Page 1

HYPERSTEAM MODEL HY-5G/(2)HY-5G

Table of Contents

SECTION 5B: HYPERSTEAM MODEL HY-5G

(GAS FIRED STEAM GENERATOR)

PAGE

5B.1 SPECIFICATIONS............................................................5B-1

5B.1.1 Model Designation ............................................................5B-1

5B.1.2 Construction......................................................................5B-1

5B.1.3 Operation ..........................................................................5B-1

5B.1.4 Electrical Requirements....................................................5B-1

5B.1.5 Water Supply Requirements ............................................5B-2

5B.1.6 Gas Supply ......................................................................5B-2

5B.1.7 Gas Jet Orifice Size..........................................................5B-2

5B.1.8 Gas Jet Orifice Size Charts ..............................................5B-3

5B.2 ELECTRICAL DIAGRAMS ............................................ 5B-5

5B.2.1 Electrical Schematic Diagram - HY-5G ............................5B-5

.2.2 Interconnect Block Wiring Diagram - HY-5G ....................5B-7

5B

5B.3 DIAGNOSTICS .............................................................. 5B-9

5B.4 ASSEMBLY/DISASSEMBLY PROCEDURES................ 5B-9

5B.4.1 Side Panels ......................................................................5B-9

5B.4.2 Top Cover..........................................................................5B-9

5B.4.3 Adjustable Legs

5B.4.4 Pilot Switch (SW3)..........................................................5B-10

5B.4.5 Main Gas Valve (GV2) and Gas

Pressure Adjustment

.4.6 Igniter Module ................................................................5B-11

5B

.4.7

5B

5B.4.8 Steam Generator Manifold Assembly ............................5B-12

.4.9 Gas Solenoid Valve ........................................................5B-13

5B

5B.4.10 Gas Generator Drain Valve ............................................5B-14

5B.4.11 Water Flow Reducer ......................................................5B-14

5B.4.12 Water Inlet Valve ............................................................5B-14

5B.4.13 Water Inlet Valve Coil......................................................5B-15

.4.14 Steam Generator ............................................................5B-15

5B

5B.4.15 High Limit Thermostat ..................................................5B-17

5B.4.16 Steam Generator Probes (High and Low Water)............5B-17

.4.17

5B

5B.4.18 Control Voltage Transformer ..........................................5B-18

5B.4.19 Timer Assembly ..............................................................5B-18

5B.4.20 Light and Timer PC Board ............................................5B-18

Pilot Bur

Current Check/Adjustment..............................................5B-12

Supply

ner Replacement/

oltage

V

................................................................5B-9

............................................................

erminal Block........................................5B-17

T

5B-10

(2/02)

5B-

i

Page 2

HYPERSTEAM MODEL HY-5G/(2)HY-5G

Table of Contents

5B.4.21 Steamer Control PC Board ............................................5B-18

5B.4.22 Fan..................................................................................5B-19

5B.4.23 Fan Motor Assembly ......................................................5B-19

5B.4.24 Motor Starting Capacitor ................................................5B-19

5B.4.25 Steam Generator Ready Thermostat..............................5B-19

5B.4.26 Steam Port, Front ..........................................................5B-19

5B.4.27 Cavity Hose Assemblies ................................................5B-20

5B.4.28 Door Removal/Installation/Alignment..............................5B-20

5B.4.29 Door Switch ....................................................................5B-20

5B.4.30 Door Reversing Procedures ..........................................5B-20

5B.4.31 Door Gasket....................................................................5B-20

5B.4.32 Door Components: Handle, Cam, Spacer, etc. ..............5B-20

5B.4.33 Door Spring ....................................................................5B-21

5B.4.34 Door Latch Pin................................................................5B-21

5B.4.35 Wiring Harnesses ..........................................................5B-21

5B.4.36 Cleaning System Eductor ..............................................5B-22

PAGE

5B.5 PARTS IDENTIFICATION HY-12G/24E ........................5B-23

nal Cabinet and Sheet Metal..................................5B-23

5B.5.1

5B.5.2 Electrical Circuit; Steam Hoses; Drain Valve...................5B-27

5B.5.3 Line Connection Assembly; Electronic

.5.4 Plumbing Components on Steamer Base.......................5B-31

5B

5B.5.5 Water Hose Connections ................................................5B-33

5B.5.6

5B.5.7 Gas Piping and Steam Generator...................................5B-36

5B.5.8 Gas Valve Piping Assembly ............................................5B-37

.5.9

5B

.5.10

5B

Exter

............................................................5B-29

Control Assemb

Parts Inside Steamer Cavity ...........................................5B-35

old Assembly ..........................................................5B-38

Manif

Water Inlet Valves ...........................................................5B-39

ly

5B-ii

(2/02)

Page 3

HY-5GF (“Single Stack”)

37

40

37

39

34

33

34

38

5 PLCS

39137A

1

HYPERSTEAM MODEL HY-5G/(2)HY-5G

Specifications

5B.1 SPECIFICATIONS

5B.1.1 Model Designation

HY - HyPerSteam

5 - Maximum Capacity of 2-1/2" Deep Pans

G - Gas Fired Steam Generator

F - Stand Mounted

HY - 5 GF

(2)HY - 24 GF

NOTE: Since the double-stacking arrangement involves an inter-

linked deliming system, there is no field retrofit kit available.

5B.1.2 Construction

Dimensions HY-5GF: 28-3/8'' high x 21-5/8'' wide x

-5GF: 71-3/8'' high x 21-5/8'' wide x

(2)HY

Two (2) HY-5 G’s stacked

33-5/16'' deep

35-3/16'' deep

Weight: HY-5GF: 203 pounds; (2)HY-5GF: 460 pounds

Cladding Material: Stainless Steel No

. 4 Finish

5B.1.3 Operation

Steam Generator: Atmospheric Steam at 212 degrees F.

60 min

ute timer with buzz

er and LED indicators

.

MAXIMUM PAN CAPACITY

HY-5G (2)HY-5G

an Size/T

P

12 x 20 x 1 5 12 x 20 x 1 10

(steamer) (steamer)

12 x 20 x 2-1/2

(steamer)

12 x 20 x 4 3 12 x 20 x 4 6

(steamer) (steamer)

5B.1.4

ype Number Pan Size/Type Number

5

12 x 20 x 2-1/2

(steamer)

Electrical Requirements

120 Volts AC, single phase, 60 Hz., 15 ampere service.

10

(2/02)

-5GF

(2)HY

(two HY-5G unit factory

ked)

le-stac

doub

138489A

5B-1

Page 4

HYPERSTEAM MODEL HY-5G/(2)HY-5G

Specifications

5B.1.5 Water Supply Requirements

3/4 inch N.H. cold water supply hose connection to be used.

Supply shall be not less than 1.50 GPM.

Pressure: 30 psi min. - 60 psi max.

Water Quality (minimum): Total dissolved solids (TDS) contents

should have a minimum value of 30-40 parts/million and the

water pH should be 7.0 to 9.0.

5B.1.6 Gas Supply

Gas services shall be natural or propane by means of 3/4 inch

N.P.T. pipe.

Each steam generator: 62,000 BTU/hour.

Gas Operating Pressure:

3.2'' W.C. - Natural Gas

10.5'' W.C. - Propane Gas

Recommended Incoming Gas Feed Rate:

5'' W.C

12

. min. - 14'' W.C. max. - Natural Gas

. min. - 14

'' W.C

. max. - Propane Gas

'' W.C

5B.1.7

IMPORTANT: The gas jet orifice size and the flame holder for

each jet on the assembly manifold MUST be properly sized for

the type of gas being used (Natur

tude (f

Improper gas jet sizes will result in either too much gas being

used or not enough gas to achieve proper heating of the steam

gener

Please refer to the chart providing the proper gas jet orifice sizes

(Groen P

plies and for various elevations from sea level to 12,000 feet.

If there is a question as to what size is installed, the column

labeled “DRILL SIZE” indicates the diameter or number of the

ill bit which will fit the gas jet or

dr

Gas Jet Orifice Size

eet above sea le

.

ator

t Numbers) f

ar

al or Propane) and for the alti-

vel) at which the steamer is to be used.

or both Natur

al and Propane gas sup-

.

ifice

5B-2

(2/02)

Page 5

5B.1.8 Gas Jet Orifice Size Charts

BURNER JET SIZING CHART

GROEN PART

NUMBER

SIZE OF ORIFICE

DIM "A"

TYPE OF GAS

ALTITUDE

#57 (.043)

099926

BLANK

106523

NAT. 0'-2000'

NAT. 2001'-4000'

099928

#1.45 mm (.0571)

NAT. 4001'-6000'

099929

#54 (.055)

LP. 0'-2000'

LP. 2001'-4000'

138474

#72 (.025)

LP. 4001'-6000'

099935

.85 mm (.0335)

099936

#67 (.0320)

LOW FIRE HIGH FIRE

#1.05 mm (.0413)

#60 (.040)

.90 mm (.0354)

.60 mm (.0236)

099934

139321

106526

139127

SIZE OF ORIFICE

BLANK

#53 (.0595)

DIM "A"

GROEN PART

NUMBER

099927

099926

#73 (.0240)

139128

(2 PER MANIFOLD) (6 PER MANIFOLD)

HYPERSTEAM MODEL HY-5G/(2)HY-5G

Specifications

(2/02)

