Page 1

OPERATOR MANUAL

IMPORTANT INFORMATION, KEEP FOR OPERATOR

This manual provides information for:

MODELS BPM-15/30/40E

& BPP-30/40E

Domestic

ECLIPSE™ ERGONOMIC

TILTING BRAISING PAN

· Stainless Steel

· Manual or Power Tilt

· Electrically Heated

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE.

READ, UNDERSTAND AND FOLLOW THE INSTRUCTIONS AND

WARNINGS CONTAINED IN THIS MANUAL.

FOR YOUR SAFETY

Do not store or use gasoline or other ammable vapors

and liquids in the vicinity of this or any other appliance.

WARNING

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, injury or

death. Read the installation, operating and maintenance

instructions thoroughly before installing or servicing this

equipment.

NOTIFY CARRIER OF DAMAGE AT ONCE

It is the responsibility of the consignee to inspect the container upon receipt of

same and to determine the possibility of any damage, including concealed damage. Unied Brands suggests that if you are suspicious of damage to make a

notation on the delivery receipt. It will be the responsibility of the consignee to le

a claim with the carrier. We recommend that you do so at once.

Manufacture Service/Questions 888-994-7636.

Information contained in this document is known to be current and accurate at the time

of printing/creation. Unified Brands recommends referencing our product line websites,

unifiedbrands.net, for the most updated product information and specifications.

PART NUMBER 148727, REV. E (04/13)

1055 Mendell Davis Drive

Jackson, MS 39272

888-994-7636, fax 888-864-7636

unifiedbrands.net

Page 2

IMPORTANT - READ FIRST - IMPORTANT

CAUTION: BE SURE OPERATORS READ, UNDERSTAND AND FOLLOW THE OPERATING INSTRUCTIONS, CAUTIONS,

AND SAFETY INSTRUCTIONS IN THIS MANUAL.

WARNING: THIS UNIT IS INTENDED FOR USE IN THE COMMERCIAL HEATING, COOKING AND HOLDING OF WATER

AND FOOD PRODUCTS, PER THE INSTRUCTIONS CONTAINED IN THIS MANUAL. ANY OTHER USE COULD

RESULT IN SERIOUS PERSONAL INJURY OR DAMAGE TO EQUIPMENT AND WILL VOID WARRANTY.

WARNING: ELECTRICALLY GROUND THE PAN AT THE TERMINAL PROVIDED. FAILURE TO GROUND UNIT COULD

RESULT IN ELECTROCUTION AND DEATH.

WARNING: THE BRAISING PAN MUST BE INSTALLED BY PERSONNEL WHO ARE QUALIFIED TO WORK WITH

ELECTRICITY. IMPROPER INSTALLATION COULD RESULT IN PERSONAL INJURY OR EQUIPMENT DAMAGE.

CAUTION: STAND AWAY FROM HOT WATER OR FOOD PRODUCTS WHILE TILTING THE PAN DIRECT CONTACT COULD

RESULT IN SEVERE BURNS.

WARNING: WHEN TILTING BRAISING PAN FOR PRODUCT TRANSFER:

1) WEAR PROTECTIVE OVEN MITT AND PROTECTIVE APRON.

2) USE CONTAINER DEEP ENOUGH TO CONTAIN AND MINIMIZE SPLASHING.

3) PLACE CONTAINER ON STABLE, FLAT SURFACE, AS CLOSE TO PAN AS POSSIBLE.

4) STAND TO SIDE OF PAN WHILE POURING — NOT DIRECTLY IN POUR PATH OF HOT CONTENTS.

5) RETURN PAN BODY TO LEVEL POSITION AFTER CONTAINER IS FILLED OR TRANSFER IS COMPLETE.

6) DO NOT OVER FILL CONTAINER. AVOID DIRECT SKIN CONTACT WITH HOT CONTAINER AND ITS

CONTENTS.

WARNING: DO NOT HEAT AN EMPTY PAN FOR MORE THAN FIVE MINUTES AT A SETTING HIGHER THAN 300˚F.

WARNING: AVOID ANY EXPOSURE TO THE STEAM ESCAPING FROM THE COVER VENT. DIRECT CONTACT COULD

RESULT IN SEVERE BURNS

WARNING: AVOID ALL DIRECT CONTACT WITH HOT EQUIPMENT SURFACES. DIRECT SKIN CONTACT COULD RESULT

IN SEVERE BURNS.

WARNING: AVOID ALL DIRECT CONTACT WITH HOT FOOD OR WATER IN THE BRAISING PAN. DIRECT CONTACT

COULD RESULT IN SEVERE BURNS.

WARNING: IF THE PAN CONTAINS ITEMS IN SAUCE OR MELTED FAT, THEY COULD SLIDE FORWARD SUDDENLY

DURING TILTING AND CAUSE HOT LIQUID TO SPLASH OUT.

WARNING: USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY THE MANUFACTURER OR ITS

AUTHORIZED DISTRIBUTORS VOIDS ALL WARRANTIES AND MAY CAUSE BODILY INJURY OR EQUIPMENT

DAMAGE. SERVICE PERFORMED BY OTHER THAN FACTORY AUTHORIZED PERSONNEL WILL VOID ALL

WARRANTIES.

WARNING: TURN OFF ELECTRIC POWER BEFORE WORKING ON INTERNAL COMPONENTS.

WARNING: BEFORE ANY CLEANING OPERATION, TURN THE THERMOSTAT TO “OFF” TO CUT OFF POWER TO THE

HEATING ELEMENTS. BEFORE CLEANING ANY PART OTHER THAN THE INSIDE OF THE PAN, DISCONNECT

THE ELECTRICAL SUPPLY AT THE CIRCUIT BREAKER OR FUSE BOX.

2 OM-BPM/BPP-E

Page 3

IMPORTANT - READ FIRST - IMPORTANT

WARNING: BE CAREFUL TO AVOID CONTACT WITH CLEANING PRODUCTS IN ACCORDANCE WITH SUPPLIER AND

MANUFACTURER RECOMMENDATIONS. MANY CLEANERS ARE HARMFUL TO THE SKIN, EYES, MUCOUS

MEMBRANES AND CLOTHING. READ THE WARNINGS AND FOLLOW DIRECTIONS ON THE CLEANER LABEL.

CAUTION: NEVER LEAVE A CHLORINE SANITIZER IN CONTACT WITH STAINLESS STEEL FOR LONGER THAN 30

MINUTES. LONGER CONTACT CAN CAUSE CORROSION.

WARNING: DO NOT USE ANY FUSE WITH A HIGHER AMP RATING THAN THE RATING SPECIFIED FOR THAT CIRCUIT.

WARNING: KEEP WATER AND SOLUTIONS OUT OF CONTROLS AND ELECTRICAL EQUIPMENT. NEVER USE A HIGH

PRESSURE HOSE TO CLEAN THE BRAISING PAN.

WARNING: BEFORE REPLACING ANY PARTS, DISCONNECT THE UNIT FROM THE ELECTRIC POWER SUPPLY.

IMPORTANT: SERVICE PERFORMED BY OTHER THAN FACTORY AUTHORIZED PERSONNEL WILL VOID WARRANTIES.

OM-BPM/BPP-E 3

Page 4

Table of Contents

Important Operator Warnings ......................................................page 2-3

References.................................................................................... page 4

Equipment Description............................................................... page 5-6

Inspection and Unpacking ............................................................ page 7

Installation .................................................................................. page 8-9

Initial Start-Up................................................................................ page 9

Operation ................................................................................ page 10-11

Sequence of Operation ................................................................ page 12

Cleaning.................................................................................. page 13-14

Maintenance................................................................................. page 15

Troubleshooting............................................................................ page 16

Parts Lists .............................................................................. page 17-23

Schematics/Wiring Diagram ................................................ page 24-30

Service Log ................................................................................. page 31

References

NATIONAL FIRE PROTECTION ASSOCIATION

60 Battery March Park

Quincy, Massachusetts 02269

NFPA/70 - The National Electrical Code

NSF INTERNATIONAL

789 N. Dixboro Road

P.O. Box 130140

Ann Arbor, Michigan 48113-0140

NSF/ANSI - Standard 4

UNDERWRITERS LABORATORIES, INC.

