets t oo

low and the heating elements overheat, the highlimit control will open and shut off power to the

elements until the kettle cools. Sett ing the

operating thermostat dial to “OFF” shuts down all

control and heating circuits.

12

Page 13

Maintenance

NOTICE: Con tact an authorized Groen rep resen tative when repairs are req uired.

A Maintenance & Service Log is provided at the

back of this manual with the warranty

information. Each t ime maintenance is

performed on your Groen kettle, enter the date

on which the work was done, w hat was done,

and who did it. Keep this manual on file and

avai lable for operators t o use.

Periodic inspection will minimize equi pment

down time and increase the efficiency of

operation. The following points should be

checked:

1. Jacket Vacuum/

Removing Air Fro m Jacket

(By Operator)

Every day, while the kettle is cold, read the

pressure/ vacuum gauge. A positive reading

or a negative reading between zero and 20"

vacuum on the pressure/ vacuum gauge

indicates excess air in the jacket. Air in the

jacket slows kettle heati ng and can prevent

the kettle from reaching operating

temperature. To remove air:

a. Start the ket t le. (S ee the Operation

section).

b. Make sure the elbow on t he outlet of

the pressure reli ef valve i s turned so

that escapi ng steam is directed down

toward the floor. Be s ure and follow the

instruct ions on the at t a ched pres sure

relief valv e tag.

The pressure gauge should show a vacuum

of 20 to 30 inches when the kettle i s cold.

c. When the pressure/vacuum gauge reaches

a positive pressure reading of 5 PS I, release

trapped air by lifting the pressure relief valve

ring for about one second. Repeat this step,

then let the v alve ring snap closed, s o the

valve will seat properly and not leak.

2. Pressure Relief V al ve

(By Operator)

At least twice a month, test t he pressure

relief valv e. Test the v alve wi t h the kettle

operating at 15 P SI (105 kPa), by holding

the test ring for at least fi ve seconds. Then

release the ring and permit t he valve t o snap

shut. If the ring does not activate, if there is

no discharge, or if the valve leaks, stop

using the ket t le immediately and cont act a

authorized Groen service repres ent ative.

OM-TDB

Make sure that the open end of the elbow on

the pressure relief valve is directed

downward.

WARNING

AVOID ANY EXPOSURE TO THE STEAM

BLOWING OUT OF THE PRESSURE

RELIEF VALVE. SEVERE BURNS CAN

RESULT ON EXPOSED SKIN.

FAILURE TO CHECK PRESSURE RELIEF

VALVE OPERATION PERIODICALLY

COULD RESULT IN PERSONAL INJURY

A ND/OR DAMAGE TO EQUIP MENT.

13

Page 14

OM-TDB

3. Grease / Lubrication

(By Service)

For TDB Models:

grease the two trunnion beari ngs . The

bearings are located withi n t he ket tle support

housing. Remove the access panels from

the support housing with a screwdriver t o

gain access t o t he grease fittings. Us e a

lithium-based, multi-purpose greas e. When

the access panels are removed, t he

mounting bolts for the trunni on bearings and

tilt switch can also be checked for tight ness.

When finished, reas semble access panels to

support housing.

For TDBC Mod e ls:

been fitted for proper lubricat ion of moving

parts. Since the gears do not run in oil,

periodic lubri cat ion wi th grease is essenti al.

Frequency of lubrication depends on

operating condi tions, but should occur at

least once every six months. Groen

recommends the use of a Number Two

grade LGI lit hium grease. Add grease

through the Zerk fittings on t he gear housing

until grease flows out of t he bearings around

the trunnion s haft . Place a liberal amount of

grease on the gear to cover the arc that is in

contact wi t h the worm gear.

KEEP GREASE AWAY FROM ELE CTRICAL

PARTS LOCATED NEAR THE G EARS.

4. Jacket Filling

Every day, before you turn on the unit,

make sure the water level i s approx imately

in the center of the water gauge glass. The

jacket was filled at the factory wit h the

proper amount of treated water, and is airtight, but over time steam may be vented

and water lost.

From time to time, you may need t o restore

the water t o its proper level. The procedure

for adding water follows.

At least twice a y ear,

The gear housing has

CAUTION

The pressure relief valve and fill plug are

located directly b ehind the pressure/vacuu m

gauge.

b. Allow the kettle to cool completely.

Remove the pipe plug from the jacket

fill assembly. Pour i n t he distilled or

treated water. Using a funnel will help

you i n this proces s. Hold the pressure

relief valv e open while y ou pour, to let

air escape from the jacket. Continue

adding wat er until the wat er level rises

to the center of the round sight glass.

c. Air that gets into the jacket during the

filling operati on must be removed,

because it w ill make heating less

efficient. Follow t he procedure in

Jacket Vacuum/Remo vi n g Air From

Jacket above, t o restore a negati ve

pressure readi ng.