5B-3

Page 6

HYPERSTEAM MODEL HY-5G

TRANSFORMER

STEAMER CONTROL BOARD

132

J1

T2

321J44

J5A1

J5

LIGHT AND TIMER BOARD

J5B1

J9

J8

TIMER

2

1

9

63457

8

1310111214

2

1

9

6

3

4

5

7

8

10

3127546108

9

3

4

2

1

6

7

3

4

5

2

1

K1

24(DONE)

21

22(TIMING)

11

12(MANUAL)

BLUE

RED

RED

BLUE

TERMINAL

AUTO TEST

SW2

STEAMER SELECT

S1

ON

SWITCH

STEAMER SELECT TABLE

1 2

0 1

LOW PROBE

HIGH PROBE

+12VDC

24VAC

HIGH POWER 1

DRAIN

EDUCTOR

HIGH POWER 2

LOW POWER

FILL

FAN SPRAY

LEFT

TSTAT

READY

WHITE

BLACK

BLUE

RED

21

DOOR SWITCH

20VAC CT

21

RIGHT

K3

BLUE

WHITE

(PV)TH

(PV)TR

GND(4)

PV(3)

MVPV(2)

MV(1)

IGNITER

ORANGE

B A

GREEN/YELLOW

SWITCH

PILOT

SW3

BLACK

GV1

PC1

BLOCK TB1

24VAC

2

K1

CIRCUIT

4

AMP

BLACK

120V

COM24VAC LO

CUTOUT

BREAKER

4

T1

24VAC HI

TRANSFORMER

24VAC 75VA

ACHI

GREEN/

YELLOW

BROWN

BLACK

ACLO

CIRCUIT

10 AMP

BREAKER

WHITE

2 1

CB-1

1

2

BLACK

1 2

WV1

WV2

BROWN

RED/BLK

BLK/RED

(MV)TH

(MV)TR

0 1

G

C D

SW3

24V(6)

24V(5)

BLACK

GV2

BLUE

BLUE

BLUE

BLUE

BLUE

BLUE

BLUE

BLUE

BLUE

BLUE

BLUE

BLUE

BLUE

+5VDC

WV5

WV6

WV3

WV4

DV

K4

24VDC

K4

RED

DRAIN

START CAP

WHITE

BROWN

YELLOW

VIOLET

ORANGE

BLACK

MAIN

START

BLUE

RED

BROWN

RED

120=6uf

RED

WHITE

YELLOW

BLUE

VIOLET

BROWN

BROWN

RED

RED

ORANGE

KEY

BLACK

M1

MOTOR

3600 RPM

C1

JUMPER

P/N 123123

120

1

0

HY-5G ON ON

1

15

OVRTMP S'DOWN CNTRL

FILL VALVE

EDUCTOR VALVE

LOW POWER RELAY

543

HIGH POWER RELAY

16

OVERTEMP SENSE IN

24 VAC SWITCHED

DRAIN (DC+)

+12VDC-OUT

24VAC UNSWITCHED (DRAIN)

24 VAC LOW

24VAC SWITCHED

GRN/YEL

BROWN

ORANGE

BLACK

RED

RED/WHT

WHT/RED

BLK/ORNG

BLU/WHT

RED/BLU

BLK/RED

RED/BLK

WHITE

DRAIN (DC-)

1413121110

9

6

17

18

LO PROBE

HI PROBE

BLK/BLU

WHT/BLU

C

NC

HL1

8

BLK/GRN

24VAC SWITCHED

6

ACHI

ACLO

5

10

8

1

GREEN/YELLOW

WHITE/ORANGE

WHITE/ORANGE

2

4

2

2

1

J6

1

J2

WHITE

BLACK

BLACK/BLUE

WHITE/BLUE

J7

123456789

10111213141516

GRN/YEL

BROWN

ORANGE

BLACK

RED

RED/WHT

WHT/RED

BLK/ORNG

BLK/GRN

BLUE

RED/BLU

BLK/RED

RED/BLK

WHITE

BLU/WHT

RED/YEL

ACHI

ACLO

P7

CONDENSATE SPRAY VALVEBLU7

PILOT

K3

CUTOUT

4 2

8 6

8 6

4 2

WHITE

130396

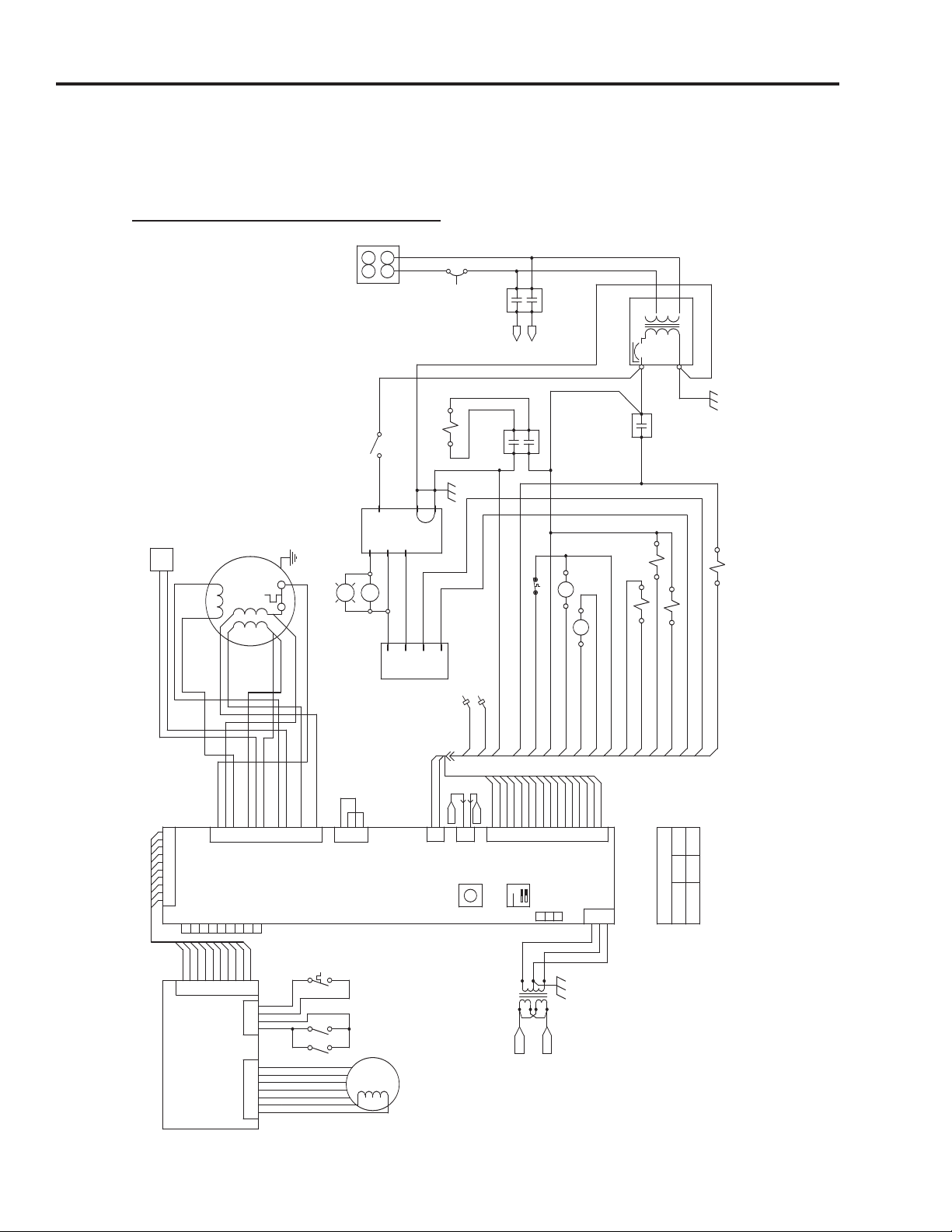

Electrical Diagrams

5A.2 ELECTRICAL DIAGRAMS

5A.2.1 Electrical Schematic Diagram - HY-5G

5B-4

(2/02)

Page 7

HYPERSTEAM MODEL HY-5G

Timer

ON

J7

P7A

RED

BLUE

BLUE

BLUE

BLUE

BLUE

BLUE

BLUE

BLUE

BLUE

WHITE

RED/BLU

BLK/RED

BLUE

RED/BLK

WV5

WV2BLACK

BLUE

B

LACK

WHITE

BROWN

GRN/YEL

RED

RED

BLACK

ORANGE

BLACK

BLACK

BLACK

RED

GREEN

WHITE

WHITE

RED

MOTOR CAP

FAN MOTOR

MOTOR ASSY.

