Page 1

OPERATOR MANUAL

IMPORTANT INFORMATION, KEEP FOR OPERATOR

This manual provides information for:

MODEL DH/INA/2-100

STEAM JACKETED

KETTLE

· Self-Contained

· Gas Heated

· Floor Mounted

· Tilting

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE.

READ, UNDERSTAND AND FOLLOW THE INSTRUCTIONS AND

WARNINGS CONTAINED IN THIS MANUAL.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

POST IN A PROMINENT LOCATION

Instructions to be followed in the event user smells gas.

This information shall be obtained by consulting your

local gas supplier. As a minimum, turn off the gas and

call your gas company and your authorized service agent.

Evacuate all personnel from the area.

WARNING

Improper installation, adjustment, alteration, service or

maintenance can cause property damage, injury or death.

Read the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment.

NOTIFY CARRIER OF DAMAGE AT ONCE

It is the responsibility of the consignee to inspect the container upon receipt of

same and to determine the possibility of any damage, including concealed dam-

age. Unied Brands suggests that if you are suspicious of damage to make a

notation on the delivery receipt. It will be the responsibility of the consignee to le

a claim with the carrier. We recommend that you do so at once.

Manufacture Service/Questions 888-994-7636.

Information contained in this document is known to be current and accurate at the time

of printing/creation. Unified Brands recommends referencing our product line websites,

unifiedbrands.net, for the most updated product information and specifications.

PART NUMBER 176302, REV. A (01/18)

1055 Mendell Davis Drive

Jackson, MS 39272

888-994-7636, fax 888-864-7636

unifiedbrands.net

Page 2

IMPORTANT - READ FIRST - IMPORTANT

WARNING: FAILURE TO DISCONNECT POWER BEFORE SERVICING COULD RESULT IN ELECTROCUTION AND

DEATH.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING THIS EQUIPMENT.

WARNING: DO NOT PLACE HANDS, TOOLS OR HOSES IN KETTLE WHILE AGITATOR IS MOVING. AGITATOR CAN

BE JOGGED WHILE KETTLE IS TILTED.

WARNING: THE UNIT MUST BE INSTALLED BY PERSONNEL QUALIFIED TO WORK WITH ELECTRICITY AND

PLUMBING. UNIT MUST BE INSTALLED IN ACCORDANCE WITH ALL APPLICABLE CODES.

WARNING: DO NOT ATTACH THE UNIT TO A TYPE “B” VENT. IT COULD CAUSE FIRE OR PROPERTY DAMAGE.

WARNING: DO NOT CONNECT ANY PIPING TO THE SAFETY VALVE. IT MUST BE FREE TO VENT STEAM AS

NEEDED. TO AVOID BURNS FROM THE VENTED STEAM THE VALVE DISCHARGE SHOULD POINT

DOWNWARD.

DANGER: ELECTRICALLY GROUND THE UNIT AT THE TERMINAL PROVIDED. FAILURE TO GROUND THE UNIT

COULD RESULT IN ELECTROCUTION AND DEATH.

CAUTION: BE SURE ALL OPERATORS READ, UNDERSTAND AND FOLLOW THE OPERATING INSTRUCTIONS,

CAUTIONS AND SAFETY INSTRUCTIONS CONTAINED IN THIS MANUAL.

CAUTION: DO NOT OVERFILL THE KETTLE WHEN COOKING, HOLDING OR CLEANING. KEEP LIQUIDS A

MINIMUM OF 2-3” (5-8 CM) BELOW THE KETTLE BODY RIM TO ALLOW CLEARANCE FOR STIRRING,

BOILING AND SAFE TRANSFER OF PRODUCT.

CAUTION: KEEP FLOORS IN FRONT OF KETTLE WORK AREA CLEAN AND DRY. IF SPILLS OCCUR, CLEAN

IMMEDIATELY TO AVOID SLIPS OR FALLS.

WARNING: KEEP WATER AND SOLUTIONS OUT OF CONTROLS AND BURNERS. NEVER SPRAY OR HOSE DOWN

THE CONTROL CONSOLE, ELECTRICAL CONNECTIONS, ETC.

CAUTION: MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES, MUCOUS MEMBRANES AND CLOTHING. TAKE

PRECAUTIONS: WEAR RUBBER GLOVES, GOGGLES OR FACE SHIELD AND PROTECTIVE CLOTHING.

CAREFULLY READ WARNINGS AND FOLLOW DIRECTIONS ON CLEANER LABELS .

NOTICE: NEVER LEAVE A SANITIZER IN CONTACT WITH STAINLESS STEEL SURFACES LONGER THAN 10

MINUTES. LONGER CONTACT CAN CAUSE CORROSION.

WARNING: FAILURE TO PERIODICALLY CHECK SAFETY VALVE OPERATION COULD RESULT IN PERSONAL

INJURY AND/OR DAMAGE TO EQUIPMENT.

WARNING: WHEN TESTING, AVOID EXPOSURE TO THE STEAM BLOWING OUT OF THE SAFETY VALVE. DIRECT

CONTACT COULD RESULT IN SEVERE BURNS.

WARNING: TO AVOID INJURY, READ AND FOLLOW ALL PRECAUTIONS STATED ON THE LABEL OF THE WATER

TREATMENT COMPOUND.

WARNING: BEFORE REPLACING ANY PARTS, DISCONNECT THE UNIT FROM THE ELECTRIC POWER SUPPLY

AND CLOSE THE MAIN GAS VALVE. ALLOW FIVE MINUTES FOR GAS TO VENT.

CAUTION: USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY GROEN OR AUTHORIZED

DISTRIBUTORS CAN CAUSE INJURY TO THE OPERATOR AND DAMAGE TO THE EQUIPMENT AND

WILL VOID ALL WARRANTIES.

2 OM-DH/INA/2-100

Page 3

IMPORTANT - READ FIRST - IMPORTANT

WARNING: KEEP AREA AROUND KETTLE FREE AND CLEAR OF ALL COMBUSTIBLE MATERIALS. FAILURE TO DO

SO COULD RESULT IN FIRE OR PROPERTY DAMAGE.

CAUTION: HEATING AN EMPTY KETTLE MAY CAUSE THE RELEASE OF STEAM FROM THE SAFETY VALVE.

IMPORTANT: SERVICE PERFORMED BY OTHER THAN FACTORY AUTHORIZED PERSONNEL WILL VOID ALL

WARRANTIES.

OM-DH/INA/2-100 3

Page 4

Table of Contents

Important Operator Warnings ....................................................page 2-3

References.................................................................................... page 4

Equipment Description.................................................................. page 5

Inspection and Unpacking ......................................................... page 6-7

Installation .................................................................................. page 8-9

Initial Start-Up............................................................................... page 10

Operation ................................................................................ page 11-16

Cleaning........................................................................................ page 17

Maintenance............................................................................ page 18-20

Sequence of Operation ............................................................... page 21

Troubleshooting...................................................................... page 22-23

Part Lists ............................................................................ page 24-36

Wiring Diagram ............................................................................ page 37

Service Log ................................................................................. page 39

References

KLENZADE SALES CENTER

ECOLAB. Inc.

370 Wabasha

St. Paul, Minnesota 55102

800/352-5326 or 612/293-2233

NATIONAL FIRE PROTECTION ASSOCIATION

60 Battery March Park

Quincy, Massachusetts 02269

NFPA/54 Installation of Gas Appliances &

Gas Piping

NFPA/70 The National Electrical Code

NSF INTERNATIONAL

789 N. Dixboro Rd.

P.O. Box 130140

Ann Arbor, Michigan 48113

UNDERWRITERS LABORATORIES, INC.

333 Pngsten Road

Northbrook, Illinois 60062

4 OM-DH/INA/2-100

ZEP MANUFACTURING CO.

1310-T Seaboard Industrial Blvd.

