Page 1

? IMPORTANT INFORMATION ? KEEP FOR OPERATOR ? IMPORTANT INFORMATION ?

OPERATOR MANUAL OM-NGB/3(S)

CSD-1 FIELD INSTALLATION SUPPLEMENT

Part Number 123490 DOMESTIC

Model: NGB/3, NGB/3/E

Steam Boilers — CSD-1 Kit

Gas Heated

200,000 BTU/hr firing rate

120,000 BTU into product

3.7 effective boiler horsepower

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

READ THE BASIC OPERATOR MANUAL, AND INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING, OPERATING OR SERVICING THIS EQUIPMENT.

POST IN A PROMINENT LOCATION

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT USER SMELLS GAS. THIS INFORMATION SHALL

BE OBTAINED BY CONSULTING YOUR LOCAL GAS SUPPLIER. AS A MINIMUM, IMMEDIATELY TURN

OFF THE GAS AND CALL YOUR GAS COMPANY AND YOUR AUTHORIZED SERVICE AGENT.

EVACUATE ALL PERSONNEL FROM THE AREA.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH.

Information contained in this document is

known to be current and accurate at the time

of printing/creation. Unified Brands recommends referencing our product line websites,

unifiedbrands.net, for the most updated

product information and specifications.

Page 2

OM-NGB/3(S)

IMPORTANT — READ FIRST — IMPORTANT

WARNING: THE UNIT MUST BE INSTALLED BY PERSONNEL QUALIFIED TO WORK WITH GAS,

ELECTRICITY AND PLUMBING. IMPROPER INSTALLATION CAN CAUSE INJURY TO

PERSONNEL AND/OR DAMAGE TO THE EQUIPMENT. THE UNIT MUST BE INSTALLED IN

ACCORDANCE WITH APPLICABLE CODES.

CAUTION: AN ELECTRICAL GROUND IS REQUIRED.

CAUTION: DO NOT LOCATE THE BOILER CABINET DIRECTLY OVER A FLOOR DRAIN OR FLOOR

SINK. HUMIDITY OR WATER FROM A DRAIN WILL DAMAGE ELECTRICAL PARTS OF A

UNIT.

WARNING: TO AVOID DAMAGE OR INJURY, FOLLOW THE WIRING DIAGRAM EXACTLY WHEN

CONNECTING A UNIT.

CAUTION: DO NOT USE PLASTIC PIPE. DRAIN MUST BE RATED FOR STEAM AND BOILING WATER.

WARNING: DO NOT CONNECT THE DRAIN DIRECTLY TO A BUILDING DRAIN.

WARNING: BLOCKING THE DRAIN MAY BE HAZARDOUS.

IMPORTANT: Improper drain connection will void warranty.

WARNING: ALLOW COOKING CHAMBERS TO COOL BEFORE CLEANING.

WARNING: CAREFULLY READ THE WARNINGS AND FOLLOW THE DIRECTIONS ON THE LABEL OF

EACH CLEANING AGENT. USE SAFETY GLASSES AND RUBBER GLOVES AS

RECOMMENDED BY DELIMING AGENT MANUFACTURER.

WARNING: DO NOT MIX DE-LIMING AGENTS (ACID) AND DE-GREASERS (ALKALI) IN THE STEAM

GENERATOR OR ON THE COOKING CHAMBER WALLS.

NOTICE: Do not use a cleaning or de-liming agent that contains any sulfamic acid or any chloride,

including hydrochloric acid (HCl). If the chloride content of any product is unclear, consult

the manufacturer.

NOTICE: Do not use a de-greaser that contains potassium hydroxide or sodium hydroxide or that is

highly alkaline.

WARNING: USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY GROEN OR

THEIR AUTHORIZED DISTRIBUTOR VOIDS ALL WARRANTIES AND CAN CAUSE BODILY

INJURY TO THE OPERATOR AND DAMAGE THE EQUIPMENT. SERVICE PERFORMED BY

OTHER THAN FACTORY-AUTHORIZED PERSONNEL WILL VOID ALL WARRANTIES.

WARNING: HIGH VOLTAGE EXISTS INSIDE CONTROL COMPARTMENTS. DISCONNECT FROM

BRANCH BEFORE SERVICING. FAILURE TO DO SO CAN RESULT IN SERIOUS INJURY OR

DEATH.

WARNING: DO NOT EXPOSE SKIN TO ESCAPING STEAM. SEVERE BURNS CAN RESULT.