P/N 096740

P/N 096857

P

/N 119815

P/N 070178

P/N 070178

P/N 088865

P/N 096857

1

1

1

1

1

1

1

1

1

1

T2-8

T2-10

T2-6

T2

WHITE

BLACK

T2-5

T2-1

20VAC CT

GRN/YEL

WHT/ORN

WHT/ORN

RED

BLUE

BLUE

BLUE

BLUE

BLUE

B

LUE

WHITE

BLACK

BLACK

WHITE

GRN/YEL

WHT/ORN

WHT/ORN

LO PROBE

HI PROBEBLK/BLU

WHT/BLU

BLACK

WV6

BLACK

RED/BLU

WV2

WV1

WHITE

RED

BLACK

RED

GREEN

BLACK

BLACK

WHITE

RED

RED

BLACK

ORANGE

BROWN

GRN/YEL

21

D

IAGNOSTIC

SELECT

STEAMER

SELECT

TMRMOT 2

T

MRMOT 1

24

21

22

11

12

READY B

READY A

DRSW R2

DRSW R1

DRSW L2

DRSW L1

RED

BLUE

BLUE

BLUE

BLUE

BLUE

BLUE

BLUE

BLUE

RED

B

LUE

BLUE

BLUE

BLUE

BLUE

BLUE

RED

P/N 119871

P/N 119868

P/N 123120

J1

TSTAT

DOOR RIGHT

DOOR LEFT

+12VDC

LOW PROBE

HIGH PROBE

J7

J2

J

6

J4

J5

J9

J8

J5A1

J5B1

LOW PROBE

HIGH PROBE

EDUCTOR VALVE

FILL VALVE

137221 STEAMER CONTROL

BOARD

1

19817 LIGHT AND

TIMER BOARD

+5VDC

FAN / SPRAY

FILL

LOW POWER

HIGH POIWER 2

EDUCTOR

DRAIN

HIGH POWER 1

24VAC

P/N 125788

R

ED

P

/N 123123

P/N 090827

P/N 090827

P/N 123122

P/N 096826

P/N 096812

HY5G INTERCONNECT DOMESTIC

24-SEPT-2001

P/N 106233

P/N 119813

P/N 096892

BLACK

BLACK

WHITE

WHITE

BLACK

T1-COM

T1-120

T1-120

T1-COM

BROWN

BROWN

BLK/ORN

BLK/ORN

RED

K1-4

K1-4

K1-2

K1-2

K1-1

K1-1

K1-0

ORANGE

BLK/ORN HL1-NC

HL1-C

T1-24LO GRN/YEL

T1-24HI

BLACK

GRN/YEL

BLACK

T1-24LO

T1-24HI

T

B1

HL1

24VAC CUTOUT

K1

T1

24VAC

HIGH LIMIT

L2

L

1

B

LACK

WHITETB1-1

TB1-2

P/N 003887

P/N

CB1-2

CB1-1

PILOT CUTOUT

P/N 119814

K3

E-GND

GRN/YEL

BLACK

BLACK

P/N 106627

BROWN

WHITE

GV1-2

GV1-1

HIGH POWER #1

GV1

G

RN/YEL

GRN/YEL

GRN/YEL

GRN/YEL

P/N 085153

P/N 096705

IGNITION PLUG

IGNITION MODULE

WHITE

IGN-9

IGN-6

IGN-5

IGN-5

I

GN-4

IGN-4

ORANGE

ORANGE

IGN-3

IGN-2

IGN-1

IGN

BLUE

BLUE

BLACK

SW3-D

P/N 087951

BLUE

ORANGE

BLUE

BLACK

SW3-B

SW3-C

SW3-C

SW3-A

PV-TH

MV-TR

MV-TH

WHITE

BLK/RED

SW3

PILOT SWITCH

MAIN VALVE(NAT)

GV2

PV-TR

BLUE

BLUE PV-TR

RED/BLK

K

3-0

K3-1

K3-1

BLACK

BLACK

B

LUE

K3-0 BLUE

BLACK

BLACK K3-8

K3-8

WHITE

WHITE K3-4

K3-4

BLACK K3-6

WHITE K3-2

P/N 098443

DRAIN VALVE

P/N 074594

WHITE

RED

DV1-1

DV1-2

K4-2

K4-6

BLK/ORN

GRN/YEL

BLACK

BLACK

GRN/YEL

K4-1

K4-4

K4-8

K4-8

K4-4

DRAIN RELAY

P/N138420

K4

WHT/RED K4-0

T2-2 WHITE

T2-4 BLACK

WV3

WV4

BLUE

BLK/GRN

P/N 090827

SPRAY VALVE

P/N 130399

P/N 130397

P/N 130398

11

BLU/WHT

BLK/GRN

BLK/ORN

WHT/RED

RED/WHT

RED

BLACK

ORANGE

BROWN

GRN/YEL

BLK/BLU

W

HT/BLU

RED

BLUE

BLUE

RED

BLACK

*KEY*

ORANGE

RED

BROWN

RED

VIOLET

BROWN

WHITE

YELLOW

BLUE

WHITE

YELLOW

BLUE

VIOLET

BROWN

BROWN

RED

RED

ORANGE

BLACK

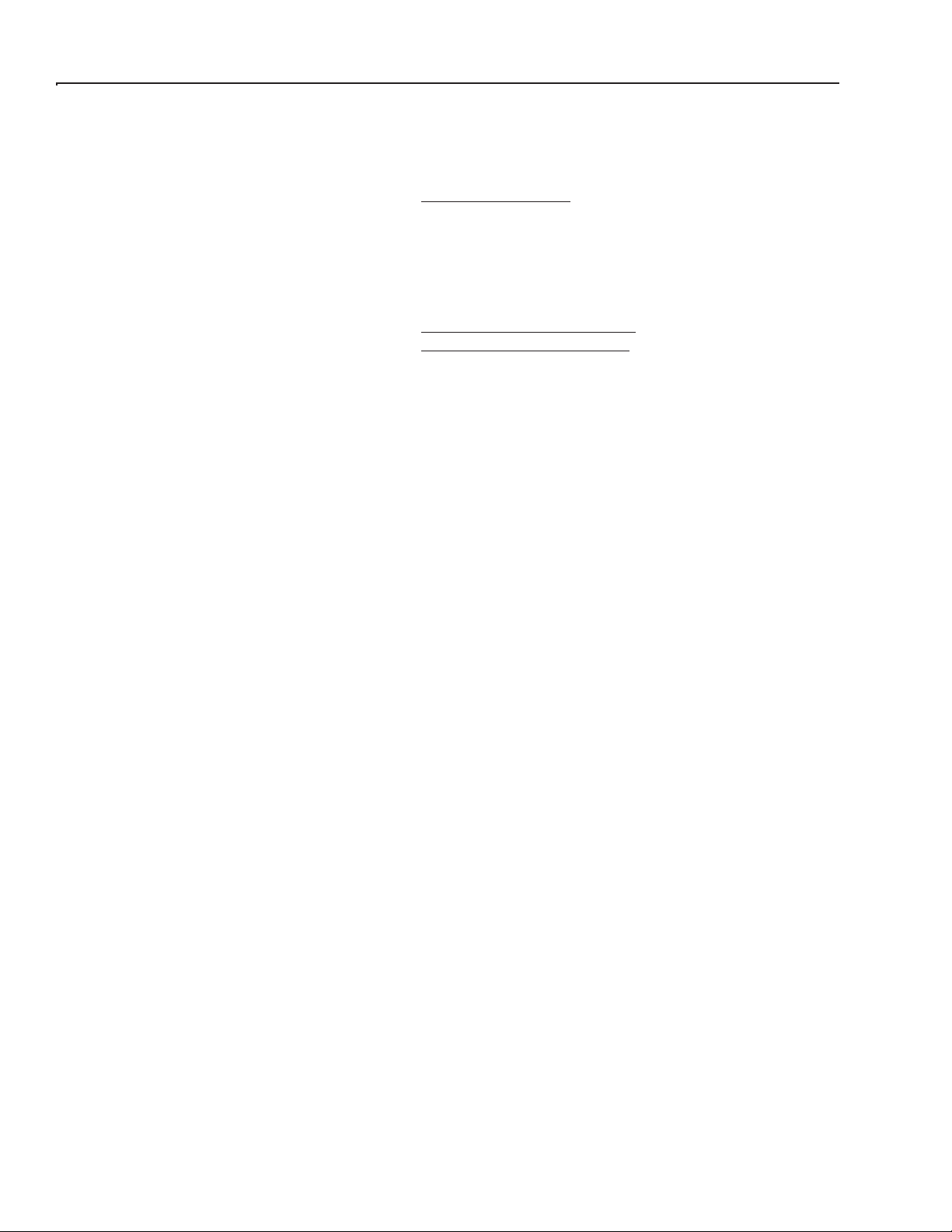

Electrical Diagrams

5A.2.1 Interconnect Block Diagram - HY-5G

(2/02)

5B-5

Page 8

HYPERSTEAM MODEL HY-5G/(2)HY-5G

Diagnostics

5B.3 DIAGNOSTICS

Diagnostic procedures are the same for all Steamer Ovens. Refer

to Section 4.2.

5B.4 ASSEMBLY/DISASSEMBLY PROCEDURES

GENERAL INFORMATION:

The following procedures are based upon having access to the

steamer on all four sides. If the steamer is installed between other

appliances and there is not adequate room on the sides for access,

the steamer must be pulled out from its position to gain proper

access.

Care should be exercised in moving the steamer so as not to stress

or pull on electrical, w

ater or gas connections.

5B.4.1 Side Panels

Right Side (Louv

Left Side (Smooth):

Please refer to Section 4.3, Paragraph 4.3.1 for Assembly/

Disassembly procedures.

5B.4.2 Top Cover

Single (or Double Stack Upper): P/N 138536

Bracket, Top Retainer

P/N 123156 (qty 2)

Please refer to Section 4.3, Paragraph 4.3.2 for Assembly/

Disassembly procedures.

Double Stack (2)HY

1.

Disconnect power to the steamers.

2. Remove right and left side covers.

3. On bac

4. In upper unit, disconnect clean hose that comes through

5. Remo

6. Remo

7. Remove lower unit top panel.

k of units, remove vent tube and drain box.

bushing. Remove clamp from hose.

ve four bolts and flat washers.

e top unit.

v

-5G Lower Unit T

ered): P/N 138532

P/N 138534

op Panel Removal

(2/02)

5B.4.3 Adjustable Legs

P/N 042505

Please refer to Section 4.3, Paragraph 4.3.4 for Assembly/

Disassembly procedures.

