Page 1

INTRODUCTION

How to Use This Manual

This manual covers the basic areas to help you service the combination

steamerovens.

Before using this manual, you should have knowledge of combination

steameroven operation as described in the Operator Manuals, and a good

understanding of service techniques as presented in the Groen Service School.

It is also recommended that you read and become familiar with the Water

Conditioning section in the Operator Manual. Water quality problems are the most

common cause of steamer failure.

This manual is organized as follows:

Sections CC10-E, CC20-E, CC10-G, CC20-G, C/2-E and C/2G provide

specifications, installation check procedures, a basic theory of operation, electrical

diagrams, and an illustrated parts list for each combination oven.

The SERVICE CODES section is a guide to help you troubleshoot oven problems

when a service code is displayed in the Time display window, or in the Time display

and Cook Temperature display windows.

The TROUBLESHOOTING section guides you through general troubleshooting

procedures for problems that could occur. All possible problems, of course, could

not be listed in this service manual; however, the more common faults are

included.

Voltage, current, and continuity check measurements, component replacement

procedures, and solid-state calibration instructions are located in the

MAINTENANCE section.

The TECHNICAL BULLETINS section should be used to file all of the technical

briefs sent from the factory. When you receive a technical brief, remove the

numbered label from the brief and place it in the appropriate subject area in the

manual; then file the bulletin in numerical sequence in this section. When you

come across the numbered label, go to the technical brief, with the same number,

for additional service information.

The INDEX is an alphabetical listing of the topics covered in this manual, keyed to

the page number where each topic begins.

This non-warranty symbol is used throughout the manual to tell you which repair

actions may not be covered in the equipment warranty.

This service manual should be taken with you on all oven service calls.

Use only Groen Certified Replacement Parts when performing oven repairs.

1-1

Page 2

INTRODUCTION

Safety

The safety precautions in this. manual are in accordance with ANSI 535

Standards. Three different signal words alert you to a hazardous situation:

DANGER, WARNING, and CAUTION.

DANGER: The signal word DANGER indicates that a hazardous situation is about

to happen and, if not avoided, will result in death or serious injury.

WARNING: The signal word WARNING tells you that a possible hazardous

situation is about to take place which, if not avoided, could cause death or serious

injury.

CAUTION: This signal word tells you that a hazardous situation which, if not

avoided, may result in minor or moderate injury.

Two other signal words, not directly related to personal safety, are also used in this

manual: NOTICE and IMPORTANT.

NOTICE: NOTICE is used to alert you to hazards that may result in component

and/or equipment damage.

IMPORTANT: IMPORTANT is used to highlight an operating or maintenance tip or

suggestion.

The following summary lists general safety practices. Safety precautions

pertaining to a particular task or situation are included in that section and may not

be repeated in the summary. It is possible that the safety precautions listed in this

summary may not be repeated elsewhere in the manual.

DANGER

Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of this or any other appliance.

When you open the oven door, be very careful not to let steam touch you.

Steam can cause burns.

Do not put hands or other objects into the cooking chamber during fast

cool operation. Rotating fan blades can cause severe injury.

ARNING

W

Always turn off oven power before removing any partition or panel.

Disconnect oven from the power source before performing any internal

service work.

1-2

Page 3

INTRODUCTION

Safety

CAUTION

Oven may be hot. Take precautions to prevent any contact with hot

surfaces.

Be sure all interior partitions have been installed before operating the

oven in any mode.

All oven operators and service personnel should be familiar with

correct and safe oven operating procedures.

Be sure oven drain is not blocked as this could result in improper oven

operation.

1-3

Page 4

Oven Electrical Specifications

CC10-E

Specifications

AC Input

Voltage

280V

240V

Water Line Pressure

30 to 60 PSIG. A pressure regulator is required for water pressure above

60 PSIG.

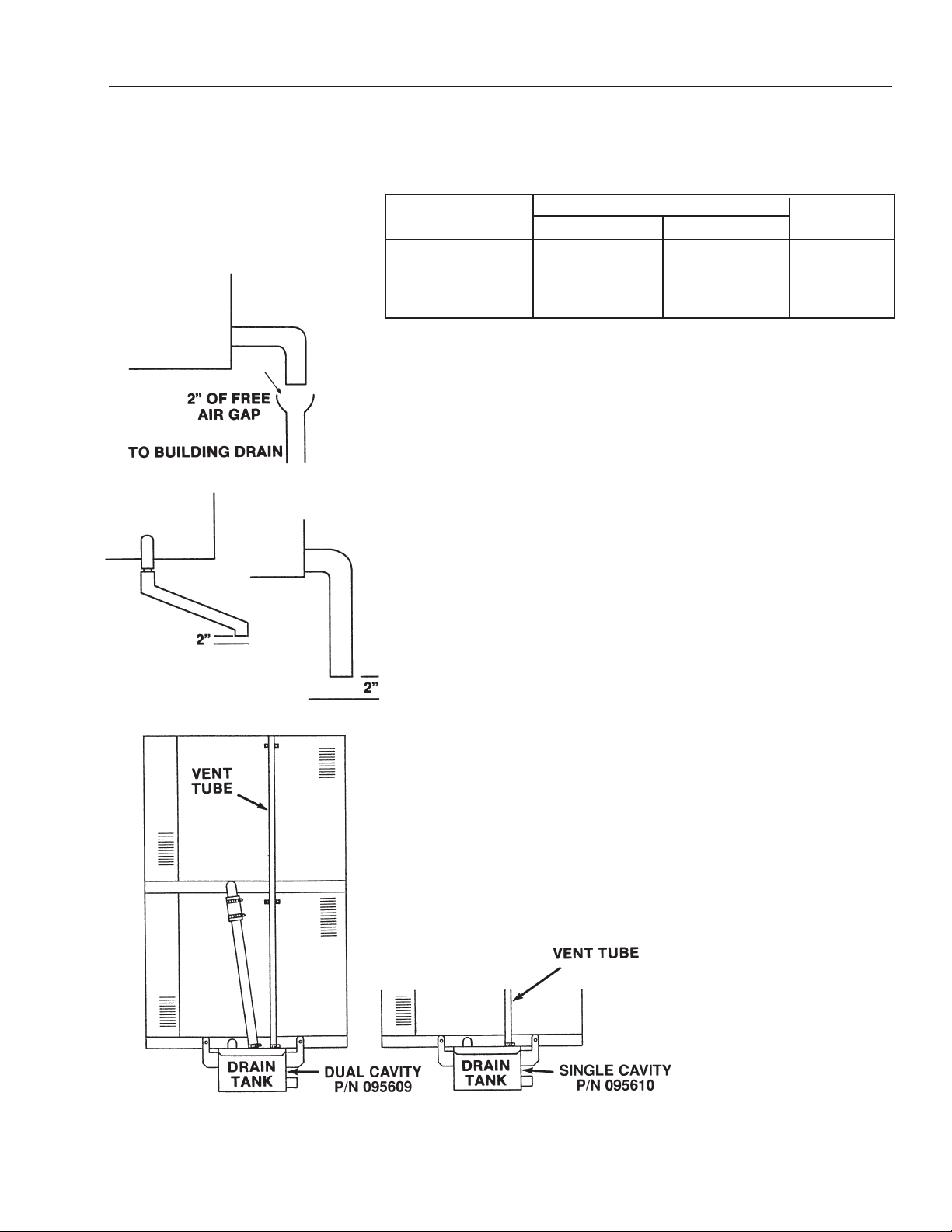

Drain Connection

Without Drain Box:

1. Drain hose cannot be connected directly to a building drain; there

cannot be any elbows or other restrictions between the oven drain and

the two inch free air gap.

2. Free Air Gap: 2” free air gap required between drain hose and building

drain.

3. Drain Line: 1-1/2” ID drain hose between oven and building drain with

a constant downward pitch.

Current Rating

1-Phase

44.9A

39.1A

3-Phase/Line

27.5A

24.1A

Power

9.3KW

9.3KW

4. Plastic pipe cannot be used for a drain line.

With Drain Box:

1. Drain hose to a building drain can be connected directly.

2. The drain box has an air vent that eliminates the need for an air gap.

3. Do not block the air vent in any way.

4. Do not attach anything to the vent tube or reduce the size of the vent

tube.

(Revised 1/02)

2-1

Page 5

CC10-E

Installation Checks

General

––––– Make sure there is no heat source within 12

inches of louvered right side of oven.

Heat Shield - Single Cavity (1) 092210

Double Cavity (2)

––––– Make sure there is a minimum six inch free

space on louvered side of oven.

––––– Make sure oven is level or pitched slightly

rearward.

––––– Check that fan is clear of packaging

materials.

––––– Check that air and water heating elements

are clear of packaging materials.

––––– Make sure boiler is clear of packaging

materials.

––––– Check that water level probes and probe

holders are clear or packaging materials.

––––– If permitted by local codes, check that hose

onnection is flexible to allow oven

c

movement for servicing.

––––– Check that water line is at least 112 inch ID.

––––– Check that water line is not putting high

stress on inlet water valve.

––––– Check that inlet water pressure is 30 to 60

PSIG.

––––– The water supply should not contain more

than 30 to 40 parts per million total

dissolved solids (TDS) and has a pH of 7.0

or higher.

Drain Connections

––––– Make sure drain plumbing connections

comply with local codes.

––––– Check that drain hose connection is flexible

to allow oven movement for servicing.

Electrical Checks

––––– Make sure oven is properly grounded per

NEC.

––––– Verify that electrical connections conform to

local code and NEC requirements.

––––– Make sure that branch circuit protection

conforms to oven specifications specified on

oven nameplate.

––––– For single-phase ovens, check that there

are no connections to terminal L3. Refer to

label above power distribution block.

–––––

––––– Check that phase selector plug is properly .

Cold Water Supply Connections

––––– Make sure plumbing connections conform

2-2

For three-phase ovens, check connections

to L1, L2, and L3. Refer to label above

power distribution block.

connected. See labels above power

distribution block and on motor bracket.

to local codes.

––––– Make sure drain line is 1-1/2 inches in

diameter.

––––– Check that drain is free vented.

––––– Make sure drain line is not directly

connected to the building drain.

––––– Check that drain line is suitable for boiling

water. Make sure PVC is not being used for

drain plumbing.

––––– Check that drain line is pitched downward.

––––– Make sure drain line is free of obstruction.

Oven Door Check

––––– Make sure door gasket is making good

contact with cavity.

––––– Check that door opens easily and freely.

–––––

Confirm that operators are leaving the door

open when unit is shut down overnight or

longer.

(Revised 1/02)

Page 6

CC10-E

Sequence Of Events

Prior to Serial Number C7439MS

perating Conditions

O

• Oven cavity below 200°F.

• Oven door closed.

• No service codes displayed in the time display window.

• There are no apparent oven operating problems.

Steam Mode (Prior to Serial Number C7439MS)

Refer to the Steam mode circuit diagrams on page 2-13 and/or the schematic

diagrams on pages 2-16 and 2-17 for the following sequence of events.

1. Relays K15 and K13 energized. Boiler drain valve closes and boiler fill valve

opens. Boiler fill begins.

2. Relay K6 energized. Fan motor turns on.

3. When water reaches low water probes, relays K1, K2, K3, and K4 energize.

High water heating elements turn on.

4. When water reaches high water probe, relay K13 de-energizes and boiler fill

valve closes.

5. When boiler water reaches “ready” temperature, relays K1, K2, K3, and K4 deenergize and water heating elements turn off.

Relay Operation Summary

1. K15 and K13 energized. (Drain and Fill)

2. K6 energized. (Fan)

3. K1 through K4 energized. (Boiler Heat)

K13 de-energized. (Fill)

4.

5. K1 through K4 de-energized. (Boiler Heat)

Combo Mode (Prior to Serial Number C7439MS)

Refer to the Combo mode circuit diagrams on page 2-14 and/or the schematic

diagrams on pages 2-16 and 2-17 for the following sequence of events.

1. Relays K15 and K13 energized. Boiler drain valve closes and boiler fill valve

opens. Boiler fill begins.

2. Relay K6 energized. Fan motor turns on.

3. When water reaches low water probes, relays K1, K2, K3, and K4 energize.

High water heating elements turn on.

(Revised 1/02)

4. When water reaches high water probe, relay K13 de-energizes and boiler fill

valve closes.

2-3

Page 7

CC10-E

Sequence Of Events

Prior to Serial Number C7439MS

5. When boiler water reaches “ready” temperature, relays K1, K3, and K4

deenergize and water heating elements turn off.

. Relay K2 remains energized.

6

7. K5 energized. BH1 and BH2 are turned on.

8. K14 energized and condensate spray valve opens.

9. Relays K9, K10, K11, and K12 energize. Air heating elements turn on.

10.When oven temperature reaches the temperature set point, relays K9, K10,

K11, and K12 de-energize. Air heating elements turn off.

Relay Operation Summary

1. K15 and K13 energized. (Drain and Fill)

2. K6 energized. (Fan)

3. K1 through K4 energized. (High Water)

4. K13 de-energized. (Fill)

5. K1, K3, and K4 de-energized. K5 energized. (High Heat to Low Heat)

6. K9 through K12 energized. (High Air)

7. K9 through K12 de-energized. (High Air)

Oven Mode (Prior to Serial Number C7439MS)

Refer to the Oven mode circuit diagrams on page 2-15 and/or the schematic

diagrams on pages 2-16 and 2-17 for the following sequence of events.

1. Relay K6 energized. Fan motor turns on.

2. Relays K9, K10, K11, and K12 energize. Air heating elements turn on.

When oven temperature reaches the temperature set point, relays K9, K10,

3.

K11, and K12 de-energize. Air heating elements turn of

Relay Operation Summary

1. K6 energized. (Fan)

f.

K9 through K12 energized. (High

2.

3. K9 through K12 de-energized. (High Air)

2-4

Air)

(Revised 1/02)

Page 8

CC10-E

Sequence Of Events

Prior to Serial Number C7439MS

Hold Mode (Prior to Serial Number C7439MS)

Refer to the schematic diagrams on pages 2-16 and 2-17 for the following

sequence of events.

NOTE: Low humidity on older panels only. When “Lo” humidity is selected there

is no water in steam generator.

1. Relays K15 and K13 energized. Boiler drain valve closes and boiler fill valve

opens. Boiler fill begins.

2. Relay K6 energized. Fan motor turns on. Fan will cycle on and off as required.

3. When water reaches low water probes, relays K1, K2, K3, and K4 energize.

4. When water reaches high water probe, relay K13 de-energizes and boiler fill

valve closes.

5. When boiler water reaches “ready” temperature, relays K1, K2,

K3, and K4 de-energize, and water heating elements turn off.

6. K14 energizes and condensate spray valve opens.

7. Relays K9, K10, K11, and K12 energize. Air heating elements turn on.

8. When oven air temperature is 10° below temperature set point, relays K10 and

K11 de-energize. Air heating elements operate at reduced power.

9. When oven temperature reaches the temperature set point, relays K9 and K12

de-energize. Air heating elements turn off.

Relay Operation Summary

K15 and K13 energized. (Drain and Fill)

1.

2. K6 energized. (Fan)

3. K1 through K4 energized. (High Water)

4. K13 de-energized. (Fill)

5. K1 through K4 de-energized. (High Water)

6. K14 energized. (Condensate Spray)

7. K9 through K12 energized. (High Air)

(Revised 1/02)

8. K10 and K11 de-energized. (Low Air)

K9 and K12 de-energized. (Air Heat)

9.

2-5

Page 9

CC10-E

Sequence Of Events

Prior to Serial Number C7439MS

Two Stage Cleaning Cycle (Prior to Serial Number C7439MS)

Refer to the schematic diagrams on pages 2-16 and 2-17 for the

ollowing sequence of events.

f

Phase 1

1. CL:50 is displayed in the time display window.

2. Relay K15 energized. Drain valve closes and boiler fills.

3. Relay K6, K7, and K8 energized. Fan motor turns on.

4. Relays K1, K2, K3, and K4 energize and water heating elements

turn on.

5. When the water temperature is approximately 150°F, relays K1, K2, K3, and

K4 de-energize.

6. Relays K1, K2, K3 and K4 energize and water heating elements turn on.

7. Relay K14 energizes and condensate spray valve opens.

8. Relay K15 de-energizes and drain valve opens.

9. Relays K1, K2, K3 and K4 de-energize and water heating elements turn off.

10. Relay K14 de-energizes and condensate spray valve closes.

Phase 2 (Oven Door Open)

11. Relay K15 energizes and drain valve closes. Boiler fills.

12. Relays K1 through K4 energize and water heating elements turn on.

13. When water temperature is approximately 150°F, relays K1 through K4

de-energize and water heating elements turn off.

14. Relays K1 through K4, and K14 energize. Water heating elements are on and

condensate spray valve opens.

Relay K15 de-energizes and boiler fill valve opens to drain boiler

15.

16. Relays K1 through K4, and K14 de-energize. The water heating elements turn

off and the condensate spray valve closes.

Relay K15 energizes and the drain valve closes.

17.

18. Relays K1 through K4, and K14 energize. Water heating elements are on and

condensate spray valve opens.

19. Relay K15 de-energizes and boiler fill valve opens to drain boiler.

The boiler fills.

.

20. Relays K1 through K4, and K14 de-energize. The water heating elements turn

off and the condensate spray valve closes.

2-6

(Revised 1/02)

Page 10

CC10-E

Sequence Of Events

After Serial Number C7439MS

Operating Conditions

Oven cavity below 200°F.

•

• Oven door closed.

• No service codes displayed in the time display window.

• There are no apparent oven operating problems.

Steam Mode (After Serial Number C7439MS)

Refer to the Steam mode circuit diagrams on page 2-13 and/or the schematic

diagrams on pages 2-16 and 2-17 for the following sequence of events.

1. Relays K15 and K13 energized. Boiler drain valve closes and boiler fill valve

opens. Boiler fill begins. Relay K9 through K12 energizes air elements.

2. Relay K6 energized. Fan motor turns on.

3. When water reaches low water probes, relays K1, K2, K3, and K4 energize.

High water heating elements turn on. Relay K9 through K12 de-energize

4. When water reaches high water probe, relay K13 de-energizes and boiler fill

valve closes.

5. When boiler water reaches “ready” temperature, relays K1, K3, and K4 deenergize and K2 remains energized. K5 energizes and the water heating

elements go to low heat. Relays K9 through K12 energize until cavity is at

200°F. Relay K9 through K12 de-energize.

Relay Operation Summary

1. K15 and K13 energized. (Drain and Fill)

2. K6 energized. (Fan)

3. K1 through K4 energized. (Boiler Heat)

4. K13 de-energized. (Fill)

K1, K3 and K4 de-energized. (Boiler Heat). K2 remains energized, K5

5.

energized, K9 through K12 energized.

6. K9 through K12 de-energized.

Combo Mode (After Serial Number C7439MS)

(Revised 1/02)

Refer to the Combo mode circuit diagrams on page 2-14 and/or the schematic

diagrams on pages 2-16 and 2-17 for the following sequence of events.

1. Relays K15 and K13 energized. Boiler drain valve closes and boiler fill valve

opens. Boiler fill begins. Relay K9 through K12 energizes air elements.

Relay K6 energized. Fan motor turns on.

2.

2-7

Page 11

CC10-E

Sequence Of Events

After Serial Number C7439MS

3. When water reaches low water probes, relays K1, K2, K3, and K4 energize.

High water heating elements turn on. Relay K9 through K12 de-energize.

4. When water reaches high water probe, relay K13 de-energizes and boiler fill

valve closes.

5. When boiler water reaches “ready” temperature, relays K1, K3, and K4

deenergize and water heating elements turn off.

6. Relay K2 remains energized.

7. K5 energized. BH1 and BH2 are turned on.

8. K14 energized and condensate spray valve opens.

9. Relays K9, K10, K11, and K12 energize. Air heating elements turn on.

10. When oven temperature reaches the temperature set point, relays K9, K10,

K11, and K12 de-energize. Air heating elements turn off.