Atlanta, Georgia 30318

Page 5

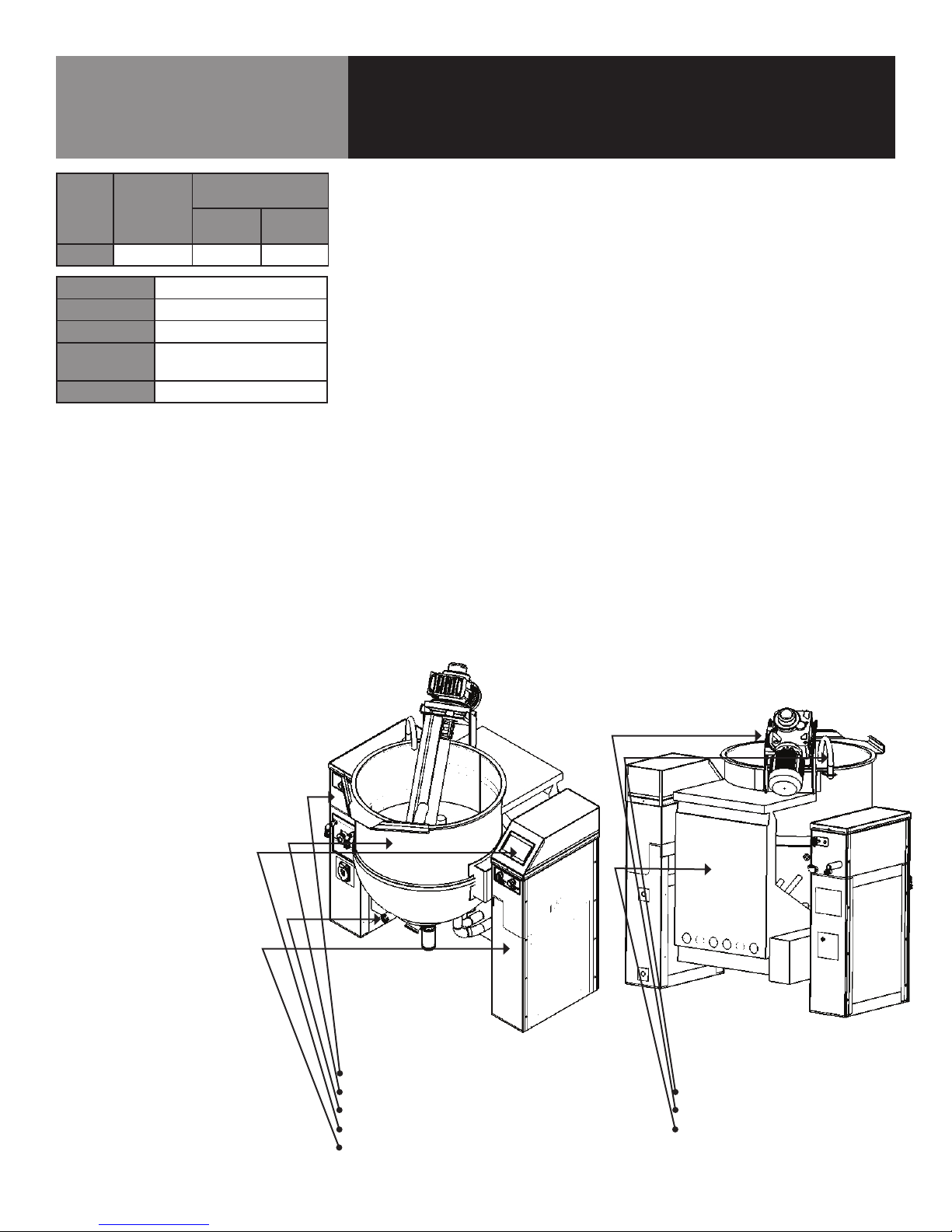

Equipment Description

Model Ignition

DH-400L

Capacity

Diameter

Overall Width

Overall

Front-to-Back

Rim Height

Electronic 360,000 360,000

FIRING RATE,

BTU/HOUR

Natural

Gas

100 gallons

34” (86 cm)

64¼” (163 cm)

54” (137 cm)

54¼” (138 cm)

Propane

Gas

Groen Model DH-400L is a stainless steel, steam jacketed, floor mounted, tilting kettle

with a self-contained, gas heated steam source. The kettle body is welded into one

piece and furnished with a reinforced bar rim and welded “butterfly” pouring lip. The

interior of the kettle is polished to a 180 emery grit finish and the exterior given a

uniform Number 3 finish.

The unit is ASME shop-inspected and is registered with the National Board for working

pressures up to 50 PSI. Kettle supports mount directly to the floor by use of lag bolts.

A power tilt feature is standard. Options available include: “Gallon Master” metering

system, product outlet strainer, and a power-assist cover, and a digital time-temperature

recorder.

The self-contained steam source is heated by either propane or natural gas. The

ignition system is spark or standing pilot. The kettle is charged at the factory with

chemically pure water containing corrosion inhibitors. The steam source provides kettle

temperatures of 150 to approximately 280ºF. Controls for the unit include a thermostat,

pressure gauge, water level glass, safety valve, pressure limit control, low water cutoff,

gas regulator valve, and a printed circuit board that monitors product temperature. The

gas supply shuts down automatically when the kettle is tilted. The agitator operates only

in partial rotation mode when the kettle is tilted.

The unit must be specified for use with natural or propane gas. Service connections

are required for gas, electric, air (if the air-operated valve is specified), water (if Gallon

Master metering is specified).

Left Stanchion

Kettle Body Assembly Fill Spout

Sight Glass Power-Aid Hinge

Touch Screen Control Flue Stack, Combustion Chamber

Right Stanchion and Burner Assemblies

OM-DH/INA/2-100 5

Page 6

Inspection & Unpacking

WARNING

THIS UNIT MUST BE INSTALLED BY

PERSONNEL WHO ARE QUALIFIED TO

WORK WITH ELECTRICITY AND PLUMBING.

IMPROPER INSTALLATION CAN CAUSE

INJURY TO PERSONNEL AND/OR DAMAGE

TO THE EQUIPMENT. THE UNIT MUST

BE INSTALLED IN ACCORDANCE WITH

APPLICABLE CODES.

WARNING

SHIPPING CHANNELS (BRACES) ARE VERY

HEAVY. USE PROPER LIFTING AND HANDLING

EQUIPMENT FOR MOVEMENT.

CAUTION

WATCH OUT FOR NAILS AND SPLINTERS

WHILE DISMANTLING THE SHIPPING CRATE.

CAUTION

UNIT HASAN APPROXIMATE SHIPPING

WEIGHT OF 1600 LBS. (727 KG.). FOR SAFE

HANDLING, INSTALLER SHOULD OBTAIN

PROFESSIONAL RIGGING HELP AS NEEDED

AND USE MATERIAL HANDLING EQUIPMENT

(SUCH AS A FORKLIFT, OVERHEAD HOIST, OR

PALLET JACKS) TO REMOVE THE UNIT FROM

THE SKID AND MOVE IT TO ITS PLACE OF

INSTALLATION.

The unit is delivered completely assembled, on a heavy skid surrounded by a wooden

crate. Immediately upon receipt, inspect the unit for damage. Report any shipping damage

or an incorrect shipment to the delivery agent.

Write down the model number, serial number, and installation date of your unit, and keep

this information for future reference. Space for these entries is provided at the top of the

Service Log provided at the rear of this manual. The unit is anchored to two metal shipping

channels (braces) which may be discarded after installation. Carefully unbolt one side of

shipping channel. Position the kettle and remove second shipping channel.

The unit is delivered crated and

bolted to a heavy skid.

Two heavy shipping channels

(braces) anchor the unit for

shipment.

Shipping Channels (Braces)

When installation is to begin, unbolt the unit from the skid, and lift the unit straight up and

off the skid.

WARNING

TO AVOID DAMAGE OR INJURY, FOLLOW THE

ELECTRICAL SCHEMATIC EXACTLY WHEN

CONNECTING THE UNIT.

6 OM-DH/INA/2-100

UTILITY REQUIREMENTS

1. Electrical Supply Connection-3 Phase Operation Only

a. The panel must be removed to gain access to the electrical supply connection.

Open the wiring and control panel by unscrewing the eight screws which hold it in

place. Grasp the panel by the base at the bottom edge. While lifting the panel, swing

its bottom toward you. Set the panel aside.

b. Supply Voltage: The unit must operate at the rated nameplate voltage, plus or minus

10 percent.

c. Wiring Information: Refer to the electrical schematic for wiring information. A copy

of the schematic is found inside the control panel and at the rear of this manual.

d. Terminal Block: The terminal block for incoming power is located at the back of the

control compartment. The ground terminal is located next to the terminal block. The

unit must have a separate ground wire for safe operation.

e. High Voltage safety

Page 7

Inspection & Unpacking

f. Branch Circuit Protection: Each conductor must have over-current protection. Refer

to the label on the back of the unit for the proper wire type and size. Connections to

the unit must be watertight.

We strongly recommend that the Kettle have its own branch circuit protection.

Current and power demands for the different voltage units are as follows:

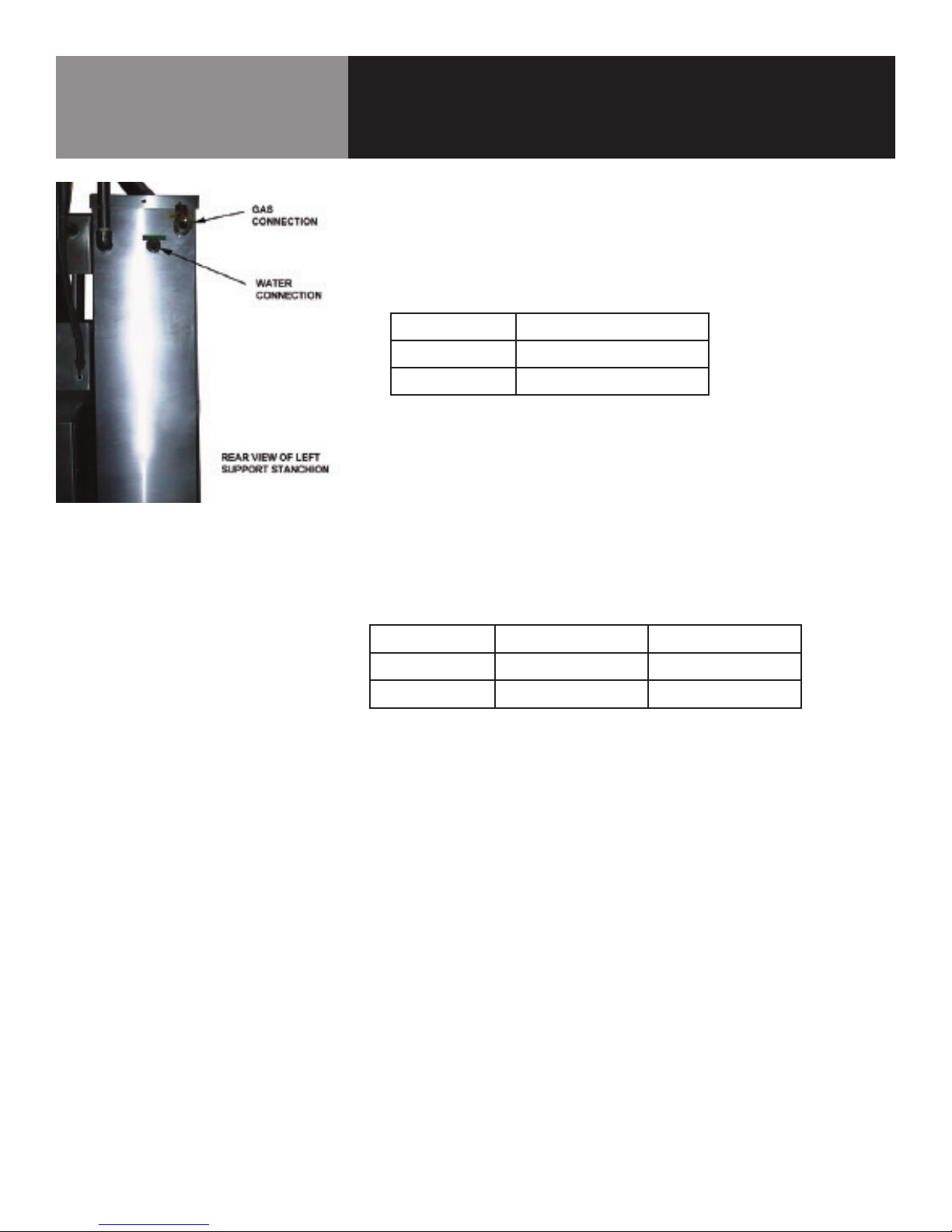

Gas and Water Connections are on the

back of the left stanchion.

