Groen BPM-30G, BPM-40G Operation Manual

OPERATOR/SERVICE MANUAL

IMPORTANT INFORMATION, KEEP FOR OPERATOR

This manual provides information for:

MODELS

BPM-30/40G(CE) International

ECLIPSE™ ERGONOMIC

TILTING BRAISING PAN

· Stainless Steel

· Manual Tilt

· Gas Heated

READ, UNDERSTAND AND FOLLOW THE INSTRUCTIONS AND

WARNINGS CONTAINED IN THIS MANUAL.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

POST IN A PROMINENT LOCATION

Instructions to be followed in the event user smells gas.

This information shall be obtained by consulting your

local gas supplier. As a minimum, turn off the gas and

call your gas company and your authorized service agent.

Evacuate all personnel from the area.

WARNING

Improper installation, adjustment, alteration, service or

maintenance can cause property damage, injury or death.

Read the installation, operating and main

thoroughly before installing or servicing this equipment.

NOTIFY CARRIER OF DAMAGE AT ONCE

It is the responsibility of the consignee to inspect the container upon receipt of

same and to determine the possibility of any damage, including concealed damage. Unified Brands suggests that if you are suspicious of damage to make a

notation on the delivery receipt. It will be the responsibility of the consignee to file

a claim with the carrier. We recommend that you do so at once.

tenance instructions

.ECNEREFER ERUTUF ROF DENIATER EB TSUM LAUNAM SIHT

Manufacture Service/Questions 888-994-7636.

Information contained in this document is known to be current and accurate at the time

of printing/creation. Unified Brands recommends referencing our product line websites,

unifiedbrands.net, for the most updated product information and specifications.

PART NUMBER 160812, REV. E (11/08)

PART NUMBER 160812, REV. C (06/07)

1055 Mendell Davis Drive

Jackson, MS 39272

888-994-7636, fax 888-864-7636

groen.com

IMPORTANT — READ FIRST — IMPORTANT

THESE APPLIANCES MUST BE INSTALLED BY A COMPETENT PERSON IN CONFORMITY WITH THE

INSTALLATION AND SERVICING INSTRUCTIONS AND NATIONAL REGULATIONS IN FORCE AT THE TIME.

PARTICULAR ATTENTION MUST BE PAID TO THE FOLLOWING:

I. E. E. REGULATIONS FOR ELECTRICAL INSTALLATIONS

ELECTRICITY AT WORK REGULATIONS

GAS SAFETY (INSTALLATION & USE REGULATIONS

HEALTH AND SAFETY AT WORK ACT

FIRE PRECAUTIONS ACT

LOCAL AND NATIONAL BUILDING REGULATIONS

DETAILED RECOMMENDATIONS ARE CONTAINED IN INSTITUTE OF GAS ENGINEERS PUBLISHED

DOCUMENTS: IGE/UP/1, IGE/UP/2, BS6173 AND BS5440.

THESE APPLIANCES HAVE BEEN CE-MARKED ON THE BASIS OF COMPLIANCE WITH THE GAS

APPLIANCE DIRECTIVE, EMC AND LOW VOLTAGE DIRECTIVE FOR THE COUNTRIES, GAS TYPES AND

PRESSURES AS STATED ON THE DATA PLATE.

WARNING: TO PREVENT SHOCKS, ALL APPLIANCES WHETHER GAS OR ELECTRIC, MUST BE

EARTHED.

ON COMPLETION OF THE INSTALLATION, THESE INSTRUCTIONS SHOULD BE LEFT WITH THE

ENGINEER-IN-CHARGE FOR REFERENCE DURING SERVICING. FURTHER TO THIS, THE USERS

INSTRUCTIONS SHOULD BE HANDED TO THE USERS AND THE INSTALLER SHOULD INSTRUCT THE

RESPONSIBLE PERSON(S) IN THE CORRECT OPERATION AND MAINTENANCE OF THE APPLIANCE.

EMPHASIS SHOULD BE MADE WITH REGARD TO SAFE OPERATION OF DRAIN VALVE.

IT IS MOST IMPORTANT THAT THESE INSTRUCTIONS BE CONSULTED BEFORE INSTALLING AND

COMMISSIONING THE APPLIANCE. FAILURE TO COMPLY WITH THE SPECIFIED PROCEDURES MAY

RESULT IN DAMAGE OR THE NEED FOR A SERVICE CALL.

CAUTION: SHIPPING STRAPS ARE UNDER TENSION AND CAN SNAP BACK WHEN CUT.

CAUTION: UNIT WEIGHS 420 TO 560 LB. (165 TO 255 KG). FOR SAFE HANDLING, INSTALLER

SHOULD OBTAIN HELP AS NEEDED, OR EMPLOY APPROPRIATE MATERIALS HANDLING

EQUIPMENT (SUCH AS A FORKLIFT, DOLLY, OR PALLET JACK) TO REMOVE THE UNIT

FROM THE SKID AND MOVE IT TO THE PLACE OF INSTALLATION.

WARNING: INSTALLATION OF THE BRAISING PAN MUST BE DONE BY PERSONNEL QUALIFIED TO

WORK WITH GAS AND ELECTRICITY. IMPROPER INSTALLATION CAN RESULT IN INJURY

TO PERSONNEL AND/OR DAMAGE TO EQUIPMENT.

WARNING: THIS UNIT IS DESIGNED FOR COMMERCIAL USE. NEVER USE HOME OR RESIDENTIAL

GRADE GAS CONNECTIONS. THEY DO NOT MEET GAS CODES AND COULD BE

HAZARDOUS.

