Groen CC10-G, C/2-20G, CONVECTION COMBO 2CC10-G, CONVECTION COMBO 2C/2-20G, CONVECTION COMBO CC10-G Operator's Manual

...Page 1

• •

• •IMPORTANT INFORMATION

IMPORTANT INFORMATION • •

• •• •

IMPORTANT INFORMATION IMPORTANT INFORMATION

• • KEEP FOR OPERATOR

KEEP FOR OPERATOR • •

• •• •

KEEP FOR OPERATOR KEEP FOR OPERATOR

• • IMPORTANT INFORMATION

IMPORTANT INFORMATION • •

• •• •

IMPORTANT INFORMATION IMPORTANT INFORMATION

• •

• •• •

OPERATOR MANUAL OM-CC-G and C/2-G

Part Number 121086 DOMESTIC

MODEL: CC10-G, (2)CC10-G

C/2-20G, (2)C/2-20G

CONVECTION COMBO™

Combination Steamer-Oven

C/2-20GF with

optional pan racks

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE. READ, UNDERSTAND AND

FOLLOW THE INSTRUCTIONS AND WARNINGS CONTAINED IN THIS MANUAL.

(2)CC10-GF

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE .

POST IN A PROMINENT LOCATION

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT USER SMELLS GAS.

THIS INFORMATION SHALL BE OBTAINED BY CONSULTING YOUR LOCAL

GAS SUPPLIER. AS A MINIMUM, TURN OFF THE GAS AND CALL YOUR

GAS COMPANY AND YOUR AUTHORIZED SERVICE AGENT. EVACUATE

ALL PERSONNEL FROM THE AREA.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION,

SERVICE OR MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY

OR DEATH. READ THE INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

Information contained in this document is

known to be current and accurate at the time

of printing/creation. Unified Brands recommends referencing our product line websites,

unifiedbrands.net, for the most updated

product information and specifications.

Page 2

OM-CC-G and C/2-G

IMPORTANT — READ FIRST — IMPORTANT

WARNING: THE UNIT MUST BE INSTALLED BY PERSONNEL QUALIFIED TO WORK WITH GAS,

ELECTRICITY AND PLUMBING. IMPROPER INSTALLATION CAN CAUSE INJURY TO

PERSONNEL AND/OR DAMAGE TO THE EQUIPMENT. THE UNIT MUST BE INSTALLED IN

ACCORDANCE WITH APPLICABLE CODES.

CAUTION: SHIPPING STRAPS ARE UNDER TENSION AND CAN SNAP BACK WHEN CUT.

CAUTION: DO NOT INSTALL THE UNIT IN ANY WAY WHICH WILL BLOCK THE RIGHT SIDE VENTS,

OR WITHIN 12 INCHES OF A HEAT SOURCE SUCH AS A BRAISING PAN, FRYER, CHAR

BROILER OR KETTLE.

CAUTION: LEVEL THE UNIT FRONT TO BACK, OR PITCH IT SLIGHTLY TO THE REAR, TO AVOID

DRAINAGE PROBLEMS.

WARNING: TO AVOID DAMAGE OR INJURY, FOLLOW THE WIRING DIAGRAM EXACTLY WHEN

CONNECTING A UNIT.

CAUTION: DO NOT USE PLASTIC PIPE. DRAIN MUST BE RATED FOR BOILING WATER.

WARNING: DO NOT CONNECT THE DRAIN DIRECTLY TO A BUILDING DRAIN.

WARNING: BLOCKING THE DRAIN IS HAZARDOUS.

IMPORTANT: Improper drain connection will void warranty.

IMPORTANT: Do not allow any water traps in the line. A trap can cause pressure to build up inside the

cavity during steaming, which will make the door gasket leak.

WARNING: WHEN YOU OPEN THE DOOR, STAY AWAY FROM STEAM COMING OUT OF THE UNIT.

STEAM CAN CAUSE BURNS.

WARNING: BEFORE CLEANING THE OUTSIDE OF THE OVEN, DISCONNECT THE ELECTRIC POWER

SUPPLY. KEEP WATER AND CLEANING SOLUTIONS OUT OF CONTROLS AND

ELECTRICAL COMPONENTS. NEVER HOSE OR STEAM CLEAN ANY PART OF THE UNIT.

WARNING: ALLOW COOKING CHAMBER TO COOL BEFORE CLEANING.

WARNING: CAREFULLY READ THE WARNINGS AND FOLLOW THE DIRECTIONS ON THE LABEL OF

EACH CLEANING AGENT.

RECOMMENDED BY DELIMING AGENT MANUFACTURER.

WARNING: DO NOT MIX DE-LIMING AGENTS (ACID) AND DE-GREASERS (ALKALI).

WARNING: DO NOT PUT HANDS OR TOOLS INTO THE COOKING CHAMBER UNTIL THE FAN HAS

STOPPED TURNING.

WARNING: DO NOT OPERATE THE UNIT UNLESS THE REMOVABLE RIGHT SIDE PANEL HAS BEEN

RETURNED TO ITS PROPER LOCATION.

NOTICE: DO NOT USE A CLEANING OR DE-LIMING AGENT THAT CONTAINS ANY SULFAMIC ACID

OR ANY CHLORIDE, INCLUDING HYDROCHLORIC ACID. IF THE CHLORIDE CONTENT OF

ANY PRODUCT IS UNCLEAR, CONSULT THE DISTRIBUTOR OR MANUFACTURER.

NOTICE: DO NOT USE ANY DE-GREASER THAT CONTAINS POTASSIUM HYDROXIDE OR SODIUM

HYDROXIDE OR THAT IS ALKALINE.

WARNING: USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY GROEN OR

THEIR AUTHORIZED DISTRIBUTOR VOIDS ALL WARRANTIES AND CAN RESULT IN

BODILY INJURY TO THE OPERATOR AND DAMAGE THE EQUIPMENT. SERVICE BY

OTHER THAN FACTORY-AUTHORIZED PERSONNEL WILL VOID ALL WARRANTIES.

WARNING: HIGH VOLTAGE EXISTS INSIDE CONTROL COMPARTMENTS. DISCONNECT FROM

BRANCH BEFORE SERVICING. FAILURE TO DO SO CAN RESULT IN SERIOUS INJURY

OR DEATH.

USE SAFETY GLASSES AND RUBBER GLOVES AS

2

Page 3

OM-CC-G and C/2-G

Table of Contents

IMPORTANT OPERATOR SAFETY WARNINGS .................................. 2

EQUIPMENT DESCRIPTION ................................................. 4

INSPECTION AND UNPACKING .............................................. 5

WATER QUALITY AND TREATMENT .......................................... 6

INSTALLATION ............................................................7

INITIAL START-UP ........................................................ 11

OPERATING INSTRUCTIONS ............................................... 13

CLEANING ............................................................... 19

MAINTENANCE .......................................................... 23

TROUBLESHOOTING ...................................................... 23

DIAGRAMS AND SCHEMATICS .............................................. 25

REFERENCES............................................................ 26

SERVICE LOG ............................................................ 27

3

Page 4

OM-CC-G and C/2-G

Equipment Description

Your Groen Convection Combo™ has a stainless

steel cooking chamber, an air heating compartment

with heat exchange tubes and fan, a steam

generator, and a control compartment which houses

electrical components.

All major components of the Convection Combo™

are encased in a 16 gauge stainless steel cabinet.

The cabinet is lined with 1½ to 2 inches (4 to 5 cm)

thick glass fiber insulation. A removable drip tray is

located beneath the door.

The door is reversible so that it may open from the

left or right. Operator controls are located on the right

front of the unit, except for the pilot control switch

and manual gas shut-off valve, which are behind the

sliding access door on the right side of the unit.

Standard controls let you to operate the Convection

Combo in any one of three cooking modes:

1. As a convection oven

2. As a self-contained pressureless steamer

3. As a combination oven-steamer

Models CC10-G and C/2-20G differ in cooking

chamber size and pan capacity:

CC10-G: 4 steam table pans (12x20x2½”), or

7 half-size (13x18") US bake pans

C/2-20G: 10 steam table pans (12x20x2½”), or

9 full-size (18x26") US bake pans

Units are supplied on a stainless steel stand. The

smaller Convection Combo™ is available as the

single CC10-GF or the double stacked (2) CC10-GF.

The larger unit is available as the single C/2-20GF or

the double-stacked (2)C/2-20GF.