333 Pngsten Road

Northbrook, Illinois 60062

UL/ANSI - Standard 197

4 OM-BPM/BPP-E

Page 5

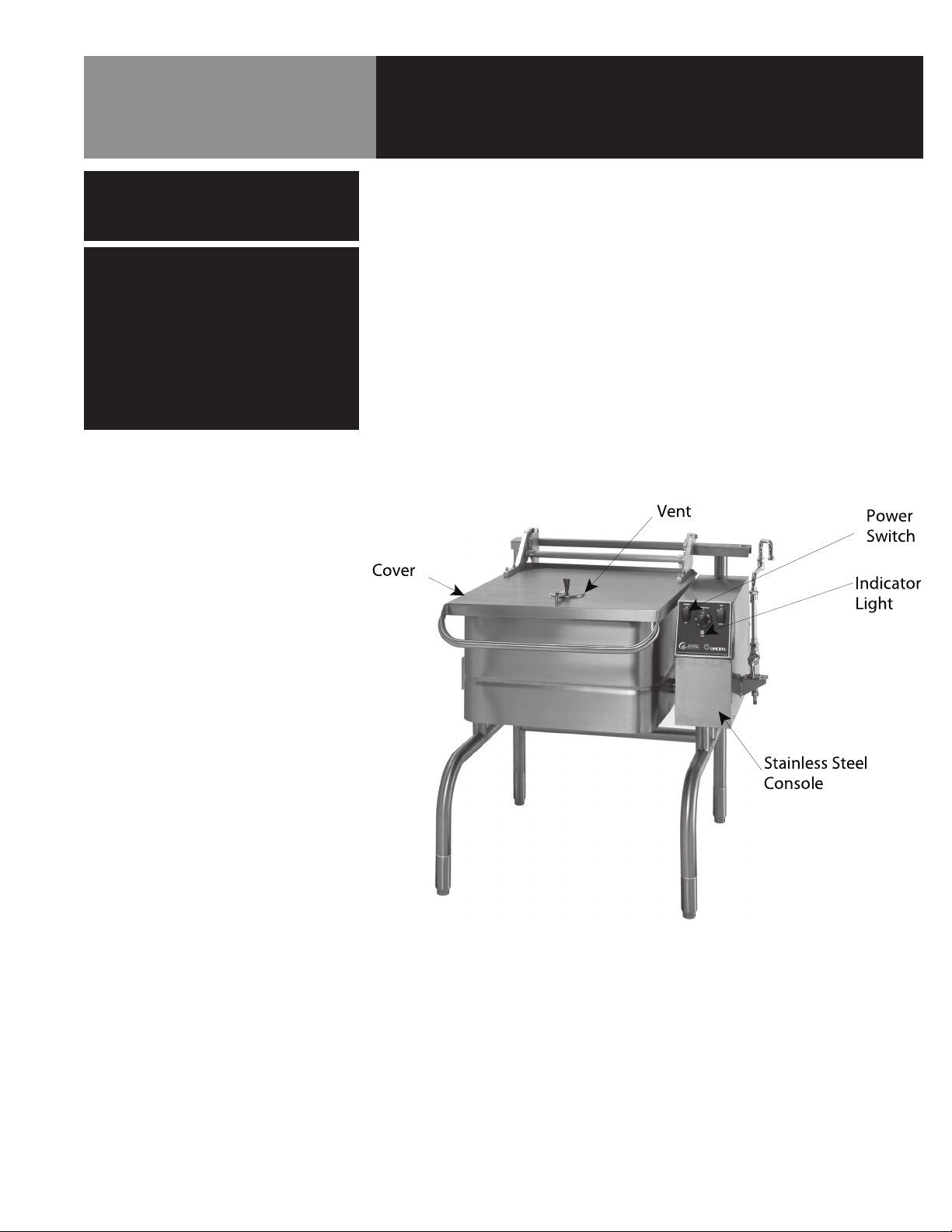

Equipment Description

The BPM/BPP is a stainless steel, electrically heated Braising Pan which is equipped

with integrated heating elements, a hand operated or motor powered tilting

mechanism, electrical controls and a hinged cover. The Braising Pan serves as a

braising unit, griddle, fry pan, oven, kettle, bain-marie, or food warmer and server. It

can also be adapted for use as a non-pressure steamer.

The pan body is constructed of heavy-duty stainless steel, welded into a solid piece.

It has a polished interior and exterior finish. A pouring lip is welded to the top of the

front wall. The cooking surface is a stainless steel clad plate fitted with clampedon electrical heating elements. The elements are positioned to ensure uniform heat

transfer over the entire surface.

Pans are mounted on an open-leg frame which is fabricated from tubular stainless

steel.

An easily operated worm and gear mechanism tilts the pan body and provides precise

control for pouring or dumping its contents.

This tilting mechanism is located in a stainless steel console to right of the pan body.

For power tilt units a three position switch on the front of the control console gives the

operator positive, smooth-acting control of tilt. To facilitate cleaning, the pan body can

be tilted past the vertical position.

Heating elements and other electrical components are enclosed for safety. The

thermostat, heating indicator light and tilting switch are contained in a compact

control console which is mounted to the right of the pan body.

The thermostat provides automatic control of cooking temperature. Turning the

thermostat dial starts and stops heating and sets the pan temperature. Only one

electrical connection is required to install the unit.

A vented, heavy gauge, one-piece, stainless steel cover with a rear condensate drip

shield on the underside is standard on the braising pan. A fully enclosed torsion bartype counter-balance provides easy operation to open the cover to maintain it open

at any position. The cover opens to the back. It is hinged to the frame, so it moves

independently from the pan body.

The following sizes and options are available:

Model

BPM-15E

BPM-30E

BPM-40E

BPP-30E

Left to Right Front to Rear Depth

18-1/8" (460 mm) 28-1/4" (718 mm) 8" (203 mm) Manual

26-1/4" (667 mm) 28-1/4" (718 mm) 10" (254 mm) Manual

35-3/4" (908 mm) 28-1/4" (718 mm) 10" (254 mm) Manual

26-1/4" (667 mm) 28-1/4" (718 mm) 10" (254 mm) Power

PAN DIMENSIONS (inside)

Tilt

BPP-40E

35-3/4" (908 mm) 28-1/4" (718 mm) 10" (254 mm) Power

OM-BPM/BPP-E 5

Page 6

Optional Tangent Draw-off

Equipment Description

The following optional equipment may be added to any floor model listed above:

1. Fill faucet - swing spout single or double pantry

2. Fill faucet - 48” or 60” spray hose assembly - single or double pantry

3. Caster mounting kit

4. Flanged Feet Kit

5. Draw-Off Valve (can not be field installed)

6. Steamer insert set

7. Steamer pan carrier

8. Pouring Lip Strainer

9. Strainer for 2” TDO valve

6 OM-BPM/BPP-E

Page 7

Inspection & Unpacking

CAUTION

SHIPPING STRAPS ARE UNDER TENSION

AND CAN SNAP BACK WHEN CUT.

CAUTION

UNIT WEIGHS 420 TO 560 LB (190 TO 255

KG). FOR SAFE HANDLING, INSTALLER

SHOULD OBTAIN HELP AS NEEDED, OR

EMPLOY APPROPRIATE MATERIALS

HANDLING EQUIPMENT (SUCH AS A

FORKLIFT, DOLLY, OR PALLET JACK) TO

REMOVE THE UNIT FROM THE SKID AND

MOVE IT TO THE PLACE OF INSTALLATION.

The unit is strapped to a skid, and shipped

in a heavy cardboard carton. (Shown is a

40-gallon model with optional right side

mounted, double pantry faucet assembly.)

The unit will arrive completely assembled, wrapped in protective plastic on a heavy skid,

in a heavy cardboard carton. Immediately upon receipt, inspect the carton for damage.

Report any apparent shipping damage or an incorrect shipment to the delivery agent.

When installation is to begin, get someone to assist in removing the carton. Lift it straight

up and away from the unit. Do not simply raise it and push backwards - it will break

the cover assembly vent handle. Write down the model number, serial number, and

installation date of your unit, and keep this information for future reference. Space for

these entries is provided at the top of the Service Log in this manual.