5. Water Treatment

WARNING

TO AVOID INJURY, READ AND FOLLOW

ALL PRECAUTIONS STATED ON THE

LABEL OF THE WATER TREATMENT

COMPOUND.

a. If y ou are replaci ng water lost as

steam, use dis tilled water. Do not use

tap water. If you are replacing treated

water that was drained from the jacket,

prepare more treated water as directed

below.

a. Fill a mixing container with the amount

of water required. Use only disti lled

water.

Model

TDB-20, TDBC-20 20 Qt 18.9 # 7 Qt 6.6 #

TDB-40, TDBC-40 40 Qt 37.8 # 9 Qt 8.5 #

14

Kettle

Capacity

Jacket

Capacity

Page 15

b. Hang a strip of pH t est paper on the ri m

of the container, with about 1 inch of

the strip below the surface of the wat er.

c. Stir the water continuously, while y ou

slowly add water treatment compound

until a color between i ndicating a pH of

10.5 and 11.5 is reached. (Shown on

the pH test kit chart.) Judge the pH by

frequently comparing the test stri p with

the color chart provided in the pH t est

kit. If there is a problem dist inguis hing

color, use a pH meter.

OM-TDB

d. Use a measuring cup to add the

compound so that you may record the

exact amount used.

e. The amount may be used again, if the

same water sources and compound

are used in the fut ure. Howev er, it is

best to check the pH each time treated

water i s prepared.

15

Page 16

OM-TDB

Component Replacement

WARNING

BEFORE REPLACING ANY PARTS,

DISCONNECT THE UNIT FROM THE

ELECTRIC POWER SUPPLY.

All internal wi ring is marked as shown on the

circuit schematic drawings . Be sure that new

components are wired i n t he same manner

as the old components.

WARNING

USE OF ANY REPLACEMENT PARTS

OTHER THAN THOSE SUPPLIED BY

GROEN OR THEIR AUTHORIZED

DISTRIBUTORS CAN CAUSE INJURY TO

THE OPERATOR AND DAMAGE TO THE

EQUIPMENT AND WILL VOID ALL

WARRANTIES.

CAUTION

REMOVE ELECTRICAL POWER BEFORE

PERFORMING ANY MAINTENANCE ON

THI S KETTLE.

WARNING

THIS KETT L E IS DESIGNED T O BE WATER

RESISTANT. FAILURE TO FOLLOW

PROPER MAINTENANCE PROCEDURES

MAY VOID THE WARRANTY.

1. Removal of Right Hand Side Cover

Remove the 10 phillips head screws

securing the cover.

b. Remove wires from contactor. Starting

on the bottom left hand side, remove:

i. T-1 one red wire

ii. T-2 two yellow wires

iii. T-3 two tan wires

iv . T-4 one blue wire

c. Starting on the top left hand side,

remove:

i. L-1 red wire

ii. L-2 yellow wire

iii. L-3 two brown wires

iv . L-4 blue wire

d. From the two spade terminals on the

rear of the contactor, remove the left

hand blue wire and the right hand green

wire.

e. Remove the two 1/4" mounti ng s crews.

f. Remove contactor.

5. Installation of Contactor

a. Inst all contactor.

b. On the rear of the contactor, install the

left hand blue wire and the ri ght hand

green wire on the two spade terminals.

c. Install wires on contact or. Starting on

the bottom left hand side, install:

i. T-1 one red wire

ii. T-2 two yellow wires

iii. T-3 two tan wires

iv . T-4 one blue wire

d. Starti ng on the top left hand side, install:

i. L-1 red wire

ii. L-2 yellow wire

iii. L-3 two brown wires

iv . L-4 blue wire

e. Inst all right hand side cover (see Section

#2 above).

6. Removal of Transformer

2. Installation of Right Hand Side Cover

In sta ll all 10 s c r ews in side cover to maintain

water resistance. Ti ght en to 10 in-lb torque.

3. Replacement of Fuse

a. Remov e right hand side cover (s ee

section #1 above).

b. Remove and replace fuse (refer to Parts

List for proper fuse).

c. Reinstall right hand side cover (see

section #2 above).

4. Removal of Contactor

a. Remove right hand s ide cover (see

Section #1 above).

a Remove right hand side cover (see

Section #1 above).

b. Remove wires in the following order:

i. On the bottom of the transformer,

remove the blue wire w hich comes

from the terminal block.

ii. Remove the red wire which comes

from the fuse.

iii. On the top, remove the red and

green wires which come from the

water control board.

c. Remove the tw o 1/4" mounting screws.

d. Remove the transformer.

