Groen HY-12E Installation Manual

IMPORTANT INFORMATION

IMPORTANT INFORMATION IMPORTANT INFORMATION

IMPORTANT INFORMATION KEEP FOR OPERATOR

KEEP FOR OPERATOR KEEP FOR OPERATOR

KEEP FOR OPERATOR IMPORTANT INFORMATION

IMPORTANT INFORMATION IMPORTANT INFORMATION

IMPORTANT INFORMATION

Model HY-24EF (New Model)

OPERATOR MANUAL OM-HY-12E/24E

Part Number 148667 DOMESTIC

Model: HY-12E and HY-24E

HyCapacity HyPerSteam™

Atmospheric Convection

Steamer

Self-Contained

Electric Heated

Model HY-12E

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE. READ,

UNDERSTAND AND FOLLOW THE INSTRUCTIONS AND WARNINGS

CONTAINED IN THIS MANUAL.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE

.

OPERATOR MANUAL

Part Number 148667 Rev. D

OM-HY-12E/24E

IMPORTANT - READ FIRST - IMPORTANT

WARNING: THE UNIT MUST BE INSTALLED BY PERSONNEL QUALIFIED TO WORK WITH ELECTRICITY AND

PLUMBING. IMPROPER INSTALLATION CAN CAUSE INJURY TO PERSONNEL AND/OR DAMAGE

TO THE EQUIPMENT. THE UNIT MUST BE INSTALLED IN ACCORDANCE WITH APPLICABLE

CODES.

CAUTION: DO NOT INSTALL THE UNIT IN ANY WAY WHICH WILL BLOCK THE RIGHT SIDE VENTS, OR

WITHIN 12 INCHES OF A HEAT SOURCE SUCH AS A BRAISING PAN, DEEP FRYER, CHAR

BROILER OR KETTLE.

NOTICE: Level the unit front to back, or pitch it slightly to the rear, to avoid drainage problems.

CAUTION: DO NOT LOCATE THE CABINET DIRECTLY OVER A FLOOR DRAIN OR FLOOR SINK. HUMIDITY

OR WATER FROM A DRAIN WILL DAMAGE ELECTRICAL PARTS OF A UNIT.

WARNING: TO AVOID DAMAGE OR INJURY, FOLLOW THE WIRING DIAGRAM EXACTLY WHEN CONNECTING

A UNIT.

WARNING: DO NOT CONNECT THE DRAIN DIRECTLY TO A BUILDING DRAIN.

CAUTION: DO NOT USE PLASTIC PIPE. DRAIN MUST BE RATED FOR BOILING WATER.

WARNING: BLOCKING THE STEAM GENERATOR OR CAVITY DRAIN SCREEN MAY BE HAZARDOUS.

IMPORTANT: Improper drain connection will void warranty.

WARNING: WHEN YOU OPEN THE DOOR, STAY AWAY FROM STEAM COMING OUT OF THE UNIT. STEAM

CAN CAUSE BURNS.

WARNING: BEFORE CLEANING THE OUTSIDE OF THE STEAMER, DISCONNECT THE ELECTRIC POWER

SUPPLY. KEEP WATER AND CLEANING SOLUTIONS OUT OF CONTROLS AND ELECTRICAL

COMPONENTS. NEVER HOSE OR STEAM CLEAN ANY PART OF THE UNIT.

WARNING: ALLOW COOKING CHAMBERS TO COOL BEFORE CLEANING.

WARNING: CAREFULLY READ THE WARNINGS AND FOLLOW THE DIRECTIONS ON THE LABEL OF EACH

CLEANING AGENT. USE SAFETY GLASSES AND RUBBER GLOVES AS RECOMMENDED BY

DELIMING AGENT MANUFACTURER.

WARNING: DO NOT MIX DE-LIMING AGENTS (ACID) AND DE-GREASERS (ALKALI) IN THE STEAM

GENERATOR OR ON THE COOKING CHAMBER WALLS.

WARNING: DO NOT PUT HANDS OR TOOLS INTO THE COOKING CHAMBER UNTIL THE FAN HAS STOPPED

TURNING.

WARNING: DO NOT OPERATE THE UNIT UNLESS THE REMOVABLE RIGHT SIDE PANELS HAVE BEEN

RETURNED TO THEIR PROPER LOCATIONS.