Cut the straps holding the unit on the skid, and lift the unit straight up off the skid.

OM-BPM/BPP-E 7

Page 8

Installation

CAUTION

BEFORE ANY ELECTRICAL CONVERSION,

VERIFY THAT THE BRANCH CIRCUIT

WIRING IS ADEQUATE TO HANDLE ANY

INCREASE IN AMPERAGE REQUIREMENTS.

REFER TO THE ELECTRICAL

SPECIFICATIONS LISTED BELOW.

WARNING

INSTALLATION OF THE BRAISING PAN

MUST BE DONE BY PERSONNEL QUALIFIED

TO WORK WITH ELECTRICITY. IMPROPER

INSTALLATION CAN RESULT IN INJURY TO

PERSONNEL AND/OR DAMAGE

TO EQUIPMENT.

Electronic spark ignition

Internal wiring for the Braising Pan is supplied complete. When you receive the unit, it

is ready for connection. A wiring diagram is located inside the control box on the right

side of the pan, as well as in this manual.

Your pan was performance-tested at the factory to confirm that all controls and

heating elements were functioning correctly.

Installation is as follows:

1. Set the unit in place and level it by turning the adjustable feet. Crank the pan

body to a completely horizontal position. Check levelness by placing a spirit level

on the bottom of the pan. The unit must be level to avoid uneven cooking across

the pan.

2. Make a waterproof connection with the incoming power line at the electrical

service entrance at the bottom of the connection box at rear of control console.

A BX connection is NOT recommended. ELECTRICALLY GROUND THE UNIT at the

proper terminal.

3. Provide the proper electrical supply as specified on the electrical information

plate. Comply with local codes and the National Electrical Code ANSI/NFPA 7latest edition.

4. Use only copper wire, rated at least 75ºC and of proper gage. See chart below.

5. Standard equipment is shipped ready for 208V, 240V, or 480V, 3-phase

operation. Refer to the wiring diagram located on the inside cover of the control

box and the instructions below for conversion to single-phase operation.

A jumper wire and “conversion” label are included with the unit. They can be

found in a plastic bag attached to the trunnion assembly inside the control box.

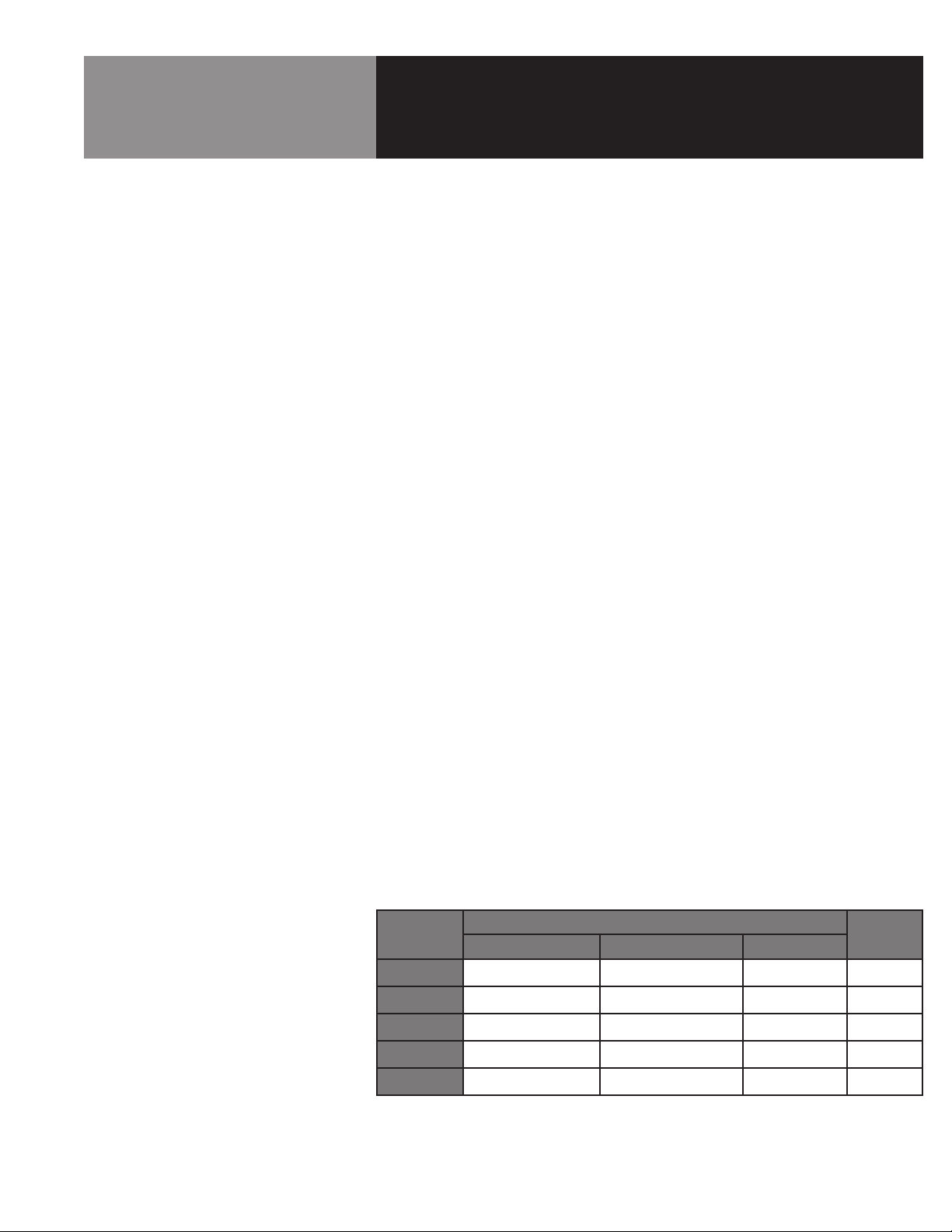

Electrical Requirements

NOTE: Use only copper wire rated for 75°c or higher; Gauge recommendations (AWG) are for 25’ runs from the breaker

box (if longer runs are required, increase wire size accordingly)

Model

BPM-15E

BPM-30E

BPP-30E

BPM-40E

BPP-40E

Power

Kw Amps

7.6 37 8 32 8 21 10 18 10 9 12 7.0 9 12

11.5 56 6 48 6 32 8 28 8 14 12 10.5 14 12

11.5 56 6 48 6 32 8 28 8 14 12 10.5 14 12

15.3 74 4 64 4 43 8 37 8 19 10 14.0 19 10

15.3 74 4 64 4 43 8 37 8 19 10 14.0 19 10

208 Volt,

Single Phase

Wire

(AWG)

240 Volt,

Single Phase

Amps

(AWG)

Wire

208 Volt,

3-Phase

Amps

Wire

(AWG)

240 Volt,

3-Phase

Amps

Wire

(AWG)

480 Volt,

3-Phase

Amps

Wire

(AWG)

Power

KW Amps

440 Volt,

3-Phase

Wire

(AWG)

8 OM-BPM/BPP-E

Page 9

Installation

6. For conversion from 3-phase to 1-phase

a. Verify that the branch circuit wiring is adequate for any increased

amperage requirements. (See table on previous page)

b. 1-phase requires two jumper wires. One jumper wire exists on the terminal

block for 3- phase input. The second jumper wire is located in a plastic bag

inside the control box.

c. Attach jumper wires to terminal block as per wiring diagram for 1 phase

supply.

d. Complete “conversion label” (supplied in bag) and adhere it to the control

box near the UL data plate.

WARNING

WATER IS EXTREMELY HOT AND CAN CAUSE

SEVERE BURNS. AVOID CONTACT WITH HOT

WATER WHEN EMPTYING UNIT.

CAUTION

ALWAYS RAISE PAN COVER BEFORE

TILTING TO AVOID DAMAGING THE HINGE

AND COUNTERBALANCE.

Initial Start-Up

Now that your braising pan has been installed, you should test it to ensure that the

unit is operating correctly.

1. Remove all literature and packing materials from the interior and exterior of the

unit.

