Page 1

CKPF/3 MOBILE PUMP/FILL STATION

IMPORTANT INFORMATION! * KEEP FOR OPERATOR * IMPORTANT INFORMATION!

OPERATOR’S MANUAL OM-CKPF/3

Page 2

CKPF/3 MOBILE PUMP/FILL STATION

Model CKPF/3

Table of Contents

Description

Operator Warnings 3-6

Equipment Description 7-8

Installation and Start-up Instructions 9-10

Operation 11-14

Equipment Cleaning and Sanitization Procedures 15-16

Maintenance Schedule 17

Troubleshooting 18

Suggested Spare Parts List 19-20

Schematic 21

Service Log 22

Limited Warranty 23

Operator’s Manual page 2 OM-CKPF/3

Rev. 1 2-6-03

Page

Page 3

CKPF/3 MOBILE PUMP/FILL STATION

IMPORTANT! — READ FIRST — IMPORTANT!

Operator Warnings

WARNING: Do NOT attempt to install, set up or operate this machine BEFORE you have

read and understand this manual and ALL accompanying manuals. KEEP ALL MANUALS

FOR FUTURE REFERENCE.

WARNING: Be sure operators read, understand and follow the operating instructions,

cautions and safety instructions in this manual. Additional manuals are supplied with the

CKPF/3 Mobile Pump/Fill Station. Be sure operators read, understand and follow ALL

operating instructions, cautions and safety instructions in these additional manuals. Any

potential user of the equipment MUST be trained in safe and correct operating

procedures.

WARNING: When using this machine, ALL operating instructions, safety instructions and

precautions MUST be followed and strictly adhered to.

WARNING: This machine is intended for use in the commercial transfer and packaging of

food products, per the instructions contained in this manual. Other use could result in

personal injury or damage to the equipment and will void ALL warranties.

WARNING: AVOID ALL direct contact with HOT equipment surfaces. Direct skin contact

could result in severe burns.

WARNING: AVOID ALL direct contact with HOT food. Direct skin contact could result in

severe burns.

WARNING: Use of any replacement parts other than those supplied by Groen or its

authorized distributors voids ALL warranties and may cause bodily injury or equipment

damage. Service performed by other than authorized personnel will void ALL warranties.

WARNING: Turn the electric power OFF and unplug the unit BEFORE working on internal

components.

WARNING: Turn the electric power OFF and unplug the unit BEFORE performing any

cleaning operation.

WARNING: Be careful to AVOID contact with cleaning products in accordance with the

supplier and manufacturer recommendations. Many cleaners are harmful to the skin, eyes,

mucous membranes and clothing. Read the warnings and follow directions on the cleaner

label.

CAUTION: NEVER leave a chlorine sanitizer in contact with stainless steel for longer than

30 minutes. Longer contact can cause corrosion.

WARNING: Do NOT use a fuse with a higher AMP rating than the rating specified for that

circuit.

Operator’s Manual page 3 OM-CKPF/3

Rev. 1 2-6-03

Page 4

CKPF/3 MOBILE PUMP/FILL STATION

IMPORTANT! — READ FIRST — IMPORTANT!

Operator Warnings Continued

Grove

WARNING: NEVER place fingers or other body parts in the Tipper Tie clipper groove where

the clips seal the casings.

Main Air

Line

Air Switch

TURN KNOB

CLOCKWIZE TO

TURN AIR OFF

INDICATOR

FRONT VIEW FRONT VIEW

INDICATOR

TURN KNOB

COUNTER

CLOCKWISE TO

TURN AIR ON

WARNING: ALWAYS place the air switch in the OFF position and disconnect the air hose

on the Tipper Tie clipper when removing a clip jam. ALWAYS follow manufacturer’s

instructions and use a screwdriver to REMOVE a clip jam. NEVER attempt to REMOVE a

clip jam with your fingers.

Operator’s Manual page 4 OM-CKPF/3

Rev. 1 2-6-03

Page 5

CKPF/3 MOBILE PUMP/FILL STATION

R

Operator Warnings Continued

Clips

Die Area

WARNING: If a clip jams in the die area of the Tipper Tie clipper, do NOT attempt to cycle

the machine again until the jam is cleared. Follow ALL safety procedures! Place the air

switch in the OFF position and disconnect the air supply BEFORE attempting to REMOVE

the clip or other obstruction from the die area.

WARNING: Disconnect both air hoses on the air operated ball valve BEFORE disassembly.

Air Hose Connection

Valve

Air Hose Connection

Clipper Air Turn

Off Valve

Electrical Cord

DO NOT LAY ON

FLOOR IN WATE

WARNING: The CKPF/3 Mobile Pump/Fill Station electrical power cord should NOT be on

the floor in a water or moisture environment.