16

Page 17

7. Installation of Transformer

OM-TDB

12. Removal of Thermostat

a. Mount the t ransformer using the two 1/ 4"

mounting screws.

b. Inst all wires on the trans former in the

following order:

i. On top, install the red and green

wires which come from the water

control board.

ii. On the bottom, install the red wire

which comes from the fuse and the

blue wire which comes from the

terminal block.

c. Install right hand side cover (s ee S ect ion

#2 above).

8. Removal of Water Control Board

a. Remove right hand s ide cover (see

Section #1 above).

b. Starti ng on the top left hand side,

remove wires in the following order:

i. Two green ground wires

ii. The black jumper wire

iii. Blue wire from tilt micro switch

iv . Blue wire from harness

c. To remove board, reach behind the

board and squeeze the plasti c s tand-offs

together and pull the board off.

9. Install ation of Water Level Control Bo ard

a. Snap board back onto plastic s t and-offs.

b. Inst all wires in t he followi ng order

starting on the bottom right hand s ide:

i. Blue wire from harness

ii. Blue wire from tilt micro swit ch

iii. Black jumper wire

iv . Two green ground wires

10. Removal of Tilt Micro Switch

a. Remove right hand s ide cover (see

Section #1 above).

b. Tilt kettle 90°.

c. Remove red and blue wire from bottom

two spade te rminals.

d. Remove two screw s securing s witch.

e. Remove switch.

a. Remove knob by pulling st raight out.

b. Remove the two s crews securi ng t he

thermostat to the kettle skirt.

c. Tilt kettle 90°.

d. Remove the bottom cover from the skirt.

e. Remove switch from kettle skirt.

f. Remove tan, blue and white wires from

thermostat.

g. Unscrew the thermostat bulb from the

bottom of the kettle jacket.

13. Installatio n of th ermostat

a. Tilt kettle 90°.

b. Inst all thermostat gasket in opening in

skirt.

c. Install second gasket on thermostat and

align the screw holes with the holes in

the gasket.

d. Place the thermostat through the hole i n

the kettle skirt and align screw holes.

e. Replace plastic spacer on thermostat

shaft.

f. Replace the stainless knob shroud and

align holes.

g. Start both s crews but do not tighten.

h. Put Teflon tape on the screw threads of

the thermostat bulb and ins ert into

bottom of kettle. Tighten hand ti ght plus

one turn.

i. Install bottom cover on s kirt. Tight en

screws and gasket to 10-12 in-lb torque.

j. Turn the kettle upright and tighten the

two thermostat mounting screws.

k. Install knob by pushing straight on shaft.

l. If the knob appears loose, remove and

gently spread t he t wo prongs of the shaft

and reinstall knob.

m. Check wa ter le vel.

n. Remove air from jacket.

11. Installation of Tilt Micro Switch

a. Tilt kettle 90°.

b. Align switch so arm on swi tch is pointed

forward and down.

c. Install the two mounting screws and

nuts.

d. Reinstall the red and blue wires on the

bottom two spade terminals.

e. Insure s witch actuat es when the kettle i s

returned to the upright posi t ion.

Thermostat and Gasket In stallation Detail

17

Page 18

OM-TDB

14. Removal of Pressure Switch

a. Tilt kettle 90°.

b. Remove bottom cover.

c. Unplug red and whit e wires.

d. Unscrew switch from 90° elbow and

remove.

15. Install Pressure S witch

a. Tilt kettle 90°.

b. Screw switch int o elbow.

c. Plug in red and white wires.

d. Replace bottom cover. Tighten screws

and gasket to 10-12 i n-lb torque.

e. Check water level.

f. Remove air from jacket.

16. Removal of Water Level Probe

a. Tilt kettle 90°.

b. Remove bottom cover.

1. Suggested Cleaning Suppl i es:

a. Cleaner, such as Klenzade HC-10 or

HC-32 from ECOLAB, Inc.

17. Install Water Level P r ob e

Cleaning

c. Remove blue wire from probe.

d. Unscrew probe from jacket and remove.

a. Tilt kettle 90°.

b. Screw probe int o ket tle jacket.

c. Connect blue wire.

d. Reinstall bottom cover. Tighten screws

and gasket to 10-12 i n-lb torque.

e. Check water level.

f. Remove ai r fro m jacket .

NOTE:

REPLACED. IF THE KETTLE DOES NOT

HEAT PROPERLY AND THE HEATER

ELEMENTS SHOW AN OPEN CIRCUIT, THE

KETTLE MUST BE REPLACED.

HEATER ELEMENTS CAN NOT BE

b. Scrape and flush out large amounts of

food residues. Be careful not to scratch

the kettle wi t h metal implements.

b. Kettle brushes in good condition.

c. Sanitizer such as K lenzade XY-12.

d. Film remover such as Klenzade LC-30.