2. Turn on the electrical power to the unit.

3. Put enough water into the pan to cover its bottom to a depth of 1/4” to 1/2” (6 to

13 mm). With the pan body in the horizontal position, note how the water covers

the pan bottom. This is a good method to use for confirming that the unit is

properly leveled.

4. Set the thermostat to 235°F (113°C). The heating indicator light should come on

to show that the pan is heating. Heating should continue until the water boils.

5. To shut the unit down, turn the thermostat dial to “OFF.”

6. Turn the tilting handwheel clockwise to pour out the water and to confirm that

the pan body can be tilted smoothly from horizontal to vertical. For power tilt

models, push the UP/DOWN switch to confirm operation of tilting system.

If the unit functions as described above, it is ready for use. If it does not, contact your

local Authorized Service Agency.

OM-BPM/BPP-E 9

Page 10

Operation

WARNING

KEEP THE AREA AROUND BRAISING PAN

FREE AND CLEAR OF COMBUSTIBLE

MATERIALS.

CAUTION

KEEP FLOORS IN BRAISING PAN WORK

AREA CLEAN AND DRY. IF SPILLS OCCUR,

CLEAN IMMEDIATELY TO AVOID THE

DANGER OF SLIPS OR FALLS.

CAUTION

REPLACE THE HOLE PLUG BEFORE

CLEANING OTHERWISE WATER COULD

ENTER THE ELECTRICAL CONTROL BOX

AND DAMAGE THE PARTS.

WARNING

WHEN TILTING BRAISING PAN

FOR PRODUCT TRANSFER:

1) USE CONTAINERS DEEP ENOUGH

TO CONTAIN AND MINIMIZE

PRODUCT SPLASHING.

2) PLACE CONTAINER ON A STABLE,

FLAT SURFACE, AS CLOSE TO THE

BRAISING PAN AS POSSIBLE.

3) STAND TO THE SIDE OF THE PAN

WHILE POURING — NOT DIRECTLY IN THE

POUR PATH OF HOT CONTENTS.

4) RETURN PAN BODY TO UPRIGHT

POSITION AFTER CONTAINER IS FILLED OR

TRANSFER IS COMPLETE.

5) DO NOT OVERFILL CONTAINER.

AVOID DIRECT SKIN CONTACT WITH HOT

CONTAINER AND CONTENTS.

A. Controls

Operator controls for the braising pans are:

1. Power ON Switch and Power ON indicator located on the control console.

2. The thermostat dial, located on the control console to the right of the

pan body. This dial is used to turn the thermostat on or off and to set

the thermostat for pan temperatures between 175° and 400°F (79° and

204°C).

3. Heating indicator light located on the control console, lights when the

burners have ignited.

4. A handwheel controls the worm and gear mechanism that smoothly tilts

the pan body and holds it in the desired position.

5. For power tilt units a switch is located on the control panel. It is used to

raise and lower the pan body.

B. Operating Procedure

1. To Tilt Pan Body

a. Manual Tilt Model Turn the tilting handwheel clockwise to tilt the pan body, or

counterclockwise to return the pan body to horizontal. 23 complete

turns of the handwheel will tilt the body 90 degrees to vertical.

b. Power Tilt Model -

1. Press the power tilt switch marked “up” to raise the pan or

“down” to lower the pan.

2. The spring loaded switch will return to the OFF (middle) position

when you release it.

3. If the power tilt mechanism stops working (see the

Troubleshooting section) and you must raise or lower the pan

body without delay, you can tilt the body by hand. Remove the

small plug on top of the control box and fit the provided tool

into the hole. Turn the tool clockwise to lower it. It may take

several minutes to move the pan to the desired position, but the

operation can be speeded up by substituting a reversible drill

with a 1/4” hexagonal driver bit in place of the tool.

10 OM-BPM/BPP-E

Tilting pan body

2. Set the thermostat dial to the desired temperature between 100 and 400˚F

(38° and 204°C). The Heat Indicator Light shows that the pan is heating.

When the light cycles on and off, it indicates that the pan is holding at the

set temperature. During these cycles you may hear the contactors in the

control box make a clicking sound. This is normal.

3. For best results when braising or frying, preheat the pan before putting in

any food. For an even temperature across the pan, preheat at a setting of

300˚F (149°C) or less for 15 minutes, or through several on/off cycles of the

thermostat.

Page 11

Operation

CAUTION

DO NOT HEAT AN EMPTY PAN FOR

MORE THAN FIVE MINUTES AT A

SETTING HIGHER THAN 300°F.

DAMAGE TO THE PAN COULD RESULT.

CAUTION

DO NOT OVERFILL THE BRAISING PAN

WHEN COOKING, HOLDING OR

CLEANING. KEEP LIQUIDS AT LEAST 2-3”

(5-8 cm) BELOW THE PAN BODY RIM TO

ALLOW CLEARANCE FOR STIRRING,

BOILING PRODUCT AND

SAFE TRANSFER.

WARNING

AVOID ANY EXPOSURE TO THE STEAM

ESCAPING FROM THE COVER VENT.

DIRECT CONTACT COULD RESULT IN

SEVERE BURNS.

WARNING

ITEMS IN SAUCE OR MELTED FAT CAN

SLIDE FORWARD SUDDENLY DURING TILTING

AND SPLASH THE HOT LIQUID.

C. Cooking

1. To simmer or slowly heat an item, set the dial at 210°F (99°C) or lower. Put

the cover down to minimize moisture loss, or leave it up to help dry or reduce

the product. Set the thermostat higher to cook or drive off moisture faster.

You may adjust the thermostat to any setting to cook the item exactly as

required.

2. Leave the cover vent open to let excess steam escape. For long simmering

operations, you may wish to close the vent to retain moisture.

3. To check progress when the cover is closed, lift the handle of the vent

cover slightly, and move it quickly to either side.

4. Standing to one side of the pan (to avoid the steam that will be released)

grasp the nearer corner of the cover handle and raise the cover. The cover

will stay in the open position until you push it down.

5. To pour product, remove grease, or assist in cleaning, first raise the cover,

then tilt the pan forward by turning the tilting handwheel. When you stop

turning the wheel, the pan body will hold its position.

6. To return the pan to the horizontal position, turn the wheel counterclockwise.

WARNING

AVOID ALL DIRECT CONTACT WITH HOT

EQUIPMENT SURFACES. DIRECT SKIN

CONTACT COULD RESULT IN SEVERE

BURNS. AVOID ALL DIRECT CONTACT WITH

HOT FOOD OR WATER IN THE BRAISING PAN.

DIRECT CONTACT COULD RESULT IN

SEVERE BURNS.

7. To turn the pan off, turn the thermostat to the “OFF” position.

D. Routine Clean-Up

After each use, turn the thermostat to “OFF” and clean all food contact surfaces

to ensure proper sanitation. At the end of the day, or at least once every 24

hours, turn off the heat and shut off electric power to the unit and clean both

the interior and exterior of the pan. See Page 13 for more detailed cleaning

instructions.

OM-BPM/BPP-E 11

Page 12

Sequence of Operation

The following “action-reaction” outline is provided to help you understand how the

braising pan actually functions.

When you start up the pan by turning the thermostat from “OFF” to a desired

temperature, the thermostat switch closes. This causes the contactors to close, and

allows power to flow to the heating elements and the indicator light.

When the pan temperature reaches the value set on the thermostat dial, the

thermostat switch opens and causes the contactors to open. This stops the flow of

power to the heating elements and the indicator light. As soon as the thermostat

senses that the pan is cooling below the set temperature, the thermostat closes, the

contactors close, and the heaters and indicator light come on again.

This on and off cycle continues, maintaining the pan at the set temperature. This is

why the indicator light on and off cycling is seen during normal operation. If the pan

temperature exceeds 425°F (218°C) for any reason, a high-limit thermostat shuts

off the power until the pan cools. At that point, the thermostat automatically resets to

permit normal operation to start again.

Turning the thermostat to “OFF” shuts down all control and heating circuits.

The thermostat controls heating by alternating between feeding full power and

completely cutting power off. The pan heats as fast as it can until it reaches the

set temperature, no matter what that temperature is. Turning the thermostat to a

higher setting will cause heating to continue longer, until the pan reaches a higher

temperature, but it cannot make the pan heat any faster.

