Groen HY-3E General Manual

3-Pan Capacity

Stainless Steel

Pressureless Steamer

Table Top

Self-Contained

Electric-Heated

HyPerSteam Pressureless Steamer

Description

Steamer shall be a Groen Model HY-3E stainless steel

pressureless steamer with a self-contained atmospheric

8KW electric steam generator, per Bulletin 140802, as

follows:

Construction

Steamer cavity and cabinet shall be all stainless steel

construction, with removable right and left-side panels

providing access to internal components.

Steamer door is all stainless steel with a strong continuous

hinge and is field-reversible for left or right swing, door

shall be air insulated and provided with a one-piece,

replaceable seal. Easy-open handle and latch shall

provide positive lock and seal when door is pushed or

slammed shut.

Hidden magnetic door switch cuts power to blower

and cuts power to generator when the door is opened.

Pan support racks shall be polished stainless steel and

removable for easy cleaning. A stainless steel condensate

collection tray is positioned under cavity door.

Finish

Cabinet exterior, including door, shall be finished to a

#3 uniform finish. Cavity interiors are polished stainless

steel. Control panel face plates shall be smudge-resistant

polyester film, ensuring maximum ease in cleaning and

maintaining an attractive appearance.

UL & C.U.L. Listing

Steamer shall be UL and Canadian UL-listed.

Sanitation

Unit shall be designed and manufactured to meet NSF

requirements and be NSF-listed. Unit shall allow operator

to delime steam generator through access port on top,

without tools or service call. Push button auto-delime

feature is standard.

Controls

Steamer controls shall include an ON-OFF power button;

60-minute electro-mechanical timer, with continuous

steam setting; and READY light which indicates when

cavity is ready for steaming. Auto-Delime button initiates

deliming cycle.

Performance Features

Steamer cavity shall have a powerful side-mounted

blower, which increases steam velocity and provides

efficient steam distribution throughout cavity and between

loaded pans. Steam generator delivers 2.6 KW power

input per 2 1/2” deep steam pan.

Heat-up time to READY shall be 8-10 minutes or less

under normal conditions. Cavity is kept warm and ready

for instant steam between loads. No cavity warm up

required, after READY light comes on.

DELIME indicator light warns operator of need to delime

steam generator. Unit will shut off if water level is low.

When power switch is turned off, unit automatically blows

down the steam generator, to reduce sediment build-up.

Model HY-3E Shown

Atmospheric Steam Generator

Unit shall have an electric-heated, rear-mounted steam

generator, to provide atmospheric steam to the chamber

at a temperature of approximately 212°F. Steam generator

has an electric water sensor. 8KW electric heating element

is replaceable from the side.

Pan Capacity

Pan Size / Type Number

12 x 20 x 1” 6

12 x 20 x 2 1/2” 3

12 x 20 x 4” 2

Installation

Unit requires 208, 240 or 480 Volt, single or three-phase

electric service. Unit requires 2 3/4” NH cold water supply

lines and 1 1/2” free venting drain.

Water Supply Requirements

All steam systems are subject to contamination and failure

due to mineral content found in all water supplies. To

minimize service problems, a Groen PureSteem™ Water

Treatment System is recommended.

Options/Accessories

Groen PureSteem™ Water Treatment System

Stainless steel support stand

Pan racks for support stand

4” adjustable legs

Single Water Connection (cold water)

Origin of Manufacture

Steamer shall be designed and manufactured in the United

States.

models HY-3E/EF

Short Form

Unit shall be a Groen

HyPerSteam pressureless

steamer Model HY-3E with

self-contained, atmospheric

electric- heated steam

generator, per Bulletin 140802.

All stainless steel construction,

with powerful blower to

circulate steam within cavity.

Standard operating controls

including: 60-minute electromechanical timer, constant

steam setting, ready light and

delime cycle button to initiate

deliming. Simple generator

deliming through port on top.

Door is field-reversible, with

easy-open latch and hidden

magnetic door switch. The

atmospheric steam generator

requires no pressure gauge or

switches, has automatic drain

and 8KW power input. Unit

shall come up to steam in 810 minutes from a cold start,

and provide warm cavityinstant steam capability. See

other side for required electric,

water and drain connections.

Made in the U.S.A.

Applications

Pasta

Rice

Vegetables (Fresh & Frozen)

Seafood (Fresh & Frozen)

