Page 1

OPERATOR MANUAL

VAPORS AND LIQ

UIDS IN THE VICINITY OF THIS OR ANY

OTHER APPLIANCE

POST IN A PROMINENT LOCATION

GAS. THIS INFORMATION SHALL BE OBTAINED BY

CONSULTING YOUR LOCAL GAS SUPPLIER. AS A MINIMUM,

TURN OFF THE GAS AND

CALL YOUR GAS COMPANY AND

YOUR AUTHORIZED SERVICE AGENT. EVACUATE ALL

PERSONNEL FROM THE AREA.

DAMAGE, INJURY OR DEATH. READ THE INSTALLATION,

MODEL: CC40-G

Combo SuperSystem 40™

Combination Steamer-Oven

Roll-in loading Gas heated

OM-CC40-G

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT USER SMELLS

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTER

ATION, SERVICE OR MAINTENANCE CAN CAUSE PROPERTY

OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGH

LY BEFORE INSTALLING OR SERVICING THIS EQUIPMENT.

Page 2

IMPORTANT — READ FIRST — IMPORTANT

The Groen unit you have purchased has been handcrafted from the finest materials, meticulously

inspected, and pretested at our factory to ensure that you receive the best possible product. With

reasonable care and periodic maintenance, it will provide years of faithful service.

PLEASE READ THIS MANUAL CAREFULLY BEFORE INSTALLING OR OPERATING THE

EQUIPMENT ! It contains information you will need to properly install, operate, and maintain the

equipment.

It is recommended that you establish a timetable for periodic maintenance as outlined in this manual.

Space has been provided in the Service Log. Keep it up-to-date and on file with the warranty information.

Please pay special attention to the section on WATER CONDITIONING. Water quality problems are the

most common cause of steamer failure and are not covered by provisions of the product warranty.

The warranty on this unit does not extend to:

1. Installation and start-up.

2. Simple adjustments, such as tightening fittings and electrical connections.

3. Malfunction as a result of improper maintenance.

4. Repairs made by anyone other than qualified service personnel as recommended by Groen.

5. Damage caused in shipment or damage as a result of improper use.

6. Normal maintenance as outlined in the operator manual.

7. Damage as a result of excessive moisture in components. DO NOT SPRAY THIS EQUIPMENT WITH

WATER OR STEAM.

8. Damage caused by tampering with, removal of, or change of any preset control or safety device.

9. Damage caused by hitting a surface of the unit with a cooking implement or by rubbing or scraping the

surface with abrasive materials.

10. Malfunction as a result of sediment and/or lime in the valves or scale build-up in the steam

generator.

NOTE: MINIMUM water quality STANDARDS MUST BE MET to insure proper operation. WATER

SOFTENING IS RECOMMENDED if the quality of your water does not meet the following

standards. Total dissolved solids (TDS) content should not exceed 30 parts per million, and water

pH should be 7.0 or higher.

11. Labor involved in moving other equipment to gain access to the unit. The user must maintain the

accessibility of the unit for service under the warranty.

12. Damage to electronics caused by exposure to excessive heat or improper spacing of unit from other

sources of heat. A minimum of 2" (5 cm) must be maintained between right side (louvered side) and

any other equipment. A minimum of 12" (31 cm) must be maintained between the unit and any heat

source (braising pan, kettle, etc.).

13. Malfunction or damage to unit due to improper drain connection.

WARNING: USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY

GROEN OR THEIR AUTHORIZED DISTRIBUTOR CAN CAUSE INJURY TO THE

OPERATOR AND DAMAGE TO THE EQUIPMENT AND WILL VOID ALL

WARRANTIES.

SERVICE PERFORMED BY OTHER THAN FACTORY AUTHORIZED

PERSONNEL WILL VOID ALL WARRANTIES.

If you have any questions about warranty coverage, operating procedure, or maintenance, contact your

area Groen representative or an authorized Groen Service Agency.

Page 3

Table of Contents

EQUIPMENT DESCRIPTION.........................................................2, 3, 4

WATER CONDITIONING......................................................................5

INSTALLATION........................................................................6, 7, 8, 9

INITIAL START-UP .......................................................................10, 11

OPERATION.................................. 12, 13, 14, 15, 16, 17, 18, 19, 20, 21

CLEANING & MAINTENANCE

CLEANING.....................................................22, 23, 24, 25, 26, 27

MAINTENANCE......................................................................... 28

DIAGRAMS & SCHEMATICS ............................................................ 29

TROUBLESHOOTING........................................................................ 30

TROUBLESHOOTING GUIDE............................................................ 31

REFERENCES.................................................................................. 32

SERVICE LOG .................................................................................. 33

WARRANTY...................................................................................... 34

1

Page 4

Gas Combo SuperSystem 40

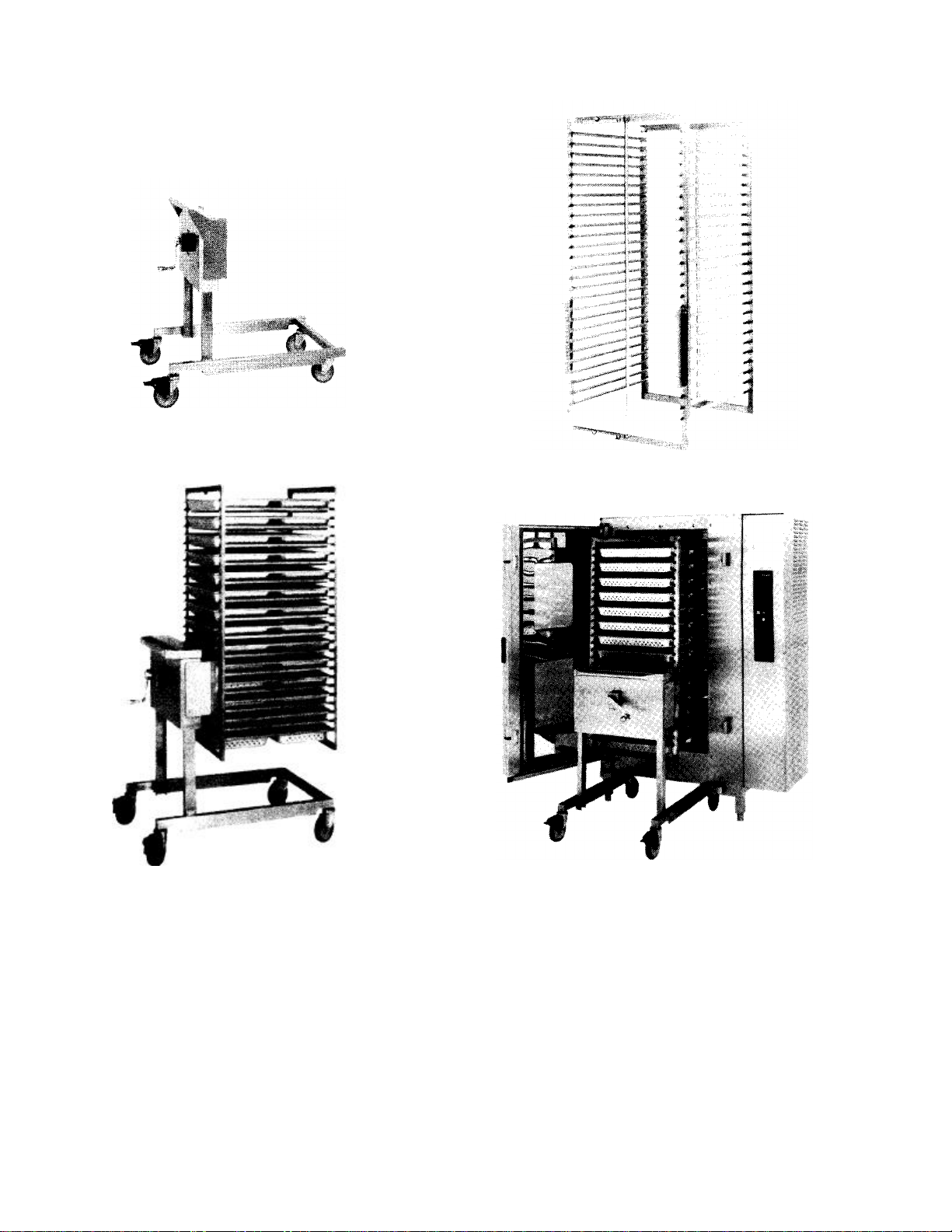

Transport Cart Pan Rack

Transport Cart With Pan Rack

Locked In Place For Loading Etc.

Combo SuperSystem 40 With Cart

And Rack In Loading Position

2

Page 5

Equipment Description

The Groen Convection Combo™ consists of a stainless steel cooking chamber, an air heating

compartment with heat exchange tubes and dual fans, a steam generator, and a control compartment

housing electrical components.

All major components of the Convection Combo are encased in a 16 gauge stainless steel cabinet. Glass

fiber insulation, 1 to 2 inches (2 to 5 cm) thick, lines the cabinet.

The oven has a double door with two large, tempered glass windows in each door. Oven viewing lights

are mounted between the inner and outer doors. Separate hinges allow easy access to the space

between the doors for window cleaning and light fixture maintenance. A condensate collection tray at the

bottom diverts condensate to the oven drain. An optional solid door is available. The solid door does not

provide viewing lights.

All operator controls are on the front panel, with the exception of the pilot ignition switch and main gas

shutoff valve, which are located behind the sliding access door on the front side of the unit.