2. Precautions

Before any cleaning operat ion, shut off the

kettle by turning the thermostat dial to

"OFF", and shut off all electric power to the

unit at a remote sw itch, such as the circui t

breaker.

WARNING

KEEP WATER AND SOLUTIONS OUT OF

CONTROLS AND B URNERS. DO NOT USE

A HIGH PRESSURE HOSE TO CLEAN THE

CONTROL CONSOLE, ELECTRICAL

CONNECTIONS, ETC.

3. Procedure

a. Clean food contact surfaces as soon as

possible after us e, preferably whi le the

kettle is still warm. If the unit is in

continuous us e, clean and saniti ze

inside and outsi de at least once every

12 hours.

CAUTION

NEVER LEAVE A CHLORINE SANITIZER IN

CONTACT WITH STAINLESS STEEL

SURFACES FOR LONGER THAN 30

MINUTES. LONGER CONTACT CAN

CA USE CORROSION.

WARNING

AVOID DIRECT CONTACT WITH HOT

SURFACES. DIRECT SKIN CONTACT

COULD RESULT IN SEVERE BURNS.

c. Prepare a solution of t he

detergent/cleaning compound as

instruct ed by the supplier. Clean the

unit thoroughly. A cloth moistened w ith

cleaning solution can be used to clean

controls, housi ng, electrical conduit, etc.

d. Rinse the ket tle thoroughly with hot

water. Then drai n completely.

18

Page 19

CAUTION

MOST CLEANERS ARE HARMFUL TO THE

SKIN, EYES, MUCOUS MEMBRANES AND

CLOTHING. PRECAUTIONS SHOULD BE

TAKEN TO WEAR RUBBER GLOVES,

GOGGLES OR FACE SHIELD AND

PROTECTIVE CLOTHING. CAREFULLY

READ THE WARNINGS AND FOLLOW

LABEL DIRECTIONS.

e. As part of the daily cleaning program, clean

all inside and outside surfaces t hat may

have been soiled. Remember to check such

parts as the underside of the cover, control

housing, etc.

OM-TDB

f. To remove burned-on foods, use a

brush, sponge, cloth, plast ic or rubber

scraper, or plasti c wool along with the

cleaning solution. To reduce effort

required in washing, let the detergent

solution sit i n t he ket tle for a few minutes

and soak into t he residue. Do NOT use

abrasive materials or metal tools that

might scratch the surface. S crat ches

make the surface harder to clean and

provi de places for bacteria to grow. Do

not use steel wool, which will leave

particles i n the surface and cause

eventual corrosion and pitt ing.

g. The outside of the unit may be cleaned

wit h a warm water (100°F or less) spray.

Do not use a high pressu re spray.

h. The outside of the unit may be polished

with a recognized stai nless steel cleaner

like “Zepper” from Zep Manufacturing

Company.

i. When the equipment needs to be

sanitized, use a sanitizing solution

equiv alent t o one that supplies 200 part s

per million chlorine. Obtain advice on

the best sanitizing agent from your

supplier of sani tizing product s. Following

the supplier’s instructions, apply the

sanitizing agent after the unit has been

cleaned and drained. Rins e off the

sanitizer thoroughly.

Scrapers, steel wool or metal implements will

harm the kettle surface.

Use only a sponge, cloth or plastic brush t o

clean the kettle.

j. It i s recommended that the uni t be

sanitized just before use.

k. Clean the kettle thoroughly . If there is

difficulty removing mineral deposits or a

film left by hard water or food residues,

then

use a de-liming agent, s uch as Groen

De-limer De-Scaler (Part Number

114800), Lime- Away from ECOLAB or

an equiv alent, followi ng manufacturer

directi ons.

l. Rinse and drai n t he unit thoroughly

before further use.

m. If especi ally difficult cleaning problems

persist, contact your cleaning product

supplier for assistance. The supplier has

a trained technical staff with laboratory

facilities to serve y ou.

19

Page 20

OM-TDB

Troubleshooting

Your Groen kettle i s designed t o operate smoothly and efficiently if properly maintained. However, the

following is a li st of checks to make in the ev ent of a problem. Wiring diagrams are furnished inside the

service panel. If an i t em on the lis t is followed by

representative.

USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY GROEN OR THEIR

A UTHORIZED DISTRI BUTORS CAN CAUS E INJURY TO THE OPERATOR A ND DAMAGE TO THE

EQUIPMENT AND WILL VOID ALL WARRA NTIES.

<, the work should be done by a qualified s ervice

SYMPTOM WHO WHA T TO CHECK

Kettle is hard to tilt.

(TDBC only)

Kettle wi ll not heat, and

heating indicator will not

come on.