Poultry

Potatoes

Eggs

Meats

Reheat Cook-Chill &

Prepared Foods

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Groen HyPerSteam, Page 1

160185B

Revised 08/09

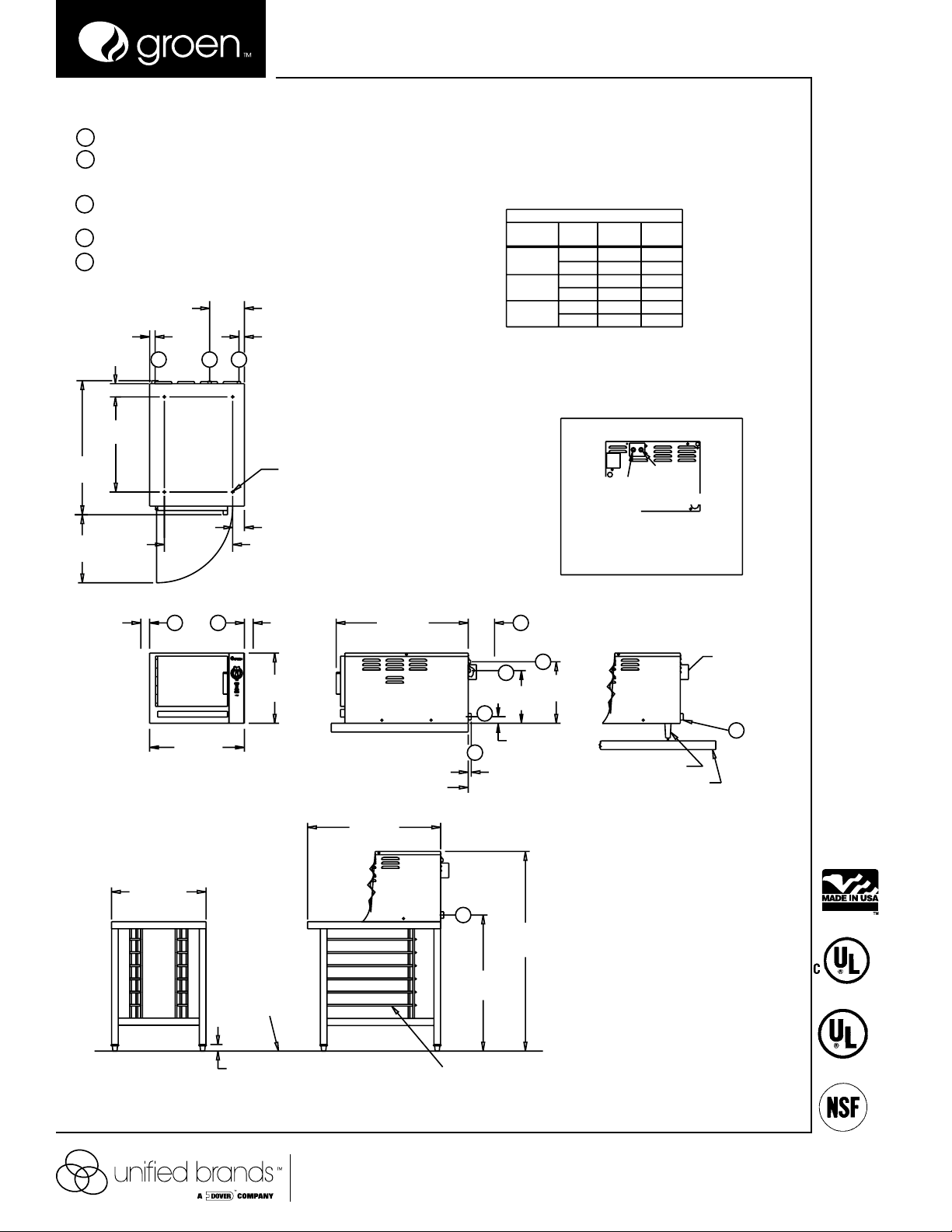

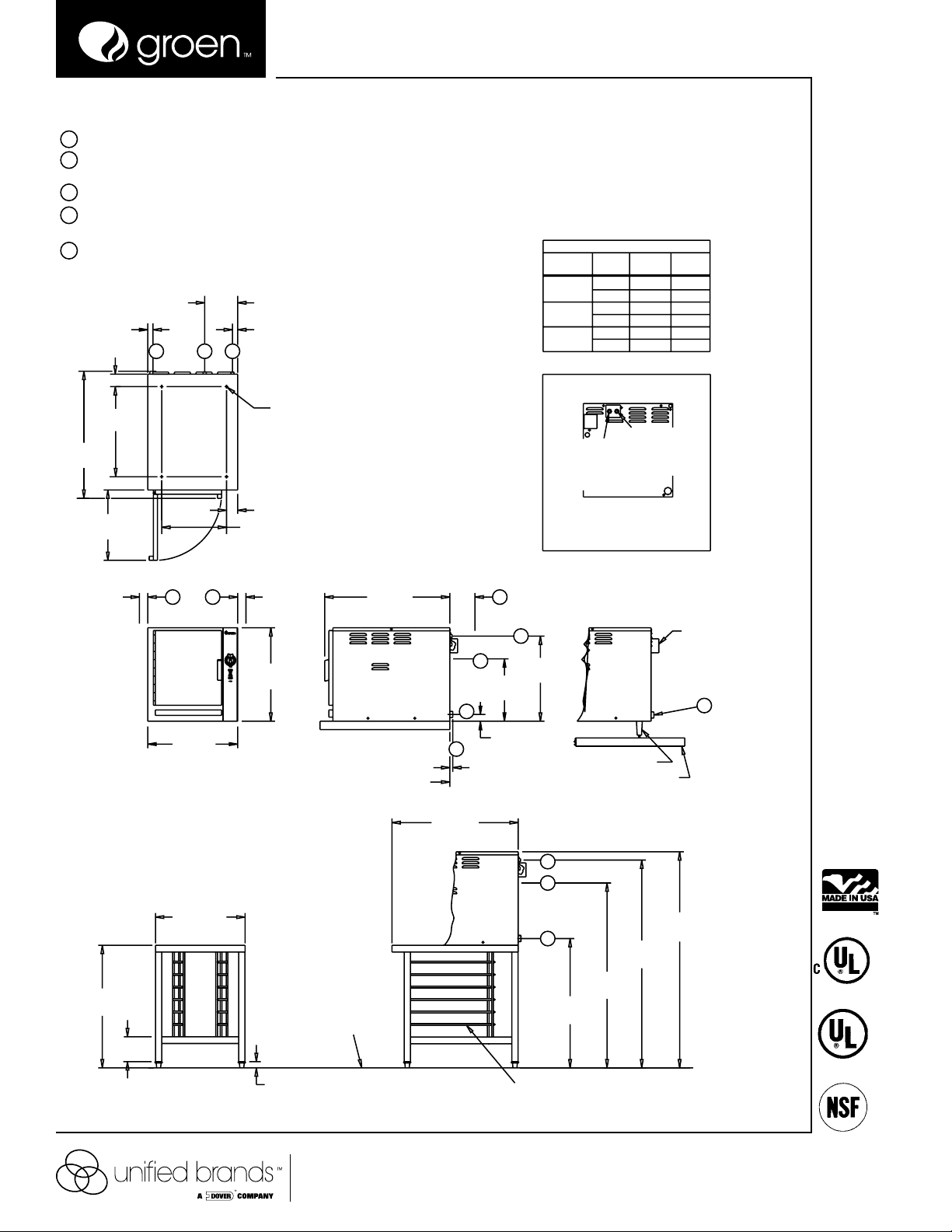

39

331

20

1

23

3

3

AMPS

240

KW

MAX.