Maximum Voltage Three Phase Current, Per Line

208 Volts

240 Volts

480 Volts

7 AMP

7 AMP

3.5 AMP

2. Water Connection(s)

Install a check valve in the incoming cold water line, if required by local plumbing

codes. Water pressure in the line should be between 30 and 60 PSIG (210 and 420

kPa). A ¾ NPT connector is needed to attach the water supply to the water inlet valve.

The minimum recommended water feed line diameter is ½ inch (13mm). Do not allow

the connection to leak, no matter how slowly. THE INSTALLER MUST PROVIDE THE

CHECK VALVE (ANTI-SYPHON DEVICE) IF REQUIRED BY LOCAL CODES.

3. Gas Connection

Connect 1 NPT gas line to the gas inlet valve on the rear of the left stanchion. Be sure

that the gas supply meets the following criteria:

Natural Gas Propane

Minimum

Maximum

7” W.C. 11” W.C.

10” W.C. 14” W.C.

OM-DH/INA/2-100 7

Page 8

Installation

WARNING

THIS UNIT IS FOR COMMERCIAL USE.

NEVER USE HOME OR RESIDENTIAL

GRADE GAS CONNECTIONS.

THEY DO NOT MEET GAS CODES AND

COULD BE HAZARDOUS.

WARNING

DO NOT ATTACH THE UNIT TO A TYPE “B”

VENT. FAILURE COULD RESULT IN FIRE OR

PROPERTY DAMAGE.

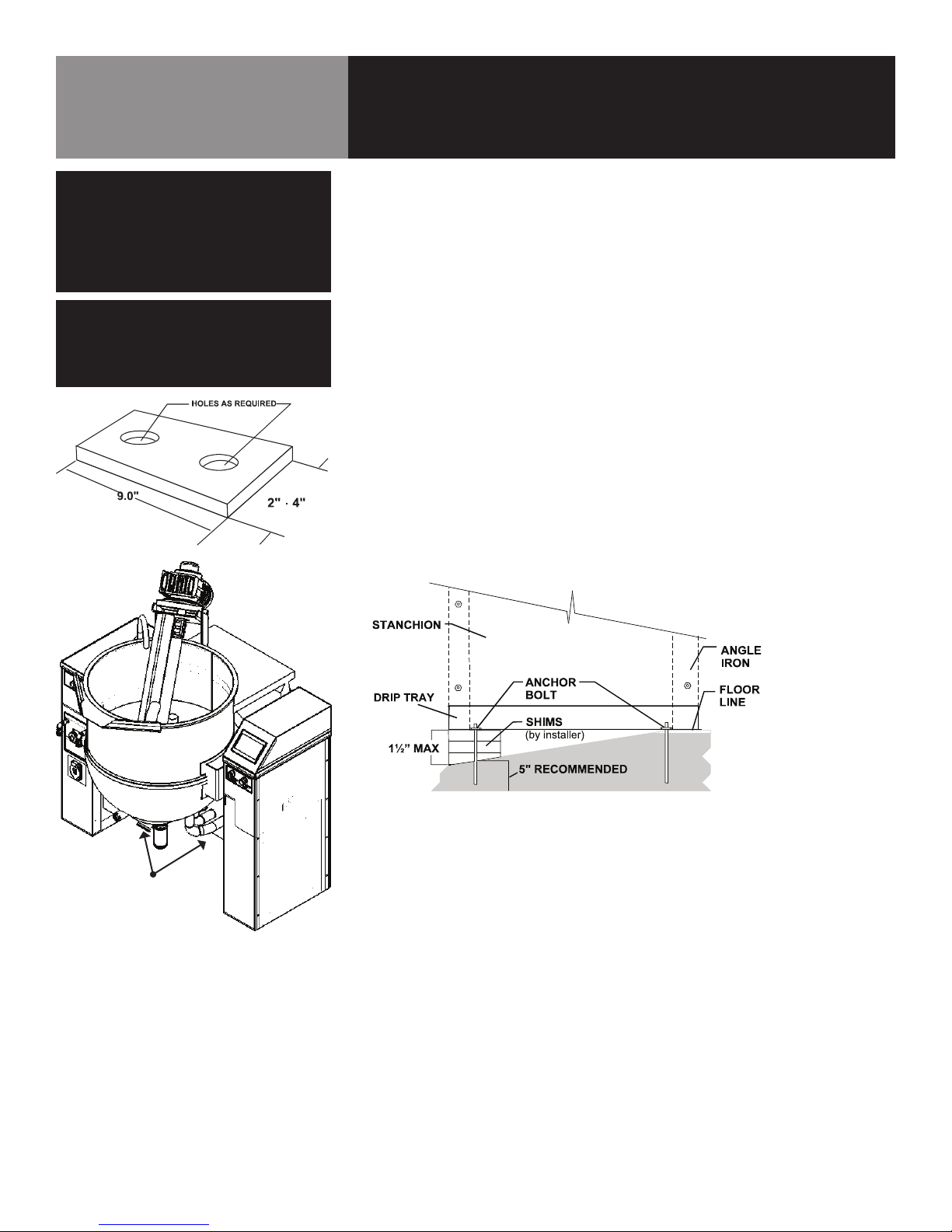

Recommended shim size.

The unit should be installed in a well-ventilated room on non-combustible flooring.

Anything which might obstruct or restrict the flow of air for combustion and ventilation

must be removed. The area directly around the appliance must be free of combustible

materials.

1. Installation requires connection with air, gas, water and electric services. See items

8 to 14 for details.

2. To protect the unit from damage, leave it on the shipping pallet until installation. When

ready to start installation, disassemble the shipping crate, unbolt the stanchions,

disconnect the shipping channels (braces) and raise the unit straight up off the skid.

Do not lift the kettle at the heat exchanger. Lifting the kettle at the heat exchanger

could damage the unit.

3. Install the unit with at least 22 inches clearance from the back walls. Also leave

enough room for easy cleaning, maintenance, and service.

4. Do not alter the kettle in any way. Any mechanical, electrical, or gas change must be

approved by the Groen Food Service Engineering Department.

5. Level the unit as follows:

The stanchions are each supplied with a drip tray in which the angle frame is placed.

Steel leveling shims (not included, supplied by installer) are placed between the drip

tray and frame so that the drip tray will be flush with the floor, as shown.

Don’t lift here

8 OM-DH/INA/2-100

Start with the right stanchion and level it as shown in the sketch. Once the right

stanchion is levelled and properly anchored front to rear, level the left stanchion front

to rear and side to side.

Level the entire unit side to side by placing a four foot carpenter’s level on the kettle

rim. Once the rim is level from side to side, rotate the level to check front to back.

Shim the left stanchion in the same manner as the right, and anchor the equipment

firmly to the floor through the shims.

6. Make sure the jacket water level is correct by confirming that it is in the middle of

the bulls-eye sight glass at the front of the kettle. If the water level is low, follow the

instructions under “Jacket Filling” in the “Maintenance” Section of this manual.

7. To protect personnel from steam coming from the safety valve, the open end of the

elbow at the outlet must be directed downward. If it is not, turn the elbow to the

correct position.

8. INSTALL:

Check valve in the incoming cold water line, if required by local plumbing codes, as

described in Paragraph 2, page 6.

Page 9

Installation

WARNING

DO NOT CONNECT ANY PIPING TO THE POP

SAFETY VALVE. IT MUST BE FREE TO VENT

STEAM AS NEEDED. THE ELBOW SHOULD

POINT DOWN TOWARD FLOOR. IMPROPER

INSTALLATION WILL VOID WARRANTY.

DANGER

ELECTRICALLY GROUND THE UNIT AT THE

TERMINAL PROVIDED. FAILURE TO

GROUND UNIT COULD CAUSE

ELECTROCUTION AND DEATH.

9. Provide electrical service per Paragraph 1, Electrical Supply Connecton in the

Inspection and Unpacking, Requirements Section, Page 6. Use ½ inch waterproof

conduit and waterproof connections. Observe local Codes and/or The National

Electrical Code in accordance with ANSI/NFPA 70 - latest edition. AN ELECTRICAL

GROUND IS REQUIRED. The electrical schematic is located on the inside of the

service panel. In Canada, provide electrical service in accordance with the Canadian

Electrical code, CSA C22.1 Part 1 and/or local codes.

10. The internal gas lines of the unit were cleaned and closed with a gas cock before

the unit was shipped from the factory. Ensure that external gas lines are free of lint,

dirt, metal chips, sealant, grease, oil or other contaminants, before you connect the

line to the kettle.