Kettle wi ll not heat, but

heating indicator comes

on.

Kettle continues heating

after it reaches the

desired temperature.

Kettle stops heating

before it reaches the

desired temperature.

Kettle heats slowly. User a. For air in the jacket. S ee “Jacket V acuum” in the “Maint enance”

Pressure Relief Valve

pops.

Auth

Service

Rep Only

User a. Electric power s upply to the unit. (Check the circuit breaker.)

Auth

Service

Rep Only

Auth

Service

Rep Only

User a. Thermostat dial se t ting.

Auth

Service

Rep Only

User a. Thermostat dial setting.

Auth

Service

Rep Only

Auth

Service

Rep Only

User a. For air in the jacket. See “Jacket Vacuum” in the “Maintenance”

Auth

Service

Rep Only

<

< indicates items which must be performed by an authorized technician.

<<

a. Gears for foreign materials, and lubri cat ion. <

b. Gears for alignment. <

c. Worn gears or broken gears. <

b. Water level in jacket.

c. Control circuit fus es. Replace a blown fuse only with a fuse of

the same AMP rat ing. <

d. For loose or broken wires. <

e. Tilt cut-off switch. <

f. That pressure switch is open. <

g. Operation of variable thermostat. <

h. Low water cutoff. <

a. Thermostat calibrati on. <

b. Heater elements wi t h ohmmerter for ground short or open

element. If element is defective, call Groen. <

b. Thermostat circui t for short. <

c. Thermostat operation. The thermostat should click when the

dial is rotated above and below the setting for the temperature

of the kettle. <

d. Contactor, to determine whether i t is energized or stuck. <

b. Thermostat calibration. <

c. Thermostat operati on. The thermostat should click when the

dial is rotated above and below the setting for the temperature

of the kettle. <

section of this manual.

b. Heater elements with ohmmeter for ground short or open

element. If an element is defective, call Groen. <

c. Voltage of main power s ource. <

section of this manual.

b. Pressure switch setting. <

c. Thermostat operati on. Thermostat should click when the dial i s

rotated abov e and below the setting for the temperature of the

kettle. <

d. Pressure relief valve. If the v alve pops at pressures below 49

PSI, replace it.

e. Contactor, to determine whether i t is energi zed. <

20

Page 21

OM-TDB

Parts List - TDBC

To order part s, contact your Groen Authorized Service Agency. Suppl y the model desi gnation, part descripti on, part

number, quantity, and, where applicable, volt age and phase.

21

Page 22

OM-TDB

Parts List - TDBC

To order parts, contact your Groen Authori zed Service Agency. S uppl y t he model designation, part

description, part num ber, quantity, and, where appl i cable, voltage and phase.

Key Description Part No. Key Description Part No.

1 Cover, Thermostat 114830 23 Weldment Kettle Body 304, 208/ 240V (20 qt) 137615

2 Knob, Thermostat 002868 23 Weldment Kettle Body 316, 208/ 240V (20 qt) 137726

3 Nut, hex 1/2-13 ss 005603 23 Weldment Kettle Body 304, 208/240V (40 qt) 137561

4 Washer lock 1/2 ss 005657 23 Weldment Kettle Body 316, 208/240V (40 qt) 137898

5 Weldment, Pedestal - TDB 122388 24 E-Ring, .1875" Di a 138357

6 Light and locknut, I ndicator, Red 116383 25 Bracket Faucet 137738

7 Gasket, Light 137434 26 Screw, 1/4-20 x 1/2 Truss Hd ss 012700

8 Screw, 10-32 x 1/2 137766 27 Seal, Shaft 136087

9 Cover, Cabi net 137618 28 Bumper Stop 137735

10 Liquid Level Indicat or 108554 29 Screw Hex Head 005070

11 Assembly, Gear Carrier 124741 30 Washer Lock 1/2 SS 005657

12 Shaft, Worm 122374 31 Collar Shaft Seal 136091

13 Gear, Worm 128001 32 Nut 1/4-20 Hex Keps 012940

14 Assembly, Gear Sector 128028 33 Pin, Roll 1/4 x 1.63 lg. 128036

15 Assembly, Handwheel 124719 34 O-Ring 138358

16 Key, 1/4 S q. x 1" lg. 122371 35 Screw, 3/8 - 24 x ½ 137786

17 Assembly, Beari ng Block 128021 36 O-Ring 138359

18 Pin Roll 1/4 x 1. 25" Lg. 012614 37 E-Ring 1.00" Dia 138356

19 Retaining Ring 1.500 124764 38 Collar, Shaft Seal 138354

20 Washer Lock 3/8" 005618 39 Seal, Shaft 1.00" Dia 136088

21 Screw 3/8-16 x 1" hex head 005612 40 Kit, Light and Gas ket (NOT SHOWN) 137892

22 Washer Flat 3/8" 005830 41 Kit, Switch and Gasket (NOT SHOWN) 137893

42 Kit, Thermostat (NOT SHOWN) 137894

43 Washer, Lock 005657

44 Screw, Hex HD Cap 005623

45 Nut, Hex (NOT SHOWN) 005603

22

Page 23

OM-TDB

Parts List - TDB

To order parts, contact your Groen Authori zed Service Agency. S uppl y t he model designation, part

description, part num ber, quantity, and, where appl i cable, voltage and phase.