WARNING: Do NOT operate the CKPF/3 Mobile Pump/Fill Station with the pump rotor

housing cover removed, or without ALL bolts installed.

Operator’s Manual page 5 OM-CKPF/3

Rev. 1 2-6-03

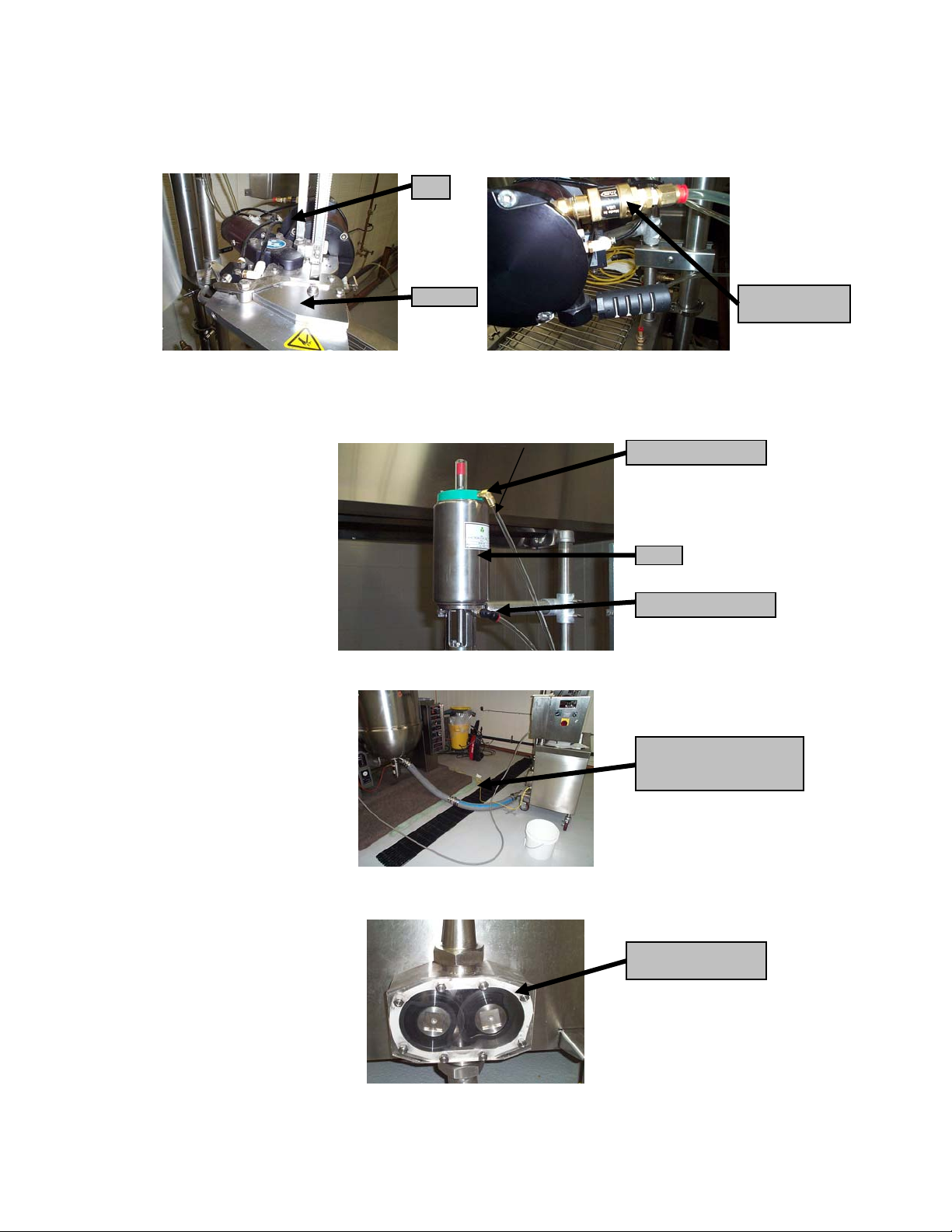

Pump Rotor Housing

Cover

Page 6

CKPF/3 MOBILE PUMP/FILL STATION

r

p

Operator Warnings Continued

Control Panel

Inverte

WARNING: Do NOT spray the CKPF/3 Mobile Pump/Fill Station control panel or inverter

with water.

CAUTION: When Working with the parts of the product supply system, be careful the metal

surfaces and housing may be HOT.

Back View of Pum

CAUTION: When removing the rotor housing from the CKPF/3 Mobile Pump/Fill Station,

ensure that you have a good grip on both sides of the housing and slowly pull the housing

toward you. Rotors may be HOT. REMOVE rotors with tool. Keep your feet and other

objects clear of the rotor housing during rotor removal and installation.