Controls and monitoring displays for cooking times,

operating mode and temperature selection are on

the control panel. The upper portion of the panel has

a digital cooking time readout and touch pads for

setting cook times. Below the timer section are lights

which indicate the status of the unit and touch pads

to select the mode of operation and to switch on

power.

this port into a fill tank, from which it is transferred to

the steam generator during the unique Groen

automatic cleaning cycle.

The air heating space which contains the heat

exchanger tubes is also separated from the cooking

chamber by removable left, right, top and bottom

partitions. The compartment which contains the

unit’s automatic controls and other electrical

components is on the right side of the unit, and is

accessed by removing the right outside panel.

A drain is located in the removable bottom of the

cooking chamber. Fluids drain from this removable

bottom and from the permanent floor to the stainless

steel drain pipe outside the oven. The drain pipe

includes a spray condensor which suppresses any

steam escaping from the chamber and a drain box.

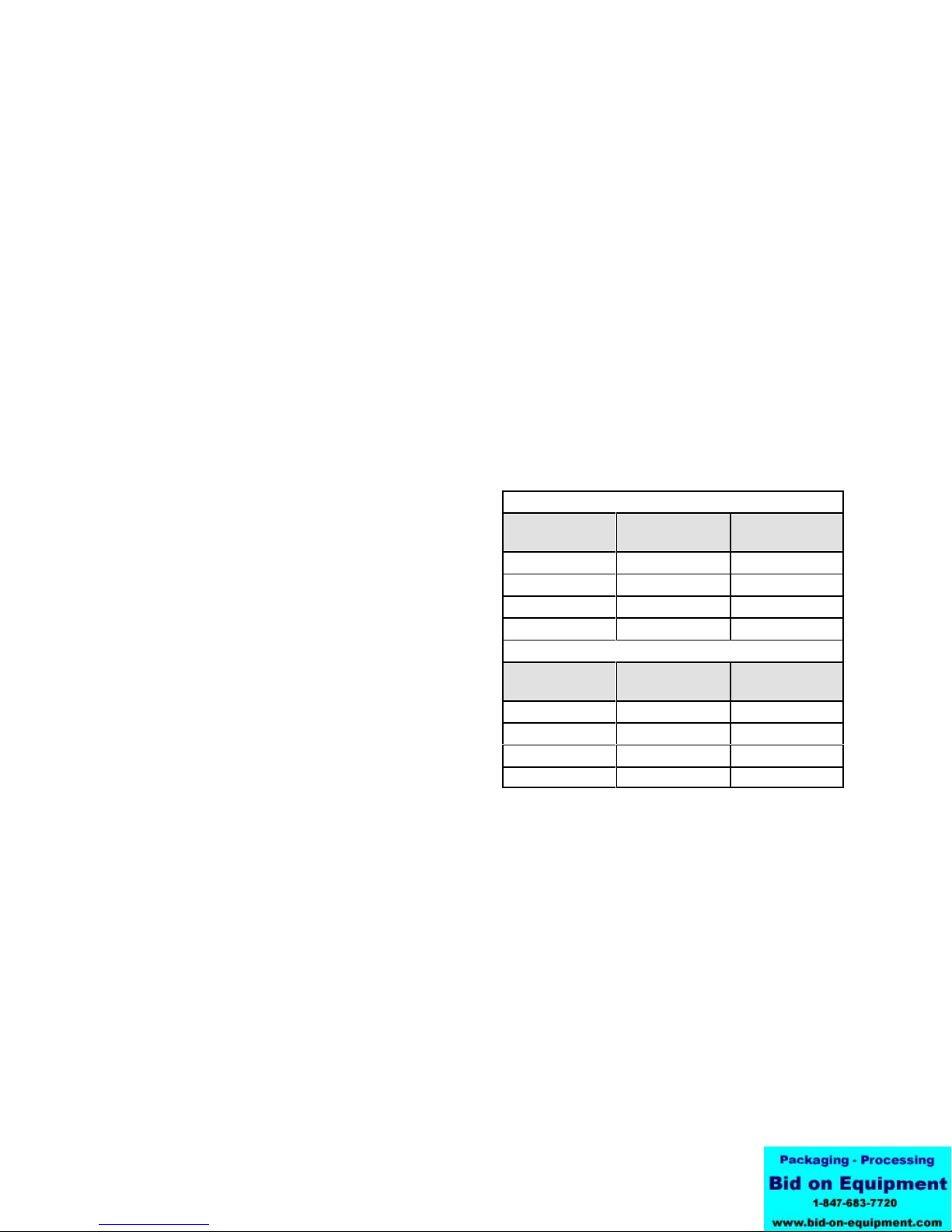

BURNER FIRING RATES

Input Rates, BTU/hour

CC10-G or per chamber for (2)CC10-G

Mode

Oven 45,000 45,000

Steam 48,000 48,000

Combo 54,600 54,600

Preheat (Max) 93,000 93,000

C/2-20G or per chamber for (2)C/2-20G

Mode

Oven 90,000 90,000

Steam 100,000 100,000

Combo 100,000 100,000

Preheat (Max) 186,000 186,000

*Manifold Pressure

Natural Gas

at 3.7" W.C.*

Natural Gas

at 4.5" W.C.*

L.P. Gas

at 10.5" W.C.*

L.P. Gas

at 10.0" W.C.*

A digital readout shows the selected temperature,

which is entered by turning a dial. Pilot burner

status is shown by a light on the pilot ignition switch.

An insulated, gas-fired steam generator is mounted

behind the oven. Steam enters the oven through a

connecting tube near the bottom left rear corner of

the oven.

The deliming port is located on the stand just below

the control panel. De-liming solution goes through

4

Page 5

Inspection and Unpacking

OM-CC-G and C/2-G

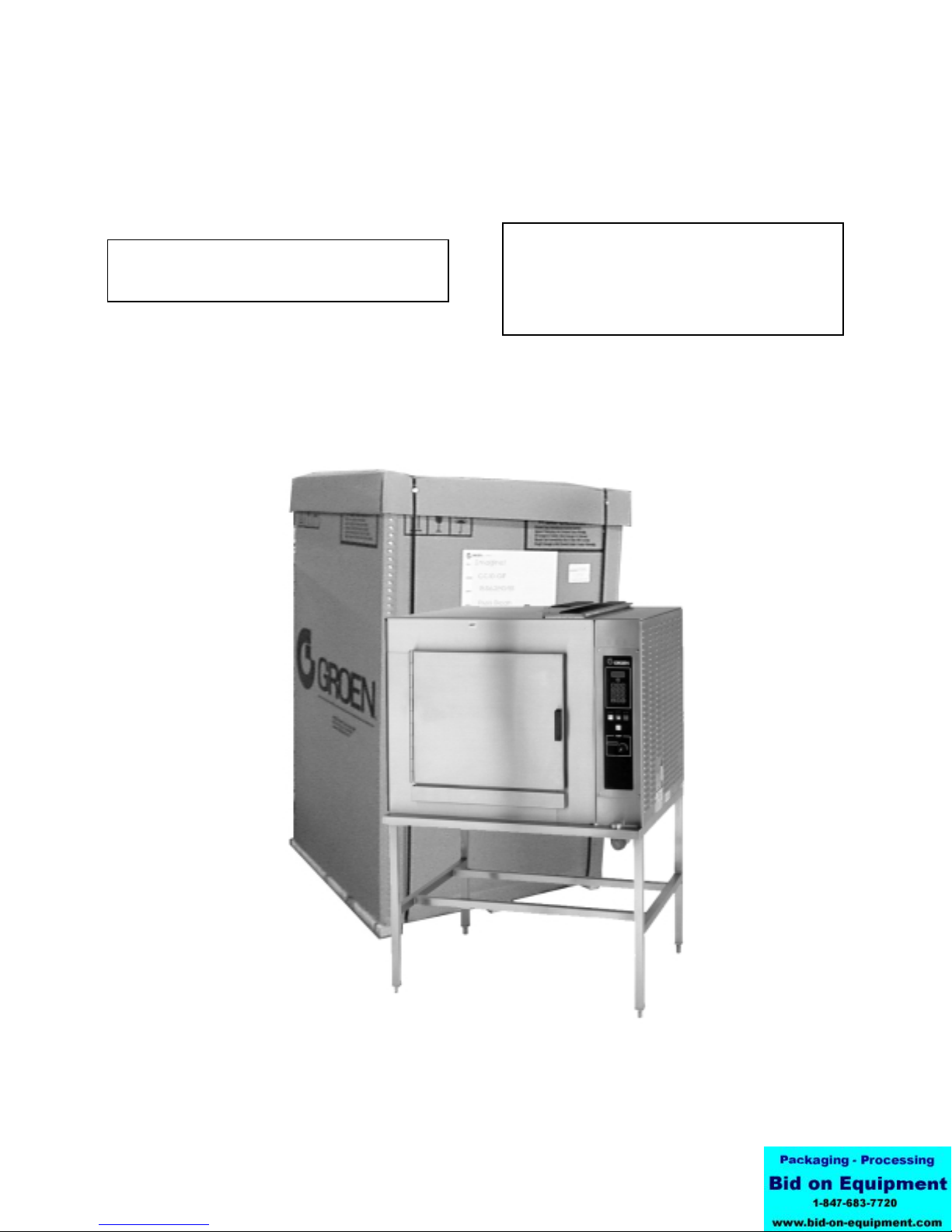

Your Convection Combo™ will be completely

assembled in a heavy shipping carton (CC10-G) or

wooden crate (C/2-20G), and attached to a skid. On

receipt, inspect the carton or crate carefully for

exterior damage.