Relay Operation Summary

1. K15 and K13 energized. (Drain and Fill)

2. K6 energized. (Fan)

3. K1 through K4 energized. (High Water)

4. K13 de-energized. (Fill)

5. K1, K3, and K4 de-energized. K5 energized. (High Heat to Low Heat)

K9 through K12 energized. (High Air)

6.

7. K9 through K12 de-energized. (High Air)

Oven Mode (After Serial Number C7439MS)

Refer to the Oven mode circuit diagrams on page 2-15 and/or the schematic

diagrams on pages 2-16 and 2-17 for the following sequence of events.

1. Relay K6 energized. Fan motor turns on.

2. Relays K9, K10, K11, and K12 energize. Air heating elements turn on.

3. When oven air temperature is 5° below temperature set point, relays K10 and

1 de-energize.

K1

4. When oven temperature reaches the temperature set point, relays K9 and K12

de-energize. Air heating elements turn of

2-8

Air heating elements operate at reduced power

f.

.

(Revised 1/02)

Page 12

CC10-E

Sequence Of Events

After Serial Number C7439MS

Relay Operation Summary

1. K6 energized. (Fan)

2. K9 through K12 energized. (High Air)

3. K10 and K11 de-energized.

4. K9 and K12 de-energized. (High Air)

Hold Mode (After Serial Number C7439MS)

Refer to the schematic diagrams on pages 2-16 and 2-17 for the following

sequence of events.

NOTE: Low humidity on older panels only. When “Lo” humidity is selected there

is no water in steam generator.

1. Relay K6 energized. Fan motor turns on. Fan will cycle on and off as required.

2. Relays K9, K10, K11, and K12 energize. Air heating elements turn on.

3. When oven air temperature is 5° below temperature set point, relays K10 and

K11 de-energize. Air heating elements operate at reduced power.

4. When oven temperature reaches the temperature set point, relays K9 and K12

de-energize. Air heating elements turn off.

Relay Operation Summary

1. K15 and K13 energized. (Drain and Fill)

2. K6 energized. (Fan)

3. K1 through K4 energized. (High Water)

4. K13 de-energized. (Fill)

5. K1 through K4 de-energized. (High Water)

6. K14 energized. (Condensate Spray)

7. K9 through K12 energized. (High Air)

8. K10 and K11 de-energized. (Low Air)

(Revised 1/02)

9. K9 and K12 de-energized. (Air Heat)

2-9

Page 13

CC10-E

Sequence Of Events

After Serial Number C7439MS

Two Stage Cleaning Cycle (After Serial Number C7439MS)

Refer to the schematic diagrams on pages 2-16 and 2-17 for the following

equence of events.

s

Phase 1

1. C1 is displayed in the time display window. Spray degreaser around the cavity

and press “START.”

2. Relay K15 energized. Drain valve closes and boiler fills.

3. Relay K6 energized. Fan motor turns on.

4. Relays K1, K2, K3, and K4 energize and water heating elements turn on.

5. When the water temperature is approximately 150°F, relays K1, K2, K3, and

K4 de-energize.

6. Relays K1, K2, K3 and K4 energize and water heating elements turn on.

7. Relay K14 energizes and condensate spray valve opens.

CL:50 is displayed in the time display window.

8. Relay K15 de-energizes and drain valve opens.

9. Relays K1, K2, K3 and K4 de-energize and water heating elements turn off.

10. Relay K14 de-energizes and condensate spray valve closes.

in the time display window.

Phase 2 (Oven Door Open) - add delimer in the boiler.

11. Relay K15 energizes and drain valve closes. Boiler fills.

12. Relays K1 through K4 energize and water heating elements turn on.

13. When water temperature is approximately 150°F, relays K1 through K4

de-energize and water heating elements turn off.

Relays K1 through K4, and K14 energize. W

14.

condensate spray valve opens.

15. Relay K15 de-energizes and boiler fill valve opens to drain boiler.

16. Relays K1 through K4, and K14 de-energize. The water heating elements turn

off and the condensate spray valve closes.

17. Relay K15 energizes and the drain valve closes. The boiler fills.

Relays K1 through K4, and K14 energize. W

18.

condensate spray valve opens.

ater heating elements are on and

ater heating elements are on and

C2 is displayed

19. Relay K15 de-energizes and boiler fill valve opens to drain boiler.

20. Relays K1 through K4, and K14 de-energize.

off and the condensate spray valve closes.

2-10

The water heating elements turn

(Revised 1/02)

Page 14

CC10-E

Operation

Prior to Serial Number C7439MS

The model CC10-E is a combination steamer-oven with a stainless steel cooking

chamber, a steam generator, and electronic circuitry for controlling unit operation.

It can operate from a single-phase or three-phase, 208 or 240 volt, 60 hertz power

source.

It can function as a convection oven, a self-contained pressureless steamer, or as

a combination oven-steamer. Mode of operation is controlled by the control panel

touch pad switches.

Replaceable electric (air) elements and the blower fan provide oven temperatures

up to a maximum of 575°F.

Replaceable heating elements are used to generate steam. The steam generator

cavities are adjacent to the cooking compartment and easily accessible. All of the

condensate leaves the oven through the cavity drain. When the unit is turned off,

or the oven cooking mode is selected, the steam generator cavity automatically

drains.

The control panel is a solid-state controller. The solid-state circuitry has a selfdiagnostic program to assist you in troubleshooting, and a pre-programmed

cleaning cycle to assist the operator in daily cleaning.

The door interlock switch operates to turn off the fan and oven elements when the

door is opened. The boiler elements go to low heat.

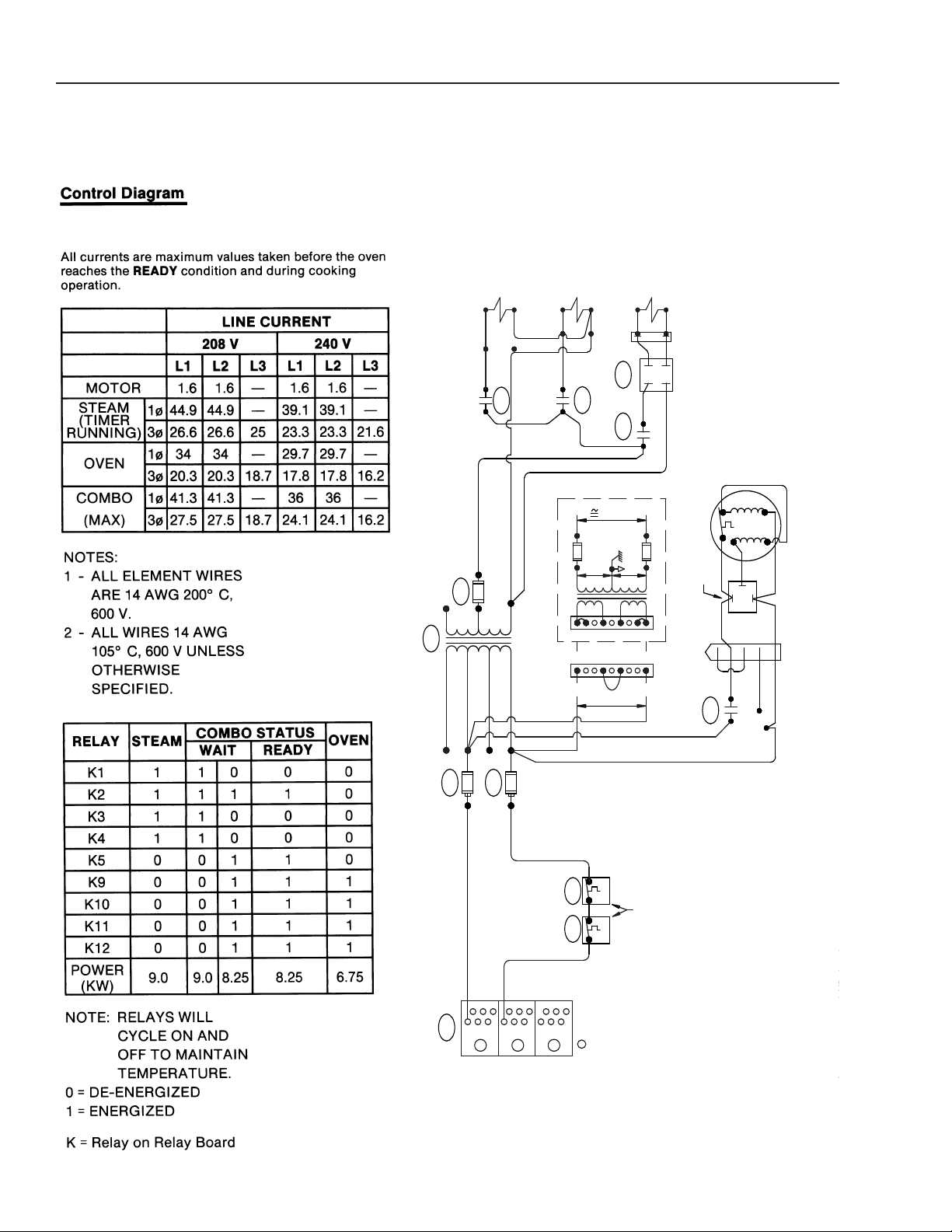

The electrical circuits that are active for the three operating modes are shown in

the following illustrations.

(Revised 1/02)

2-11

Page 15

CC10-E

Operation

After Serial Number C7439MS

The model CC10-E is a combination steamer-oven with a stainless steel cooking

chamber, a steam generator, and electronic circuitry for controlling unit operation.

It can operate from a single-phase or three-phase, 208 or 240 volt, 60 hertz power

ource.

s

It can function as a convection oven, a self-contained pressureless steamer, or as

a combination oven-steamer. Mode of operation is controlled by the control panel

touch pad switches. Hold mode is optional.

Replaceable electric (air) elements and the blower fan provide oven temperatures

up to a maximum of 575°F.

Replaceable heating elements are used to generate steam. The steam generator

cavities are adjacent to the cooking compartment and easily accessible. All of the

condensate leaves the oven through the cavity drain. When the unit is turned off

the steam generator automatically drains. When the oven cooking mode is

selected, the steam generator cavity automatically drains. When no mode is

selected the steam generator fills and water is held at 160°F.

The control panel is a solid-state controller. The solid-state circuitry has a selfdiagnostic program to assist you in troubleshooting, and a pre-programmed

cleaning cycle to assist the operator in daily cleaning.

The door interlock switch operates to turn off the fan and oven/ steamer elements

when the door is opened.

The electrical circuits that are active for the three operating modes are shown in

the following illustrations.

2-12

2-12

(Revised 1/02)