2

Page 3

OM-NGB/3(S)

Introduction

This document supplements the basic OM-NGB/3 Operator Manual by providing instructions for modifying boilers

with a new A.S.M.E. CSD-1 code-compliant control system. Performing this modification alters the boiler system

as described in OM-NGB/3-E Supplement New Boiler Control System (Part Number 133530), which is

incorporated into this supplement as Section II, Operation. Other than the instructions in that supplement/ section,

the provisions of OM-NGB/3 apply.

Section I - Installation Instructions

WARNING

THIS MODIFICATION MUST BE MADE BY PERSONNEL WHO ARE WELL-QUALIFIED TO WORK WITH

ELECTRICITY. IMPROPER MODIFICATIONS CAN CAUSE INJURY TO PERSONNEL AND/OR DAMAGE TO

EQUIPMENT. THE UNIT MUST BE INSTALLED IN COMPLIANCE WITH APPLICABLE CODES.

THE BOILER MUST BE THOROUGHLY TESTED FOLLOWING MODIFICATION, AS DIRECTED IN THIS

SUPPLEMENT, TO ENSURE THAT CONNECTIONS WERE PROPERLY MADE AND TO PREVENT

HAZARDOUS CONDITIONS.

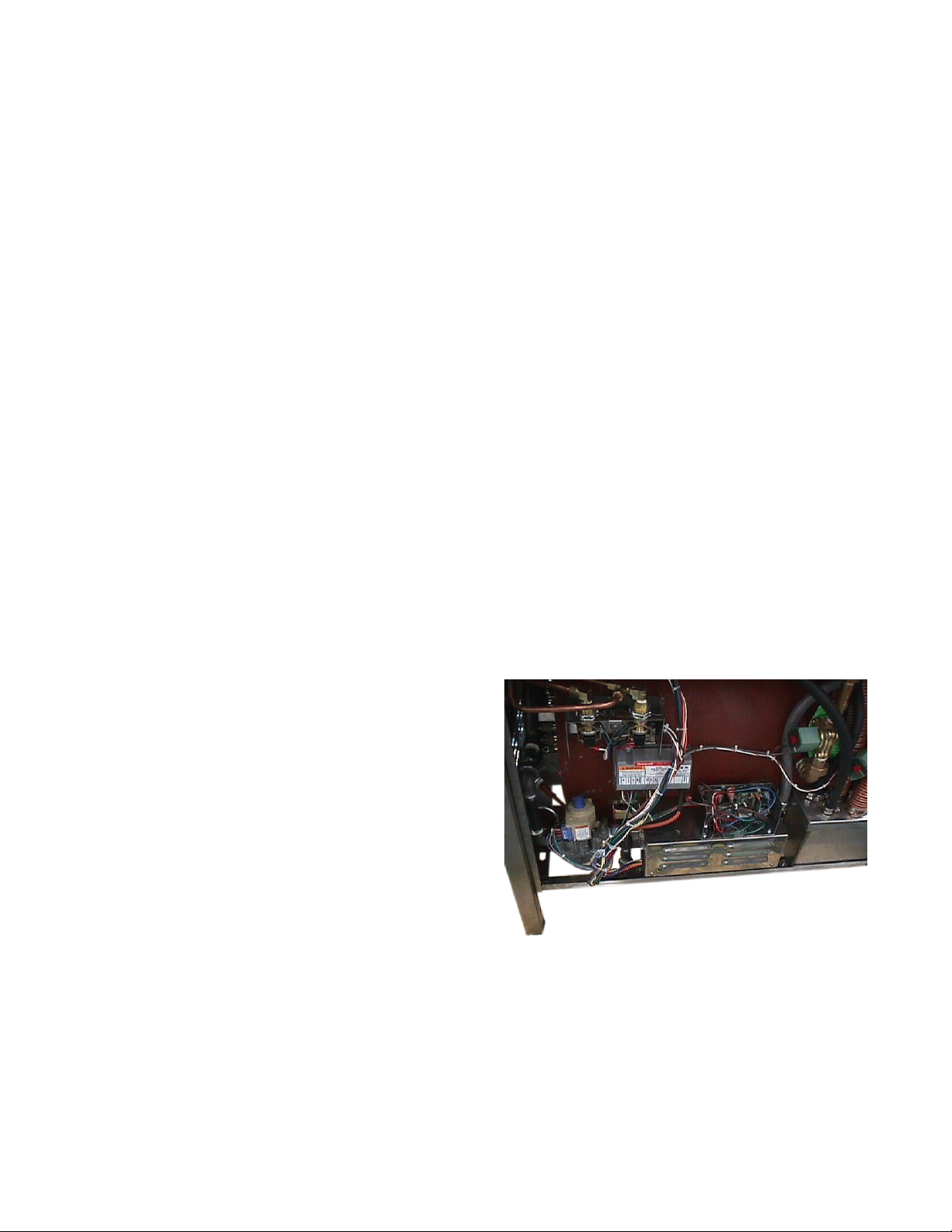

A. REMOVAL (Refer to the schematic appropriate

to the unit).

1. Turn off unit and completely disconnect power at

its source.

2. Shut off the gas supply in the line leading to the

unit or at the main valve.

3. If the unit has water in the boiler at the time of

shut-down, it will drain.

WARNING

THE OUTSIDE OF THE BOILER MAY BE VERY

HOT AND CAN CAUSE BURNS. COOL OR

ALLOW THE BOILER TO COOL COMPLETELY

BEFORE PROCEEDING.

(Note: Draining by cutting off power can be used to

cool the boiler more rapidly: Once it has drained,

reconnect the power and allow the unit to fill with

cold water. Repeat this process until the unit is

cool.) Be sure to turn the unit off and disconnect

from power before any wiring is disturbed.

4. Remove the side panels.

5. Cut wire ties which are holding wiring harnesses

located at the left side of the control box, along

the top left of the front control panel and along

the left side of the unit frame tubing. Use pliers

to cut the wire ties.

6. Disconnect the wiring from the boiler shell,

probes, front panel, and drain valve, noting

Remove the wire ties to disconnect wiring.

location and markings of the wires.

Disconnect the wiring from the gas valve and the

spark ignition module, but DO NOT disconnect

the wiring which runs directly from the module to

the gas valve. (These wires are a separate

three-wire harness which will be reused in the

new installation). DO NOT disconnect the large

orange spark ignition lead wire.

7. Remove the four screws that attach the spark

ignition module to its bracket. This will allow

