Groen HY-12GF Service Manual

OPERATOR MANUAL &

SERVICE MANUAL

IMPORTANT INFORMATION, KEEP FOR OPERATOR

This manual provides information for:

HY-12GF(CE) & HY-24GF(CE)

HYPERSTEAM

™

ATMOSPHERIC CONVECTION

STEAMER INTERNATIONAL

· Self-Contained

· Gas Heated

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE.

READ, UNDERSTAND AND FOLLOW THE INSTRUCTIONS AND

WARNINGS CONTAINED IN THIS MANUAL.

NOTIFY CARRIER OF DAMAGE AT ONCE

It is the responsibility of the consignee to inspect the container upon receipt of

same and to determine the possibility of any damage, including concealed dam

age. Unified Brands suggests that if you are suspicious of damage to make a

notation on the delivery receipt. It will be the responsibility of the consignee to file

a claim with the carrier. We recommend that you do so at once.

Manufacture Service/Questions 888-994-7636.

PART NUMBER 132465, REV. C (1/09)

PART NUMBER 132465, REV. B (4/06)

-

1055 Mendell Davis Drive

Jackson, MS 39272

888-994-7636, fax 888-864-7636

unifiedbrands.net

2 OM/SM-HY-12GF(CE) & HY-24GF(CE)

OM/SM-HY-12GF(CE) & HY-24GF(CE)

IMPORTANT — READ FIRST — IMPORTANT

IT IS MOST IMPORTANT THAT THESE INSTRUCTIONS AND THE OPERATOR AND SERVICE MANUALS BE

CONSULTED BEFORE INSTALLING AND COMMISSIONING THE APPLIANCE. FAILURE TO COMPLY WITH

SPECIFIED PROCEDURES MAY RESULT IN DAMAGE OR THE NEED FOR A SERVICE CALL.

THESE APPLIANCES HAVE BEEN CE MARKED ON THE BASIS OF COMPLIANCE WITH THE GAS

APPLIANCE DIRECTIVE, EMC AND LOW VOLTAGE DIRECTIVE FOR THE COUNTRIES, GAS TYPES AND

PRESSURES AS STATED ON THE DATA PLATE.

THESE APPLIANCES MUST BE INSTALLED BY A COMPETENT PERSON IN CONFORMITY WITH THE

INSTALLATION AND SERVICING INSTRUCTIONS AND NATIONAL REGULATIONS IN FORCE AT THE TIME.

PARTICULAR ATTENTION MUST BE PAID TO THE FOLLOWING:

I. E. E. REGULATIONS FOR ELECTRICAL INSTALLATIONS

ELECTRICITY AT WORK REGULATIONS

GAS SAFETY (INSTALLATION AND USE) REGULATIONS

HEALTH AND SAFETY AT WORK ACT

LOCAL AND NATIONAL BUILDING REGULATIONS

FIRE PRECAUTIONS ACT

DETAILED RECOMMENDATIONS ARE CONTAINED IN INSTITUTE OF GAS ENGINEERS PUBLISHED

DOCUMENTS: IGE/UP/1, IGE/UP/2, BS6173 AND BE5440.

FURTHERMORE, IS A NEED ARISES TO CONVERT THE APPLIANCE FOR USE WITH ANOTHER GAS, A

COMPETENT PERSON MUST BE CONSULTED. THOSE PARTS WHICH HAVE BEEN PROTECTED BY THE

MANUFACTURER MUST NOT BE ADJUSTED BY THE USER.

USERS SHOULD BE CONVERSANT WITH THE APPROPRIATE PROVISIONS OF THE FIRE PRECAUTIONS

ACT AND THE REQUIREMENTS OF THE GAS SAFETY REGULATIONS. IN PARTICULAR THEY SHOULD

BE AWARE OF THE NEED FOR REGULAR SERVICING BY A COMPETENT PERSON TO ENSURE THE

CONTINUED SAFE AND EFFICIENT PERFORMANCE OF THE APPLIANCE.

WARNING: TO PREVENT SHOCKS, ALL APPLIANCES GAS OR ELECTRIC, MUST BE EARTHED.

UPON COMPLETION OF THE INSTALLATION, THE OWNERS MANUAL SHOULD BE HANDED TO THE

USERS AND THE INSTALLER SHOULD INSTRUCT THE RESPONSIBLE PERSON(S) IN THE CORRECT

OPERATION AND MAINTENANCE OF THE APPLIANCE.

THIS EQUIPMENT IS ONLY FOR PROFESSIONAL USE, AND SHALL BE OPERATED BY QUALIFIED

PERSONS. IT IS THE RESPONSIBILITY OF THE SUPERVISOR OR EQUIVALENT TO ENSURE THAT USERS

WEAR SUITABLE PROTECTIVE CLOTHING AND TO DRAW ATTENTION TO THE FACT THAT, SOME

PARTS WILL, BY NECESSITY, BECOME VERY HOT AND WILL CAUSE BURNS IF TOUCHED

ACCIDENTALLY.

WARNING: BEFORE REMOVING ANY PARTITION OR PANEL, ALWAYS TURN OFF THE ELECTRIC

POWER AND ALLOW THE FAN TO STOP ROTATING. BEFORE WORKING ON ANY

ELECTRICAL COMPONENT, DISCONNECT THE POWER SOURCE FROM THE UNIT.

NOTE: IT IS IMPORTANT THAT THE END-USER ROUTINELY EXAMINE THE FLUE OUTLET ON A

REGULAR BASIS. DEBRIS COVERING THE FLUE OUTLET CAN CAUSE A POTENTIALLY

HAZARDOUS CONDITION. REMOVE ANY FOREIGN MATERIAL BEFORE USING THIS PIECE

OF EQUIPMENT.

WARNINGS AND CAUTIONS PROVIDED IN THE BASIC OPERATOR AND SERVICE MANUALS (OM-HY-6G

AND GROEN HYPERSTEAM SERVICE MANUAL) MUST BE COMPLIED WITH.

OM/SM-HY-12GF(CE) & HY-24GF(CE) 3

OM/SM-HY-12GF(CE) & HY-24GF(CE)

TABLE OF CONTENTS

WARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1. INSTALLATION, ASSEMBLY AND COMMISSIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

2. SERVICING AND CONVERSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

PARTS IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

STEAMER BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

INTERCONNECT BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

CONTROL BOARD BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

CONTROL BOARD LED LOCATIONS DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

TRUTH TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

ELECTRICAL SCHEMATIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

TROUBLESHOOTING CHARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4. OPERATOR MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

EQUIPMENT DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

WATER CONDITIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

SERVICE LOG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4 OM/SM-HY-12GF(CE) & HY-24GF(CE)

1. Installation, Assembly and Commissioning

CAUTION

IT IS MOST IMPORTANT THAT THESE INSTRUCTIONS AND THE OPERATOR AND SERVICE MANUALS BE

CONSULTED BEFORE INSTALLING AND COMMISSIONING THE APPLIANCE. FAILURE TO COMPLY WITH

SPECIFIED PROCEDURES MAY RESULT IN DAMAGE OR THE NEED FOR A SERVICE CALL.

These appliances have been CE marked on the basis of

compliance with the gas appliance directive, EMC and

low voltage directive for the countries, gas types and

pressures as stated on the data plate.

These appliances must be installed by a competent

person in conformity with the installation and servicing

instructions and national regulations in force at the time.

Particular attention must be paid to the following:

I. E. E. Regulations For Electrical Installations

Electricity at Work Regulations

Gas Safety (Installation And Use) Regulations

Health And Safety at Work Act

Local And National Building Regulations

Fire Precautions Act

Detailed recommendations are contained in Institute of

Gas Engineers published documents: IGE/UP/1,

IGE/UP/2, BS6173 and BE5440. Furthermore, is a need

arises to convert the appliance for use with another gas,

a competent person must be consulted. Those parts

which have been protected by the manufacturer must not

be adjusted by the user.