11. Connect the kettle gas cock to the gas service main using a 1” NPT gas connection.

12. Installation must conform with local codes, or in the absence of local codes, with

the National Fuel Gas Code, ANSI Z 223.1-1988 (or latest edition). The unit should be

installed in an well-ventilated room with a provision for adequate air supply. The best

ventilation will use a vent hood and exhaust fan with no direct connection between

the vent duct and the unit flue.

Do NOT obstruct the flue or vent duct after installation. In Canada, the installation

must conform with the CAN/CGA B149 Installation Codes for Gas Burning Appliances

and Equipment and/or local codes.

13. Adequate space for proper service and operation is required. Do NOT block any

air intake spacings to the combustion chamber or obstruct the air flow by piling or

stacking anything near the kettle.

14. After the kettle has been connected to the gas supply, all gas line joints must be

checked for leaks. DO NOT USE A FLAME TO CHECK FOR LEAKS. A thick soap solution

or other suitable leak detector should be used.

15. The appliance and its individual shutoff valve must be disconnected from the gas

supply piping system during any pressure testing of that system at test pressures

in excess of ½ PSIG (3.48 kPa). The appliance must be isolated from the gas supply

piping system by closing its individual manual shutoff valve during any testing of the

gas system at pressures equal to or less than ½ PSIG (3.48 kPa).

16. Check the following to confirm that your kettle has been installed properly:

• Enough room between the kettle and nearby objects for cleaning and service.

• Minimum clearance of 24 inches from sides and 24 from back.

• Unit vented to an exhaust hood.

• Kettle level.

• Correct amount of water in the jacket.

• Safety valve outlet pointed down.

• Connected with a waterproof electric power cable in accordance with Paragraph

1 Electrical Supply Connecton (above) and local electrical codes.

• Gas lines cleaned before connection.

• Gas connected with 1 NPT or larger.

• Gas line joints checked for leaks.

• No obstruction to air supply or venting.

• Gas lines (1 NPT) connected to supply.

• Water supply connection (¾”) completed.

OM-DH/INA/2-100 9

Page 10

Initial Start-Up

After the kettle has been installed, the installer should test to ensure that the unit is

operating correctly.

1. Remove all literature and packing materials from the inside and outside of the unit.

Clean out any material that might clog or damage the product outlet.

2. Add 50 gallons (180 liters) of water to the kettle to provide sufficient product for

testing.

3. Make sure the supplies of gas and electric power are on.

4. Following “Start Kettle Heating” instructions in the “Operating Instructions” section

of this manual, begin heating the water at the highest thermostat setting. The pilot

lamp should come on as soon as you pull out the emergency stop and turn on power.

Heating should continue until the water boils.

5. To turn off the unit, follow “To Stop Kettle Heating” in “Operating Instructions,” below.

If the kettle functions as described, it is ready for use. If the unit does not operate as

designed, contact an authorized Groen Service agent.

10 OM-DH/INA/2-100

Page 11

Operation

WARNING

ANY POTENTIAL USER OF THE EQUIPMENT

MUST BE TRAINED IN SAFE AND CORRECT

OPERATING PROCEDURES.

WARNING

KEEP AREA AROUND KETTLE FREE AND

CLEAR OF ALL COMBUSTIBLE MATERIALS.

CAUTION

HEATING AN EMPTY KETTLE MAY

CAUSE THE RELEASE OF STEAM FROM

THE SAFETY VALVE.

CONTROLS

Refer to the drawing on the following page for identification and function of kettle

controls.

OPERATING INSTRUCTIONS

Refer to the drawing on the following page for identification and function of kettle

controls.

1. CHECK THE WATER LEVEL IN THE JACKET EVERY DAY. The level must be in the middle

of the bulls-eye sight glass. If the level is low, see “Jacket Filling” in the “Preventive

Maintenance” section of this manual.

2. With the kettle cold, check the pressure gauge. If it does not show 20 or more inches

of vacuum (a reading of 20 to 30 below 0), see “Jacket Vacuum” in the “Preventive

Maintenance” section of this manual.

3. Start Kettle Heating

a. Open main gas supply valve.

b. Pull OUT the emergency stop and turn ON the control power switch on the front

of the right stanchion.

c. The touch-screen control panel should be ON (if not, check that mains power is

connected to the unit and the mains circuit breaker is on).

OM-DH/INA/2-100 11

Page 12

Operation

WARNING

DO NOT ATTEMPT TO LIGHT PILOT

MANUALLY WITH A FLAME.

4. Cooking Control

a. Touch the COOK CONTROL on the screen. The display will change to show the

main cooking control screen. This screen allows user to control kettle tilt, cooking

operation, water fill, turbo heat; and displays current product temperature in

degrees Celsius, desired cooking temperature in degrees Celsius; and lamp

status of the pilot, main gas vale, low fire burner and high fire burner.

b. Ensure kettle is tilted fully upright. If not, press TILT CONTROL on the screen.

The pop-up tilt control will appear. Press continuously on either TILT UP or TILT

DOWN until the kettle comes to a fully upright position. The tilt controls will turn

bright green when pressed and will go dark when released [Note: Press TILT

CONTROL to minimize the tilt feature on the screen.]

12 OM-DH/INA/2-100

c. The PILOT and MAIN indicators on the screen should show green.

d. Press FAUCET FILL on the screen. The pop-up faucet fill controls will appear.

Page 13

Operation

CAUTION

KEEP FLOORS IN FRONT OF KETTLE WORK

AREA CLEAN AND DRY. IF SPILLS OCCUR,

CLEAN IMMEDIATELY TO AVOID THE

DANGER OF SLIPS OR FALLS.

The kettle can be filled automatically or manually by tapping on the FILL control.

i. In the AUTO mode, tap on the WATER FILL SETPOINT – a display will appear

allowing you to select a desired quantity of Liters and enter them.

Tapping once on the START FILL control will initiate water fill through the

faucet. The control will turn bright green during the fill operation and go dark

once the fill setpoint is reached. Automatic fill can be interrupted by either

setting the FILL switch to MANUAL or pushing in an EMERGENCY STOP.

ii. In the MANUAL mode, press on the START FILL control and hold until the

desired quantity of water is delivered through the faucet. The TOTAL LITERS

counter can be used to observe manual fill operation – press the RESET

COUNTER to clear the indication before starting manual fill operation.

iii. Kettle must not be allowed to heat without at least 25% of its capacity of

product/water present. The rate-of-Rise feature will shut the kettle down if

there is insufficient product present during heating.

NOTE: Press FAUCET FILL to minimize the water fill feature on the screen.

OM-DH/INA/2-100 13

Page 14

Operation

e. Press COOK CONTROL on the screen. The pop-up cook controls will appear.

i. Tap on the COOK SETPOINT to bring up a key pad to select the desired

cooking temperature. Enter the numerical value in degrees Celsius and press

ENTER. The display should change to the selected value.

ii. Tap the COOK switch to turn ON or OFF the cook function. During the cook

function the burners will cycle to provide the necessary amount of heating

– during heat up to cook temperature, both the LOW FIRE and HIGH FIRE

burner indicators will indicate green – once the temperature approaches the

setpoint, the HIGH FIRE burner will shut off and the indicator will go dark.

NOTE: The BATCH CONTROL function is used in conjunction with an

externally located multi-channel electronic chart controller. Both the kettle

and the chart recorder have to be connected to an Ethernet router to allow

communications between devices. Setup and operation of the batch control

function are described in a separate manual.

14 OM-DH/INA/2-100

iii. The TEMPERATURE RATE OF RISE EXCEEDED!!! caution will appear on

screen and shut the unit down on both low and high fire. Add more water or

product to the kettle, press the ROR RESET to clear the lockout, and restart

the kettle cooking feature by switching the COOK switch to ON.

Page 15

Operation

WARNING

DO NOT STAND IN FRONT OF KETTLE

DURING TILTING. PRODUCT IS HOT AND

WILL CAUSE BURNS. EXERCISE EXTREME

CARE WHED HANDLING OR NEAR

HOT OR BOILING LIQUIDS.

f. Once the cooking setpoint is reached, the TURBO HEAT function can be used to

provide a short burst (factory preset at 30 seconds) of both high and low fire if

needed to fine tune the cooking function.

g. If mains power is interrupted during a cooking cycle, the kettle and display will

power up automatically, but the cook cycle will have to be re-started on the

COOK CONTROL pop-up display. All of the setting will have been preserved in

non-volatile memory, and will not have to be re-entered.

h. To turn off the cook process, tap the COOK switch on the COOK CONTROL

display to the OFF position. Both the LOW FIRE and HIGH FIRE indicators should

go dark.

i. To empty the kettle, first raise the cover, and then press the TILT DOWN button

on the TILT CONTROL display to slowly empty the kettle contents into suitable

capacity container(s).

5. Kettle Shut-Down

a. Clean the kettle thoroughly at the end of a cook cycle, making sure that all

surfaces are free of dirt and cooking material. Sanitize all cooking surfaces, let

dry and rinse clear.

b. Turn OFF the control power switch on the front of the right stanchion.

c. If the kettle will remain off for more than one day, turn off the mains power circuit

breaker switch.

20” to 30” of Vacuum (below 0 mark)

Top of the Window

(kettle tilted fully upright)

PRESSURE GAUGE/INDICATORS/WATER LEVEL

Check Vacuum and Water Level Daily

OM-DH/INA/2-100 15

Page 16

Emergency Stop Switch (Left)

HMI Controller

Operation

LEFT & RIGHT STANCHION CONTROLS

Control Power On/Off Switch

Emergency Stop Switch (Right)

16 OM-DH/INA/2-100

Page 17

Cleaning

OM-TD

another container, being sure to avoid

contact with hot product and hot basket

or. . .

f) Place basket with food on stable, at

surface, setting it inside a solid steamer

or bake pan, to catch any remaining hot

water which might drain from product.

c. Prepare a hot solution of the detergent/

cleaning compound as instructed by the

supplier.