Standard controls permit the Convection Combo to operate in four modes:

1. As a convection oven

2. As a self-contained, pressureless steamer

3. As a combination oven-steamer

4. With or without the meat probe operating

Cooking chamber capacity:

28 Steam table pans (12 x 20 x 2-1/2"), or

20 Bake pans (18 x 26"), or

40 Gastronorm pans (1/1)

All units are supplied on stainless steel legs.

Controls and monitoring displays for cooking time, operating mode, and temperature occupy the control

panel. The upper portion of the panel has a digital time readout and touch pads for setting the time. Below

the timer section are lights to indicate the status of the unit plus touch pads that select the mode of

operation and switch on the power. A digital readout shows the chosen temperature, which is selected

with a dial. Status of the pilot burners is indicated by the lights above the pilot ignition switch, located

behind the sliding door in the front of the unit.

An insulated, gas fired steam generator is mounted next to the oven. Steam enters the cooking chamber

through two connecting tubes at the top and bottom on the right side of the cavity.

The deliming solution is poured through a port just below the front control panel of the unit. Our unique

automatic cleaning system transfers de-liming solution to the steam generator.

The air heating space, containing the heat exchanger tubes and fans, is separated from the cooking

chamber by removable left, right, top, and bottom partitions.

The compartment containing the automatic controls and other electrical components is on the right-hand

side of the unit and is entered by removing the right outside panel or by opening the hinged panel in the

front.

A drain is located in the removable bottom of the cooking chamber. Fluids drain from this removable

bottom and from the permanent floor to the stainless steel drain pipe outside the oven. This drain pipe

includes a spray condenser, which suppresses any steam escaping from the chamber. The drain

assembly includes a built in vent with overflow protection.

The roll-in loading and unloading equipment for Combo SuperSystem 40 consists of the Model CCS

"Smart Cart" and the separate Model CRS rack. When the rack is engaged with the cart, a hand crank

raises the rack for transportation and lowers the rack to position it in the oven. The cart is disengaged

from the rack and removed before the oven door is closed. Design of the system allows the rack to be

easily held in and transferred between reach-in or walk-in refrigerators and freezers, blast chillers, and

holding cabinets.

3

Page 6

Natural

Gas at

L.P.

Gas at

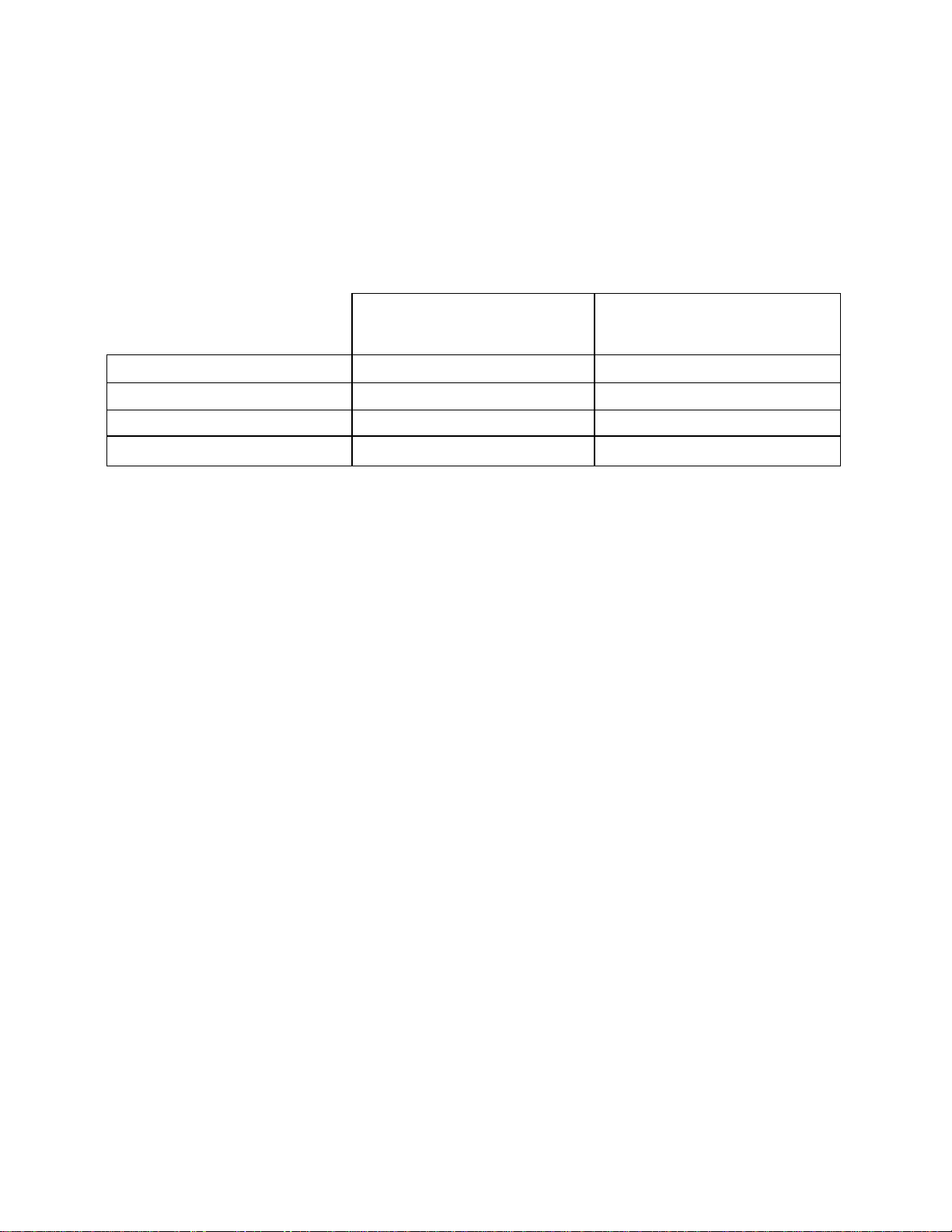

Oven Mode 240,000 (70 kw) 240,000 (70 kw)

Steam Mode 280,000 (82 kw) 280,000 (82 kw)

Combo Mode 300,000 (88 kw) 300,000 (88 kw)

Preheat (Max) 520,000(152 kw) 520,000(152 kw)

*Manifold pressure

Equipment Description

BURNER FIRING RATES

Input Rates, BTU/hr

CC40-G

3.5" W.C. (0.9 kPa)*

10" W.C. (2.5 kPa)*

4

Page 7

Water Conditioning

It is desirable to supply the steamer with water that will not form scale. Scale formation depends on the

hardness of the water and the hours of operation. In a few areas of the United States, the water supply is

sufficiently free of minerals to avoid scale formation. However, most water supplies carry heavy loads of

minerals, which will form scale and possibly cause premature failure of components.

Your local water utility can provide a statement on the scale forming qualities of the water supply. Water

supplied to the boiler should contain not more than 30 parts per million total dissolved solids (TDS) and

should have a pH of 7.0 or higher.

Please follow these simple precautions:

1. Do not rely on "water treaters" commonly sold as scale preventers and scale removers. They do not

work. The only proven way to prevent scale build-up is to feed in water practically free of scaleforming minerals.

2. If your water supply carries scale-forming minerals, as most water supplies do, run the water through

a properly maintained softener. Exchangeable softener cartridges or a regeneratable softener can be

used. In either case, establish a regular program of exchanging the cartridges or regenerating the

softener. Installing a water meter on the inlet line between the softener and the steamer will give an

accurate check of water consumption and a way of determining when to change the cartridge or

regenerate the softener. By using a softener and operating within the softener's capacity to

exchange minerals, the user will optimize performance and minimize maintenance of the steamer.

3. If you notice a slowing of steam production, have your authorized Groen service representative

check the unit for build-up of scale. Heavy scale will reduce the unit's ability to boil water and can

cause a fire tube in the steam generator to overheat and burn out.

TO MINIMIZE SCALE PROBLEMS, USE AND PROPERLY MAINTAIN A SOFTENER, AND CLEAN THE

STEAMER PERIODICALLY OR AS NEEDED.