CAUTION: REMOVE product tubes and rotors BEFORE removing rotor housing.

CAUTION: Unit MUST have a separate ground wire for safe operation.

Pump Rotors

Operator’s Manual page 6 OM-CKPF/3

Rev. 1 2-6-03

Page 7

CKPF/3 MOBILE PUMP/FILL STATION

Equipment Description

General Description/Mini-Spec:

The CapKold CKPF/3 Mobile Pump/Fill Station is designed to rapidly and gently transfer HOT or

cold food from one or more adjacent jacketed steam kettles into flexible plastic casings or other

containers. The pedestal-mounted control package allows fast and simple adjustment of pumping

speed to accommodate a broad range of products and accurate control of pre-measured volume.

The rotary pump will transfer product with food solids up to I¼" (32mm) diameter, without

damage.

Standard features

1. Integrated positive displacement pump, exterior rear-mounted for easy cleaning

2. Air-operated casing clipper, complete with regulator and filter

3. 15-foot air hose supplied for easy field connection

4. All stainless steel construction

5. Unit designed to accommodate of right-to-left operator fill sequence

6. Quick action air-activated product flow control valve

7. USDA food transfer hose—two (2) hose sections, 3-inch diameter by 3 feet long, with

fittings to interconnect Kettle and CKPF/3 Mobile Pump/Fill Station

8. Full surface spill tray with drain and removable stainless steel grate

9. Manufactured to latest sanitary standards and HACCP-compliant

Standard integral control package

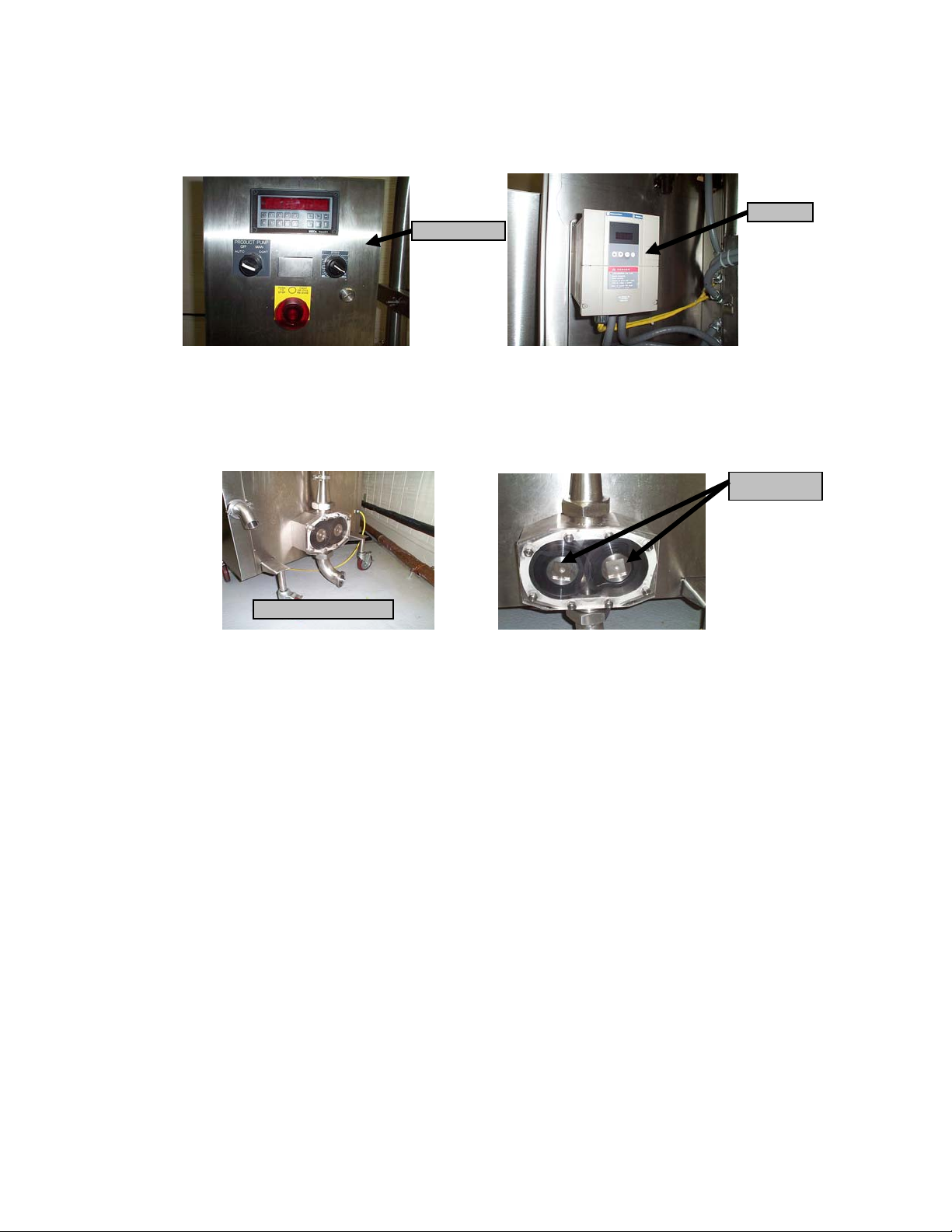

Controller

Product Pump

Control

The control panel is pedestal-mounted to the fill station and provided with a water- resistant case