DANGER: ELECTRICALLY GROUND THE UNIT AT THE TERMINAL PROVIDED. FAILURE TO GROUND

UNIT COULD RESULT IN ELECTROCUTION AND DEATH.

WARNING: KEEP THE APPLIANCE AREA FREE AND CLEAR OF COMBUSTIBLE MATERIALS.

CAUTION: BE SURE ALL OPERATORS READ, UNDERSTAND AND FOLLOW THE OPERATING

INSTRUCTIONS, CAUTIONS AND SAFETY INSTRUCTIONS CONTAINED IN THIS MANUAL.

CAUTION: KEEP FLOORS IN BRAISING PAN WORK AREA CLEAN AND DRY. IF SPILLS OCCUR,

CLEAN IMMEDIATELY TO AVOID THE DANGER OF SLIPS OR FALLS.

WARNING: WHEN TILTING BRAISING PAN FOR PRODUCT TRANSFER:

1) USE CONTAINER DEEP ENOUGH TO CONTAIN AND MINIMIZE PRODUCT SPLASHING.

2) PLACE CONTAINER ON STABLE, FLAT SURFACE, AS CLOSE TO PAN AS POSSIBLE.

2 OM/SM-BPM-G

3) STAND TO SIDE OF PAN WHILE POURING — NOT DIRECTLY IN POUR PATH OF HOT

CONTENTS.

4) RETURN PAN BODY TO LEVEL POSITION AFTER CONTAINER IS FILLED OR

TRANSFER IS COMPLETE.

5) DO NOT OVER FILL CONTAINER. AVOID DIRECT SKIN CONTACT WITH HOT

CONTAINER AND ITS CONTENTS.

WARNING: DO NOT HEAT AN EMPTY PAN FOR MORE THAN 5 MINUTES AT A SETTING HIGHER

THAN 300ºF (150ºC).

WARNING: IF THE PAN CONTAINS ITEMS IN SAUCE OR MELTED FAT, THEY CAN SLIDE FORWARD

SUDDENLY DURING TILTING AND CAUSE THE HOT LIQUID TO SPLASH OUT.

WARNING: AVOID ALL DIRECT CONTACT WITH HOT FOOD OR WATER IN THE PAN. DIRECT

CONTACT COULD RESULT IN SEVERE BURNS.

WARNING: IT IS RECOMMENDED THAT WATER AND SOLUTIONS BE KEPT OUT OF CONTROLS AND

BURNERS. DO NOT USE HIGH PRESSURE SPRAY DIRECTLY ON THE CONTROL CONSOLE,

ELECTRICAL CONNECTIONS AND BURNERS. USE A GARDEN HOSE SPRAY CONNECTED

TO CITY WATER SUPPLY.

CAUTION: MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES, MUCOUS MEMBRANES AND

CLOTHING. PRECAUTIONS SHOULD BE TAKEN TO WEAR RUBBER GLOVES, GOGGLES

OR FACE SHIELD AND PROTECTIVE CLOTHING. CAREFULLY READ THE WARNINGS AND

FOLLOW THE DIRECTIONS ON THE LABEL OF THE CLEANER TO BE USED.

WARNING: BEFORE REPLACING ANY PARTS, DISCONNECT THE UNIT FROM THE ELECTRIC POWER

SUPPLY AND CLOSE THE MAIN GAS COCK. ALLOW FIVE MINUTES FOR UNBURNED GAS

TO VENT. FAILURE TO DISCONNECT COULD RESULT IN ELECTROCUTION AND DEATH.

CAUTION: USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY GROEN OR

AUTHORIZED DISTRIBUTORS CAN CAUSE INJURY TO THE OPERATOR AND DAMAGE TO

THE EQUIPMENT AND WILL VOID ALL WARRANTIES.

IMPORTANT: Service performed by other than factory authorized personnel will void all warranties.

OM/SM-BPM-G 3

Table of Contents

IMPORTANT OPERATOR WARNINGS (READ FIRST) ............................................. 2

REFERENCES ............................................................................. 4

EQUIPMENT DESCRIPTION ................................................................. 5

1. INSTALLATION ......................................................................... 7

2. ASSEMBLY AND COMMISSIONING ........................................................10

3. SERVICING AND CONVERSION .......................................................... 12

4. USER INSTRUCTIONS .................................................................. 17

5. CLEANING ........................................................................... 19

6. SAFETY PRECAUTIONS ................................................................ 20

7. MAINTENANCE ........................................................................ 20

8. TROUBLESHOOTING ................................................................... 21

9. PARTS LIST .......................................................................... 23

10. SERVICE LOG ........................................................................ 35

References

Canadian Standards Association

8501 East Pleasant Valley Rd.

Cleveland, Ohio 44131

Z83-11 Gas FoodService Equipment

Z223.1 National Fuel Gas Code

American National Standards Institute

1403 Broadway

New York, New York 10018

Canadian Gas Association

55 Scarsdale Road

Don Mills, Ontario M3B 2 R3

National Fire Protection Association

60 Battery March Park

Quincy, Massachusetts 02269

NFPA/54 Installation of Gas Appliances &

Gas Piping

NFPA/70 The National Electrical Code

NFPA/96 Ventilating Hoods

National Sanitation Foundation

3475 Plymouth Road

Ann Arbor, Mic

higan 48106

Underwriters Laboratories, Inc.