5

Page 8

Installation

cm) of any

cm) of a heat source, like a

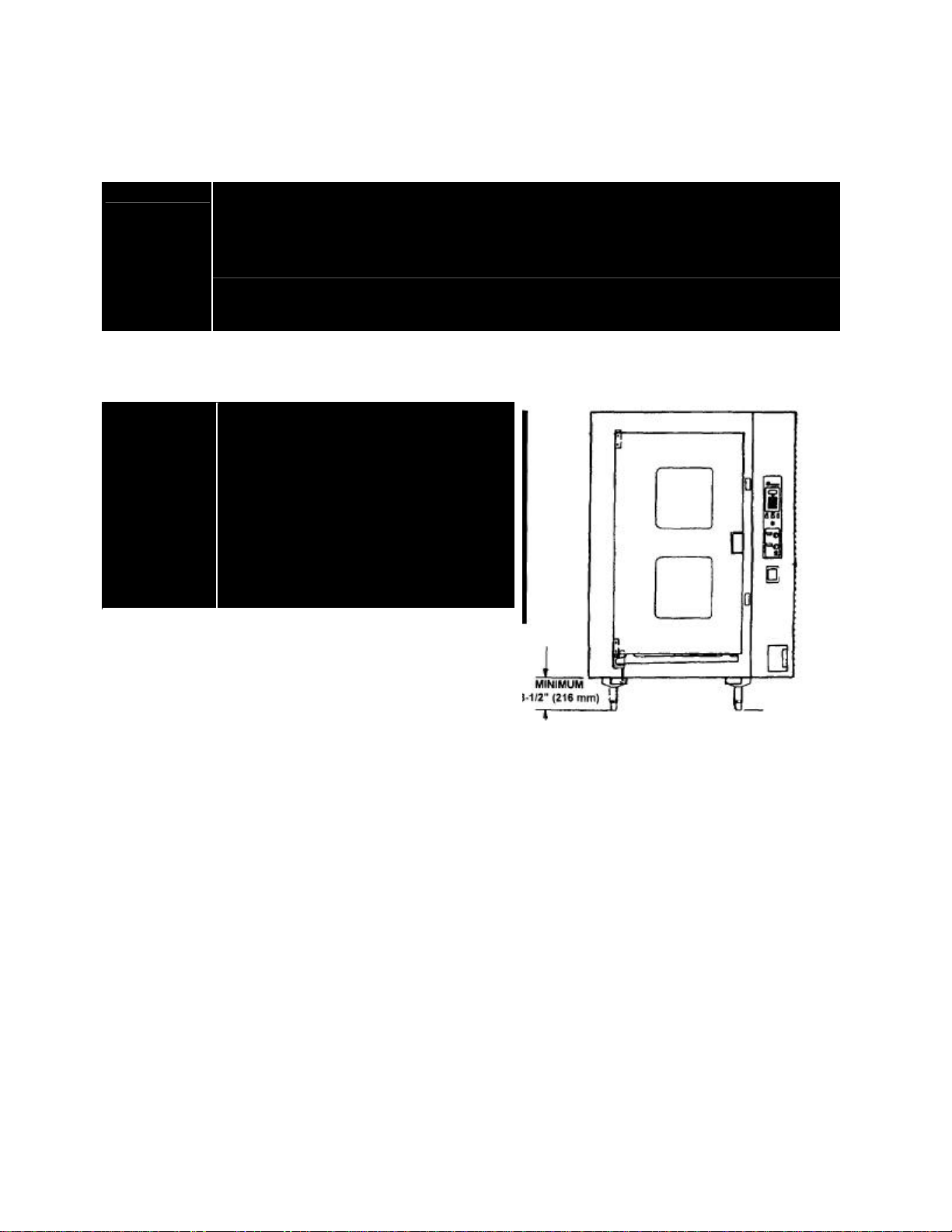

A. Mounting

When the combination oven is received, immediately inspect the unit thoroughly for external and internal

damage. Report any damage to the carrier.

WARNING:

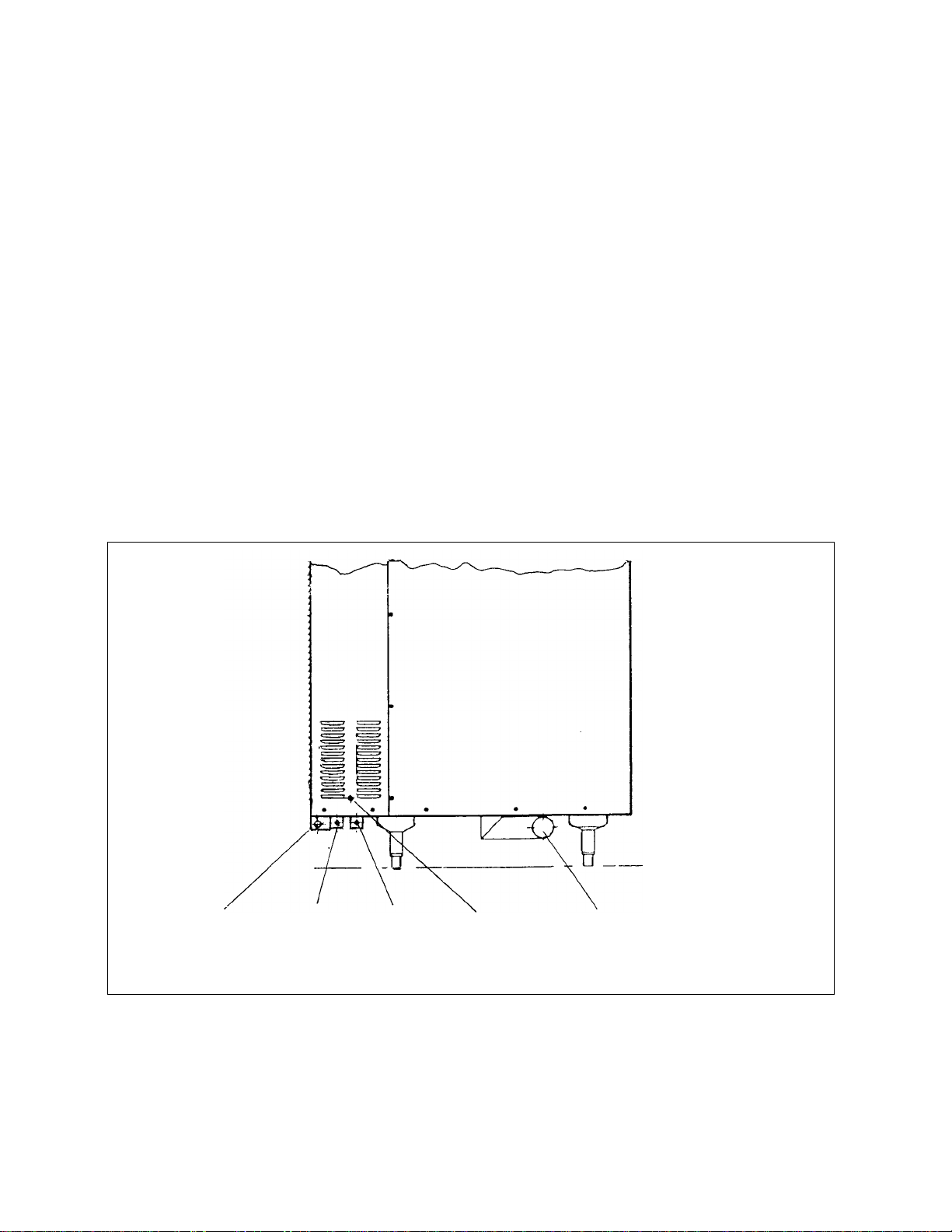

To avoid drainage problems, level the unit front-to-rear, or provide a slight pitch to the rear. Maintain a

minimum 8-1/2 inch (22 cm) clearance between the cabinet and the floor (Figure 2), to permit proper

operation of the cart.

WARNING: THE UNIT MUST BE INSTALLED BY

The CC40-G combination oven is suitable for installation in

combustible and noncombustible locations. The flooring in

all installations must be of a noncombustible material. The

minimum clearances for Installations are:

CAUTION: The CC40-G combination oven

The unit must be installed in an adequately ventilated room with a provision for adequate air supply to the

unit. The unit must be completely installed under a ventilation hood, since flue products exit the appliance

over its entire depth. All items which may obstruct or restrict the flow of air for combustion and ventilation

must be removed. Do not obstruct the flue cover or any front, side, rear, or top vents after installation. The

area directly around the appliance must be cleared of all combustible material. The installation must

conform with local codes, or, in the absence of local codes, with the National Fuel Gas Code, ANSI

Z223.1-latest edition, including:

The appliance and its individual shutoff valve must be disconnected from the gas supply piping system

during any pressure testing of that system at test pressures in excess of 1/2 psig (3.45 kPa). The

appliance must be isolated from the gas supply piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply piping system at test pressures equal to or less than

1/2 psig (3.45 kPa).

Do not install a unit in these locations:

• Where the right side vents are blocked or within 2 inches (5

combustible material or within 12 inches (31

braising pan, deep fryer, char broiler, or kettle.

• To the left of any open-flame equipment.

• With less than 7 inches (18 cm) of clearance at the rear.

PERSONNEL QUALIFIED TO WORK

WITH ELECTRICITY AND PLUMBING.

IMPROPER INSTALLATION CAN

CAUSE INJURY TO PERSONNEL

AND/OR DAMAGE TO THE

EQUIPMENT. THE UNIT MUST BE

INSTALLED IN ACCORDANCE WITH

ALL APPLICABLE CODES.

Right side 2 inches (5 cm)

Left side 0 inches (0 cm)

Rear 7 inches (18 cm) Figure 2

requires 24 inches (61 cm) clearance on the right side for proper service.

6

Page 9

B. Gas Supply Connection

GAS

TREATED UNTREATED

ELECTRICAL

3" (76

mm) DRAIN

NOTICE: Making any electrical or mechanical change in the unit without prior approval from the Groen

Food Service Engineering Department may void all warranties.

Connection to the gas supply can be completed with 1" (2.5 cm) NPT pipe or approved equivalent.

Although the immediate connection to the appliance is 1" (2.5 cm) NPT, gas supply piping must be large

enough to provide 520,000 BTU/hr (152 kw) for each CC40-G. Supply pressure, measured at the back of

the oven, must be at least 6.5" W.C. [1.6 kPa] (maximum 14" W.C. [3.5 kPa]) for natural gas or at least

12" W.C. [3 kPa] (maximum 14" W.C. [3.5 kPa]) for LP gas. In Canada, the installation must conform to

the Canadian Gas Code, CAN 1-B149, Installation Codes for Gas Burning Appliances and Equipment,

and/or local codes.

After the unit has been connected to the gas supply, all gas joints must be checked for leaks. No flame

should be used when checking for leaks. A thick soap solution or other suitable leak detector should be

used.

C. Electrical Supply Connection

For the oven provide 115 VAC, 60 HZ, 1 PH, 15 AMP service. Local codes and/or the National Electrical

Code should be observed in accordance with ANSI/ NFPA 70-1987 (or latest edition). AN ELECTRICAL

GROUND IS REQUIRED. The electrical schematic is located in the service compartment and in this

manual. Maximum load per oven is 11 amps. In Canada, provide electrical service in accordance with the

Canadian Electrical Code, CSA C22.1 Part 1, and/or local codes.