access to the pressure switch enclosure located

directly above the module.

3

Page 4

OM-NGB/3(S)

8. Remove the cover from the pressure switch

enclosure.

9. Loosen the screws and remove the wires from

the pressure switches. Note that the high limit

switch is toward the rear of the unit and that its

wiring is marked PSH. The operating pressure

switch is toward the front of the unit. Its wiring is

marked PSL. Remove the wires from the

pressure switch enclosure.

10. Remove high limit pressure switch P/N 099223

and replace with P/N 118255 supplied with kit.

11. Remove the cover from the main electrical

control box.

NOTE: If the unit does not have HyPLUS steamer

cavities installed, skip steps 12, 13 and 14)

12. Disconnect the three wiring plug terminals that

come from the steamer cavities, noting the

markings on each. These are located in the

conduit that comes from the steamer cavities at

the right side of the control box facing the right

side of the boiler cabinet.

13. Loosen the screws on the transformer labeled

H1 and H2 and remove the two fork terminals

that lead to the steamer cavities. (Note: see

Installation Step 3, below, if terminal H2 is not

used in unit installation).

14. Remove the conduit connector nut and the

conduit connector and its wiring from the control

box.

2. Mount the transformer into the new control box

using the four mounting screws.

3. Connect wiring to the transformer at terminals

XF, X2, H1, and H2. Note that the X2 terminal

has a wire labeled X2 and a green ground wire.

Also note that the H3 or H4 terminals may be

used in your installation if unit supply voltage is

other than 120 Volts. The H2 terminal is for 120

Volt installations.

4. Place the control box in the cabinet and mount it

with four screws.

5. Install the conduit connector at the right of the

control box and attach the wiring plug and fork

terminals that were removed in steps 11, 12, and

13. Connections are the same as for the

previous installation.

6. Connect wiring to the fill valve, spray valve,

thermostat switch, spark ignition module, and

gas valve.

7. Insert the six wires with fork terminals into the

pressure switch enclosure. Using the pressure

switch that was removed for reference, attach

the three terminals marked PSH to the high limit

pressure switch. Attach the two terminals

marked PSL to the operating pressure switch.

8. Loosen the screw that attaches the pressure

switch enclosure to the bracket at the left side of

15. Remove the four mounting screws at the bottom

of control box which attach the box to the cabinet

frame.