Page 16

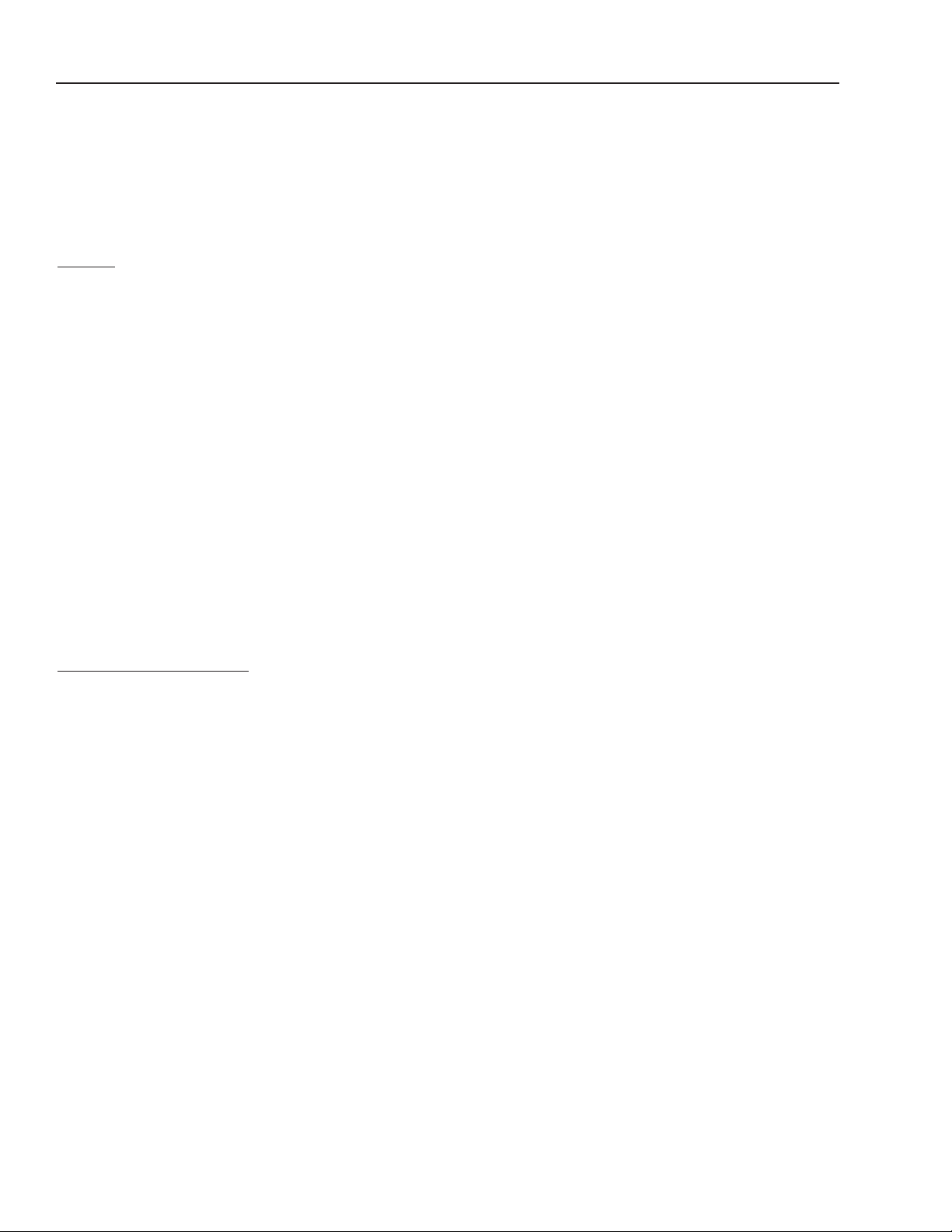

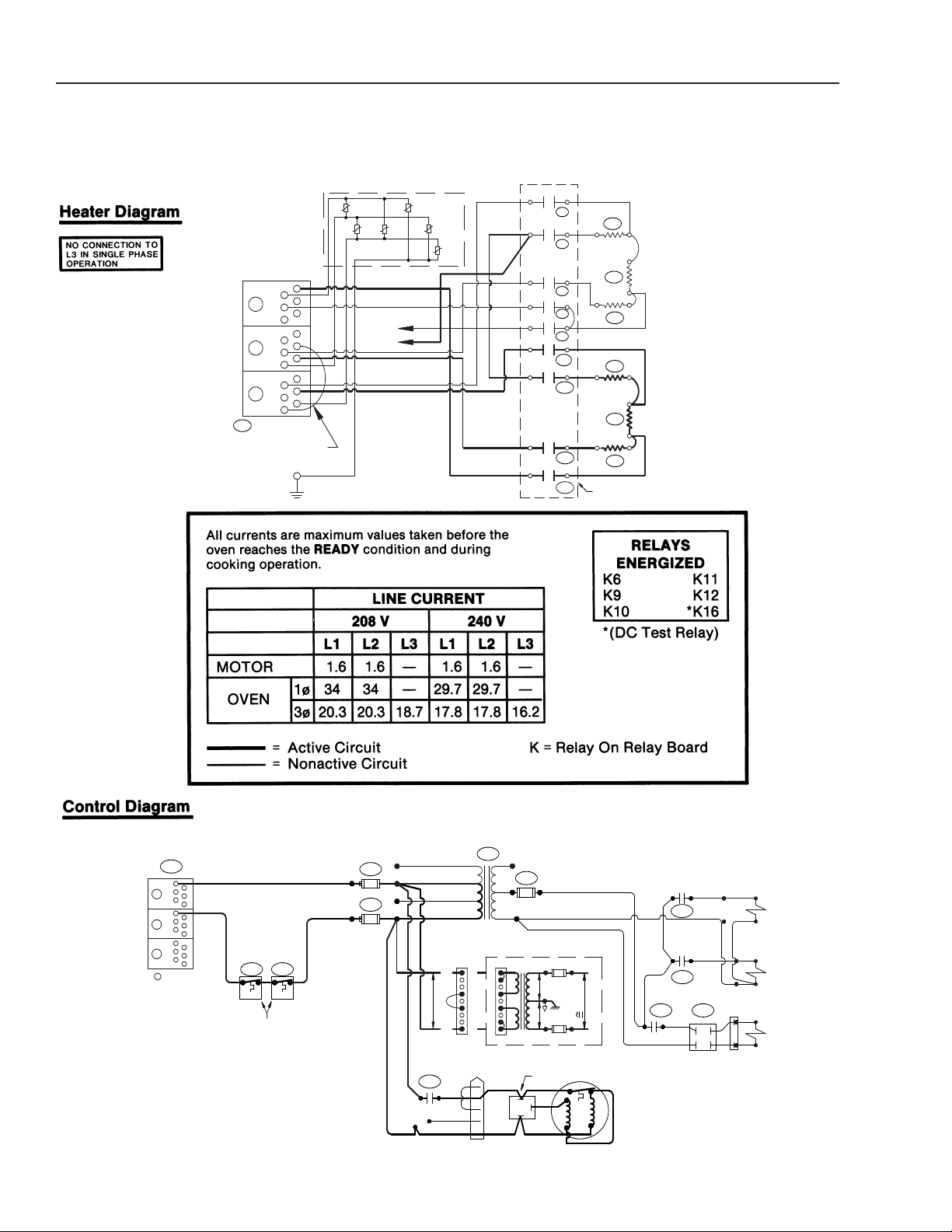

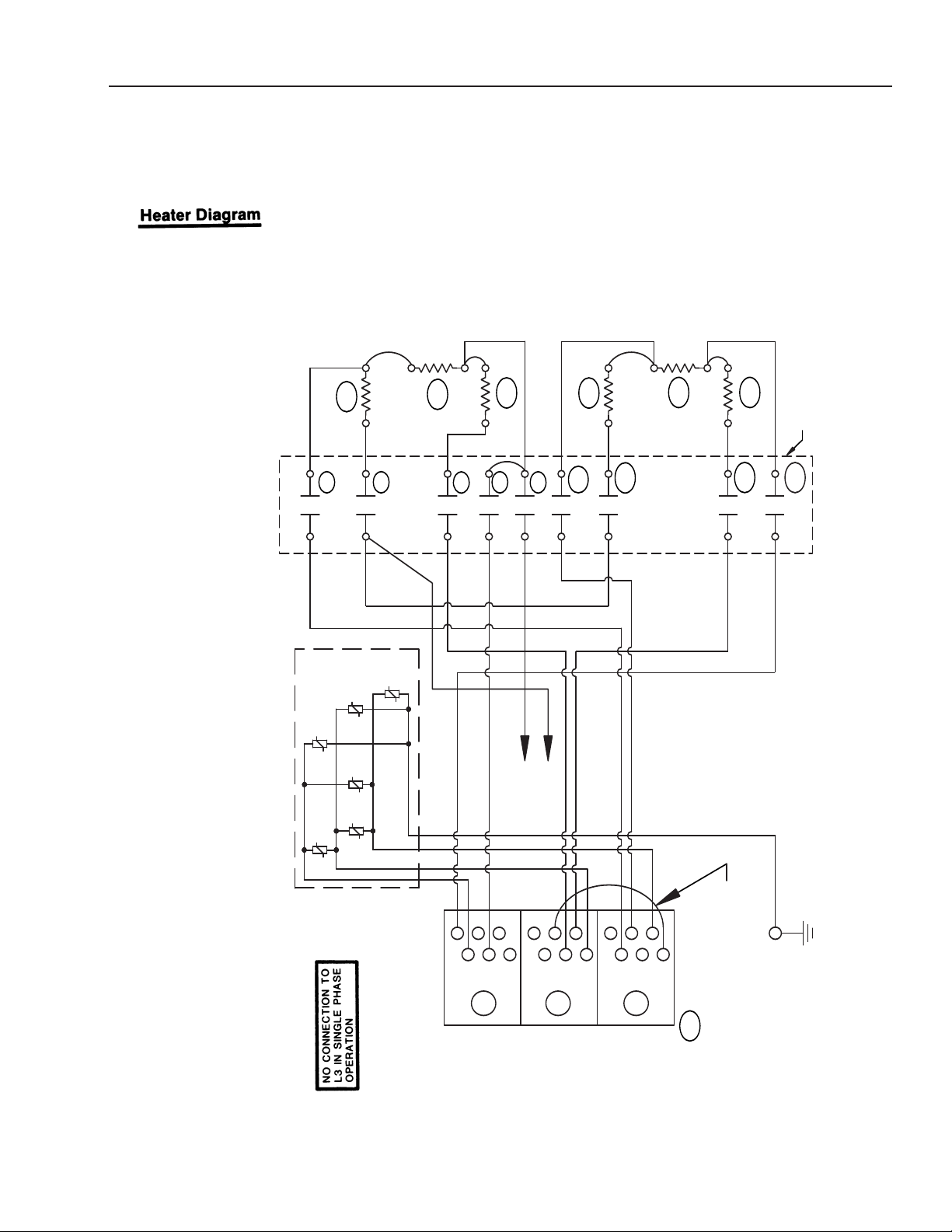

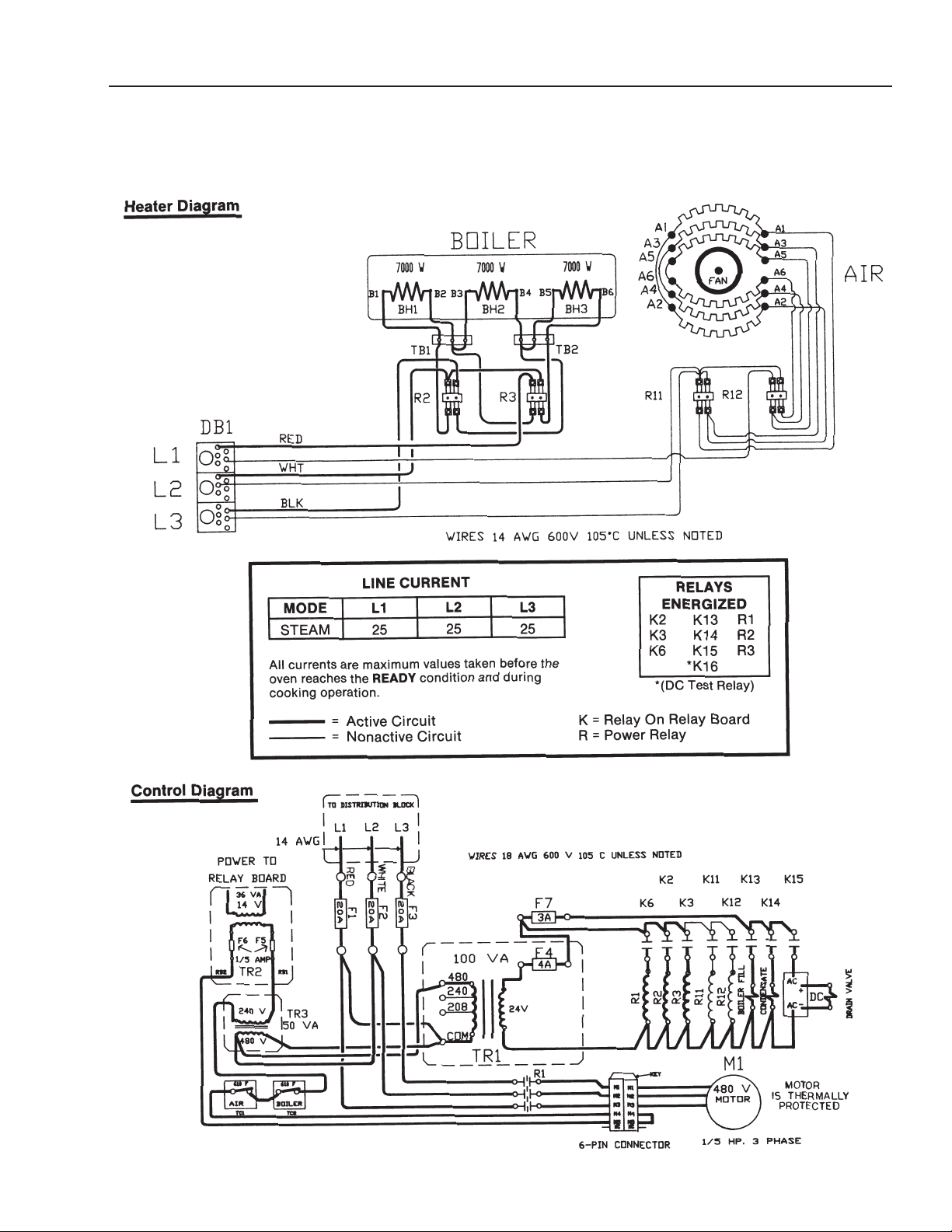

CC10-E

Operation

Prior to Serial Number C7439MS

team Mode Circuit

S

(Revised 1/02)

2-13

Page 17

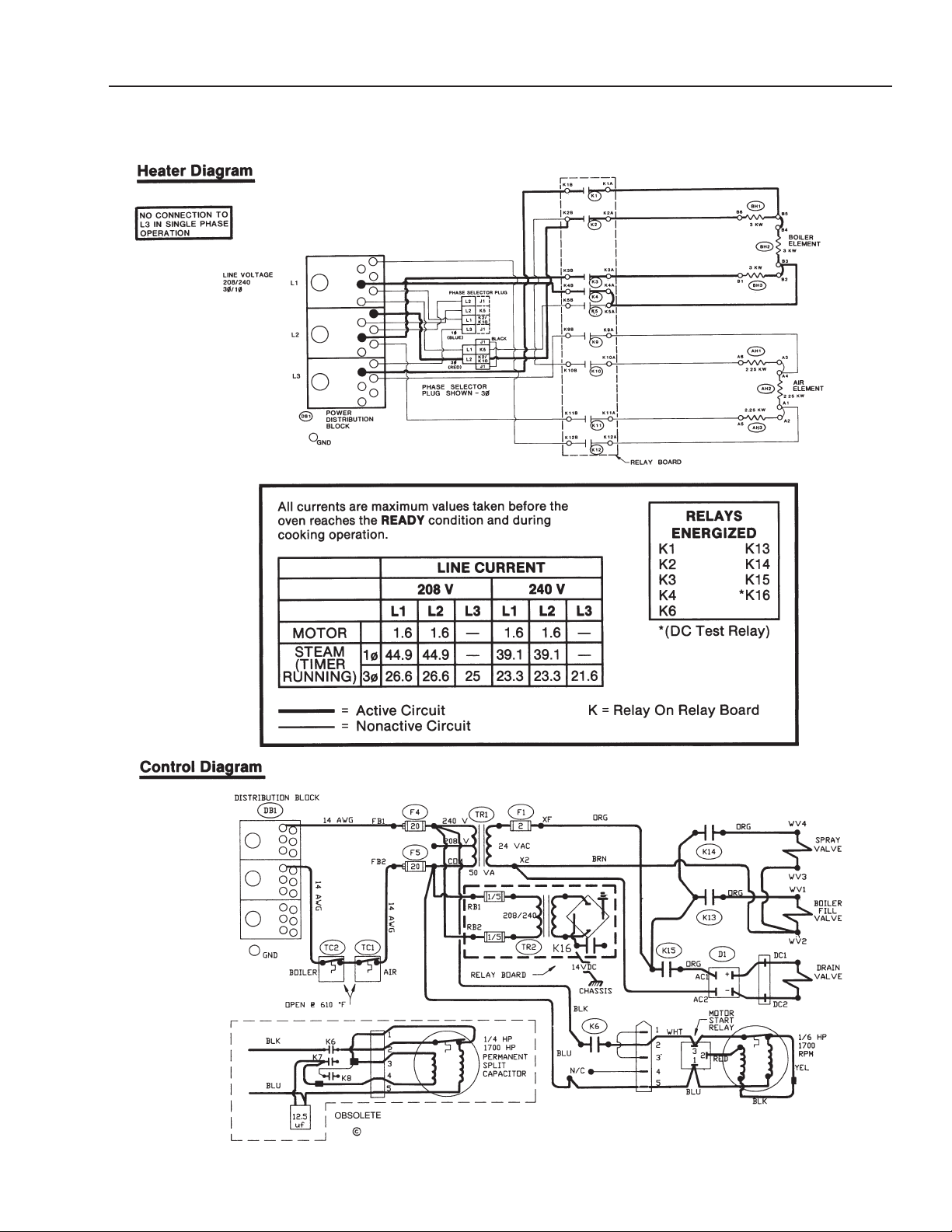

CC10-E

Operation

Prior to Serial Number C7439MS

Combo Mode Circuit

2-142-142-14

(Revised 1/02)

Page 18

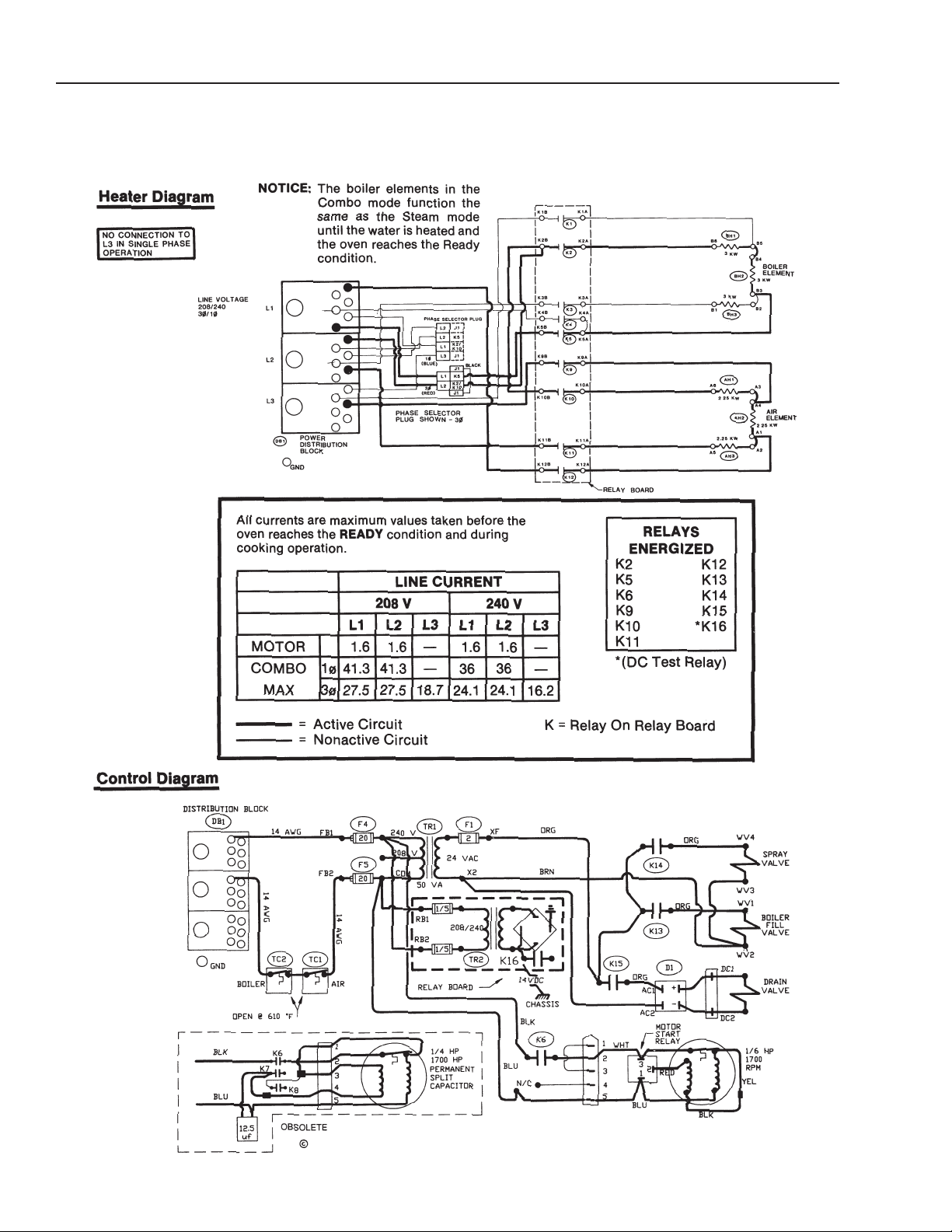

CC10-E

Operation

Prior to Serial Number C7439MS

ven Mode Circuit

O

(Revised 1/02)

2-15

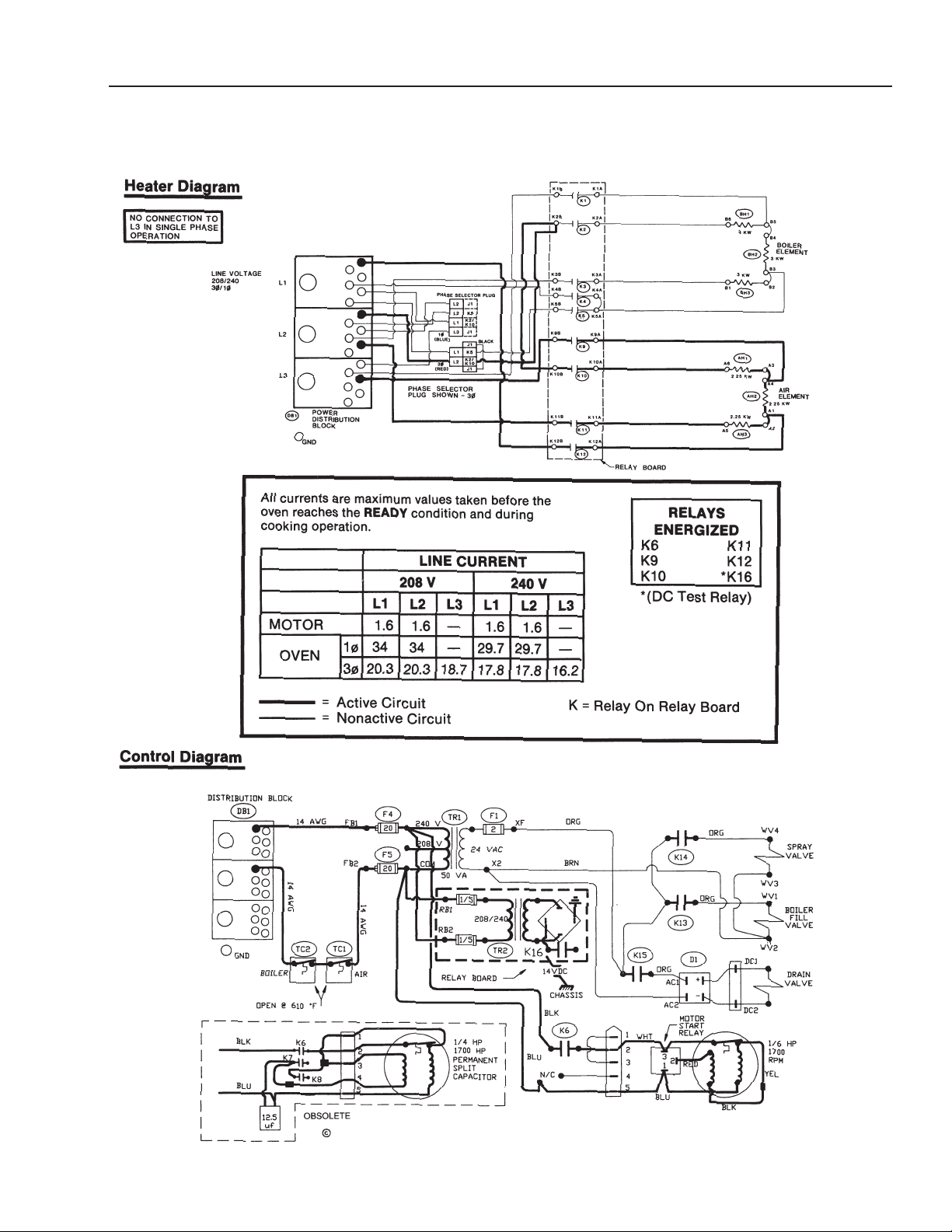

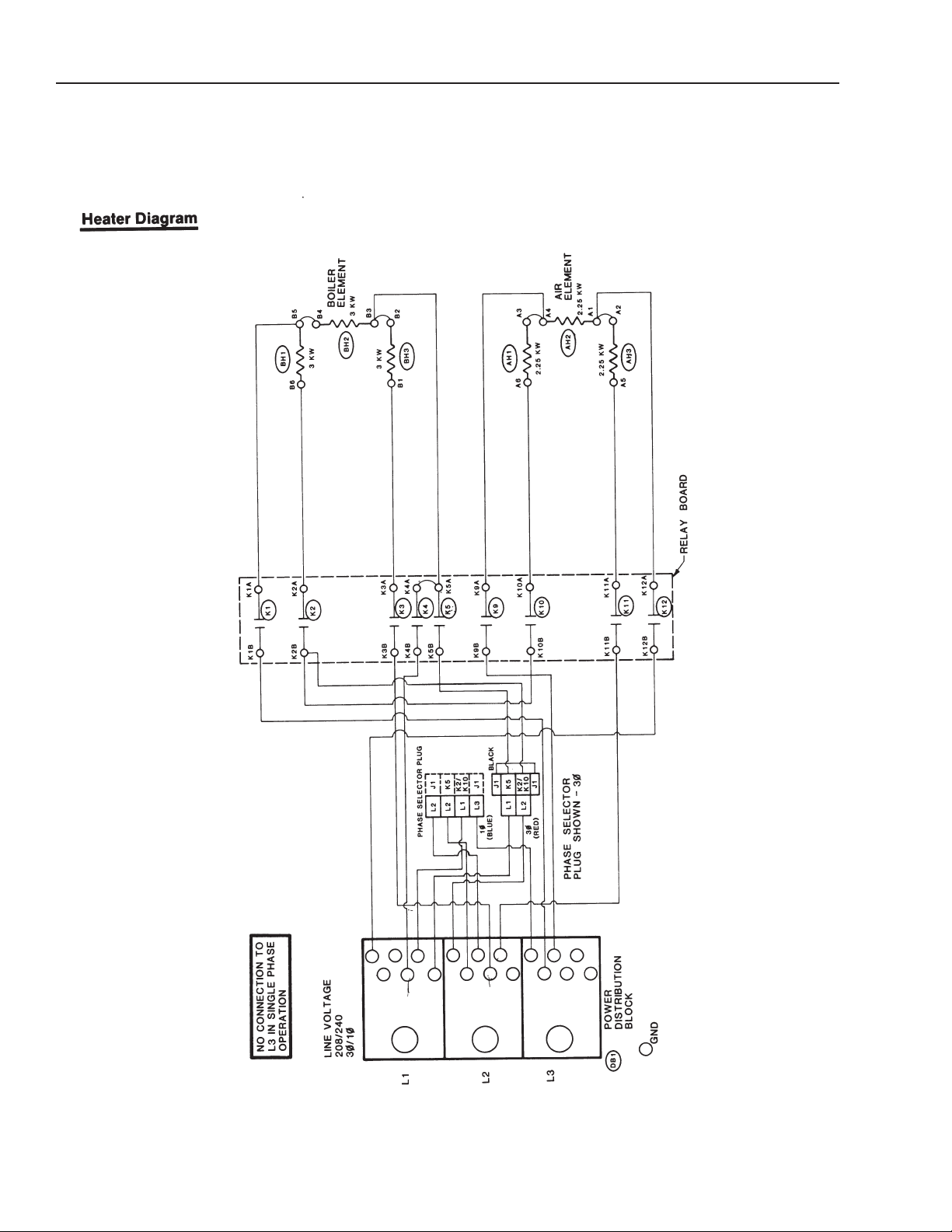

Page 19

CC10-E

Electrical Diagrams

Prior to Serial Number C7439MS

Schematic Diagrams for CC10-E

2-162-16

(Revised 1/02)