5B-7

Page 9

HYPERSTEAM MODEL HY-5G/(2)HY-5G

Assembly/Disassembly Procedures

5B.4.4 Pilot Switch (SW3)

P/N 087951

Please refer to Section 4.3, Paragraph 4.3.5 for Assembly/

Disassembly procedures.

5B.4.5 Main Gas Valve (GV2) and

Gas Pressure Adjustment

Natural: P/N 098443

Propane:

1. Turn off gas and electric power to steamer.

2. Remove the right side panel.

3. Turn the manual gas shut-off valve to the OFF position.

P/N 098444

4. Note the positions of wires connected to terminals of the

o gas solenoid valves, then disconnect the wires.

tw

5. Disconnect the four wires from the main gas valve.

They are:

blue:

white: Terminal (PV) TH

black: Terminal (MV) TR

red:

6. Using open-ended wrenches to loosen the compression

nuts, remove the five sections of aluminum tubing between

the valve and piping assembly and the steam generator

manifold assembly. Be careful not to excessively move or

bend the aluminum tubing.

7. With a pipe wrench or ChannelLock, open the pipe union

between the main gas valve and the manual gas shut-off

valve. Remove the assembly.

8. With the main gas valve held in a vise, ChannelLock or pipe

wrench, use a ChannelLoc

both sides of the main gas v

Terminal (PV) TR

Terminal (MV) TH

k to remo

.

e

alv

e the nipples from

v

5B-8

To Install:

9.

Remo

old valve and install on the side of the new valve, using pipe

thread compound.

e the elbo

v

w compression fitting from the side of the

(2/02)

Page 10

Figure 1.

Gas Pressure Regulator

Adjustment Screw

HYPERSTEAM MODEL HY-5G/(2)HY-5G

Assembly/Disassembly Procedures

10. Screw in and tighten the nipples into both sides of the main

gas valve using pipe thread compound.

IMPORTANT: The elbow and elbow installed on the end of the

valve near the adjustment screw must be positioned at 10 degrees

away from vertical, for correct installation of the assembly back into

the steamer.

11. Using a pipe wrench or ChannelLock, reconnect to the

union near the manual gas shut-off valve and tighten.

DSC00003

12. Attach all aluminum tubing and tighten compression nuts

with an open-ended wrench.

13. Plug in the four terminal wires to the main gas valve, per

step 5 on page 5B-10.

14. Plug in wires at the terminals of the gas solenoid valves.

Figure 2.

Gas Pressure Tap

with Plug

138585A

Gas Pressur

e Adjustment:

Adjust the gas pressure after installing the main gas valve.

1. Remove the gas pressure tap plug (Figure 2) on gas man-

old.

if

2. Connect manometer to gas pressure tap.

3. Remo

ve cap from gas pressure regulator adjustment screw

on the main gas valve (Figure 1). Adjust the gas pressure

regulator screw until the manometer reads 3.2" W.C. for

natural gas or 10.5" W.C. for propane gas. Turn the adjustment screw in to increase pressure and out to decrease

pressure

4. Install cap on pressure regulator scre

manometer and install manif

.

w. Disconnect

old plug.

5B.4.6 Igniter Module

P/N 085153

Please ref

er to Section 4.3, P

aph 4.3.7 f

r

ag

ar

or Assemb

ly/

Disassembly procedures.

(2/02)

5B-9

Page 11

HYPERSTEAM MODEL HY-5G/(2)HY-5G

Assembly/Disassembly Procedures

5B.4.7 Pilot Burner Replacement/

Current Check/Adjustment

Natural Gas: P/N 098641

Propane: P/N 098642

Please refer to Section 4.3, Paragraph 4.3.8 for Assembly/

Disassembly procedures.

5B.4.8 Steam Generator Manifold Assembly

Weldment Only: P/N 138523

Complete Assembly: See Page 5B-3/5B-4

and 5B-38

NOTE: The complete manif

weldment with the following parts installed. Burner jets for the

chosen gas type and altitude; flame holders, and pilot burner, for

the chosen gas type.

1. Turn off gas and electric power to the steamer.

2. Remove the right side panel.

3. Turn the manual gas shut-off valve to the OFF position.

4. Disconnect the igniter cable from the pilot burner. It is a fric-

tion fitting similar to a spark plug wire.

5. Using open-ended wrenches, remove the five sections of

aluminum tubing between the valve and piping assembly

and the gas gener

6. Remove the two screws securing the pilot burner’s mount-

acket to the manifold, and remove the pilot burner.

ing br

7. Use a nut driver or socket wrench to remove four bolts

which hold the manifold assembly to the steam generator.

old assembly consists of the manifold

ator manif

old assemb

ly.

5B-10

8. The manifold assembly may be removed for inspection,

component replacement or assembly replacement.

o Install:

T

9.

If a ne

the tw

to the manif

w manifold assembly is being installed, first remove

ner’s mounting bracket

ws secur

o scre

old, and remo

ing the pilot b

e the pilot b

v

ur

ur

ner

.

(2/02)

Page 12

HYPERSTEAM MODEL HY-5G/(2)HY-5G

Table of Contents

10. Carefully fit the manifold assembly in place on the steam

generator, so that the flame holders are not damaged by

striking the radiation shield. Install and tighten four bolts to

secure the manifold in place.

11. Fit the pilot burner in position under the bottom of the man-

ifold and install two screws to hold its mounting bracket in

place.

12. Reconnect five sections of aluminum tubing between the

valve and piping assembly and the manifold assembly. Use

open-ended wrenches to tighten the compression nuts.

13. Connect the igniter cable to the pilot burner.

5B.4.9 Gas Solenoid Valve

P/N 099906

Main Gas Valve

DSC00006

1. Turn off gas and electric power to the steamer.

2. Remove the right side panel.

3. Turn the manual gas shut-off valve to the OFF position.

4. Note the positions of wires connected to ter

minals of the

two gas solenoid valves, then disconnect the wires.

e.

5. Disconnect the f

our wires from the main gas v

alv

They are:

blue: Terminal (PV) TR

white:

Terminal (PV) TH

black: Terminal (MV) TR

red: Terminal (MV) TH

6. Using open-ended wrenches to loosen the compression

nuts, remove the five sections of aluminum tubing between

the valve and piping assembly and the steam generator

manifold assembly. Be careful not to excessively move or

bend the aluminum tubing.

7. With a pipe wrench or ChannelLoc

k, open the pipe union

between the main gas valve and the manual gas shut-off

. Remove the assembly.

e

alv

v

(2/02)

8. With the tee or elbow near the solenoid valve being

replaced held in a vise

ChannelLoc

k to disconnect the v

, ChannelLoc

k or pipe wrench, use a

e from the nipple

alv

.

5B-11

Page 13

HYPERSTEAM MODEL HY-5G/(2)HY-5G

Assembly/Disassembly Procedures

To Install:

Gas Solenoid Valves

HY-5G

9.

Remove the elbow compression fitting from the side of the

old valve and install on the side of the new valve, using pipe

thread compound. Remove the compression fitting from the

end of the old valve and install on the end of the new valve,

using pipe thread compound.

10. Mount the valve back onto the nipple, using pipe thread

compound.

G70

11. Using a pipe wrench or ChannelLock, reconnect to the

union near the man

ual gas shut-off valve and tighten.

12. Attach all aluminum tubing and tighten compression nuts

with an open-ended wrench.

13. Plug in the four terminal wires to the main gas valve, per

step 5 on page 5A.1-13.

14. Plug in wires at the terminals of the gas solenoid valves.

5B.4.10 Steam Generator Drain Valve

P/N 074594

Removal:

1. Turn off steamer power.

2. Disconnect hoses from the dr

ain valve and remove from

the mounting bracket.

3. Replace hose adapters if damaged.

Installation:

1. Wr

ap pipe threads

, of the hose adapters

, with pipe thread

tape (Teflon tape).

2. Install the hose adapters and drain valve in the reverse

order of removal.

5B.4.11

Water Flow Reducer

P/N 112720

Please ref

er to Section 4.3, P

aragraph 4.3.10 for Assembly/

Disassembly procedures.

5B-12

(2/02)

Page 14

HYPERSTEAM MODEL HY-5G/(2)HY-5G

Assembly/Disassembly Procedures

5B.4.12 Dual Water Inlet Valves

2 way: P/N 071235 (qty 1)

1 way: P/N 100934 (qty 1)

Please refer to Section 4.3, Paragraph 4.3.11 for Assembly/

Disassembly procedures.

5B.4.13 Water Inlet Valve Coil

If a solenoid coil in the water inlet valve is defective, replace the

valve. Refer to Section 4-3, Paragraph 4.3.11.

5B.4.14 Steam Generator

With Insulation Blanket, Water Level Probes and

High Limit Thermostat: P/N 138577

Weldment Only: P/N 138521

1. Shut off power, water and gas supply to steamer.

2. Remove both side panels.

3. Turn manual gas shut-off valve to the OFF position.

4. Disconnect the long steam hose from the steam generator.

Use hose clamp pliers to loosen the clamp on the hose and

slide it down the hose for later use. Remove the hose from

the steam generator fitting. Repeat this step for the short

steam hose.

5. Unplug the igniter cable from the igniter porcelain heat sen-

sor with a do

a spark plug wire.