OM-TD

OM-TD

another container, being sure to avoid

contact with hot product and hot basket

or. . .

f) Place basket with food on stable, at

surface, setting it inside a solid steamer

or bake pan, to catch any remaining hot

water which might drain from product.

c. Prepare a hot solution of the detergent/

cleaning compound as instructed by the

supplier.

OM-TD

WARNING

KEEP WATER AND SOLUTIONS OUT OF

CONTROLS AND ELECTRICAL EQUIPMENT.

DO NOT USE A HIGH PRESSURE HOSE TO

CLEAN THE CONTROL CONSOLE,

ELECTRICAL CONNECTIONS, ETC.

CAUTION

NEVER LEAVE A CHLORINE SANITIZER IN

CONTACT WITH STAINLESS STEEL

SURFACES FOR LONGER THAN 30

MINUTES. LONGER CONTACT CAN

MOST CLEANERS ARE HARMFUL TO THE

SKIN, EYES, MUCOUS MEMBRANES AND

CLOTHING. PRECAUTIONS SHOULD BE

CAUSE CORROSION.

CAUTION

TAKEN TO WEAR RUBBER GLOVES,

GOGGLES OR FACE SHIELD AND

PROTECTIVE CLOTHING. CAREFULLY

READ THE WARNINGS AND FOLLOW

LABEL DIRECTIONS.

Use a brush, sponge, cloth, plastic or

rubber scraper, or plastic wool to clean.

Don’t use metal implements

or steel wool when cleaning.

1. Suggested Cleaning Supplies:

a. A high quality detergent and sanitizer, or a combination cleaning-

sanitizing agent.

b. Kettle brushes in good condition.

c. Groen Spray Degreaser (PN 114801) or equivalent.

d. Groen De-limer/De-scaler (PN 114800) or equivalent.

e. A high quality stainless steel cleaner.

2. Precautions

Before any cleaning operation, turn off the burner system by setting the COOK

switch on the COOK CONTROL screen to the OFF position. Cut off electric power to

the unit by setting the CONTROL POWER switch to the OFF position.

3. Procedure

a. Clean food contact surfaces as soon as possible after use, preferably while the

kettle is still warm. If the unit is in continuous use, clean and sanitize inside and

outside at least once every 12 hours.

b. Scrape and flush out large amounts of food residues. Be careful not to scratch

the kettle with metal implements.

c. Prepare a solution of the detergent/cleaning compound as instructed by the sup-

plier. Clean the unit thoroughly. A cloth moistened with cleaning solution can be

used to clean controls, housing, electrical conduit, etc.

d. Rinse the kettle thoroughly with hot water. Then drain completely.

e. As part of the daily cleaning program, clean all inside and outside surfaces that

may have been soiled. Remember to check such parts as the underside of the

cover, control housing, etc.

f. To remove burned-on foods, use a brush, sponge, cloth, plastic or rubber scrap-

er, or plastic wool along with the cleaning solution. To reduce effort required in

washing, let the detergent solution sit in the kettle for a few minutes and soak

into the residue. Do NOT use abrasive materials or metal tools that might scratch

the surface. Scratches make the surface harder to clean and provide places for

bacteria to grow. Do not use steel wool, which will leave particles in the surface

and cause eventual corrosion and pitting.

g. The outside of the unit may be polished with a recognized stainless steel cleaner.

h. When the equipment needs to be sanitized, use a sanitizing solution equivalent

to one that supplies 100 parts per million chlorine. Obtain advice on the best

sanitizing agent from your supplier of sanitizing products. Following the suppliers instructions, apply the sanitizing agent after the unit has been cleaned and

drained. Rinse off the sanitizer thoroughly.

i. It is recommended that each piece of equipment be sanitized just before use.

j. If there is difficulty removing mineral deposits or a film left by hard water or food

residues, clean the kettle thoroughly and then use a deliming agent, like Groen

Delimer/Descaler (Part Number 114800), in accordance with the manufacturer’s

directions. Rinse and drain the unit before further use.

k. If cleaning problems persist, contact your cleaning product supplier for assis-

tance. The supplier has a trained technical staff with laboratory facilities to serve

you.

OM-DH/INA/2-100 17

Page 18

Maintenance

WARNING

AVOID ANY EXPOSURE TOTHE STEAM

BLOWING OUT OF THE SAFETY VALVE. SEVERE

BURNS CAN RESULT ON EXPOSED SKIN.

FAILURE TO CHECK SAFETY VALVE OPERATION

PERIODICALLY COULD RESULT IN PERSONAL

INJURY AND/OR DAMAGE TO EQUIPMENT.

WHEN TESTING, AVOID ANY EXPOSURE

TO THE STEAM BLOWING OUT OF THE

SAFETY VALVE. DIRECT CONTACT COULD

RESULT IN SEVERE BURNS.

This section describes actions the operator must take to maintain warranty coverage

and to keep the unit working safely and efficiently.

1. Jacket Vacuum/Removing Air from Jacket

Every day, while the kettle is cold, read the pressure/vacuum gauge. A positive

pressure reading or a vacuum reading between zero and 20 on the pressure/ vacuum

gauge indicates excess air in the jacket. Air in the jacket slows kettle heating and

can prevent the kettle from reaching operating temperature. To remove air:

a. Start the kettle. (See the “Operation” section of this manual).

b. Make sure the elbow on the outlet of the safety valve is turned so it will direct

escaping steam down toward the floor.

c. When the pressure/vacuum gauge reaches a positive pressure reading of five

PSI, release entrapped air and steam by lifting the safety valve lever for about

one second. Repeat this step, then let the valve lever snap back into the closed

position, so the valve will seat properly and not leak.

2. Test Safety Valve

At least twice a month, test the safety valve. Test the valve with the kettle operating

at 15 psi (105 kPa), by holding the test lever for at least five seconds. Then release

the lever and permit the valve to snap shut. If the lever does not activate, there is no

discharge, or the valve leaks, stop using kettle immediately and contact a qualified

factory service representative.

3. Jacket Filling

Every day, before you turn on the unit, make sure the water level is between the

marks on the water gauge glass. The jacket was filled at the factory with the proper

amount of treated water. From time to time, you may need to restore the water to

its proper level, either because water was lost as steam during venting or because

treated water was lost by draining. The procedure follows.

a. If you are replacing water lost as steam, use distilled water. Do not use tap water.

If you are replacing treated water that was drained from the jacket, prepare more

treated water first, as directed below.

b. Allow the kettle to cool completely. Remove the pipe plug from the jacket fill

assembly. Then open the gate valve and pour in the distilled or treated water.

Using a funnel will help you in this process. Hold the safety valve open while you

pour, to let air escape from the jacket. Continue adding water until the water level

rises to a point between the marks on the gauge glass.

c. Close the gate valve.

d. Air that gets into the jacket during the filling operation must be removed because

it will make heating less efficient. Follow the procedure in “Jacket Vacuum,”

above to restore a negative pressure reading.

18 OM-DH/INA/2-100

Page 19

Maintenance

WARNING

TO AVOID INJURY, READ AND FOLLOW ALL

PRECAUTIONS STATED ON THE LABEL OF

THE WATER TREATMENT COMPOUND.

4. Water Treatment

a. Fill a mixing container with the amount of water required (distilled water

preferred). The kettle requires 5½ gallons (20.4 liters).

b. Follow instructions. Apply to Groen water treatment kit part number 110324.

c. Hang a strip of pH test paper on the rim of the container, with about 1 inch of the

strip below the surface of the water.

d. Stir the water continuously, while you slowly add water treatment compound

until a color between indicating a pH of 10.5 and 11.5 is reached. (Shown on the

pH test kit chart.) Judge the pH by frequently comparing the test strip with the

color chart provided in the pH test kit.

e. Use a measuring cup to add the compound so that you may record the exact

amount used. The amount may be used again, if the same water sources and

compound are used in the future. However, it is best to check the pH each time

treated water is prepared.

5. Venting System

Periodically check the hood to make sure that nothing will block or hinder the free

flow of exhaust gases.

OM-DH/INA/2-100 19

Page 20

Maintenance

WARNING

AVOID ANY EXPOSURE TO THE STEAM

BLOWING OUT OF THE SAFETY VALVE. SEVERE

BURNS CAN RESULT ON EXPOSED SKIN.

A Service Log is provided at the rear of this manual. Each time service is performed on

this Groen equipment, enter the date on which the work was done, and who did it. Keep

this manual with the equipment.

1. Periodic Service

Periodic inspection will minimize equipment down time and increase efficiency of

operation. The following points should be checked regularly.

a. Every day, when the kettle is cold, the pressure/vacuum gauge should show a

vacuum of 20 to 30 inches. If it does not, see ”Jacket Vacuum” in the “Preventive

Maintenance” section of this manual.

b. Every day, the jacket water level must be in the middle of the bulls-eye sight

glass. If it is not, see “Jacket Filling” in the “Preventive Maintenance” section of

this manual.

c. Keep the primary air shutter of the burner gas jets free of dust and lint.

d. The pilot flame should be blue and should envelop about ½ inch of the flame

sensor tip.

e. Keep electrical wiring and connections in good condition.

f. Keep the inside of the control console clean and dry.

g. Keep the burner ports clean.

h. Keep the burner shield and adjacent parts clean.

i. Twice a month, check the safety valve to make sure that it works freely. When

gauge pressure is about 5 PSI, lift the valve lever enough to vent steam, then

quickly let it snap back into place.