NOTICE: Do not use a cleaning or de-liming agent that contains any sulfamic acid or any chloride, including

hydrochloric acid. If the chloride content of any product is unclear, consult the manufacturer.

WARNING: USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY GROEN OR THEIR

AUTHORIZED DISTRIBUTOR VOIDS ALL WARRANTIES AND CAN CAUSE BODILY INJURY TO THE

OPERATOR AND DAMAGE THE EQUIPMENT. SERVICE PERFORMED BY OTHER THAN FACTORYAUTHORIZED PERSONNEL WILL VOID ALL WARRANTIES.

WARNING: HIGH VOLTAGE EXISTS INSIDE CONTROL COMPARTMENTS. DISCONNECT FROM BRANCH

BEFORE SERVICING. FAILURE TO DO SO CAN RESULT IN SERIOUS INJURY OR DEATH.

OM-HY-12E/24E

2

OM-HY-12E/24E

Table of Contents

IMPORTANT OPERATOR SAFETY WARNINGS ....................................2

EQUIPMENT DESCRIPTION ....................................................4

WATER CONDITIONING/REQUIREMENTS ........................................4

INSTALLATION AND START-UP INSTRUCTIONS ...................................6

OPERATION ...............................................................10

CLEANING .................................................................12

MAINTENANCE .............................................................14

TROUBLESHOOTING ........................................................15

PARTS LIST

................................................................

WIRING DIAGRAM ..........................................................

SERVICE LOG ..............................................................

16

18

19

REFERENCES ..............................................................

WARRANTY PROTECTION ...................................................

20

21

OM-HY-12E/24E

3

3

OM-HY-12E/24E

The HY-24EF has two independent

cavities, each with its own steam

generator (New model shown).

Equipment Description

Your Groen HY-12E HyCapacity HyPerSteam is

designed to give years of service. It consists of a

stainless steel cavity (cooking chamber) which is served

by an electrically-heated atmospheric steam generator.

The HY-24EF has two cavities and two generators.

Two powerful blowers circulate the steam in each cavity

to increase heating efficiency.

A dual position pan rack on the left side of the cavity

can be quickly changed to allow for the use of either 12"

x 20" steamer pans, or 18" x 26" bake pans. The

following table lists pan capacities:

Pan Size/Type

Number of Pans

HY-12E HY-24EF

12 x 20 x 2 ” (steamer) 12 24

12 x 20 x 4" (steamer) 8 16

13 x 18" (half-size bake) 24 48

18 x 26" (bake) 12 24

A stainless steel cabinet encases the cavity, steam

generator and a control compartment which houses

electrical components. Access to the control

compartment is gained by removing the right side

louvered panel. Door hinges are reversible so that the

door may be opened to the left or right. Operating

controls are on the front panel.

Newer model HY-12E and HY-24EF steamers

(manufactured since November 1999) are equipped

with fully electronic controls and a button-activated preprogrammed CLEAN cycle.

These units are readily identified by their unique control

panels. Touch pad controls, and the distinctive symbol

for steam is integrated into the panel design. The new

models also have fewer panel louvers on the right side

and rear.

The drain system includes a spray condenser, which

helps keep steam from coming out of the unit drain or

entering the building’s drain.

Water Conditioning

It is essential to supply the steam generator with water

that will not form scale. Even though the steam

generator is engineered to minimize scale formation,

scale development depends on the hardness of your

water and the number of hours the equipment

operates.

In some areas of the country, water is low enough in

minerals to avoid scale formation. But most water

supplies are full of minerals which form scale. It is this

scale which could lead to an early component failure.

Your water utility or treatment specialists can test and

tell you about the minerals in your water. The water

going to the steam generator should have between 10

and 30 parts per million (ppm) total dissolved solids

(TDS) and should have a pH (acidity rating) of 7.0 or

higher.

Please follow these simple precautions:

1. The best way to prevent scale is to use a Groen

PureSteem™ Water Treatment System which has

been specifically designed for Groen steamers and

combination ovens. Do not rely on unproven

water treatment systems sold for scale

prevention and removal. They are not

specifically designed to work with Groen

steamers and combination ovens.