Manual tilt models, turning the hand wheel rotates a worm, which turns a gear wheel

on one of the trunnions supporting the pan body. Turning the gear produces the tilting

action.

Power tilt models, pushing the up/down switch operates a gear motor which turns

worm and gear wheel as described above.

For all braising pans, the power to the heaters is cut off when the pan is tilted past a

slight inclination of 10° degrees. It is acceptable to cook with the pan tilted forward at

a small angle (about 5 - 7 degrees) to let liquids collect to front of pan or allow them

to drain out of the draw off valve.

12 OM-BPM/BPP-E

Page 13

Cleaning

WARNING

KEEP WATER AND SOLUTIONS OUT OF

CONTROLS AND ELECTRICAL EQUIPMENT.

DO NOT USE A HIGH PRESSURE HOSE TO

CLEAN THE CONTROL CONSOLE,

ELECTRICAL CONNECTIONS, ETC.

CAUTION

MOST CLEANERS ARE HARMFUL TO THE

SKIN, EYES, MUCOUS MEMBRANES AND

CLOTHING. PRECAUTIONS SHOULD BE

TAKEN TO WEAR RUBBER GLOVES,

GOGGLES OR FACE SHIELD AND

PROTECTIVE CLOTHING. CAREFULLY READ

THE WARNINGS AND FOLLOW THE

DIRECTIONS ON THE LABEL OF THE

CLEANER TO BE USED.

WARNING

BEFORE ANY CLEANING OPERATION,

TURN THERMOSTAT DIAL TO “OFF” TO

CUT ANY POWER TO THE HEATING

ELEMENTS. BEFORE CLEANING ANY PART

OTHER THAN THE INSIDE OF THE PAN,

DISCONNECT ELECTRICAL SUPPLY AT

CIRCUIT BREAKER OR FUSE BOX.

A. Suggested Tools

1. A good stainless steel cleaner

2. Brushes in good condition

3. Cloth for cleaning controls

4. Chlorine sanitizer

5. Heavy Duty Cleaner (if required)

B. Procedure

1. Clean all food-contact surfaces soon after use. It is best to clean the pan

before it has completely cooled. If the unit is in continuous use, completely

clean and sanitize both the inside and outside at least once every 12 hours.

2. To remove any large amount of food left in the pan, tilt the pan all the way

up and flush it with lukewarm water. Do not damage the surface of the pan

by scraping it with a metal tool. Scratches make the surface more difficult

to clean, and provide ideal breeding places for bacteria.

3. Following the supplier’s directions, make up a warm solution of the cleaner.

Carefully wash the inside and outside of the pan body with the cleaning

solution.

4. Use a cloth moistened with cleaning solution to clean controls, the control

console, and electric conduit.

5. Rinse the pan very well with lukewarm water, and drain it completely.

6. As part of the daily cleaning program, clean all inside and outside surfaces

that may have been soiled. Remember to check such parts as the undersides of the cover, the electrical console and other more remote spots.

Clean between the pan body and the consoles using a brush.

Use a brush, sponge, cloth, plastic or

rubber scraper, or plastic wool to clean.

Don’t use metal implements or steel wool.

Do not spray water directly on burners

and gas combustion chambers.

7. Controls and the control console may be cleaned with a damp cloth or

sprayed with a garden hose spray connected to city water supply. Do not

use a pressure sprayer directly on the unit or electrical parts.

8. To remove materials stuck to the equipment, use a brush, sponge, cloth,

plastic or rubber scraper, or plastic wool with the cleaning solution. To

make washing easier, let the cleaning solution sit in the unit and soak

into the residue, or heat the solution briefly. Do not use any gritty cleaner

or metal tool that might scratch the surface. Scratches make the surface

harder to clean, and also provide places for bacteria to grow. Do not use

steel wool. Small bit of steel wool left in the surface of the unit can cause

rusting and pitting.

9. The outside of the unit may be polished with a recognized stainless steel

cleaner such as Zepper from the Zep Manufacturing Company.

10. When the equipment needs to be sanitized, use a sanitizing solution

equivalent to one that supplies 100 parts per million available chlorine.

Get advice about the best sanitizing agent from you supplier of sanitizing

products.

OM-BPM/BPP-E 13

Page 14

Cleaning

CAUTION

NEVER LEAVE A CHLORINE SANITIZER IN

CONTACT WITH STAINLESS STEEL

SURFACES FOR LONGER THAN 30 MINUTES.

LONGER CONTACT CAN CAUSE CORROSION.

CAUTION

KEEP CAUSTIC COMPOUNDS SUCH AS

FRYER BOILOUT CLEANERS AWAY FROM

ALUMINUM PARTS OF THE LID HINGE

SYSTEM AND THE COUNTERBALANCE

ASSEMBLY. HIGHLY CAUSTIC COMPOUNDS

COULD DAMAGE THIS MATERIAL.

11. Following supplier instructions, apply the sanitizing agent after the unit has

been cleaned and drained. Thoroughly drain off the sanitizer.

12. After the unit has been cleaned, sanitized and drained, let all surfaces air

dry unless the unit must be used again right away.

13. It is recommended that the unit be sanitized just before use. Follow the

directions of the sanitizer supplier.

14. About once a week (more often if the water is very hard), use a heavy

duty cleaner to remove any mineral deposits or film left by hard water or

foods. Follow the supplier’s directions very carefully, and rinse the unit off

thoroughly, as soon as cleaning is finished.

15. If especially difficult cleaning problems persist, contact your cleaning

product supplier for help. The supplier has a trained technical staff with

laboratory facilities to serve you.

14 OM-BPM/BPP-E

Page 15

Maintenance

WARNING

ELECTRIC POWER ALWAYS SHOULD BE

SHUT OFF BEFORE WORK IS DONE ON

INTERNAL COMPONENTS.

WARNING

DISCONNECT ELECTRICAL POWER FROM

THE UNIT BEFORE ATTEMPTING TO GREASE

THE TRUNNION BEARINGS.

Your braising pan is designed to require minimum maintenance, but certain parts

may need replacement after prolonged use. After installation, no user adjustment

should be necessary. If a service need arises, only authorized personnel should

perform the work.

Service personnel should check the unit at least once a year. This periodic maintenance should include inspecting electrical wires and connections, cleaning the

inside of the control console, and possible adjustment of the pilot light. (Units with