CAUTION

SHIPPING STRAPS ARE UNDER TENSION AND

CAN SNAP BACK WHEN CUT.

Carefully cut the straps around the carton and detach

the sides of the carton from the skid. Pull the carton

up off the unit. Be careful to avoid personal injury or

equipment damage from nails and sharp pieces of

wood or staples which might be left in carton walls.

Write down the model number, serial number and

installation date and keep this information for future

reference. Space for these entries is provided at the

top of the Service Log in the back of this manual.

CAUTION

THIS UNIT IS VERY HEAVY. YOU SHOULD GET

HELP AS NEEDED AND USE MATERIAL

HANDLING EQUIPMENT TO REMOVE THE UNIT

FROM THE SKID AND MOVE IT TO ITS PLACE

OF INSTALLATION.

When starting installation, use material handling

equipment to lift the unit straight up off the skid.

Check packing materials to make sure loose parts

are not discarded with the material.

The unit will be delivered in either a heavy carton (CC10-G

and C/2-20GF) or a heavy wooden crate ((2)CC10-G and

(2) C/2-20GF), strapped to a wooden skid. (CC10-GF

pictured)

5

Page 6

OM-CC-G and C/2-G

Water Quality and Treatment

It is essential to supply the steam generator/boiler

with water that will not form scale. Even though the

steam generator/boiler is engineered to minimize

scale formation, scale development depends on the

hardness of your water and the number of hours you

operate the equipment each day.

Most water supplies contain minerals which form

scale. It is this scale which could lead to an early

component failure.

Your local water utility can tell you about the

minerals in your water. The water going to the

steam generator should have between 30 and 40

parts per million (ppm) total dissolved solids (TDS)

and should have a pH (acidity rating) of 7.0 to 9.0.

Please follow these simple precautions:

1. The best way to prevent scale is to use a Groen

Water Treatment System which has been

specifically designed for Groen steamers and

combination ovens. Do not rely on unproven

water treatments sold for scale prevention and

removal. They are not specifically designed

to work with Groen steamers and

combination ovens.

2. A well-maintained water treatment system and a

regular cartridge replacement schedule is

essential.

3. Using a Groen water treatment system will

provide longer steam generator/boiler life, higher

steam capacity, and reduce maintenance

requirements.

4. If you notice a slowdown in steam production or

an increase in deliming, have the Combo

checked for scale build-up. This could be an

indication that the water treatment cartridges

need replacing. Heavy scale reduces the unit’s

ability to boil water, and can even cause

component failure.

MINIMIZE SCALE PROBLEMS BY INSTALLING

AND MAINTAINING A GROEN WATER

TREATMENT SYSTEM AND BY DELIMING THE

STEAM GENERATOR/BOILER REGULARLY.

Groen Convection Combo™ ovens feature two

separate water inlets — one for the steam

generator/boiler (for treated water), the other for the

spray condenser (untreated water). The second

intake will reduce water treatment requirements

resulting in significant savings.

The dual water connections are on the rear of the

unit.

Standard water connections for steam

generator and drain spray condenser.

6

Page 7

OM-CC-G and C/2-G

Installation and Start-Up

WARNING

THE UNIT MUST BE INSTALLED BY PERSONNEL WHO ARE QUALIFIED TO WORK WITH GAS,

ELECTRICITY AND PLUMBING. IMPROPER INSTALLATION CAN CAUSE INJURY TO PERSONNEL AND/OR

DAMAGE TO THE EQUIPMENT. THE UNIT MUST BE INSTALLED IN ACCORDANCE WITH APPLICABLE

CODES.

CAUTION

DO NOT INSTALL THE UNIT WITH THE RIGHT SIDE VENTS BLOCKED OR WITHIN 12 INCHES OF A HEAT

SOURCE (SUCH AS A BRAISING PAN, DEEP FRYER, CHAR BROILER OR KETTLE).

DO NOT INSTALL TO THE LEFT OF ANY OPEN-FLAME EQUIPMENT. DO NOT INSTALL UNIT WITHIN FOUR

FEET OF A STEAM DRAIN.

TO AVOID DRAINAGE PROBLEMS, LEVEL THE UNIT FRONT TO BACK.

INSTALLATION MUST BE IN ACCORDANCE WITH ALL APPLICABLE CODES.

Installation

1. Mounting

2. Gas Supply Connections

Minimum rear clearance is 6" from back of oven.

If you wish to install a Convection Combo™ on

top of another, you should obtain a double

stacked unit from the factory.

The unit must be installed in an adequately

vented room with a provision for an ample air

supply to the unit. The unit must be installed

completely under a ventilation hood, since flue

products exit the appliance over its entire depth.

Anything which might restrict the flow of air for

ventilation and combustion must be removed.

Do not obstruct the flue cover or any front, side,

top or rear vents after installation. The area

directly around the Convection Combo™ must

be cleared of all combustible material.

Installation must comply with local codes, or in

the absence of local codes, conform to the

National Fuel Gas Code ANSI Z223.1 - latest

edition, including:

“The appliance and its individual shut-off valve

must be disconnected from the gas supply

piping system during any pressure testing of that

system at test pressures in excess of ½ psig

(3.45 kPa). The appliance must be isolated

from the gas supply by closing its individual

manual shut-off valve during any pressure

testing of the gas supply piping system at test

pressures equal to or less than ½ PSI (3.45

kPa).”

THIS UNIT IS FOR COMMERCIAL USE. NEVER

WARNING

USE HOME OR RESIDENTIAL GRADE GAS

CONNECTIONS. THEY DO NOT MEET GAS

CODES AND COULD BE HAZARDOUS.

Connect to the gas supply using ½ NPT pipe for

the CC10-E and ¾ NPT pipe for the C/2-20E or

an approved equivalent. Although the immediate

connection to the Convection Combo™ is either

½ or ¾ NPT, the gas supply piping must be large

enough to provide 93,000 BTU/hour for each

CC10-G cooking chamber or 186,000 BTU/hour

for each C/2-20G cooking chamber. Supply

pressure must be at least 5" W.C. (maximum 14"

W.C.) for natural gas or 12" W.C. (maximum 14"

W.C.) for LP gas. In Canada, the installation

must conform to the Canadian Gas Code, CAN

1-B149, Installation Codes for Gas Burning

Appliances and Equipment, and/or local codes.

For units on casters, complete the gas supply

connection using only connectors that meet the

standards for movable gas appliances, ANSI

Z21.69 — latest edition. Restrain movement of

the unit by attaching a cable or chain to the

eyelet (provided at the back of the frame) and

anchoring the cable or chain to the wall or floor.

Make the length and location of the cable such

that the unit cannot pull on the gas connection

while the cable is connected.

7

Page 8

OM-CC-G and C/2-G

2. Electrical Supply Connection

For a single oven, or for each oven in a double

stacked unit, provide 115 VAC, 60 Hz, single

phase, 15 AMP service. Local codes and/or the

National Electrical Code should be observed in

accordance with ANSI/NFPA 70-1987 (or latest

edition). AN ELECTRICAL GROUND IS

REQUIRED. The electrical schematic is located

in the service compartment and this manual.

Maximum load per oven is 5½ AMPs. In

Canada provide electrical service in accordance

with the Canadian Electrical Code, CSA C22.1

Part 1, and/or local codes.