OM-HY-12E/24E

4

OM-HY-12E/24E

The optional separate water intake can significantly reduce treated water

volume requirements.

2. A well-maintained water treatment system and a

regular cartridge replacement schedule is

essential.

3. Using a Groen PureSteem™ Water Treatment

System will provide longer steam generator/boiler

life, higher steam capacity, and reduce

maintenance requirements.

4. If you notice a slowdown in steam production or an

increase in deliming, have the steamer checked for

scale build-up. This could be an indication that the

water treatment cartridges need replacing. Heavy

scale reduces the unit’s ability to boil water, and

can even cause component failure.

.

OM-HY-12E/24E

5

5

OM-HY-12E/24E

Installation and Start-Up

WARNING

THE UNIT MUST BE INSTALLED BY PERSONNEL WHO ARE QUALIFIED TO WORK WITH

ELECTRICITY AND PLUMBING. IMPROPER INSTALLATION CAN CAUSE INJURY TO

PERSONNEL AND/OR DAMAGE TO THE EQUIPMENT. THE UNIT MUST BE INSTALLED IN

ACCORDANCE WITH APPLICABLE CODES.

WARNING

TO AVOID DAMAGE OR INJURY, FOLLOW THE ELECTRICAL SCHEMATIC EXACTLY

WHEN CONNECTING THE UNIT.

CAUTION

DO NOT INSTALL WITH THE RIGHT SIDE VENTS BLOCKED OR WITHIN 12 INCHES OF A

HEAT SOURCE (BRAISING PAN, DEEP FRYER, CHAR BROILER, OR KETTLE). TO AVOID

DRAINAGE PROBLEMS, LEVEL THE UNIT FRONT TO BACK.