Page 20

CC10-E

Electrical Diagrams

Prior to Serial Number C7439MS

chematic Diagrams for CC10-E

S

(Revised 1/02)

2-172-17

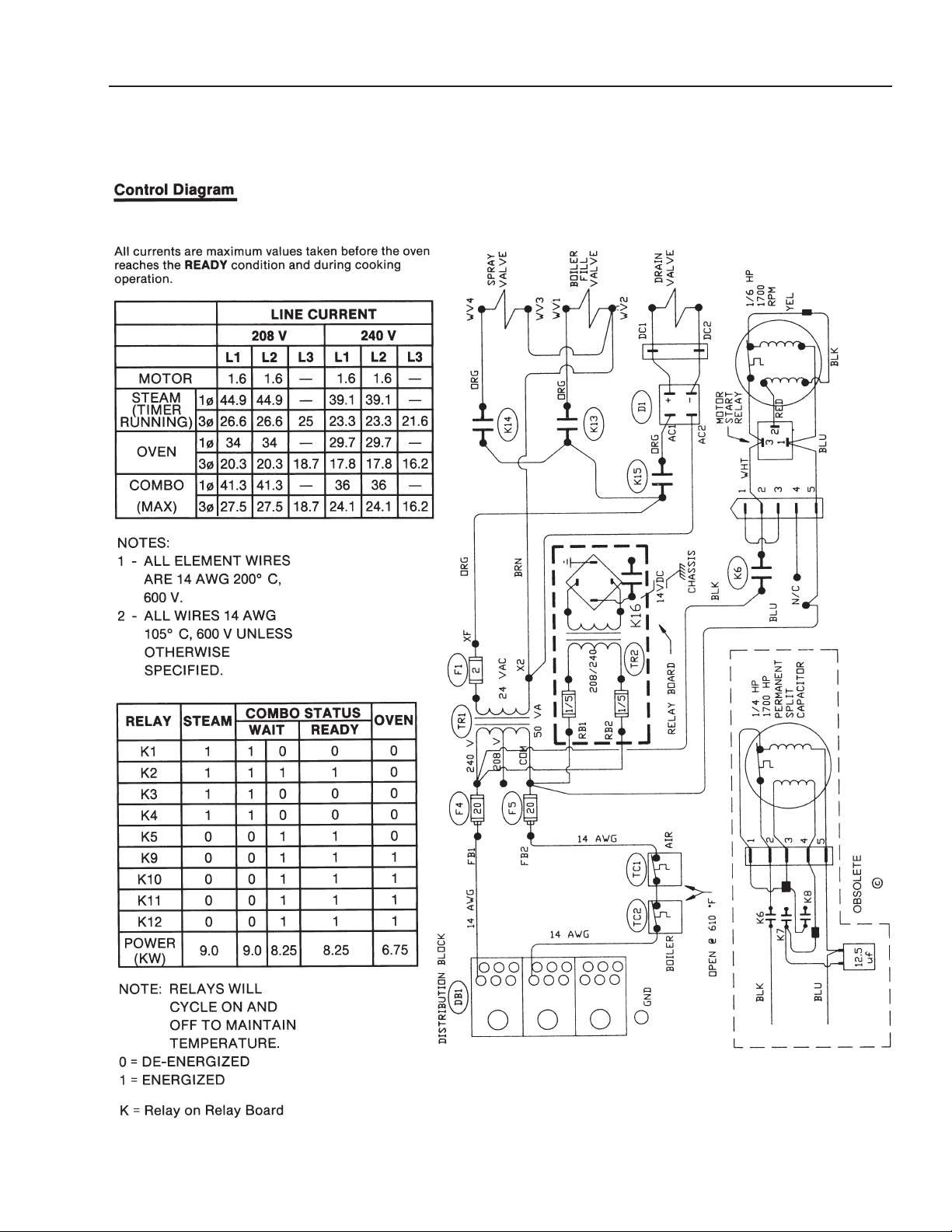

Page 21

CC10-E

GND

D

B1

L3

BLOCK

D

ISTRIBUTION

POWER

208/220/240V

1ø, 3ø

L2

LINE VOLTAGE

L1

-2

MOV

-4

-6

M

OV

MOV

-1

MOV

-3

-5

MOV

MOV

MOV BOARD

A6

ELEMENT

AIR

K12B

K11B

K10B

AH3

K11

RELAY BOARD

K12

K12A

2.25 KW

2.25 KW

K

11A

A5

K10

K

10A

A1

2.25 KW

A2

AH2

A3

A4

ELEMENT

BOILER

K

5B

K9B

K

4B

K

3B

K2B

K1B

BH2

3 KW

3 KW

K5A

K

9A

K9

K5

K4A

K4

K3

B1

AH1

B

3

B2

BH3

K

3A

K

2

K1

K2A

K1A

B6

B4

3 KW

B5

BH1

G

ND

12AWG

(1ph ONLY)

Xph

Yph

SEE

TABLE

DISTRIBUTION BLOCK

OPEN @ 610° F

BOILER

TC2

DB1

14 AWG

AIR

TC1

FB2-A

FB1-A

F4

FB2-B

F5

20

20

FB1-B

24 VAC

50 VA

COM

200/208V

TR1

X2

2

F1

XF

1700 RPM

1/6 HP

BLU

AC2

N/C

BLU

K6

BLK

2

5

3

4

WHT

1

BLK

RED

3

1

2

-

RELAY

START

MOTOR

YEL

DC2

SPRAY

VALVE

BOILER

K14

ORG

K13

AC1

K15

BRN

BRN

ORG

+

D1

ORG

DC1

DRAIN

VALVE

WV2

WV1

FILL

VALVE

ORG

WV3

WV4

L2

L1

L3

GND

208V-240V

A

B

14VAC

RELAY BOARD

14VAC

3

J4

1

21

64

654

9

987

POWER TO

1.25 AMP

C

28VAC

D

RELAY BOARD

1.25 AMP

14 AWG

14 AWG

220/230/240V

440/460/480V

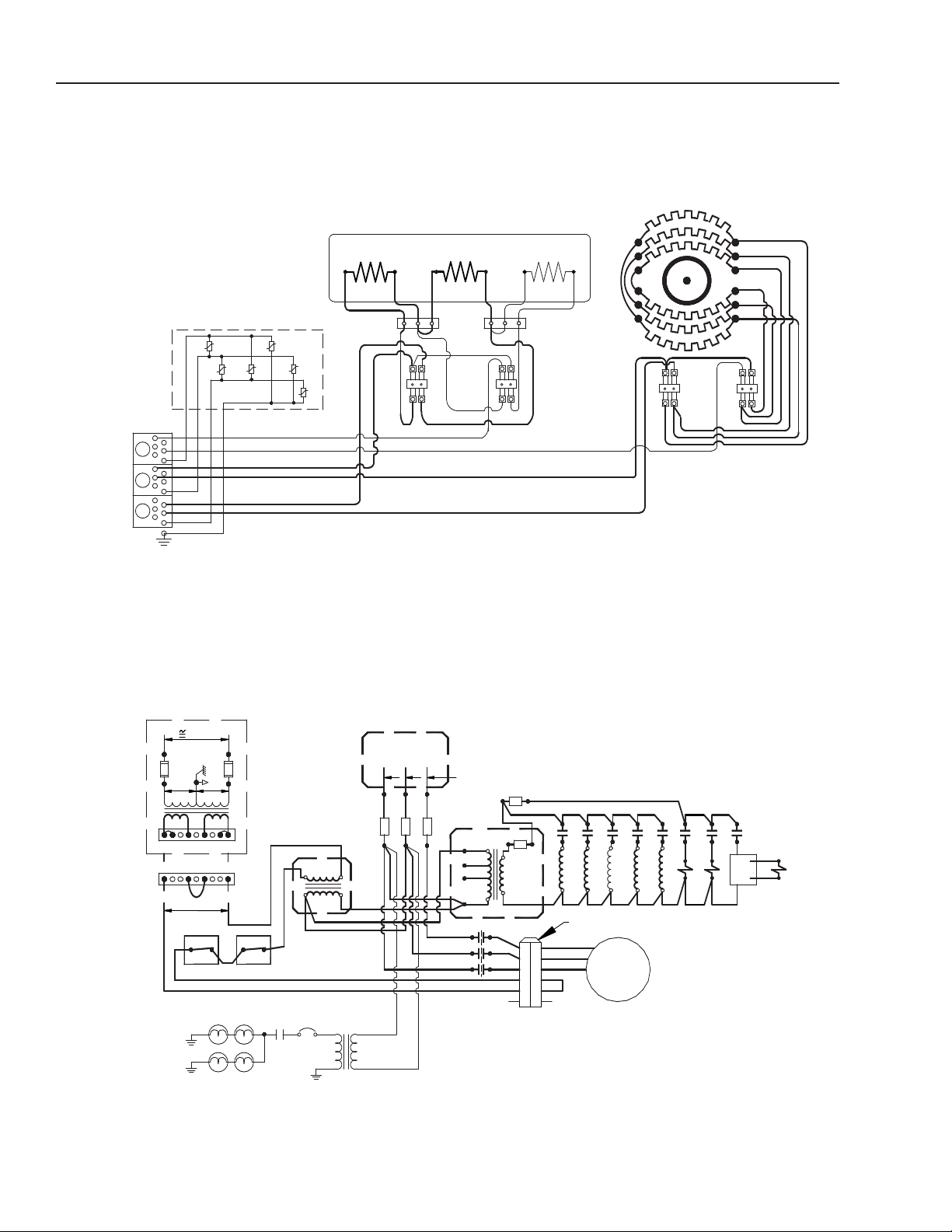

Electrical Diagrams

After Serial Number C7439MS

Steam Mode Circuit

2-18

(Revised 1/02)

Page 22

GND

DB1

L

3

BLOCK

DISTRIBUTION

POWER

208/220/240V

1ø, 3ø

L2

LINE VOLTAGE

L1

-

2

MOV

-4

-6

MOV

MOV

-1

MOV

-3

-5

MOV

MOV

MOV BOARD

A6

ELEMENT

AIR

K12B

K11B

K

10B

AH3

K11

RELAY BOARD

K12

K12A

2.25 KW

2.25 KW

K11A

A

5

K10

K10A

A

1

2.25 KW

A

2

AH2

A3

A

4

ELEMENT

BOILER

K5B

K

9B

K4B

K3B

K2B

K1B

BH2

3 KW

3 KW

K

5A

K9A

K9

K5

K4A

K

4

K3

B

1

AH1

B3

B2

BH3

K3A

K2

K

1

K2A

K1A

B

6

B

4

3 KW

B

5

B

H1

GND

12AWG

(1ph ONLY)

Xph

Yph

SEE

TABLE

DISTRIBUTION BLOCK

OPEN @ 610° F

BOILER

TC2

DB1

14 AWG

AIR

TC1

FB2-A

FB1-A

F4

FB2-B

F5

20

20

FB1-B

24 VAC

50 VA

COM

200/208V

TR1

X2

2

F1

XF

1700 RPM

1/6 HP

BLU

AC2

N/C

BLU

K6

BLK

2

5

3

4

WHT

1

BLK

RED

3

1

2

-

RELAY

START

MOTOR

YEL

DC2

SPRAY

VALVE

BOILER

K14

ORG

K13

AC1

K15

BRN

BRN

ORG

+

D1

ORG

DC1

DRAIN

VALVE

WV2

WV1

FILL

VALVE

ORG

WV3

WV4

L2

L1

L3

GND

208V-240V

A

B

14VAC

RELAY BOARD

14VAC

3

J4

1

21

64

654

9

987

POWER TO

1.25 AMP

C

28VAC

D

RELAY BOARD

1.25 AMP

14 AWG

14 AWG

220/230/240V

440/460/480V

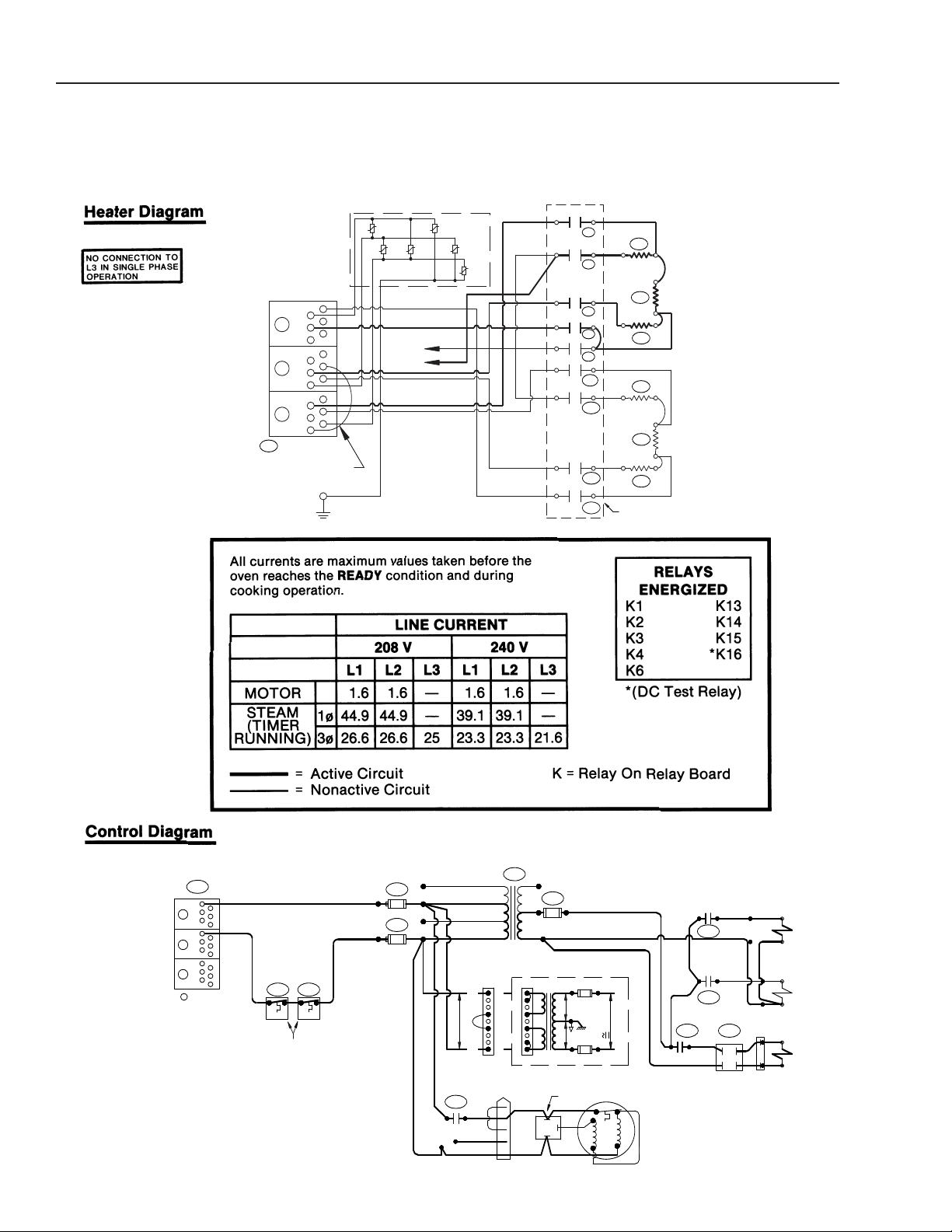

CC10-E

Electrical Diagrams

After Serial Number C7439MS

ombo Mode Circuit

C

(Revised 1/02)

2-19

Page 23

CC10-E

GND

DB1

L3

BLOCK

DISTRIBUTION

POWER

208/220/240V

1ø, 3ø

L2

LINE VOLTAGE

L1

-2

MOV

-4

-6

MOV

MOV

-1

MOV

-3

-5

MOV

MOV

MOV BOARD

A

6

ELEMENT

AIR

K12B

K

11B

K

10B

AH3

K11

RELAY BOARD

K12

K

12A

2.25 KW

2.25 KW

K11A

A5

K10

K10A

A1

2.25 KW

A2

A

H2

A

3

A4

ELEMENT

BOILER

K5B

K

9B

K4B

K3B

K

2B

K1B

BH2

3 KW

3 KW

K5A

K9A

K9

K

5

K4A

K4

K3

B1

AH1

B3

B

2

BH3

K3A

K2

K1

K

2A

K1A

B

6

B4

3 KW

B

5

BH1

GND

12AWG

(1ph ONLY)