4. Water Supply Connection

A check valve (anti-siphonage device) must be

installed in the incoming cold water lines in

keeping with local plumbing codes. Water line

pressure should be between 30 and 60 PSI (210

and 410 kPa). A pressure regulator is required

above 60 PSI (410 kPa).

A ¾ inch (19 mm) NH connector is required to

connect each water supply to the water inlet

valve. The water feed line diameter may not be

less that ½ inch (13 mm). Use a washer (or if

necessary, two washers) in the hose connection.

Do not allow the connections to have any leaks,

no matter how small.

Minimum flow rate for water delivery is 1.5

gallons per minute. Below this rate your Combo

oven will not operate. Condensate spray rate at

30 PSI is 0.34 gallons per minute for CC10-G

units, and 0.7 gallons per minute for the

C/2-20G. Double stacked units require double

the rates. To convert a steamer or combination

oven to a single water connection, order single

cold water adapter (part # 138473).

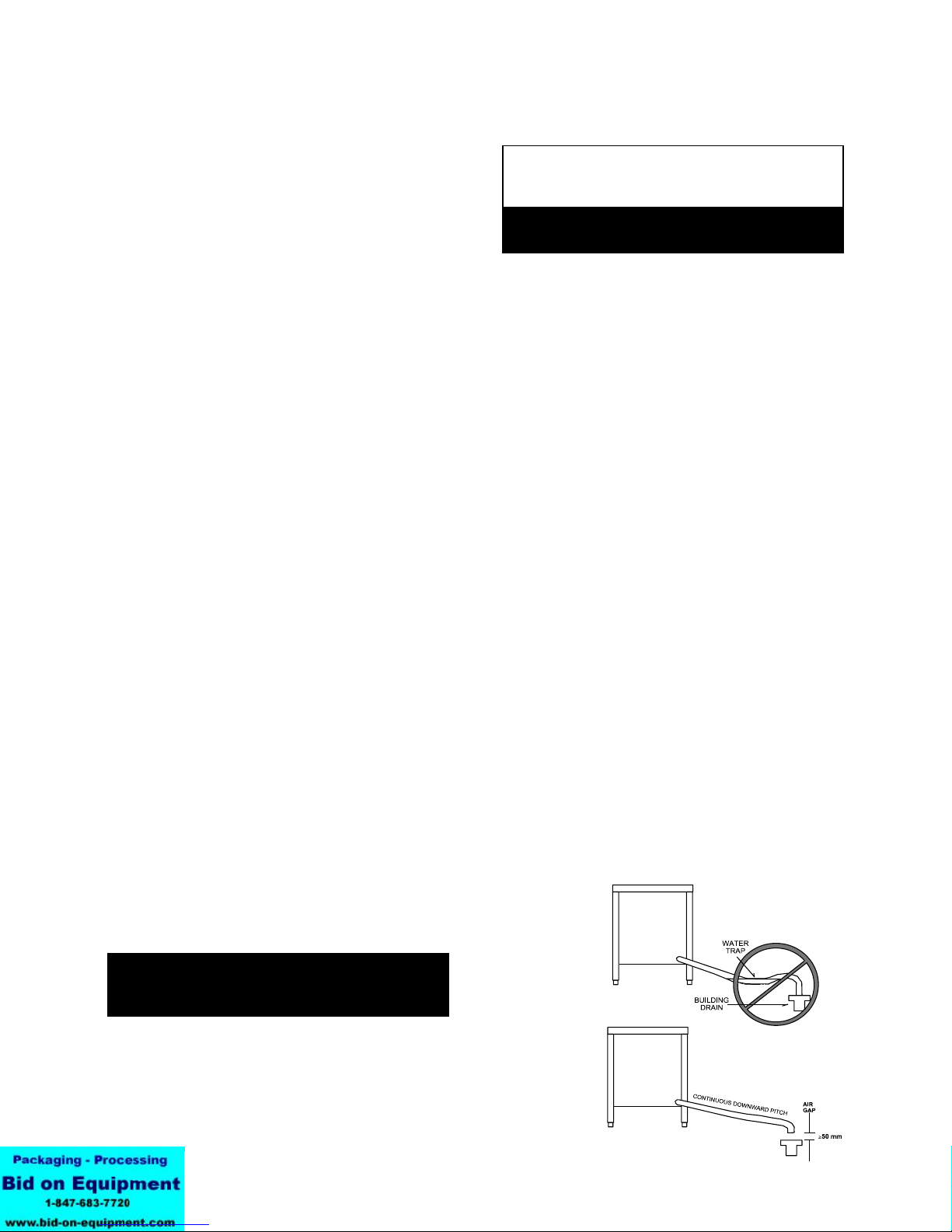

5. Drain Connection

a. Unit Without Drain Tank

(See figures on page 10)

A 1½ inch (4 cm) ID (CC10-G) or 2 inch (5

cm) ID hose (C/2-20G) may be attached to

the supplied drain outlet with a clamp. Do

not use plastic pipe, because the drain must

withstand very hot water.

other elbows or other restrictions between

the unit drain and the free air gap.

CAUTION

DO NOT USE PLASTIC PIPE. DRAIN MUST BE

RATED FOR VERY HOT WATER.

WARNING

BLOCKING THE DRAIN IS HAZARDOUS.

On a double stacked unit, there must be a

minimum of two inches free air gap on each

drain, as close to each oven as possible.

Double stacked units may only share a

common drain hose downstream of both

free air gaps.

Install the drain line with a constant

downward pitch. This is especially important

for double-stack units. The bottom unit is

conceptually shown below.

IMPORTANT: Do not allow any water traps in the

line. A trap can cause pressure to build up

inside the cavity during steaming, which will

make the door gasket leak.

NOTE: Improper drain connection will void the

warranty.

b. Units With Drain Tank

(See figures on page 10)

A hose may be attached to the supplied

drain elbow with a clamp. Use 1½ inch ID

hose for CC10-G or 2" ID hose for C/2-20G.

The hose may be connected directly to a

building drain since the drain tank has an air

vent, which eliminates the need for a free air

gap at the building drain.

Do not block the air vent in any way. Do not

attach anything to the vent tube or reduce its

size.

Do NOT use plastic pipe in the drain line,

because the drain must withstand very hot

water.

WARNING:

DO NOT CONNECT THE OVEN DRAIN

DIRECTLY TO A BUILDING DRAIN.

There must be a free air gap between the

end of the hose and the building drain. The

free air gap should be as close as possible

to the unit’s drain. There must also be no

8

Page 9

OM-CC-G and C/2-G

Convection Combo™ Utility Connections

NOTE: Remove right side panel to make connections

at terminal block in rear of control compartment.

9

Page 10

OM-CC-G and C/2-G

Proper Drain Line Connections

10

Page 11

Initial Start-Up

OM-CC-G and C/2-G

ANY POTENTIAL USER OF THE EQUIPMENT SHOULD BE TRAINED IN SAFE AND CORRECT OPERATING

PROCEDURES.

After the Convection Combo™ has been installed,

test it to ensure that it is operating correctly.

1. Remove all literature and packing materials from

the interior and exterior of the unit.

2. Check that the cold water supply line is open and

that the fittings are not leaking.

3. Make sure that the gas supply line is open. On

newer units, turn the knob of the main gas valve

so that it is lined up with the pipe.

WARNING

7. Once the pilot burner flame has been

established (the green light at the pilot switch is

on), all operator commands are executed via the

front control panel touch pads. See the

Operation section for details.

8. High Altitude Operation. At altitudes above

5,000 feet (1524m), the unit will not operate in

the Steamer or Combo Modes unless the altitude

is set. The Convection Combo™ is delivered

with the altitude set for 1000 feet as default. You

can program the altitude as follows:

a. If the unit is on, turn it off by pressing the ON

touch pad.

b. Press and hold the STEAM touch pad while

turning the unit on by pressing the ON touch

pad. The Time/Status display will show the

letters AL and a number representing the

altitude in thousands of feet. If the altitude

has not been set for your unit, the display

will be 0.

These controls are behind the sliding door on

the right side panel, facing the unit.

4. Turn on electrical service to the unit. Because

the unit will not operate without electrical

power, no attempt should be made to operate

the unit in the event of a power failure.

5. The control panel will not operate until the pilot

burner has been ignited. To light the pilot

burner, activate the pilot switch located next to

the main gas valve. Once the pilot ignition

sequence has been successfully completed, a

green light will glow, and power will be supplied

to the front panel.