Convection Combo Utility Connections

NOTE: Remove right side panel and make electrical connection at terminal block in rear of control

compartment.

CONNECTION

1"(25mm)

COLD WATER

CONNECTION

CONNECTION

Figure 3

7

CONNECTION

Page 10

Installation (cont'd)

D. Water Supply Connection

Two water connections are provided. One supplies water to the steam generator (treated water), and the other is for

the condensate spray (untreated water). A back siphonage device (check valve) must be installed in each incoming

cold water line according to local plumbing code. The water line pressure should be between 30 and 60 PSIG (210

and 410 kPa). A pressure regulator is required above 60 PSIG (410 kPa). Two 3/4 inch NH (garden hose type)

connectors are required to connect the water supply to the water inlet valves. The minimum diameter of each water

feed line is 1/2 inch (13 mm). Use a washer (or, if necessary, two washers) in the hose connection. Do not allow the

connection to have any leak, regardless of how small.

E. Drain Connection

A hose may be attached to the outlet of the drain by means of a clamp. Use 3" (7.6 cm) ID hose for CC40-G.

The hose may be connected directly to an atmospherically vented building drain.

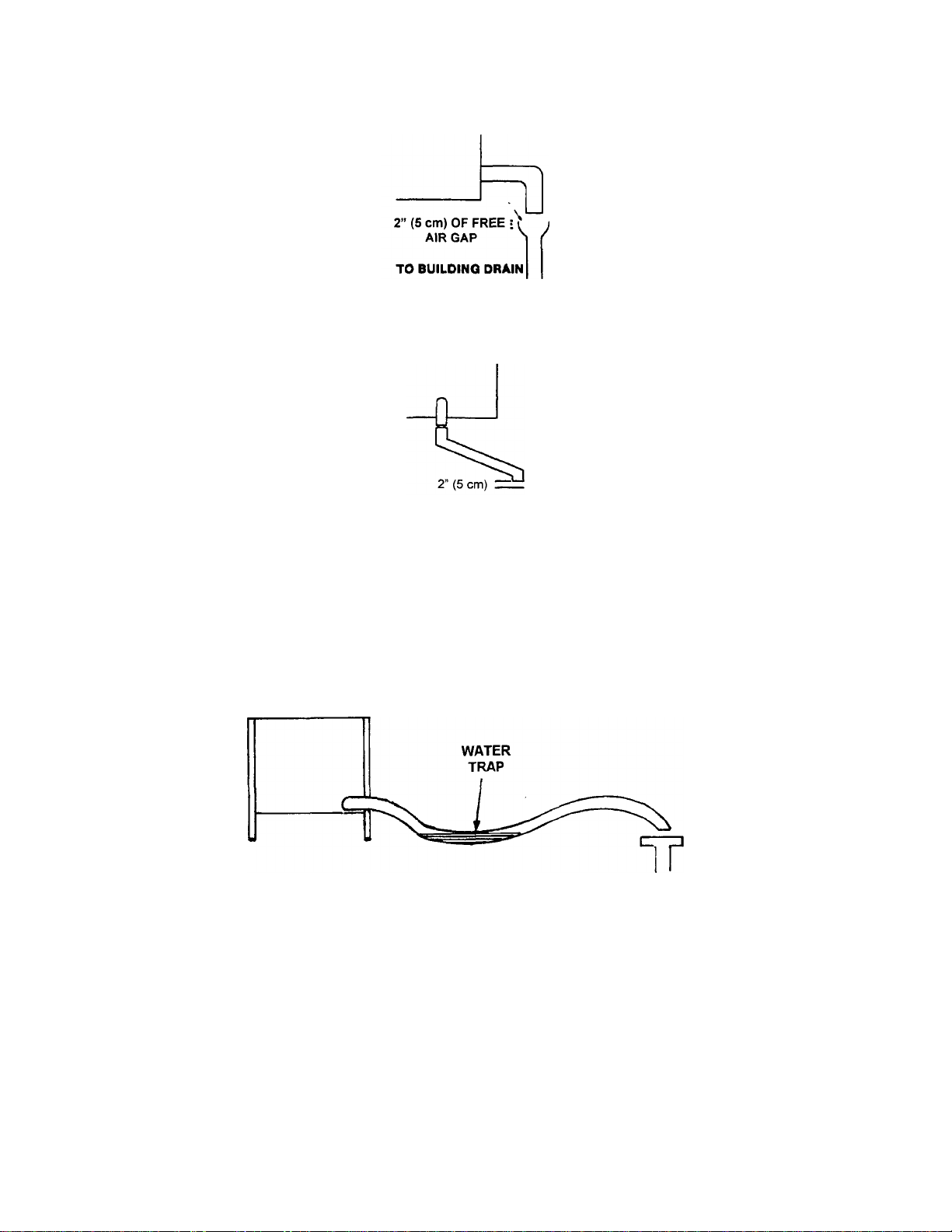

The drain has a 2 inch (5 cm) air vent, which eliminates the need for a free air gap at the connection to the

building drain, unless such a gap (Figure 4) is required by local code. Do not block the air vent in any way. Do

not attach anything to the vent tube or reduce the size of the vent tube.

Do NOT use plastic pipe in the drain line, because the drain must withstand boiling water. Install the drain

line with a constant downward pitch. Do NOT create any water trap (Figure 5) in the line.

8

Page 11

Proper Drain Line Connection

Figure 4

Improper Drain Line Connection

BUILDING

DRAIN

Figure 5

9

Page 12

Initial Start-Up

After the Convection Combo has been installed, perform initial testing to ensure that the unit is operating

correctly.

1. Remove all literature and packing materials from the interior and exterior of the unit.

2. Make sure both cold water supply lines are open and none of the fittings are leaking.

3. Make sure that the gas supply line is open. Turn the knob of the main gas shutoff valve (Figure 6) so it

is lined up with the pipe.

4. Turn on electrical service to the unit. Because the unit will not operate without electrical power, no

attempt should be made to operate the unit during a power failure.

5. The front control panel will not operate until the pilot burners have been ignited. To light the pilot

burners, activate the pilot switch located next to the main gas valve. When the pilot ignition sequence

has been successfully completed, the red lights will glow, and power will then be supplied to the front

control panel.

6. The "trial for ignition" period is roughly 90 seconds. If the pilot burners do not ignite within about 90

seconds after the pilot switch is activated, then the ignition system automatically stops gas flow to the

pilot burner and terminates the ignition trial. If the ignition trial is terminated, turn off the pilot switch

and repeat the trial for ignition. During the initial start-up, the pilots may require several trials for

ignition to bleed air from the gas piping. Subsequent start-ups should require only about 5 seconds to

achieve pilot ignition.

NOTE: See Automatic Operation of Pilot at the end of this section.

7. Once the pilot burner flames have been established (both red lights on top of the pilot switch are on),

subsequent operator commands are executed via the front control panel touch pads. See the

Operation section for details.

8. High altitude operation. The altitude of operation can be programmed into the Convection Combo.

At altitudes above 2,000 feet (610 m), the unit will not operate in Steamer or Combo Mode unless the

altitude is set. This setting should agree with the nameplate. To set the altitude:

a. If the unit is on, turn it off by pressing the ON touch pad.

b. Press and hold the STEAM touch pad while turning the unit on by pressing the ON touch pad. The

timer display will show the letters AL and a number that represents the altitude in thousands of feet.

If the altitude has never been set on your unit, the number displayed will be 1.

c. Enter the proper altitude value, between 1 and 15, using the numbered touch pads. For example, if

the unit will be used at an altitude of 7,000 feet (2100 m), press the 7 touch pad.

d. Press the START touch pad.

9. To test Steamer Mode operation, turn on the unit. (For details of operating procedure, see the

Operation section of this manual.) Clear any time from the time display, close the door, and press the

STEAM touch pad. (If the HOT light is on, see the Fast Cool instructions in the Operation section.)

The WAIT light will stay on while the oven burners preheat the cooking chamber and the steam

generator fills with water and heats the water. Within 15 minutes the WAIT light should go off and the

READY light should come on, indicating that the water has reached the standby temperature. The

timer controls operation (in Steamer Mode only), so enter a time, then push START. The colon on the

time display will blink, and the generator will begin to produce steam. The timer will not count down, if

the READY light is not lit.

WARNING: STEAM CAN CAUSE BURNS. AVOID ESCAPING STEAM WHEN OPENING DOOR.

NOTE: You cannot change modes if the timer is running.

10

Page 13

VALVE

PILOT

10. To test Combo Mode operation, turn the power on and clear any time from the timer display, Press

the COMBO touch pad. Set the COOK temperature to 300°F (150°C). The WAIT light will come on and

stay on, while (1) the steam generator fills with water and heats the water to standby temperature and

(2) the oven burners raise air temperature to 300*F (150°C ). Both actions should be completed in

about 15 minutes, starting with a cold unit. Then the WAIT light will go off and the READY light will

come on.

WARNING: STEAM CAN CAUSE BURNS. AVOID ESCAPING STEAM WHEN OPENING

DOOR.

NOTICE: The timer does not control the oven in Combo Mode or Oven Mode.

11. To test Oven Mode operation, turn the power on and clear any time from the timer display. Press the

OVEN touch pad. Set the COOK temperature to 350°F (175°C). The WAIT light will come on. Within

10 minutes from a cold start, the WAIT light should go off and the READY light should come on. When

that happens, turn the COOK temperature setting down to 300°F (150°C). The HOT light will come on.

