DUST COLLECTOR

MODEL G1032

INSTRUCTION MANUAL

COPYRIGHT © 1992 BY GRIZZLY INDUSTRIAL

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

REVISED NOVEMBER, 1997. PRINTED IN USA

DISCONTINUED MACHINE MANUAL DISCLAIMER

THE INFORMATION IN THIS MANUAL REPRESENTS THE LAST CONFIGURATION OF THE MACHINE BEFORE IT WAS DISCONTINUED. MACHINE CON-

FIGURATIONS MAY HAVE CHANGED AS PRODUCT IMPROVEMENTS WERE INCORPORATED. IF YOU OWN AN EARLIER VERSION OF THE MACHINE,

THIS MANUAL MAY NOT EXACTLY DEPICT YOUR MACHINE . CONTACT CUSTOMER SERVICE IF YOU HAVE ANY QUESTIONS ABOUT DIFFERENCES.

PREVIOUS VERSIONS ARE NOT AVAILABLE ONLINE.

-B- G1032 Dust Collector

WARNING

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement, and

other masonry products.

• Arsenic and chromium from chemically treated

lumber.

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such

as those dust masks that are specially designed to filter out microscopic particles.

G1032 Dust Collector -1-

Table Of Contents

PAGE

1. SAFETY ....................................................................................................................2

SAFETY RULES FOR ALL TOOLS ....................................................................2

ADDITIONAL SAFETY INSTRUCTIONS FOR DUST COLLECTORS................3

2. CIRCUIT REQUIREMENTS...................................................................................... 4

G110 VOLT WIRING............................................................................................4

GROUNDING ......................................................................................................4

3. GENERAL INFORMATION ...................................................................................... 5

UNPACKING ........................................................................................................6

PIECE INVENTORY ............................................................................................6

SITE CONSIDERATIONS ....................................................................................7

4. ASSEMBLY .............................................................................................................. 8

BEGINNING ASSEMBLY ....................................................................................8

BASE ....................................................................................................................8

SUPPORT COLUMN............................................................................................9

FAN / MOTOR......................................................................................................9

COLLECTOR......................................................................................................10

BAGS..................................................................................................................10

5. OPERATIONS..........................................................................................................11

TEST RUN..........................................................................................................11

SET UP ..............................................................................................................11

MOBILE ..............................................................................................................12

STATIONARY ....................................................................................................12

SYSTEM GROUNDING ....................................................................................13

7. MAINTENANCE ......................................................................................................14

GENERAL ..........................................................................................................14

LUBRICATION ..................................................................................................14

8. CLOSURE................................................................................................................15

PARTS BREAKDOWN AND PARTS LISTS ......................................................16

MACHINE DATA ................................................................................................17

WARRANTY AND RETURNS............................................................................18

WARRANTY CARD............................................................................................19

-2- G1032 Dust Collector

WARNING: For Your Own Safety Read

Instruction Manual Before Operating Collector

Safety Instructions For Power Tools

These safety rules cannot cover every situation in a work shop. Consider your conditions when setting up

or operating your dust collector.

SECTION 1: SAFETY

a) Always wear eye protection.

b) Always keep guards in place and in proper

operating condition.

c) Keep hands away from inlet during opera-

tion.

9. USE PROPER EXTENSION CORD. Make

sure your extension cord is in good condition. When using an extension cord, be sure

it is rated Hard Service (grade S) or better.

Conductor size must be 16 A.W.G. for cords

up to 100 feet in length. An undersized cord

will cause a drop in line voltage resulting in

loss of power and overheating. Your extension cord must also contain a ground wire

and plug pin. Always repair or replace

extension cords if they become damaged.

Minimum Gage for extension cord:

16 A.W.G. 50ft

16 A.W.G. 100ft

14 A.W.G. 200ft

12 A.W.G. 300ft

10. WEAR PROPER APPAREL Do not wear

loose clothing, gloves, neckties, rings,

bracelets, or other jewelry which may get

caught in moving parts. Non-slip footwear is

recommended. Wear protective hair covering

to contain long hair.