23

Page 24

OM-TDB

Parts List - TDB

To order parts, contact your Groen Authori zed Service Agency. S uppl y t he model designation, part

description, part num ber, quantity, and, where appl i cable, voltage and phase.

Key Description Part No. Key Description Part No.

1 Cover, Thermostat 114830 22 Washer Flat 3/8" 005830

2 Knob, Thermostat 002868 23 Weldment Kettle Body 304, 208/ 240V (20 qt) 137615

3 Nut, hex 1/2-13 ss 005603 23 Weldment Kettle Body 316, 208/240V (20 qt) 137726

4 Washer lock 1/2 ss 005657 23 Weldment Kettle Body 304, 208/240V (40 qt) 137561

5 Weldment, Pedestal - TDB 122388 23 Weldment Kettle Body 316, 208/ 240V (40 qt) 137898

6 Light, Indicator, Red 116383 24 E-Ring, .1875" Dia 138357

7 Gasket, Light 137434 25 Bracket Faucet 137738

8 Screw, 10-32 x 1/2 137766 26 Screw, 1/4-20 x 1/2 Truss Hd ss 012700

9 Cover, Cabi net 137618 27 Nut Hex 3/8"-16 005619

10 Liquid Level Indicat or 108554 28 Bumper Stop 137735

11 Shaft, Handle 018963 29 Screw Hex Head 005070

12 Ring, ½” 012692 30 Washer Lock 1/2 SS 005657

13 Ball, Red 012691 31 Collar Shaft Seal 136091

14 Spacer, Pillow Block 137692 32 Nut 1/4-20 Hex Keps 012940

15 Pillow Block 002989 33 Screw Set Socket 003400

16 Collar, Set 003118 34 Screw, 3/8 - 24 x ½ 137786

Screw Hex HD CAP

17

3/8"-16 x 1-1/2"

18 Pin Roll 1/4 x 1. 25" Lg. 012614 36 Kit, Switch and Gasket (NOT SHOWN) 137893

19 Washer, 3/8" Lock 005618 37 Kit, Thermostat (NOT SHOWN) 137894

20 Washer Lock 3/8" 005618 38 Washer, Lock 005657

21 Screw 3/8-16 x 1" hex head 005612 39 Screw, Hex HD Cap 005623

005615

35 Kit, Light and Gas ket (NOT SHOWN) 137892

40 Spacer, Collar 139042

24

Page 25

OM-TDB

Parts List

TDB and TDBC

To order parts, contact your Groen Authori zed Service Agency. S uppl y t he model designation, part

description, part num ber, quantity, and, where appl i cable, voltage and phase.

Key Description Part No. Key Description Part No.

1 Pressure Switch 096963 5

2 Thermostat 012313 6 Gasket, B ot tom Cover (NOT SHOWN) 137969

3 Water Level Electrode 015589 7 Screw, ¼-20 x 1 ½” (NOT SHOWN) 012597

4 Bracket 137736 8 Gasket, Bottom Cover Screw (NOT SHOWN) 137968

Cover (NOT SHOWN)

25

003141

Page 26

OM-TDB

Parts List

To order parts, contact your Groen Authori zed Service Agency. S uppl y t he model designation, part

description, part num ber, quantity, and, where appl i cable, voltage and phase.

Key Description Part No. Key Descri ption Part No.

1 Gauge, Compound Pressure w/Dual 084208 3 A ssy , Water Fill Sub 137438

2 Valve, Pressure Relief 50 PSI 097005 4 Elbow, ½” NPT 90 Deg Street Blk 096905

26

Page 27

Replacement Electrical Parts

208/240V

OM-TDB

Key Description Part No. Key Descri ption Part No.