PHASE

VOLTAGE

208

480

3 10

1 17

8

8

8

8

8

8

ELECTRICAL REQUIREMENTS

8"

1 1/4"

TABLE TOP OR COUNTER

(CUSTOMER PROVIDED)

[203]

[32]

3"

21 11/16"

3" [76]

15 19/32

[76]

[551]

[397]

REAR OF TABLE

OR COUNTER

TABLE TOP OR COUNTER

OPTIONAL 4" LEGS

MOUNTING HOLES IN BASE

USE 3/8" 16 BOLTS WHICH

MUST NOT EXTEND INTO STEAMER

BY MORE THAN 3/8" (10).

30 13/16"

[783]

SERVICE CONNECTIONS & NOTES:

1 DRAIN CONNECTION: 1 1/2" TUBE (DRAIN FREE VENTING).

2

3

21 5/8"

[549]

16"

[406]

30 1/8"

[765]

2 3

4

2"

[51]

4

1

11/16"

[17]

6"

[152]

12"

[305]

3

[356]

14"

2

FRONT VIEW SIDE VIEW

OPTIONAL SUPPORT STAND

21 9/16

[548]

1 1/2 [38] MINIMUM

2 5/8 [67] MAXIMUM

FINISHED FLOOR

33 3/8

[772]

OPTIONAL RACKS TO

HOLD (6) STEAMER PANS

31"

[787]

45 1/2

[1156]

1

UNTREATED

WATER

SUPPLY

CONNECTION

DETAIL VIEW

OF WATER CONNECTIONS

REAR OF STEAMER

1

1

1 1/4"

[32]

1

1 5/8"

[41]

FUSE

BOX

ONE ELECTRICAL CONNECTION: 3/4 "CONDUIT FITTING.

[SEE ELECTRICAL REQUIREMENT TABLE]

4 MINIMUM SIDE AND REAR CLEARANCE.

DIMENSIONS IN BRACKETS [ ] ARE MM.5

4

2"

[51]

15 1/2 [394]

SWING DOOR

COLD WATER SUPPLY AT 30 TO 60 PSIG

WITH A FLOW RATE OF 1.5 - 3.0 GPM

AND WITH A 3/4" NH CONNECTION.

TREATED

WATER

SUPPLY

CONNECTION

Models HY-3E/EF

P/N 125776 REV C

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of

Dover Corporation.

HyPerSteam Pressureless Steamer

Description

Steamer shall be Groen Model (2)HY-3E stainless steel

stacked pressureless steamers, each with a self-contained atmospheric 8KW electric steam generator, per

bulletin 140803 as follows:

Construction

Each steamer cavity and cabinet shall have all stainless

steel construction with removable right side and left side

panels providing access to internal components. Interunit water catch pan with rear drain shall separate units.

Steamer doors are all stainless steel with strong continuous hinge and are field reversible for left or right swing,

doors shall be insulated and provided with a one piece,

replaceable seal. Easy open handle and latch shall

provide positive lock and seal when door is pushed or

slammed shut.

Hidden magnetic door switch cuts power to blower and

shuts down power to that generator when that door is

opened. Pan support racks shall be polished stainless

steel and removable for easy cleaning. A stainless steel

condensate collection tray is positioned under each cavity door.

Finish

Cabinet exterior including doors shall be finished to a

#3 uniform finish. Cavity interiors are polished stainless

steel. Control panel face plates shall be smudge resistant

polyester film, ensuring maximum ease in cleaning and

maintaining an attractive appearance.

UL & CUL Listing

Steamers shall be UL and Canadian UL listed.

Sanitation

Unit shall be designed and manufactured to meet NSF

codes and be NSF listed. Unit shall allow operator to

delime each steam generator through deliming ports on

top, without tools or service call. Push button auto-clean

feature is standard.

Controls

Steamer controls for each unit shall include an ON/OFF

power button; 60 minute mechanical timer, with continuous steam setting; and READY light which indicates when

cavity is ready for steaming. Auto-CLEAN button initiates

deliming cycle.

Performance Features

Each steamer shall have a powerful side-mounted blower, which increases steam velocity and provides efficient

steam distribution throughout cavity and between loaded

pans. Steam generator delivers 2.6 KW power input per 2

1/2” deep steam pan.

Heat up time to READY shall be 10 minutes or less

under normal conditions. Cavity is kept warm and ready

for instant steam between loads. No cavity warm up

required, after READY light comes on.

delime indicator light warns operator of need to delime

steam generator. Unit will shut off if water level is low.

When power is turned “off”, unit automatically drains that

steam generator, to reduce sediment build-up.

Model (2)HY-3E shown

Atmospheric Steam Generators

Each unit shall have an electric heated rear mounted steam

generator, to provide atmospheric steam to the chamber at

a temperature of approximately 212°F. Each steam generator has an electric water sensor and 8KW electric heating

element which is replaceable from the side.

Pan Capacity

Pan Size Per Cavity Total

12 x 20 x 1” 6 12

12 x 20 x 2 1/2” 3 6

12 x 20 x 4” 2 4

Installation

Unit requires two 208, 240 or 480 volt, single or three

phase electrical service connections. Unit requires two 3/4”

NH cold water supply lines and 1-1/2” free venting drain.

Water Supply Requirements

To minimize service problems, a PureSteem water treatment (softening) system is recommended when water

quality is found to exceed limits stated below and in operator manual.

Recommended MINIMUM water quality standards are:

Total dissolved solids (TDS) content should have a value

of 30 to 40 parts per million; and the water pH should be

7.0 to 9.0

Options/Accessories

Stainless steel support stand

Pan racks for support stand

4” adjustable legs

Optional second water connection for

spray condensers

Origin of Manufacture

Steamer shall be designed and manufactured in the United

States.

models (2)HY-3E/EF/EC

6 Pan Total Capacity

Stainless Steel Stacked

Pressureless Steamers

Table Top or Stand

Mounted

Self-Contained

Electric Heated

Short Form

Unit shall be Groen double

stacked HyPerSteam pressureless steamers Model

(2)HY-3E, each with self-contained, atmospheric electric

heated steam generator, per

Bulletin 140803. All stainless

steel construction with a powerful blower to circulate steam

within each cavity. Standard

operating controls including:

60 minute mechanical timer,

constant steam setting, ready

light and CLEAN cycle button to initiate deliming. Simple

generator deliming through

deliming ports on top. Doors

are field reversible, with easy

open latch and hidden magnetic door switch. Atmospheric

steam generators require no

pressure gauge or switches,

have automatic water drain

and 8KW power input. Units

shall come up to steam in

10 minutes or less from a

cold start, and provide warm

cavity-instant steam capability. See other side for electric,

water and drain connections

required. Made in the U.S.A.