12. To test Meat Probe operation, turn the PROBE knob clockwise to activate the probe. Confirm that

the temperature shown in the TIME display is the actual temperature of the probe. Then turn the

PROBE knob counterclockwise to inactivate the probe.

13. The heat-up times stated above may vary slightly due to differences in gas and water pressures.

14. To shut down the unit, first clear the timer. Then press the mode touch pad for the mode the unit is in.

Switch off the power. The pilot burner may also be switched off to conserve energy.

15. If the Convection Combo behaves as described, the unit is functioning correctly and ready for use.

Automatic Operation of Pilot

Once either pilot burner has been ignited, it essentially functions as a standing pilot. When the pilot switch

is on, if the pilot is accidentally extinguished (by a very strong gust of wind or the like), then it will be reignited automatically. The unit will shut off completely for a few seconds while the pilot is re-ignited, then

the unit will come back on and resume operation in the mode and (running) timer value existing just prior

to shutdown. The pilot switch may be turned off during "off hours" to conserve energy.

After the unit has been running, if the pilot burner ever fails to re-ignite automatically within 90 seconds,

then wait 5 minutes before you attempt to reactivate the pilot switch. In the unlikely event that ignition

problems persist, contact your authorized Groen Service Agency.

KNOB

SWITCH

Figure 6

11

Page 14

Figure 7

12

Page 15

NOTICE: All potential users of the equipment should be trained

in safe and correct operating procedure.

CAUTION: DO NOT OPERATE THE UNIT IN ANY MODE,

UNLESS ALL EIGHT REMOVABLE INTERIOR

PARTITIONS HAVE BEEN RETURNED TO THEIR

PROPER LOCATIONS.

NOTICE: Before the control panel can be operated as

described in this Operation section, the pilot burner

flame must be established. See the Initial Start-Up

section for details.

A. Controls and Indicators

The control features routinely used by the operator are on

the right front side of the unit and are described as follows.

(Refer to Figure 7).

1. Time Section

In the Oven and Combo Modes of operation, the timer

functions only as a "cooking time minute minder" and

does not turn the unit on or off. In the Steamer Mode,

the timer controls the operation of the steaming function.

a. Display Window — Displays the operating time

remaining in the Steamer, Oven, or Combo Mode,

because the timer counts down. Format of the

display is "hours : minutes". Maximum minute

display accepted by the unit is 59. Any recipe

calling for more than 59 minutes should be

converted to hours and minutes format, e.g., 90

minutes is equal to 1 hour and 30 minutes. Display

will read 01:30.

b. Time touch pads — used to enter time values.

c. CLEAR — Pressing this touch pad once stops the

beeper and resets the timer to the timer that was

last set. Pressing twice clears the timer to 00:00.

(At the end of a cooking period, opening the door

has the same effect as pressing CLEAR once.)

d. START — Pressing this touch pad will start the

timer and, if the unit is in Steamer Mode, also

cause steaming to begin.

2. Status Lights

a. HOT— Indicates the chamber temperature is more

than 15°F (8°C) above the cook temperature

setting (see item 5 in this section).

13

Page 16

Operation (cont'd)

b. SERVICE — Indicates a problem that may

require a service call. If such a problem has

occurred, the beeper will sound and the

SERVICE light will be on, when power is

switched on. The unit may continue to

operate, depending on the type of problem.

Refer to the Troubleshooting section to

determine the nature of the problem.

c. WAIT— Indicates the unit is either

heating or cooling toward the set

temperature. The HOT and WAIT

lights will be on together, if the

chamber is more than 15°F (8°C)

above the set point.

d. READY— Indicates the unit is ready

for use.

3. Cooking Mode Selection

These touch pads are used to select the

mode of operation. If a mode is off,

pressing the pad for that mode will switch

the mode on. If the mode is on, pressing its

pad will switch the mode off. A light just

above each pad shows which mode has

been selected

a. STEAM — Selects steamer operation. .

b. COMBO—Selects combined steam and

convection oven operation.

c. OVEN — Selects operation of the

convection oven only.

4. Power

This touch pad is used to switch the unit on

or off. When power is on, the ON light just

above the pad is lit Use of this pad does

not reset the controls, so the unit will come

on in the same mode it was in when it was

last switched off.

5. TEMP Section

a. The window displays the selected

temperature in either Oven or Combo

Mode. It is blank in the Steamer Mode.

b. Turning the knob selects the cooking

temperature in 5°F or 5°C increments. The

control ranges are:

Oven Mode 200 to 500*F (93 to 260°C)

Combo Mode 220 to 500*F (105 to 260°C)

6. Meat Probe Selection

This rotating knob is used to turn on or off the hold function. By selecting a certain temperature

(ranging between 80*F [27°C] and 200*F [93°C]) the food can be maintained at a constant

temperature for a fixed amount of time.

7. Door Lights Selection

Door lights can be turned on/off to view the food inside by using this touch pad. These lights are

not available with the optional solid door.

14

Page 17

B. Operating Instructions

1. Steamer Mode

a. If the unit is off, switch on the electric power by

pushing the ON touch pad. (If the SERVICE

indicator lights when power is switched on, see the

Troubleshooting section.)

b. If power is already on and any number is showing

in the time display window, press the CLEAR touch

pad one or more times to reset the time display to

zero.

NOTICE: You cannot change mode while the timer is

running

c. The unit will be in the mode of operation that was

used last, so the indicator for that mode will be lit. If

the unit is not already in Steamer Mode, press the

STEAM touch pad. The STEAM indicator will light,

and the TEMP window will go blank.

d. If the unit has just been used in Oven or Combo

Mode, lighting of the HOT indicator may show that

the cooking chamber is too hot for use as a

steamer. The unit can be cooled quickly to the

proper temperature range for steaming by leaving

the door open or by following the Fast Cool

procedure described near the end of this section.

WARNING: STEAM CAN CAUSE BURNS.

AVOID ESCAPING STEAM

WHEN OPENING DOOR.

While the door is open, the generator can fill and

heat water to 200°F (93°C), but it cannot produce

steam.

e. The WAIT indicator will be lit until the water reaches

approximately 200°F (93°C). Then the WAIT light

will go off and the READY indicator will light. You

are now ready to steam foods in your Convection

Combo.

f. Load the food into the pan or pans so there is a

uniform layer.

g. Make sure the hooks on the rack are fully

engaged in the slots of the cart while raising the

rack. The pan stop should be in the center position

when moving the cart with the rack engaged.

NOTICE: Use the brakes on the rear wheels to hold

the cart in steady position.

h. Place the pans in the rack, which is on the cart. If

there are only few pans, uniformly distribute them

in the center of the rack.

i. Press the numbered touch pads to set the cooking

time. The time set will appear in the time display

window. If you enter the wrong number, press the

CLEAR pad to erase the time from the display,

then set the time again.

j. Carefully open the door, then move the cart so the

rack goes into the oven cavity. Using the hand

crank, lower the rack to the floor of the cavity.

Remove the cart and close the door.

15

Page 18

Operation (cont'd)

k. When the correct cooking time has been entered,

press the START pad. The colon will blink, and the

timer will count down the cooking time. (The unit must

be READY before the timer can count down.)

I. Opening the door during the cooking period stops the

production of steam and interrupts (but does not reset) the

timer. Closing the door allows steaming and timing to continue.

WARNING: STEAM CAN CAUSE BURNS. AVOID ESCAPING STEAM

WHEN OPENING DOOR.

m. When the timer has counted down to zero, it will stop the

generation of steam and sound a beeper alarm. Water in the

steam generator will be held at the standby temperature (about

200°F or 93°C). The beeper will continue until the door is

opened or the CLEAR pad is pressed.

n. Carefully open the door. If the food is cooked, engage the cart

with the rack. Make sure the hooks on the rack are fully

engaged in the slots of the cart. Then crank the rack up, and

remove the rack from the oven.

o. After the timer display has counted down to zero, opening the

door or pressing CLEAR once will reset the display to the time

that was used last. Pressing START will repeat the cook cycle.

If the same cooking time will be used repeatedly, you need to

press the number keys only when you first use that time.

p. After the timer display has counted down to zero the timer can

be reset to zero by either (1) opening the door and pressing

CLEAR or (2) pressing CLEAR twice. A new cooking time

must be set by using the number keys.

2. Oven Mode

a. To use the Convection Combo as a convection oven,

first switch on the electric power by pushing the ON

touch pad. (If the SERVICE indicator lights when the

power is switched on, see the Troubleshooting

section.) The fans will begin to operate, if the door is

closed and the cooking chamber temperature is

above 200°F (93°C).

b. If power is already on and any number is showing in

the time display window, press the CLEAR touch pad

to erase the time display.

NOTICE: You cannot change mode while the timer is running.

c. The unit will be in the mode of operation that was

used last, so the indicator for that mode will light. If

the unit is not already in Oven Mode, press the OVEN

touch pad. The OVEN indicator will light, and the oven

fans will operate.

16

Page 19

d. Using the dial in the TEMP section of the control

panel, set the desired cooking temperature, which

will appear in the temperature display window

beside the dial. Unless the cooking chamber is

already at or above the set temperature, the unit

will begin heating the chamber, and the WAIT

indicator will light.

e. If the unit has just been used at a temperature

more than 15°F (8°C) higher than the desired

temperature, the HOT and WAIT indicators will

light. The unit can be cooled quickly to the correct

temperature by leaving the door open or by

following the Fast Cool procedure near the end of

this section.

f. The READY light will indicate when the oven is at

the desired temperature.

g. Make sure the hooks on the rack are fully

engaged in the slots of the cart while raising the

rack. The pan stop should be in the center position

when moving the cart with the rack engaged.