6. The “trial for ignition” period is roughly 90

seconds. If the pilot burner does not light within

90 seconds of pilot switch activation, the ignition

system automatically stops the gas flow to the

pilot burner and cancels the ignition trial. If the

ignition trial is terminated, turn off the pilot switch

and repeat the trial for ignition. During initial

start-up, the pilot may require several trials in

order to bleed air from the gas piping.

Subsequent start-up should only require about

five seconds to achieve ignition.

NOTE: See Automatic Operation of Pilot at the end

of this section.

c. Enter an altitude value between 0 and 15,

using the numbered touch pads. For

example, if the unit will be operating at 7,000

feet, enter 7.

d. Press the START touch pad to accept the

change.

Altitude Metric Conversion

Altitude

Feet Meters

1000 305 1

2000 610 2

3000 914 3

4000 1219 4

5000 1524 5

6000 1830 6

7000 2133 7

8000 2438 8

9000 2745 9

10000 3048 10

11000 3353 11

12000 3658 12

13000 3962 13

14000 4267 14

15000 4572 15

Setting

11

Page 12

OM-CC-G and C/2-G

9. Select Fahrenheit or Celsius Temperatures.

The Convection Combo™ is delivered with the

Fahrenheit scale as default. To change the

temperature scale, hold the 5 key in, and press

ON. The Time/Status display will show dEG°F or

dEG°C. Press the 5 key to change from one to

the other. Press START to accept the change.

10. To Test Steamer Mode Operation, turn on the

unit. (For operating procedure details, see the

Operation section of this manual.) Clear time

from the time display. Close the door and press

the STEAM touch pad. (If the HOT light is on,

see Fast Cool in the Operation section.)

The WAIT light will stay on while the steam

generator fills with and heats the water. It should

turn off within three minutes, and the READY

light should come on. This indicates that the

water is at its standby temperature. The timer

only controls operations in the Steamer Mode.

Enter a time and press START. (“Time” is set in

minutes and hours only. Seconds are not

displayed).

Examples: 2 minutes = 00:02

(Just press 2).

1 hour and 30 minutes = 01:30

(Press 1, 3, and 0, or press 9 and 0

the timer will change to 1:30)

The colon [:] between the numbers will blink and

the generator will begin to produce steam. Time

only counts down when the READY light is lit.

11. Test Combo Mode Operation, turn on the

power and clear any time from the Time/Status

display. Press the COMBO touch pad. Set the

COOK temperature to 350

o

F (175oC). The WAIT

light will come on. It will remain on while (1) the

steam generator fills with water and heats it to its

standby temperature and (2) the air heater raises

the air temperature to 350

o

F. Both actions

should be completed in five to eight minutes,

starting with a cold unit. When the set

temperature is attained, the WAIT light will go

off, and the READY light will come on. NOTE:

The timer does not control the oven in either the

Combo or Oven Modes.

12. Test Oven Mode Operation, turn on the power

and clear the Time/Status display. Press the

OVEN touch pad. Set the cook temperature to

o

350

F (175oC). The WAIT light will come on.

Within eight minutes of a cold start, the WAIT

light should go out and the READY light come

on. When that happens, turn the COOK setting

down to 320

o

F (160oC). The HOT light will come

on. Heat-up times may vary slightly with voltage

or water pressure differences.

13. To shut down the unit, switch off the power. The

pilot burner may also be turned off to conserve

energy.

14. If the Convection Combo™ works as described,

the unit is functioning correctly and is ready for

use.

NOTE: You cannot change modes if the timer is

running.

WARNING

WHEN YOU OPEN THE DOOR, STAY AWAY

FROM STEAM COMING OUT OF THE UNIT.

THE STEAM CAN CAUSE BURNS.

12

Page 13

OM-CC-G and C/2-G

Operation

WARNING

ANY POTENTIAL USER OF THE EQUIPMENT SHOULD BE TRAINED IN SAFE AND CORRECT OPERATING

PROCEDURES.

DO NOT OPERATE THE UNIT AT ALL, UNLESS ALL FOUR REMOVABLE COOKING COMPARTMENT

PARTITIONS HAVE BEEN RETURNED TO THEIR PROPER LOCATION.

DO NOT OPERATE THIS EQUIPMENT WITHOUT ELECTRIC POWER.

NOTE: Before the control panel can be used, the pilot burner flame must be on. See “Initial Start-Up.”

A. Controls and Indicators

Operator controls are on the right front side of the

unit. Their use is described below:

1. Time Section

In Oven and Combo Modes, the timer functions

only as a “cooking time minute minder” and does

not turn the unit on or off. In the Steamer Mode,

however, it controls the steaming function.

a. Time/Status Display — Shows operating

time remaining in the Steamer, Oven or

Combo Mode. The timer counts down. If

the unit is equipped with, and operating in

the optional Hold Mode, the timer will count

up alternating with the word “Hold,” and will

show the total accumulated time that the

product has been holding. The display

shows operating time in “hours:minutes”

format. For example, entering 9 and 0 will

result in a display of 01:30.

b. Number touch pads — used to enter time

values.

c. CLEAR — Pressing this touch pad once

stops the beeper and resets the timer to the

time that was last set. Pressing twice clears

it to 00:00. At the end of a cooking period,

opening the door is the same as pressing

CLEAR once.

d. START — Press this touch pad to start the

timer. If the unit is in Steamer Mode, it will

also cause steaming to begin.

2. Status Lights

a. HOT — Indicates chamber temperature is

more than 15

temperature. (See Paragraph 5 in this

section)

o

F (8oC) over the set

b. SERVICE — Indicates that there is a

problem which might require a service call.

If there is such a problem, the beeper will

sound and the SERVICE light will be on

when you switch on the power. The unit

may continue to operate, depending on the

type of problem. Refer to the

Troubleshooting section to determine the

nature and severity of the problem.

c. WAIT — Indicates the unit is either heating

or cooling toward the set temperature. The

HOT and WAIT lights will both be on if the

chamber is more than 15

set point.

d. READY — Indicates the unit is ready for

use.

e. CLEAN - Indicates the unit needs cleaning.

The unit will temporarily function if this light

is flashing.

3. Cooking Mode Selection

These touch pads are used to select the mode of

operation. If a mode is off, pressing the pad for

that mode will turn it on. If the mode is on,

pressing its pad will turn it off. A light just above

each pad indicates which has been selected.

o

F (8oC) above the

13

Page 14

OM-CC-G and C/2-G

Standard Operating Controls

14

Page 15

OM-CC-G and C/2-G

a. STEAM — Selects steamer operation only.

b. COMBO — Selects superheated steam and

convection oven operation.

c. OVEN — Selects convection oven operation

only.

4. Power

The ON touch pad turns the unit on or off. When

power is on, the ON light just above the touch

pad is lit. Use of this pad does not reset the

controls. The unit will always come on in the

same mode it was in when shut down.

5. Temperature (TEMP) Section

a. The Cook display shows the selected

temperature in either Oven or Combo Mode.

It is blank in the Steamer Mode.

b. Turning the Temperature Control Knob

selects the cooking temperatures in 5

increments. The control ranges are:

Oven Mode 200-575

Combo Mode 220-575

o

F (95-300oC)

o

F (105-300oC)

B. Operating Instructions

1. Steam Mode

a. If the unit is off, switch on the electric power

by pressing the ON touch pad. (If the

SERVICE light comes on when you turn on

the power, see the Troubleshooting section).

b. If the power is already on, and there is a

number in the time display window, press

the CLEAR touch pad one or more times to

reset the time to zero.

NOTE: You cannot change operating modes

while the timer is running

c. The unit will be in the mode of operation in

which it was last used. Because of this, the

indicator light for that mode will be lit. If the

unit is not already in the Steamer Mode,

press the STEAM touch pad. The STEAM

light will come on and the Cook display will

go blank.

d. If the unit was recently used in Oven or

Combo Mode, the HOT light may come on,

indicating that the cooking chamber is too

hot for use as a steamer. The unit can be

cooled quickly to the steaming temperature

range by leaving the door open or following

the Fast Cool procedure described near the

end of this section (Paragraph 4). With the

door open, the generator can fill and heat

o

F

the water to 200

produce steam.

o

F (93oC), but it cannot

NOTE: Maximum temperature is limited to

500°F when either the optional probe or

optional hold mode is in use.

6. Optional Features

If the following features are included, please

refer to the control panel guide which was

provided with the unit:

Cook Only Guide: P/N 121084

Programmable: P/N 121042

Probe & Hold: P/N 121072

WARNING

WHEN YOU OPEN THE DOOR STAY AWAY

FROM ANY STEAM COMING OUT OF THE UNIT.