6. Remo

7. Remo

8. Remove drain valve and steam generator drain hose.

v

graph 5B4.8.

v

Please ref

Disassembly procedure.

wnward motion. It is a friction fitting similar to

e steam gener

o scre

e tw

er to Section 4.3, P

ator manif

ws and remove radiation shield.

old assembly. See para-

raph 4.3.9 for

ag

ar

(2/02)

ertical gas flue (if (2)HY-5G) from steam genera-

e v

9. Remo

10. To remove each flue, lift the vertical flue enough to clear lip

v

tor by removing two screws which hold the vertical flue

mounting bracket to the rear panel. Remove two screws

tical flue to the horizontal flue.

secur

on hor

ing the v

ontal flue

iz

er

.

5B-13

Page 15

HYPERSTEAM MODEL HY-5G/(2)HY-5G

Assembly/Disassembly Procedures

11. Remove drain vent pipe. Remove one screw at the top of

the vent pipe and lift pipe out.

12. Remove drain box. Remove drain box mounting screw on

back panel. Loosen and move hose clamp inside the frame

on the left side. Pull drain box out of steamer.

13. Remove two 8-32 screws securing the live connection

assembly to the inside of the back panel. Disconnect wires

from the assembly.

14. Remove two 8-32 screws securing water inlet valve assembly to the back panel of the steamer.

15. Remove four 10-32 truss head machine screws and

remove back panel.

16. Disconnect the wires from the side of the steam generator

which are attached to the high heat thermostat.

17. Slide back the rubber boots covering the water level probe

terminals to expose the terminal wires. Use a 5/16 nut driver to loosen, but not remove, the nuts holding the wires on

the probe terminals. Un-snap the wires by gently pulling on

the terminals. With an open-ended wrench, disconnect high

and low water level probes from the steam generator. Clean

or replace probes.

18. At the left side of the steamer

loosen the clamp on the w

wn the hose for later use. Pull the hose off the end of the

do

trap tube. Then use an open-ended wrench to disconnect

the trap tube from the fitting on the steam generator.

19. Remove two bolts holding steam generator braces to the

steamer base.

CAUTION: Because of the weight of the steam generator,

two people are required to lift and move it.

20. The steam generator(s) may now be removed. It is suggested that the

This is easier and avoids damage to adjacent components.

21. The steam generator is covered with an insulation blanket.

Carefully remove this blanket without tearing so that it can

be used on its replacement.

y be removed from the rear of the steamer.

, use hose clamp pliers to

ater fill/clean hose and mo

ve it

5B-14

22. Remove the water fill brass fitting, elbow and hose fitting,

high heat thermostat and safety valve from old steam generator weldment and install them on the new steam generator weldment.

(2/02)

Page 16

HYPERSTEAM MODEL HY-5G/(2)HY-5G

Assembly/Disassembly Procedures

To Install:

23.

24. Slide the steam generator into position from the back of the

25. From the back of the steamer, fasten the steam generator

26. To install all parts and components reverse the removal

27. Connect the steam hose by easing the end of the hose onto

Carefully wrap the insulation blanket onto the new steam

generator weldment. Make sure it fits snugly with no air

spaces between the blanket and the steam generator.

Fasten seams with aluminum duct tape.

CAUTION: Because of the weight of the steam generator,

two people are required to lift and move it.

steamer

into place on the steamer base using the two bolts and a

socket wrench (with an extension). An open-ended wrench

ma

procedures of steps 6 through 18 abo

the steam generator fitting. Make sure the hose engages

the fitting all the way. Using hose clamp pliers, slide the

hose clamp down the hose and position it so that the clamp

is no more than 1/4 inch from the end of the hose. Repeat

this step for the long steam hose.

.

y also be used.

ve.

28. Fasten the igniter spark cable to the pilot light porcelain

heat sensor.

5B.4.15 High Limit Thermostat

P/N 096892

Please ref

Disassemb

5B.4.16 Steam Generator Probes (High and Low Water)

Please refer to Section 4.3, Paragraph 4.3.16 for Assembly/

Disassembly procedures.

er to Section 4.3, Paragraph 4.3.14 for Assembly/

ly procedures

P/N 070178

.

(2/02)

5B-15

Page 17

HYPERSTEAM MODEL HY-5G/(2)HY-5G

Assembly/Disassembly Procedures

5B.4.17 Supply Voltage Terminal Block

P/N 003887

1. Turn off the power to the steamer.

2. Remove the four wires going to the terminal block with a flat

blade screwdriver.

3. The terminal block is held to the bracket on the back panel

with one slotted screw. To remove, turn screw until device is

free.

o Install:

T

4.

5. Reattach wires.

5B.4.18 Control Voltage Transformer

Please refer to Section 5.1, Paragraph 5.1.4.20 for Assembly/

Disassembly procedures

5B.4.19 Timer Assembly

Please refer to Section 4.3, Paragraph 4.3.17 for Assembly/

Disassembly procedures.

5B.4.20 Light and Timer PC Board

Position terminal block and screw in.

P/N 106233

P/N 119815

.

P/N 096826

Timer Fastener Nut

P/N 101145

P/N 119817

5B-16

raph 4.3.12 for Assembly/

ag

Please ref

Disassembly procedures.

5B.4.21 Steamer Control PC Board

Please refer to Section 4.3, Paragraph 4.3.13 for Assembly/

Disassembly procedures.

er to Section 4.3, P

P/N 119801

ar

(2/02)

Page 18

HYPERSTEAM MODEL HY-5G/(2)HY-5G

Assembly/Disassembly Procedures

5B.4.22 Fan

P/N 096790

Please refer to Section 4.3, Paragraph 4.3.18 for Assembly/

Disassembly procedures.

NOTE: There are two fans on the HY-5G/(2) HY5-G steamers.

5B.4.23 Fan Motor Assembly

P/N 096740

Motor Insulator

P/N 094135

Motor Shaft Seal

P/N 096868

Oil Slinger Washer (Part of Fan Motor Assembly)

Please refer to Section 4.3, Paragraph 4.3.19 for Assembly/

Disassemb

ly procedures.

Steam Gener

Mounted On Steam P

ator Ready

(HY-5G Shown)

Thermostat

t

or

5B.4.24 Motor Starting Capacitor

3 mfd: P/N 096813

Please refer to Section 4.3, Paragraph 4.3.20 for Assembly/

Disassembly procedures.

IMPORTANT: Be sure to use the correct value capacitor: 3 mfd

at 250 volts.

5B.4.25

Steam Generator Ready Ther

mostat

P/N 099947

This thermostat is attached to the cavity steam port by two 6-32

screws.

1. Turn off power to the steamer.

2. Unplug the tw

o wires from the ther

mostat from the wiring har-

ness.

3. Using a flat b

lade screwdriver, remove the two 6-32 screws

holding the thermostat to the steam port.

4. T

o install a new thermostat, use a small amount of heat sink

compound (1 drop), applied to bottom of thermostat. Seat the

thermostat on the steam port and fasten with the two screws

G41

(as abo

ve).

5. Plug the thermostat into the wiring harness.

(2/02)

5B-17

Page 19

HYPERSTEAM MODEL HY-5G/(2)HY-5G

Assembly/Disassembly Procedures

5B.4.26 Steam Port

P/N 106511

Steam Port Gasket

P/N 099250

Please refer to Section 4.3, Paragraph 4.3.22 for Assembly/

Disassembly procedures.

NOTE: There is one (1) steam port (per cavity) on the

HY-5G/(2)HY-5G Steamers.

5B.4.27 Cavity Hose Assemblies

Steam Hose, Long: P/N 138445

Steam Hose, Short: P/N 138446

Please refer to Section 4.3, Paragraph 4.3.23 for Assembly/

Disassembly procedures.

NOTE: There are two (2) steam hose assemblies (per cavity) on

the HY-5G/(2)HY-5G Steamers, one to each steam port.

5B.4.28 Door Removal/Installation/Alignment

Door Assy, Complete: P/N 125922

Please refer to Section 4.3, Paragraph 4.3.24 for Assembly/

Disassembly procedures.

5B.4.29

Please refer to Section 4.3, Paragraph 4.3.26 for Assembly/

Disassembly procedures.

5B.4.30

Please refer to Section 4.3, Paragraph 4.3.25 for Assembly/

Disassemb

5B.4.31 Door Gasket

Please refer to Section 4.3, Paragraph 4.3.27 for Assembly/

Disassembly procedures.

Door Switch

P/N 096857

Door Reversing Procedures

ly procedures

P/N 125907

.

5B-18

(2/02)

Page 20

HYPERSTEAM MODEL HY-5G/(2)HY-5G

Assembly/Disassembly Procedures

5B.4.32 Door Components (common to all Steamers)

Door Handle

P/N 129723

Door Cam

P/N 074252

Door Spacer

P/N 071206

Magnet and Block Assembly

P/N 069762

Screws

P/N 005764

Please refer to Section 4.3, Paragraph 4.3.28 for common Door

Component part numbers.

Door Components (unique to HY-5G/(2)HY-5G)

U-Channel Assembly

P/N 125924

Outer Door Panel

P/N 125923

Inner Door Panel

P/N 125927

Door Insulation Board

P/N 125926

Please refer to Section 4.3, Paragraph 4.3.28 for Assembly/

Disassembly, Alignment procedures and common Door

Component par

5B.4.33 Door Spring

Please refer to Section 4.3, Paragraph 4.3.29 for Assembly/

Disassemb

5B.4.34 Door Latch Pin

Please refer to Section 4.3, Paragraph 4.3.30 for Assembly/

Disassembly procedures.