NOTICE: Use the brakes on the rear wheels to hold the

cart in steady position.

h. Load the food into the pan or pans so there is a

uniform layer.

i. Place the pans in the rack. which is on the cart. If

there are only few pans, uniformly distribute them

in the center of the rack.

j. The Convection Combo will operate in Oven Mode

with the timer either on or off. If you wish to time

the cooking, press the numbered pads at the TIME

portion of the control panel to set the cooking time.

The time set will appear in the time display

window. If you enter the wrong number, press the

CLEAR touch pad twice to erase the time from the

display, then set the time again. Remember that

the timer does not control the unit in Oven Mode.

WARNING: HOT AIR CAN CAUSE BURNS.

AVOID ESCAPING HOT AIR

WHEN OPENING DOOR.

k. Carefully open the cooking chamber door. Push the

cart so the rack goes into the oven cavity. Using

the hand crank, lower the rack to the floor of the

cavity. Remove the cart and close the door.

I. If cooking time has been set on the timer,

immediately press the START touch pad. Timing

will begin, and the time shown in the display will

decrease. When the timer has counted down to

zero, it will sound a beeper. The beeper will sound

until door is opened or the CLEAR touch pad is

pressed.

m. To stop cooking, engage the cart with the rack.

Make sure the hooks on the rack are fully engaged

in the slots of the cart. Then crank the rack up, and

remove the rack from the oven. The unit will

continue heating to keep the cooking chamber at

the set temperature, until the temperature controls

are reset or power is shut off.

17

Page 20

Operation (cont'd)

n. Opening the door during operation shuts off power

to the oven burners and fans and stops the timer,

but it has no other effect on the controls. When the

door is closed, operation continues as before. Note

that leaving the door open will extend the cooking

time.

3. Combo Mode

a. If the unit has been turned off, switch on the

electric power by pushing the ON touch pad. (If the

SERVICE indicator lights when power is switched

on, see the Troubleshooting section.) The fans

will begin to operate, if the door is closed and the

cooking chamber temperature is above 200°F

(93°C).

b. If power is already on and any number is

showing in the time display window, press the

CLEAR touch pad to erase the time display.

NOTICE: You cannot change mode while the

timer is running.

c. The unit will be in the mode of operation that was

used last, so the indicator for that mode will be lit.

If the unit is not already in Combo Mode, press

the COMBO touch pad. The COMBO indicator

will light. If the steam generator is not already full

of water, water will flow into it and be heated.

d. Set the desired oven temperature (between 220

and 500°F or 105 and 260°C) with the dial in the

TEMP section of the control panel. The set

temperature will be shown in the temperature

display window beside the dial.

e. If the unit has just been used in Oven or Combo

Mode, the HOT indicator may light, showing that

the cooking chamber is too hot for use at the set

temperature. The chamber may be cooled

quickly by leaving the door open or by following

the Fast Cool procedure near the end of this

section.

WARNING: STEAM CAN CAUSE BURNS.

AVOID ESCAPING STEAM WHEN OPENING

DOOR.

While the door is open, the fans and oven

burners will not operate, but water in the steam

generator will be kept ready for steam

production.

f. The WAIT indicator will be lit until the water in

the steam generator reaches the boiling point

and the air in the cooking chamber reaches the

set temperature. Then the WAIT light will go off

and the READY light will come on, indicating that

the oven is at the desired temperature.

18

Page 21

g. Make sure the hooks on the rack are fully

engaged in the slots of the cart while raising the

rack. The pan stop should be in the center position

when moving the cart with the rack engaged.

NOTICE: Use the brakes on the rear wheels to hold

the cart in steady position.

h. Load the food into the pan or pans so there is a

uniform layer.

i. Place the pans in the rack, which is on the cart. If

there are only few pans, uniformly distribute

them in the center of the rack.

WARNING: STEAM CAN CAUSE BURNS.

AVOID ESCAPING STEAM WHEN

OPENING DOOR.

j. The unit will operate in Combo Mode with the

timer either on or off. If you wish to time the

cooking, press the numbered pads in the TIME

portion of the control panel to set the cooking

time. The set time will appear in the time display

window. If you enter the wrong number, press

the CLEAR touch pad twice to erase the time

from the display, then set the time again.

k. Carefully open the door, then move the cart so

the rack goes into the oven cavity. Using the

hand crank, lower the rack to the floor of the

cavity. Remove the cart and close the door.

I. If the timer has been set, immediately press the

START touch pad. The time shown in the display

will decrease. When the timer has counted down

to zero, it will switch on the beeper. The beeper

will sound until the door is opened or the CLEAR

pad is pressed. Remember that the timer does

not control or shut off the unit in Combo Mode.

m. To stop cooking, engage the cart with the rack.

Make sure the hooks on the rack are fully engaged

in the slots on the cart. Then crank the rack up,

and remove the rack from the oven. The unit will

continue steaming and heating the oven, until the

temperature controls are reset or power is shut off.

4. Fast Cool

a. When the HOT indicator is lit and the timer has

been cleared, the unit can be cooled quickly by

opening the door and pressing the START touch

pad. The fans will operate, and the TIME window

will display the word "COOL". This is the only time

the fans will operate with the door open.

WARNING: DO NOT PUT HANDS OR OTHER OBJECTS

INTO THE COOKING CHAMBER DURING

FAST COOL OPERATION. ROTATING

FANS CAN BE HAZARDOUS AND RESULT

IN SERIOUS INJURY AND DEATH.

19

Page 22

b. Pressing any touch pad or closing the door will

stop the Fast Cool operation.

5. Shutting Down

To shut down the Convection Combo unit, first press the

mode touch pad for the mode in which the unit is

operating. Then switch off the power by pressing the ON

touch pad. The pilot switch may also be turned off to

conserve energy. Leave the door at least slightly open,

if local sanitation regulations permit.

6. Meat Probe

The meat probe function holds meat at a constant

temperature after the meat has been cooked. This

function can be turned on or off by rotating the PROBE

knob (Figure 8).

a. Set the controls for Oven or Combo Mode

operation and set the COOK temperature.

b. Insert the probe to an appropriate position in the

meat.

c. Using the PROBE knob, set the desired final internal

meat temperature within a range of 80°F (27° C) to

200° F (93° C). This set point temperature can be

seen in the PROBE display. The TEMP display

shows the cooking temperature set for the oven.

d. The actual temperature of the probe is shown in the

TIME display at the top of the panel. The display will

remain in this state until the probe temperature

reaches the set point. Then the beeper will sound,

heat to the steam generator will shut off, and oven

operation will regulate the air temperature at the

probe set point.

e. The meat temperature will now be displayed in the

TIME window and will blink.

f. After 1 minute of beeping or if CLEAR is pressed or if

the door is opened, the TEMP display will begin

counting up in hours:minutes to indicate how long the

food has been at the set point.

NOTE: The meat probe will not operate in the Steam

Mode.

The meat probe cannot be selected if the timer is

running or paused.

7. Door Lights

a. The door lights can be turned on by pressing the

Light touch pad.

b. Once turned on, the lights will be on for 30

seconds or until the touch pad is pressed again to

turn the lights off.

These lights are not available with the optional solid

door.

20

Page 23

21

Figure 8

Page 24

Cleaning & Maintenance

2.

3.

7. Spray bottle

THE LABEL OF EACH CLEANING AGENT.

DO NOT PUT HANDS OR TOOLS INTO THE COOKING CHAMBER UNTIL

NOTICE:

Do not use a cleaning or de

-

liming agent that contains sulfamic acid or any

including hydro

chloric acid (HCI). To check for content of these substances, refer

CLEANING INSTRUCTIONS

Cleaning should be done regularly to keep the Convection Combo in proper operating condition and to

make the cleaning process faster.

A. Recommended Cleaners and Tools

1. Mild detergent

Stainless steel cleaner, for example, Zepper from Zep Manufacturing Co.

Steam generator de-liming agent, like Groen delimer/descaler P/N 114800 or Lime-A-Way from

Ecolab (1-800/352-5326). De-liming agent should contain phosphoric acid, not to exceed 30%

total volume. See notice about sulfamic acid and chlorides below.

4. Oven degreaser, like Groen spray degreaser P/N 114801, Easy-Off non-caustic, Encompass,

Malone 34, Oven Cleaner 200, or Con-Lie

5. Cloth or sponge

6. Plastic wool or brush with soft bristles

8. Measuring cup

9. Nylon, scrub pad

10. Towels

11. Plastic disposable gloves

B. Precautions

WARNING: TO AVOID BODILY INJURY, BEFORE CLEANING THE OUTSIDE OF THE

STEAMER, OR REMOVING ANY PARTITION OR PANEL, DISCONNECT

THE ELECTRIC POWER SUPPLY. KEEP WATER AND CLEANING

SOLUTIONS OUT OF CONTROLS AND ELECTRICAL COMPONENTS.

NEVER HOSE OR STEAM CLEAN ANY PART OF THE UNIT.

ALLOW COOKING CHAMBER TO COOL BEFORE CLEANING.

CAREFULLY READ THE WARNINGS AND FOLLOW THE DIRECTIONS ON

DO NOT MIX DE-LIMING AGENT (ACID) AND DEGREASER (ALKALI) IN

THE STEAM GENERATOR OR ON THE COOKING CHAMBER WALLS.

THE FANS HAS STOPPED TURNING.