333 Pfingsten Road

Northbrook, Illinois 60062

NSF INTERNATIONAL

789 N. Dixboro Rd.

P.O. Box 130140

Ann Arbor, Michigan 48113-0140

4 OM/SM-BPM-G

Equipment Description

The following dimensions apply to CE model BPM braising pans:

Model Width Depth Height Weight (Kg)

BPM-30G 984 mm 1010 mm 1100 mm 190

BPM-40G 1226 mm 1010 mm 1100 mm 255

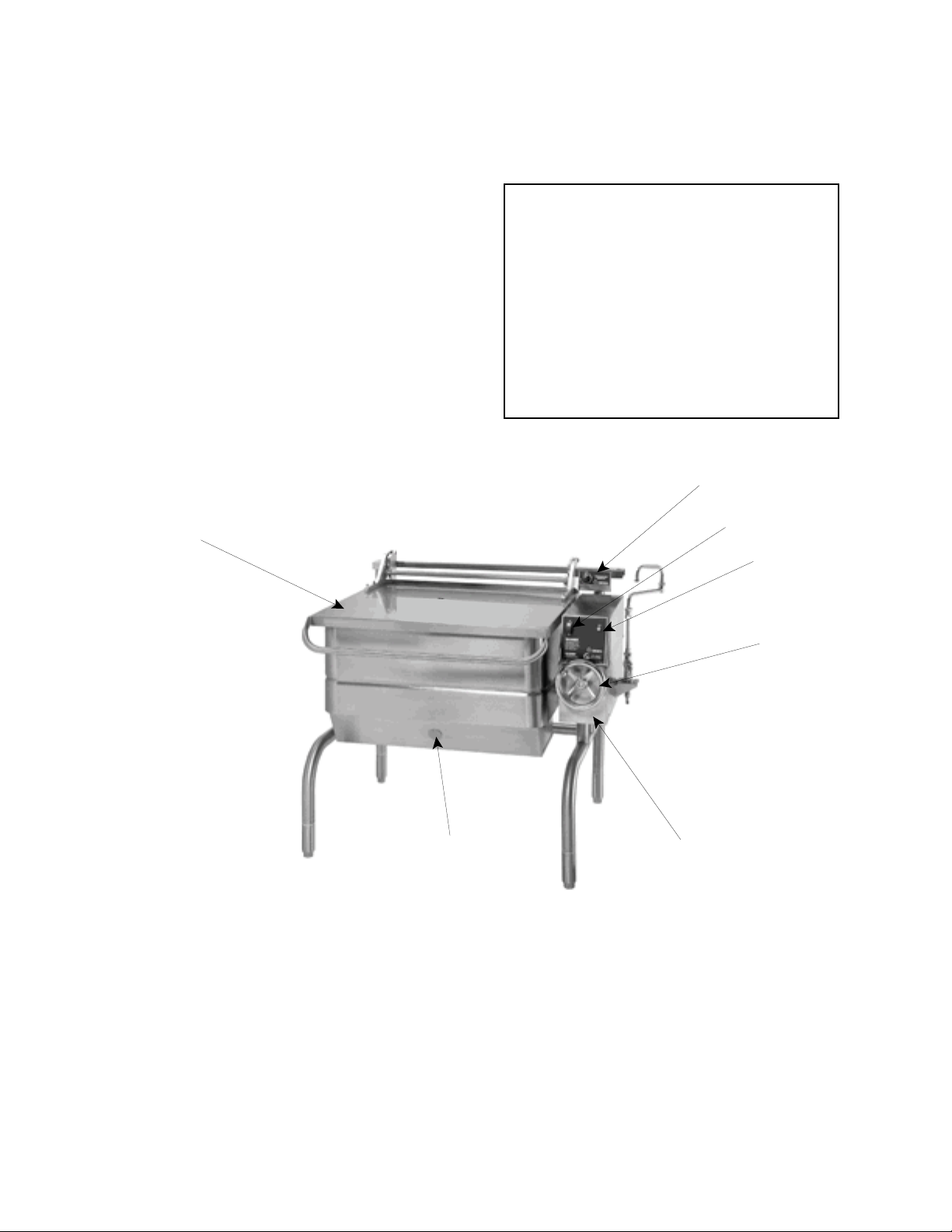

Groen™ Gas-HeatedEclipse™ Ergonomic Tilting

Braising Pans provide a stainless steel pan

equipped with patented heat transfer fins,

burner/combustion chamber, hand-operated or

electric powered tilting mechanism, thermostatic

controls, and hi nged cover. Eclipse serves as

braising pan, griddle, fry pan, oven, kettle, bainmarie and food warmer/server, can be adapted

for use as a non-pressure steamer and can be

used to stir-fry, reheat and saute foods.

The pan body is made from heavy-duty stainless

steel welded into one solid piece, with a polished

interior and exterior. A pouring lip is welded to the

front wall. The cooking surface is a stainless steel

clad plate fitted

with welded heat transfer fins

which assureuniform heat transfer over the entire

surface. The gas burner/combustion chamber

supplies the heat.

Aneasily operatedworm andgear mechanism tilts

the pan and provides precise control for pouring or

dumping thecontents of the pan. This hand-wheel

controlled mechanism is located in a stainless

steel consoleto the right of thepan body. Toassist

cleaning, the panbody can be tilted past the

vertical position. When the pan is tilted, the

burners shut off automatically.

The thermostat provides automatic control of

cooking temperature. Operating the thermostat

dial on the front of the control console turns the

heat on or off and s

ets the pan temperature.

A vented,heavy gauge, one-piece, stainless steel

cover with a condensate drip shield on the rear

edge is standard on the Braising Pan. A fully

enclosed, torsion bar type counterbalance

provides easy operation to open the cover and to

maintain it open at any position. The coveropens

to theback and is hingedto theframe, so itmoves

independently of the pan body.

The braising pan ismounted onan open-leg frame

fabricated from tubular stainless steel. It has an

ignitionsystem that uses electronic spark ignition.