5B.4.35 Wiring Harnesses

t n

or par

F

page 5B-7/5B-8.

Please ref

Disassembly procedures.

t numbers.

P/N 078911

ly procedures

P/N 078914

Jam Nut

P/N 003823

umbers

er to Section 4.3, P

, ref

.

er to Interconnect Bloc

am,

k Diag

aph 4.3.31 for Assembly/

r

ag

ar

r

(2/02)

5B-19

Page 21

HYPERSTEAM MODEL HY-5G/(2)HY-5G

Assembly/Disassembly Procedures

5B.4.36 Cleaning System Eductor

P/N 086460

Removal:

1. Turn off steamer power.

2. Disconnect hoses from the eductor and remove from the

mounting bracket.

3. Replace hose adapters if damaged.

Installation:

1. Wrap pipe threads, of the hose adapters, with pipe thread

tape (T

2. Install the hose adapters and eductor in the reverse

order of removal.

eflon tape).

5B-20

(2/02)

Page 22

HYPERSTEAM MODEL HY-5G

1

4

6 78

5

10

11

12

1

3

14

15

1

6

17

18

20 19

23

9

Parts Identification

External Cabinet

PARTS IDENTIFICATION

Key Description Part No.

1 Right Side Panel 138532

2 Door Assy, Complete 125922

3 Door Handle 129723

4

Door Gasket 125907

5 Left Pan Rack 125901

6 Blower Cover/Rack (fan baffle) 125902

7

8 Door Pin Lock Nut 003823

Door Latch Pin

078914

9 Left Side Panel 138534

10 Timer Knob 123100

ront Panel Overlay 138424

11

F

12 Top Panel 138536

x - Item not depicted/called out in drawings

(2/02)

PARTS IDENTIFICATION

Key Description Part No.

13 Funnel, Delime 106624

14 Back Panel 138530

15 Optional Table 100913

16

17 Timer Fastener Nut 101145

18 Drain Tube 138546

19 W

20 Water Valve Double 071235

x Motor Shaft Seal 096868

x Optional Legs 041121

x

x Cavity Fan 096790

Drip Tray 094151

e Single 100934

alv

V

ater

Groen De-limer/De-scaler

114800

5B-21

Page 23

HYPERSTEAM MODEL (2)HY-5G

2

2

8

5

1

3

13

3 PLCS

2 PLCS

2 PLCS

4

13

14

10

7

6

8

5

7

22

4

13

13

1

3

12

11

3

1

7

19

18

17

16

20

20

15

16

Parts Identification

Parts listed below only apply to model (2) HY-5G. Common parts are listed on page .

External Cabinet

PARTS IDENTIFICATION

Key Description Part No.

1 Table 138759

2

3 Flue, Inside 138406

4 Flue, Vertical 138401

5

6 Hose 2" 090742

7 Clamp 2" 015663

8 Hose Vent 138463

Spacer 138594

ent Pipe

ain and

Dr

V

138458

5B-22

Key Description Part No.

9 Drain T-Connector 126003

10

11 Clamp 099284

12 Bullet Foot 042505

13 W

14 Hose Connector 101189

15 Overlay Top

16 Overlay Bottom

PARTS IDENTIFICATION

Hose Drain 138471

ater Hose

138470

(2/02)

Page 24

HYPERSTEAM MODEL HY-5G

6

25

6

6

9

1

8

19

2

1

16

1

7

1

2

3

11

12

4

31

SECTION A-A

SECTION B-B

15

14

13

20 7

5

Parts Identification

Electrical Parts; Steam Hoses

Except items 10-12, all parts occur in upper and

lower units of (2)HY-5G.

10-12 are in lower units only.

PARTS IDENTIFICATION

No. Description Qty. Part No.

1 Cover, Control Panel 1 119806

2 Standoff, Hex Male/Female 1 119826

6-32 x 3/4"

3 Light and Timer PC Board Assy 1 119817

4 Knob, Timer 1 123100

5 Nut Rotary Shaft Seal 1 101145

096826

, 60 Hz

Timer

6

7 Steamer Control PC Board Assy 1 119801

8 Standoff, Hex Male/Female 2 119827

6-32 x 1-1/4"

9 Door Switch (Note 2) 2 096857

10 Funnel Assemb

Clamp, Constant

11

12 Hose, Boiler Cleanout 1 106580

1-1/2" I.D. x 8-1/2" Long

13 Switch Rock

14 Fitting, Steam (Steam Port, Front) 1 138418

15 Gasket, Steam Port 1 099250

16

17 Top Electrical Assembly 1 138551

(Pilot Ignition)

(Note 3)

Universal Thermostat 1 099947

(Ready

Ther

ly 1 106624

ension CTB-19

T

er w/LED

mostat)

1

126011

2

1 087951

PARTS IDENTIFICATION

No. Description Qty. Part No.

19 Motor Assembly (Fan Motor) 1 096740

20 Bottom Electr

, Steam Inlet

Hose

21

1-1/2" I.D. x 7-7/8" Long

Clamp

22

23 Hose Steam 1 138445

1-1/2" I.D

24 Main Power Assembly 1 138429

25 Motor Insulator 1 094135

26 Seal, Steamer Motor (Note 4) 1 096868

ube 1-1/2" O

T

27

28 Valve-Drain, 1/2" I.D. 1 074594

31 Igniter Cable 1 106495

TES:

NO

or Part Numbers of har

F

1.

see page 5B-5.

2. One door switch is mounted on each side of the steam-

3. Mounting flange (shown by dotted lines) is covered by

4.

.

vity

er ca

cavity insulation blanket.

Before installing seal, saturate it with about 0.1 ounce of

Lubricant, Motor Shaft, Groen P/N 099948.

ical Assemb

, Constant Tension, CTB-47 4 127526

x 10-1/2" Long

.

x 45

.

.D

ly

1 138561

138446

1

° 1 138412

, jumpers and cab

nesses

les,

(2/02)

5B-23

Page 25

HYPERSTEAM MODEL HY-5G

T

ORQUE:

30-32 IN-LBS

6 PLCS

4

6

5

6

3

1

2

Parts Identification

Rear Cover And Vent Assembly

5B-24

Description

No.

1 Weldment, Rear Cover 1 138530

2 Bracket, Steam Vent 1 138413

Scre

3

4 Tube, Steam Vent 1 138544

Hose, 3/4" I.D

5

Clamp

6

CTB-24

7 Loctite #242 A/R 073242

NOTES:

Apply one drop of item #7 (Loctite) to item #3 (Screw) prior to assembly.

1.

PARTS IDENTIFICATION

w 10-32" x 3/8" LG Truss HD 6 004173

, Hose Constant

x 4-1/2" LG

.

Tension 2 127524

Qty.

1

Part No.

138463

(2/02)

Page 26

HYPERSTEAM MODEL HY-5G

5

3

4

2

1

6

7

TORQUE: 8-10 IN-LBS

12 PLCS

TORQUE: 8-10 IN-LBS

9

10

Parts Identification

Top Electrical Assembly

PARTS IDENTIFICATION

No. Description Qty. Part No.

1 Weldment, Electrical Components 1 138453

Bracket

2 Transformer, 75VA, 120V Primary 1 106233

24V Secondary

3 Relay, Cutout 24V 1 119814

119813

, 12VDC

y

Rela

4

ransformer, 20 VAC 1 119815

T

5

6 Screw, 6-32 x .375 LG Hex 12 069788

Slotted Washer Head

7 Screw, 6-32 x .250 LG Hex 2 069777

Slotted Washer Head

Ignition Module 1 085153

8

9 Clamp, Loop 1/2" Dia. Nylon 2 089343

10 Weldment, Mounting Support 1 138454

Electr

11 Loctite #242 A/R 073282

NOTES:

1. Apply one drop it item #11 (Loctite) to items #6 & 7 (screws) prior to assembly.

ical Panel Bracket

1

(2/02)

5B-25

Page 27

HYPERSTEAM MODEL HY-5G

1

1

3

2

2

TORQUE: 8-10 IN-LBS

3 PLCS

4

4

3

Parts Identification

Bottom Electrical Assembly

5B-26

PARTS IDENTIFICATION

No. Description Qty. Part No.

1 Weldment, Electrical Components 1 138455

Bottom Bracket

2 Screw 6-32 x .375 Hex Slotted 3 069788

asher Head

W

, DPST No. 24VDC Panel 1 138420

Relay

3

4 Capacitor Foil 3 MFD 1 096813

Loctite #242

5

NOTES:

Apply one drop it item #5 (Loctite) to item #2 (screw) prior to assembly.

1.

A/R

073282

(2/02)

Page 28

HYPERSTEAM MODEL HY-5G

10

4

8

5

12

7

3

3 7

1

2

5

TORQUE:

8-10 IN-LBS

TORQUE:

8-10 IN-LBS

Parts Identification

Main Power Box

PARTS IDENTIFICATION

No. Description Qty. Part No.

1 Weldment, Main Power 1 138456

Box Bracket

2 Terminal Block, 2-Pole 1 003887

3 Lug, Ground 1 129714

4 Fuse Holder 1 077854

5 Bushing, Snap 1/2" I.D. x 5/8" 1 009884

MTG Hole #SB-625-8

6 Bushing Snap 11/16" I.D. x 7/8" 1 012864

MTG Hole #SB-875-11

7 Screw 6-32 x 1-1/4" LG Round 1 011236

Head Machine

8 Screw 6-32 x .375 LG Round 1 009697

9

10 Fuse, 3 AMP 1 077853

11 Loctite #242 A/R 073282

NOTES:

1.