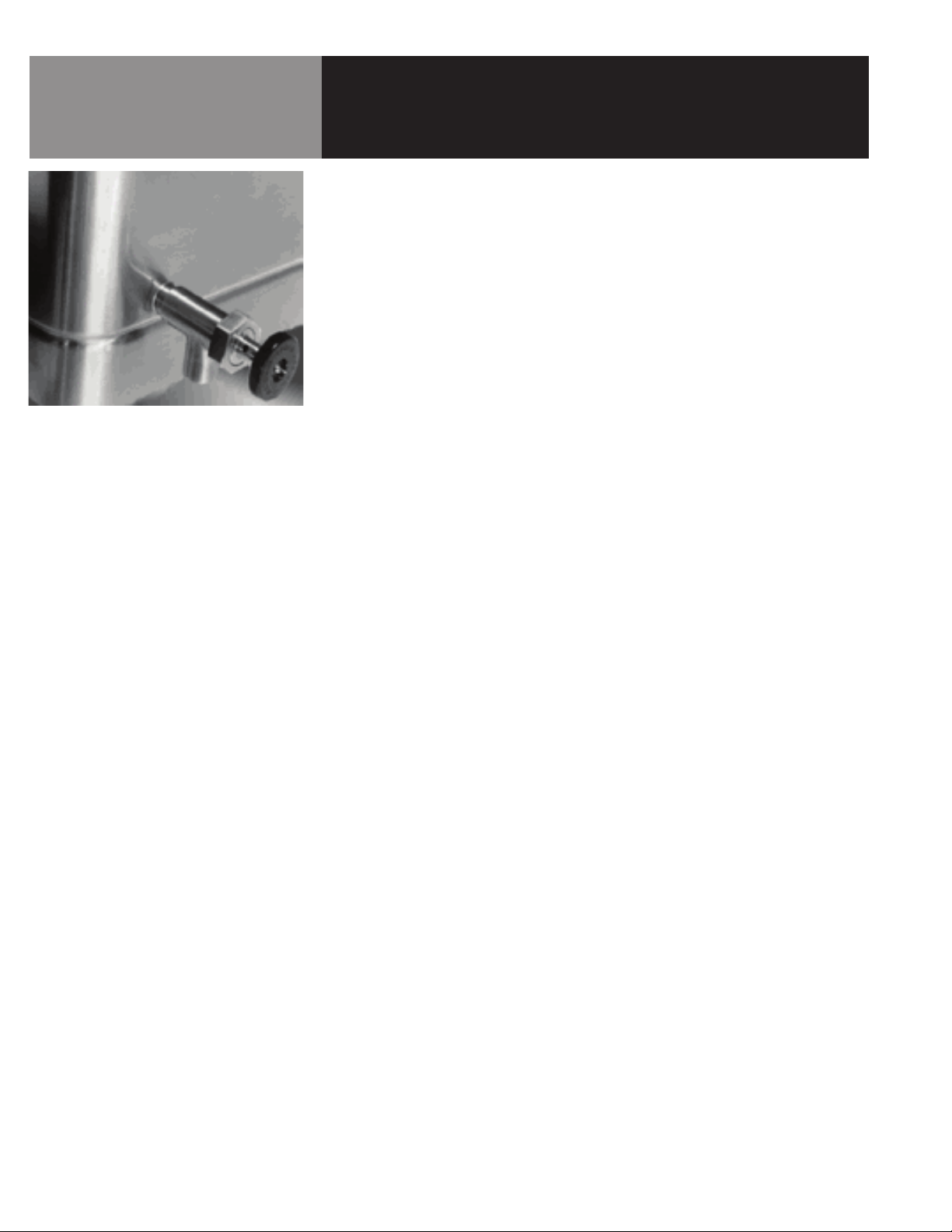

standing pilot ignition only) At least twice a year, grease the two trunnion bearings

and worm gear.

We recommend the use of number two grade LGI lithium grease. Add grease through

the zerk fittings on the gear hosing until grease flows out of the bearings around trunnion shaft. Also, add grease in the gear to cover arc that is in contact with the worm

gear. Clean up excess grease.

A Service Log is provided with the warranty information at the back of this manual.

Each time service is performed on your equipment, enter the date on which the work

was done, what was done, and who did it. Keep the manual with the equipment for

quick and easy reference.

OM-BPM/BPP-E 15

Page 16

Troubleshooting

Your braising pan will operate smoothly and efficiently if properly maintained. However, the following is a list of checks to make in

the event of a problem. If the actions suggested do not solve the problem, call your qualified Service Representative. If an item on

the list is followed by X, the work should only be performed by a qualified service representative.

WARNING

ELECTRICAL POWER MUST BE SHUT OFF BEFORE WORK IS DONE ON INTERNAL COMPONENTS.

USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY THE MANUFACTURER OR THEIR AUTHORIZED

DISTRIBUTOR CAN CAUSE INJURY TO THE OPERATOR AND DAMAGE TO THE EQUIPMENT AND WILL VOID ALL WARRANTIES.

SERVICE PERFORMED BY OTHER THAN FACTORY-AUTHORIZED PERSONNEL WILL VOID ALL WARRANTIES.

SYMPTOM WHO WHAT TO CHECK

(X indicates work that should only be performed by a qualified service representative)

Pan will not heat, but

indicator light comes on.

Pan will not heat, and

indicator light will not

light.

Pan continues to heat

after it reaches desired

temperature.

Pan does not reach

desired temperature.

Rapid clicking noise

(chattering).

Authorized

Service Rep Only

User a. That power supply is on.

Authorized

Service Rep Only

User a. Thermostat dial setting. Turn down if too high.

Authorized

Service Rep Only

User a. Thermostat dial setting. Turn up if too low.

Authorized

Service Rep Only

User a. For low voltage.

Authorized

Service Rep Only

a. Heating elements for short circuit. X

b. Fuses, accessible by removing caps on the side of the control box.

c. For loose or broken wires. X

d. Thermostat functioning, by listening for a click when the switch

opens or closes. X

e. Contactor functioning. X

b. Thermostat functioning. X

c. Thermostat calibration. X

d. Contactor, to determine if it is de-energized. X

b. Heating elements for ground short or open (burned out) element. X

c. Thermostat functioning, by listening for a click when the switch

opens or closes. X

d. Thermostat calibration. X

e. Contactor functioning. X

b. Contactor for dirt or corrosion on the contacts. X

Uneven cooking due

to “hot spots.”

Uneven cooking due

to “cold spots.”

Pan is hard to tilt

(Manual Tilt Models).

Pan will not tilt

(Power Tilt Models).

16 OM-BPM/BPP-E

User a. That the pan body is level.

Authorized

Service Rep Only

User a. Gears for foreign materials, lubrication and alignment.

User a. That electrical power supply is on.

Authorized

Service Rep Only

a. For open (burned out) heating element. X

b. For overheated actuator motor. Wait 15 minutes for motor to cool,

then operate the power tilt.

c. For blown fuse on motor control circuit - Replace fuse with approved

equal. X

d. For damaged DC rectier and operating relays. X

e. Correct setting of upper and lower limit switches. X

Page 17

Key Description Part #

1 CASTER KIT (SET OF 2 WITH

BRAKE AND 2 W/O BRAKE)

1 CASTER WITH BRAKE (W/O

FOOT ADAPTER)

1 CASTER WITHOUT BRAKE

(W/O FOOT ADAPTER)

NOT SHOWN

2 FOOT ADAPTER 146516

3 FLANGED FOOT

(W/O FOOT ADAPTER)

4 BULLET FOOT

(W/O FOOT ADAPTER)

5 FRICTION RING 146520

146354

146513

146515

146521

146628

Parts List

Stand & Foot Assembly

OM-BPM/BPP-E 17

Page 18

Key Qty Description Part #

1 1 COVER &

COUNTERBALANCE

ASSEMBLY,

15 GALLON

1 1 COVER &

COUNTERBALANCE

ASSEMBLY,

30 GALLON

1 1 COVER &

COUNTERBALANCE

ASSEMBLY,

40 GALLON

3 4 STUD WELD,

1/4”-20 X 1-1/4”

4 4 WASHER, LOCK 3/8” 005618

162232

162235

144812

145480

144453

144790

012589

Parts List

Cover & Counterbalance Assemblies

5 4 SCREW, HEX HEAD CAP

3/8”-16 X 1”

6 4 NUT, HEX 3/8”-16 005619

7 4 DOME NUTS, 1/4-20 090567

8 2 SCREW, TRUSS HEAD,

#10-32 X 3/8”

9 1 VENT COVER ASSY. MS17494

005612

004173

18 OM-BPM/BPP-E

Page 19

Parts List

8

9

17

13

3

5

18

1

2

20

21

OM-BPM/BPP-E 19

Page 20

Parts List

20 OM-BPM/BPP-E

Page 21

Parts List

To order parts, contact your Authorized Service Agent. Supply the model designation, serial number, part description, part number,

quantity, and when applicable, voltage and phase.

KEY DESCRIPTION PART NO.

1 STAND ASSEMBLY - 15 GAL 155725

1 STAND ASSEMBLY - 30 GAL 144848

1 STAND ASSEMBLY - 40 GAL 144332

2 PAN WELDMENT - 15 GAL 162573

2 PAN WELDMENT - 30 GAL 145654

2 PAN WELDMENT - 40 GAL 144789

3 KNOB THERMOSTAT 003908

4 OPERATING THERMOSTAT 002180

5 LIGHT, AMBER 116384

6 TILT SWITCH 143319

7 CONTACTOR 148102

8 GOUND TERMINAL 119829

9 TERMINAL BLOCK 003888

10 FUSE HOLDER 077854

11 FUSE, 3 AMP 077853

12 TRANSFORMER - 208/240V 137441

12 TRANSFORMER - 480V 137694

13 POWER SWITCH 155546

14 HIGH LIMIT THERMOSTAT 142755

15 ELEMENT - 208V 145656

15 ELEMENT - 240V 146185

15 ELEMENT - 480V 149114

16 COVER ELEMENT HOUSING - 15 GAL 162575

16 COVER ELEMENT HOUSING - 30 GAL 146186

KEY DESCRIPTION PART NO.