to simplify cleanup and protect solid-state control systems. The raised control panel reduces

operator fatigue and simplifies pump speed and volume setting changes for different products.

Speed Control

On/Off Button

Operator’s Manual page 7 OM-CKPF/3

Rev. 1 2-6-03

Page 8

CKPF/3 MOBILE PUMP/FILL STATION

Equipment Description Continued

1, 2, & 5

4

The operating controls include:

Selection OFF for manual, metered or continuous pumping modes

1. Operator input of pump speed from 0 to 20 gallons per minute (GPM)

2. Operator input of metered volume from .0 to 10 gallons in 0.01 gallon increments

3. Foot-activated fill switch

4. Knee-and hand-operated STOP switches

5. LED digital display of volume pumped per casing, total casings pumped and total fill

volume per batch

3

Optional features and accessories

• Temperature monitor with casing clipper lockout, to prevent packaging at less than

180°F

• Product temperature recorder

• High volume air ejector-type vacuum pump (for reducing product packaging size in

cook tank production)

• Empty casing holding bin (hangs on the side of the CKPF/3 Mobile Pump/Fill Station)

• Pan fill adapter

• Manual KIWI label maker with one set of letters and initial ink supply (for contents

and production date labeling on Tyvek tape labels)

• Data Max Labeler

• Additional 3-foot food transfer hose section with fittings

• Prison package

Operator’s Manual page 8 OM-CKPF/3

Rev. 1 2-6-03

Page 9

CKPF/3 MOBILE PUMP/FILL STATION

Installation and Start-up

The CapKold CKPF/3 Mobile Pump/Fill Station is a mobile unit. Carefully REMOVE the unit from

its crate. If you note any damage to the equipment or the crate, notify the delivery agent

immediately. Ensure that no associated loose parts are thrown away with the packing materials.

Move the station to its intended location. Check the casters to see that they are inserted fully into

the leg sockets.

The CapKold CKPF/3 Mobile Pump/Fill Station is equipped with a Casing Tipper Tie Clipper.

Compressed air MUST be supplied at sufficient pressure to maintain an air regulator setting

between 80 PSI and 90 PSI minimum on the clipper. Operation of the clipper at 10 cycles per

minute will require approximately 60 CFM bursts of clean dry air. Inadequate air supply will

cause the clipper to malfunction. A 15-foot flexible hose terminated with a quick disconnect fitting

is supplied for connecting the CKPF/3 Mobile Pump/Fill Station to your facility’s compressed air

supply.

Electric power MUST be supplied to the power cord, which can run in any direction from beneath

the cabinet. The cord is equipped with a twist-lock plug that requires a NEMA L6-30R receptacle

(Hubbell 2621 or equivalent). Power supplied MUST be 1PH, 50 or 60 HZ and in the voltage

range of 208-240 AMP. The unit will pull approximately 20 Amps maximum. THE CIRCUIT

MUST BE PROPERLY GROUNDED.

Pump

Before using the pump fill station it is recommended that the unit be cleaned and sanitized for

use.

Step One. Remove the pump cover and rotors. Inspect the pump cavity. Then wash the cavity

and rotors with HOT water and detergent. Rinse the equipment well. Slide the rotors back on to

the shafts, taking care to match the mating corners of the shaft (a new paper gasket is required

each time you clean the pump.) Install the pump cover with the edge stamped TOP uppermost.

Tighten the eight nuts with the furnished cross-wrench.

Operator’s Manual page 9 OM-CKPF/3

Rev. 1 2-6-03

Page 10

CKPF/3 MOBILE PUMP/FILL STATION

r

Installation and Start-up Continued

3” Nut

Cover Nuts

Rotors

Pump Shafts

Sanitary

Thread Elbow

Install the 3-inch sanitary thread elbow on the sanitary inlet at the bottom of the pump. Connect

the 3-inch sanitary hose to the elbow and to the outlet fitting on the kettle. When everything is

located as desired, tighten the 3-inch nuts with the furnished aluminum wrench.

Air Regulator

Adjust the air pressure regulators between 80 PSI and 90 PSI.