Users should be conversant with provisions of the Fire

Precautions Act and requirements of Gas Safety

Regulations. In particular they should be aware of the

need for regular servicing by a competent person to

ensure safe and efficient performance of the appliance.

WARNING

TO PREVENT SHOCKS, ALL APPLIANCES GAS OR

ELECTRIC, MUST BE EARTHED

.

Upon completion of the installation, the owners manual

should be handed to the users and the installer should

instruct the responsible person(s) in the correct operation

and maintenance of the appliance.

This equipment is only for professional use, and shall be

operated by qualified persons. It is the responsibility of

the supervisor or equivalent to ensure that users wear

suitable protective clothing and to draw attention to the

fact that, some parts will, by necessity, become very hot

and will cause burns if touched accidentally.

1.1 General

Unpack the appliance and place it on a firm, level floor.

Adjust and fix the feet.

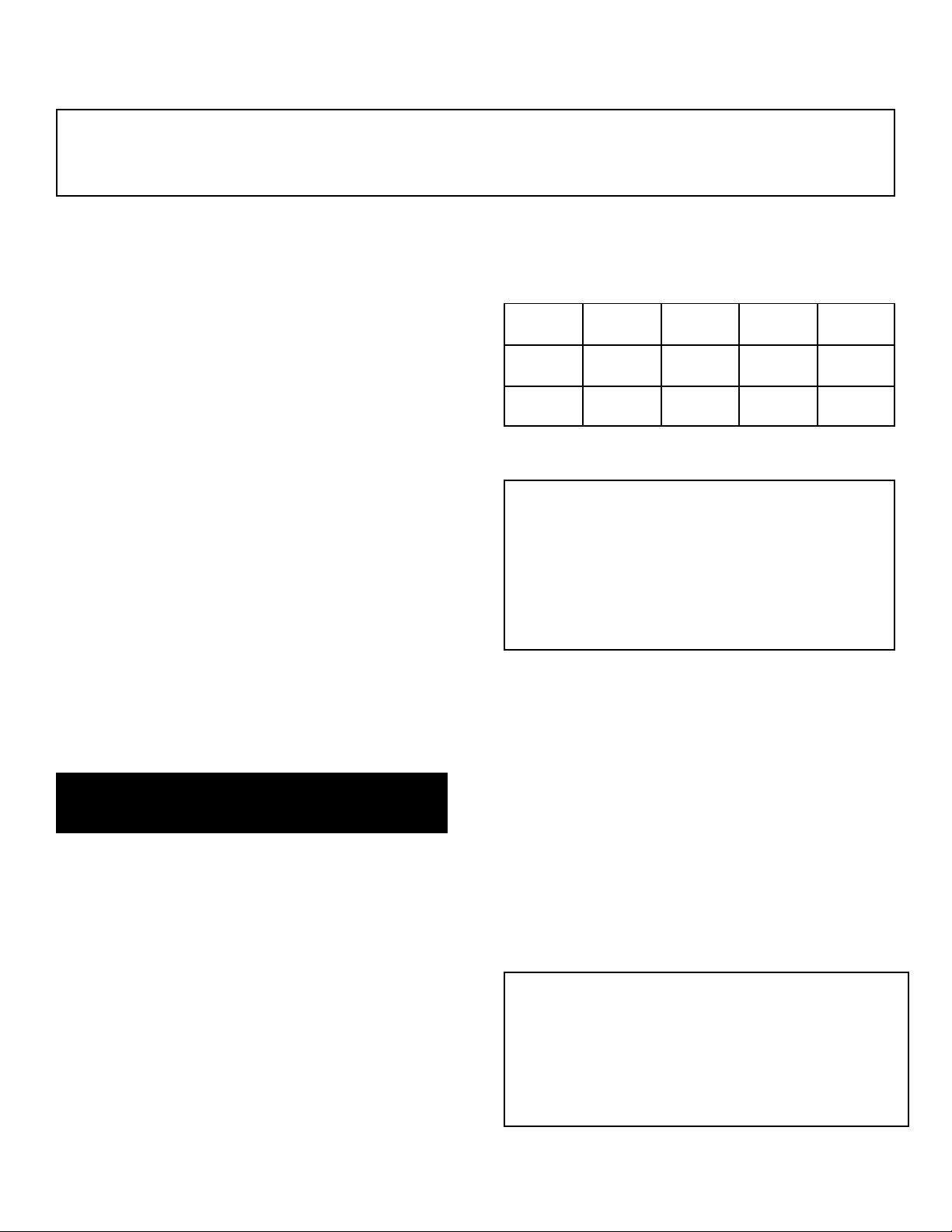

1.1.1 Model Number and Dimensions

MODEL

WIDTH

mm (in.)

DEPTH

mm (in,)

HEIGHT

mm (in.)

WEIGHT

Kg (lbs)

HY-12GF

815

(32.06)

1025

(40.4)

1590

(62.6)

256 (565)

HY-24GF

815

(32.06)

1025

(40.4)

1853

(73.37)

512

(1130)

1.1.2 Siting and Clearances

CAUTION

DO NOT INSTALL THIS UNIT SO RIGHT SIDE VENTS

ARE BLOCKED OR WITHIN 300 mm OF

A HEAT

SOURCE SUCH AS BRAISING PAN, DEEP FRYER,

CHAR BROILER OR KETTLE.

LEVEL THE UNIT FRONT TO BACK

OR PITCH IT

SLIGHTLY TO THE REAR TO AVOID DRAINAGE

PROBLEMS.

The HY-12GF(CE) steamer is suitable for

installation in combustible and noncombustible

locations. Minimum installation clearances are:

Right Side 300 mm (12 inches)

Left Side 0 mm (0 inches)

Rear of Flue 150 mm (6 inches)

The steamer requires 600 mm (24 inches)

clearance on the right side for service.

Allow minimum vertical clearance of 750 mm (30

inches) between the top edge of the flue outlet

and any overlying surface.

1.1.3 Ventilation

CAUTION

THE APPLIANCE FLUE DISCHARGES VERTICALLY

FROM THE TOP OF THE UNIT. IT MUST NOT BE

DIRECTLY CONNECTED TO ANY FLUE, MECHANICAL

EXTRACTION SYSTEM, OR DUCTS LEADING TO

OUTSIDE THE BUILDING. THE UNIT IS BEST

DISCHARGED UNDER AN OPEN CANOPY WHICH

CONNECTS WITH A VENTILATING SYSTEM

.

OM/SM-HY-12GF(CE) & HY-24GF(CE) 5

OM/SM-HY-12GF(CE) & HY-24GF(CE)

For multiple installations the requirements for

individual appliances should be added together. (See

table, page 5). Installation must comply withlocal

and/or national regulations and a competent installer

must be employed. Recommendations for

ventilation for catering appliances are given in BS

5440:2, and are shown in the table at right.