11. ALWAYS USE SAFETY GLASSES. Also

use face or dust mask if cutting operation is

dusty. Everyday eyeglasses only have

impact resistant lenses, they are NOT safety

glasses.

1. KEEP GUARDS IN PLACE and in working

order.

2. REMOVE ADJUSTING KEYS AND

WRENCHES. Form habit of checking to see

that keys and adjusting wrenches are

removed from tool before turning on.

3. KEEP WORK AREA CLEAN. Cluttered

areas and benches invite accidents.

4. DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use power tools in damp or

wet locations, or expose them to rain. Keep

work area well lighted.

5. KEEP CHILDREN AND VISITORS AWAY.

All children and visitors should be kept a

safe distance from work area.

6. MAKE WORK SHOP CHILD PROOF with

padlocks, master switches, or by removing

starter keys.

7. DON’T FORCE TOOL. It will do the job bet-

ter and safer at the rate for which it was

designed.

8. USE RIGHT TOOL. Don’t force tool or

attachment to do a job for which it was not

designed.

G1032 Dust Collector -3-

Additional Safety Instructions For Dust Collectors

17. DON’T OVERREACH. Keep proper footing

and balance at all times.

18. CHECK FOR DAMAGED PARTS. Before

further use of the tool, a guard or other part

that is damaged should be carefully checked

to determine that it will operate properly and

perform its intended function-check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any

other conditions that may affect its operation.

A guard or other part that is damaged should

be properly repaired or replaced.

19. DIRECTION OF FEED. Feed work into a

blade or cutter against the direction of rotation of the blade or cutter only.

20. NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don’t leave

tool until it comes to a complete stop.

4. Problems concerned with any moving part(s)

or accessories must be investigated and corrected with the power disconnected and after

everything has come to a complete stop.

5. DO NOT allow steel to strike against steel

which may produce a spark. Sparks can smolder in wood dust for a long time before fire or

flame is detected. If metal contacts metal during operation, immediately turn off the dust

collector, unplug the power cord from the outlet or throw the disconnect and wait for all

moving parts to stop. Remove collection bags

and empty the dust into an approved air tight

metal container in case of spark and remedy

the metal to metal contact problem before

resuming operation.

6. When emptying dust from the collection bags,

wear a respirator and safety glasses. Empty

dust into an approved container and dispose

of properly.

1. This dust collector is to be used for wood dust

collection only. DO NOT use this dust collec-

tor to pick up liquids and metal scrap including

nails and filings. Metallic debris will contact

the spinning impeller and could spark. The

spark could then cause a sawdust explosion

and severe fire hazard. Also, DO NOT pick up

material which cannot safely pass through the

impeller such as solid wood scraps.

2. DO NOT place your hands or tools near the

open inlet during operation for any reason

including unclogging material and testing suc-

tion. The impeller could cause serious dam-

age to body parts if touched while spinning.

3. Suspended dust particles in conjunction with

an ignition source may cause an explosion.

DO NOT operate the dust collector in areas

where explosion risks would be high if dust

were dispersed into the area. Areas of high

risk include areas near pilot lights and/or open

flames.

12. SECURE WORK. Use clamps or a vise to

hold work when practical. It’s safer than

using your hand and frees both hands to

operate tool.

13. MAINTAIN TOOLS WITH CARE. Keep tools

sharp and clean for best and safest performance. Follow instructions for lubricating and

changing accessories.

14. DISCONNECT TOOLS before servicing and

changing accessories, such as blades, bits,

cutters, and the like.

15. REDUCE THE RISK OF UNINTENTIONAL

STARTING. Make sure switch is in off posi-

tion before plugging in.

16. USE RECOMMENDED ACCESSORIES.

Consult the owner’s manual for recommended accessories. The use of improper accessories may cause risk of injury.