1 Asm, Electrical Mounti ng Bracket 137631 11 Barrier Insulation 003490

2 Water Level Control Brd 122192 12 Washer Shakeproof Lock #6 005715

3 Micro Sw itch, 15 AMP 125/250 VA C 002982 13 Nut Hex #4-40 003121

4 Terminal Block 4 Pole 85 AMP #14-4 088214 14 Transformer, 40VA 208/240 V PRI,

24 V SEC

5 Contactor 50 AMP RE S 4 Pole 119811 15 Lug Ground #14 - #6 AWG 129714

6 Fuse Holder Type 3 AG 077854 16 Screw #8-32 x 3/8" Hex Hd Cap 069789

7 Fuse 3.0 Amp Type 3 AG 077853 17 Screw #6-40 x 3/8" Round Hd 009697

8 PC Board Mounting Post 099901 18 Wiring Harness Asm, TDB/2C 24 V

Control (Not Shown)

9 Screw #8-32 x 1-1/ 4" Round Hd 005056 19 Wiring Harness Asm, TDB/2C

High Voltage (Not Shown)

10 Screw #4-40 x 3/4" Round Hd 003122 20 Wiring Harness Asm, TDB/2C Heaters

(Not Shown)

27

137441

137585

137603

137604

Page 28

OM-TDB

Replacement Electrical Parts

440V

Key Description Part No. Key Descri ption Part No.

1 Asm, Electrical Mounti ng B racket 137631 12 Washer Shakeproof Lock #6 005715

2 Water Level Control Brd 122192 13 Nut Hex #4-40 003121

3 Micro Sw itch, 15 AMP 125/250 VA C 002982 14 Lug Ground #14 - #6 AWG 129714

4 Terminal Block 4 Pole 85 AMP #14-4 088214 15 Screw #8-32 x 3/8" Hex Hd Cap 069789

5 Contactor, 4 Pole, 50A, 24 VAC 119811 16 Transformer, 75 VA, 440V 139803

6 Fuse Block, 1 Pole 30 AMP 077840 17 Jumper, 480V Fuse (Not Shown) 139113

7 Fuse, 6 Amp, Class CC 119823 18 Strap Cable Ty-Rap (Not Shown) 011093

8 PC Board Mounting Post 099901 19 Wiring Harness Asm, TDB/2C 24 V

Control (Not Shown)

9 Screw #8-32 x 1-1/ 4" Round Hd 005056 20 Wiring Harness Asm, TDB/2C

High Voltage (Not Shown)

10 Screw #4-40 x 3/4" Round Hd 003122 21 Wiring Harness Asm, TDB/2C Heaters

(Not Shown)

11 Barrier Insulati on 003490

28

137585

137603

137604

Page 29

Replacement Electrical Parts

480V

OM-TDB

Key Description Part No. Key Descri ption Part No.

1 Asm, Electrical Mounti ng B racket 137631 12 Washer Shakeproof Lock #6 005715

2 Water Level Control Brd 122192 13 Nut Hex #4-40 003121

3 Micro Sw itch, 15 AMP 125/250 VA C 002982 14 Lug Ground #14 - #6 AWG 129714

4 Terminal Block 4 Pole 85 AMP #14-4 088214 15 Screw #8-32 x 3/8" Hex Hd Cap 069789

5 Contactor, 4 Pole, 50A, 24 VAC 119811 16 Jumper, 480V Fuse 139113

6 Fuse Block, 1 Pole, 30 AMP 077840 17 Transformer, 40VA 480V 137694

7 Fuse 6, AMP, Class CC 119823 18 Strap Cable TY-RAP (Not Shown) 011093

8 PC Board Mounting Post 099901 19 Wiring Harness Asm, TDB/2C 24 V

Control (Not Shown)

9 Screw #8-32 x 1-1/ 4" Round Hd 005056 20 Wiring Harness Asm, TDB/2C

High Voltage (Not Shown)

10 Screw #4-40 x 3/4" Round Hd 003122 21 Wiring Harness Asm, TDB/2C Heaters

(Not Shown)

11 Barrier Insulati on 003490

29

137585

137603

137604

Page 30

OM-TDB

Schematics

480V or 460V, 1 or 3 Phase, 60 Hz208V or 240V, 1 or 3 Phase, 60 Hz

30

Page 31

Schematics

440V, 3 Phase, 60 Hz

OM-TDB

31

Page 32

OM-TDB

Service Log

Model No. _______________________________ Purchased Fr o m _________________________

Serial No. _______________________________ Location ________________________________

Date Purchased __________________________ Date Install ed ___________________________

Purchase Order No. ______________________ For Service Call __________________________

Date Service Performed Performed By

32

Page 33

References

KLENZADE SALES CENTER ECOLAB. Inc.

370 Wabasha

St. Paul, Minnesot a 55102

800/352-5326 or 612/293-2233

NATIONAL FIRE PROTECTION ASSOCIATION

60 Battery March P a rk

Quincy, Mass achus et ts 02269

NFPA/70 - The National Electrical Code

NATIONA L SANI TATION FOUNDATION

3475 Plymouth Rd.

Ann Arbor, M ichigan 48106

UNDERWRITERS LA BORATORI ES, INC.