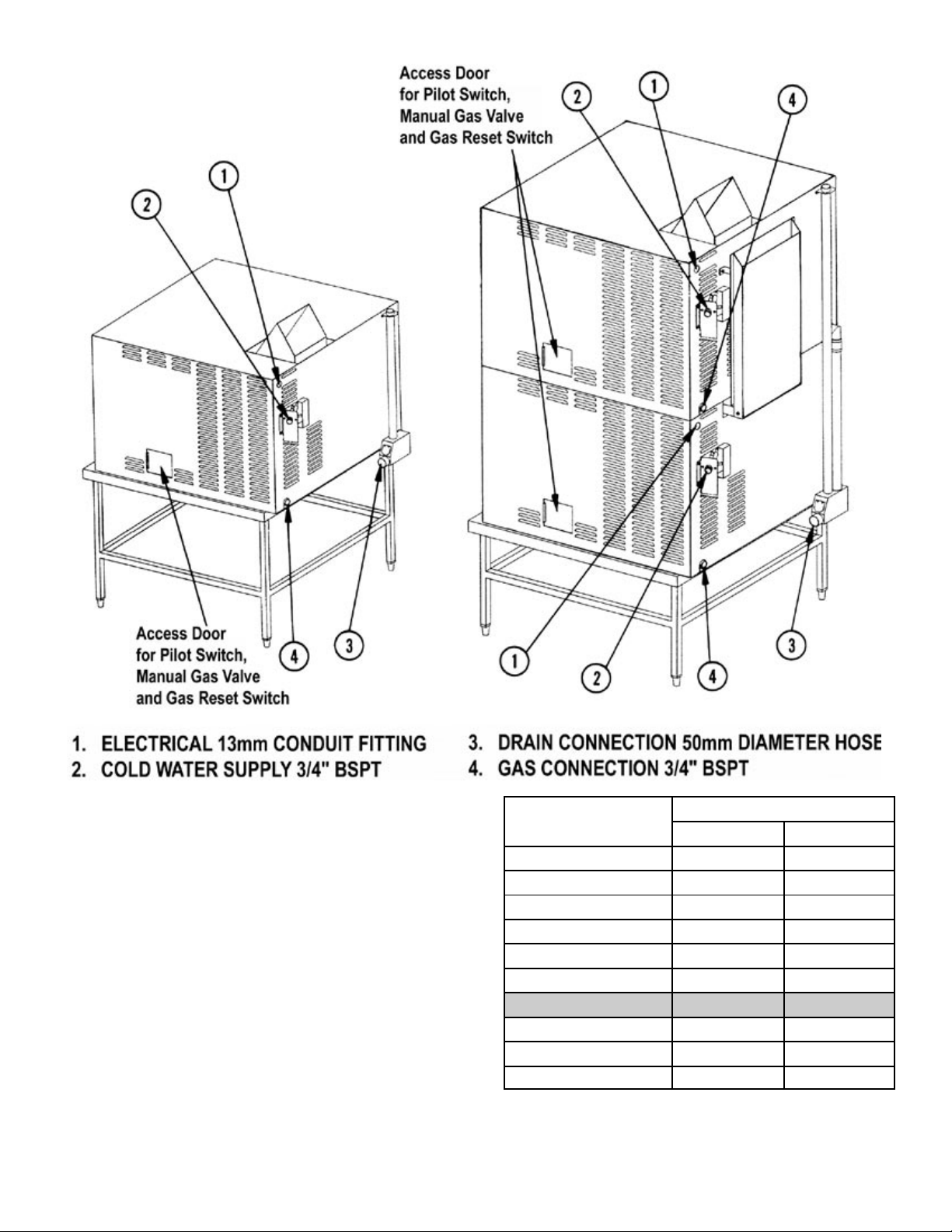

1.2 Electrical Supply Connection

The unit is designed for connection to fixed wiring. A

suitably rated isolating switch with contact separation

of at least 3 mm on both poles must be fitted to the

installation.

Wiring must be executed in accordance

with the regulations listed in this manual.

Equipment

Required Ventilation Rate

m³/min ft³/m

Units Type Range 17 600

Pastry Oven 17 600

Fryer 26 900

Grill 17 600

Steak Grill 26 900

Boiling Pan 17 600

Steamer 17 600

Sterilizing Sink 14 500

Bains Marie 11 400

Tea/Coffee Machine 8.5 - 14 300 - 500

6 OM/SM-HY-12GF(CE) & HY-24GF(CE)

OM/SM-HY-12GF(CE) & HY-24GF(CE)

Cable entry is at the top rear right side of the appliance

for model HY-12GF(CE). There are two cable entries on

model HY-24GF(CE), at the rear right side of each

cavity. Access is gained as described in the Operator

and Service Manuals for this appliance.

Provide 230 Volt, 50 Hz, Single Phase, 15 Ampere

service. Maximum load is 2½ Amps. The electrical

schematic is located in the service compartment and

in this manual.

WARNING

THIS APPLIANCE MUST BE EARTHED.

1.3 Gas Supply Connection

Incoming service must be of sufficient size to supply

full rate without excessive pressure drop. A gas

meter is connected to the service pipe by the Gas

Supplier. Any existing meter should be checked out

by the Gas Supplier to ensure that it has adequate

capacity to provide the required rate of gas to the

steamer, in addition to any other installed equipment.

GAS INPUT RATE BTU/HR AND KW

Natural Gas Propane Gas

HY-12GF

150130 BTU/hr

44 KW

150130 BTU/hr

44 KW

HY-24GF

2 x 150130

BTU/hr

2 x 44 KW

2 x 150130

BTU/hr

2 x 44 KW

Installation pipe work must be fitted in accordance

with IGE/UP/2.

The appliance governor is suitable for both natural

and propane gas without conversion. The governor

is incorporated in the gas control valve, which is

inside the control cabinet.

Connection to the gas supply can be completed with

¾” BSPT pipe. Although the immediate connection

to the appliance is ¾” BSPT, gas supply piping must

be large enough to provide 160,000 BTU/hour.

Minimum supply pressure is 20 mBar for natural gas,

or 37 mBar for propane gas.

An isolating cock must be located close to the

appliance to allow shut down in an emergency, or for

servicing. The installation must be tested for gas

soundness and purged as specified in IGE/UP/1.

For the part of the integral gas supply downstream

from the gas valve, leak detection spray or some

solution may be used with the burners lit.

1.3.1 Gas Pressure Adjustment

Gas pressure has been set at the factory but

should be checked by connecting a manometer

to the pressure tap on the burner manifold. The

adjusted gas pressures are shown in the table

below.

Model

Natural Gas Propane Gas

mBar WCI mBar WCI

HY-12GF(CE) 7.75 3.1 25 10

HY-24GF(CE) 7.75 3.1 25 10

If necessary, the gas pressure may be

readjusted as described in Section 3..

1.3.2 Injector Diameters

Natural Gas Propane Gas

Injector

Dia. (mm)

No. of

Injectors

Injector

Dia. (mm)

No. of

Injectors

HY-12GF(CE)

Main Burner

(high fire)

1.18 30 0.70 30

HY-24GF(CE)

Main Burner

(high fire)

1.18 30 x 2 0.70 30 x 2

HY-12GF(CE)

Igniter Burner

(low fire)

0.64

1 0.41 1

HY-24GF(CE)

Igniter Burner

(low fire)

0.64 1 x 2 0.41 1 x 2

HY-12GF(CE)

Pilot Burner

0.60

1 0.36 1

HY-24GF(CE)

Pilot Burner

0.6 1 x 2 0.36 1 x 2

1.3.3 Burner Air Adjustment

The unit is equipped with fixed aeration type

burners which have no provision for air inlet

adjustment.