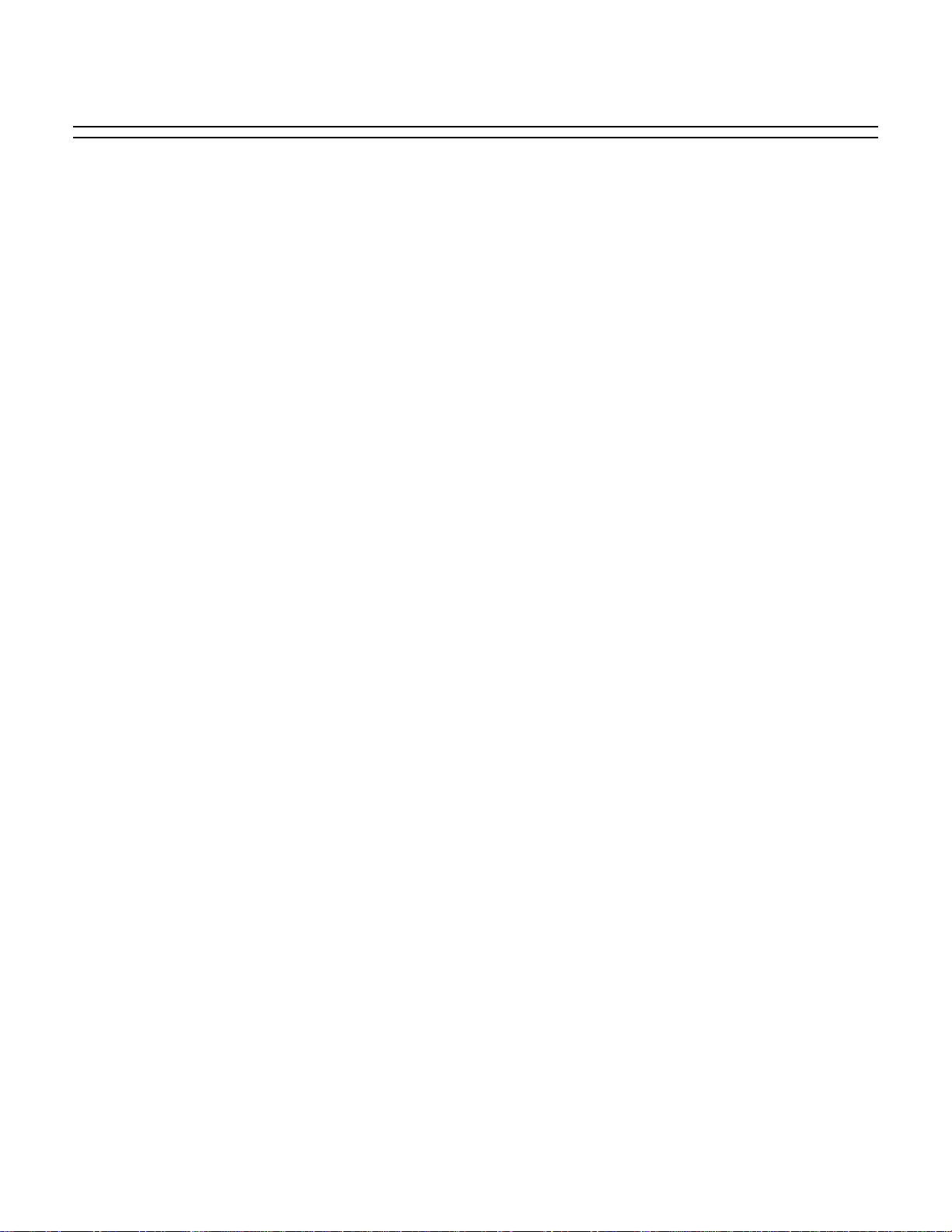

Figure 1.