DO NOT OPERATE THE UNIT UNLESS THE REMOVABLE RIGHT SIDE

PANEL HAS BEEN RETURNED TO ITS PROPER LOCATION.

"Material Safety Data" sheet provided by the cleaning agent manufacturer.

NOTICE: Use no degreaser that contains potassium hydroxide or sodium hydroxide or that

highly alkaline.

22

Page 25

C. Cleaning Outside

1. Prepare a warm solution of the detergent as instructed by the supplier. Wet a cloth with this

solution and wring it out. Use the moist cloth to clean the controls, control panel, and other

electrical parts that must not have liquid running freely on them.

WARNING: BE CAREFUL IN CLEANING THE TOP FLUE COVER AND THE TOP OF THE

OVEN, THESE AREAS MAY BE VERY HOT.

2. To remove materials stuck to the unit, use plastic wool, a soft-bristle brush, or a plastic or

rubber scraper with detergent solution. Do not use any metal material (like a metal sponge)

or metal implement (like a spoon, scraper, or wire brush) that might scratch the surface.

Scratches make the surface hard to clean and provide places for bacteria to grow. Do not

use steel wool, which may leave particles imbedded in the surface and cause eventual

corrosion and pitting.

3. Stainless steel surfaces on the outside of the unit may be polished with a recognized

stainless steel cleaner.

D. Cleaning Inside

To automatically clean the cooking chamber and/or de-lime the steam generator, a special sequence of

operations (the Clean Cycle) has been programmed into the Convection Combo computer. To run this

automatic Clean Cycle for cooking chamber cleaning, steam generator de-liming, or both actions at the

same time, follow the instructions as outlined in the table below:

Degrease Cooking

Chamber Only

Omit Step 2 Omit Step 1 Perform all steps

Following the oven cleaner supplier's instructions, you must bring the oven to a temperature of 200°F

(93°C) or less. Do not begin degreasing or de-liming while the oven is above 200°F (93°C).

Close the door, put the unit into Oven Mode, and select 200°F (93°C). If the HOT light is on, use the Fast

Cool Mode to cool the oven until the HOT light goes off. If the HOT light does not come on, immediately

open the door to shut off the oven burners. Once the HOT light is off, you can proceed safely.

When the oven has reached the desired temperature, take the unit out of Oven Mode by clearing the timer

and pressing the OVEN touch pad. Enter "99" (00:99) into the timer. The timer window will display "CC" or

"CL".

WARNING: DO NOT REACH INTO THE OVEN DURING FAST COOL. BEFORE

YOU REACH INTO THE OVEN TO REMOVE PARTITIONS, EXIT THE FAST COOL

MODE BY PRESSING ANY BUTTON OR BY CLOSING AND REOPENING THE

DOOR. ALLOW THE FANS TO STOP BEFORE CONTINUING. FAILURE TO DO SO

CAN RESULT IN SERIOUS INJURY OR DEATH.

Step1. Degreasing

During most Clean Cycles, adequate cleaning can be done by just removing the top and bottom

partitions and swinging open the side partitions to apply the oven cleaner. Remove all

partitions only when more complete cleaning is necessary.

Open the door, wait until the fans stop moving, and then remove the oven rack and the top and

bottom partitions. Use a glove if the oven is hot. Left and right side partitions do not need to be

removed for cleaning; they can just be swung open. To remove the partitions (even if the left and

right side partitions have to be removed), follow in reverse order the installation procedure

described below.

De-Lime Steam

Generator Only

Degrease Chamber and

De-Lime Generator

23

Page 26

Cleaning & Maintenance (cont'd)

CAUTION: Do not operate the unit in any mode unless all eight removable partitions

have been returned to their proper locations.

Make sure to clean all food particles out of the drain. Following the oven cleaner supplier's

instructions, apply cleaner to the oven walls and heat exchange tubes and to the rear face of

each of the eight removable partitions. Return the eight partitions to their proper locations in the

following order.

Top: The top partition is flat and has no holes. Install it by pushing up, then pushing from

right to left to rest it on the solid bars at the top of the cavity.

Bottom: The bottom partition has a small circular pattern of drain holes. Lay the panel flat and

push all the way to the rear by holding the latch in the vertical position. Drop the latch

down once the partition is in place (Figure 9).

Right: The right side partitions include a large, circular, flared opening that must be

centered in front of the fans. Line up the upper hole on the upper partition with the

upper pin and lift the partition all the way up. Now line up the bottom hole with the

bottom pin and release the partition. Swing the partition into place with the latch

handle in the open position, then close the latch (Figure 10). Similar procedure is

followed to place the right side lower fans partition.

Left: The left side inner partitions are solid plates, while the outer partitions have louvers in

them. Line up the top pin on the plate with the top hinge hole in the cavity, and

release it so that the bottom pin lines up with the bottom hinge hole. Similar

procedure is followed for the other inner and outer partitions on the left side. Latching

can be done by swinging the partitions into place with the latch handle moved to the

open position. Close the outer partitions and push the latch handle behind the pin

(Figure 9).

Apply oven cleaner to the interior faces of the eight partitions and to the inner door panel. If you

wish, you may also apply oven cleaner to the rack and return the rack to the oven.

The drip pan in the cart must be cleaned along with the cart and the rack.

24

Page 27

Figure 9

Figure 10

25

Page 28

Cleaning & Maintenance (cont'd)

Step 2. De-Liming

Hardness of the water affects how well the de-limer works. If the water is very hard, stronger

solutions of the de-limer may be needed, and de-liming may need to be done more often. Use a

properly maintained water softener. (Refer to the Water Conditioning section of this manual.)

Following the directions of the supplier, pour de-limer into the de-liming port located under the

control panel on the front of the unit. The capacity of the steam generator is 12 gal (45 L). If you

are using Lime-A-Way, pour in 2 3/4 quarts (2.6 L).

NOTICE: Do not use more than the recommended amount of de-liming agent. Overflow of

excess agent could damage the unit.

Pour 1 cup of liquid de-limer directly into the cooking chamber drain.

WARNING: IF THERE IS OVEN CLEANER ON OR NEAR THE OVEN FLOOR

DRAIN, POUR ONLY A SMALL AMOUNT OF DE-LIMER AT FIRST, TO

MAKE SURE THERE IS NO RAPID REACTION BETWEEN THE OVEN

CLEANER AND DE-LIMER. DO NOT BREATHE ANY RESULTING FUMES.

Step 3. Degreasing and/or De-Liming

Close the oven door and press START. The display will now read "CL:45", and the colon will

blink once each second. The unit will now begin an automatic sequence that involves heating,

draining, and refilling the steam generator at various time intervals. The display will count down

each minute.

NOTICE: To exit the Clean Cycle at any time, press and hold the CLEAR touch pad for 3

seconds.

After you exit the Clean Cycle, and before you cook any food in the unit, be sure to

wash out all chemical residues thoroughly by filling and draining the steam generator.

To fill the generator, enter Steam Mode and wait about 4-5 minutes. To drain the

generator, take the unit out of all modes, or turn the unit off; then wait 10 minutes. It

is strongly recommended that the unit be run 10 minutes in Steam Mode prior to use.

Also, wipe chemical residues from the cooking chamber interior with a wet, clean

cloth before you cook in the unit. Rinse the cloth often. This cleaning includes both

sides of each of the eight removable partitions, the rack, and the tubes and walls

behind the partitions. The partitions can be rinsed in a sink.

When the Clean Cycle is complete, the display will read "00:00".

WARNING: THE OVEN MAY BE HOT ENOUGH TO BURN YOU. DO NOT TOUCH ANY

HOT SURFACE.

Before you use the unit for cooking, wipe the whole interior with a clean, wet cloth. Rinse the

cloth often. This cleaning includes both sides of each of the eight removable partitions, the rack,

and the tubes and walls behind the partitions. The partitions can be rinsed in a sink.

CAUTION: Do not operate the unit in any mode unless all eight removable interior

partitions have been returned to their proper locations.

If the unit will not be used right away, leave the door open long enough to let the chamber dry

completely.

26

Page 29

Cleaning & Maintenance (cont'd)

E. Errors During Cleaning

If the timer stops, the beeper sounds continuously, and the SERVICE light stays on, there has been an

error that prevents the unit from completing the Clean Cycle. There are two types of error:

1. Non-critical error. It is signaled by three quick beeps with the SERVICE light going out after 30

seconds. The timer does not stop.

If the Service Code displayed is 1 or 2, but not both, the unit may need more cleaning.

2. Critical error. It is signaled by a continuous 5 second beep with the SERVICE light staying on. the

timer stops. Take the following steps.

a) Perform a reset. With the unit turned off, press and hold the COMBO touch pad. Then press

the ON touch pad.

b) If the Service Codes displayed are 1 and 3 or 2 and 3 or 8, press CLEAR, and restart the

Clean Cycle by entering "99" (00:99) on the timer. Refill the CLEAN tank with de-liming agent.

Then continue the Clean Cycle by pressing START.

c) If the Service Codes displayed are 1 and 2 or 6, call your authorized Groen Service Agency for

immediate service.

If there are other errors, see the Troubleshooting section.

F. Clean Cycle Counter

The unit totalizes the number of complete clean cycles. To see this total, first turn off the unit. Press and

hold the 0 touch pad while you turn the unit on. The total will be displayed in the timer window. The Clean

Cycle counter cannot be reset.

27

Page 30

MAINTENANCE BY THE OPERATOR

The Convection Combo is designed f or minim um m aintenance. Certain parts may need replacement after

prolonged use. If a service need arises , only Groen personnel or authorized Groen repres entatives should

perform the work.