X

ph

Yph

SEE

TABLE

DISTRIBUTION BLOCK

OPEN @ 610° F

BOILER

TC2

DB1

14 AWG

AIR

TC1

FB2-A

FB1-A

F4

FB2-B

F5

20

20

FB1-B

24 VAC

50 VA

COM

200/208V

TR1

X2

2

F1

XF

1700 RPM

1/6 HP

BLU

AC2

N/C

BLU

K6

BLK

2

5

3

4

WHT

1

BLK

RED

3

1

2

-

RELAY

START

MOTOR

YEL

DC2

SPRAY

VALVE

BOILER

K14

ORG

K13

AC1

K15

BRN

BRN

ORG

+

D1

ORG

DC1

DRAIN

VALVE

WV2

WV1

FILL

VALVE

ORG

WV3

WV4

L2

L1

L3

GND

208V-240V

A

B

14VAC

RELAY BOARD

14VAC

3

J4

1

21

64

654

9

987

POWER TO

1.25 AMP

C

28VAC

D

RELAY BOARD

1.25 AMP

14 AWG

14 AWG

220/230/240V

440/460/480V

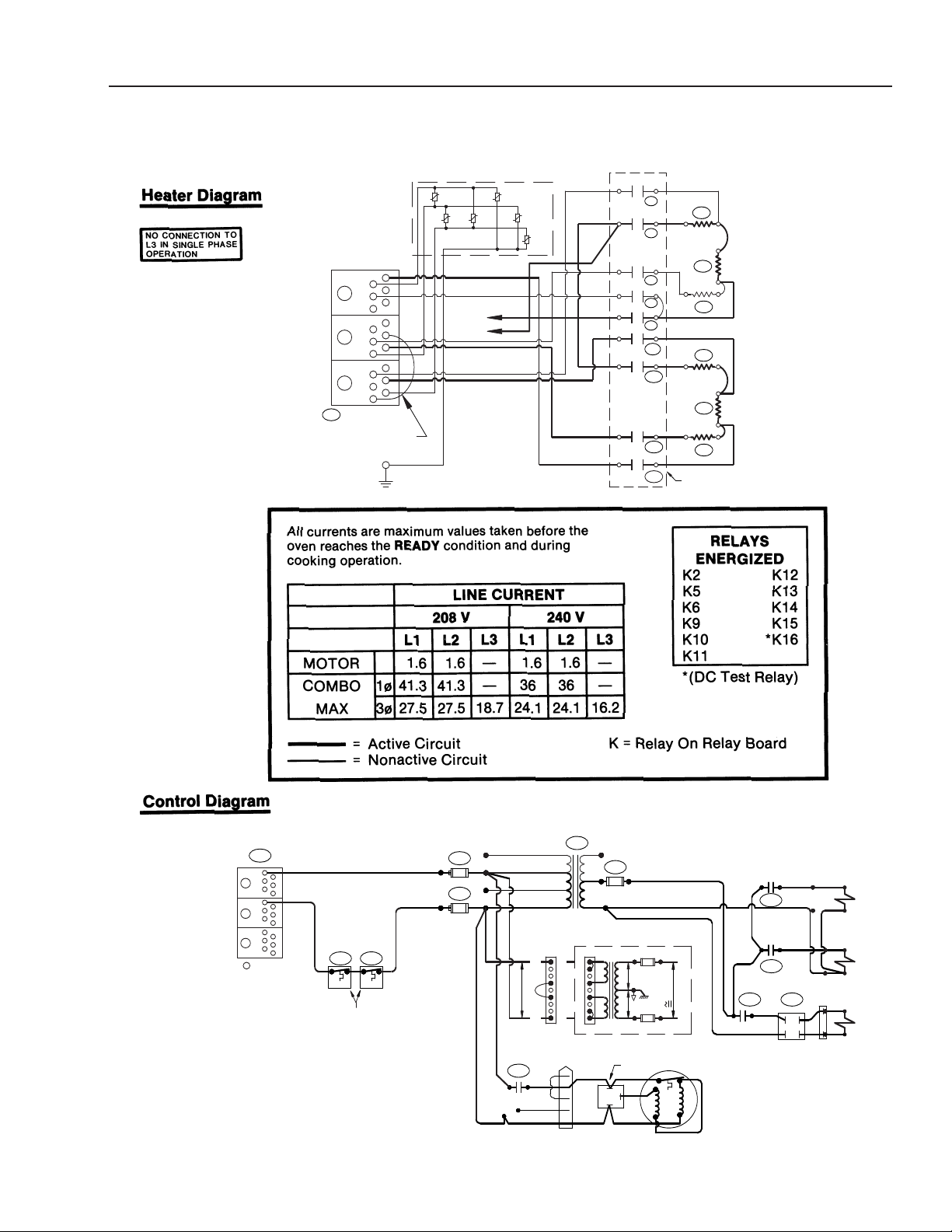

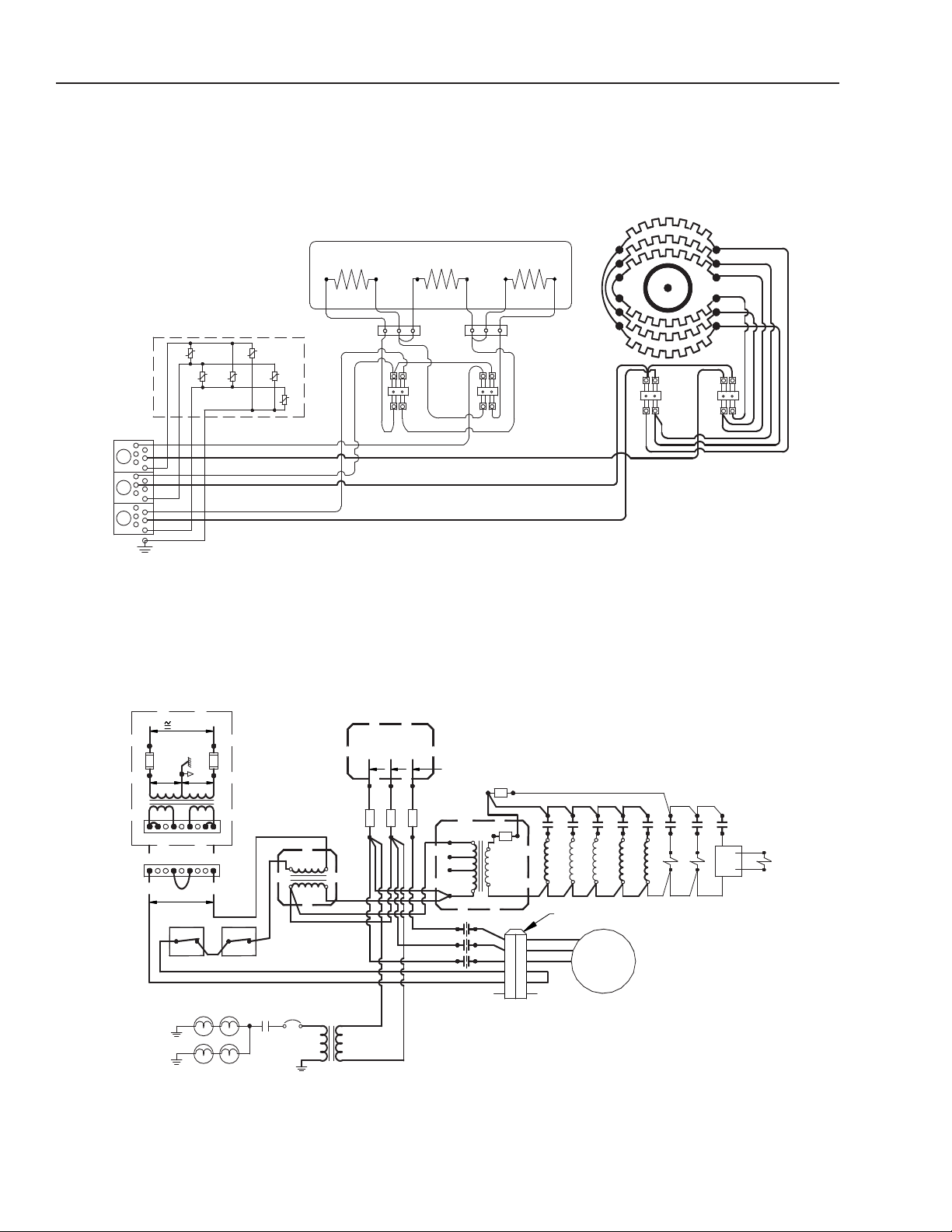

Electrical Diagrams

After Serial Number C7439MS

Oven Mode Circuit

2-20

(Revised 1/02)

Page 24

CC10-E

GND

DB1

L3

BLOCK

DISTRIBUTION

POWER

208/220/240V

1ø, 3ø

L2

LINE VOLTAGE

L1

-2

MOV

-4

-6

MOV

MOV

-1

MOV

-3

-5

MOV

MOV

MOV BOARD

A6

ELEMENT

AIR

K12B

K11B

K10B

AH3

K11

RELAY BOARD

K12

K12A

2.25 KW

2.25 KW

K11A

A5

K10

K10A

A1

2.25 KW

A2

AH2

A3

A4

ELEMENT

BOILER

K5B

K9B

K4B

K3B

K2B

K1B

BH2

3 KW

3 KW

K5A

K9A

K9

K5

K4A

K4

K3

B1

AH1

B3

B2

BH3

K3A

K2

K1

K2A

K1A

B6

B4

3 KW

B5

BH1

GND

12AWG

(1ph ONLY)

Xph

Yph

SEE

TABLE

Electrical Diagrams

After Serial Number C7439MS

Schematic Diagrams for CC10-E

(Revised 1/02)

2-21

Page 25

CC10-E

DISTRIBUTION BLOCK

OPEN @ 610° F

BOILER

TC2

DB1

14 AWG

AIR

TC1

FB2-A

FB1-A

F4

FB2-B

F5

20

20

FB1-B

24 VAC

50 VA

COM

200/208V

TR1

X2

2

F1

XF

1700 RPM

1/6 HP

BLU

AC2

N/C

BLU

K6

BLK

253

4

WHT

1

BLK

RED

3

1

2

-

RELAY

START

MOTOR

YEL

DC2

SPRAY

VALVE

BOILER

K14

ORG

K13

AC1

K15

BRN

BRN

ORG

+

D1

ORG

DC1

DRAIN

VALVE

WV2

WV1

FILL

VALVE

ORG

WV3

WV4

L2

L1

L3

GND

208V-240V

A

B

14VAC

RELAY BOARD

1

4VAC

3

J4

1

21

64

654

9

987

P

OWER TO

1.25 AMP

C

28VAC

D

RELAY BOARD

1.25 AMP

14 AWG

14 AWG

220/230/240V

440/460/480V

Electrical Diagrams

After Serial Number C7439MS

chematic Diagrams for CC10-E

S

2-22

(Revised 1/02)

Page 26

CC10-E

Parts List

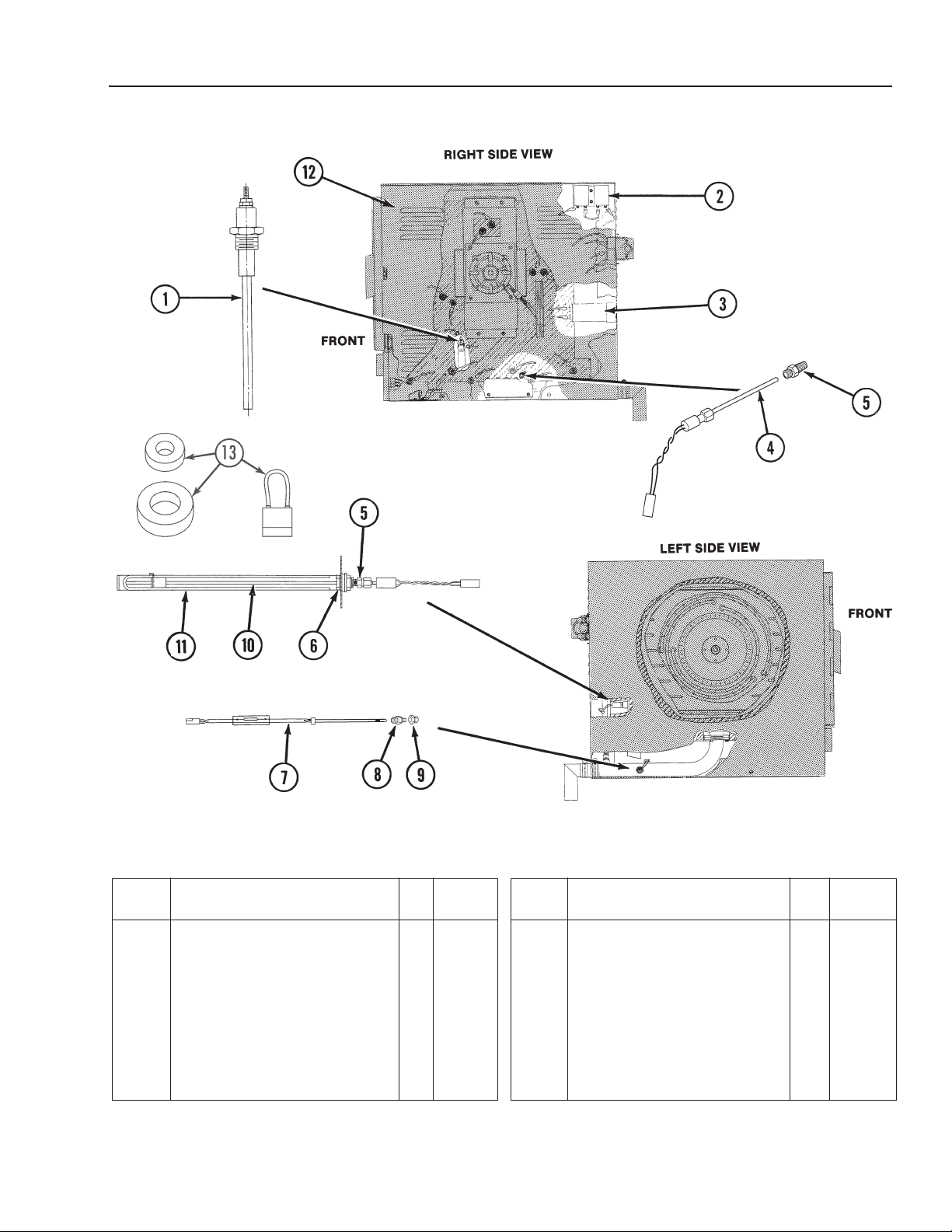

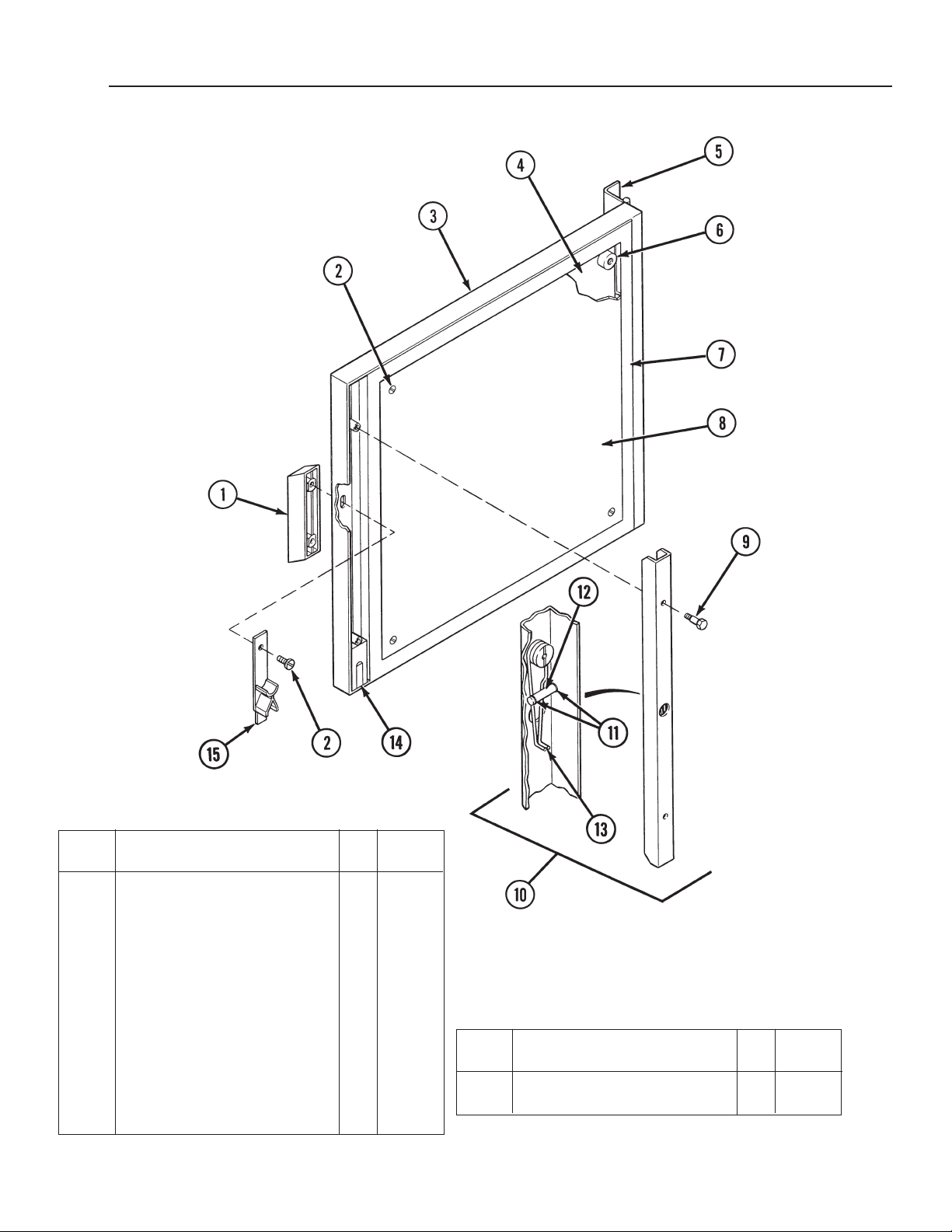

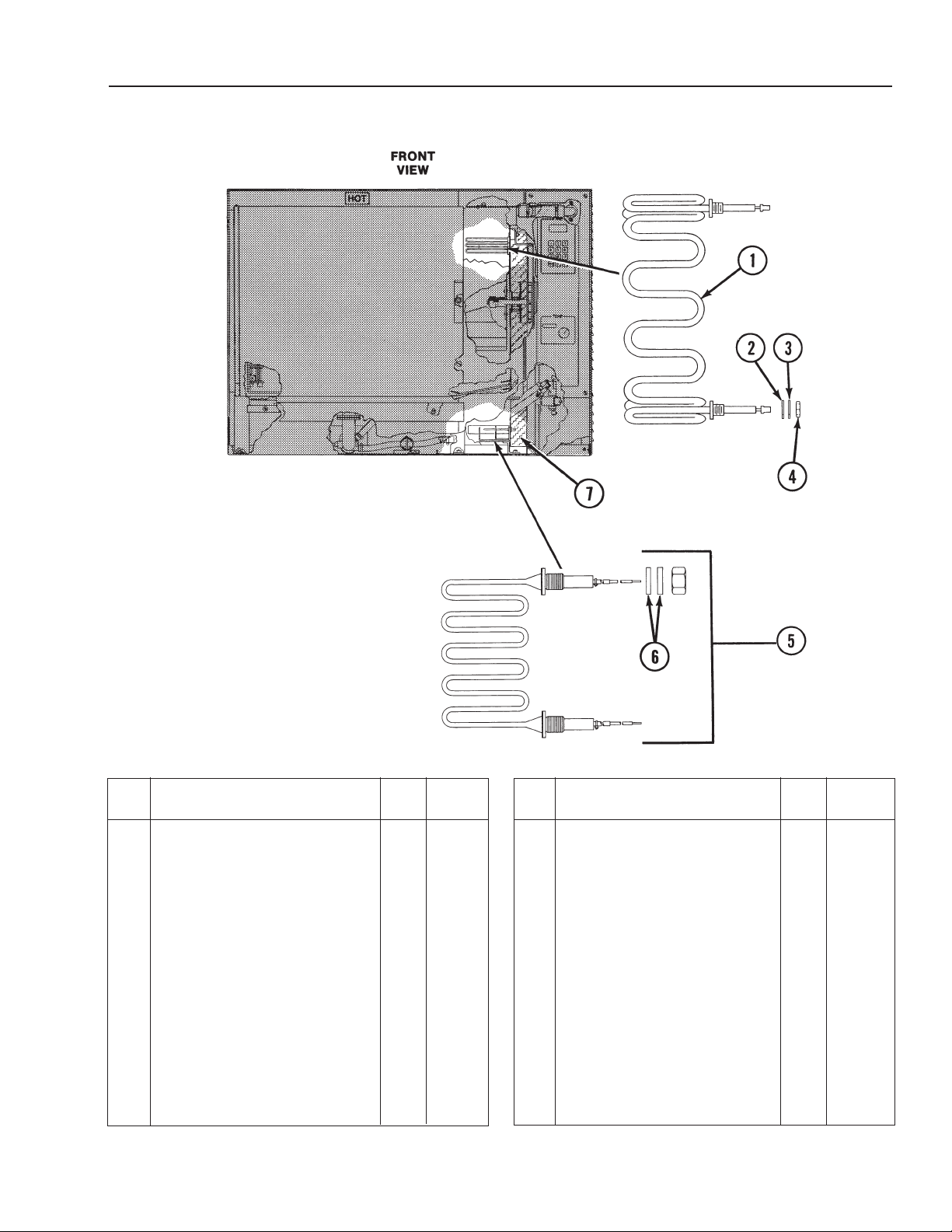

Item Description Qty.

1 Probe, Water . . . . . . . . . . . . . . 2 070178

2 Thermostat . . . . . . . . . . . . . . . . 2 071499

3 Capacitor . . . . . . . . . . . . . . . . . 1 071291

4 Kit, Boiler Temperature

Probe . . . . . . . . . . . . . . . . . . . . 1 077804

5 Fitting, Male Brass . . . . . . . . . . 2 071217

6 Fitting S.S. . . . . . . . . . . . . . . . . 1 071231

†7 Kit, Drain Temperature

Probe . . . . . . . . . . . . . . . . . . . 1 077805

(Revised 1/02)

FIGURE 1

Part

No.

Figure 1. Sensors

Item Description Qty.

8 Connector, Male Brass . . . . . . 1 071251

9 Bushing Teflon . . . . . . . . . . . . 1 072163

10 Kit, Air Temperature

11 Air Probe Guard . . . . . . . . . . . 1 074827

12 Right Side Louvered Cover . . 1 070468

13 EMI Kit . . . . . . . . . . . . . . . . . . 1 118830

* Air & Drain Probe Harness . . 1 073272

* Water Probe Harness . . . . . . . 1 073268

* Not Shown† Not used on ovens after serial number C7439MS-electric

Part

No.

Probe . . . . . . . . . . . . . . . . . . 1 077803

2-23

2-23

Page 27

CC10-E

Parts List

2-24

Item Description Qty.