Applications

Pasta

Rice

Vegetables (Fresh & Frozen)

Seafood (Fresh & Frozen)

Poultry

Potatoes

Eggs

Meats

Reheat Cook-Chill &

Prepared Foods

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Groen HyPerSteam, Page 2

140803C

Revised 08/09

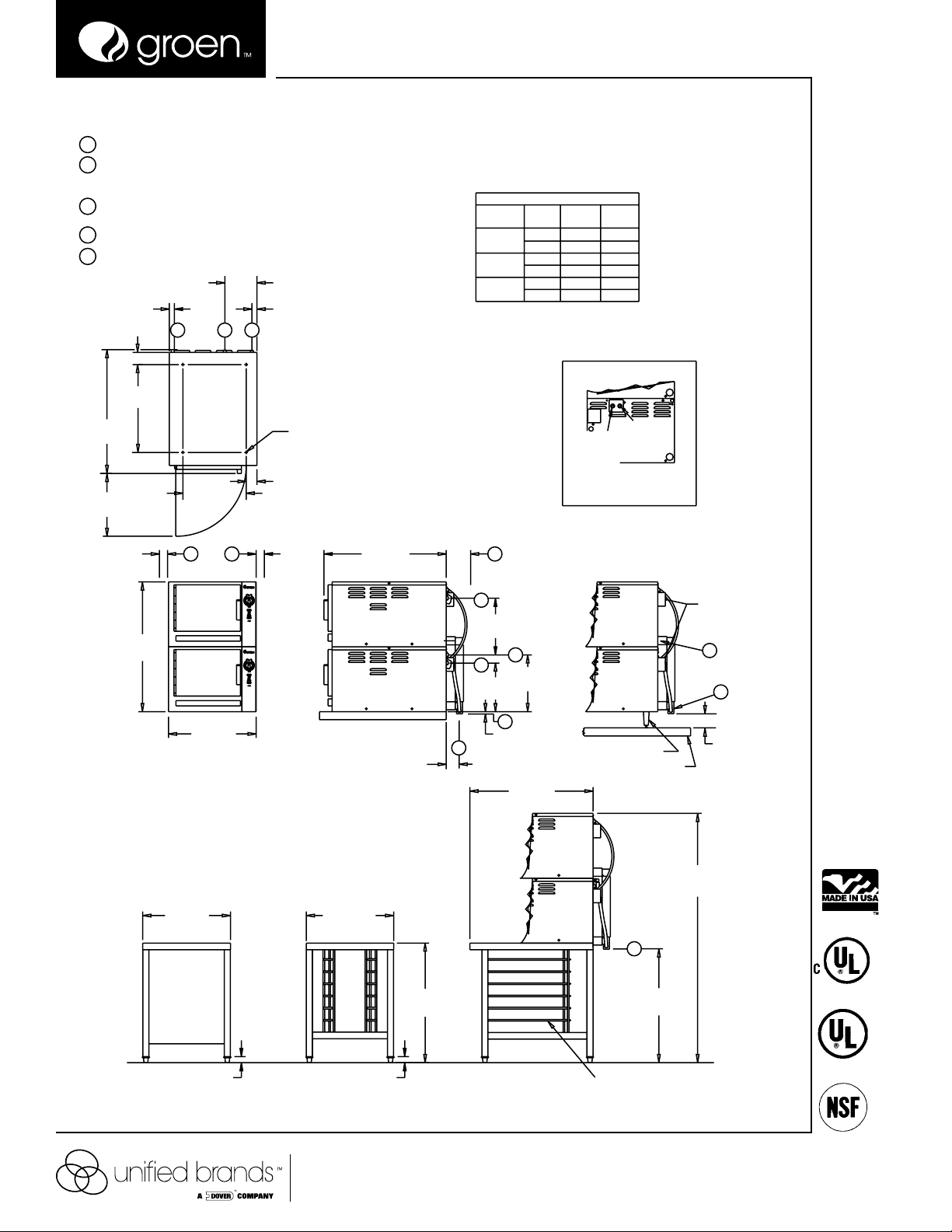

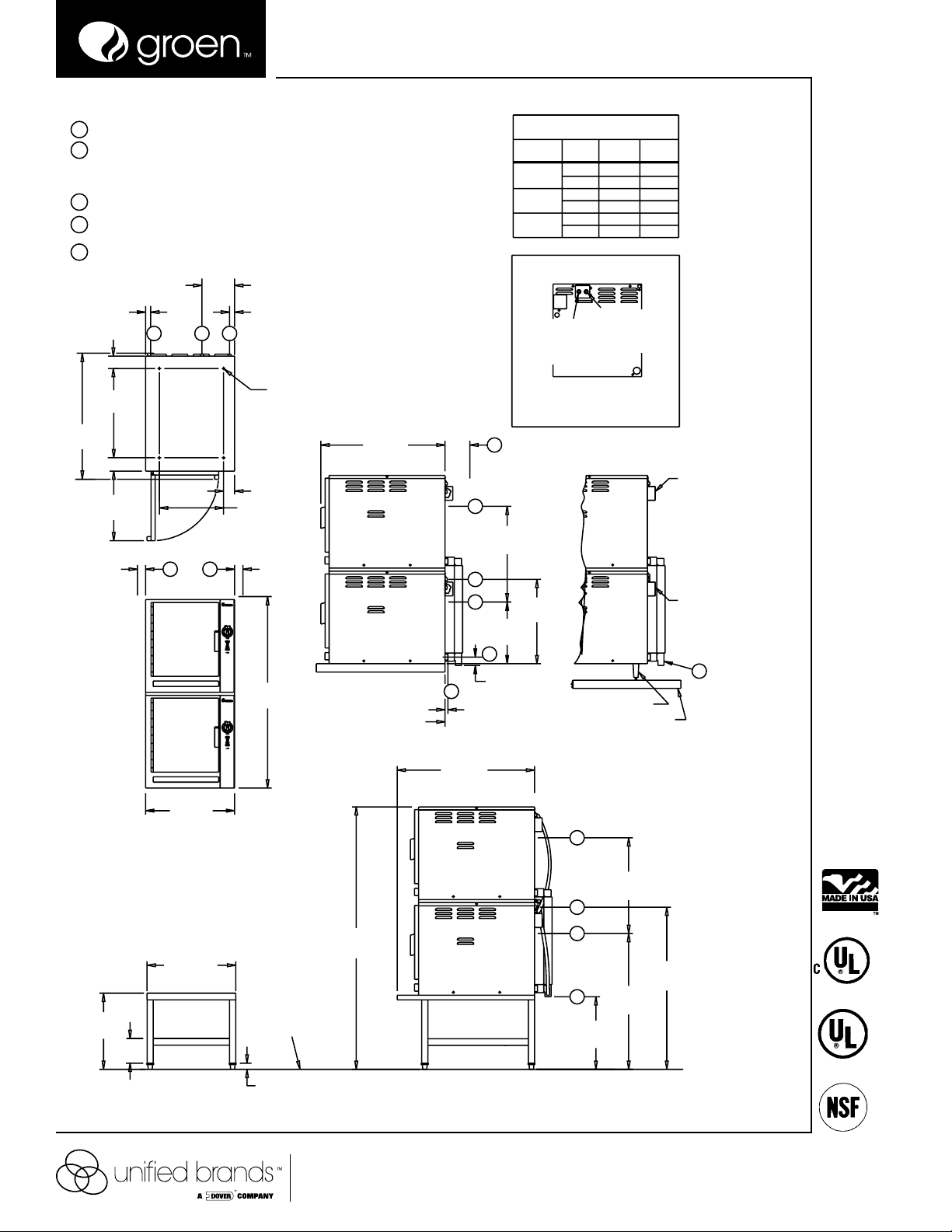

39

331

20

1

23

3

3

AMPS

240

KW

MAX.

PHASE

VOLTAGE

208

480

3 10

1 17

8

8

8

8

8

8

ELECTRICAL REQUIREMENTS - EACH UNIT

SERVICE CONNECTIONS & NOTES:

1 ONE DRAIN CONNECTION: 1-1/2" TUBE (DRAIN FREE VENTING).

2

3

DETAIL VIEW

OF WATER CONNECTIONS

REAR OF STEAMER

TABLE TOP OR COUNTER

(CUSTOMER PROVIDED)

[549]

21 5/8"

4

[51]

2"

OPTIONAL 4" LEGS

TABLE TOP OR COUNTER

OR COUNTER

REAR OF TABLE

[765]

30 1/8"

3/8"

[305]

3 3/16"

[81]

1

1

[10]

12"

3

[356]

14"

2

[152]

6"

4

1

1

33" [838]

MOUNTING HOLES INBASE

USE 3/8" - 16 BOLTS WHICH

MUST NOT EXTEND INTO STEAMER

BY MORE THAN 3/8" (10).

[397]

15 19/32

[551]

[76]

21 11/16"

3"

1 2 3

[76]3"

1 1/4"

[32]

[203]

8"

[32]

1 1/4"

30 13/16"

[783]

3

[432]

17"

[67] MAXIMUM

[38] MINIMUM

[548]

21 5/8"

2 5/8

1 1/2

OPTIONAL SUPPORT STANDS

OPTIONAL RACKS TO

HOLD (6) STEAMER PANS

SIDE VIEW

[1551] MIN.

61 1/16"

[703] MIN.

27 11/16"

1

33 3/8"

[772]

28-1/16" [713]

MIN.

1 1/2

2 5/8

[38] MINIMUM

[67] MAXIMUM

21 5/8" [549]

OPEN

ENCLOSED

(FRONT VIEWS)

UNIT

FUSE

BOX

COLD WATER SUPPLY AT 30 TO 60 PSIG WITH A FLOW RATE