STEAM CAN CAUSE BURNS.

e. The WAIT light will be on until the water

reaches 200

o

F (93oC). It will then turn off

and the READY light will come on. You are

now ready to steam foods in your

Convection Combo™.

f. Load the food into pans in an even, uniform

layer.

g. Carefully open the door and slide the pan or

pans onto the pan racks in the cooking

chamber. If you are only using one pan,

place it in the middle position. Close the

door.

15

Page 16

OM-CC-G and C/2-G

h. Press the numbered touch pads to set the

cooking time. The time will appear in the

Time/Status display. If you enter the wrong

number, press the CLEAR touch pad to

erase the time from the display, and enter

the time again.

i. When the correct cooking time has been

entered, press the START pad. The colon in

the Time/Status display will blink and the

time will count down the cooking time. (The

unit must be READY before the timer can

count down.)

j. If you open the door during the cooking

period, steaming and the timer will stop (but

will not reset). When you close the door,

steaming and timing will resume.

WARNING

WHEN YOU OPEN THE DOOR STAY AWAY

FROM ANY STEAM COMING OUT OF THE UNIT.

STEAM CAN CAUSE BURNS.

k. When the timer reaches zero, it stops steam

generation and sounds a beeper. Water in

the steam generator stays at its standby

temperature (200

o

F - 93oC). On older

models, the beeper will sound until the door

is opened or CLEAR is pressed.

l. Carefully open the door. If the food is

cooked, remove the pans using hot pads or

oven mitts to protect your hands.

m. After the display has counted down to zero,

opening the door or pressing CLEAR once

will reset the display to the time that was last

used. Pressing START will repeat the cook

cycle. If the same cooking time will be used,

you only need to press the number keys

when you first set that time.

n. After the Time/Status display has counted

down to zero, you can reset the time to zero

by either (1) opening the door and pressing

CLEAR or pressing CLEAR twice. A new

cooking time may then be set by using the

number keys.

2. Oven Mode

If the door is closed and the cooking

temperature is above 250

o

F (120oC) the fan

will begin to operate.

b. If the power is already on, and there is a

number in the Time/Status display, press

CLEAR one or more times to reset the time

to zero.

NOTE: You cannot change operating modes

while the timer is running

c. The unit will power up in the mode in which it

was last used. Because of this, the indicator

light for that mode will be lit. If the unit is not

already in the Oven Mode, press the OVEN

touch pad. The OVEN light will come on and

the oven fan will operate.

d. Use the Temperature Control Knob to set

the desired cooking temperature between

o

200

and 575o F (93o to 300o C). NOTE:

Maximum temperature is limited to 500°F

when the either the optional probe or

optional hold mode is in use. The

temperature will appear in the Cook display.

Unless the cooking chamber is already at or

above the selected temperature, the unit will

start heating and the WAIT light will come

on.

e. If the unit was recently used at a

temperature 15

o

F (8oC) or more over the

selected temperature, the HOT and WAIT

lights will come on. The unit can be cooled

quickly to the desired cooking temperature

by leaving the door open or following the

Fast Cool procedure described near the end

of this section (Paragraph 4).

f. The READY light will indicate when the oven

is at the desired temperature.

g. Load the food into the pan or pans in a

uniform layer.

h. The Convection Combo™ will operate in

Oven Mode with the timer either on or off. If

you want to time cooking, press the

numbered pads in the Time/Status portion of

the control panel to set the cooking time.

The time will appear in the Time/Status

display . If you enter the wrong number,

press CLEAR to erase the time from the

display, and reenter the time. Remember

that the timer does not control the unit in

the Oven Mode.

a. To use the Convection Combo™ as a

convection oven, switch on the electric

power by pushing the ON touch pad. (If the

SERVICE light comes on when you turn on

the power, see the Troubleshooting section).

16

Page 17

i. Open the door and slide the pan or pans

onto the pan racks in the cooking chamber.

If you are only using one pan, place it in the

middle position. Close the door.

j. If the correct time has been set on the timer,

press the START pad. The colon [:]

between the numbers in the Time/Status

display will blink and the time will count

down the cooking time. When the timer has

counted down to zero, it will sound a beeper.

This sound will continue until the door is

opened or the CLEAR pad is pressed.

k. To stop cooking, take the pans out of the

oven using hot pads or oven mitts to protect

your hands from the hot pans. The unit will

continue heating to keep the chamber at the

set temperature until the temperature control

is reset, or the power is shut off.

OM-CC-G and C/2-G

NOTE: You cannot change operating modes

while the timer is running

c. The unit will power up in the mode of

operation in which it was last used. Because

of this, the indicator light for that mode will

be lit. If the unit is not already in the Combo

Mode, press the COMBO touch pad. The

COMBO light will come on and if the steam

generator is not already full, water will flow

into it and begin heating.

d. Use the Temperature Control Knob to set

the desired oven temperature between 220

and 575

will appear in the Cook display.

e. If the unit was recently used at a

temperature more than 15

than the temperature selected, the HOT and

WAIT lights will turn on. The unit can be

cooled quickly by leaving the door open or

following the Fast Cool procedure described

near the end of this section (Paragraph 4).

o

F (105 to 300oC). The temperature

o

F (-8oC) higher

WARNING

PANS AND INTERNAL PARTS OF THE OVEN

WILL BE VERY HOT. AVOID CONTACT WITH

HOT SURFACES.

l. Opening the door during operation shuts off

power to the heaters and fan and stops the

timer, but it has no other effect on the

controls. When the door is closed, operation

continues. Note that cooking time will be

extended by the period the door was open.

3. Combo Mode

a. If the unit is off, switch on the electric power

by pressing the ON touch pad. (If the

SERVICE light comes on when you turn on

the power, see the Troubleshooting section).

If the door is closed and the cooking

temperature is above 200

o

F (93oC) the fan

will begin to operate.

b. If the power is already on, and there is a

number in the time display window, press

the CLEAR touch pad one or more times to

reset the time to zero.

WARNING

WHEN YOU OPEN THE DOOR STAY AWAY

FROM ANY STEAM COMING OUT OF THE UNIT.

STEAM CAN CAUSE BURNS.

f. The WAIT light will be on until the water in

the steam generator reaches boiling and the

air in the cooking chamber reaches the set

temperature. It will then turn off and the

READY light will come on to indicate that the

oven is at the desired temperature.

g. The unit will operate in Combo Mode with

the timer either on or off. If you want to time

the cooking, press the numbered pads in the

Time/Status portion of the control panel to

set the cooking time. The time will appear in

the Time/Status display. If you enter the

wrong number, press the CLEAR touch pad

to erase the time from the display, and enter

the time again. The timer does not control

the unit in Combo Mode.

h. Load the food into the pan or pans in a

uniform layer.

17

Page 18

OM-CC-G and C/2-G

WARNING

WHEN YOU OPEN THE DOOR STAY AWAY

FROM ANY STEAM COMING OUT OF THE UNIT.

STEAM CAN CAUSE BURNS.

i. Open the door and slide the pan or pans

onto the pan racks in the cooking chamber.

If you are only using one pan, place it in the

middle position. Close the door.

j. If the timer has been set, press the START

pad. The colon [:] between the numbers in

the Time/Status display will blink and the

time will count down the cooking time.

When the timer has counted down to zero, it

will sound a beeper. This beeping will

continue until the door is opened or the

CLEAR pad is pressed.

a. When the HOT indicator is lit and the timer is

cleared, the unit can be cooled quickly by

opening the door and pressing START. The

fan will operate, and the Time/Status display

will show the word “COOL.” This is the only

time the fan operates with the door open.

WARNING

DO NOT PUT HANDS OR OTHER OBJECTS

INTO THE COOKING CHAMBER DURING THE

FAST COOL OPERATION. THE ROTATING FAN

CAN BE HAZARDOUS.

b. To stop the Fast Cool operation, press any

touch pad or close the door.

5. Shutting Down

a. Press the touch pad for the mode in which

the unit is operating.

b. Switch off the power by pressing the ON

touch pad.

k. To stop cooking, take the pans out of the

oven using hot pads or oven mitts to protect

your hands from the hot pans. The unit will

continue steaming and heating the oven at

the set temperature until the temperature

control is reset or the power is shut off.

4. Fast Cool

Leave the door at least partially open, if local

sanitation regulations permit.