16. Remove the control box and any wires which

may still be connected.

17. Loosen the screws labeled X1 and XF on the

transformer and remove the transformer wiring.

Remove the four mounting screws which hold

the transformer and disconnect the transformer

from the old control box.

18. Remove power cord and its connector from the

old control box.

B. INSTALLATION(Refer to the appropriate

schematic at the back of this supplement).

1. Install power cord and connector in new control

box.

All wiring must be reconnected when the new

control box is installed.

box. Do not remove! Place the remaining

terminal marked BLR – GND behind this screw

and tighten the screw.

9. Mount the spark ignition module using four

screws.

4

Page 5

10. Place the water level probe covers over the

terminals on the wires marked LO, MID, and HI.

Place the terminals on their respective water

level probes. Since these will be removed during

testing, only hand-tighten the nuts at this time.

11. Position the indicator light overlay to the left of

the start switch approximately one inch away.

Use tape to hold overlay in position. Mark the

position of three indicator light holes with a

center punch. Remove the overlay.

12. Drill three c” pilot holes in the front panel at

marked position. Further drill these holes out

using a ¼" drill then a d” bit.

OM-NGB/3(S)

Carefully connect Control Panel wiring.

provided at the left side of the control box.

Install the cover on the control box, making sure

that wiring is not pinched by the cover.

C. TESTING

The Indicator Light Overlay is positioned to the

left of the Start Switch.

13. Apply the overlay over the holes.

14. Connect front panel wiring to the front panel

components as follows: WF – water fill

indicator, LW – low water indicator, HP – high

pressure indicator, RES – reset indicator, S1 –

on / off switch, S2 – start switch. See diagram

shown below for further switch terminal

identification.

15. Route the drain valve wires along the front panel,

down the left front corner, and along the frame.

Connect the wires to the drain valve.

16. Using wire ties, attach the front panel wires and

drain valve wires to the clips provided. Be sure

no wiring is near the gas burner or the boiler

shell. Only water level probe wiring may touch

the boiler shell.

17. Complete the installation by loosely bundling the

wiring harness and attaching it to the anchor

1. Connect unit to power supply. Leave gas

supply turned off.

2. Turn unit on. Water Fill and Low Water indicator

lights should come on. Wait until both indicators

go out and the Reset light comes on.

3. Press START. The Reset light should go out

and green light inside the start switch should

come on to indicate normal operation. This

should be followed by trial for ignition during

which you should be able to see and hear the

electronic spark near the main burner at the pilot

burner. The trial for ignition will continue for

approximately 90 seconds. If this is the case

proceed with the test.

4. First turn the unit off, then turn on the gas

supply.

5. Repeat steps 2 and 3. When the Start switch is

depressed, trial for ignition should be followed by

pilot burner ignition, which in turn should be

followed by main burner ignition. If this is the

case proceed with the test.

6. Turn unit off, and then on again. Wait until the

Low Water and Water Fill indicator lights go out

and the Reset light comes on.

7. Remove the water probe wire marked LOW from

the water probe. Wait 3 to 6 seconds. The Low

Water indicator light should come on. Touching

the terminal to the probe should make the Low

5

Page 6

OM-NGB/3(S)

Water indicator go out and the Reset light come

on. Reconnect the terminal to the probe.

8. Repeat step 7 for the wire marked MID. The

same results should occur.

9. Turn off the power switch. If steps 7 and 8 were

successful, tighten the nuts on all three water

level probes. Bend terminals up and slip the

water level probe covers over the probes.

15. Install the cover on the pressure switch

enclosure.

16. Reinstall the cabinet covers and doors which

were removed for installation.

Water Level Probes are located on top of the

boiler, above the control box.

10. Turn unit on and wait until the Reset indicator is

lit. Press the Start switch to fire the boiler.

When main burner is lit, proceed with testing.

11. Use a small blade screwdriver to trip the high

limit pressure switch. This is the pressure switch

located toward the rear of the unit which was

changed during the installation. When the

switch is tripped, the main burner should shut

down and the High-pressure indicator light

should come on. When screwdriver is removed,

the High-pressure light should go out and the

Reset light should come on.

12. If safety checks were normal proceed with the

operational test. If not, retrace wiring

connections and correct any mistakes made.

13. Press Start switch to fire the boiler. Allow boiler

to build pressure. The main burner should shut

down at approximately 9.5 PSI.