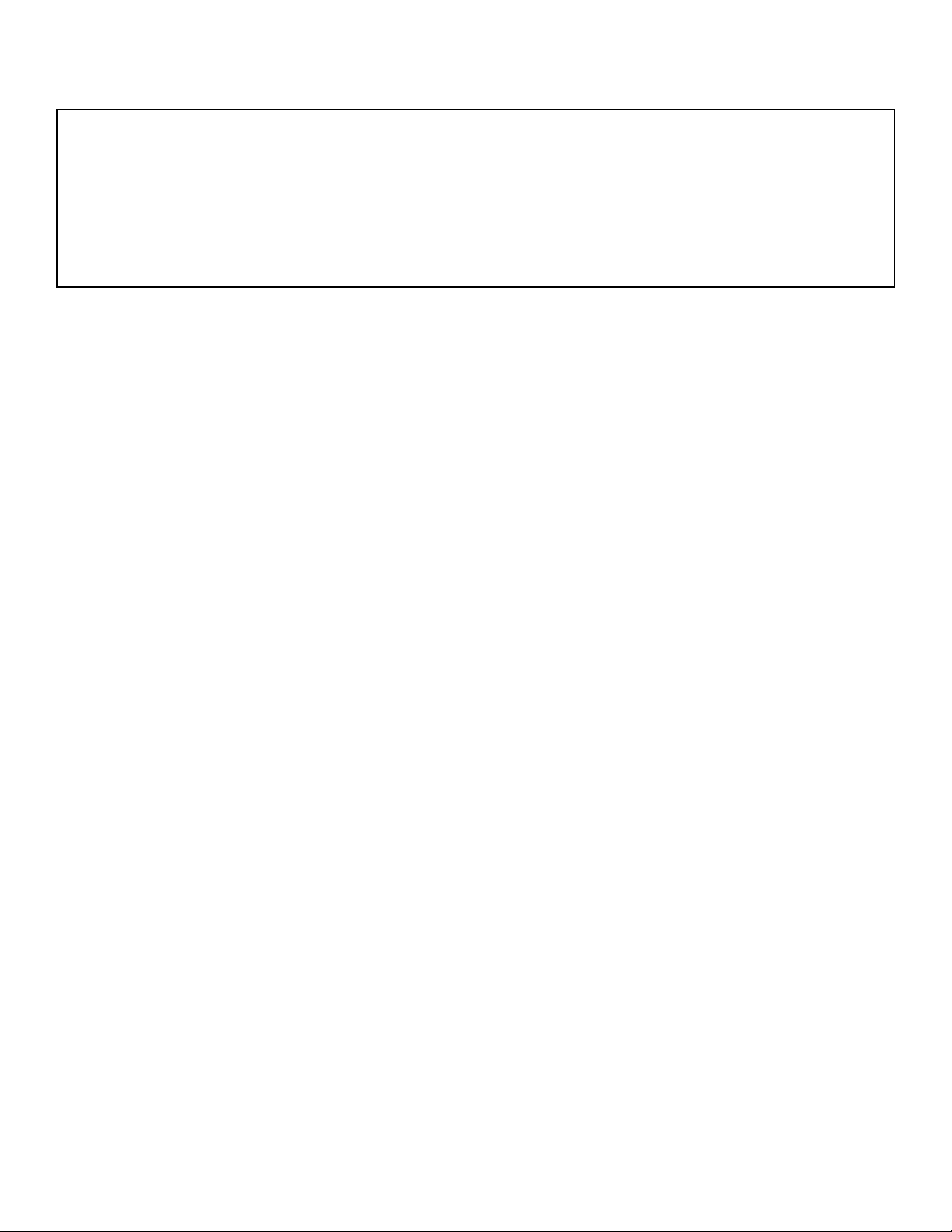

1.4 Water Supply Connection

Water entry is at the rear right side of the appliance.

There are two water entries on the HY-24GF(CE).

The steamer is fitted for a ¾ inch BSPT cold water

connection. The water supply must be provided at a

OM/SM-HY-12GF(CE) & HY-24GF(CE) 7

OM/SM-HY-12GF(CE) & HY-24GF(CE)

Drain Connection with Drain Box

rate of not less than

7.6 liters (tw

o

gallons) per minute.

Pressure must

be

2.0 to 4.0 Bar (30 to

60 PS

I) maximum.

Water qualit

y

minimums requir

e

totally dissolve

d

solids (T.D.S.) of

30

parts per million

maximum, and a

water pH of 7.0 or greater. If the available wate

r

supply fails to meet these requirements, water

treatmen

t equipment must be provided to ensure

steamer reliability and operating life

.

Install a WRAS approved double-check valve or an

equally effective backflow preventive device in the

incoming cold water line at the point of connnection(s)

to the steamer and in compliance with all local

plumbing codes. This installation must be per WRASIRN R160 Schedule 2-15(1). For units with the dual

water connection option, a double-check valve shall

be installed on each water line.

1.

5 Drain Connection

The unit must be leveled front to back or pitched

slightly to the rear (one to two degrees)

by

adjustment of the bullet feet on the cabinet base. All

units are shipped from the factory with a drain box

and vent pipe.

The drain box and vent pipe provide the necessary

air gap when properly installed. The illustrations

at

right shows proper installation of drain lines.

Leave

a air gap to any building drain. Do NOT

create any water traps in the drain line.

A trap could

cause pressure to build up in the cavity durin

g

steaming and cause the door gasket to leak

.

WARNING

VARIATION FROM THESE INSTRUCTIONS CAN

CREA

TE A HAZARD.

DO NOT USE PLASTIC PIPING — DRAIN MUST

WITHSTAND VERY HOT WATER.

1.

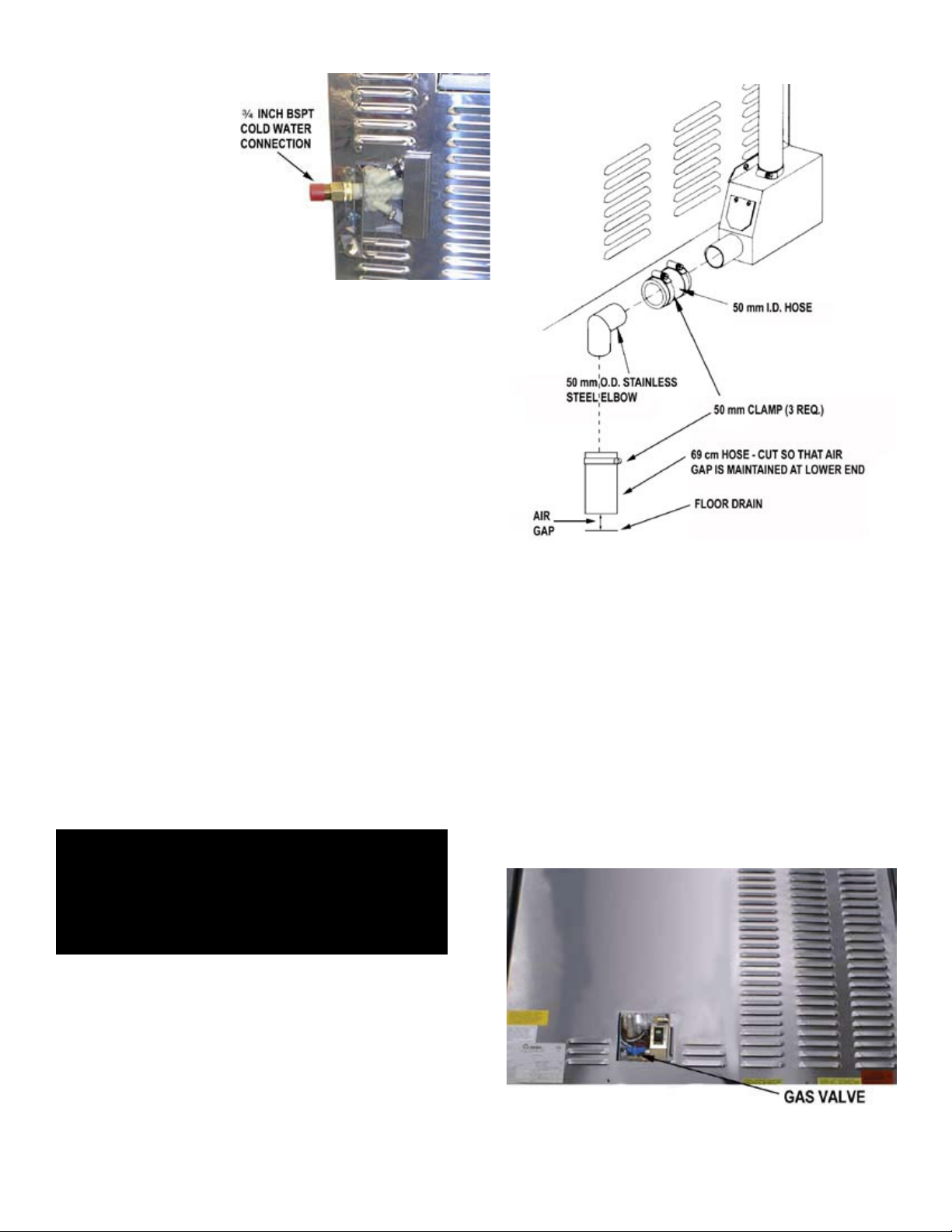

6 Initial Start-Up

After the HY-12GF(CE) Steamer has been installed, test

it to be sure that it is operating correctly.