A. Installation

OM-HY-12E/24E

6

OM-HY-12E/24E

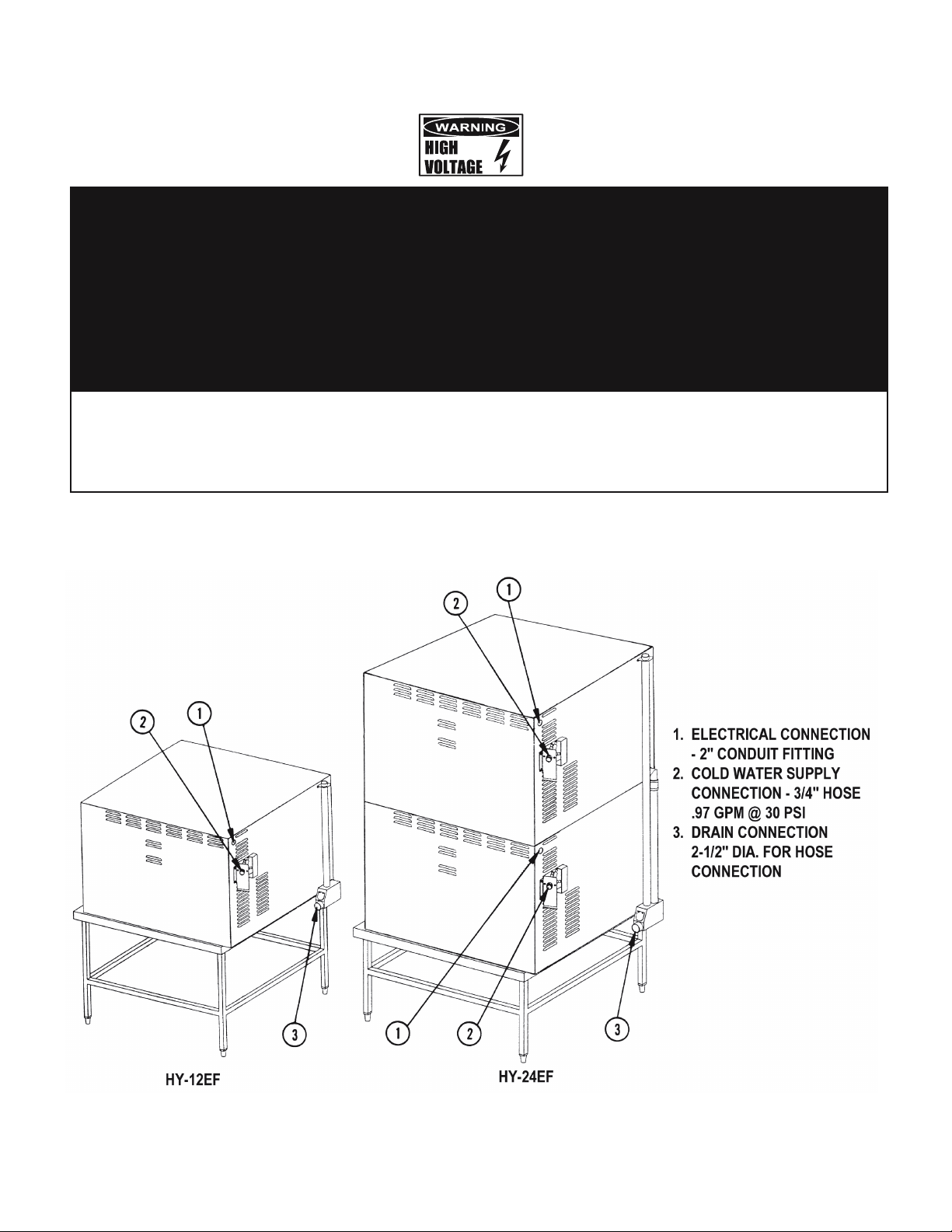

1. Electrical Supply Connection

a. Panel Removal

Open the wiring and control panel by removing the

three screws on the right side panel and sliding the

panel forward. Set the panel aside.

b. Supply Voltage

The unit must be operated at the rated nameplate

voltage, plus or minus 10 percent.

c. Terminal Block

The terminal block for incoming power is located at

the back of the control compartment.

The ground terminal is located in the wiring

compartment above the terminal block.

The unit must have a separate ground wire for

safe operation. This wire must be at least

8 AWG for 208/240V, or 10 AWG for 480V.

d. Supply Wire

To determine the wire you need for the power

supply, find the operating voltage and phase on the

unit data plate. Refer to the table below or to the

label on the unit’s back for correct wire size and

insulation temperature rating. The “Electrical

Supply Connection” label inside the unit gives

directions for proper connection of the terminal

block jumpers.

The specified wire must be used in order to meet

Underwriters Laboratories and National Electric

Code requirements.

The knockout hole is sized for a two inch conduit

fitting.

e. Branch Circuit Protection

Groen strongly recommends that the HY-12E

Steamer or each cavity of the HY-24EF have its

own branch circuit protection. Each currentcarrying conductor must have overcurrent

protection. Refer to the label for proper wire size

and type. Watertight connections to the unit are

required.

2. Water Connection(s):

Install a check valve to prevent back flow in the

incoming cold water line, as required by local plumbing

codes. Water pressure in the line should be between

30 and 60 PSIG (210 and 420 kPa). If pressure is

above 60 PSIG, a pressure regulator will be needed. A

inc h R connector (garden hose type) is used to

attach the water supply to the water inlet valve. The

minimum water feed line diameter is inc h (13mm).

Use a washer in the hose connection. Do not allow the

connection to leak, no matter how slow it may be.