18

Page 19

OM-CC-G and C/2-G

Cleaning

To keep your Convection Combo™ in proper operating condition and to make the cleaning process easier,

cleaning should be a daily activity.

A. Suggested Tools and Cleaners

1. Mild detergent

2. Stainless steel exterior cleaner such as

Zepper®

3. Steam generator de-liming agent, such

as Groen Delimer Descaler, (P/N

114800) Lime-A-Way® or an equivalent.

A liquid de-liming agent will be easier to

use than crystals or powders. See the

warning about chlorides below.

4. De-greaser, such as EncompasS®, Groen

Degreaser, Malone 34®, Puritan

Puribrute®, or Con-Lie®

5. Cloth or sponge

6. Plastic wool or a brush with soft bristles

7. Spray bottle

8. Measuring cup

9. Nylon pad

10. Towels

11. Plastic disposable gloves

B. PROCEDURE

1. Exterior Cleaning

a. Prepare a warm solution of the mild

detergent as instructed by the supplier.

Wet a cloth with this solution and wring it

out. Use the moist cloth to clean the

outside of the unit. Do not allow freely

running liquid to touch the controls, the

control panel, any electrical part or any

open louver.

b. To remove material which may be stuck to

the unit, use plastic wool, a fiber brush, or

a plastic or rubber scraper with a

detergent solution.

c. Stainless steel surfaces may be polished

with a recognized stainless steel cleaner

such as Zepper®.

d. For glass surfaces, use a mild detergent

without abrasives or a high quality

glass/surface cleaner with a clean cloth or

sponge. Do not spray hot glass with water

or chemicals. This could cause the glass to

break from thermal shock.

e. Use a mild soap without abrasives and warm

water to clean the door gasket. DO NOT

use caustic oven cleaners on the door

gasket, as this will damage it.

PRECAUTIONS

WARNING

DISCONNECT THE POWER SUPPLY

BEFORE CLEANING THE OUTSIDE OF

THE UNIT.

KEEP WATER AND CLEANING

SOLUTIONS OUT OF CONTROLS AND

ELECTRICAL COMPONENTS. NEVER

HOSE OR STEAM CLEAN ANY PART OF

THE UNIT.

BE CAREFUL CLEANING THE TOP FLUE

COVER AND THE OVEN TOP. BOTH

AREAS MAY BE VERY HOT.

DON’T MIX DE-LIMING AGENTS (ACID)

WITH DE-GREASERS (ALKALI)

ANYWHERE IN THE UNIT

AVOID CONTACT WITH ANY CLEANERS,

DE-LIMING AGENT OR DE-GREASER AS

RECOMMENDED BY THE SUPPLIER.

MANY ARE HARMFUL. READ THE

WARNINGS AND FOLLOW THE

DIRECTIONS!

EVEN WHEN THE UNIT HAS BEEN SHUT

OFF, DON’T PUT HANDS OR TOOLS INTO

THE COOKING CHAMBER UNTIL THE FAN

HAS STOPPED TURNING.

DON’T USE ANY CLEANING OR DELIMING AGENT THAT CONTAINS ANY

SULFAMIC AGENT OR ANY CHLORIDE,

INCLUDING HYDROCHLORIC ACID (HCl).

TO CHECK FOR CHLORIDE CONTENT

SEE ANY MATERIAL SAFETY DATA

SHEETS PROVIDED BY THE CLEANING

AGENT MANUFACTURER.

UNIT MAY BE HOT. TAKE PRECAUTIONS

TO PREVENT CONTACT WITH HOT

SURFACES.

To clean the cooking chamber and/or de-lime the steam

generator of the CC10-G or C/2-20G, a special

sequence of operations (the Clean Cycle) has been

programmed into the Convection Combo™ computer.

To run this automatic Clean Cycle for cleaning, deliming or both actions at the same time, follow the

instructions outlined on the following page.

DO NOT USE ANY METAL MATERIAL (SUCH AS METAL SPONGES) OR METAL IMPLEMENTS (SUCH AS A SPOON, SCRAPER OR

WIRE BRUSH) THAT MIGHT SCRATCH THE SURFACE. SCRATCHES MAKE THE SURFACE HARD TO CLEAN AND PROVIDE PLACES

FOR BACTERIA TO GROW. DO NOT USE STEEL WOOL, WHICH MAY LEAVE PARTICLES IMBEDDED IN THE SURFACE WHICH COULD

EVENTUALLY CAUSE CORROSION AND PITTING.

IMPORTANT

19

Page 20

OM-CC-G and C/2-G

WARNING

DO NOT SPRAY OR CLEAN THE DOOR WHILE

HOT. GLASS BREAKAGE MAY OCCUR IF THE

DOOR IS RAPIDLY COOLED WITH WATER.

f. Always check

the jumper cord

between the oven

front panel and

the door after

cleaning. Make

sure that it is

properly positioned

as shown to

prevent damage.

2. Interior CLEANING STEPS

For the (2)CC-10G and (2)C/2-20G double-stacked

units, the cleaning processes must be performed

on each cavity. When double-stack units are being

cleaned, wait five minutes after starting the first oven

clean cycle (Time/Status display will show CL:40)

before you start to clean the second cavity.

Clean Cooking

Chamber Only

Omit step 3 Omit step 2

Before beginning this procedure, make sure the oven

HOT light is not on. If the HOT light is on, use the

FAST COOL instructions on page 18 to cool the

oven cavity.

De-Lime Steam

Generator Only

Clean Chamber and

De-Lime Generator

Perform all steps

in order

STEP 1

After cooling the oven to 200ºF (90ºC) or less,

take the oven out of any mode in which it may

have been operating. (Wait at least two minutes,

or until the steam generator starts to fill, before

adding an deliming solution.) Enter 99 into the

timer. The Time/Status display will read

CC or CL.

WARNING

BEFORE REACHING INTO THE OVEN TO

REMOVE PARTITIONS, EXIT THE FAST COOL

MODE BY PRESSING ANY BUTTON OR BY

CLOSING AND REOPENING THE DOOR. DO

NOT REACH IN THE OVEN UNTIL THE FAN HAS

STOPPED MOVING.

OVEN MAY BE HOT — WEAR GLOVES OR USE

OVEN MITTS TO AVOID BURNS.

DO NOT OPERATE THE UNIT IN ANY MODE

UNLESS ALL FOUR REMOVABLE PARTITIONS

HAVE BEEN RETURNED TO THEIR PROPER

LOCATIONS.

STEP 2

Make sure to clean all food particles out of the

drain.

On a daily basis, follow the degreaser supplier’s

instructions, and apply degreaser to the entire

cooking cavity and pan racks.

WARNING

UNIT MAY BE HOT. DO NOT TOUCH HOT

SURFACES.

DO NOT PUT HANDS OR OTHER OBJECTS

INTO COOKING CHAMBER WHILE

CONVECTION COMBO™ IS OPERATING. THE

ROTATING FAN CAN BE HAZARDOUS.

20

Once a week, remove oven racks and partitions

in order. Use an oven mitt if the oven is hot. To

remove partitions:

Left

— The left partition includes a back

plate and an air distribution baffle. Lift up to

disengage the four hooks from their support

posts and remove the partition from the

chamber (see pictures on next page).

Right

— The right partition includes a large,

circular, flared opening that is centered in

front of the fan. Push upward to disengage

the four hooks from their support posts and

remove the partition from the chamber.

— The bottom partition has a small

Bottom

circular pattern of drain holes. Lift it directly

up and off from its four support posts.

Page 21

OM-CC-G and C/2-G

Top — The top partition is flat and has no holes.

Remove it by pushing upward, then pushing from

left to right to disengage the four hooks to their

support posts.

Cooking Chamber with Partitions in Place

posts. If absolutely necessary, you may

remove the wire rack support.

Left

— The left partition includes a back

plate and an air distribution baffle. Push

down to engage the four hooks to their

support posts. If absolutely necessary,

you may disassemble the back plate, baffle

and wire rack support.

FOR CAVITY CLEANING ONLY,

GO TO STEP 4.

WARNING

DO NOT OPERATE THE UNIT IN ANY MODE

UNLESS ALL FOUR REMOVABLE PARTITIONS

HAVE BEEN RETURNED TO THEIR PROPER

LOCATIONS.

STEP 3 (Deliming Only)

Water hardness affects the de-limer’s

performance. In very hard water, stronger

solutions and more frequent applications of

de-limer may be necessary. (Refer to Water

Quality and Treatment on Page 6).