1. Remove all literature and packing materials from

the interior and exterior of the unit.

2. Make sure the water supply line is open.

3. Make sure the gas supply line is open and that

the gas shut-off valve in the unit is in the OPEN

position. This valve is located behind an access

panel on the right side of the uni

t

4. Turn on electrical service to the unit. The unit

will not operate without electrical power. Do not

try to operate the un

it during a power failure.

5. The steamer will not operate until the pilot burner

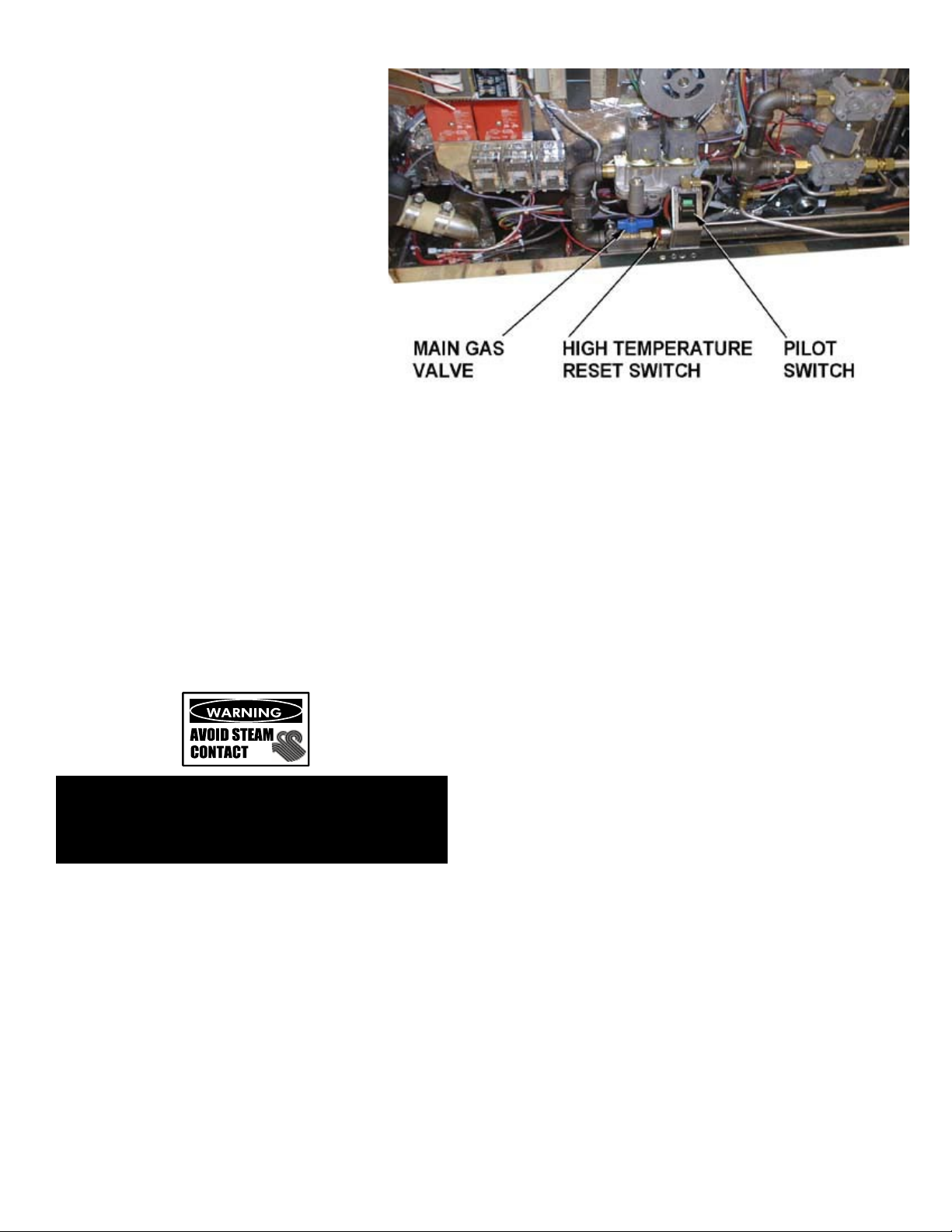

has been ignited. To light the pilot burner

,

ac

tivate the pilot switch next to the main gas

valve. (See photo below)

. When the ignition

sequence is successful a green light on the

electrical panel will glow.

8 OM/SM-HY-12GF(CE) & HY-24GF(CE)

OM/SM-HY-12GF(CE) & HY-24GF(CE)

6. The “trial for ignition” period is roughly

90 seconds. If the pilot burner does

not light within 90 seconds, the system

automatically stops gas flow to the pilot

burner and lights the Lockout neon on

the front control panel. If this happens,

turn off the pilot switch, push the Gas

Reset switch, and repeat the trial for

ignition. During the first start-up, the

pilot may require several trials for

ignition to bleed air from the piping.

Subsequent start-ups should only need

about five seconds to achieve pilot

ignition. NOTE:See Automatic Pilot

Operation at the end of this section.

7. Once the pilot flame has been

established (the green light on the

electrical panel is on), press the “ON”

switch for the desired steamer cavity.

The steam generator will fill with water.

NOTE:The door MUST be closed for the main

(high) heater to work.

8. When the steam generator has filled with water,

the main and low burners will automatically light.

The READY light should come on within 10

minutes, to show that the water has reached its

standby temperature. When the READY light is

on, the operator may take any of the following

steps:

a. Set the timer to the desired time for timed

steaming.

WARNING

WHEN YOU OPEN THE DOOR, STAY AWAY FROM

STEAM COMING OUT OF THE UNIT. THE STEAM

CAN CAUSE BURNS.

b. Turn the timer knob to the manual ON

position for continuous steam.

c. Let the unit wait at standby temperature. The

steam generator is equipped with a high-limit

thermostat which will trip if the liquid level

probe fails.

9. If this happens, the High Temperature neon on

the front control panel will glow and trip a reset

switch. The Reset Switch must be pressed to

re-start steam generation. This switch is located

next to the pilot switch (towards the rear of the

unit) and can be reached through the access

door on the right side of the unit.

10. To shut down the unit, turn the ON switch to the

OFF position. The steam generator will

automatically drain. You may also switch OFF

the pilot switch to conserve energy

11. If your steamer works as described, it is

functioning correctly and is ready for use.

Automatic Pilot Operation

Once the pilot burner has been lit, it essentially

functions as a standing pilot. When the pilot switch

is on, if the pilot is accidentally extinguished (by a

very strong gust of wind or the like), it will re-ignite

automatically. The unit will shut off completely for a

few seconds while the pilot is re-ignited. The unit will

then come back on and resume operation in the

mode and at the (running) timer value existing just

prior to shutdown. The pilot switch may be turned off

during “off hours” to conserve energy.