OF 1.50 - 3.00 GPM PER CAVITY (3.00 - 6.00 GPM TOTAL)

AND WITH A 3/4" NH CONNECTION.

4

[51]

2"

TWO ELECTRICAL CONNECTIONS: 3/4" CONDUITFITTING.

[SEE ELECTRICAL REQUIREMENT TABLE]

4 MINIMUM SIDE AND REAR CLEARANCE.

DIMENSIONS IN BRACKETS [ ] ARE MM.5

15 1/2" [394] DOOR

SWING

3 5/8"

[92]

UNTREATED

WATER

SUPPLY

CONNECTION

TREATED

WATER

SUPPLY

CONNECTION

Models (2)HY-3E/EF/EC

P/N 125774 REV C

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of

Dover Corporation.

5-Pan Capacity

Stainless Steel

Pressureless Steamer

Table Top

Self-Contained

Electric-Heated

HyPerSteam Pressureless Steamer

Description

Steamer shall be a Groen Model HY-5E stainless steel

pressureless steamer with a self-contained atmospheric

15.5 KW electric steam generator, per Bulletin 140807,

as follows:

Construction

Steamer cavity and cabinet shall be all stainless steel

construction, with removable right and left-side panels,

providing access to internal components.

Steamer door is all stainless steel with a strong continuous hinge and is field-reversible for left or right-swing,

door shall be provided with a one-piece, replaceable seal.

Easy-open handle and latch shall provide positive lock

and seal when door is pushed or slammed shut.

Hidden magnetic door switch cuts power to blower

and cuts power to generator when the door is opened.

Pan support racks shall be polished stainless steel and

removable for easy cleaning. A stainless steel condensate

collection tray is positioned under cavity door.