Options available with these models are:

1. Fill faucet with swingspout. (Leftor rightmounted)

- specify single or double pantry

2. Fill faucet with 48" or 60" spray hose assembly

(left or right mounted) - s

pecify single or double

pantry

3. Flanged Feet

4. Fold-down work tray (pan support) mounted on

right side.

5. 2” Tangent draw-off (Factory-installed must be

indicated on initial order)

6. Steamer Insert set.

7. Steamer Pan Carrier.

8. Pouring Lip Strainer.

9. Strainer for 2" TDO valve.

Optional Tangent Draw-Off

OM/SM-BPM-G 5

OM-BPM-G

ThermostatThermostat

Power

Switch

Cover

Indicator

Light

Manual Tilt

Handwheel

Stainless Steel

Console

The unit will arrive completely assembled,

on a heavy skid, in a heavy cardboard carton.

Immediately upon receipt, inspect the carton

for damage. Report any apparent shipping

damage or an incorrect shipment to the

delivery agent.

When installation is to begin, get someone to

assist in removing the carton. Lift it straight up

and away from the unit. Do not simply raise it

and push backwards - it could damage the unit.

Write down the model number, serial number,

and installation date of your unit, and keep

this information for future reference. Space for

these entries is provided at the top of the

Service Log in this manual.

Cut the straps holding the unit on the skid, and lift

the unit straight up off the skid.

CAUTION

SHIPPING STRAPS ARE UNDER TENSION

AND CAN SNAP BACK WHEN CUT.

UNIT WEIGHS 420 TO 560 LB (190 TO 255

KG). FOR SAFE HANDLING, INSTALLER

SHOULD OBTAIN HELP AS NEEDED, OR

EMPLOY APPROPRIATE MATERIALS

HANDLING EQUIPMENT (SUCH AS A

FORKLIFT, DOLLY, OR PALLET JACK) TO

REMOVE THE UNIT FROM THE SKID AND

MOVE IT TO THE PLACE OF INSTALLATION.

The unit is strapped to a skid, and shipped in a heavy cardboard carton.

(Shown is model BPM-40G with optional right side mounted, double pantry faucet assembly.)

Flame Observation

Port

Inspection & Unpacking

6 OM/SM-BPM-G

1. Installation

The following information pertains to the CE model BPM-G, and replaces or augments the information provided in

OM-BPM. These appliances must be installed by a competent person in conformity with the installation and

servicing instructions and national regulations in force at the time. Particular attention must be paid to the

following:

I. E. E. Regulations for Electrical Installations

Electricity at Work Regulations

Gas Safety (Installation & Use Regulations

Health and Safety at Work Act

Fire Precautions Act

Local and National Building Regulations

Detailed recommendations are contained in institute of gas engineers published documents: IGE/UP/1, IGE/UP/2,

BS6173 AND BS5440.

OM/SM-BPM-G 7

1.1

1.1.1

1.1.2

1.1.3

1.1.4

1.1.5

Installing Clearances

Vertical clearance of at least 1000 mm should be

allowed between the top edge of the flue outlet and

any overlying surface.

Adequate ventilation, whether natural or

mechanically induced, must be provided to ensure a

supply of fresh air for gas combustion, and to

facilitate effective removal of the products of

combustion.

Ventilation recommendations for catering appliances

are provided in BS 5440 : 2. Furthermore, guidance

on the column of ventilation air required for different

types of catering equipment to ensure sufficient

room ventilation is provided at right.

For multiple installations, the requirements for

individual appliances should be added together.

Installation should be made in accordance with local

and national regulations applying at the time. A

competent installer must be employed.

The appliance flue discharges horizontally from the

1.1.7

The gas connection for a unit on casters must be made

with a quick-disconnect device that complies with

ANSI Z21.41 - CSA 6.9.

1.1.6

For a unit on casters, the installation shall be made with

a connector that complies with the standard for

Connectors for Moveable Gas Appliances, ANSI Z21.69

- CSA 6.16. Restrain movement of the unit by attaching

a cable or chain to the eyelet provided at the back of

the frame and anchor the cable or chain to the wall or

floor. Make the length and location of the cable such

that the unit cannot pull on the gas connection while

the cable is connected or quick-disconnect.

rear of the unit. It must not be directly connected to

any flue, mechanical extraction system, ducting, etc.,

which leads to the outside of the building. The

appliance is best discharged under an open canopy

connected with a ventilating system.

1.2 Gas Supply

Incoming service must be of sufficient size to supply

full rate without excessive pressure drop. A gas

meter is connected to the service pipe by the gas

supplier.

Any existing meter should be checked by the

supplier to ensure that the meter has the capacity for

passing the required rate of gas for the braising pan

in addition to any other gas equipment installed.

EQUIPMENT

Ventilation Rate Required

m³/min ft³/min

Range, Unit Type 17 600

Pastry Oven 17 600

Fryer 26 900

Grill 17 600

Steak Grill 26 900

Boiling Pan 17 600

Steamer 17 600

Sterilizing Sink 14 500

Bain-Marie 11 400

Tea/Coffee Machine 8.5-14 300-500

The appliance governor is incorporated in the gas

control valve which is situated in the left control

cabinet. The control valve governor is suitable for

both natural and propane gases without conversion.

Installation pipework should be fitted in compliance

with IEGE/UP/2. The pipework should not be smaller

than the gas inlet connection (Rp½ [½” B.S.P.]).

An isolating cock must be located close to the

appliance to allow shut-down during emergencies or

service. Installation must be tested for gas

soundness and purged as specified in IGE/UP/1.