Sanitary Hoses

Oile

Check the oil level in the lubricator bowl. Use the squeeze bottle to add oil, if necessary. A light

application of oil to the clipping parts of the Casing Clipper will give smoother operation.

Operator’s Manual page 10 OM-CKPF/3

Rev. 1 2-6-03

Page 11

CKPF/3 MOBILE PUMP/FILL STATION

Operation

1. Connect air and electrical connectors

2. Connect food transfer hose to the desired kettle

3. Load magazine with clips, then check printer and label paper, if applicable.

Air Connection

Selector Switch Knob

Air On, Indicator

Turned Counter

Clock Wise, Left

Position

4. Turn air valve to UP position. Make sure the 4-position selector switch is in the OFF

position.

Air Off, Indicator

Turned Clock

Wise, Up Position

Power Cord Plug

Operator’s Manual page 11 OM-CKPF/3

Rev. 1 2-6-03

Page 12

CKPF/3 MOBILE PUMP/FILL STATION

Product Pump Control

STOP Knob

Control Panel

Speed Control

5. Turn control power on by pulling

6. Sanitize the pump and adjacent piping (refer to chemical manufactures recommended

procedures and recommendations) by pumping HOT water through (not to exceed 140ºF):

a. Connect the product suction line to the kettle

b. Divert the spout to a drain

c. Allow HOT water to enter the pump, then turn control panel selector switch to

CONTINOUS and step ON the foot switch

d. Adjust the pump speed to desired flow rate

e. Let the HOT water run out of the kettle, then turn the control panel selector switch

to OFF

7. Use an approved commercial sanitization agent and follow directions

STOP knob

Operator’s Manual page 12 OM-CKPF/3

Rev. 1 2-6-03

Page 13

CKPF/3 MOBILE PUMP/FILL STATION

Operation Continued

8. Set the batch size:

a. Press ∆ to scroll UP or ∇ to scroll DOWN to P1

b. Press key until PGM flashes in the left corner of the read-out panel

c. Press CLR to clear

d. Set each batch volume (example: “1”, “5”, “0”, ENT —for approximately 1½ gallons

of food per bag)

e. Test setting in AUTO Mode and make necessary adjustments to P1 mode until

desired results are obtained

f. Press key to set program and return to RUN mode

g. Turn selector switch to AUTO

h. Place high barrier flexible packaging bag over the pump spout

Pump Spout

Operator’s Manual page 13 OM-CKPF/3

Rev. 1 2-6-03

Page 14

CKPF/3 MOBILE PUMP/FILL STATION

Operation Continued

Foot Switch

i. Depress foot switch one

Clipper Slot

Position the area of the bag between both hands into the clipper slot, gently pulling the

bag toward you (clipper will clip and cut top of bag OFF)

j. REMOVE clipped bag by backing down out of clipper slot

time per bag

9. Pump Warm-up (this procedure allows the pump body to warm up and the rotors to expand

in order to pump product at uniform quantities):

Product Pump

Control

Selector

Switch

Turn selector switch to MANUAL

a. Set a clean empty container under the outlet spout

Operator’s Manual page 14 OM-CKPF/3

Rev. 1 2-6-03

Page 15

CKPF/3 MOBILE PUMP/FILL STATION

Operation Continued

b. Depress and hold the foot switch pedal until the container is filled with product (to

STOP the pump, simply take your foot OFF the foot switch pedal)

c. Pour the contents of the container back into the kettle (repeat these steps as

necessary)

10. Pump product into bags:

a. Turn the selector switch to AUTO

b. Place high barrier flexible packaging bag over the pump spout

c. Depress foot switch one time

d. Empty each bag of most of its air by keeping the right hand just above the product

level, while squeezing air out toward the bag opening with the other hand

e. Place entire top of bag into the clipper slot and gently pull toward

you (clipper will clip and cut top of bag OFF)

11. Place each bag into the product chilling device

Between Batches

REMOVE any food product trapped inside the kettle that may affect the next batch Rinse

out kettle at the end of each batch.

a. Pump at HIGHEST speed until water

runs clear

b. Turn rinse water OFF and when kettle is

empty, turn pump OFF and CLOSE

kettle flush valve

c. Start next batch

Thermal Assurance Option

Thermal Assurance is provided in the system for operations that require clipping of bags

with product at or above a minimum set temperature. The default value is <180°F>. This

means that the product packaged is at or above 180°F (at this temperature, product is

pasteurized).

During tests, the set point temperature could be lowered to below ambient temperature

for clipper to operate. However, the set point should be set to a minimum of 180°F for

normal operation.

