Page 1

CAPKOLD® COOK-CHILL SYSTEMS

PROJECT NAME:

LOCATION:

ITEM NO:

MOBILE PUMP/FILL STATION MODEL CKPF

CapKold® Model CKPF/3 & CKPF/3N Mobile Pump/Fill Stations with integrated rotary positive displacement

pump, for the transfer of hot and cold food from a steam jacketed kettle into flexible plastic casings or other

containers. Pedestal mounted control package allows fast and simple adjustment of pumping speed and

volume.

AVAILABLE MODELS:

CKPF/3

CKPF/3N

STANDARD FEATURES:

• Heavy duty stainless steel construction

• Unit mounted on four 5” heavy duty locking swivel

casters

• Air actuated casing clipper complete with regulator

and filter. 15’ air hose supplied for easy field

connection.

• Quick action air activated product flow control valve

• USDA food transfer hose. Two (2) hose sections 3”

in diameter by 3’ long, with fittings to interconnect

kettle and fill station.

• Exterior rear mounted rotary positive displacement

pump for easy cleaning

• Full surface spill tray with drain and removable

stainless steel grate

• Stainless steel elbow with 10’ hose provided for spill

tray

• Manufactured to latest sanitary standards and

HACCP compliant

• CKPF/3N is NSF listed

INTEGRAL CONTROL PACKAGE:

Control panel is pedestal mounted to fill station

and provided with a water resistant case to simplify

cleanup and protect solid state control systems. Eye

level digital input of pump speed and volume setting

changes for different products. Operating controls

include:

• Selection of manual, metered or continuous

pumping modes

• Operator input of pump speed from 0 to 20

gallons per minute

• Operator input of metered volume from 0.5 to 2.0

gallons in 0.01 gallon increments

• Foot activated fill switch

• Knee and hand operated emergency stop

switches

• LED digital display of volume pumped per casing,

total casings pumped and total fill volume per

batch

NOTES:

• Unit requires single phase electric service

• Clipper sold separately on CKPF/3N

ORIGIN OF MANUFACTURE: Designed and

manufactured in the United States.

QTY:

MODEL NO:

AIA NO:

SIS NO:

CKPF/3 and CKPF/3N mobile pump/

fill station

OPTIONS/ACCESSORIES:

Temperature monitor with cas-

ing clipper lockout to prevent

packaging at less than 180°F

(82°C)

Product temperature recorder

High volume air eductor (For

vacuum packaging products for

Cook Tank Production)

Empty casing holding bin

(Hangs on side of Fill Station)