Head Machine

w 6-32 x .375 LG Hex Slotted 2 069788

Scre

Washer Head

Apply one drop it item #11 (Loctite) to items #7, 8 and 9 (screws) prior to assembly.

(2/02)

5B-27

Page 29

HYPERSTEAM MODEL HY-5G

TORQUE:

30-32 IN-LBS

TORQUE:

30-32 IN-LBS

SEE NOTE #1

TOUQUE:

25-30 IN-LBS

SEE NOTE #4

2

11

2 16

16

18

1

7

12

13

10

8

4

2

7

6

7

5

B

B

9

1

Parts Identification

Base Plumbing

ARTS IDENTIFICA

P

No. Description Qty. Part No.

eldment, Base Pan - HY-5G 1 138500

W

1

2 Assembly Delime Eductor - HY-5G 1 138421

, Clamp Eductor 1 106561

Plate

3

4 Screw, 10-32 x .375 LG Truss HD 1 004173

5 Valve, Check .375 Hose Barb 1 138428

6 Hose .375 I.D. x 1.75 LG 1 138448

Clamp, Hose

7

8 Bracket, Drain Valve 1 138592

9 Nut, 10-32 KEPS 2 071256

Valve Solenoid 1/2" NPT 1 074594

10

11 Fitting, Straight 1/2" x 3/4" Hose 1 138441

Beaded Brass

Fitting, 90

12

Hose Beaded Brass

13 Fitting, Hose Barb To Male Pipe 1 069732

3/8" I.D

14 Pipe Dope A/R 078938

15 Loctite #242 A/R 073282

le

, Doub

1/2" NPT x 3/4"

°

Hose x 1/4" NPT

.

Wire

TION

, DW.9.5 2 127527

138442

1

5B-28

PARTS IDENTIFICATION

No. Description Qty. Part No.

16 Eductor, 1/2-14 NPT 1 086460

17 Elbow 90° 1/2-14 x 1/2 Hose Blk 1 106613

HDLP

Male Adapter, 3/8-18 x 3/8 Hose 1 106614

18

Blk HDLP

19 Elbow 90° 1/2-14 x 3/8 Hose 1 139126

BLK HDLP

NOTES:

1. Use ground screw that comes with item 10 (valve

solenoid) to secure item 10 (valve solenoid) to

item 9 (bracket, drain valve).

2. Apply a small amount of item 14 (pipe dope) on threads

of items 11, 12 & 13 pr

3. Apply one drop of item 15 (Loctite) prior to assembly of

items 4 & 9.

Assemb

4.

pointed toward item 2 (delime eductor).

le item 5 (chec

ior to assemb

e) so flo

alv

k v

ly.

w direction arrow is

(2/02)

Page 30

HYPERSTEAM MODEL HY-5G

A

A

B

B

D

D

C

SECTION A-A

SECTION B-B

DETAIL C

1211

2

3

7

14

16

15

1

7

8

9

6

10

1

5 4

5

2 PLCS

TORQUE:

1

8-20 IN LBS

2 PLCS

TORQUE:

18-20 IN LBS

20

18

19

20

Parts Identification

Base Plumbing

PARTS IDENTIFICATION

t No.

ar

P

Qty.

106591

1

1 138449

No. Description Qty. Part No.

11 Retainer, Top 2 123156

12 Screw, 8-32 x 3/8" LG Truss HD 2 005764

13 Screw, 10-32 x 3/8" LG Truss HD 3 004173

14 Plug, 1" Snap-In Unvented 1 139000

oly

P

15 Drain Extension 1 138546

16 Hose 1 125955

Clamp HC-38

17

Hose 3/4" x 7-3/8" LG

18

19 Hose 3/4" x 4" LG 1 138465

20 Clamps CTB-27 4 138457

Description

No.

Funnel Assembly 1 106624

1

2 Door Keeper 1 106531

, 8" x 3/8" LG Pan HD Type “F”

Scre

w

3

4 Hose, Boiler Cleanout 1 106580

Clamp, Hose

5

, Constant Tension 2 127526

CTB-47

6 Weldment, Delime Tube Assembly 1 138415

7 Nut, 10-32 KEPS 1 071256

x 4.0 Long

.

.D

, 3/8 O

Hose

8

9 Clamp, Hose, Double Wire DW-9.5 2 127527

10 Weldment, Top Cover 1 138536

(2/02)

P

ethlene

TS IDENTIFICA

AR

TION

2 126010

1

138464

5B-29

Page 31

HYPERSTEAM MODEL HY-5G

6

25

6

6

9

18

192116

17

1

2

3

11

12

4

31

SECTION A-A

SECTION B-B

6

B

B

AA

23

15

14

13

20 7

5

24

22

8 10

TORQUE:

18-20 IN-LBS

Parts Identification

Electric, Gas and Hose Assembly

PARTS IDENTIFICATION

No. Description Qty. Part No.

1 Valve, Single Water 1 100934

alve, Double Water 1 071235

V

2

3 Screw, 8-32 x 3/8" Truss HD 4 005764

4 Hose, 3/8 I.D. x 64" LG 1 138467

Clamp, Hose Double Wire DW-9.5 2 127527

5

6 Clamp, Hose Constant Tension 4 126095

CTB-19

Hose, 3/8 I.D. x 46" Long 1 138452

7

8 Hose, 3/8 I.D. x 42" Long 1 138468

9 Hose, 1/2 I.D. x 29.0 LG 1 138451

“Delime

To Trap”

10 Clamp, Double Wire DW-11.5 1 127662

11 Reducer, Water Flow (.078 I.D.) 1 088877

Clamp Hose Low Pressure 1 093482

12

1/4 Min 25/32 Max

13 Assembly, Bottom Electrical 1 138561

Assembly, Top Electrical 1 138551

14

15 Assembly, Main Power Box 1 138429

16 Nut, 10-32 Hexagon KEPS 2 071256

17 Washer Flat 10-32 2 010414

18 U-Bolt 1 n87786

5B-30

PARTS IDENTIFICATION

No. Description

19 Nut, 1/4-20 He

xagon KEPS 2 012940

20 Assembly, Gas Train - HY-5G 1 138564

21 Washer, Flat 1/4-20 2 005472

22 Bracket, Switch 1 106451

23 Switch 1 087951

Screw, 8-32 x 3/8" Flat HD 2 127178

24

Undercut Phil

25 Clamp, Hose Constant Tension 1 127522

26

CTB-16

ness, Power (Not Shown) 1 130397

Har

27 Harness Drain (Not Shown) 1 130398

28

Har

, Control (Not Sho

ness

wn) 1

29 Cable Hi Volt Spark Ignition 1 085154

(Not Shown)

30 Loctite #242 A/R 073242

31 Boiler Trap 1 106229

TES:

NO

1. Apply one drop of item 30 (Loctite) prior to assembly of

items 16, 19 & 24.

t item 11 (Reducer) into item 8 (Hose) and secure with

Inser

2.

item 12 prior to assembly of item 8 (Hose) on to unit.

Qty. Part No.

130399

(2/02)

Page 32

HYPERSTEAM MODEL HY-5G

12

10

15

16

17

11

9

13

8

14

7

6

5

1

2

3

4

Parts Identification

Gas Train Assembly

PARTS IDENTIFICATION

No. Description Qty. Part No.

1 Valve, Gas 1 098443

Nipple, 1/2" NPT x 3" Long

2

3 Valve, Gas Manual Shutoff 1 098458

1/2" NPT

4 Nipple, 1/2" NPT x 10" Long 1 005558

5 Elbow, 90° Street 1/2" NPT 1 004185

6 Nipple, 1/2" NPT x 3-1/2" Long 1 008227

Elbo

7

1/2" x 3/8" NPT

ee, 3/8" NPT 1 012794

T

8

9 Elbow, 90° Street 3/8" NPT 1 009853

Automatic Gas Valve, 25V 1 099906

10

, 90° Street 1 005680

w

005553

1

(2/02)

PARTS IDENTIFICATION

No. Description Qty. Part No.

11 Elbow, 90° 3/8" x 1/2" Tube 1 090737

Connection 1/8" MPT x 1/4" 1

12

ube Straight

T

Nipple, 3/8" NPT x 3-1/2" Long

13

14 Nipple, 3/8" NPT x 2" Long 1 005679

15 Connection 3/8" MPT x 3/8" Tube 1 050879

Compression

16 Tube, Gas Lo-Fire - HY-5G 1 138426

17 Tube, Gas Hi-Fire - HY-5G 1 138425

Pipe Dope

18

NOTES:

1. Apply a small amount of item #18 (Pipe Dope) on to pipe

threads prior to assembly.

075055

008128

1

A/R 078938

5B-31

Page 33

HYPERSTEAM MODEL HY-5G

3

2

7

5

6

4

1

Parts Identification

Burner Manifold Assembly

5B-32

PARTS IDENTIFICATION

No. Description Qty. Part No.

ner Manifold 1 138523

1 Bur

2 Burner Jets .0595 orifice 6 099927

Natural Gas

2 Burner Jets .035 orifice 6 099934

Propane Gas

3 Flame Holder 8 056965

ube

Connector 3/8" MPT x 1/2"

4

Compression

Connector 3/8" MPT x 3/8"

5

Compression

Pipe Plug 1/8" NPT He

6

Sunk Head

ner Jets .043 orifice Natural

Bur

7

Gas

ner Jets .025 or

Bur

7

Gas

TES:

NO

1. Flame Holders must point down.

2. Apply Loctite to all threaded connections.

ifice Propane

T

ube

T

x Counter

054493

1

050879

1

010286

1

106523

2

138474

2

(2/02)

Page 34

HYPERSTEAM MODEL HY-5G

B

AA

D

D

B

C

DETAIL C

VIEW D-D

SEE NOTE #1

SECTION A-A SECTION B-B

7

1

2

4

TORQUE:

72-75 IN-LBS

4 PLCS

TORQUE:

30-32 IN-LBS

TORQUE:

30-32 IN-LBS

3

6

8

5

9

Parts Identification

Pilot Burner Assembly

PARTS IDENTIFICATION

No. Description Qty. Part No.