See Temperature Controller Manual for detailed information.

per bag

Operator’s Manual page 15 OM-CKPF/3

Rev. 1 2-6-03

Page 16

p

CKPF/3 MOBILE PUMP/FILL STATION

Equipment Cleaning/Sanitization Procedures

Fill Valve

Tipper Tie Clipper

Pump Discharge Tubing

Pum

Product In feed

All parts of the equipment should be cleaned with ambient water plus chlorine sanitization

agent. Equipment sanitization should be done, with 200 ppm chlorine water.

BEFORE kettle use, the agitator kettle should be filled with water and an approved

commercial sanitization agent, following directions. Agitate for several minutes. Pump out

the water via the Pump/Fill Station. This will sanitize the Pump/Fill hose and pump

assembly. Other kettles need only to empty the sanitizing solution to the drain and rinse.

Between product batches, rinse the kettle. Adding water and pump at the HIGHEST

CONTINUOUS speed until water runs clear.

System Cleaning and Disassembly

At the END of each day disassemble and clean system. REMOVE and clean scrapper blades,

blade holders, drop-down valve and outlet fitting. Clean kettle using high-pressure hose spray

and brushes. Do NOT use stainless steel scrub pads or other materials which may scratch kettle

surface. Reassemble kettle.

Food Transfer Hose

Disassemble and clean, using high-pressure food transfer hose and brush, and then reassemble.

REMOVE the sanitary hose, then wash the fittings and hose with a hose brush long enough to

reach all parts of the hose. NOTE: May clean all components except gaskets and pump rotors in

pot washing machine.

Pump/Fill Station

Disassemble entire pumping path assembly. Disassemble pump, including removal of pump

rotors, pump body and seals. Clean pump components and sanitize with an approved

commercial sanitization agent. Clean top shelf and sides of the Pump/Fill Station. REMOVE the

Equipment Cleaning/Sanitization Procedures Continued

pump cover and rotors and clean them in the wash sink. Loosen the 2-inch piping and

Operator’s Manual page 16 OM-CKPF/3

Rev. 1 2-6-03

Page 17

CKPF/3 MOBILE PUMP/FILL STATION

disassemble the pipe fittings and valve. REMOVE the pump shaft seals.

Pump Reassembly

Place lip seals firmly in pump body with attachment bolts and push on drive shafts, ensuring that

notch on rotor align with notch (dot) on drive shaft. Put new paper gasket in place. Attach cover

plate and tighten with tool—do NOT over-tighten. Water line should be wiped clean with an

approved commercial sanitization agent.

Cleaning Instructions:

When you are finished with a kettle load and are ready to clean up, CLOSE the kettle outlet valve,

rinse the kettle down with high-velocity water spray, and brush to clean the kettle to your

satisfaction. Then OPEN the kettle outlet valve. Turn the switch to CONTINUOUS. The pump

will run CONTINUOUSLY and the kettle will empty completely through the pump. The

wastewater will flow into filler sink, down the drain hose and on to the floor drain. If you wish to

minimize the BOD rating due to debris in the wastewater, an option is to use a strainer or pores

bag to remove the solids. This arrangement effectively strains solids out of your pumped cleanup water. This procedure will usually suffice for a between batch cleaning.

At the END of a day’s run, pump HOT water with a small amount of detergent through the

system. Pump the system empty. THEN SHUT OFF ELECTRIC POWER

unplugging the unit.

REMOVE the sanitary hose, then wash the fittings and hose with a hose brush long enough to

reach all parts of the hose. REMOVE the pump cover and rotors and clean them in the wash

sink. Loosen the 2-inch piping and disassemble the pipe fittings and valve. REMOVE the pump

shaft seals.

Wash and scrub down the exterior of the cabinet. Use a damp wet cloth with mild soap to clean

the control panel. DO NOT SPRAY ELECTRIC CONTROLS

We recommend that you consult with your local supplier of commercial cleaning supplies on the

proper chemicals for cleaning and sanitizing your Pump/Fill Station and other equipment. The

supplier is in direct contact with technical advisors who know the best methods for cleaning with

the water in your specific area.

with a high-pressure hose.

TO THE SYSTEM by

Operator’s Manual page 17 OM-CKPF/3

Rev. 1 2-6-03

Page 18

CKPF/3 MOBILE PUMP/FILL STATION

Maintenance Schedule

The CKPF/3 Mobile Pump/Fill Station requires regular maintenance. Please refer to the

maintenance schedule for the Pump and Tipper Tie Clipper below.

Pump

Schedule

Inspect rotors for nicks, cuts or separation from Daily

the metal base.

Inspect lip seals for integrity-NOT split, cut or Daily

frayed.

Maintenance Schedule Continued

Check oil levels in the pump and drive gearboxes. Weekly

Change oil in the drive and pump gearboxes. Semi-annually

Use Shell Turbo Oil 100 or equivalent.