16 COVER ELEMENT HOUSING - 40 GAL 144343

17 RIGHT SIDE COVER 145688

18 LEFT TRUNNION COVER ASSEMBLY 144776

19 TILT SWITCH BRACKET ASSEMBLY 145689

20 CONTROL BOX ASSEMBLY 147313

21 ELECTRICAL BOX ASSEMBLY 147315

22 TERMINAL BLOCK BOX 146205

23 TERMINAL BLOCK BOX BOTTOM 146207

x TRANSFORMER, POWER TILT 480V 051469

x OVERLAY, MANUAL TILT 147305

x OVERLAY, POWER TILT 147307

x HARNESS, CONTROL 148538

x HARNESS, POWER 208/240V 148539

x HARNESS, POWER 480V 149291

x HARNESS, ELEMENTS 208/240V - 15 GAL 157600

x HARNESS, ELEMENTS 480V - 15 GAL 157607

x HARNESS, ELEMENTS 208/240V - 30 GAL 148560

x HARNESS, ELEMENTS 480V - 30 GAL 149293

x HARNESS, ELEMENTS 208/240V - 40 GAL 148561

x HARNESS, ELEMENTS 480V - 40 GAL 149292

x- Item not depicted/called out in drawing or photograph

OM-BPM/BPP-E 21

Page 22

Key Qty Description Part #

1 1 GEAR CARRIER 002624

2 1 SHAFT, HANDWHEEL 144834

3 1 GEAR, WORM 128001

4 1 GEAR SECTOR 009829

5 1 KEY GIB 012031

6 1 HANDWHEEL 139152

7 2 PIN ROLL 012614

8 2 SCREW SET SOCKET 012060

9 2 BEARING ROLLER 002790

10 2 BEARING SLEEVE 137239

11 1 PLUG PIPE 010286

14 1 FITTING GREASE 90

(NOT SHOWN)

15 1 BUSHING SNAP

(NOT SHOWN)

16 2 WASHER LOCK 005618

17 2 SCREW HEX HEAD CAP 005612

012195

000453

Parts List

Manual Tilt Assembly

22 OM-BPM/BPP-E

Page 23

Key Qty Description Part #

1 1 ELECTRIC TILT SHAFT 144791

2 1

3 1 SHAFT COUPLING 144615

4 1 GEAR CARRIER ASSY 137880

4a 1 CARRIER GEAR 002624

4b 2 BEARING ROLLER 002790

4c 2 BEARING SLEEVE 137239

4d 1 PLUG PIPE 010286

4e 1 FITTING GREASE 90 012195

5 1 GEAR, WORM 128001

6 1 GEAR SECTOR 009829

6a 2 SCREW SET SOCKET 012060

7 1 KEY GIB 012031

8 1 PIN ROLL 012614

9 1 MOTOR BRACKET 146114

10 1 REAR MOTOR BRACKET 146117

11a 1 FUSE HOLDER [MOTOR] 077840

11b 1 FUSE 144856

11c 1 RECTIFIER 145660

11d 2

12 5 NUT HEX HEAD 1/4”-20 005601

13 5 WASHER LOCK 1/4” 005655

14 3

15 2 SCREW HEX HEAD CAP 005609

16 2 WASHER LOCK 3/8” 005618

17 2

18 1

- 1 HOLE PLUG-1” 146369

- 1

- 1

- 2

- 1

- 1

POWER LIFT MOTOR

[204/240 VOC]

RELAY [24VAC, DPST,

N0]-2 REQ’D

SCREW HEX HEAD CAP

1/4”-20 X 2-1/2” LONG

SCREW HEX HEAD CAP

3/8”-16 X 1” LONG

ELECTRIC TILT SHAFT KEY

MANUAL OVERRIDE

CRANK

POWER TILT SWITCH,

RECESSED ROCKER NO

INDICATOR

TILT LIMIT SWITCH

(POWER TILT UP/DN )

WIRE HARNESS,LOW

VOLTAGE

WIRE HARNESS-HIGH

VOLTAGE

144794

119814

052584

005612

013386

145659

144857

002982

146197

148769

Parts List

Power Tilt Assembly

OM-BPM/BPP-E 23

Page 24

Schematics

15 Gallon Manual Tilt

TERMINAL BLOCK

208/240/440/480 VAC

[TB]

3 PHASE

SUPPLY

BLK

COM

24

L1

L2L1

X2

RED

BLK

RED

CONNECT APPROPRIATE TRANSFORMER

LEAD TO MAIN VOLTAGE LINE

208

240

24

VAC

24COM

GRN/YEL

BLU

GRN/YEL

L3

L3

X1

TRANSFORMER

[XFMR]

YEL

BLK

RED

YEL

GND

BLK

TERMINAL BLOCK

[TB]

208/240 VAC

1 PHASE

SUPPLY

X1

L1

L2 XL2

L1

L2 X

X2

RED

YEL

208/240V

YEL

BLK

K1

L1

T1

T2

T3

RED

L2

YEL

BLK

L3

480V

B

A

H1

H4

H2

H5

H3

H6

K2

L1

T1

BLK

L2

T2

RED

YEL

T3

L3

K1

L1

T1

BLK

BLK

BLK

RED

L2

T2

YEL

BLK

T3

L3

K2

L1

T1

BLK

L2

T2

RED

YEL

T3

L3

B

A

H1

H4

RED

H2

H5

H3

H6

480

440/480 V

OPTION

24

VAC

8

2

R

7

3

A

F1

B

BLU

24 OM-BPM/BPP-E

HL

NC C

HEAT LAMP

A

[OT]

BLU

BLU

NC C

BLU

[TS]

NO C

K2

BLU

A B

K1

BA

157598 REV. A

Page 25

Schematics

30 Gallon Manual Tilt

TERMINAL BLOCK

[TB]

208/240/480 VAC

3 PHASE

SUPPLY

BLK

COM

L3/X

X2

L3/X

X1

BLK

RED

GND

BLK

RED

YEL

A

B

K2

L1

T1

L2

T2

BLK

RED

H1

H3

H5

H2

H4

RED

YEL

K1

L1

T1

L2

T2

208/240V

RED

YEL

L2

L1

L2

L1

RED

TERMINAL BLOCK

[TB]

208/240 VAC

1 PHASE

SUPPLY

X1

L1

L2 X

L1

L2 X

X2

H6

YEL

L3 T3

YEL

H7

H8

BLK

BLK

L3T3

H9

REDBLK

CONNECT APPROPRIATE TRANSFORMER

LEAD TO MAIN VOLTAGE LINE

A

B

240 208

TRANSFORMER

24

24

GRN/YEL

[XFMR]

VAC

24COM

YEL

480

480 V

24

OPTION

VAC

H1

H3

H5

H2

H4

H6

H7

H8

K2

L1

T1

BLK

L2

RED

YEL

L3

BLK

T2

BLK

BLK

T3

K1

L1

T1

RED

L2

T2

YEL

BLK

T3

L3

480V

H9

BLU

GRN/YEL

8

2

R

7

3

HEAT LAMP

A

F1

B

BLU

HL

NC C

[OT]

BLU BLU

C

NC

BLU

[TS]

NO C

A B

K2

BLU

A

A B

K1

148535 REV. B

OM-BPM/BPP-E 25

Page 26

Schematics

30 Gallon Power Tilt (208/240V)

TERMINAL BLOCK

[TB]

208/240

3 PHASE

SUPPLY

TRANSFORMER

[XFMR]

L3/X

X2

L3/X

X1

GND

BLK

RED

YEL

A B

K2 K1

H1

L1 L2

VAC

L1 L2

BLK

RED

TERMINAL BLOCK

[TB]