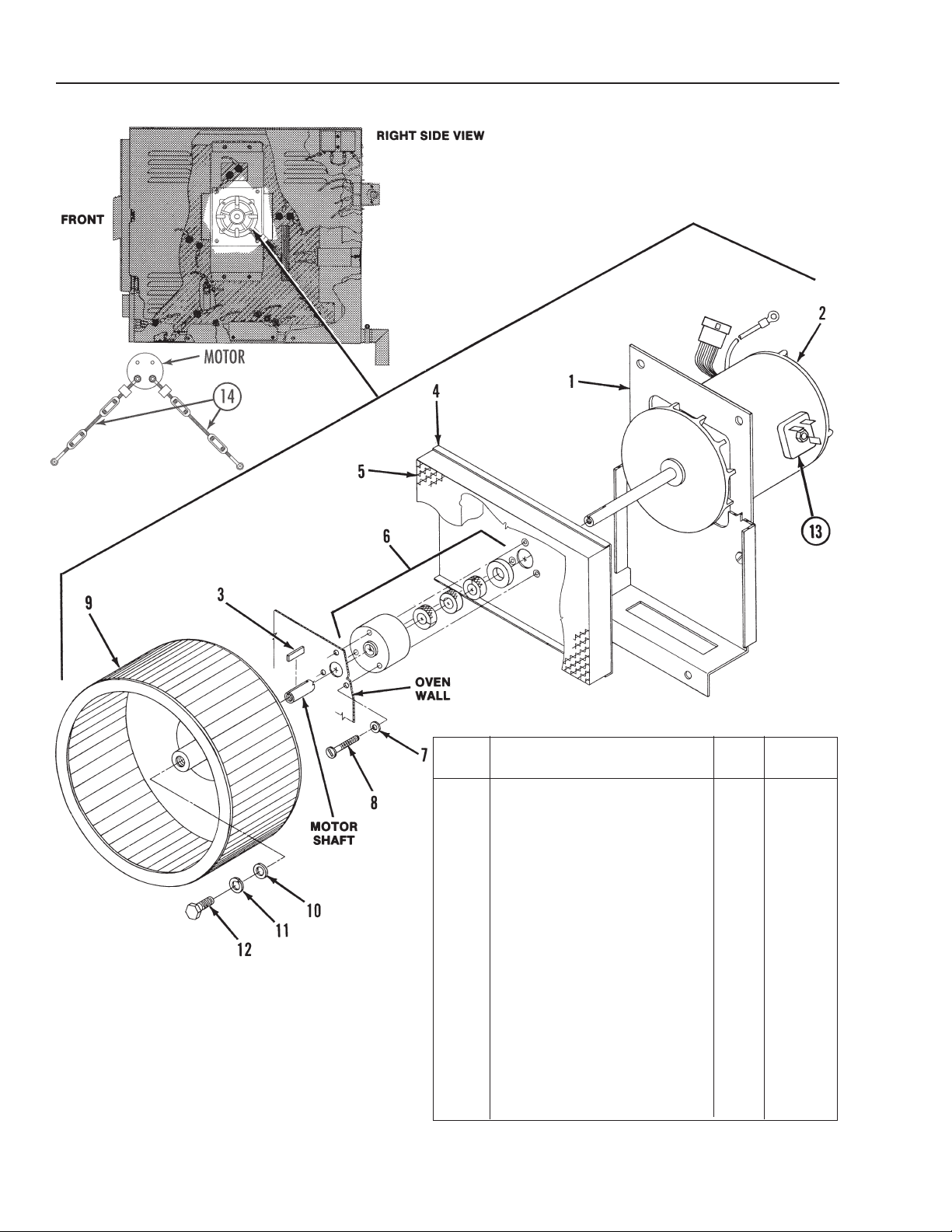

1 Bracket Assy. . . . . . . . . . . . . . 1 070100

2 Motor & Heat Slinger Assy.

3 Key, 1/8’ Square 303 S.S. . . . 1 071288

4 Insulation Retainer Assy. . . . . 1 071228

5 Insulation Nut Plate . . . . . . . . 1 069770

6 Motor Seal Assy. . . . . . . . . . . 1 071299

7 Washer, Fiber . . . . . . . . . . . . 3 071300

8 Screw, Truss Head S.S. . . . . 3 081698

9 Blower Wheel Assembly . . . . 1 074227

10 Washer, Flat . . . . . . . . . . . . . 1 059228

11 Washer, Lock . . . . . . . . . . . . 1 05656

12 Screw, Hex Head Cap S.S. . . 1 05613

13 Motor Start Relay . . . . . . . . . 1 077826

14 Kit Fan Isolator . . . . . . . . . . . 1 098684

Figure 3. Fan and Motor

Part

No.

- 280V/240V . . . . . . . . . . . . . 1 078802

• Washer Seal Housing . . . . . 1 070458

• Packing . . . . . . . . . . . . . . . . 3 070459

• Motor shaft Housing Seal . . 1 070457

(Revised 1/02)

Page 28

CC10-E

Parts List

(Revised 5/95)

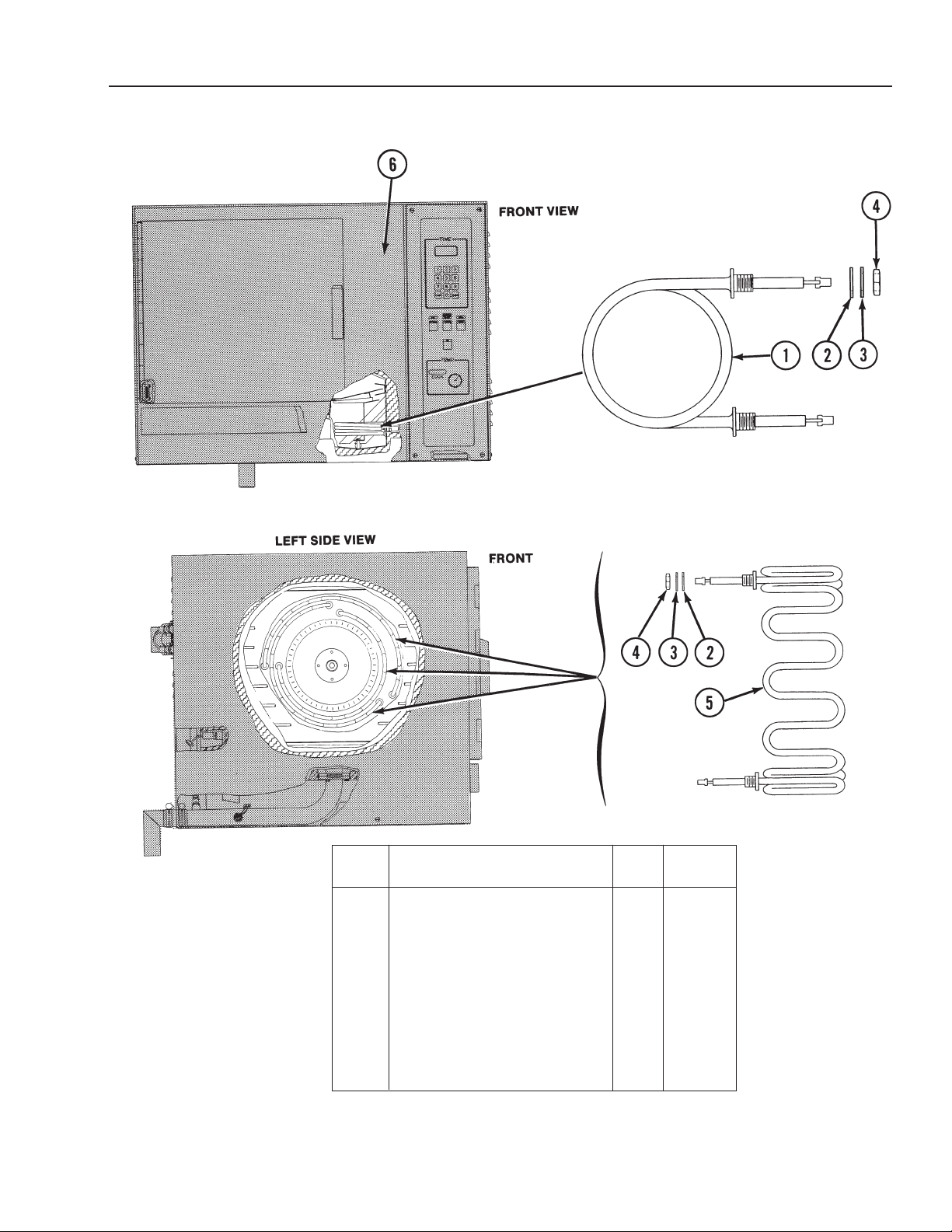

Item Description Qty.

1 Water Heating Element -

208V . . . . . . . . . . . . . . . . . . . 3 070200

1 Water Heating Element -

240V . . . . . . . . . . . . . . . . . . 3 072112

2 • Fiber Washer . . . . . . . . . . . 14 072183

3 • Washer . . . . . . . . . . . . . . . . 14 *

4 • Nut . . . . . . . . . . . . . . . . . . . 14 *

5 Air Heating Element -

208V . . . . . . . . . . . . . . . . . . 3 070196

5 Air Heating Element -

240V . . . . . . . . . . . . . . . . . . 3 072111

6 Front Panel . . . . . . . . . . . . . . . 1 070472

* Supplied with element.

Figure 3. Heating Elements

Part

No.

2-25

Page 29

CC10-E

Parts List

2-26

Part

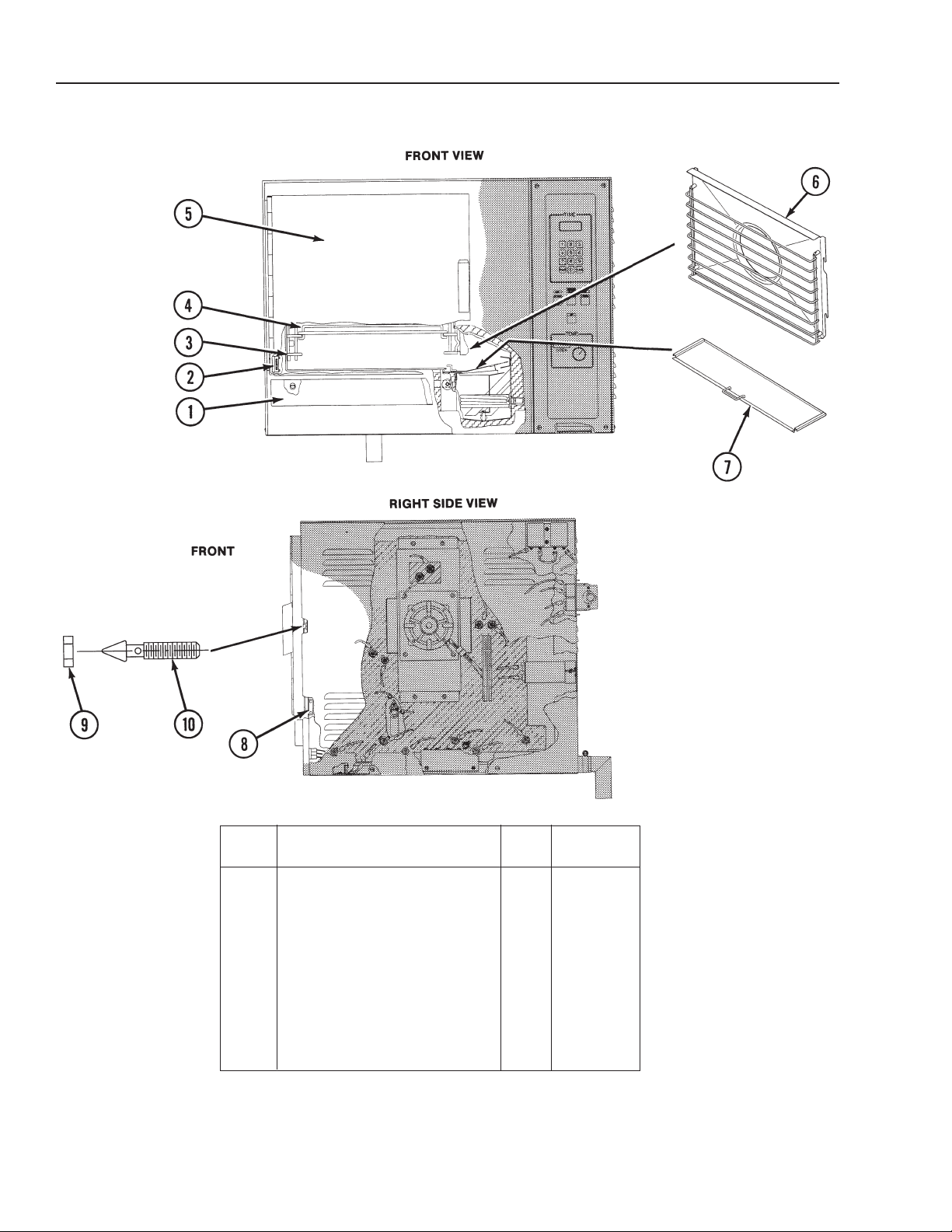

Item Description Qty.

1 Drip Tray . . . . . . . . . . . . . . . . . 1 070471

2 Left Side Door Switch . . . . . . 1 078903

3 Left Side Rack . . . . . . . . . . . . 1 070180

4 Middle Rack . . . . . . . . . . . . . . 4 069764

5 Door Assembly . . . . . . . . . . . . 1 See Fig. 7

6 Shroud Assembly . . . . . . . . . . 1 078920

7 Baffle Assembly Cover . . . . . . 1 070165

8 Right Side Door Switch . . . . . 1 078904

9 Door Pin Locking Nut . . . . . . . 1 003823

10 Door Latch Pin . . . . . . . . . . . . 1 078914

Figure 4. Doors, Racks and Tray

No.

(Revised 5/96)

Page 30

CC10-E

Parts List

(Revised 1/02)

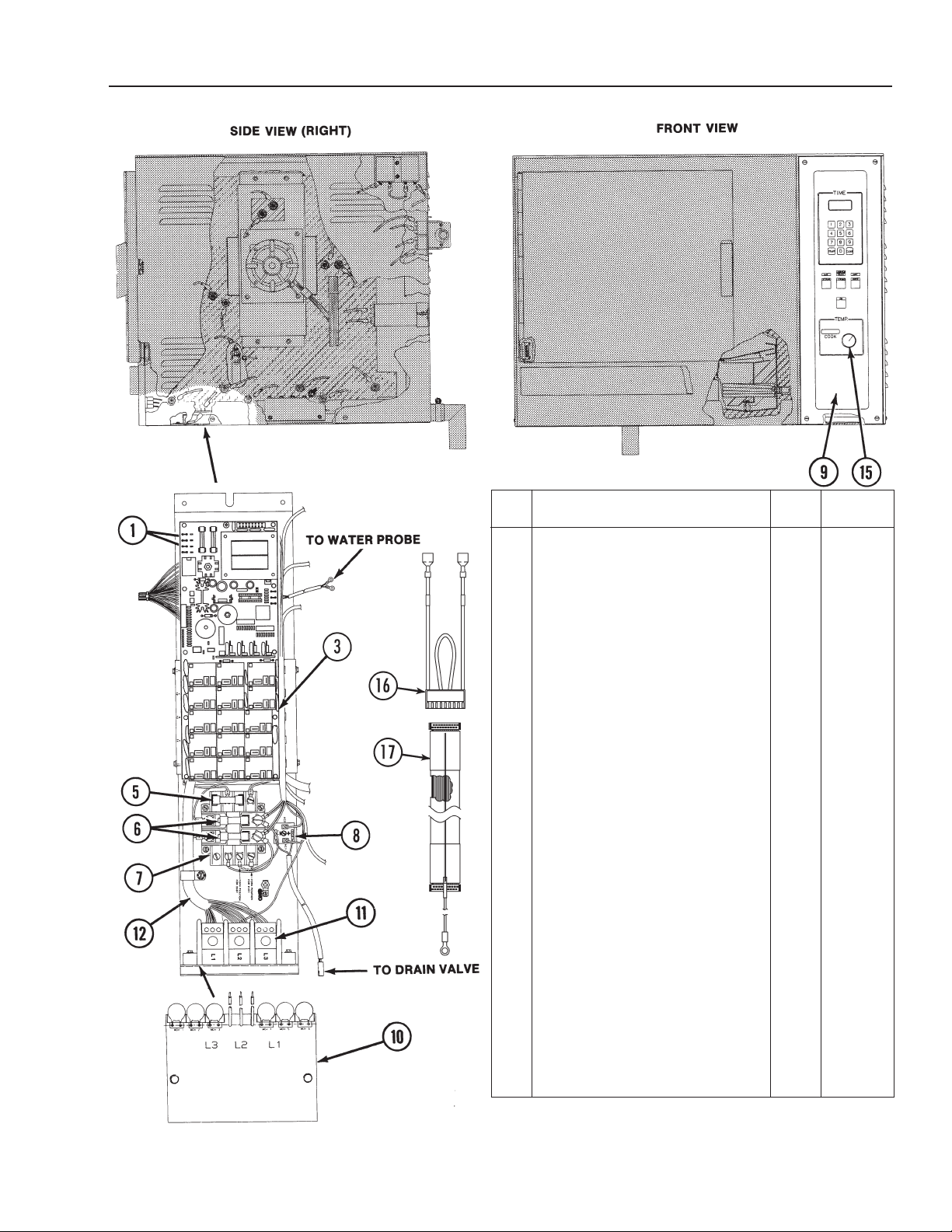

Item Description Qty.

1 Fuse, 0.2 Amp., Slow Blow . . . . . . . 2 073271

Prior to Serial No. C7439MS

3 Relay Board Retrofit Kit . . . . . . . . . . 1 070184

Cook Only . . . . . . . . . . . . . . . . . . . . 1 112980

Cook

annd Hold . . . . . . . . . . . . . . . . 1 112988

Starting at Serial No. C7439MS

3 Relay

5 Fuse, 2 Amp . . . . . . . . . . . . . . . . . . . 1 071488

6 Fuse, 20 Amp . . . . . . . . . . . . . . . . . . 3 071489

7 Transformer . . . . . . . . . . . . . . . . . . . 1 071490

8 Bridge Rectifier . . . . . . . . . . . . . . . . 1 071487

9* Control Panel . . . . . . . . . . . . . . . . . .

+ Cook Only . . . . . . . . . . . . . . . . . . . . 1 112960

+

*+ Top, Cook Only . . . . . . . . . . . . . . . . 1 1

*+ Bottom, Cook Only . . . . . . . . . . . . . . 1 112960

*+ Top, Cook and Hold . . . . . . . . . . . . . 1 112961

*+ Bottom, Cook and Hold . . . . . . . . . . 1 112961

+ EPROM . . . . . . . . . . . . . . . . . . . . . . 1 112954

10 Surge Suppressor, 208/240V . . . . . . 1 098703

11 Terminal Block . . . . . . . . . . . . . . . . . 1 070185

12 Harness Line Side . . . . . . . . . . . . . . 1 072101

13 Harness Heater Side . . . . . . . . . . . . 1 072187

14 Harness Drain and Air Probe . . . . . . 1 073272

15 Control Panel Knob . . . . . . . . . . . . . 1 073430

16 Voltage Plug . . . . . . . . . . . . . . . . . . . 1 106826

17 Flexible Cable with Grounded Shield 1 114423

* Change the mounting frame with the old panel.

+ EPROM must be ordered with control panel.

Board . . . . . . . . . . . . . . . . . . 1 120718

Prior To Serial No. C7439MS

Single Oven

Cook Only Retrofit Kit . . . . . . . . . . . 1 112980

Cook

and Hold Retrofit Kit . . . . . . . . 1 112982

Double Stacked

Top, Cook Only Retrofit Kit . . . . . . . 1 112980

Bottom, Cook Only Retrofit Kit . . . . . 1 1

Top, Cook and Hold Retrofit Kit . . . . 1 112982

Bottom, Cook and Hold Retrofit Kit

Starting At Serial No. C7439MS

Single Oven

Cook and Hold . . . . . . . . . . . . . . . . . 1 112961

Double Stacked

Figure 4. Control Panel and Relay

Bracket Assembly

Part

No.

12980

. . . 1 112982

12960

2-27

Page 31

CC10-E

Parts List

Part

Item Description Qty.