Finish

Cabinet exterior, including door, shall be finished to a

#3 uniform finish. Cavity interiors are polished stainless

steel. Control panel face plates shall be smudge-resistant

polyester film, ensuring maximum ease in cleaning and

maintaining an attractive appearance.

UL Listing

Steamer shall be UL-listed and Canadian UL-listed.

Sanitation

Unit shall be designed and manufactured to meet NSF

requirements and be NSF-listed. Unit shall allow operator

to delime steam generator through access port on top

without tools or service call. Push button auto-delime

feature is standard.

Controls

Steamer controls shall include an ON-OFF power button;

60-minute electro-mechanical timer, with continuous

steam setting; and READY light which indicates when

cavity is ready for steaming. Auto-Delime button initiates

deliming cycle.

Performance Features

Steamer cavity shall have a powerful side-mounted blower, which increases steam velocity and provides efficient

steam distribution throughout cavity and between loaded

pans. Steam generator delivers 3.1 KW power input per 2

1/2” deep steam pan.

Heat-up time to READY shall be 8-10 minutes or less,

under normal conditions. Cavity is kept warm and ready

for instant steam between loads. No cavity warm up

required, after READY light comes on.

DELIME indicator light warns operator of need to delime

steam generator. Unit will shut off if water level is low.

When power is turned “off”, unit automatically blows

down the steam generator to reduce sediment build-up.

Model HY-5E Shown

Atmospheric Steam Generator

Unit shall have an electric-heated, rear-mounted steam

generator to provide atmospheric steam to the chamber

at a temperature of approximately 212°F. Steam generator

has an electric water sensor. Electric heating elements are

replaceable from the side.

Pan Capacity

Pan Size / Type Number

12 x 20 x 1” 10

12 x 20 x 2 1/2” 5

12 x 20 x 4” 3

Installation

Unit requires 208, 240 or 480 Volt, single or three-phase

electric service. Unit requires dual 3/4” NH cold water supply lines and 2” free venting drain.

Water Supply Requirements

All steam systems are subject to contamination and failure

due to mineral content found in all water supplies. To

minimize service problems, a Groen PureSteem™ Water

Treatment System is recommended.

Options/Accessories

Groen PureSteem™ Water Treatment System

Factory stacking kit

Stainless steel support stand

Pan racks for support stand

Single water connection (cold water)

4” adjustable legs

Origin of Manufacture

Steamer shall be designed and manufactured in the United

States.

models HY-5E/EF

Short Form

Unit shall be a Groen

HyPerSteam pressureless

steamer Model HY-5E with

self-contained, atmospheric

electric-heated steam

generator, per Bulletin 140807.

All stainless steel construction,

with powerful blower to

circulate steam within cavity.

Standard operating controls

including: 60-minute electromechanical timer, constant

steam setting, ready light and

Delime cycle button to initiate

deliming. Simple generator

deliming through port on top.

Door is field-reversible, with

easy-open latch and hidden

magnetic door switch. The

atmospheric steam generator

requires no pressure gauge or

switches, has automatic drain

and 15.5 KW power input.

Unit shall come up to steam

in 8-10 minutes from a cold

start, and provide warm cavityinstant steam capability. See

other side for required electric,

water and drain connections .

Made in the U.S.A.

Applications

Pasta

Rice

Vegetables (Fresh & Frozen)

Seafood (Fresh & Frozen)

Poultry

Potatoes

Eggs

Meats

Reheat Cook-Chill &

Prepared Foods

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Groen HyPerSteam, Page 3

140807C

Revised 08/09

74.5

64.61

38.2

1

44.0

3

3

AMPS

240

KW

MAX.

PHASE

VOLTAGE

208

480

3 19.1

––– –––

15.5

15.5

15.5

15.5

–––

15.5

ELECTRICAL REQUIREMENTS

8"

1 1/4"

TABLE TOP OR COUNTER

(CUSTOMER PROVIDED)

[203]

[32]

3"

21 11/16"

3"

15 19/32"

[76]

[551]

[76]

[397]

REAR OF TABLE

OR COUNTER

TABLE TOP OR COUNTER

OPTIONAL 4" LEGS

MOUNTING HOLES IN BASE

USE 3/8" 16 BOLTS WHICH

MUST NOT EXTEND INTO STEAMER

BY MORE THAN 3/8" [10]

30 13/16"

[783]

SERVICE CONNECTIONS & NOTES:

1 DRAIN CONNECTION: 2" [50.8] TUBE (DRAIN FREE VENTING).

2

3 ONE ELECTRICAL CONNECTION: 1" [25.4] CONDUIT FITTING.

4 MINIMUM REAR AND SIDE CLEARANCE: REAR = 6" [152.4]

LEFT SIDE = 2" [50.8] RIGHT SIDE = 2" [50.8]

21 5/8"

[549]

22 1/2"

[571]

30 1/8"

[765]

2 3

4

2"

[51]

4

1

11/16"

[17]

6

[152]

15"

[381]

3

[520]

20 1/2"

2

FRONT VIEW SIDE VIEW

OPTIONAL SUPPORT STAND

21 9/16"

[548]

6"

[152]

1 1/2" [38] MINIMUM

2 5/8" [67] MAXIMUM

FINISHED FLOOR

33 3/8"

[772]

OPTIONAL RACKS TO

HOLD (6) STEAMER PANS

29 3/4"

[756] MIN

50 9/16"

[1284] MIN

1

UNTREATED

WATER

SUPPLY

CONNECTION

DETAIL VIEW

OF WATER CONNECTIONS

(IF 2nd CONNECTION ORDERED)

REAR OF STEAMER

DIMENSIONS IN BRACKETS [ ] ARE MM.5

1

1

1 1/4"

[32]

1

1 5/8"

[41]

UNIT FUSE

BOX

17 3/8"

[441]

4

[51]

2"

[1092]

43" MIN

[1232]

48 1/2"

3

2

[713] MIN

28 1/16"

COLD WATER SUPPLY AT 30 TO 60 PSIG WITH A FLOW RATE OF

0.75 - 1.50 GPM AND WITH A 3/4" NH CONNECTION.