Pan fill adapter

Pan fill conveyor

Stand alone label printer

Additional 3’ food transfer hose

section with fittings

In-line ricer for size reduction

of food solids

Prison package

CapKold Packaging

CKPF 160380 RevB

Revised 11/13

Page 2

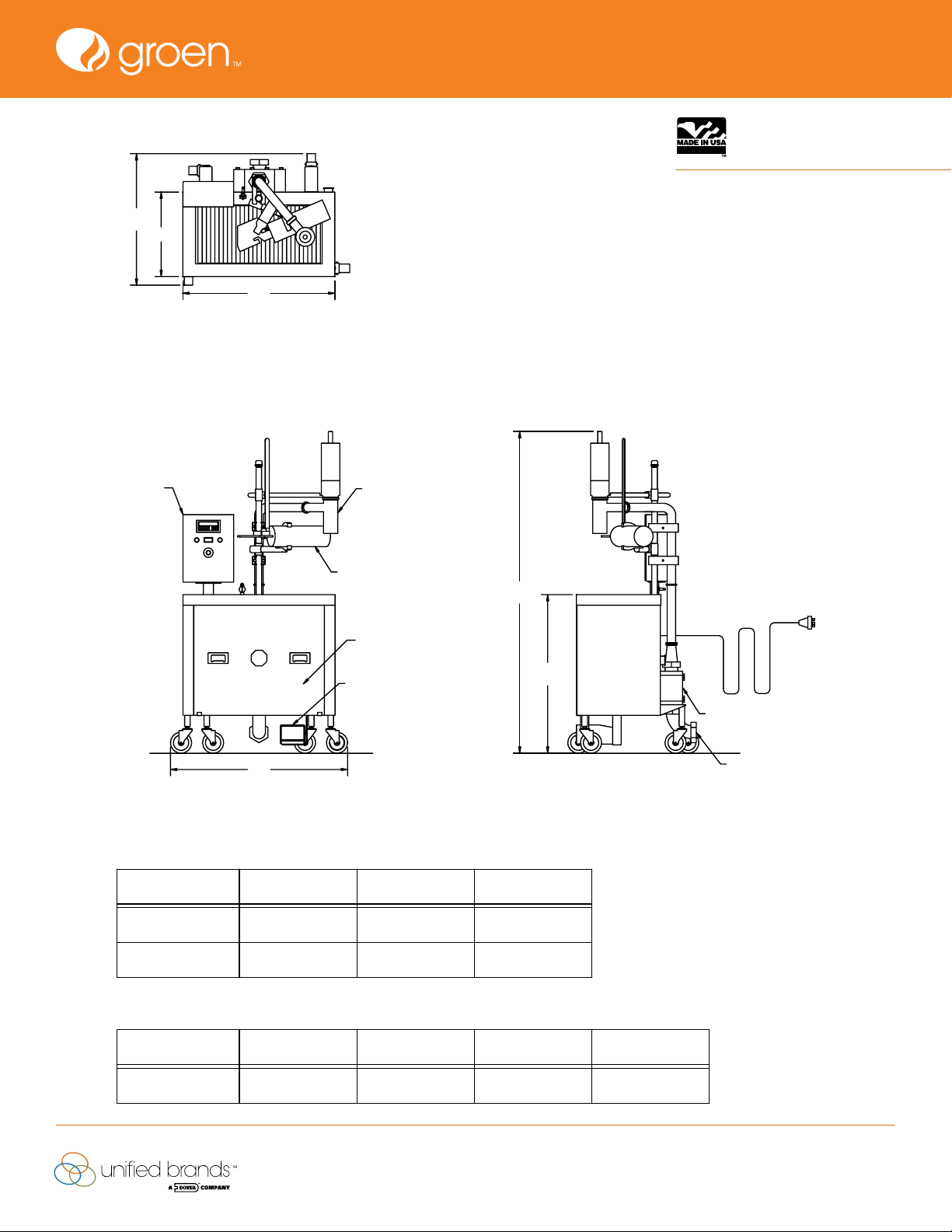

CKPF/3 & CKPF/3N

31 1/4"

CONTROL

PANEL

20"

CA

TOP VIEW

CA

36"

IW

PRODUCT VALV E

OUTLET

CLIPPER (SOLD

SEPARATELY ON

CKPF/3N)

76 1/4"

160379 REV B

EP

FRONT VIEW SIDE VIEW

UTILITY CONNECTIONS

SYMBOL

DESCRIPTION

CONNECTION

UTILITY REQUIREMENTS

MODEL

CKPF/3 &

CKPF/3N

ACCESS/EMERGENCY STOP

PANEL

FOOT SWITCH

42"

CA

COMPRESSED AIR

INLET

3/8 DISCONNECT #2621 HUBBLE PLUG

W/ 15 FT HOSE

COMPRESSED AIR

INLET

8 CFM @ 80-90 PSI

IW EP

INDIRECT WASTE POWER SUPPLY

2" HOSE

ELECTRICAL

208/1/60 @ 10A

37 1/2"

W/ 15 FT CORD

SHIPPING WEIGHT OPERATING WEIGHT

755 LBS

IW

PUMP

PRODUCT INLET

650 LBS

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2013 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of Dover Corporation.

Loading...

Loading...