If the pilot burner ever fails to re-ignite automatically

within 90 seconds, after the unit has been running,

the Gas Lockout neon on the front control panel will

light. Wait five minutes and push the Gas Reset

switch to reignite the pilot. Should ignition problems

persist, contact your authorized Groen Service

Agency.

1.7 Setting the Gas Pressure

1. During commissioning, a gas pressure check is

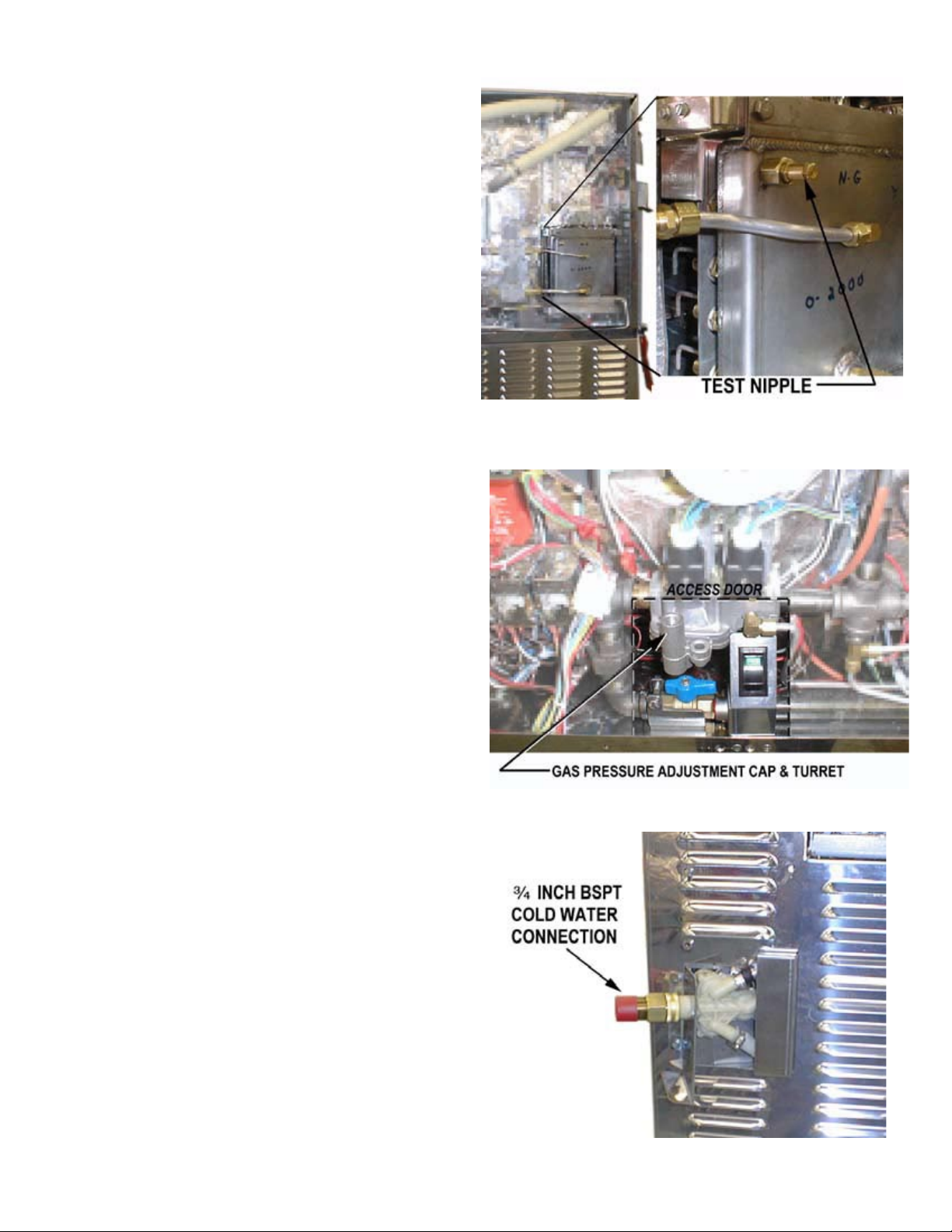

essential. Connect a suitable pressure gauge to

the gas manifold to perform this test. The

pressure gauge should be connected to the test

nipple (See photograph at right).

OM/SM-HY-12GF(CE) & HY-24GF(CE) 9

OM/SM-HY-12GF(CE) & HY-24GF(CE)

Adjust Gas Pressure by Turning the Screw inside the

Gas Pressure Adjustment Turret.

To test pressure, attach a pressure gauge to the test

nipple on the gas manifold.

2. Turn the main gas and electricity supply on.

3. Light the burners as described in Paragraph 1.6

above.

4. Manifold gas pressure should be as noted in

Section 1.3.1 of the manual. If adjustment is

necessary, follow steps below.

5. Remove the governor cap screw on the gas

control valve to gain access to the screw inside

the turret. (See photograph).

6. The governor is suitable for both natural and

propane gas.

7. Turn the screw inside the turret clockwise to

increase the pressure, anti-clockwise to reduce

it. Check the burner pressure again after 15

minutes operation, and adjust if necessary.

8. Disconnect the pressure gauge from the test

point. Reseal the test point and test for gas

soundness.

9. Replace governor cap screw, and replace

control box panel and lid.

NOTE

: For operation at high altitudes (1000 meters and

above) consult the Groen Food Service

Engineering Department.

1.8 Instructions to User

IMPORTANT: After installing and commissioning the

appliance, the User’s Instructions should be handed

to the user or purchaser. Ensure that the

instructions for lighting, turning off, correct use and

cleaning are properly understood. Emphasize the

location of the main gas isolating valve and

demonstrate the emergency shut down procedure.

10 OM/SM-HY-12GF(CE) & HY-24GF(CE)

OM/SM-HY-12GF(CE) & HY-24GF(CE)

2. Servicing and Conversion

CAUTION

BEFORE ATTEMPTING ANY SERVICING, ENSURE THAT THE ISOLATING COCK IS TURNED OFF AND CANNOT

BE INADVERTENTLY TURNED ON. CHECK THAT THE ELECTRICITY SUPPLY IS DISCONNECTED.

AFTER ANY MAINTENANCE TASK CHECK THE APPLIANCE TO ENSURE THAT IT PERFORMS CORRECTLY AND

CARRY OUT ANY NEEDED ADJUSTMENTS AS DETAILED IN SECTION 1.

AFTER CARRYING OUT ANY SERVICING OR EXCHANGE OF GAS CARRYING COMPONENTS ALWAYS CHECK FOR

GAS SOUNDNESS.

Conversion

To change from natural gas to propane gas or vice

versa, change the following:

• Burner injectors (high fire orifices)

• Rimner Tube Injector (low fire orifice)

• Pilot orifice

• Pressure setting

• Data Plate

The governor spring does not need to be changed —

only the pressure setting.

After Servicing

1. Test for gas soundness as specified in IGE/UP1

as appropriate after any gas connection has

been disturbed.

2. Check for correct operation (see Commissioning

of Appliance)

2.1 Assembly/Disassembly Procedures

GENERAL INFORMATION

The procedures which follow are based on having full

access to the steamer on all four sides. If the steamer is

installed between other appliances and there is not

enough room on the sides for access, it must be puled

out from its position. Exercise care when moving the

steamer to avoid stress or pull on electrical, water and

gas connections.

2.1.1 Right Side Panel (Louvered) — Removal

P/N 123196

1.

With a flat blade screwdriver, remove the two

10-32 screws on the lower edge of the panel.