2. Component Replacement

When replacement involves breaking a gas pipe connection, check the new

connection with soap solution or other appropriate leak detector.

DO NOT USE A FLAME TO TEST FOR LEAKS. Internal wiring is marked as shown on

circuit schematic drawings. Be sure that new components are wired in the same

manner.

20 OM-DH/INA/2-100

Page 21

Sequence of Operation

The following “action-reaction” outline is provided to help service personnel understand

how the unit functions for systematic troubleshooting and fault isolation.

When the operator turns the heat to “ON”, electric power at 120V is supplied to the

thermostat. The automatic gas control is then energized. Simultaneously, an electric

arc is established at the spark gap, and the automatic valve for the pilot burner opens.

When the electric spark ignites gas flowing from the pilot burner, a pilot flame probe

detects the flame. The probe sends a control signal that causes the spark to shut off and

a circuit to close for 24 V power.

The 24 V provides power for the heating indicator light and the main automatic valve.

Gas flowing from the main burner is ignited by the pilot flame. If a pilot flame is not

sensed within 60 seconds after the spark, a timer shuts down the whole operation.

As heat from the main burner brings the temperature of steam in the jacket up to

the thermostat setting, the thermostat switch opens. With electric power cut off, the

main burner valve closes and turns off the burner. When jacket steam cools below the

thermostat set point, the thermostat switch closes and begins another heating cycle.

On-off cycling continues to maintain the kettle at the desired temperature.

The thermostat controls heating by alternately calling for flames at the full capacity of

the main burner or signaling the control to shut the burner completely off. Because the

control works in this “all or nothing” way, the kettle will heat as fast as it can until it

reaches the set temperature, no matter what that temperature is.Turning the thermostat

dial to a higher setting will cause heating to continue longer, until the kettle reaches the

higher temperature, but it cannot make the unit heat any faster.

The unit is equipped with a Pressure Limit Switch, Low Water Cut-Off and a Safety

Valve. These safety features operate as follows:

1. Pressure limit switch: If jacket steam pressure exceeds 43 PSI, the switch opens and

breaks the electrical circuit to the main gas valve solenoid coil. The valve closes and

stays closed until jacket pressure decreases to 44 PSI. The pressure limit switch

then closes, energizes the gas valve coil, and allows operation to resume.

2. Low-water cutoff: As long as steam jacket water touches the cutoff electrode, kettle

operation can continue. If the water falls below the end of the electrode, an electrical

control circuit is broken, and the main gas valve closes. Jacket water must be

restored to a safe operating level before the kettle can be heated again.

3. Safety valve: If steam pressure in the jacket reaches 50 PSI, the valve will open and

relieve the excess pressure.

OM-DH/INA/2-100 21

Page 22

Troubleshooting

Your Groen kettle is designed to operate smoothly and efficiently if properly maintained. However, the following is a list of checks to

make in the event of a problem. Wiring diagrams are furnished inside the service panel. X indicates items which must be performed

by an authorized technician.

WARNING

BEFORE REPLACING ANY PARTS, DISCONNECT THE UNIT FROM THE ELECTRIC POWER SUPPLY AND

CLOSE THE MAIN GAS VALVE. ALLOW FIVE MINUTES FOR UNBURNED GAS TO VENT.

CAUTION

USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY GROEN OR THEIR AUTHORIZED DISTRIBUTOR CAN

CAUSE INJURY TO THE OPERATOR AND DAMAGE TO THE EQUIPMENT AND WILL VOID ALL WARRANTIES.

SYMPTOM WHO WHAT TO CHECK

Kettle continues heating

after it reaches desired

temperature.

Kettle stops heating before

it reaches the desired

temperature.

Pilot burner and/or burner

will not light or goes out

after working for a while.

Kettle heats slowly. User a.

User a.

User a. That the temperature controller setting is correct.

b. That the Heat on/o switch is ON.

c. Reading of the pressure/vacuum gauge. If it is not 20 to 30

User a. That the main gas valve is open (handle is in line with the gas

b. That the Heat on/o switch is ON.

c. That the temperature controller is at the correct setting.

d. Use the “Start Kettle Procedure.” See the manual’s “Operation”

e. Jacket water level. If it is low, see “Jacket Filling” in the

f. That electric power is turned on at the circuit breaker or fuse

g. Gas supply to your building.

h. Is steam trap working?

That the temperature controller is correct.

below zero when the kettle is cold, see “Jacket Vacuum” in the

“Preventive Maintenance” section of this manual.

pipe)

Section.

“Preventive Maintenance” section of this manual.

box, and that power is being supplied to your building.

Reading of the pressure/vacuum gauge. If not 20 to 30 below

zero when the kettle is cold, see “Jacket Vacuum” in the

“Preventive Maintenance” section of this manual.

Authorized

Service Rep Only

Safety valve pops. User a.

22 OM-DH/INA/2-100

b. Check operation of pressure limit switch. X

Reading of the pressure/vacuum gauge. If it is not 20 to 30

below zero when the kettle is cold, see “Jacket Vacuum” in the

“Preventive Maintenance” section of this manual.

Page 23

Troubleshooting

System does not produce a

spark.

Spark is present but the

pilot will not light.

Pilot lights, but main burner

will not come on, and

spark does not stay on.

Authorized

Service Rep Only

Authorized

Service Rep Only

Authorized

Service Rep Only

a. Thermostat, and close the contacts if they are open. X

b. AC voltage between terminals “2” and “GR”. If it is not 24 Volt:

(1) Check high limit switch, which should be closed. X

(2) Replace the transformer. X

c. Pilot spark gap. Regap, if it is not 7/64 inch. X

d. Pilot electric ceramic for crack or break. X

e. That the high tension cable is rmly attached and in good

condition. If cracked or brittle, replace the pilot. X

f. Replace the electronic portion of the G60 electronic system. X

That the pilot valve is securely connected to terminals “1” and

a.

“GR”. Some models have the pilot valve grounded internally. X

b. That gas pressure meets the control manufacturer’s

specications. X

c. For gas at the pilot. If it is not owing:

(1) Check the pilot gas line for kinks and obstructions. X

(2) Replace the pilot valve. X

d. That the pilot spark gap is 7/64 inch and located in the pilot gas

stream. If not, adjust or replace the pilot. X

e. Pilot orice, and clean, if necessary. X

f. For drafts. Shield the pilot burner, if necessary. X

a. For 24 V between terminals “3” and “GR”. If voltage is not

correct, replace the G60 electronics. X

b. That the gas pressure meets the control manufacturer’s

specications. X

c. Electrical connections to the main valve to terminals “3” and

“GR”, to assure that they are securely attached. If they are,

replace the main valve.”

Pilot lights, but main burner

will not come on, the spark

stays on.

Authorized

Service Rep Only

Sensor cable, to make sure of secure and attachments to the

a.

sensor and to terminal “4” the G60. X

b. That the cable is not grounded. If it is, correct the ground fault. X

c. Cable for continuity and insulation condition. X

d. Sensor ceramic for cracks. X

e. That sensor probe current is less than 0.7 microamp, by

disconnecting the sensor cable from terminal “4” and

connecting a DC microammeter between the sensor cable

terminal and terminal “4”. If the current is equal to or greater

than 0.7 microamp, replace the G60 electronics. X

If the current is less than 0.7 microamp:

(1) Check the gas pressure. X

(2) Clean the pilot assembly. X

(3) Tighten mechanical and electrical connections. X

f. Pilot application and correct to increase sensor probe current,

by:

(1) Increasing or decreasing pilot orice size. X

(2) Shielding the pilot from drafts. X

OM-DH/INA/2-100 23

Page 24

172194

KETTLE BODY ASSEMBLY

Location Function or Connection

A LEFT TRUNNION

B RIGHT TRUNNION

C POUR LIP

D WELL AND COUPLING FOR RTD

E WATER LEVEL SIGHT GLASS

F HEAT EXCHANGE FIN-TUBES

G COUPLING FOR WATER LEVEL PROBE

H COUPLING FOR TEMPERATURE PROBE

I ASME DATA PLATE

Ref Description Part #

- LABEL, DISTILLED WATER Z026450

Parts List

- PROBE, TEMPERATURE, 6” LONG 115369

- VALVE, SAFETY, 50 PSI, ¾ NPT Z005587

- ASSEMBLY, WATER FILL 115372

- ELBOW, 90 DEGREE, ¾ NPT Z010668

- ASSEMBLY, PLATE & CHAIN Z8832

ASSEMBLY, FAUCET BRACKET&

SPOUT

FLUE STACK/COMBUSTION

CHAMBER ASSEMBLY

115247

149665

24 OM-DH/INA/2-100

Page 25

172278

LEFT STANCHION ASSEMBLY

Ref Description Part #

1

NIPPLE, 1 NPT, 7" LONG

2

NIPPLE, 1 NPT, 21" LONG

3

ELBOW, 90 DEGREE, 1" NPT

ELBOW, 90 DEGREE, 3/4 NPT, SS

4

5

NIPPLE, 3/4 NPT, 6-1/2" LONG, SS

HOSE, WATER FILLER

6

7

ADAPTER, SWIVEL, 3/4 NPT, SS

8

ADAPTER, 3/4 NPT, SS

ASSEMBLY, WATER PIPING

9

10

NIPPLE, 1 NPT, 15-1/2" LONG

JOINT, SWIVEL, 1 NPT, (GAS)