TREATED

WATER

SUPPLY

CONNECTION

Models HY-5E/EF

P/N 125999 REV B

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of

Dover Corporation.

HyPerSteam Pressureless Steamer

Description

Steamer shall be a Groen Model (2)HY-5E stainless steel

double stacked pressureless steamer, each with a selfcontained atmospheric 15.5 KW electric steam generator,

per bulletin 140808 as follows:

Construction

Each steamer cavity and cabinet shall be all stainless

steel construction with removable right and left side panels providing access to internal components.

Steamer doors are all stainless steel with strong continuous hinge and are field reversible for left or right swing,

doors shall be provided with a one piece, replaceable

seal. Easy open handle and latch shall provide positive

lock and seal when door is pushed or slammed shut.

Hidden magnetic door switch cuts power to blower and

shuts down power to generator when that door is opened.

Pan support racks shall be polished stainless steel and

removable for easy cleaning. A stainless steel condensate

collection tray is positioned under each cavity door.

Finish

Cabinet exterior including doors shall be finished to a

#3 uniform finish. Cavity interiors are polished stainless

steel. Control panel face plates shall be smudge resistant

polyester film, ensuring maximum ease in cleaning and

maintaining an attractive appearance.

UL Listing

Steamer shall be UL listed.

Sanitation

Unit shall be designed and manufactured to meet NSF

codes and be NSF listed. Unit shall allow operator to

delime steam generator through deliming port on top,

without tools or service call. Push button auto-clean

feature is standard.

Controls

Steamer controls shall include an ON-OFF power button; 60 minute mechanical timer, with continuous steam

setting; and READY light which indicates when cavity is

warm and ready for steaming. Auto-clean button initiates

deliming cycle for each unit.

Performance Features

Each steamer shall have a powerful side mounted blower,

which increases steam velocity and provides efficient

steam distribution throughout cavity and between loaded

pans. Steam generator delivers 3.1 KW power input per 2

1/2” deep steam pan.

Heat up time to READY shall be 10 minutes or less,

under normal conditions. Cavity is kept warm and ready

for instant steam between loads. No cavity warm up

required, after READY light comes on.

delime indicator light warns operator of need to delime

steam generator. Unit will shut off if water level is low.

When power is turned “off”, unit automatically blows

down the steam generator to reduce sediment build-up.

Model (2)HY-5E Shown

Atmospheric Steam Generator

Each unit shall have an electric heated rear mounted steam

generator to provide atmospheric steam to the chamber at

a temperature of approximately 212°F. Steam generator

has an electric water sensor. Electric heating elements are

replaceable from the side.

Pan Capacity

Pan Size Per Cavity Total

12 x 20 x 1” 10 20

12 x 20 x 2 1/2” 5 10

12 x 20 x 4” 3 6

Installation

Unit requires two 208, 240 or 480 volt, single or three

phase electric service connections. Unit requires dual 3/4”

NH cold water supply lines and 2” free venting drain.

Water Supply Requirements

All steam systems are subject to contamination and failure

due to mineral content found in all water supplies. To

minimize service problems, a Groen PureSteem Water

Treatment System is recommended.

Options/Accessories

Groen PureSteem Water Treatment System

Single cold water connection adaptor

Origin of Manufacture

Steamers shall be designed and manufactured in the

United States.

models (2)HY-5E/EF

10 Pan Total Capacity

Stainless Steel Stacked

Pressureless Steamers

Table Top or

Stand Mounted

Self-Contained

Electric Heated

Short Form

Unit shall be a Groen

double stacked HyPerSteam

pressureless steamer Model

(2)HY-5E each with selfcontained, atmospheric electric

heated steam generator, per

bulletin 140808. All stainless

steel construction with powerful

blower to circulate steam

within each cavity. Standard

operating controls including:

60 minute mechanical timer,

constant steam setting, ready

light and CLEAN cycle button

to initiate deliming. Simple

generator deliming through

deliming port on top. Doors are

field reversible, with easy open

latch and hidden magnetic

door switch. The atmospheric

steam generators require no

pressure gauge or switches,

have automatic drain and 15.5

KW power input. Unit shall

come up to steam in 7-10

minutes from a cold start, and

provide warm cavity-instant

steam capability. See other

side for electric, water and

drain connections required.

Made in the U.S.A.

Applications

Pasta

Rice

Vegetables (Fresh & Frozen)

Seafood (Fresh & Frozen)

Poultry

Potatoes

Eggs

Meats

Reheat Cook-Chill &

Prepared Foods

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Groen HyPerSteam, Page 4

140808C

Revised 08/09

74.5

64.61

38.2

1

44.0

3

3

AMPS

240

KW

MAX.

PHASE

VOLTAGE

208

480

3 19.1

1 32.3

15.5

15.5

15.5

15.5

15.5

15.5

ELECTRICAL REQUIREMENTS

(EACH UNIT)

8

1 1/4

TABLE TOP OR COUNTER

(CUSTOMER PROVIDED)

[203]

[32]

3

21 11/16

3

15 19/32

[76]

[551]

[76]

[397]

REAR OF TABLE

OR COUNTER

TABLE TOP OR COUNTER

OPTIONAL 4 LEGS

MOUNTING HOLES IN BASE

USE 3/8" 16 BOLTS WHICH

MUST NOT EXTEND INTO STEAMER

BY MORE THAN 3/8" [10]

30 13/16

[783]

SERVICE CONNECTIONS & NOTES:

1 DRAIN CONNECTION: 2" [50.8] TUBE (DRAIN FREE VENTING).

2

3

TWO ELECTRICAL CONNECTIONS: 1" [25.4] CONDUIT FITTING

4

MINIMUM REAR AND SIDE CLEARANCE: REAR = 6 "[152.4]

LEFT SIDE = 2" [50.8] RIGHT SIDE = 2 [50.8]

21 5/8

[549]

46 1/2

[1181]

2 3

1

11/16

[17]

15

[381]

3

[520]

20 1/2

2

SIDE VIEW

OPTIONAL SUPPORT STAND

21 9/16

[548]

6

[152]

1 1/2

[38] MINIMUM

2 5/8

[67] MAXIMUM

UNTREATED

WATER

SUPPLY

CONNECTION

DETAIL VIEW

OF WATER CONNECTIONS

REAR OF STEAMER

DIMENSIONS IN BRACKETS [ ] ARE MM.