The panel is retained to the steamer by an

interlocking guide track on the top edge and

three spring-like clips at the rear edge.

2. Once the screws are removed, SLIDE the panel

toward the front of the appliance with a lifting

motion. Do not attempt to pry the panel. Once

the panel is clear of the rear clips, it may be lifted

off of the top rack.

ASSEMBLY TIP: When replacing the panel, press the

rear edge inward so that all three clips are retained by

the back flange. Make sure that the holes in the panel

align with the two tapped holes in the steamer so that

replacing the screws will be easy and will not damage the

threads.

2.1.2 Left Side Cover — Removal

Left P/N 123197

Under normal conditions, the left side cover should never

have to be removed, since there are no operational or

replacement parts to be accessed. The single exception

occurs when the door has been reversed so that the

handle is on the left and the Door Interlock Switch

requires replacement. The door switches for both door

positions are installed at the factory, so there is no need

to have access to them if the door is to be reversed.

1. If the left side cover is to be removed because of

a faulty door switch, remove the right side panel

first. Using a 7mm nut driver and the flat blade

screwdriver, remove the retaining clip and the

two screws on the lower edge of the left side

cover. The assembly may then be slid forward.

Once clear of the retaining clip, it may be lifted

off.

ASSEMBLY TIP: When replacing the left cover

assembly, be sure that the retaining clip is replaced and

screwed down tightly.

2.1.3 Water Inlet Valve — Three Way

P/N 090827

1. Turn off power and water supply to the steamer.

2. Remove the water supply hose connection on

the rear of the steamer.

3. Remove the right side panel, as described in

Paragraph 2.1.1, above.

OM/SM-HY-12GF(CE) & HY-24GF(CE) 11

4. Remove the screws holding the water inlet valve

bracket, and pull the bracket with the valve a few

cm away from the body of the appliance.

5. The water inlet valve branches to three individual

solenoid-activated valves within its housing.

These are connected with the following three

sets of wires:

Steam Generator Fill . . . . . . . . Yellow & Orange

Steam Generator Clean . . . . . . . . Violet & Gray

Condensate Spray . . . . . . . . . . . . Green & Blue

6. Using a 7 mm nut driver, loosen the hose

clamps on the inlet valve.

7. Slide the hose clamps down the hose until

needed for reassembly. Loosen and remove the

hoses from the valve with a gentle rocking

motion.

8. Remove the bracket from the valve and lower

the valve

WITH THE WIRES STILL ATTACHED.

9. Carefully unplug the connectors one at a time

and attach to the new valve.

10. To install a new valve, reverse the procedures.

First install the six wires (three sets) as listed in

item 5, above. Make certain that the valve is

NOT installed upside down.

11. Attach the valve to its bracket with the two

screws and return it to its position.

12. Re-attach the hoses to the valve. Slide the

hoses all the way so that the end of the hose is

flush against the face of the valve.

IMPORTANT: Be sure the correct hose is connected to

the corresponding outlet.

13. Slide the clamps back into position around the

end of the hoses and tighten the clamps.

CAUTION

DO NOT OVER-TIGHTEN THE CLAMPS. OVERTIGHTENING CAN DAMAGE THE VALVE.

2.1.4 Adjustable Legs

P/N 042505

1. Each leg is provided with a screw-type support

post. These may be extended or retracted by

turning them with a wrench or Channel Lock. Be

sure that all four legs are in tight contact with the

floor for proper steamer support.

2. If damaged, the posts may be replaced by

tapping out the threaded fitting (on the opposite

side of the leg) which is friction-held in each leg.

The stainless steel leg and threaded fitting are a

single assembly.

2.1.5 Main Gas Valve and Gas Pressure

Adjustment P/N 122158

1. Disconnect power to the steamer.

2. Remove the right side panel, as described in

Paragraph 2.1.1, above.

3. Turn the manual gas valve to the closed

position. Disconnect the wire to the solenoids.

4. Note the color and position of the two connectors

for assembly.

5. Remove all aluminum tubing from the piping

assembly using an open-ended wrench. Be

careful not to move the aluminum tubing

excessively, or to bend it.

6.

With a pipe wrench or Channel Lock, open the

pipe union on the left side of the main gas valve

and the right side near the solenoid valves.

Remove the assembly.

7. From both sides of the main gas valve, using a

Channel Lock, turn to remove the nipples.

Support the valve with a vise or Channel

Lock/pipe wrench.

To Assemble:

8. Screw in and tighten the nipples into both sides

of the main gas valve using approved gas pipe

sealant.

12 OM/SM-HY-12GF(CE) & HY-24GF(CE)

9. Using a pipe wrench or Channel Lock attach the

union and tighten.

10. Attach all aluminum tubing and tighten with an

open-ended wrench.

11. Plug in the two connectors to the main gas valve:

2.1.6 Gas Solenoid Valve

P/N 122120

The gas solenoid valves must be removed as an

assembly along with the regulators, using the following

procedures:

1. Turn off the gas supply and power to the

steamer.

2. Disconnect wires from the main gas (Step 4,

Paragraph 2.1.5) and from the gas solenoid

valves.

3. From the front of the steamer, using a Channel

Lock wrench, loosen and disconnect the pipe

union which connects the assembly to the main

gas valve.

4. From the left side (or back) of the steamer, use

an open-ended wrench to loosen and disconnect

the compression fittings which connect the 9.5

mm aluminum tubing, from the inner and outer

manifolds.

5. From the left side (or back) of the steamer, use

an open ended wrench to loosen and disconnect

the compression fittings which connect the 9.5

mm aluminum tubing, from the inner and outer

manifolds.

6. The entire assembly of both regulators and the

gas solenoid valves for the upper and lower

steam generators may be removed as an

integrated unit.

7. Remove the failed gas solenoid valve.

To Reinstall:

8. Clean pipe threads and apply compound to all

joints being connected.

9. Install the new gas solenoid valve.

10. Slide the assembly into the steamer and align

the tee fitting with the pipe union. Align the gas

valves with their respective aluminum tubing.

11. Connect the pipe union using a Channel Lock

wrench.

12. Using an open-ended wrench, connect the 9.5

mm aluminum tubing to the inner and lower

steam generator manifold.

13. Using an open-ended wrench, connect the 12.7

mm aluminum tubing from the inner and outer

steam generator manifolds.

14. Reconnect the wires to the correct valve.

2.1.7 Igniter Module

P/N 154059

1. Shut off power and gas to the steamer.

2. Remove the cover to the electrical compartment.

OM/SM-HY-12GF(CE) & HY-24GF(CE) 13

OM/SM-HY-12GF(CE) & HY-24GF(CE)

3. The igniter module is located next to the motor.

4. Note or tag the wires for reinstallation before

unplugging. Carefully disconnect the seven

push terminals from the igniter module. be

careful not to pull the terminal by the wire. Use

needle nose plers to grip onto the terminal itself.

5. Use a nut driver (preferably with a magnetic tip)

to remove the two 6-32 screws.

6.

To Install:

7.

8. When all screws are in place, tighten them

one at a time.

9. Plug in each of the six terminals. Double check

to ensure that they are correct.

2.1.8 Pilot Switch (SW3) Removal

P/N 087951

1. Shut off the power supply. Disconnect the four

color coded wires from the switch assembly.

Remove the two retaining screws which attach

the switch bracket to the lower frame rail of the

steamer.

2. The switch snaps into the bracket where it is

retained by plastic tabs on the top and bottom.

To remove the switch from the bracket, press in

on both tabs at the same time and slide the

switch out of the bracket hole.

To replace the switch

3. Insert the new switch into the bracket hole until

its tabs clear the hole and snap into position.