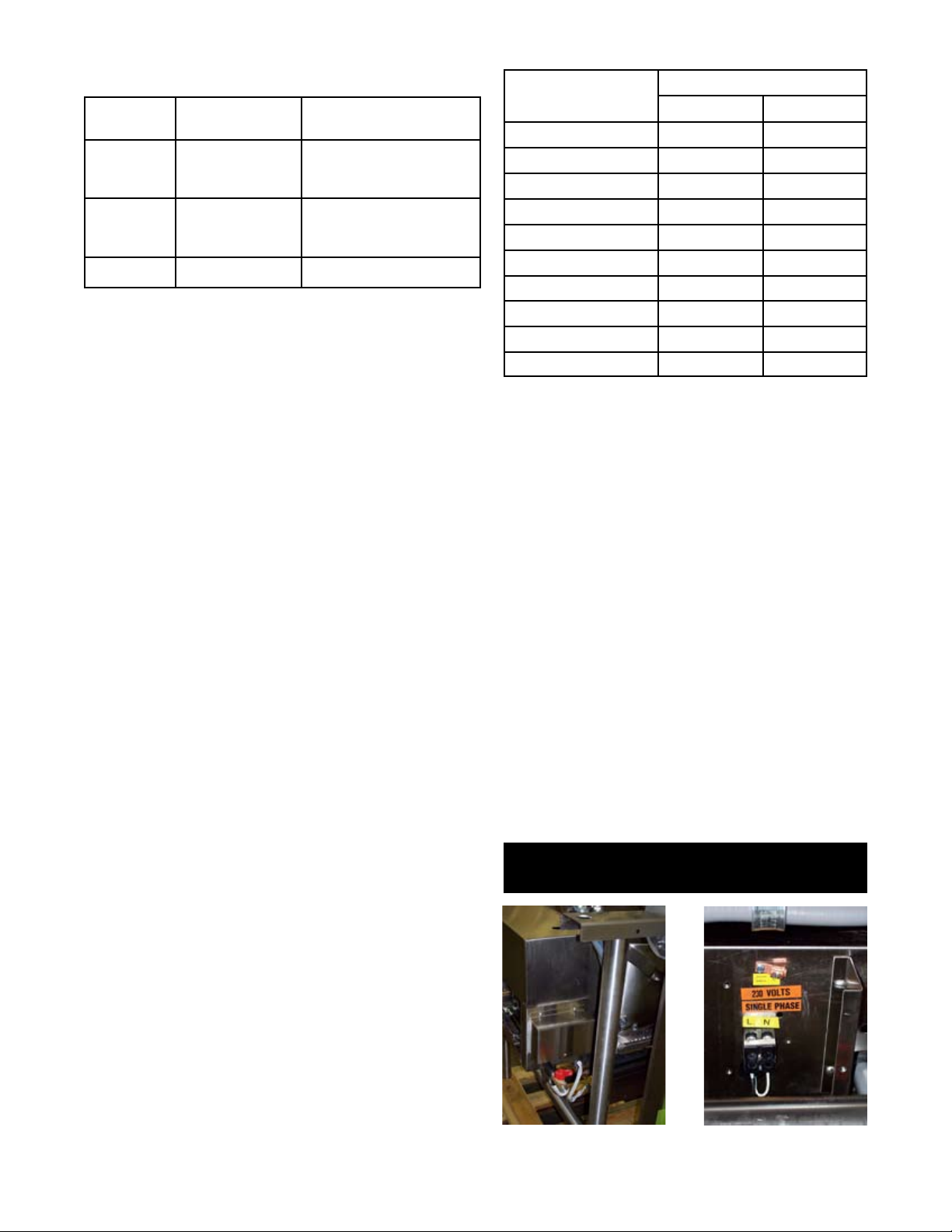

1.3 Electrical Supply

This unit is designed for connection to fixed wiring.

A suitably rated isolating switch with contact

separation of at least three millimeters on both poles,

must be fitted to the installation.

The wiring must be executed in accordance with

Power supply to this unit must be 230V, 1 Phase, 50/60hz

with wiring suitable for an electronic load of 50 watts.

the regulations listedinside the cover page of this

manual supplement.

Cable entry is at the control box on the rear right side

of the appliance. Access to the terminals is gained by

removing terminal block cover.

WARNIN

G

THIS APPLIANCE MUST BE EARTHED.