1 Solenoid Valve (2-Way) . . . . . 1 071235

2 Hose Clamp . . . . . . . . . . . . . . 6 071271

3 Condensate Hose, 27” Long . 1 071283

4 Spray Nozzle . . . . . . . . . . . . . 1 078933

5 Drain Seal . . . . . . . . . . . . . . . 1 072128

6 Drain Pipe Assembly . . . . . . . 1 074233

7 Radiator Hose, 1-1/2’ ID X

2-1/2” Long. . . . . . . . . . . . . . 1 073254

8 Hose Clamp . . . . . . . . . . . . . . 2 073259

9 Drain Elbow Assembly . . . . . . 1 072159

10 Drain Valve and Bracket

Assembly . . . . . . . . . . . . . . . 1

11 • Drain Valve . . . . . . . . . . . . . 1 071234

12 • Bracket Assembly . . . . . . . . 1 069794

13 Silicone Hose . . . . . . . . . . . . . 1 071275

14 90° Elbow, 1/2” NPT . . . . . . . 1 013667

15 Water Inlet Assembly . . . . . . 1 072151

15A Nut . . . . . . . . . . . . . . . . . . . . . 078922

15B Washer . . . . . . . . . . . . . . . . . . 072182

15C Gasket . . . . . . . . . . . . . . . . . . 072183

16 Hose, 3/8” ID . . . . . . . . . . . . . 2 074205

17 Tube, 3/8” OD . . . . . . . . . . . . 1 074204

18 Tee . . . . . . . . . . . . . . . . . . . . 1 072162

19 Screw Socket Hd.

1/4x20x3/4 . . . . . . . . . . . . . . . 3 084285

20 Straight Barb Hose Fitting . . . 1 071270

No.

Item Description Qty.

21 Back Cover . . . . . . . . . . . . . . . 1 072135

* Element Side Insulation . . . . . 1 069740

* Left Side Insulation . . . . . . . . 1 069759

* Back Insulation . . . . . . . . . . . . 1 069741

* Bottom Insulation . . . . . . . . . . 1 069758

* Boiler Bottom Insulation . . . . . 1 069756

* Boiler Side Insulation . . . . . . . 1 071233

* Not Shown

Part

No.

2-28

Figure 5. Water Inlet, Drain and Insulation

(Revised 1/02)

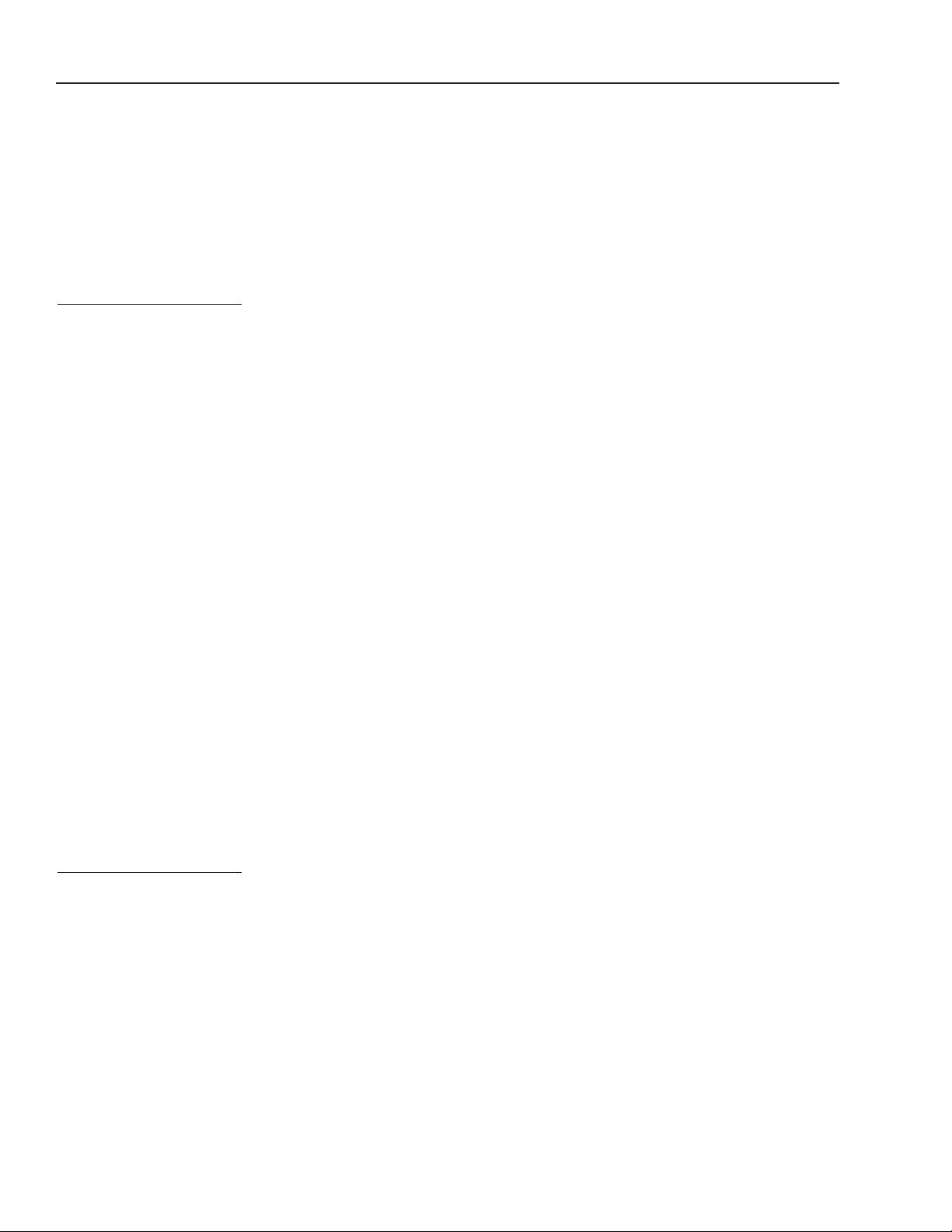

Page 32

CC10-E

Parts List

Part

Item Description Qty.

Door Assembly . . . . . . . . . . . . 1 073284

1 Handle . . . . . . . . . . . . . . . . . . 1 129723

2 Truss Head Screw S.S. . . . . . 6 005764

3 Door Front Panel . . . . . . . . . . 1 073281

4 Insulator Board . . . . . . . . . . . 1 070110

5 Hinge . . . . . . . . . . . . . . . . . . . 1 070199

6 Door Spacer . . . . . . . . . . . . . . 4 071206

7 Gasket . . . . . . . . . . . . . . . . . . 1 070121

8 Inner Panel . . . . . . . . . . . . . . 1 070112

9 Hex Head Cap Screw S.S. . . 2 005608

10 Latch Assembly . . . . . . . . . . . 1 078906

11 • Retaining Ring . . . . . . . . . . . 2 073278

12 • Spring Support Pin . . . . . . . . 1 073280

13 • Door Spring . . . . . . . . . . . . . 1 078911

14 Block and Magnet Assembly 1 069762

15 Door Cam . . . . . . . . . . . . . . . . 1 074252

(Revised 1/02)

No.

Item Description Qty.

* Loctite 242 . . . . . . . . . . . . . . . 1 073282

* RTV Sealant 159 . . . . . . . . . . 1 078939

* Not Shown

Figure 6. Oven Door

Part

No.

2-29

Page 33

CC20-E

Specifications

Oven Electrical Specifications

AC Input

Voltage

280V, 3-Phase

240V, 3-Phase

480V, 3-Phase

30 to 60 PSIG. A pressure regulator is required for water pressure above

60 PSIG.

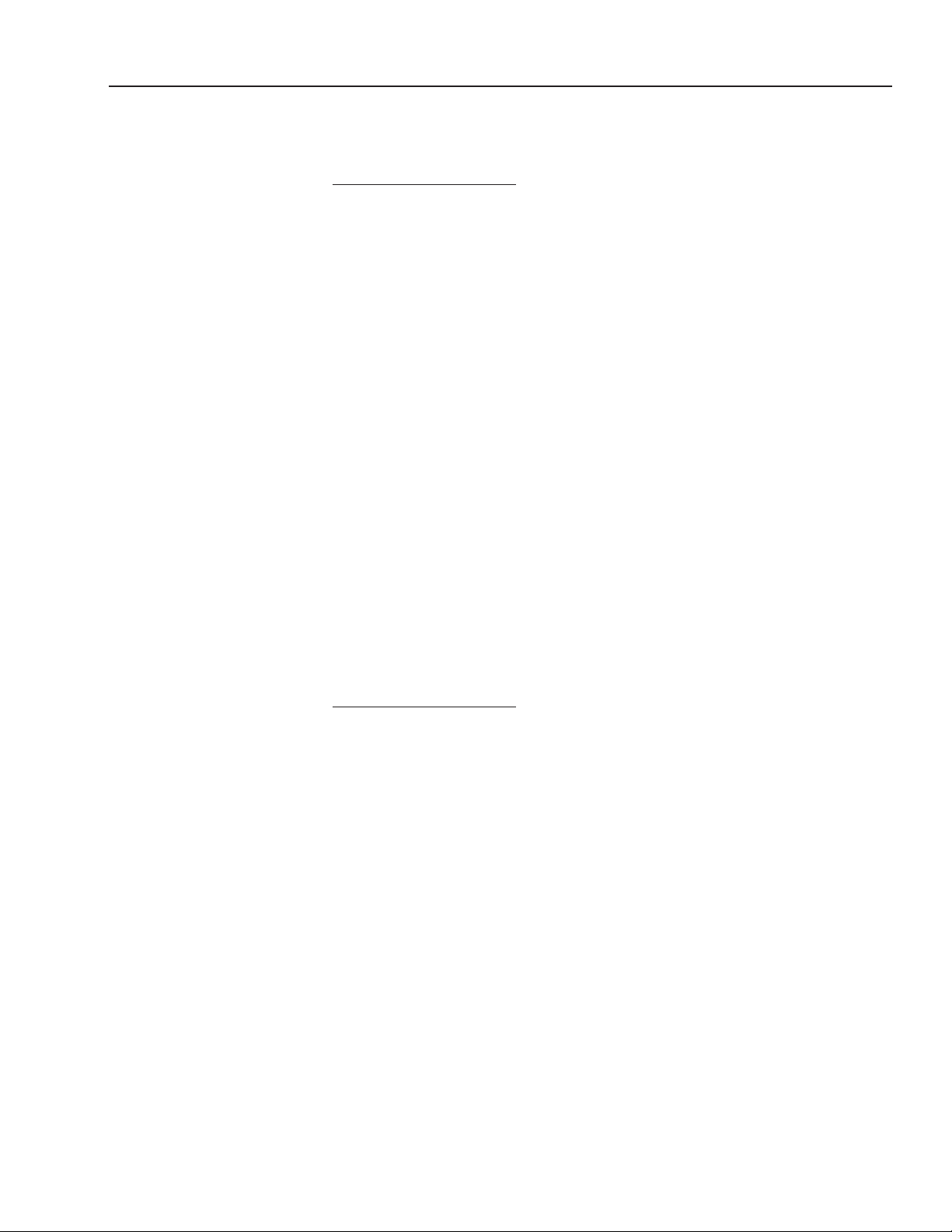

Without Drain Box:

1. Drain hose cannot be connected directly to a building drain; there

cannot be any elbows or other restrictions between the oven drain and

the two inch free air gap.

2. Free Air Gap: 2” free air gap required between drain hose and building

drain.

Current Rating

Per Line

65.4A

56.7A

28.3A

Power

21KW

21KW

21KW

Water Line Pressure

Drain Connection

3. Drain Line: 2” ID drain hose between oven and building drain with a

constant downward pitch.

4. Plastic pipe cannot be used for a drain line.

With Drain Box:

Drain hose to a building drain can be connected directly

1.

2. The drain box has an air vent that eliminates the need for an air gap.

3. Do not block the air vent in any way.

4. Do not attach anything to the vent tube or reduce the size of the vent

tube.

.

(Revised 1/02)

3-1

Page 34

CC20-E

Installation Checks

General

––––– Make sure there is no heat source within 12

inches of louvered right side of oven.

Heat Shield P/N 086449 - Single Cavity (1)

Double Cavity (2)

–––––

––––– Make sure oven is level or pitched slightly

––––– Check that fan is clear of packaging

Make sure there is a minimum six inch free

space on louvered side of oven.

rearward.

materials.

––––– Check that water line is at least 1/2 inch ID.

––––– Check that water line is not putting high

stress on inlet water valve.

––––– Check that inlet water pressure is 30 to 60

PSIG.

––––– The water supply should not contain more

than 30 to 40 parts per million total

dissolved solids (TDS) and has a pH of 7.0

or higher.

Drain Connections

––––– Check that air and water heating elements

are clear of packaging materials.

––––– Make sure boiler is clear of packaging

materials.

––––– Check that water level probes and probe

holders are clear or packaging materials.

Electrical Checks

––––– Make sure oven is properly grounded per

NEC.

––––– V

––––– Make sure that branch circuit protection

––––– Check the power source is three-phase.

––––– Check that connections to L1, L2, and L3

erify that electrical connections conform to

local code and NEC requirements.

conforms to oven specifications specified

on oven nameplate.

are correct. Refer to label above distribution

block.

––––– Make sure drain plumbing connections

comply with local codes.

–––––

––––– Make sure drain line is two inches in

––––– Check that drain is free vented.

––––– Make sure drain line is not directly

––––– Check that drain line is suitable for boiling

––––– Check that drain line is pitched downward.

––––– Make sure drain line is free of obstruction.

Oven Door Check

––––– Make sure door gasket is making good

Check that drain hose connection is flexible

to allow oven movement for servicing.

diameter.

connected to the building drain.

water. Make sure PVC is not being used for

drain plumbing.

contact with cavity

.

Cold Water Supply Connections

––––– Make sure plumbing connections conform

to local codes.

–––––

3-2

If permitted by local codes, check that hose

connection is flexible to allow oven

movement for servicing.

––––– Check that door opens easily and freely.

––––– Confirm that operators are leaving the door

open when unit is shut down overnight or

longer.

(Revised 1/02)

Page 35

CC20-E

Sequence Of Events

Prior to Serial Number C7439MS

208V and 240V Units

perating Conditions

O

• Oven cavity below 200°F.

• Oven door closed.

• No service codes displayed in the time display window.

• There are no apparent oven operating problems.

Steam Mode (Prior to Serial Number C7439MS)

Refer to the Steam mode circuit diagrams on pages 3-23 and 3-24, and/or the

schematic diagrams on pages 3-32 and 3-33 for the following sequence of

events.

1. Mercury relay R1 energized.

2. Relays K15 and K13 energize. Boiler drain valve closes and boiler fill valve

opens. Boiler fill begins.

3. Relays K6, K7 and K8 energize. Fan motor turns on.

4. When water reaches low water probes, relays K2, K3, K4, R2, R3, and R4

energize.

5. When water reaches high water probe, relay K13 de-energizes and boiler fill

valve closes.

6. When boiler water reaches “ready” temperature, relays K3, K4, R3, and R4

de-energize, and K2, K5, and R2 are energized and water heating elements

turn to low power.

Relay Operation Summary

1. R1 energized. (Mercury Relay)

K15 and K13 energized. (Drain and Fill)

2.

3. K6, K7 and K8 energized. (Fan)

K2 through K4, and R2 through R4 energized. (W

4.

5. K13 de-energized. (Fill)

6. K3 and K4, and R3 and R4 de-energized. (Water Heat) K2 and K5

energized.

ater Heat)

(Revised 1/02)

Combo Mode (Prior to Serial Number C7439MS)

Refer to the Combo mode circuit diagrams on pages 3-26 and 3-27, and/or the

schematic diagrams on pages 3-32 and 3-33 for the following sequence of

events.

1. Mercury relay R1 energized.

3-3

Page 36

CC20-E

Sequence Of Events

Prior to Serial Number C7439MS

2. Relays K15 and K13 energize. Boiler drain valve closes and boiler fill valve

opens. Boiler fill begins.

3. Relays K6, K7, and K8 energize. Fan motor turns on.

4. When water reaches low water probes, relays K2, K3, K4, R2, R3, and R4

energize.

5. When water reaches high water probe, relay K13 de-energizes and boiler fill

valve closes.

6. When boiler water reaches “ready” temperature, relays K3, K4, R3, and R4

de-energize. Relays K2 and R2 remain energized.

7. K5 and K14 energized. Condensate spray valve opens.

8. Relays K11, K12, R11, and R12 energize. Air heating elements turn on.

9. When oven temperature reaches the temperature set point, relays K11, K12,

R11, and R12 de-energize. Air heating elements turn off.

10. Relays K11, K12, R11, and R12 will cycle ON and OFF to maintain oven

temperature.

Relay Operation Summary

1. R1 energized. (Mercury Relay)

2. K15 and K13 energized. (Drain and Fill)

3. K6, K7, and K8 energized. (Fan)

4. K2 through K4, and R2 through R4 energized. (Water Heat)

5. K13 de-energized. (Fill)

6. K3, K4, R3, and R4 de-energized. K2, R2. (Water Heat)

7. K5 and K14 energized. (Low Water Heat)

8. K11, K12, R11, and R12 energized. (Air Heat)

9. K11, K12, R11, and R12 de-energized. (Air Heat)

10. K11, K12, R11, and R12 energize and de-energize.

Oven Mode (Prior to Serial Number C7439MS)

Refer to the Oven mode circuit diagrams on pages 3-29 and 3-30,

and/or the schematic diagrams on pages 3-32 and 3-33 for the

following sequence of events.

1. Mercury relay R1 energized.

2. Relays K6, K7, and K8 energize. Fan motor turns on.

3. Relays K11, K12, R1

3-4

1, and R12 energize.

Air heating elements turn on.

(Revised 1/02)

Page 37

CC20-E

Sequence Of Events

Prior to Serial Number C7439MS

4. When oven temperature reaches the temperature set point, relays K11, K12,

R11, and R12 de-energize. Air heating elements turn off.

5. Relays K11, K12, R11, and R12 will cycle ON and OFF to maintain the oven

temperature.

Relay Operation Summary

1. R1 energized. (Mercury Relay)

2. K6, K7, and K8 energized. (Fan)

3. K11, K12, R11, and R12 energized. (Air Heat)

4. K11, K12, R11, and R12 de-energized. (Air Heat)

5. K11, K12, R11, and R12 energize and de-energize.

Hold Mode (Manual) (Prior to Serial Number C7439MS)

Refer to the schematic diagrams on pages 3-32 and 3-33 for the following

sequence of events.

NOTE: Low humidity on older panels only. When “Lo” humidity is selected there

is no water in steam generator.

1. Mercury relay R1 energized.

2. Relays K15 and K13 energized. Boiler drain valve closes and boiler fill valve

opens. Boiler fill begins.

3. Relays K6, K7, and K8 energize. Fan motor turns on. Fan will cycle on and

off as required.

4. When water reaches low water probes, relays K2, K3, K4, R2, R3, and R4

energize.

5. When water reaches high water probe, rely K13 de-energizes and boiler fill

valve closes.

6. When boiler water reaches “ready” temperature, relays K2, K3, K4, R2, R3,

and R4 de-energize and water heating elements turn off.

7. K14 energizes and condensate spray valve opens.

Relays K1

8.

1, K12, R1

1, and R12 energize. Air heating elements turn on.

(Revised 1/02)

9. When oven air temperature is 10° below temperature set point, relays K12

and R12 de-energize. Air heating elements operate at reduced power.

10.

When oven temperature reaches the temperature set point, relays K11 and

R11 de-energize. Air heating elements turn off.

3-5

Page 38

CC20-E

Sequence Of Events

Prior to Serial Number C7439MS

Relay Operation Summary

1. R1 energized. (Mercury Relay)

2. K15 and K13 energized. (Drain and Fill)

3. K6, K7 and K8 energized. (Fan)

4. K2 through K4, and R2 through R4 energized. (Water Heat)

5. K13 de-energized. (Fill)

6. K2 through K4, and R2 through R4 de-energized. (Water Heat)

7. K14 energized. (Condensate Spray)

8. K11, K12, R11, and R12 energized. (Air Heat)

9. K12 and R12 de-energized. (Low Air Heat)

10. K11 and R11 de-energized. (High Air Heat)

Two Stage Cleaning Cycle (Prior to Serial Number C7439MS)

Refer to the schematic diagrams on pages 3-32 and 3-33 for the following

sequence of events.