4. Reattach the wires to the switch.

5. Replace the switch bracket with two screws.

2.1.9 Pilot Burner Replacement/Current Check/

Adjustment - Pilot Flame Sensor

Replacement

P/N 102258 (Natural) P/N 106610 (Propane)

P/N 003328 Flame Sensor

1. Turn off the main gas and power supply.

2. Remove the front cover.

3. Remove the right side panel as described in

Paragraph 2.1.1.

4. Turn the manual gas valve to the OFF position.

Place pilot switch SW3 in the OFF position.

5. Disconnect the pilot line from the pilot burner.

6. Disconnect the “spark” lead from the pilot

burner.

7. Remove the flame sensor from the flame sensor

bracket.

8. Remove the pilot burner.

Installation:

9. Connect the pilot line to the pilot burner.

10. Connect the “spark” lead to the pilot burner. Be

sure to route the lead around the outside of the

gas lines.

11. Replace the flame sensor on the flame sensor

bracket.

12. Apply anti-seize lubricant to mounting head

screw threads. Install the pilot burner and flame

sensor assembly, and tighten the screws.

NOTE

: Route the “spark” lead and flame sensor wire

away from the manifold to prevent improper

operation.

13. Turn manual gas valve to the ON position.

14. Connect unit to the branch circuit and turn on the

main gas supply.

15. Place pilot switch SW3 in the ON position.

Check for gas soundness.

Remove the igniter module.

Position the new igniter against the back wall

or mounting bracket of the electrical compartment

Place a hex head screw in the nut driver and start

each of the two screws.

14 OM/SM-HY-12GF(CE) & HY-24GF(CE)

Pilot Flame Current Check

WARNING

WHEN STEAMER POWER IS TURNED ON, THERE IS

HIGH VOLTAGE PRESENT IN THE ELECTRICAL

COMPONENTS COMPARTMENT. BE SURE THAT

STEAMER IS DISCONNECTED FROM BRANCH

CIRCUIT BEFORE PERFORMING ANY REPAIRS.

1. Turn off steamer power.

2. Disconnect the ground (green) wire from the

igniter module.

3. Connect a DC micrometer between the igniter

ground terminal and the disconnected green

wire.

WARNING

DO NOT ATTEMPT TO LIGHT THE PILOT BURNER

WITH A FLAME.

4. Ignite the pilot. The micrometer should read 3

microamps minimum.

• If current reading is correct, replace the

igniter module (see 2. 1. 7).

* If current reading is below 3 microamps,

continually check the Flame Rectification

Circuit (large orange wire, spark electrode,

pilot burner hood, and ground connections).

If necessary, tighten ground connections

and/or replace defective component(s).

5. Check for moisture around the pilot burner, and

for corrosion on the electrode and the pilot

burner hood. If necessary, remove moisture with

a dry, clean cloth. If hood and/or electrode are

excessively corroded, replace pilot burner

assembly.

2.1.10 Steam Generator Probes (High and Low

Water) P/N 070178

NOTE

: There are two probes for each steam generator.

1. Shut off power to the steamer.

2.

With an 8 mm nut driver LOOSEN, but do not

remove the nuts holding the wire(s) on the probe

terminal(s).

3. The wires are connected to wire fork terminals.

These will "snap" on and off the terminal post.

Unsnap them by gently pulling on the terminal.

4. Using a 21mm open ended wrench, turn the

probe counter-clockwise to remove. Clean or

replace water level probes.

To Install:

5. Apply high temperature pipe compound to the

probe and screw it in by hand. Using a 21mm

open ended wrench, tighten the probe into the

fitting.

6. Replace the wire(s) to the probes by snapping

the fork terminals around the terminal post.

Using an 8 mm nut driver, tighten the terminal

nut.

NOTE

: If two probes are to be replaced, either replace

them one at a time or note the color of the wires

attached to the probes. Do not mix them up.

2.1.11 Water Level Control Board

P/N 106258

1. Shut off electrical power to the steamer.

2. Remove the side panel screws and slide panel

away from steamer.

3. Remove two kep nuts and star washers securing

main control board mounting bracket. Lay main

control board to the side.

4. Unplug the three terminals on the side of the

water level control board: "C", "Low" and "High".

Note wire colors and terminal positions.

5. Remove four nuts holding the board to the

steamer frame and remove board.

6. Unplug the multi-conductor plug on the opposite

side of the board.

To Install:

7. Plug in the multi-conductor plug on the bottom of

the board. Make sure the plug is firmly and

properly seated.

8. Place the water level control board over the

mounting studs and fasten with four nuts.

9. Plug in the three terminals on the side of the

board, making sure to plug the low wire into the

OM/SM-HY-12GF(CE) & HY-24GF(CE) 15

OM/SM-HY-12GF(CE) & HY-24GF(CE)

low terminal, the high wire into the high

terminal and the "

C" into the "C" terminal.

10. Install two star washers and kep nuts to secure

main control board mounting bracket.

11. Install the side cover and fasten with screws.

2.1.12 Steam Generator Gas Jet Manifold

P/N 106224

1. Shut-off power and gas to the steamer.

2. Remove the right side panel.

3. Turn manual gas valve to the closed position.

4. Remove the three aluminum tubes connected to

the manifold. Disconnect the tubes using an

open ended wrench.

5. Remove the two screws from the pilot mounting

bracket. Remove pilot from the gas manifold.

6. Using a nutrunner or socket wrench remove the

two top and two bottom bolts which hold the

manifold to the steam generator manifold

mounting bracket.

7. Remove the burner manifold from the appliance.

8. Remove the flame retention springs and

injectors as required.

To Reassemble

:

9. Replace the injectors and retention springs.

Ensure a suitable gas sealant is used on the

threads of the injectors to ensure a gas tight

seal.

10. Fit the burner manifold to the steam generator

manifold mounting bracket.

11. Reinstall and tighten the aluminum tubes to the

burner manifold.

NOTE

: Ensure all gas connections are sound before

continuing.

2.1.13 Steam Generator Drain Valve

P/N 071234

1. Turn off power and allow steamer to drain

completely. Remove back cover panel and

loosen clamps or spring.

2. Using a 7mm nut driver or spring clamp pliers,

disconnect both ends of the drain hose from the

spray box and the steam generator.

3. Unplug and disconnect the valve electrical wires.

Remove the 10-32 kep nuts holding the valve to

the plate. Remove the valve from the threaded

studs. Then remove silicone hose from the

valve.

4. Inspect the silicone hose for any damage or lime

buildup. Clean or replace hose if required.

5. Attach new drain valve to valve bracket if bracket

applicable. Pull silicone hose through drain valve

and loosely install hose clamps over both ends

of the hose. Be sure that the silicone hose is

properly aligned and does not have any kinks,

bends or twists in it.

6. Position the valve over the valve mounting

threaded studs, and connect both ends of the

hose to drain box or drain tube and steam

generator.

7. Position the clamps so that the worm screw may

be easily tightened. Using a 7mm nut driver,

tighten both hose clamps. Be careful not to overtighten clamps since they could cut the hose. If

using spring clamps, use pliers to position them.

8. Install and tighten the valve mounting 10-32 cap

nuts.

9. Plug electrical leads into wiring harness.

Test: Operate the steamer and allow steam generator

to fill. Check for leaks and observe if the drain

valve fully closes. Turn off the steamer and

make sure that the drain valve opens and the

steam generator drains. Install back cover.

2.1.14 Drain Box Spray Nozzle

P/N 106445

Disassemble

1. Turn off power to the steamer. Turn off the water

supply to the steamer. Remove the water supply

hose connection on the rear of the steamer

2. Remove the two screws on the right side of the

water inlet panel. Pull the water inlet valve

mounting plate away from the steamer and slide

it free.

3. Loosen the hose clamp nearest the end of the

black hose. Pull the hose off from valve nipple.

Loading...

Loading...