Minimum

Clearances

Recommended

Clearances

Left Side 0mm

0mm

77mm

51mm (2”) for service,

153mm (6”) when faucet is

installed on left side

Right Side

305-405mm (12-16”),

153mm (6”) when faucet is

installed on right side

Rear

305mm (12") for service

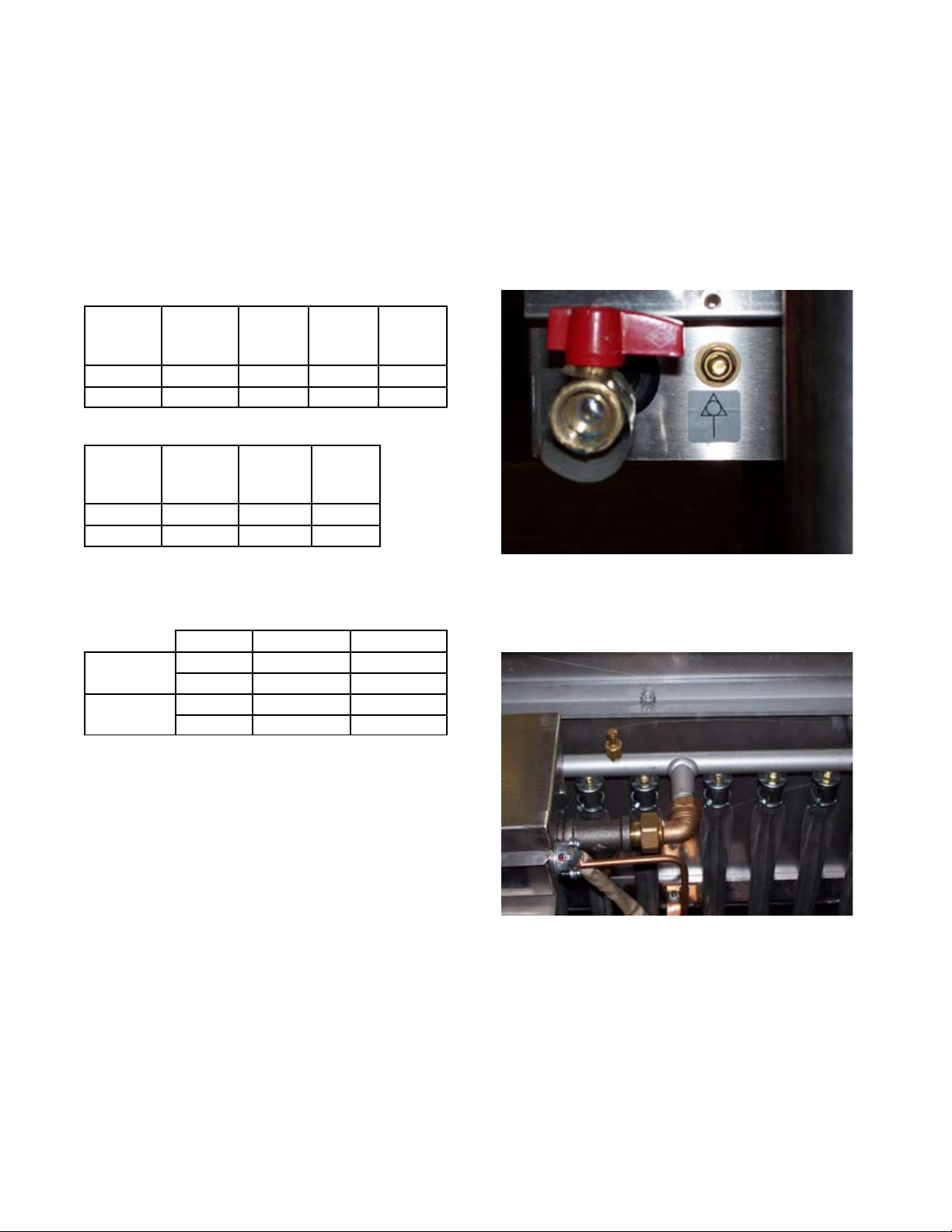

Fig. 1 Fig. 2

8 OM/SM-BPM-G

Gas is connected at the rear of the control

console.

1.4 Water Supply

Not applicable to these appliances ezcept for

optional faucets..

1.5 Gas System Performance

The tables below provide the total Gas Rates,

Injector Diameters and Pressure Adjustments for

model BPM-G (CE) using natural (G20) and

propane (G31) gas sources.

Total Gas Rate

Model

Natural

(G20)

KW

Natural

BTU/hr

Propane

(G31)

KW

Propane

BTU/hr

BPM-30G

26.1 89,100 26.1 89,100

BPM-40G

36.1 123,300 36.1 123,300

Injector Diameters-Natural & Propane Gas

Model

Natural

Gas G20

(mm)

Propane

Gas G31

(mm)

No. of

Orifices

(Injectors)

BPM-30G

1.5 0.97 11

BPM-40G

1.5 0.97 15

Gas Pressure Adjustment

A pressure test point is fitted on the burner manifold

and on the gas control valve.

Model BPM-30G BPM-40G

NATURAL

GAS G20

mbar 8.0 8.0

in. WC 3.2 3.2

PROPANE

GAS G31

mbar 19.4 19.4

in. WC 7.8 7.8

NOTE: With reference to the gas rate, pressure

adjustments and conversions, this appliance is

CE-approved for use with the following gases:

a) Gas Category I2H, G20 natural gas may be

supplied to the appliance in Austria, Denmark,

Finland, Greece, Iceland, Italy, Luxembourg,

Norway, Portugal, Spain, Sweden, Switzerland

and the United Kingdom.

b) Gas Category I3P, G31 propane gas may be

supplied to the appliance in Germany, Ireland,

the Netherlands, Portugal, Spain, Switzerland

and the United Kingdom.

Use of the appliance with non-approved gases in a

listed country, or use in other countries will void CE

certification.

1.6 Burner Adjustment

The burner primary airflow may be adjusted by

loosening the screw and sliding the aerator forward

or backward. (See photograph)