Tipper Tie Clipper

Inspect oiler and add oil if required. Add a light Daily

weight mineral oil.

Inspect air lines. Should NOT be taut, pinched or Daily

bound.

Inspect cut-off knife for severe nicks or dullness. Monthly

Inspect oiler drip rate: adjust if necessary, to 1 Monthly

drop per 6 strokes.

Inspect clipper for tightness of clip by filling a Monthly

casing with water, clipping closely (i.e. very little

or no slack), then apply pressure to the casing (i.e.

stand on the casing). Look for signs of leakage.

Schedule

Operator’s Manual page 18 OM-CKPF/3

Rev. 1 2-6-03

Page 19

CKPF/3 MOBILE PUMP/FILL STATION

Troubleshooting

The CapKold CKPF/3 Mobile Pump/Fill Station is designed to operate smoothly and efficiently if

properly maintained. However, the following is a list of checks to make in the event of a problem.

Wiring diagrams are furnished inside the service panel and in its manual. If an item on the

check list is marked with (X), it means that the work should be done by an authorized

Groen service agent.

SYMPTOM WHO WHAT TO CHECK

Unit will not pump User a. Pull the emergency STOP switch out.

b. Turn the air switch ON.

c. Is the lower front cabinet panel installed correctly?

d. Connect the electric and air lines.

e. Prime food transfer hoses with water.

f. Valve on kettle is NOT open.

g. Turn selector switch to proper position.

h. Pump motor damaged (X)

i. Ball valve assembly damaged. (X)

Tipper Tie will not operate User a. REMOVE jammed clips.

b. Turn the air switch ON.

c. Is there a minimum of 90 PSI air pressure?

d. Are there clips in the loader?

e. Product temperature is below 82°C.

f. Tipper Tie is damaged. (X)

g. Is there oil in lubricator?

h. Is there water in system?

i. Is FRL plugged in?

Bags fill too fast/slow User a. Adjust pump speed.

b. Replace worn or damaged pump rotors.

Bags fill at improper level User a. Adjust fill volume.

b. Are the food transfer hoses blocked?

Hoses leaking User a. Replace worn or missing gaskets.

b. Tighten nuts.

Reference material for the options on your CKPF/3 Mobile Pump/Fill Station is included. Refer to

the reference material if problems arise.

Operator’s Manual page 19 OM-CKPF/3

Rev. 1 2-6-03

Page 20

CKPF/3 MOBILE PUMP/FILL STATION

Suggested Spare Parts List

To order CapKold parts, contact your local authorized Groen Service Agency or contact the

CapKold Business Office at 601/371-6039 to see if you are eligible for the CapKold Parts Direct

direct parts program. Please supply model designation, serial number, part number, part

description and quantity. When applicable, please also supply voltage and phase.

CapKold Recommended

Part Description

Replacement Switch for Foot Switch 056696 1

Switch Micro Plunger Type (Knee Switch) 005329 1

Valve Solenoid Air 3-Way (Shut Off) 115532 1

2” Sanitary Clamp N53786 2

Gasket Tri-Clamp 2" 016602 4

Gasket Bevel Seat 3" 005829 2

Gasket Tri-Clamp 3" 053362 2

Wrench Hex 3" 005322 1

Valve Solenoid Air 5-Way N110490 1

Air Pressure Regulator 115533 1

Air Filter/Lubricator 115571 1

Air Muffler 115555 1

Caster 5" Wheel Swivel Type with Brake 115509 1

Hose Assembly 3" Sanitary 2 Piece 078842 1

3-Way Valve 115532 1

Inline Fill Valve Assembly 2" Complete 143072 1

Kit "O" Ring & Seals 1143075 1

Stem Protector 142878 1

Pneumatic Air Cylinder 142881 1

Valve Piston Body 142883 1

Valve Piston Seal 142884 1

End Cap, Air Cylinder 142895 1

Valve Lower Body 142908 1

Drain Hose 2" ID X 2.375" OD 115551 Per Ft.