Cooking Chamber with Partitions Removed

STEP 2, Continued

Apply cleaner to the oven walls and heat

exchange tubes. Apply it also to the rear of each

removable partition.

Return the four partitions to their proper locations

in the following order:

Top

— The top partition is flat and has no

holes. Install it by pushing upward, then

pushing from right to left to engage the four

hooks to their support posts.

Bottom

— The bottom partition has a small

circular pattern of drain holes. Place it

directly down onto the four support posts.

Right

— The right partition includes a large,

circular, flared opening that must be

centered in front of the fan. Push downward

to engage the four hooks to their support

The deliming port is located directly below the

control panel.

De-limer is poured through the port into the

delimer reservoir.

21

Page 22

OM-CC-G and C/2-G

Following the supplier’s directions, pour deliming solution into the de-liming port. If you use

Lime-A-Way® or Groen Delimer Descaler (P/N

114800) pour in one pint (½ liter) (two pints for

C/2-20G). Replace cap on the port.

Pour one cup (¼ liter) of liquid de-limer directly

into the cooking chamber drain.

WARNING

IF THERE IS OVEN CLEANER ON OR NEAR THE

OVEN FLOOR DRAIN, POUR ONLY A SMALL

AMOUNT OF DE-LIMER AT FIRST TO SEE IF

THERE IS A REACTION BETWEEN THE

CLEANER AND THE DE-LIMER. DO NOT

BREATHE ANY RESULTING FUMES.

STEP 4

Close the door and press START. The

Time/Status display will ready CL:45. The unit

will then complete the cleaning cycle, counting

down to CL:00. When double-stack units are

being cleaned, wait five minutes after starting the

first oven clean cycle (display will show CL:40)

before you start to clean the second cavity.

If both cleaning and deliming, in about two

minutes, the de-liming solution in the reservoir

will be drawn into the steam generator. Remove

the cap from the fill port and pour one quart of

clean water into the reservoir. The water will

also be drawn into the generator. Replace the

cap.

NOTE: To exit the Clean Cycle at any time press

and hold the CLEAR touch pad for three

seconds.

STEP 5

When the Clean Cycle is complete, turn off the

oven an let it cool. Thoroughly wipe down the

cooking cavity with clean water. If any baked-on

residue is still present, use a nylon scrub pad

and rinse again. Make sure all degreaser is

thoroughly wiped off oven door gaskets.

WARNING

UNIT MAY BE HOT ENOUGH TO BURN YOU.

DO NOT TOUCH HOT SURFACES.

Errors During Cleaning

If the timer stops and the SERVICE light stays

on, there has been an error which prevents the

unit from completing the clean cycle. Take the

following steps:

1) Reset the unit. Re-enter “99." The

Time/Status display should read “CC” or

“CL.” Press START.

2) If the unit fails again to complete its clean

cycle, call your authorized Groen Service

Agency.

Clean Cycle Counter

The unit tracks the total number of clean cycles

completed. To check this total, first turn off the

unit. Press and hold the 0 touch pad while

turning on the unit. The total will be displayed in

the Time/Status display.

After halting the Clean Cycle, and before you

cook any food, be sure to thoroughly wash

out all chemical residue by filling and

draining the steam generator. (Enter Steam

Mode and wait 60 to 90 seconds to fill; enter

Oven Mode, take the unit out of all modes or

simply turn it off to drain). Wait at least three

minutes before restarting the unit.

Also wipe chemical residues from the

cooking chamber with a wet, clean cloth

before you cook anything. Rinse the cloth

often. This cleaning must include both

sides of the removable partitions, the racks,

and the tubes and walls behind the

partitions. The racks and partitions may be

rinsed in a sink.

22

Page 23

Maintenance

OM-CC-G and C/2-G

The Groen Convection Combo™ is designed for

minimum maintenance. Certain parts may need

replacement after prolonged use. If there is a need

for service, only Groen personnel or authorized

Groen representatives should perform the work.

If steam or condensate is seen leaking from around

the door, take the following steps:

1. Check the door gasket. Use a 2" strip of paper

closed in between the door and the gasket. If

the paper is not snugly held in place, adjust the

latch pin as indicated in Step #3. Replace the

gasket if it is cracked or split.

2. Inspect the cooking chamber drain to be sure it

is not blocked.

Troubleshooting

A. Pilot Burner

Remember that the front control panel will not

operate until the pilot switch has been activated

and the pilot burner flame has been ignited

(green light is on). For details, see Initial StartUp on page 11. If the procedure described in

Initial Start-Up has been followed and the pilot

burner still does not light, contact your

authorized Groen Service Agency.

B. Resetting the Solid State Controls

(If problems persist call an authorized Groen

Service Agency)

If the controls stop responding to normal

commands, or the unit is behaving oddly, reset

the controls using the following procedure:

1. Switch off the power by pressing the ON

touch pad.

2. While pressing the COMBO touch pad,

switch the power back on. If no errors are

present, the unit will beep and show four

zeroes in the Time/Status display. If there

are errors, the unit will not beep, but will

display Service Codes, both in the

Time/Status and Cook displays. Note the

Service Codes. Press CLEAR to exit the

Service Mode and refer to the following

explanation of service messages.

3. Adjust the latch pin as follows:

a. Loosen the lock nut at the base of the latch

pin, and turn the latch pin ¼ turn clockwise.

Re-tighten the lock nut.

b. After adjustment, run the unit in the Steam

Mode to test for further steam leaks.

c. If leakage continues, repeat the adjustment.

d. Continue adjusting the pin clockwise until the

door fits tightly enough to prevent leaks.

C. Service Messages

There are two types of service message:

1. Non-critical error: signaled by three quick

beeps. The SERVICE light comes on for 15

seconds and then goes out.

2. Critical error: signaled by a continuous five

second beep. The SERVICE comes on and

stays on.

If there is a non-critical error you may continue to

operate the unit. As soon as possible, check the

Service Code. Turn off the unit by pressing the

ON touch pad. While pressing the COMBO

touch pad, switch the power back on. Note the

numbers and refer to the Troubleshooting Guide

which follows. Press CLEAR to exit the Service

Mode.

If there is a critical error, the unit will not operate

in its present mode, but it may operate in another

mode. Check the Service Code as instructed

above, then call your authorized Groen Service

Agency.

If the problem continues after you follow the

instructions in the Troubleshooting Guide, call

your authorized Groen Service Agency.

23

Page 24

OM-CC-G and C/2-G

Troubleshooting Guide

If a problem persists after taking the actions suggested below, call your authorized Groen service representative.

CODE INDICATES SUGGESTED ACTION

1 Low water level probe

2 High water level probe

Maximum generator fill

3

time (90 seconds) has

been exceeded.

4 Faulty air probe

6 Faulty generator probe

7 Time Between Fills

Maximum generator drain

8

time (five minutes) has

been exceeded.

Try cleaning steam generator to remove contamination from the probes.

• If either code continues, call your Groen Service Agency.

• If both codes are displayed, the unit will only operate in the Oven Mode.

• If only one code is displayed, the unit will operate in all modes, but water

may overflow from the generator into the cooking chamber during

operations in either the Steam or Combo Modes.

Make sure the water supply is fully turned on and that hoses are not

kinked or pinched.

• If the code is still displayed, the unit will operate in the Oven Mode only.

• Call your Groen Service Agency

• The unit will operate in Steamer and Clean Cycle Modes only.

• Call your Groen Service Agency

• The unit will operate in Oven Mode only.

• Call your Groen Service Agency

Check for a leaky fill valve.

• The unit will operate in Oven Mode only.

• Call your Groen Service Agency

Inspect the drain line and remove any blockage. Make certain that the

drain is free-vented as detailed in the Installation Section of this Manual.

(Paragraph 5, Page 8)

Will the Unit Operate? — After a Service Code Occurs

Will Convection Combo™ operate in ________ Mode when Code _________ is displayed?

Mode

Steam Yes Yes No Yes No No No No

Combo YesYesNoNoNoNoNoNo

Oven Yes Yes Yes No Yes Yes Yes Yes

Clean YesYesNoYesNoNoNoNo

Door Light:

operate, replace each bulb individually to isolate the failed bulb. If all bulbs fail to operate, check the installation of

the jumper cord between the door and the oven front panel (see Step F and photo on page 20).

12346781 & 2

The door has a total of four light bulbs, two pair wired in series. If the top or bottom two bulbs fail to

Service Code

24

Page 25

OM-CC-G and C/2-G

Diagrams & Schematics

25

Loading...

Loading...