Fig. 3

Fig. 4

OM/SM-BPM-G 9

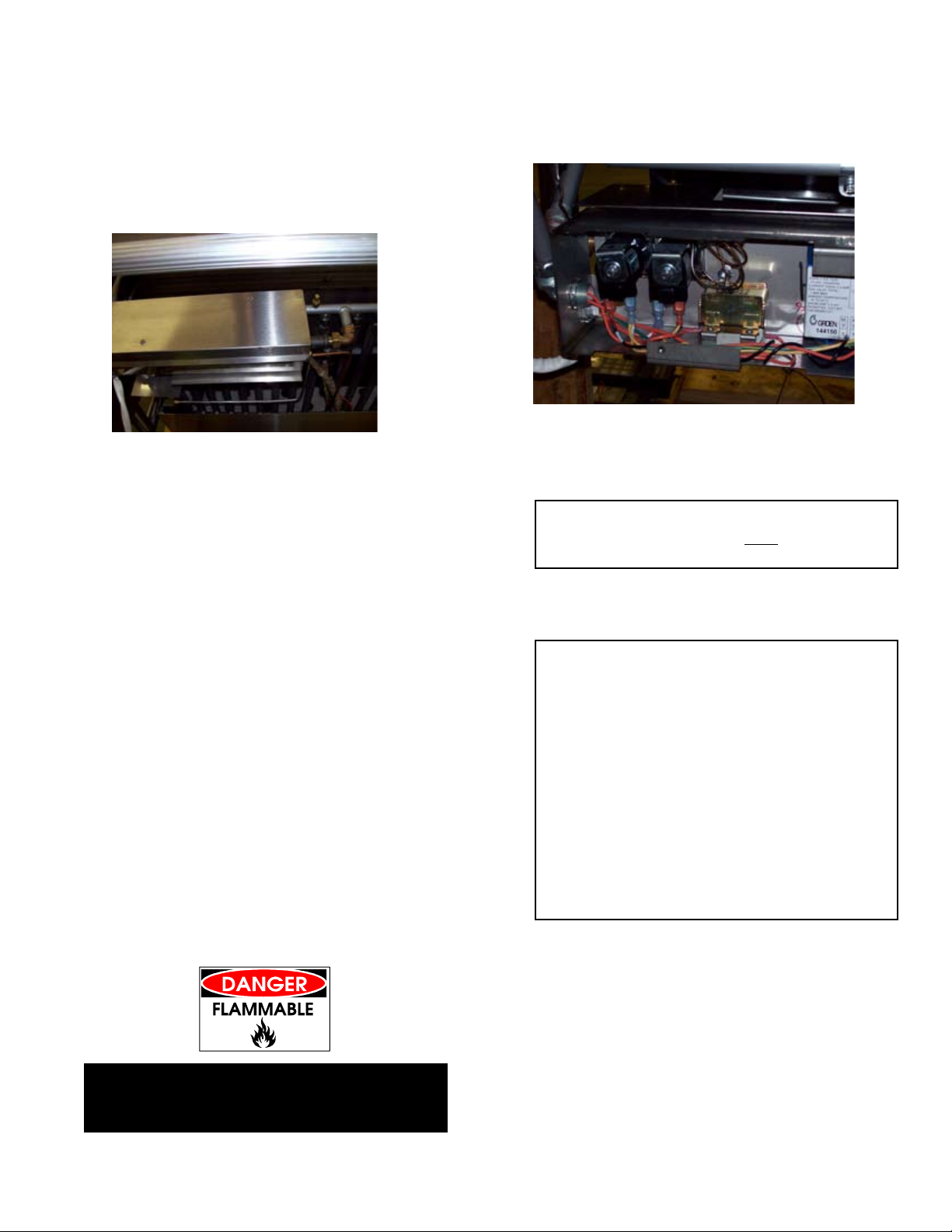

Main (Lower) Control Box

Upper Control Box

Connect a gauge to check pressure at the gas

manifold.

2. Assembly and Commissioning

2.1 Electrical Supply

Before commissioning the appliance, ensure that the

electrical installation has been performed in

compliance with relevant regulations. See

Paragraph 1.3, above.

WARNING

THIS APPLIANCE MUST BE EARTHED.

2.2 Pre-Commissioning Check

a) Remove literature and packing materials from

the interior and exterior of the unit.

b) Put enough water into the pan to cover the

c) Verify that the rear heat shield panel is in place.

bottom to a depth of 6-12mm. With the pan

body in the horizontal position, note how the

water lies in the pan, to confirm that the pan was

leveled properly during installation.