Motor Drive 1½HP 208/346VAC/3PH/60HZ 120437 1

Inverter 2HP 230VAC 120436 1

Controller Programmable Dynapar 115587 1

Pump Positive Displacement #6 Crepaco Complete 005324 1

Studs Long Round for Crepaco #6 Pump (need 3) N103533 3

Paper Gasket #6 Crepaco Pump 110898 1 Box

O-Ring #6 Crepaco Pump 005887 4

Seal Shaft #6 Crepaco Pump 005886 4

Seal Bearing #6 Crepaco Pump 060108 2

Rotor Single Lobe #6 Crepaco Pump 027179 2

Oil Food Grade #6 Crepaco Pump Gearbox 099733 1-5 Gallons

Cross Wrench #6 Crepaco Pump 005339 1

Wrench Spanner #6 Crepaco Pump N91459 1

3" Incline Ball Valve 112235 1

Part Number Quantity

Operator’s Manual page 20 OM-CKPF/3

Rev. 1 2-6-03

Page 21

CKPF/3 MOBILE PUMP/FILL STATION

Suggested Spare Parts List Continued

CapKold Recommended

Part Description

Clipper Tipper Tie Complete Assembly 097113 1

Cut-Off Knife for #Z4135 Tipper Clipper N47732 1

Punch for #Z4135 Tipper Clipper N65097 1

Die #Z4135 Tipper Clipper N65098 1

Spring Gate Holding Tipper Tie N61302 1

Channel Guard Assembly Clipper TT008397 1

Channel Guard Clipper TT098399 1

Spring Torsion Channel Guard N83759 1

Sensor End-of-Stroke Clipper N116455 1

Oil-Light Weight Clipper N83503 1 Bottle

Marking Wheel Label Maker 059509 1

Sleeve Rubber Marking Wheel 087864 1

Inking Wheel Label Maker 070431 2

Ink Label Maker 076266 1 Bottle

Conditioner (Ink Cleaner) Label Maker N93570 1 Bottle

Tape Labeling 2" x 300 Ft. Roll Label Maker 059495 5 Rolls

Letter Kit #518 083580 1

Letter Kit #516 N111849 1

Pump/Fill Relocation Kit 131218 1

4-Position Selector Switch N114275 1

Temp Sensor 115512 1

2-Way Poppet Valve 097190 1

Hose for #78842 Only 102174 Per Ft.

Ink Bottle 076366 1

Clips N80084 1 Case

Part Number Quantity

Operator’s Manual page 21 OM-CKPF/3

Rev. 1 2-6-03

Page 22

Schematic

CKPF/3 MOBILE PUMP/FILL STATION

Operator’s Manual page 22 OM-CKPF/3

Rev. 1 2-6-03

Page 23

CKPF/3 MOBILE PUMP/FILL STATION

Service Log

Model No._______________________ Purchased From____________________

Serial No._______________________ Location___________________________

Date Purchased__________________ Date Installed_______________________

Purchase Order No._______________ For Service Call_____________________

Date

Maintenance Performed Performed by

Operator’s Manual page 23 OM-CKPF/3

Rev. 1 2-6-03

Page 24

CKPF/3 MOBILE PUMP/FILL STATION

Limited Warranty to Commercial Purchasers*

(Domestic U.S., Hawaii & Canadian Sales Only)

CapKold Equipment ("CapKold Equipment") has been skillfully manufactured, carefully

inspected and packaged to meet rigid standards of excellence. CapKold warrants its Equipment

to be free from defects in material and workmanship for twelve (12) months with the following

conditions and subject to the following limitations.

I. This parts and labor warranty is limited to CapKold Equipment sold to the original

commercial purchaser/users (but not original equipment manufacturers), at its original

place of installation in the continental United States, Hawaii and Canada.

II. Damage during shipment is to be reported to the carrier, is not covered under this warranty,

and is the sole responsibility of purchaser/user.

III. CapKold, or an authorized service representative, will repair or replace, at CapKold's sole

election, any CapKold Equipment, including but not limited to, safety valves, tipper tie,

pump, motor, air components, ball valve, and electric components, found to be defective

during the warranty period. As to warranty service in the territory described above, CapKold

will absorb labor and portal to portal transportation costs (time & mileage) for the first

twelve (12) months from date of installation or fifteen (15) months from date of shipment

from Groen.

IV. This warranty does not cover calibration, periodic adjustments as specified in operating

instructions or manuals, and consumable parts such as pump motors, gaskets, packing,

etc., or labor costs incurred for removal of adjacent equipment or objects to gain access to

CapKold Equipment. This warranty does not cover defects caused by improper installation,

abuse, careless operation, or improper maintenance of equipment. This warranty does not

cover damage caused by poor water quality or improper boiler maintenance.

V. THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, EACH OF WHICH

IS HEREBY EXPRESSLY DISCLAIMED. THE REMEDIES DESCRIBED ABOVE ARE

EXCLUSIVE AND IN NO EVENT SHALL CAPKOLD BE LIABLE FOR SPECIAL,

CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR THE BREACH OR DELAY IN

PERFORMANCE OF THIS WARRANTY.

VI. CapKold Equipment is for commercial use only. If sold as a component of another (O.E.M.)

manufacturer's equipment, or if used as a consumer product, such Equipment is sold AS IS

and without any warranty.

*(Covers All Equipment Ordered After October 1, 1995)

Operator’s Manual page 24 OM-CKPF/3

Rev. 1 2-6-03

Loading...

Loading...