Phase 1

1. Press 9-9 on the touch pad. C1 is displayed in the “TIME” window. Spray

degreaser around the cavity and press “START.” CL:50 is displayed in the

time display window.

2. Mercury relay R1 energized.

3. Relays K15 and K13 energize. Boiler fills.

4. Relays K6, K7, and K8 energize. Fan motor turns on.

Water reaches low water probe. Relays K2, K3, K4, R2, R3, and R4

5.

energize. Water heating elements turn on.

ater reaches high level probe. Relay 13 de-energizes and boiler fill valve

W

6.

closes.

7. Relays K2, K3, K4, R2, R3, and R4 de-energize.

8. Relays K2, K3, K4, R2, R3, and R4 energize and water heating elements

turn on.

9. Relay K14 energizes and condensate spray valve opens.

10. Relays K2, K3, K4, R2, R3, and R4 de-energize and water heating elements

turn off.

11. Relay K15 de-energizes. Drain valve opens and boiler drains.

3-6

(Revised 1/02)

Page 39

CC20-E

Sequence Of Events

Prior to Serial Number C7439MS

12. Relay K14 de-energizes and condensate spray valve closes. C2 is displayed

in the TIME display window. Beeper sounds.

hase 2 (Oven Door Open) - add de-limer in the boiler.

P

13. Relays K15 and K13 energize. Boiler fills.

14. Water reaches low water probe. Relays K2 through K4, and R2 through R4

energize. Water heating elements turn on.

15. When water temperature is approximately 150°F, relays K2 through K4, and

R2 through R4, de-energize. The water heating elements turn off.

16. When water reaches high water probe, relay K13 de-energizes and the

boiler fill valve closes.

17. Relays K2, K3, K4, R2, R3, and R4 de-energize. Water heating elements

torn off.

18. Relays K2, K3, K4, R2, R3, and R4 energize and water heating elements

turn on.

19. Relay K14 energizes and condensate spray valve opens.

20. Relays K2, K3, K4, R2, R3, and R4 de-energize and water heating elements

turn off.

21. Relay K15 de-energizes. Drain valve opens and boiler drains.

22. Relay K14 de-energizes and condensate spray valve closes.

480V Unit

Operating Conditions

• Oven cavity below 200°F.

• Oven door closed.

• No service codes displayed in the time display window.

• There are no apparent oven operating problems.

Steam Mode (Prior to Serial Number C7439MS)

Refer to the Steam mode circuit diagrams on page 3-25 and/or the schematic

diagrams on page 3-34 for the following sequence of events.

1. Relays K15 and K13 energize. Boiler drain valve closes and boiler fill valve

opens. Boiler fill begins.

(Revised 1/02)

2. Relay K6 and mercury relay R1 energize. Fan motor turns on.

3. When water reaches low water probes, relays K2, K3, R2, and R3 energize.

4. When water reaches high water probe, relay K13 de-energizes and boiler fill

valve closes.

3-7

Page 40

CC20-E

Sequence Of Events

Prior to Serial Number C7439MS

5. When boiler water reaches “ready” temperature, relays K3 and R3 deenergize. Relays K2 and R2 energize. Water heating elements go to low fire.

Relay Operation Summary

1. K15 and K13 energized. (Drain and Fill)

2. K6 and R1 energized. (Fan)

3. K2, K3, R2, and R3 energized. (Water Heat)

4. K13 de-energized. (Fill)

5. K3 and R3 de-energized. K2 and R2 energized. (Water Heat)

Combo Mode (Prior to Serial Number C7439MS)

Refer to the Combo mode circuit diagrams on pages 3-28 and/or the schematic

diagrams on pages 3-34 for the following sequence of events.

1. Relays K15 and K13 energize. Boiler drain valve closes and boiler

fill valve opens. Boiler fill begins.

2. Relay K6 and mercury relay R1 energize. Fan motor turns on.

3. When water reaches low water probes, relays K2, K3, R2, and R3 energize.

4. When water reaches high water probe, relay K13 de-energizes

and boiler fill valve closes.

5. When boiler water reaches “ready” temperature, relays K3 and

R3 de-energize. Relays K2 and R2 remain energized.

6. Relay K14 energized. Condensate spray valve opens.

7. Relays K11, K12, R11, and R12 energize. Air heating elements turn on.

When oven temperature reaches the temperature set point, relays

8.

K11, K12, R11, and R12 de-energize. Air heating elements turn off.

9. Relays K11, K12, R11 and R12 will cycle ON and OFF to maintain oven

temperature.

Relay Operation Summary

1. K15 and K13 energized. (Drain and Fill)

2. K6 and R1 energized. (Fan)

K2, K3, R2, and R3 energized. (Water Heat)

3.

4. K13 de-energized. (Fill)

5. K3 and R3 de-energized. K2 and R2 energized. (Low Water Heat)

6. K14 energized. (Condensate Spray)

3-8

(Revised 1/02)

Page 41

CC20-E

Sequence Of Events

Prior to Serial Number C7439MS

7. K11, K12, R11, and R12 energized. (Air Heat)

8. K11, K12, R11, and R12 de-energized. (Air Heat)

9. Relays K11, K12, R11 and R12 energized and de-energized.

Oven Mode (Prior to Serial Number C7439MS)

Refer to the Oven mode circuit diagrams on page 3-28 and/or the schematic

diagrams on page 3-34 for the following sequence of events.

1. Mercury relay R1 and relay K6 energize. Fan motor turns on.

2. Relays K11, K12, R11, and R12 energize. Air heating elements turn on.

3. When oven temperature reaches the temperature set point, relays K11, K12,

R11, and R12 de-energize. Air heating elements turn off.

4. Relays K11, K12, R11 and R12 will cycle ON and OFF to maintain oven

temperature.

Relay Operation Summary

1. K6 and R1 energized. (Fan)

2. K11, K12, R11, and R12 energized. (Air Heat)

3. K11, K12, R11, and R12 de-energized. (Air Heat)

4. Relays K11, K12, R11 and R12 energized and de-energized.

Hold Mode (Manual) (Prior to Serial Number C7439MS)

Refer to the schematic diagrams on page 3-34 for the following sequence of

events.

NOTE: Low humidity on older panels only. When “Lo” humidity is selected there

is no water in steam generator.

1.

K15 and K13 energized. Boiler drain valve closes and boiler fill valve opens.

Boiler fill begins.

2. Relay K6 and mercury relay R1 energize. Fan motor turns on.

3. When water reaches low water probes, relays K2, K3, R2, and R3 energize.

4. When water reaches high water probe, relay K13 de-energizes and boiler fill

valve closes.

(Revised 1/02)

5. When boiler water reaches “ready” temperature, relays K2, K3, R2, and R3

de-energize and water heating elements turn off.

6. Relays K11, K12, R11, and R12 energize. Air heating elements turn on.

When oven air temperature is 10° below temperature set point, relays K12

7.

and R12 de-energize. Relays K11 and R11 remain energized. Air heating

elements controlled by K1

1 and R1

1 operate at reduced power.

3-9

Page 42

CC20-E

Sequence Of Events

Prior to Serial Number C7439MS

8. When oven temperature reaches the temperature set point, relays K11 and

R11 de-energize. Air heating elements turn off.

elay Operation Summary

R

1. K15 and K13 energized. (Drain and Fill)

2. K6 and R1 energized. (Fan)

3. K2, K3, R2, and R3 energized. (Water Heat)

4. K13 de-energized. (Fill)

5. K2, K3, R2, and R3 de-energized. K14 energized. (Water Heat)

6. K11, K12, R11, and R12 energized. (Air Heat)

7. K12 and R12 de-energized. K11 and R11 remain energized. (Low Air Heat)

8. K11 and R12 de-energized. (Air Heat)

Two Stage Cleaning Cycle (Prior to Serial Number C7439MS)

Refer to the schematic diagrams on page 3-34 for the following sequence of

events.

Phase 1

1. Press 9-9 on the touch pad. C1 is displayed in the TIME display window.

Spray degreaser around the cavity and press “START.” CL:50 is displayed in

the time display window.

2. Relays K15 and K13 energize. Drain valve closes and boiler fill valve opens.

Boiler fills.

3. Relay K6 and mercury relay R1 energize. Fan motor turns on.

4. Relays K2, K3, R2, and R3 energize. Water heating elements turn on.

5.

When water temperature is approximately 150

de-energize.

Relays K2, K3, R2, and R3 energize and water heating elements turn on.

6.

Relay K14 energizes and condensate spray valve opens.

7.

°F, relays K2, K3, R2, and R3

8. Relay K15 de-energizes. Drain valve opens and boiler drains.

Relays K2, K3, R2, and R3 de-energize and water heating elements turn of

9.

10. Relay K14 de-energizes and condensate spray valve closes.

in the TIME display window

3-10

. Beeper sounds.

C2 is displayed

f.

(Revised 1/02)

Page 43

CC20-E

Sequence Of Events

Prior to Serial Number C7439MS

Phase 2 (Oven Door Open) - add de-limer to the boiler.

11. Relays K15 and K13 energize. Drain valve closes and boiler fill valve opens.

Boiler fills.

12. Relays K2, K3, R2, and R3 energize. Water heating elements turn on.

13. When water temperature is approximately 150°F, relays K2, K3, R2, and R3

de-energize. The water heating elements turn off.

14. Relays K2, K3, R2, and R3 energize and water heating elements turn on.

15. Relay K14 energizes and condensate spray valve opens.

16. Relay K15 de-energizes. Drain valve opens and boiler drains.

17. Relays K2, K3, R2, and R3 de-energize and water heating elements turn off.

18. Relay K14 de-energizes and condensate spray valve closes.

19. Relays K15 and K13 energize. Drain valve closes and boiler fill valve opens.

Boiler fills.

20. Relays K2, K3, R2, and R3 energize. Water heating elements turn on.

21. Relay K14 energizes and condensate spray valve K14 opens.

22. Relay K15 de-energizes and boiler drain valve opens. Boiler drains.

23. Relays K2, K3, R2, and R3 de-energize and water heating elements turn off.

24. Relay K14 de-energizes and condensate spray valve closes.

(Revised 1/02)

3-11

Page 44

CC20-E

Sequence of Events

After Serial Number C7439MS

08V and 240V Units

2

Operating Conditions

• Oven cavity below 200°F.

• Oven door closed.

• No service codes displayed in the time display window.

• There are no apparent oven operating problems.

Steam Mode (After Serial Number C7439MS)

Refer to the Steam mode circuit diagrams on pages 3-23 and 3-24, and/or the

schematic diagrams on pages 3-32 and 3-33 for the following sequence of

events.

1. Mercury relay R1 energized.

2. Relays K15 and K13 energize. Boiler drain valve closes and boiler fill valve

opens. Boiler fill begins.

3. Relays K6, K7 and K8 energize. Fan motor turns on.

4. When water reaches low water probes, relays K2, K3, K4, R2, R3, and R4

energize.

5. When water reaches high water probe, relay K13 de-energizes and boiler fill

valve closes.

6. When boiler water reaches “ready” temperature, relays K3, K4, R3, and R4

de-energize. K2, K5, and R2 energize, and water heating elements go to low

fire.

Relay Operation Summary

1. R1 energized. (Mercury Relay)

2. K15 and K13 energized. (Drain and Fill)

K6, K7 and K8 energized. (Fan)

3.

4. K2 through K4, and R2 through R4 energized. (Water Heat)

5. K13 de-energized. (Fill)

6. K3 and K4, and R3 and R4 de-energized. K2, K5 and R2 energized. (Water

Heat)

Combo Mode (After Serial Number C7439MS)

Refer to the Combo mode circuit diagrams on pages 3-26 and 3-27, and/or the

schematic diagrams on pages 3-32 and 3-33 for the following sequence of

events.

1. Mercury relay R1 energized.

3-12

(Revised 1/02)

Page 45

CC20-E

Sequence Of Events

After Serial Number C7439MS

2. Relays K15 and K13 energize. Boiler drain valve closes and boiler fill valve

opens. Boiler fill begins.

. Relays K6, K7, and K8 energize. Fan motor turns on.

3

4. When water reaches low water probes, relays K2, K3, K4, R2, R3, and R4

energize.

5. When water reaches high water probe, relay K13 de-energizes and boiler fill

valve closes.

6. When boiler water reaches “ready” temperature, relays K3, K4, R3, and R4

de-energize. Relays K2 and R2 remain energized. K5 energized.

7. K14 energized. Condensate spray valve opens.

8. Relays K11, K12, R11, and R12 energize. Air heating elements turn on.

9. When oven temperature is 5° below temperature set point, relay K12 and

R12 de-energize. Relay K11 and R11 remain energized. Air heating

elements controlled by K11 and R11 operate at reduced power.

10. When oven temperature reaches the temperature set point, relays K11 and

R11 de-energize. Air heating elements turn off.

Relay Operation Summary

1. R1 energized. (Mercury Relay)

2. K15 and K13 energized. (Drain and Fill)

3. K6, K7, and K8 energized. (Fan)

4. K2 through K4, and R2 through R4 energized. (Water Heat)

5. K13 de-energized. (Fill)

6. K3, K4, R3, and R4 de-energized. K2, R2. (Water Heat)

7. K5 and K14 energized. (Low Water Heat)

8. K11, K12, R11, and R12 energized. (Air Heat)

9. K12 and R12 de-energized. K11 and R11 remain energized. (Air Heat)

10. K11 and R11 de-energize.

Oven Mode (After Serial Number C7439MS)

Refer to the Oven mode circuit diagrams on pages 3-22 and 3-23,

and/or the schematic diagrams on pages 3-26 and 3-27 for the

following sequence of events.

(Revised 1/02)

Mercury relay R1 energized.

1.

2. Relays K6, K7, and K8 energize. Fan motor turns on.

Relays K1

3.

1, K12, R1

1, and R12 energize.

Air heating elements turn on.

3-13

Page 46

CC20-E

Sequence Of Events

After Serial Number C7439MS

4. When oven temperature is 5° below temperature set point, relay K12 and

R12 de-energize. Relay K11 and R11 remain energized. Air heating

elements controlled by K11 and R11 operate at reduced power.

5. When oven temperature reaches the temperature set point, relays K11 and

R11 de-energize. Air heating elements turn off.

Relay Operation Summary

1. R1 energized. (Mercury Relay)

2. K6, K7, and K8 energized. (Fan)

3. K11, K12, R11, and R12 energized. (Air Heat)

4. K12 and R12 de-energized. K11 and R11 remain energized. (Air Heat)

5. K11 and R11 de-energized.

Hold Mode (Manual) (After Serial Number C7439MS)

Refer to the schematic diagrams on pages 3-32 and 3-33 for the following

sequence of events.

NOTE: Low humidity on older panels only. When “Lo” humidity is selected there

is no water in steam generator.

1. Mercury relay R1 energized.

2. Relays K6, K7, and K8 energize. Fan motor turns on. Fan will cycle on and

off as required.

3. Relays K11, K12, R11, and R12 energize. Air heating elements turn on.

4. When oven air temperature is 5° below temperature set point, relays K12

and R12 de-energize. Air heating elements operate at reduced power.

5. When oven temperature reaches the temperature set point, relays K1

R11 de-energize. Air heating elements turn off.

Relay Operation Summary

1. R1 energized. (Mercury Relay)

2. K6, K7 and K8 energized. (Fan)

3. K11, K12, R11, and R12 energized. (Air Heat)

1 and

4. K12 and R12 de-energized. (Low Air Heat)

5. K11 and R11 de-energized. (High Air Heat)

3-14

(Revised 1/02)

Page 47

CC20-E

Sequence Of Events

After Serial Number C7439MS

Two Stage Cleaning Cycle (After Serial Number C7439MS)

Refer to the schematic diagrams on pages 3-32 and 3-33 for the following

sequence of events.

Phase 1

1. Press 9-9 on the touch pad. C1 is displayed in the TIME display window.

Spray degreaser around the cavity. CL:50 is displayed in the time display

window.

2. Mercury relay R1 energized.

3. Relays K15 and K13 energize. Boiler fills.

4. Relays K6, K7, and K8 energize. Fan motor turns on.

5. Water reaches low water probe. Relays K2, K3, K4, R2, R3, and R4

energize. Water heating elements turn on.

6. Water reaches high level probe. Relay 13 de-energizes and boiler fill valve

closes.

7. Relays K2, K3, K4, R2, R3, and R4 de-energize.

8. At

9. Relay K14 energizes and condensate spray valve opens.

10. Relays K2, K3, K4, R2, R3, and R4 de-energize and water heating elements

11. Relay K15 de-energizes. Drain valve opens and boiler drains.

12. Relay K14 de-energizes and condensate spray valve closes.

Phase 2 (Oven Door Open) - add de-limer in the boiler.

13. Relays K15 and K13 energize. Boiler fills.

14. Water reaches low water probe. Relays K2 through K4, and R2 through R4

15. When water temperature is approximately 150°F, relays K2 through K4, and

16.

CL:40 relays K2, K3, K4, R2, R3, and R4 energize and water heating

elements turn on.

turn off.

C2 is displayed

in the TIME display window. Beeper sounds.

energize. Water heating elements turn on.

R2 through R4, de-energize. The water heating elements turn off.

When water reaches high water probe, relay K13 de-energizes and the

boiler fill valve closes.

(Revised 1/02)

Relays K2, K3, K4, R2, R3, and R4 de-energize. Water heating elements

17.

turn off.

18. Relays K2, K3, K4, R2, R3, and R4 energize and water heating elements

turn on.

3-15

Page 48

CC20-E

Sequence Of Events

After Serial Number C7439MS

19. Relay K14 energizes and condensate spray valve opens.

0. Relays K2, K3, K4, R2, R3, and R4 de-energize and water heating elements

2

turn off.

21. Relay K15 de-energizes. Drain valve opens and boiler drains.

22. Relay K14 de-energizes and condensate spray valve closes.

480V Unit

Operating Conditions

• Oven cavity below 200°F.

• Oven door closed.

• No service codes displayed in the time display window.

• There are no apparent oven operating problems.

Steam Mode (After Serial Number C7439MS)

Refer to the Steam mode circuit diagrams on page 3-25 and/or the schematic

diagrams on page 3-34 for the following sequence of events.

1. Relays K15 and K13 energize. Boiler drain valve closes and boiler fill valve

opens. Boiler fill begins.

2. Relay K6 and mercury relay R1 energize. Fan motor turns on.

3. When water reaches low water probes, relays K2, K3, R2, and R3 energize.

4. When water reaches high water probe, relay K13 de-energizes and boiler fill

valve closes.

5. When boiler water reaches “ready” temperature, relays K3 and R3 deenergize. Relays K2 and R2 remain energized. Water heating elements go to

low fire.

Relay Operation Summary

1. K15 and K13 energized. (Drain and Fill)

2. K6 and R1 energized. (Fan)

3. K2, K3, R2, and R3 energized. (Water Heat)

4. K13 de-energized. (Fill)

5. K3 and R3 de-energized. K2 and R2 remain energized. (Water Heat)

3-16

(Revised 1/02)

Page 49

CC20-E

Sequence Of Events

After Serial Number C7439MS

Combo Mode (After Serial Number C7439MS)

Refer to the Combo mode circuit diagrams on pages 3-28 and/or the schematic

iagrams on pages 3-34 for the following sequence of events.

d

1. Relays K15 and K13 energize. Boiler drain valve closes and boiler

fill valve opens. Boiler fill begins.

2. Relay K6 and mercury relay R1 energize. Fan motor turns on.

3. When water reaches low water probes, relays K2, K3, R2, and R3 energize.

4. When water reaches high water probe, relay K13 de-energizes

and boiler fill valve closes.

5. When boiler water reaches “ready” temperature, relays K3 and

R3 de-energize. Relays K2 and R2 remain energized.

6. Relay K14 energized. Condensate spray valve opens.

7. Relays K11, K12, R11, and R12 energize. Air heating elements turn on.

8. When oven temperature is 5° below temperature set point, relay K12 and