333 Pfingst en Road

Northbrook, Illinois 60062

ZEP MANUFACTURING CO.

1310-T Seaboard Industrial Blvd.

Atlanta, Georgi a 30318

OM-TDB

33

Page 34

OM-TDB

LIMITED WARRANTY TO

COMMERCIAL PURCHASERS*

(U.S. & Canadian Sales Only.)

Groen warrants to original commercial purchaser/users that foodservice equipment manufactured by

Groen (“Groen Equipment”) (other than CapKold foodservice equipment) shall be free from defects in

material and workmanship for (12) twelve mon th s f r o m the date of installation or fifteen (15) months from

date of shipment from Groen, whichever date first occurs (the “Warranty Period”), in accordance with the

following terms and conditi ons:

I. This warran ty is limited to replacement parts and related labor for Groen Equipment located at its

original place of installation in the United States and Canada.

II. Damage to Groen Equipment that occurs during shipment must be reported to the carrier, and is

not covered under this warranty. The reporting of any damage during shipment is the sole

responsi bility of the commercial purchaser/us er of s uch Groen E quipment.

III. For Groen Convection Combo

HyPlus

TM

Pressureless Steamers, Groen further warrants to the original commercial

TM

Steamer-Ovens, HyPerSteamTM Convection Steamers and

purchaser/users of such Groen Equipment that the atmospheric steam generators or boilers

contained in such Groen Equipment shall be free from defects in material and workma nship for

twenty-four (24) months from the date of installation or twenty-seven (27) months from date of

shipment from Groen, whichever date first occurs, provided that: (a) the original purchaser/user

shall have also purchased and installed a Groen PureSteem Water Treatment System

connection with such Groen Convection Combo

Steamer or HyPlus

TM

Pres surel ess Steamer on or before the date such Groen Equipment was

TM

Steamer-Oven, HyPerSteamTM Convection

TM

for use in

installed, (b) the original purchaser/user has continuously used suchWater Treatment System in

connection with such Groen Equipment from the date of installation, and (c) the commercial

purchaser/user shall have maintained such Water Treatment System in accordance with the

maintenance and filter cartridge replacement recommendations of Groen, and otherwise

maintained such Oven or Steamer in accordance with all other operational and maintenance

recommendations of Groen.

IV. Groen further warrants to the original com m ercial purchaser/users of Groen Convection Combo

Steamer-Ovens that th e electronic relay and control board contained in such Groen Convection

Combo

TM

Steamer-Oven shall be free from defects in material and workmanship for twenty-four

(24) months from the date of installation or twenty-seven (27) months from date of shipment from

Groen, whi chever date first occurs.

V. During the Warranty Period, Groen, directly or through its authorized service representative, will

either repair or replace, at Groen’s sole election, any Groen Equ ipm ent determined by Groen to

have a defect in material or workmanship. As to any such warranty service during the Warranty

Period, Groen will be responsible fo r re lated reasonable labor and portal to portal transportation

expenses (ti me & mileage) incurred withi n t he United St at es and Canada.

TM

VI. This warranty does not cover bo il er m aintenance, calibration, periodic adjustments as specified in

operating instructions or manuals, consumable parts (such as scraper b lades, gaskets, packing,

etc.), and labor costs incurred for removal of adjacent equipment or objects to gain access to

Groen Equipment. This warranty does not cover defects caused by impr oper installation, abuse,

careless operation, or improper maintenance of Groen Equipment. This warranty does not cover

damage to Groen Equipment caused by poor w at er quality or improper boiler maintenance.

34

Page 35

OM-TDB

VII. THIS WARRANTY IS EXCLUS IVE A ND IS IN LIE U O F ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE, EACH OF WHICH IS HEREBY EXPRESSLY

DISCLAIMED. THE REMEDIES DESCRIBED ABOVE ARE EXCLUSIVE AND IN NO EVENT

SHALL GROEN BE LIABLE FOR SPECIAL, CONSEQUENTIAL, OR INCIDENTAL DAMAGES

FOR THE BREA CH O R DE LAY IN PERFO RMANCE OF THIS WARRANTY .

VIII. Groen Equipment is for commercial use only. If sold as a component of another (O.E.M.)

manufacturer’s equipment, or if used as a cons umer product, such E quipment is sold AS IS and

without any w arrant y.

* (Covers all Groen Equipment (other than CapKold foodservice equipment) ordered after

September 11, 2001).

35

Page 36

1055 Mendell Davis Drive

Jackson, MS 39272

Telephone 601 372-3903

Fax 601 373-9587

www.groen.com

OM-TDB (Revised 04/03)

Part Number 137575 Rev A

Loading...

Loading...