Always supply water that meets the standards outlined in the Water Conditioning section of this manual If

steam or condensate is noticed leaking from around the door seal, take the following steps:

1. Check the condition of the gasket, and replace a cracked or split gasket.

2. To inspect the cooking chamber for drain blockage, remove the bottom partition and check the drain

opening in the oven floor.

3. If the previous steps do not stop leakage at the door, find the locations of the leaks by operating the

unit in Steam Mode. After the READY indicator lights, enter 10 minutes (00:10) in the timer and press

START. Mark the places around the door where water leaks out.

4. Have the following tools ready for use:

1/4 inch (6.4 mm) flat blade screwdriver 1/2 inch (12.7 mm)

combination wrench 1/2 inch (12.7 mm) socket with 3 inch (76 mm)

extension and ratchet

5. If the door leakage is on the hinge pin (left) side follow this procedure:

a) Mark the position of the 1/2 inch (12.7 mm) hex bolts on the top and bottom edge of the door near

each hinge pin.

WARNING: STEAM CAN CAUSE BURNS. AVOID ESCAPING STEAM WHEN OPENING DOOR.

b) Open door and loosen the hex bolts. If steam is leaking from the hinge bottom or top corner then

only loosen those bolts. Move the hex bolt heads toward the cavity and then retighten.

c) Repeat Steam Mode leak check and repeat steps and a & b as necessary.

6. If the door leakage is on the door pin (right) side follow this procedure.

a) Remove the two 8-32 x 3/8 inch (9.5 mm) truss head screws and cover plate behind the door pin

mounting plate.

b) Mark the position of the 1/2 inch (12.7 mm) hex nuts and the 1/2 inch (12.7 mm) hex bolts.

c) Check that the door pin is centered in each of the door slots. If necessary loosen the 1/2 inch (12.7

mm) hex bolts to reposition each door pin in the center of the door slot.

d) Loosen the 1/2 inch (12.7 mm) hex nuts on the top and bottom as needed. Move the door pin

plates(s) toward the cavity and retighten.

e) Repeat steam mode leak check and repeat step d as needed.

f) Replace cover plate and the two 8-32 x 3/8 inch (9.5 mm) truss head screws.

28

Page 31

Page 32

Troubleshooting

A. Pilot Burner

Remember that the front control panel will not operate until the pilot switch has been activated

and the pilot burner flames have been established (red lights are on). For details see the Initial

Start-Up section. If the procedure described in the Initial Start-Up section has been followed and

the pilot burner still does not ignite, then contact your authorized Groen Service Agency.

The following troubleshooting information concerns the unique self-diagnostic features of the

Groen Convection Combo and assumes that the pilot burner flames have been established.

B. Resetting the Solid Stat e Cont rols

If the controls stop responding to normal operating procedures, or if the unit is otherwise

behaving in an unusual way, reset the controls by the following procedure:

1. Switch off the power by pressing the ON touch pad.

2. While pressing the COMBO touch pad, switch the power on again. If no errors are present,

C. Meat Probe Error

If the Probe Temperature display reads PrOb OUT, then it means the meat probe is not

connected. Connect the meat probe and rotate the PROBE knob to the required temperature

setting (ranging between 80°F and 200°F).

the unit will beep and show four zeros in the timer display. If any errors are found, unit will

not beep, and Service Codes will be shown in the timer and cook temperature displays.

NOTE THESE SERVICE CODES. (A display showing "12" means error codes 1 and 2.

There is no error code 12.) Press the CLEAR touch pad to exit the Service mode, then

refer to the following explanation of service messages.

D. Service Messages

There are two types of service message:

1. Non-critical error. It is signaled by three quick beeps with the SERVICE light going out after

30 seconds.

2. Critical error. It is signaled by a continuous 5 second beep with the SERVICE light staying

on.

If there is a non-critical error, you may continue to operate the unit. When possible, inspect the

Service Code. To do this, begin with the power off. While pressing the COMBO touch pad,

switch on the power by pressing the ON touch pad. Note the number and refer to the

Troubleshooting Guide. To Clear the Service Code, press the CLEAR touch pad.

If there is a critical error, the unit will not operate in its present mode, but it may operate in

another mode. Inspect the Service Code, as instructed above, then call your authorized Groen

Service Agency.

If the problem continues after y ou follow the instructions in the Troubleshooting Guide, call your

authorized Groen Service Agency.

30

Page 33

play

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

y

Troubleshooting Guide

If a problem persists after taking the actions suggested below, call your authorized Groen Service Agency.

Service Code Action Required

1 = Low water level probe Try cleaning the steam generator to remove any

2 = High water level probe contamination from the probes.

If either code is still dis

ed after you clean the

generator, call your Groen Service Agency.

If both codes are displayed, the unit will operate in the

Oven Mode only. If only one code is displayed, the

unit will operate in all modes, but water may overflow

from the generator into the cooking chamber during

operation in Steamer or Combo Mode.

3 = Maximum generator fill time (10 minutes) Make sure the water supply is turned on fully and the

exceeded hoses are not kinked or pinched.

If the code is still displayed, the unit will operate in

Oven Mode only. Call your Groen Service Agency.

4 = Faulty air probe Call your Groen Service Agency. The unit will operate

in Steamer and Clean Cycle Modes only.

5 = Faulty drain probe Call your Groen Service Agency. The unit will operate

in all modes.

6 = Faulty generator probe Call your Groen Service Agency. The unit will operate

in Oven Mode only.

7 = Out of calibration Call your Groen Service Agency. The unit will operate

in all modes.

8 = Maximum generator drain time (2 minutes) Inspect the drain line and remove any blockage.

exceeded Make sure the drain is free vented as detailed in the

Installation section.

If the code is still displayed, the unit will operate in

Oven Mode only. Call your Groen Service Agency.

no

no

no

8

es

1 & 2

no

no

es

no

Will Convection Combo operate in Mode when Code is displayed?

no

no

no

6

es

7

es

es

es

yes

Mode Service Message Code

Steam

Combo

Oven

Clean Cycle

1

es

es

es

yes

2

es

es

es

yes

3

no

no

es

no

4

es

no

no

yes

5

es

es

es

yes

31

Page 34

References

AMERICAN GAS ASSOCIATION LABORATORIES

8501 East Pleasant Valley Road

Cleveland, Ohio 44131

AMERICAN NATIONAL STANDARDS

INSTITUTE, INC.

1430 Broadway

New York, New York 10018

CANADIAN GAS ASSOCIATION

55 Scarsdale Road

Don Mills, Ontario, Canada M3B 2R3

CAN 1-B149 Installation Codes for Gas Burning

Appliances & Equipment

ECOLAB, INC.

370 Wabasha

St. Paul, Minnesota 55102

800/352-5326 or 612/293-2233

NATIONAL FIRE PROTECTION ASSOCIATION 60

Battery March Park Quincy,

Massachusetts 02269

NFPA/70 The National Electrical Code

NATIONAL SANITATION FOUNDATION

3475 Plymouth Rd.

Ann Arbor, Michigan 48106

ZEP MANUFACTURING CO.

1310-T Seaboard Industrial Blvd.

Atlanta, Georgia 30318

32

Page 35

Limited Warranty

To Commercial Purchasers *

(Domestic U.S., Hawaii &

Canadian Sales Only)

Groen Foodservice Equipment ("Groen Equipment") has been skillfully manufactured, carefully inspected and

packaged to m eet rigid standards of excellence. Groen warrants its Equipment to be free f rom defects in material

and workmanship for (12) twelve months with the following conditions and subject to the following limitations.

I. This parts and labor warranty is lim ited to G roen Equipment sold to the original commercial purc has er /user s

(but not original equipment manufacturers), at its original place of installation in the continental United

States, Hawaii and Canada.

II. Damage during shipment is to be reported to the carrier, is not covered under this warranty, and is the sole

responsibility of purchaser/user.

III. Groen, or an authorized service representative, will repair or replace, at Groen's sole elec tion, any Groen

Equipment, including but not limited to, drawoff valves, safety valves, gas and electr ic components, f ound

to be defective during the warranty period. As to warranty service in the territory described above, Groen

will absorb labor and portal to portal tr ansportation costs (tim e & mileage) for the f irst twelve (12) months

from date of installation or fifteen (15) months from date of shipment from Groen.

IV. This warranty does not cover boiler maintenanc e, calibration, per iodic adjustm ents as specified in operating

instructions or manuals, and consumable parts such as scraper blades, gaskets, packing, etc., or labor

costs incurred for removal of adjacent equipment or objects to gain access to Groen Equipment. This

warranty does not cover defects caused by improper inst allation, abuse, careless operation, or improper

maintenance of equipment. This warranty does not cover damage caused by poor water quality or

improper boiler maintenance.

V. THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE,

EACH OF WHICH IS HEREBY EXPRESSLY DISCLAIMED. THE REMEDIES DESCRIBED ABOVE ARE

EXCLUSIVE AND IN NO EVENT SHALL GROEN BE LIABLE FOR SPECIAL, CONSEQUENTIAL OR INCIDENTAL

DAMAGES FOR THE BREACH OR DELAY IN PERFORMANCE OF THIS WARRANTY.

VI. Groen Equipment is for commercial use only. If sold as a component of another (O.E.M.) manufacturer's equipment, or

if used as a consumer product, such Equipment is sold AS IS and without any warranty.

OM-CC40-G (3/96)

* (Covers All Foodservice Equipment Ordered After October 1,1995)

1900 Pratt Boulevard Elk Grove

Village, Illinois 60007 Telephone

GROEN

(847) 439 2400 FAX (847) 439 6018

Page 36

Loading...

Loading...