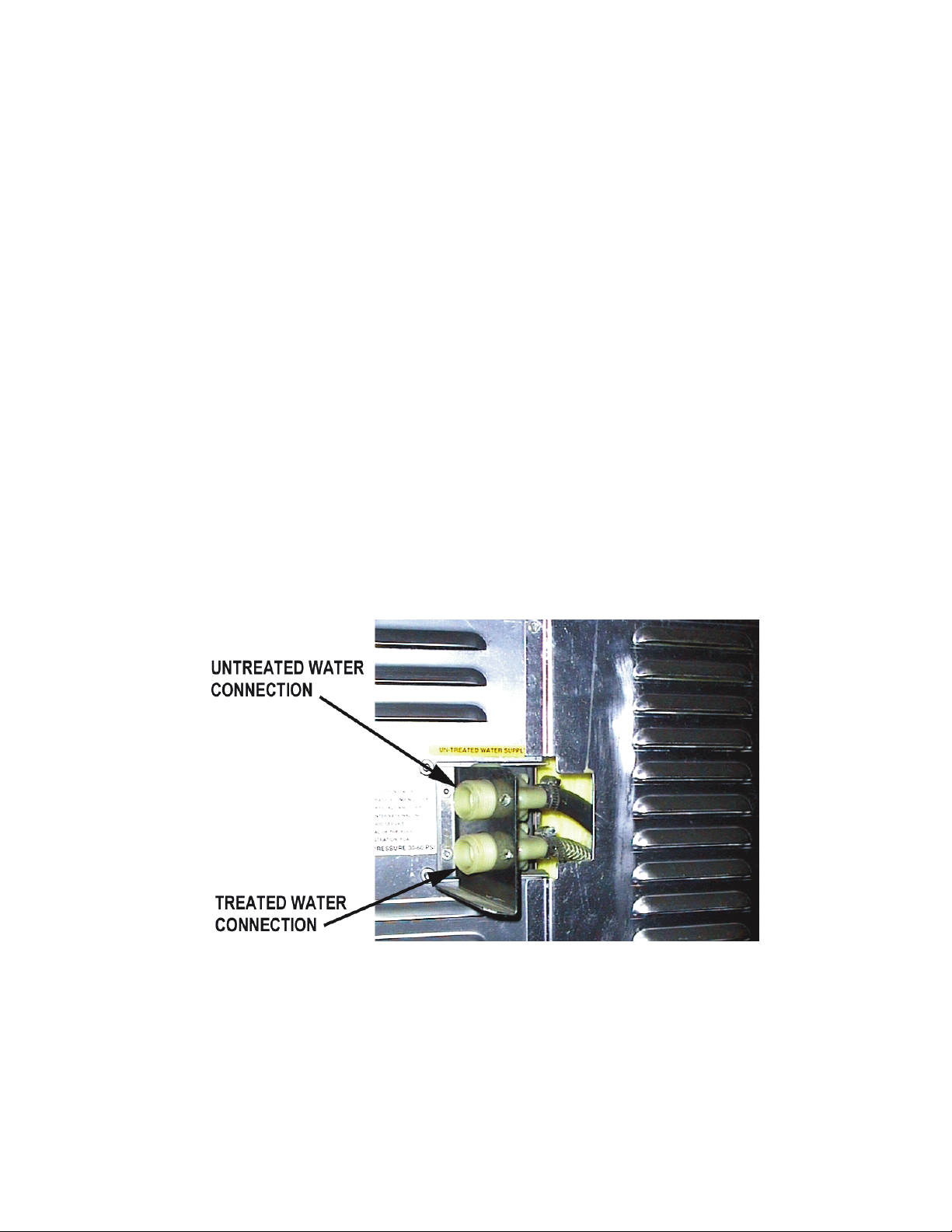

If you have the twin water connection option, put

the treated water (softened) to the bottom intake

(facing the rear of the unit), and untreated water to

the top. Connections for both are made as

described above.

Voltage

Wiring - Insulation Rating

Amperes Maximum KW

THWN (70ºC) THWN (90ºC)