5

1

1

1 1/4

[32]

1

1 5/8

[41]

UNIT FUSE

BOX

17 3/8

[441]

[765]

30 1/8

4

[152]

6

[51]

2

4

[772]

33 3/8

FRONT VIEW

UNIT FUSE

BOX

FINISHED

FLOOR

64 3/8

[1635] MIN

[470]

18 1/2

[51]

2

4

3

[597]

23 1/2

[511]

20 1/8

1

[851]

33 1/2

[597]

23 1/2

39

[991]

3

3

2

COLD WATER SUPPLY AT 30 TO 60 PSIG WITH A FLOW RATE

OF 0.75 - 1.50 GPM PER CAVITY (1.50 - 3.00 GPM TOTAL)

AND WITH A 3/4" NH CONNECTION.

TREATED

WATER

SUPPLY

CONNECTION

Models (2)HY-5E/EF

P/N 126000 REV B

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of

Dover Corporation.

5-Pan Capacity

Stainless Steel

Pressureless Steamer

Table Top

Self-Contained

Gas-Heated

HyPerSteam Pressureless Steamer

Description

Steamer shall be a Groen Model HY-5G stainless steel

pressureless steamer with a self-contained atmospheric

62,000 BTU/hr gas steam generator, per Bulletin 140805,

as follows:

Construction

Steamer cavity and cabinet shall be all stainless steel

construction with removable right and left-side panels,

providing access to internal components.

Steamer door is all stainless steel, with strong continuous hinge and is field-reversible for left or right-swing.

Door shall be insulated and provided with a one-piece,

replaceable seal. Easy-open handle and latch shall

provide positive lock and seal when door is pushed or

slammed shut.

Hidden magnetic door switch cuts power to blower

and cuts power to generator when the door is opened.

Pan support racks shall be polished stainless steel and

removable for easy cleaning. A stainless steel condensate collection tray is positioned under cavity door.

Finish

Cabinet exterior, including door, shall be finished to a

#3 uniform finish. Cavity interiors are polished stainless

steel. Control panel face plates shall be smudge-resistant

polyester film, ensuring maximum ease in cleaning and

maintaining an attractive appearance.

CSA Design Certification

Steamer shall be CSA (formerly AGA) design-certified to

ANSI Z83.11.

Sanitation

Unit shall be designed and manufactured to meet NSF

codes and be NSF-listed. Unit shall allow operator to

delime steam generator through control panel mounted

deliming port, without tools or service call. Push-button

auto-clean feature is standard.

Controls

Steamer controls shall include an ON-OFF power button;

60 minute electro-mechanical timer, with continuous

steam setting; and READY light which indicates when

cavity is warm and ready for steaming. Auto-clean button

initiates deliming cycle.

Performance Features

Steamer cavity shall have a powerful side-mounted

blower, which increases steam velocity and provides efficient steam distribution throughout cavity and between

loaded pans. Steam generator delivers 12,400 BTU/hr

power input per 2 1/2” deep steam pan.

Heat-up time to READY shall be 8-10 minutes or less,

under normal conditions. Cavity is kept warm and ready

for instant steam between loads. No cavity warm up

required, after READY light comes on.

DELIME indicator light warns operator of need to delime

steam generator. Unit will shut off if water level is low.

When power is turned “off,” unit automatically blows

down the steam generator, to reduce sediment build-up.

Model HY-5G Shown

Atmospheric Steam Generator

Unit shall have a gas-heated, rear-mounted steam generator to provide atmospheric steam to the chamber at a

temperature of approximately 212º F. The high-efficiency

steam generator has an electric water sensor and a 62,000

BTU/hr firing rate. Standing pilot with easy light electronic

ignition standard.

Pan Capacity

Pan Size / Type Number

12 x 20 x 1” 10

12 x 20 x 2 1/2” 5

12 x 20 x 4” 3

Installation

Unit requires gas service (specify natural or propane) via

1/2” NPT gas supply line or approved equivalent. Unit

requires two 3/4” NH cold water supply lines: one for treated

water and one for untreated water. A single 3/4” NH cold

water supply line may be used, but requires the optional

adapter listed below. Unit requires a 1 1/2” O.D. free venting

drain and 115 Volt single-phase electric service.

Water Supply Requirements

All steam systems are subject to contamination and failure

due to mineral content found in all water supplies. To

minimize service problems, a Groen PureSteem™ Water

Treatment System is recommended.

Options/Accessories

Groen PureSteem™ Water Treatment System

Factory stacking & stacking kit

Stainless steel support stand

Pan racks for support stand

Single Water Connection (cold water)

4” legs

Origin of Manufacture

Steamer shall be designed and manufactured in the United

States.

model HY-5G

Short Form

Unit shall be a Groen

HyPerSteam pressureless

steamer Model HY-5G with

self-contained, atmospheric

gas-heated steam generator,

per Bulletin 140805. All

stainless steel construction

with powerful blower to

circulate steam within cavity.

Standard operating controls

including: 60-minute electromechanical timer, constant

steam setting, ready light and

Delime cycle button to initiate

deliming. Simple generator

deliming through control panel.

Door is field-reversible, with

easy-open latch and hidden

magnetic door switch. The

atmospheric steam generator

requires no pressure gauge

or switches, has automatic

drain and 62,000 BTU/hr

power input. Unit shall come

up to steam in 8-10 minutes

from a cold start, and provide

warm cavity-instant steam

capability. See other side for

required gas, water and drain

connections required. C.S.A.

and N.S.F.-listed. Made in the

U.S.A.

Applications

Pasta

Rice

Vegetables (Fresh & Frozen)

Seafood (Fresh & Frozen)

Poultry

Potatoes

Eggs

Meats

Reheat Cook-Chill &

Prepared Foods

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Groen HyPerSteam, Page 5

140805C

Revised 08/09

Loading...

Loading...