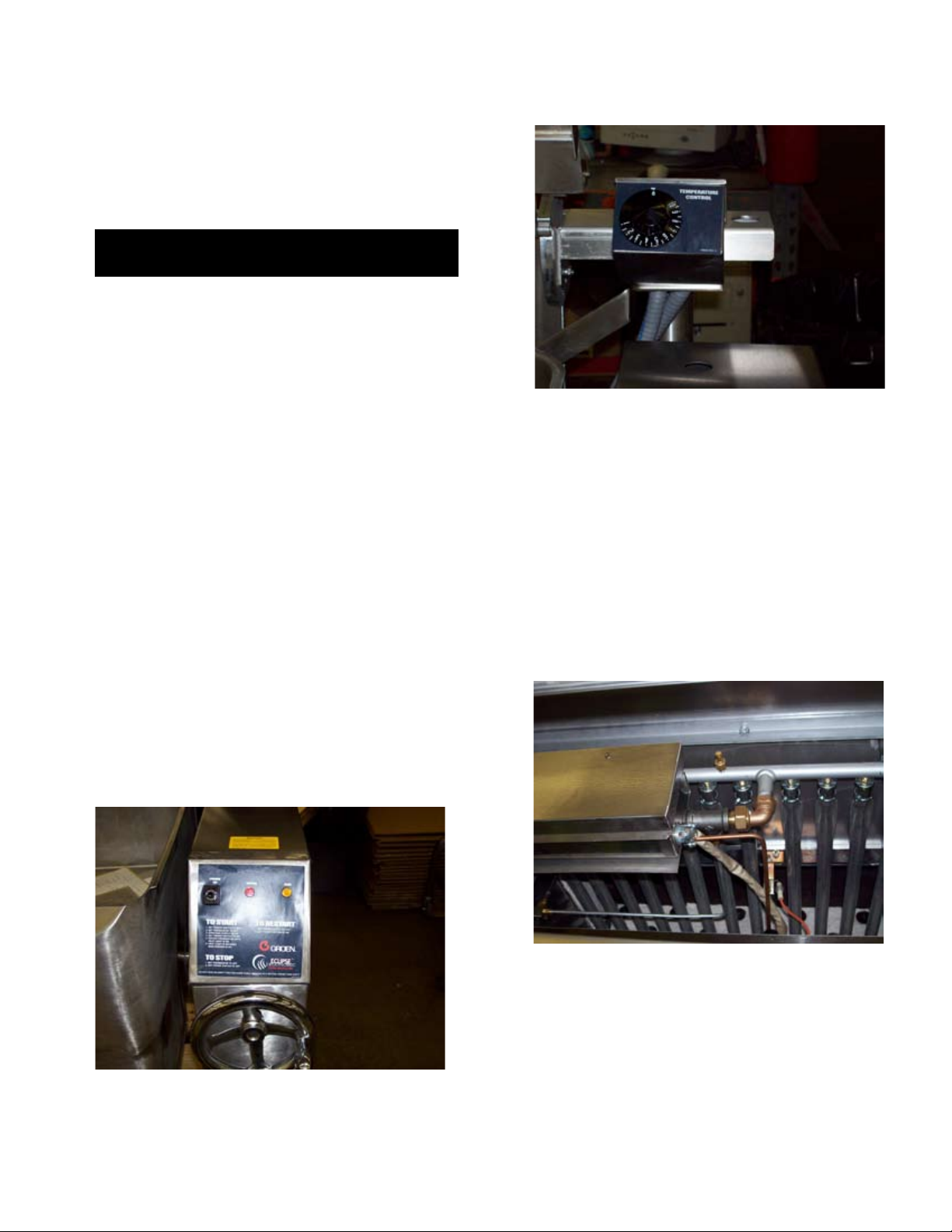

2.3 Operating the Braising Pan

2.3.1 Lighting Sequence

a) Put water in the pan (6 to 12 mm deep)

b) Check that gas and electricity mains are on.

c) Turn the toggle switch (Main Control Box) to the

“ON” position. The power neon (Main Control

Box) will illuminate.

d) Turn the thermostat (Upper Control Box) to the

desired setting.

e) Observe that the burners light by the lighting of

the heat neon (Main Control Box) (approximately

10-15 seconds).

f) Should the unit fail to light, turn the unit off and

wait for one or two minutes before attempting to

switch it on again. NOTE: Burner “ON” verification

can be confirmed by careful observation through

the Flame Observation Port. See Illustration on

page 6 of this manual for location of this port.

g) Repeat steps b through e.

h) To switch off the unit, put the toggle switch in the

Off position.

i) Turn gas and electricity mains off.

2.3.2 Setting the Gas Pressure

a) During commissioning, a gas pressure check is

essential. Connect a suitable pressure gauge to

the gas manifold to perform this test. The

pressure gauge should be connected to the test

nipple (See photograph above).

b) Turn the gas and electricity mains on.

Fig. 5

Fig. 7

Fig. 6

10 OM/SM-BPM-G

Adjust flow by turning the screw on the gas valve

governor.

c) Light the burners as described in Paragraph

2.3.1, above.

d) Manifold gas pressure should be as noted in

Section 1.5 of the manual. If adjustment is

necessary, follow steps e through j, below.

e) Remove the screws which secure the ignition

module cover and remove the ignition module

cover panel. See Fig. 8.

f) Remove the governor cap screw on the gas

control valve to gain access to the screw inside

the turret. (See photograph at right)

g) The governor is suitable for both natural and

propane gas.

h) Turn the screw inside the turret clockwise to

increase the pressure, anti-clockwise to reduce

it. Check the burner pressure again after 15

minutes operation, and adjust if necessary.

i) Disconnect the pressure gauge from the test

point. Reseal the test point and test for gas

soundness.

j) Replace governor cap screw, and replace

control box panel and lid.

2.3.3 Checking Performance of Controls

a) Light the unit as described in Paragraph 2.3.1,

above. Check that the controls produce a healthy

spark from the electrode to the earthing post,

and that ignition is smooth and without delay.

b) Turn the thermostat off and then on. Check that

the burners go out when the thermostat is turned

off, and that they reignite smoothly when it is

switched back on. Repeat several times.

c) Fill the pan with unused oil up to the mark in the pan.

WARNING

DO NOT OVERFILL WITH OIL OR FIRE MAY

RESULT!

d) Set the thermostat knob at “10" and allow the oil

to heat up. Immerse a thermometer or

thermocouple 25 mm below the oil surface at the

center of the pan. Check that the temperature

stabilizes at 190ºC, (± 5ºC).

CAUTION

THE TEMPERATURE MUST NOT

EXCEED 200ºC

OR THE HIGH LIMIT THERMOSTAT WILL TRIP.

e) If the unit fails to operate as described, the unit

should be serviced by an Engineer.

IMPORTANT

These appliances must be installed by a competent

person in conformity with the installation and

servicing instructions and national regulations in

force at the time. Particular attention must be paid

to the following:

I. E. E. Regulations for Electrical Installations

Electricity at Work Regulations

Gas Safety (Installation & Use Regulations

Health and Safety at Work Act

Fire Precautions Act

Local and National Building Regulations

Detailed recommendations are containedin institute

of gas engineers published documents: IGE/UP/1,

IGE/UP/2, BS6173 AND BS5440.

2.4 Instructions to Installer

IMPORTANT: After installing and commissioning

the appliance, the User’s Instructions should be

handed to the user or purchaser. Ensure that the

instructions for lighting, turning off, correct use

and cleaning are properly understood.

Emphasize the location of the main gas isolating

valve and demonstrate the emergency shut

down procedure.

Fig. 8

Fig. 9

OM/SM-BPM-G 11

Loading...

Loading...