208 Volt, 3 Phase

Not Approved 1/0 AWG 92 32.5

240 Volt, 3 Phase

Not Approved 1 AWG 80 32.5

480 Volt, 3 Phase

1 AWG 6 AWG 40 32.5

OM-HY-12E/24E

7

7

OM-HY-12E/24E

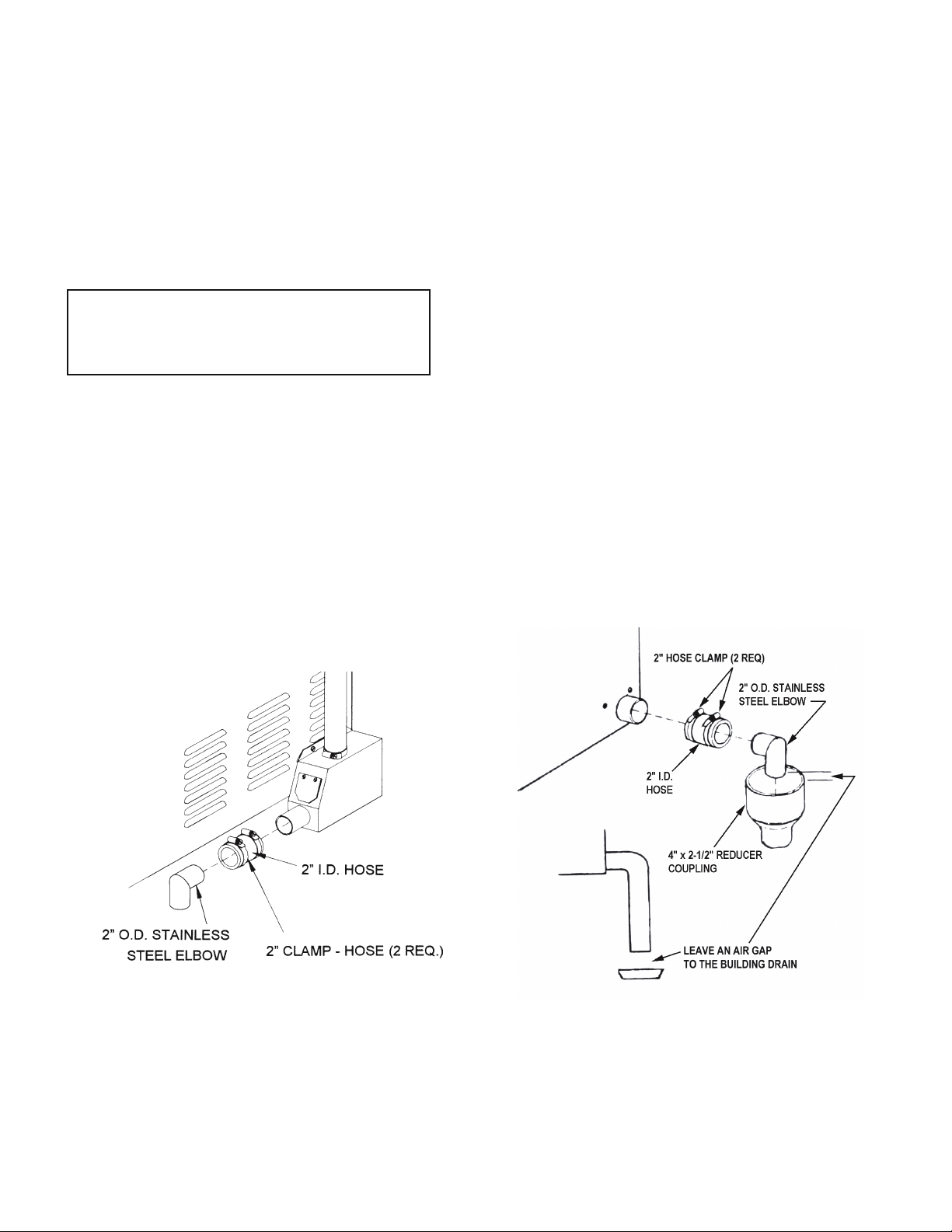

Installation of drain line without drain box

(tabletop models only).

Drain Connection with Drain Box (All units are

shipped from the factory with a drain box). Old

model shown.

3. Drain Connection

The HY-12E/24E Steamer must be leveled front to

back or pitched slightly to the rear by adjustment of

the bullet feet on the cabinet base.

All units are shipped from the factory with a drain

box and vent pipe. The drain box and vent pipe

provide the necessary air gap when properly

installed. The illustrations below show proper

installation of drain lines from the drain box, and for

tabletop installation, without a drain box.

CAUTION

DO NOT CONNECT THE HOSE DIRECTLY TO

A BUILDING DRAIN. BLOCKING THE DRAIN

COULD BE DANGEROUS.

Do not create any water traps in the drain line. A

trap would cause pressure to build up inside the

cavity during steaming and make the door gasket

leak.

NOTE: Improper drain connection will void the

warranty.

INSTALLATION OPTION ONE: From stainless steel

elbow (P/N 092273) to nearby floor drain, use Radiator

Hose (rated at least 212ºF) and one additional hose

clamp (P/N 013616).

INSTALLATION OPTION TWO: Using the hose (P/N

080688) and two hose clamps (P/N 013616), connect

two inch copper tube to floor drain. NOTE: Drain lines

must be pitched downward at approximately inc h per

foot. No water traps should be allowed in the drain line.

IMPORTANT: Leave two inches free air gap to

building drain.

OM-HY-12E/24E

8

Loading...

Loading...