Improper connections of the electrical-grounding

conductor can result in risk of electric shock. The

conductor with green or green and yellow striped

insulation is the electrical-grounding conductor. If

repair or replacement of the electric cord or plug

is necessary, do not connect the equipment

grounding conductor to a live terminal.

Under no circumstances should the grounding

pin from any three-pronged plug be removed. If it

will not fit the outlet, have the proper outlet

installed by a qualified electrician.

Check with a qualified electrician or one of our

service personnel if the grounding instructions

are not completely understood, or if in doubt as to

whether the tool is properly grounded. Use only

3-wire extension cords that have 3-prong grounding type plugs and 3-hole receptacles that accept

the tool’s plug. FIgure 1.

Repair or replace damaged or worn cord immediately.

-4- G1032 Dust Collector

110V Wiring

Your Model G1032 Dust Collector operates ideally at 110V, single phase power. The 1 HP motor

will draw roughly 8 amps at 110 volts. These

loads are not excessive, but if you operate your

machine on any circuit that is already close to

capacity, it might blow a fuse or trip a circuit

breaker. If an unusual load does not exist, and

power failure still occurs, consult a qualified electrician. Otherwise, consider a dedicated circuit for

your machine.

A 110V plug is provided with the G1032.

In the case of 220V operation, please call the

service department for further information.

Grounding

CAUTION: THIS TOOL MUST BE GROUNDED

WHILE IN USE TO PROTECT THE OPERATOR

FROM ELECTRIC SHOCK.

In the event of a malfunction or breakdown,

grounding provides a path of least resistance for

electric current to reduce the risk of electric

shock. This tool is equipped with an electric cord

having an equipment-grounding conductor. The

grounding conductor must be connected to the

grounding pin on the plug. The plug must be

plugged into a matching outlet that is properly

installed and grounded in accordance with all

local codes and ordinances.

SECTION 2: CIRCUIT REQUIREMENTS

G1032 Dust Collector -5-

Grizzly Industrial, Inc. is proud to offer the Model

G1032 Dust Collector. This dust collector is a part

of Grizzly’s growing family of fine machinery.

When used according to the guidelines set forth

in this manual, you can expect years of troublefree, enjoyable operation and proof of Grizzly’s

commitment to customer satisfaction.

The G1032 Dust Collector is the smallest stand

up model in our broad line of dust collectors.

Standard features for the dust collector includes a

push button switch, cyclone collector, and two

large filter/collection bags. The G1032 has a 1 HP

motor which is pre-wired for 110/120V and a 4"

intake port. Air movement is 450 cubic feet per

minute with a static pressure of 2.76". We also

offer a full line of optional accessories to build a

collection system for a single machine or a complete shop including a two-stage adapter and a

dust collection reference book. All accessories

are offered through the current Grizzly catalog.

We are also pleased to provide this manual for

the Model G1032. It was written to guide you

through assembly, review safety considerations,

and cover general operating procedures. It represents our latest effort to produce the best documentation possible. If you have any criticisms that

you feel we should address in our next printing,

please write to us at the Bellingham, WA address

at the end of this section.

SECTION 3: GENERAL INFORMATION

Most important, we stand behind our machines.

We have excellent regional service departments

at your disposal should the need arise. If you

have any service questions or parts requests,

please call or write to us at the location listed

below.

Grizzly Industrial, Inc.

1203 Lycoming Mall Circle

Muncy, PA 17756

Phone:(570) 546-9663

Fax:(800) 438-5901

E-Mail: techsupport@grizzly.com

Web Site: http://www.grizzly.com

To comment on this manual write to:

Grizzly Industrial, Inc.

C

⁄O Technical Documentation

P.O. Box 2069

Bellingham, WA 98227

To operate this or any power tool safely and efficiently, it is essential to become as familiar with it

as possible. The time you invest before you begin

to use your Model G1032 will be time well spent.

DO NOT operate this machine until you are com-

pletely familiar with the contents of this manual.

Loading...

Loading...