11

12

COUPLING, FULL, 1 NPT

13

BLOCK, PILLOW

BEARING, BRONZE

14

16

NUT, HEX, KEPS, 1/4-20

17

SCREW, HEX HEAD, 1/2-13, 2" LONG

18

NUT, HEX, 1/2-13

SCREW, SET, CUP POINT, 3/8-16, 5/8" LONG

19

20

SET COLLAR, 3" TRUNNION

21

FITTING, GREASE, STRAIGHT, 1/4 NPT

22

NIPPLE, 3/4 NPT, 12" LONG

23

COUPLING, FULL, 1 NPT

SCREW, TRUSS HEAD, 10-32, 1/2" LONG

24

25

COVER, STANCHION, LEFT SIDE

ASSEMBLY, INNER CLADDING, STANCHION,

26

LEFT SIDE

27

LABEL, NATURAL GAS

27

LABEL, PROPANE GAS

ASSEMBLY, OUTER CLADDING,

28

STANCHION, LEFT SIDE

GASKET, 1/16 X 1, NEOPRENE, CLOSED

29

CELL, 7' LONG

30

ASSEMBLY, FRAME, LEFT STANCHION

LABEL, WATER IN

31

32

ASSEMBLY, FRAME, POWER COVER

GASKET, NEOPRENE, 9-1/2 X 9-1/2,

33

FRAME TOP

35

NIPPLE, CLOSE, 1 NPT

ASSEMBLY, FRAME, LEFT SIDE

36

-

BOLT, HEX, 3/8-16, 1-1/4" LONG

-

NUT, HEX, 3/8-16

-

WASHER, FLAT, 3/8

40

SWITCH, EMERGENCY STOP

WASHER, LEVELING

-

42

BRACKET, KETTLE SHROUD

- NUT, ACORN, 1/4-20 Z090567

44 OVERLAY, EMERGENCY STOP 115317A

Z002490

Z014018

Z010006

Z009802

Z006230

Z014019

Z010230

Z012940

Z083944

Z003565

Z012060

Z009547

Z010230

Z072189

Z087993

Z087992

Z040232

Z005517

FA BLT0101

FA NUT0341

Z005830

Parts List

172466

115284

115283

172474

115275

115225

115268

115239

133409

172383

172267

172265

115336

172360

172366

172365

172360

N87527

172280

115310

OM-DH/INA/2-100 25

Page 26

172474

WATER PIPING ASSEMBLY

Ref Description Part #

ELBOW, STREET, 90 DEGREE, 3/4

1

NPT, SS

2

ELBOW, 90 DEGREE, 3/4 NPT, SS

3

NIPPLE, 3/4 NPT, 2" LONG, SS

4

NIPPLE, 3/4 NPT, 4" LONG, SS

METER, WATER, {MEASURES IN

5

GALLONS)

METER, WATER, [MEASURES IN

5

LITERS]

6

VALVE, SOLENOID, WATER, 24VDC

172471

172473

172472

172470

Z055211

Z098369

172475

Parts List

26 OM-DH/INA/2-100

Page 27

172378

GAS VALVE PIPING, PRESSURE GAUGE

AND BOX ASSEMBLY

Ref Description Part #

1

GASKET, CLOSED CELL, NEOPRENE

2

CAP, PROBE, WATER LEVEL

3

FITTING, PROBE, WATER LEVEL

ASSEMBLY, PIPING, GAS

4

6

COVER, ENCLOSURE, GAS VALVE

SCREW, TRUSS HEAD, 10-32 X 1/2"

7

LONG

8

NUX, HEX, 8-32

SCREW, CAP, HEX HEAD, 1/4-20 X

9

1/2" LONG

10

NUT, HEX, 1/4-20

11

COVER, ENCLOSURE, WATER LEVEL

ENCLOSURE, WATER LEVEL

13

ASSEMBLY, PIPING, PRESSURE

14

SWITCH & GAUGE

15

UNION, 3/8 NPT

16

GROMMET, 11/16 ID

17

GROMMET, 9/16 ID

18

GROMMET, 7/8 ID

19

GROMMET, 1/4 ID

20

GROMMET, STRAIN RELIEF

22

LIGHT, INDICATOR, RED, 24VAC

23

OVERLAY, OPERATING PRESSURE

GRIP, CORD, 1/2 NPT

25

FITTING, COMPRESSION, STRAIGHT,

26

3/8 NPT - 3/8 TUBE

FITTING, COMPRESSION, 90 DEGREE,

27

3/8 NPT - 3/8 TUBE

28

TUBING, COPPER, 3/8 OD, 12" LONG

29

CONNECTOR, 90 DEGREES, 1/2 NPT

30

PROBE, WATER LEVEL

MODULE, IGNITION, INTERMITTENT

31

PILOT

32

CONDUIT, GAS PIPING

GASKET, CONDUIT

33

34

RIVNUT, OPEN END, 10-32

-

CONDUIT, SEALTITE, 1/2"

TUBING, ALUMINUM, 1/4 OD, 36"

37

LONG

CABLE, HIGH VOLTAGE, IGNITION, 36"

38

LONG

39

WIRE HARNESS, MAIN

40

NUT, CONDUIT, 1/2 NPT

41

ENCLOSURE, GAS VALVE

GROMMET, SILICONE, 11/16 ID

-

-

TEE, 1/2 NPT

NIPPLE, CLOSE, 1/2 NPT

-

48

COUPLING, 1/2 RECESSED, 1/4 NPT

115336

115319B

146992

149650

115294

Z072189

Z011030

Z005608

Z005601

115290

172377

172376

Z027421

Z007245

Z074974

Z007400

Z001518

Z088239

116383

115317D

Z009196

117801

117802

Z007332

Z001668

Z076526

Z085153

115234

115299

113235

Z001697

Z006796

Z096728

115335

Z008808

115292

128863

Z013650

Z004306

Z004158

Parts List

OM-DH/INA/2-100 27

Page 28

172376

PRESSURE SWITCH AND GAUGE

PIPING ASSEMBLY

Ref Description Part #

1

PRESSURE SWITCH, SET AT 43 PSI

2

TEE, 1/4 NPT

3

PRESSURE SWITCH, SET AT 43 PSI

ELBOW, 90 DEGREE, 1/4 NPT

4

5

NIPPLE, 1/4 NPT, 1" LONG

NIPPLE, 1/4 NPT, 6-1/2" LONG

6

7

UNION, STRAIGHT, 1/4 NPT

8

NIPPLE, 1/4 NPT, 2"LONG

BUSHING, REDUCING, 3/8 NPT - 1/4

9

NPT

10

TEE, 3/8 NPT

11

NIPPLE, 3/8 NPT, 10" LONG

12

ELBOW, STREET, 90 DEGREE, 3/8 NPT

13

NIPPLE, 3/8 NPT, 6" LOG

17

ELBOW, 90 DEGREE, 3/8 NPT

GAUGE, PRESSURE

18

FITING, STRAIGHT, COMPRESSION,

19

1/4 NPT - 1/4 TUBE

20

NIPPLE, 3/8 NPT, 1-1/2" LONG

21

NIPPLE, 3/8 NPT, 1" LONG

22

TUBING, COPPER, 1/4, 24" LONG

NIPPLE, 3/8 NPT, 4" LONG

Z096963

Z008539

Z096963

Z005682

Z005683

Z003674

Z005126

Z005675

Z059907

Z012794

Z012794

Z009853

Z005752

Z055335

115293

Z064565

Z005678

Z007439

116002

Z005720

Parts List

28 OM-DH/INA/2-100

Page 29

149650

GAS VALVE PIPING ASSEMBLY

Ref Description Part #

1

UNION, STRAIGHT, 1 NPT

2

NIPPLE, CLOSE, 1 NPT

3

ELBOW, REDUCING, 1 NPT X 3/4 NPT

VALVE, GAS, MAIN

4

5

NIPPLE, CLOSE, 3/4 NPT

VALVE, GAS, SOLENOID, 3/4 NPT

6

TEE, REDUCING, 3/4 NPT X 3/4 NPT

7

X 1/2 NPT

8

NIPPLE, 3/4 NPT, 4" LONG

9

ELBOW, 3/4 NPT

ELBOW, REDUCING, 3/4 NPT X 1/2

10

NPT

11

NIPPLE, 1/2 NPT, 4" LONG

12

UNION, STRAIGHT, 1/2 NPT

13

NIPPLE, 1/2 NPT, 2" LONG

BUSHING, REDUCING, 1/2 NPT X 1/4

14

NPT

15

NIPPLE, 1/4 NPT, 2" LONG

16

UNION, STRAIGHT, 1/4 NPT

17

NIPPLE, 1/4 NPT, 3-1/2" LONG

18

ELBOW, 90 DEGREE, 1/2 NPT

19

NIPPLE, 1/2 NPT, 1-1/2" LONG

Z005534

Z005517

Z003610

115298

Z008238

108963

Z005484

Z005554

Z008124

Z008751

Z005554

Z004186

Z005551

Z008739

Z005675

Z005126

Z041509

Z008747

Z004184

Parts List

OM-DH/INA/2-100 29

Page 30

172361

RIGHT STANCHION ASSEMBLY

Parts List

Ref Description Part #

1

COVER, STANCHION, RIGHT SIDE

ASSEMBLY, FRAME, RIGHT

2

STANCHION

ASSEMBLY, OUTER CLADDING,

3

STANCHION, RIGHT SIDE

ASSEMBLY, INSIDE CLADDING,

4

STANCHION, RIGHT SIDE

SUBASSEMBLY, ELECTRICAL

5

COMPONENTS

ASSEMBLY, ENCLOSURE,

6

CONTROL PANEL

7

MOTOR, DRIVE, 1/2 HP

8

NUT, HEX, KEPS, 1/4-20

9

GEAR, 72 TOOTH

10

ASSEMBLY, MECHANICAL STOP

SCREW, CAP, SOCKET, 5/16-18,

11

2" LONG

12

COUPLING, SHAFT

13

NUT, HEX 1/2-13

172384

172293

172265

172294

172393

172390

128973

NT1101

115269

115240

115302

115276

Z003565

Ref Description Part #

FITTING, GREASE, STRAIGHT,

16

1/4 NPT

CASTING, TRUNNION GEAR

17

CARRIER

18

COLLAR, SET, 1" ID

SCREW, SET, CUP POINT, 3/8-16,

19

5/8" LONG

20

SHAFT, DRIVE

21

KEY, 1/4" SQUARE, 3-1/4" LONG

22

BEARING, ROLLER, 1"