1 Weldmont, Pilot Bracket 1 138571

2 Pilot, Burner Natural Gas 1 098649

2 Pilot, Burner Propane Gas 1 098644

3 Screw, Fillister HD Slot 2 090797

10-32 x 1/4 LG

4 Screw, 8-32 x 3/8 Hex MS 2 069789

Slot Washer HD Cap

Shield, Flame

5

6 Assembly, Burner Manifold 1 138586

Propane

, 1/4-20 x 1/2 Lg

w

Scre

7

Hex HD Cap

(2/02)

1 138466

005608

4

No. Description Qty. Part No.

10 Kit, Conversion To LP Gas 1 079802

NO

1. Apply Item #9 (Label) in approximate location as shown.

2. Assemble Item #10 (Kit Conversion) into primary gas

3. For double stack units double all quantities.

PARTS IDENTIFICATION

8 Tube, Pilot Control 1/4 Dia. 1 138427

Label, Natur

9

Label, Propane Gas Only

9

TES:

e per instr

alv

v

(Item #10).

al Gas Only

uction sheet pro

vided in kit, con

087992

1

087993

1

ersion

v

5B-33

Page 35

HYPERSTEAM MODEL HY-5G

SEE NOTE #2

11

3

2

5

1

4

4

9

5

10

9

7

6

8

2

4

10

Parts Identification

Steam Generator

ARTS IDENTIFICATION

P

No. Description Qty. Part No.

W

1

Insulation, Boliler - HY-5G 1 138588

2

3 Oven Temp Sensor 1 096892

V

4

5 Prove-Water-Combo Oven 2 070178

6 Gasket, Drain 1 106232

Plate

7

NOTES:

Apply a small amount of pipe dope (Item #12) pr

1.

assembly of items 3, 5, 9 & 10.

2. Apply tape (Item #11) after the installation of the boiler

insulation (Item #2), as shown.

eldment, Steam Generator Final

alve Pressure Relief - 1/2 P

, Dr

.S.I. 1 132183

ain

5B-34

138521

1

1 106226

ior to

ARTS IDENTIFICATION

P

No. Description Qty. Part No.

Nut, 5/16-81 He

8

Elbow, 90° 1 090737

9

.375 NPT x .50

Elbo

10

.50 NPT x .75 Hose

11 Tape, Duct 2" Wide Aluminum 35" 042359

12 Pipe Dope A/R 078938

xagon KEPS 4

ube

T

, 90° 1 138442

w

012941

(2/02)

Page 36

F

20

16

17

20

18

21

19

20

15

16

16

1

11

3

10

20

21

SEE

NOTE 2

C

C

HYPERSTEAM MODEL HY-5G

Parts Identification

Double Stack Kit

No. Description Qty. Part No.

1 Stand W/Bullet Feet Assembly 1 138579

2 Weldment, Front Double Stack Leg 2 139002

3 Weldment, Skirt Spacer 1 138594

4 Horizontal Flue Assembly 1 138405

5 Weldment, Vertical Flue 1 138401

6 Clamp 1 106530

7 Screw, 8-32 x 3/8" Long Truss HD 6 005764

8 Bracket, Mounting Verical Flue 1 138409

9 Bushing, Snap 3/4 ID x 1" 1 000453

MTG Hole

eldment,

W

10

11 Auto Clean Assembly W/Door 1 106624

12 Connector Hose 2 Way 3/4" 2 101189

Screw

13

14 Bracket, Top Retainer 2 123156

ain

15 Dr

Hose Drain 2" ID x 2" Long 3 090742

16

17 Weldment, Drain & Steam 1 138458

Vent Tube

18 Hose, 3/4 ID x 4.50 Long 1 138463

19 Hose, Oven 2" ID x 25-1/2" Long 1 138471

20 Clamp Hose 1-3/4" - 2-1/2" Capacity 8 015663

21 Clamp Hose Worm Drive 2 099284

9/16" - 1-1/16" Range

22 Hose, Water 3/8" x 26.5" Long 2 138470

PARTS IDENTIFICATION

Top Cover 1 138536

, 10-32 x 3/8 Long Truss HD 8 004173

ee Assemb

T

ly 2" 1 126003

(2/02)

5B-35

Page 37

TORQUE:

30-32 IN-LBS

37

40

37

39

28

32

34

33

34

38

5 PLCS

SECTION C-C

9

40

39

DETAIL F

HYPERSTEAM MODEL HY-5G

Parts Identification

Double Stack Kit

PARTS IDENTIFICATION

No. Description Qty. Part No.

23 Nut, 1/4-20 KEPS 2 012940

24 Washer, Plain 1/4" 4 005472

25 Screw, 1/4-20 x 3/4 Long Hex HD 4 005609

Cap

26 Bracket, Top Retainer D/S 2 138410

27 Washer, 10-32 2 010414

28 Nut, 10-32 KEPS 3 071256

29 Washer, Plain 3/8" 6 006035

30 Washer, Lock 3/8" 6 005618

31 Screw, 3/8-16 x 5/8" Long 6 005449

Hex Head Cap

32 Weldment, Delime Tube 1 138415

33 Hose, 1-1/2 ID x 2-1/2 Long Boiler 1 106580

Cleanout

, Hose Constant Tension 2 127526

Clamp

34

(CTB-47)

35 Keeper 1 106531

36 Screw #8 x 3/8 Long Pan Phillips 1 106591

Selftapping

37 Hose, 3/8 ID x 1.75 Long 2 138448

38 Tee, Barbed Hose Poly 1 138432

39 Clamp, Hose Double Wire 6 127527

40 Hose, 3/8 ID x 54.0 Long 1 138450

Loctite #242

41

A/R 073242

5B-36

NOTES:

1. Use screws that are currently in back panel to secure item 8

(bracket mounting vertical flue) to back panel.

2. One hose (item 16) and two clamp hoses (item 20) will be

shipped inside of unit for assembly onto unit at customer site.

3. Apply one drop of Loctite (item 41) prior to assembly of items

7, 13, 23, 25, 28, 31 & 36.

(2/02)

Page 38

HYPERSTEAM MODEL (2)HY-5G

TORQUE:

18-20 IN-LBS

T

ORQUE:

2

30-240 IN-LBS

4 PLCS

TORQUE:

18-20 IN-LBS

3

13

29

30

12

13

13

4

22

5

8

7

31

7

7

14

DETAIL A

DETAIL G

SECTION B-B

A

B

B

E

E

D

D

3 PLCS

4 PLCS

4 PLCS

2 PLCS

2 PLCS

SEE

NOTE1

Parts Identification

Double Stack Kit

PARTS IDENTIFICATION

.

Description

No.

2 Weldment, Front Double Stack Leg 2 139002

4 Horizontal Flue Assembly 1 138405

eldment,

W

5

6 Clamp 2 106530

7 Screw, 8-32 x 3/8" Long Truss Hd 6 005764

ac

Br

8

12 Connector Hose 2 Way 3/4" 2 101189

13 Screw, 10-32 x 3/8 Long Truss Hd 8 004173

Vertical Flue 1 138401

ket, Mounting Vertical Flue 1 138409

Qty

Part No.

(2/02)

5B-37

Page 39

HYPERSTEAM MODEL HY-5G/(2)HY-5G

24

25

2827

26

35

36

2

SECTION D-D

4 PLCS

4 PLCS

TORQUE:

230-240 IN-LBS

TORQUE:

72-75 IN-LBS

312330 29

SECTION E-E

Table of Contents

Double Stack Kit

PARTS IDENTIFICATION

No. Description Qty. Part No.

14 Bracket, Top Retainer 2 123156

22 Hose, Water 3/8" x 26.5" Long 2 138470

23 Nut, 1/4-20 KEPS 2 012940

24 Washer, Plain 1/4" 4 005472

25 Screw, 1/4-20 x 3/4 Lg Hex Hd Cap 4 005609

26 Bracket, Top Retainer D/S 2 138410

27 Washer, 10-32 2 010414

28 Nut, 10-32 KEPS 3 071256

29 Washer, Plain 3/8" 6 006035

30 Washer, Lock 3/8" 6 005618

31 Screw, 3/8-16 x 5/8" Long Hex

Head Cap 6 005449

eeper 1 106531

K

35

36 Screw #8 x 3/8 Lg Pan Phillips

Selftapping 1 106591

NOTES:

Use scre

1.

(br

2. One hose (item 16) and two clamp hoses (item 20) will be

shipped inside of unit f

Apply one drop of Loctite (item 41) pr

3.

7, 13, 23, 25, 28, 31 & 36.

ws that are currently in back panel to secure item 8

acket mounting vertical flue) to back panel.

or assemb

ly onto unit at customer site

ior to assemb

ly of items

.

5B-38

(2/02)

Loading...

Loading...