208/240

1 PHASE

SUPPLY

L2

L1

VAC

X1

X

L2L1

X

X2

H3

BLK

L1

T1

BLK

H5

T1

L1

REDRED

H2

RED

L2

T2

RED

H4

YEL

T2

L2

YEL

H6

YEL

T3L3

YEL

BLK

BLK

L3T3

H7

H8

H9

CONNECT APPROPRIATE TRANSFORMER

LEAD TO MAIN VOLTAGE LINE

COM

FUSE

F2

A

BRN

208240

BR1

B

PURPL

BRN

RECTIFIER

24

VAC

24

24COM

RELAY

[C1]

8 6

4 2

8 6

RELAY

[C2]

24

RED

BLK

LIFT MOTOR

208/240 VOLT

M

8

2

R

7

3

A

BLU

MOTOR SWITCH

26 OM-BPM/BPP-E

BLU

[TS]

NO C

BLU

A B

K1

[OT]

B

F1

BLU

NC C

A

HL

BLU

NC C

BRN

1

2

YEL

3

K2

A B

C1

C2

BA

ORG

RED

BA

HEAT LAMP

'UP' LIMIT

SWITCH (NC)

'DOWN' LIMIT

SWITCH (NC)

148536 REV. B

Page 27

Schematics

SWITCH (NC)

30 Gallon Power Tilt (480V)

TERMINAL BLOCK

[TB]

480 VAC

3 PHASE

SUPPLY

BLK

BLK

L1

L3/X

L2

L3/X

L2L1

X1

X2

RED

RED

CONNECT APPROPRIATE TRANSFORMER

LEAD TO MAIN VOLTAGE LINE

480 V

GND

BLK

RED

YEL

115 V

TERMINAL BLOCK

[TB]

480 VAC

1 PHASE

SUPPLY

X1

B

A

H1

H3

H5

BLK

L1

K2

T1

BLK

T1

K1

L1

RED

L1

L1

L2

L2

X

X

X2

H2

H4

RED

L2

T2

BLK

T2

L2

YEL

H6

YEL

L3

T3

BLK

T3

L3

BLK

H7

H8

H9

RECTIFIER

F2

BRN

B

A

BR1

PURPLE

COM

480

8

4

8

RELAY

TRANSFORMER

24

VAC

24

8

2

[XFMR]

24COM

[C2]

2

6

4

RELAY

[C1]

2

6

BLK

M

LIFT MOTOR

115 VOLT

RED

R

7

3

BLU

B

A

F1

2

MOTOR SWITCH

[OT]

BLU

NC C

HL

NC

C

BRN

1

YEL

3

BLU

BLU

[TS]

NO C

K2

A

C1

A B

C2

B

A

K1

BLU

A

BA

ORG

B

RED

HEAT LAMP

'UP' LIMIT

SWITCH (NC)

'DOWN' LIMIT

148537 REV. B

OM-BPM/BPP-E 27

Page 28

Schematics

40 Gallon Manual Tilt

TERMINAL BLOCK

[TB]

208/240/480 VAC

3 PHASE

SUPPLY

BLK

COM

TERMINAL BLOCK

[TB]

208/240 VAC

1 PHASE

SUPPLY

X1

L1

L2 XL2

L1

L2 X

X2

RED

X2

GND

L3

L3

X1

BLK

RED

YEL

BLK

RED

YEL

B

A

H1

K2

L1

T1

BLK

L2

T2

RED

H3

H5

H7

H2

H4

RED

H6

YEL

T3

L3

H8

YEL

BLK

K1

L1

T1

L2

T2

T3

L3

208/240V

RED

YEL

BLK

L1

L2L1

H9

H10

H11

H12

BLK

RED

CONNECT APPROPRIATE TRANSFORMER

LEAD TO MAIN VOLTAGE LINE

208

240

TRANSFORMER

24

24

GRN/YEL

BLU

[XFMR]

VAC

24COM

YEL

GRN/YEL

480

480 V

OPTION

24

VAC

B

A

H1

H3

H5

H7

H2

H4

H6

H8

H9

H10

H11

H12

K2

L1

T1

BLK

L2

T2

RED

YEL

T3

L3

K1

L1

T1

BLK

BLK

BLK

RED

L2

T2

YEL

BLK

T3

L3

480V

8

2

R

7

3

A

F1

B

BLU

HL

NC C

28 OM-BPM/BPP-E

HEAT LAMP

A

A B

K1

148540 REV. B

[OT]

BLU

BLU

NC C

BLU

[TS]

NO C

K2

BLU

BA

Page 29

Schematics

40 Gallon Power Tilt (208/240V)

TERMINAL BLOCK

[TB]

208/240

3 PHASE

SUPPLY

TRANSFORMER

[XFMR]

L3/X

X2

L3/X

X1

BLK

GND

L1

BLK

RED

YEL

K2

T1

BLK

B

A

H1

H3

H5

H7

RED

T1

K1

L1

RED

L2

L1

VAC

L2L1

BLK

RED

TERMINAL BLOCK

[TB]

208/240

1 PHASE

SUPPLY

L1

L2 X

VAC

L1

L2 X

X1

X2

H2

RED

L2

T2

RED

H4

YEL

T2

L2

YEL

H6

YEL

L3

T3

YEL

H8

BLK

T3

L3

BLK

H9

H10

H11

COM

CONNECT APPROPRIATE TRANSFORMER

LEAD TO MAIN VOLTAGE LINE

FUSE

F2

A

BRN

240

208

BR1

B

PURPL

RECTIFIER

24

VAC

24

24COM

BRN

H12

RELAY

[C1]

4 2

8 6

4

826

RELAY

[C2]

RED

BLK

LIFT MOTOR

208/240 VOLT

M

8

R

7

F1

BLU

2

3

A

B

HL

NC

MOTOR SWITCH

2

[OT] [TS]

BLU BLU

NC C

BLU

C

BRN

1

YEL

3

NO C

A

K2

A

C1

A

C2

HEAT LAMP

A

BLU

A B

K1

B

'UP' LIMIT

ORG

B

RED

B

SWITCH (NC)

'DOWN' LIMIT

SWITCH (NC)

148541 REV. A

OM-BPM/BPP-E 29

Page 30

Schematics

SWITCH (NC)

40 Gallon Power Tilt (480V)

TERMINAL BLOCK

[TB]

480 VAC

3 PHASE

SUPPLY

BLK

BLK

L1 L2

L1X2L2

RED

L3/X

GND

L3/X

X1

RED

CONNECT APPROPRIATE TRANSFORMER

LEAD TO MAIN VOLTAGE LINE

480 V

BLK

RED

YEL

A

115 V

TERMINAL BLOCK

[TB]

480 VAC

1 PHASE

SUPPLY

X1

L1

L1

L2

L2

X

X

X2

B

H1

H3

H5

H7

BLK

L1

K2

T1

BLK

T1

K1

L1

RED

H2

H4

RED

L2

T2

BLK

T2

L2

YEL

H6

H8

YEL

L3 T3

BLK

T3 L3

BLK

H9

H10

H11

H12

RECTIFIER

F2

BRN

B

A

BR1

PURPLE

COM

480

24

VAC

24

8

24COM

2

R

7

3

B

A

BLU

F1

2

MOTOR SWITCH

30 OM-BPM/BPP-E

TRANSFORMER

[XFMR]

BLU

NC

1

3

HL

BRN

YEL

[OT]

NC C

C

BLU

BLU

RELAY

[C2]

[TS]

NO C

A

K2

A

C1

A

C2

8

2

6

4

RELAY

[C1]

2

6

BLK

M

LIFT MOTOR

115 VOLT

8

4

RED

A B

K1

BLU

A

B

ORG

B

RED

B

HEAT LAMP

'UP' LIMIT

SWITCH (NC)

'DOWN' LIMIT

148542 REV. B

Page 31

Service Log

Model No: Purchased From:

Serial No: Location:

Date Purchased: Date Installed:

Purchase Order No: For Service Call:

Date Maintenance Performed Performed By

OM-BPM/BPP-E 31

Page 32

1055 Mendell Davis Drive • Jackson MS 39272

888-994-7636 • 601-372-3903 • Fax 888-864-7636

unifiedbrands.net

© 2013 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of Dover Corporation.

PART NUMBER 148727, REV. E (04/13)

Loading...

Loading...