23

GEAR, WORM

HMI, TOUCH SCREEN

24

CONTROLLER

ASSEMBLY, TILT SWITCH &

25

HARNESS

SCREW, TRUSS HEAD, 8-32,

26

3/8" LONG

BAR, 1/2" SQUARE, SS, 3-1/2"

27

LONG

28

KEY, 1/4" SQUARE, 2" LONG

Z009547

Z012222

Z012012

Z012060

115242

Z012468

Z012036

Z012054

172292

115282

Z005764

303208

Z009258

Ref Description Part #

WASHER, SHIM, 1-3/4 OD,

31

0.001" THICK

WASHER, SHIM, 1-3/4 OD,

32

0.003" THICK

WASHER, SHIM, 1-3/4 OD,

33

0.005" THICK

34

WASHER, FLAT, 3/8, SS

35

WASHER, LOCK, SPLIT, 3/8

36

NUT, HEX, 5/16-18

37

BLOCK, STOP, MECHANICAL

SCREW, SAP, HEX HEAD, 5/16-

38

18, 1-1/2" LONG

39

WASHER, FLAT, 5/16

40

WASHER, LOCK, 5/16

SCREW, CAP, HEX HEAD, 1/2-13,

41

2-1/2" LONG

42

PLATE, SHIP, TILT MOTOR

43

ASSEMBLY, SWITCH, 2 POSITION

Z012192

Z012193

Z012079

Z005830

Z005618

Z005602

115213

Z006017

Z012093

Z005658

Z005629

172272

115337A

14

RIVNUT, OPEN END, 10-32

SCREW, TRUSS HEAD, 10-32,

15

1/2" LONG

113235

Z072189

30 OM-DH/INA/2-100

SCREW, CAP, HEX, 3/8-16,

29

1-1/2" LONG

GASKET, NEOPRENE, CLOSED

30

CELL, 90-INCHES

Z005615

115336

44

SWITCH, EMERGENCY STOP

OVERLAY, POWER AND

45

EMERGENCY STOP

N87527

172398

Page 31

172476

ELECTRICAL SUBPANEL ASSEMBLY

Ref Description Part #

1

PLC, 1763-L16DWD

2

ANALOG OUTPUT, 1762-IR4

ETHERNET SWITCH, EKI-2525 AE 5

3

PORT

4

24 VDC POWER SUPPLY, MDR-120-24

3A CIRCUIT BREAKER, FAZ-C3/2-NA

5

UL 489 3A

1A CIRCUIT BREAKER, FAZ-C1/1SP UL

6

1077 1A

2A CIRCUIT BREAKER, FAZ-C2/1SP UL

7

1077 2A

5A CIRCUIT BREAKER, FAZ-C5/1SP UL

8

1077 5A

9

75 VA TRANSFORMER, PH75MLI 75VA

10

1.5A FUSE, ATDR1.5

172520

172521

172522

172523

172524

172525

172526

172527

172528

172529

Parts List

11

10A FUSE, ATMR10

12

FUSE HOLDER, US3J31

13

CONTACTOR, MC-9B-DC24-11S

14

CONTACTOR, MC-9B/R-DC24-22S

ON / OFF CONTROL WITH LOCKOUT,

15

MMS-32H-2.5 BRK/OL

16

RELAY, AB 700-HLT12U24

TERMINAL, 1492-J3-W 600VOLT 25

19

AMP

TERMINAL, 1492-JG3-IEC 600VOLT

20

GND

21

LOW WATER CUTOFF, PN 26B3B

- PANEL, ELECTRICAL MOUNT 172296

- NUT, HEX, 1/4-20 Z005601

172530

172531

172532

172533

172534

172535

172536

172537

172538

OM-DH/INA/2-100 31

Page 32

115282

TILT SWITCH ASSEMBLY

Ref Description Part #

SWITCH, OVERTRAVEL,

1

PLUNGER TYPE

2

BRACKET, TILT SWITCH

3

HARNESS, TILT SWITCH

115261

115221

115281

Parts List

32 OM-DH/INA/2-100

Page 33

HIGH FIRE BURNER ASSEMBLY

Ref Description Part #

1

MANIFOLD, BURNER, 40-PORT

2

NIPPLE, 1/2 NPT, 3-1/2" LONG

BUSHING, REDUCING, 1/2 NPT TO

3

1/8 NPT

BURNER JET, BRASS, 7/16-24 NS,

4

#654

5

PLUG, PIPE, RECESSED HEX, 1/8 NPT

BURNER JETS, BRASS, 7/16-24 NS

Ref

N02

N24

N46

N68

N810

L02

L24

L46

L68

L810

Elevation - Jet Orifice Size

NATURAL GAS

0-2000' ELEVATION -- 1.15MM

(0.0453)

2001-4000' ELEVATION -- 1.05MM

(0.0413)

4001-6000' ELEVATION -- 1.05MM

(0.0394)

6001-8000' ELEVATION -- 0.95MM

(0.0374)

8001-10000' ELEVATION -- 0.89MM

(0.0350)

LP GAS

0-2000' ELEVATION -- 0.79MM

(0.0310)

2001-4000' ELEVATION -- 0.71MM

(0.0280)

4001-6000' ELEVATION -- 0.70MM

(0.0276)

6001-8000' ELEVATION -- 0.65MM

(0.0256)

8001-10000' ELEVATION -- 0.61MM

(0.0240)

146985

Z008227

Z088290

SEE

ELEVATION

TABLE

Z010286

Part #

127554

106159

127560

174293

127361

102944

127563

174292

154178

104291

Parts List

OM-DH/INA/2-100 33

Page 34

LOW FIRE BURNER ASSEMBLY

Ref Description Part #

1

MANIFOLD, BURNER, 20-PORT

2

NIPPLE, 1/2 NPT, 3-1/2" LONG

BUSHING, REDUCING, 1/2 NPT TO

3

1/8 NPT

146986

Z008227

Z088290

Parts List

4

NIPPLE, 1/2 NPT, 1-1/2" LONG

BURNER JET, BRASS, 7/16-24 NS,

5

#654

6

PLUG, PIPE, RECESSED HEX, 1/8 NPT

BURNER JETS, BRASS, 7/16-24 NS

Ref

N02

N24

N46

N68

N810

L02

L24

L46

L68

L810

Elevation - Jet Orifice Size

NATURAL GAS

0-2000' ELEVATION -- 1.15MM

(0.0453)

2001-4000' ELEVATION -- 1.05MM

(0.0413)

4001-6000' ELEVATION -- 1.05MM

(0.0394)

6001-8000' ELEVATION -- 0.95MM

(0.0374)

8001-10000' ELEVATION -- 0.89MM

(0.0350)

LP GAS

0-2000' ELEVATION -- 0.79MM

(0.0310)

2001-4000' ELEVATION -- 0.71MM

(0.0280)

4001-6000' ELEVATION -- 0.70MM

(0.0276)

6001-8000' ELEVATION -- 0.65MM

(0.0256)

8001-10000' ELEVATION -- 0.61MM

(0.0240)

Z004184

SEE

ELEVATION

TABLE

Z010286

Part #

127554

106159

127560

174293

127361

102944

127563

174292

154178

104291

34 OM-DH/INA/2-100

Page 35

AGITATOR ASSEMBLY

Ref Description Part #

1

DISC, 1e DIAMETER X 10 GA (2)

2

COUPLING, QUICK DISCONNECT

3

BLADE, SCRAPER (6)

4

HOLDER SCRAPER BLADE (6)

019058

012719

005098

005099

Parts List

SCRAPER LOCKING PIN (NOT SHOWN)

-

5

LOCKING HAIRPIN CLIP (6)

7

YOKE, BLADE CARRIER (6)

003655

003652

004923

OM-DH/INA/2-100 35

Page 36

LOW FIRE BURNER ASSEMBLY

Ref Description Part #

1

REGULATOR, AIR

2

NIPPLE, 1/4” X CLOSE BRASS

3

TEE, 1/4” BRASS

4

COUPLING, FULL 3/8”

5

FITTING COMPRESSION

CONNECTION HOSE 3/8” X 65” (NOT

6

SHOWN)

7

ELBOW, 90 STREET 3/8”

8

DISCONNECT, QUICK 3/8”

9

ELBOW, 90 STREET 1/4”

FILTER, AIR, IN LINE PARKET #

10

4M-F4L-10-BN-B

FITTING COMP, 3/8” T X 1/4” P 90

11

DEG FEMALE ELBOW

CONNECTOR MALE 3/8” MPT X 3/8”

13

TUBE

050119

003923

014360

012740

091940

155102

055336

N71392

010232

069038

057218

050879

Parts List

36 OM-DH/INA/2-100

Page 37

Wiring Diagram

OM-DH/INA/2-100 37

Page 38

Wiring Diagram

38 OM-DH/INA/2-100

Page 39

Service Log

Model No: Purchased From:

Serial No: Location:

Date Purchased: Date Installed:

Purchase Order No: For Service Call:

Date Maintenance Performed Performed By

OM-DH/INA/2-100 39

Page 40

1055 Mendell Davis Drive • Jackson MS 39272

888-994-7636 • 601-372-3903 • Fax 888-864-7636

unifiedbrands.net

© 2018 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of Dover Corporation.

PART NUMBER 176302, REV. A (01/18)

Loading...

Loading...