14. Turn on both steamer cavities and verify that the

main burner cycles to maintain between five and

10 PSI. If burner fires continuously, turn off one

steamer cavity until the burner cycles. Cycling

indicates a successful operational test.

Switch Wiring Terminal Connections (Rear View)

6

Page 7

Section 2 - Operation

The new system is marked by the addition of

three indicator lights on the front panel.

Water Fill

Low Water

High Pressure

Other controls are unchanged.

When the unit is turned on, the unit will begin to

fill with water. Until it is filled, the Water Fill and

Low Water indicator lights will be on.

Once the unit is filled, and ready to operate,

those lights will go out and the Reset light will

come on. The unit is now ready for operation.

Press the start switch to light the boiler. The

Reset light will go out and the green light will

come on showing normal operation.

OM-NGB/3(S)

During operations the Low Water indicator will

only light when the water level drops below its required level. When this occurs, the boiler will immediately cease

firing and the green light will go out. Until the water has again reached the proper level, the reset light will not

come on, and the unit will not operate.

The same is true when a high pressure situation occurs. The High Pressure indicator light will come on, the boiler

will stop firing, and the green light will turn off. If this situation occurs, contact an authorized Groen service

agency. Until the high pressure situation has been resolved, the reset light will not come on and the unit will not

operate.

7

Page 8

OM-NGB/3(S)

Wiring Schematic - Electronic Ignition

8

Page 9

OM-NGB/3(S)

Wiring Schematic - Standing Pilot

9

Page 10

OM-NGB/3(S)

Parts List

Key Description Part No. Key Description Part No.

1 Assembly, Electrical Control, NGB/3 123489 5 Light. Indicator, Red 122121

2 Water Level Control 24 VAC 122192 6 Overlay, Front Panel HY6 SE & HY 6SG 122188

3 Switch, Pressure, High Limit 118255 7 Schematic, Wiring - Electric Ignition 122193

4 Light, Indicator, Yellow 122122 8 Schematic, Wiring - Standing Pilot 123416

10

Page 11

OM-NGB/3(S)

LIMITED WARRANTY TO

COMMERCIAL PURCHASERS*

(Continental U.S., Hawaii and Canadian Sales Only)

Groen Foodservice Equipment (“Groen Equipment”) has been skillfully manufactured, carefully inspected,

and packaged to meet rigid standards of excellence. Groen warrants its Equipment to be free from defects in

material and workmanship for (12) twelve months, with the following conditions and subject to the following

limitations.

This parts and labor warranty is limited to Groen Equipment sold to the original commercial

purchaser/users (but not original equipment manufacturers {O.E.M.}), at its original place of installation in

the continental United States, Hawaii and Canada.

Damage during shipment is to be reported to the carrier, is not covered under this warranty, and is the

sole responsibility of the purchaser/user.

Groen, or an authorized service representative, will repair or replace, at Groen’s sole election, any Groen

equipment, including but not limited to, drawoff valves, safety valves, gas and electric components, found

to be defective during the warranty period. As to warranty service in the territory described above, Groen

will absorb labor and portal to portal transportation costs (time and mileage) for the first twelve (12)

months from date of installation or fifteen (15) months from date of shipment from Groen.

This warranty does not cover boiler maintenance, calibration, periodic adjustments as specified in

operating instructions or manuals, and consumable parts such as scraper blades, gaskets, packings,

etc., or labor costs incurred for removal of adjacent equipment or objects to gain access to Groen

Equipment. This warranty does not cover defects caused by improper installation, abuse, careless

operation, or improper maintenance of equipment. This warranty does not cover damage caused by

poor water quality or improper boiler maintenance.

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE, EACH OF WHICH IS HEREBY EXPRESSLY DISCLAIMED. THE

REMEDIES DESCRIBED ABOVE ARE EXCLUSIVE AND IN NO EVENT SHALL GROEN BE LIABLE

FOR SPECIAL, CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR THE BREACH OR DELAY IN

PERFORMANCE OF THIS WARRANTY.

Groen Equipment is for commercial use only. If sold as a component of another (O.E.M.) Manufacturer’s

equipment, or if used as a consumer product, such Equipment is sold AS IS and without any warranty.

*(Covers all Foodservice Equipment Ordered after October 1, 1995)

11

Page 12

1055 Mendell Davis Drive

Jackson, MS 39272

Telephone: 601 372-3903

Fax: 601 373-9587

OM-NGB/3(S)

Part Number 123490

Loading...

Loading...