Page 1

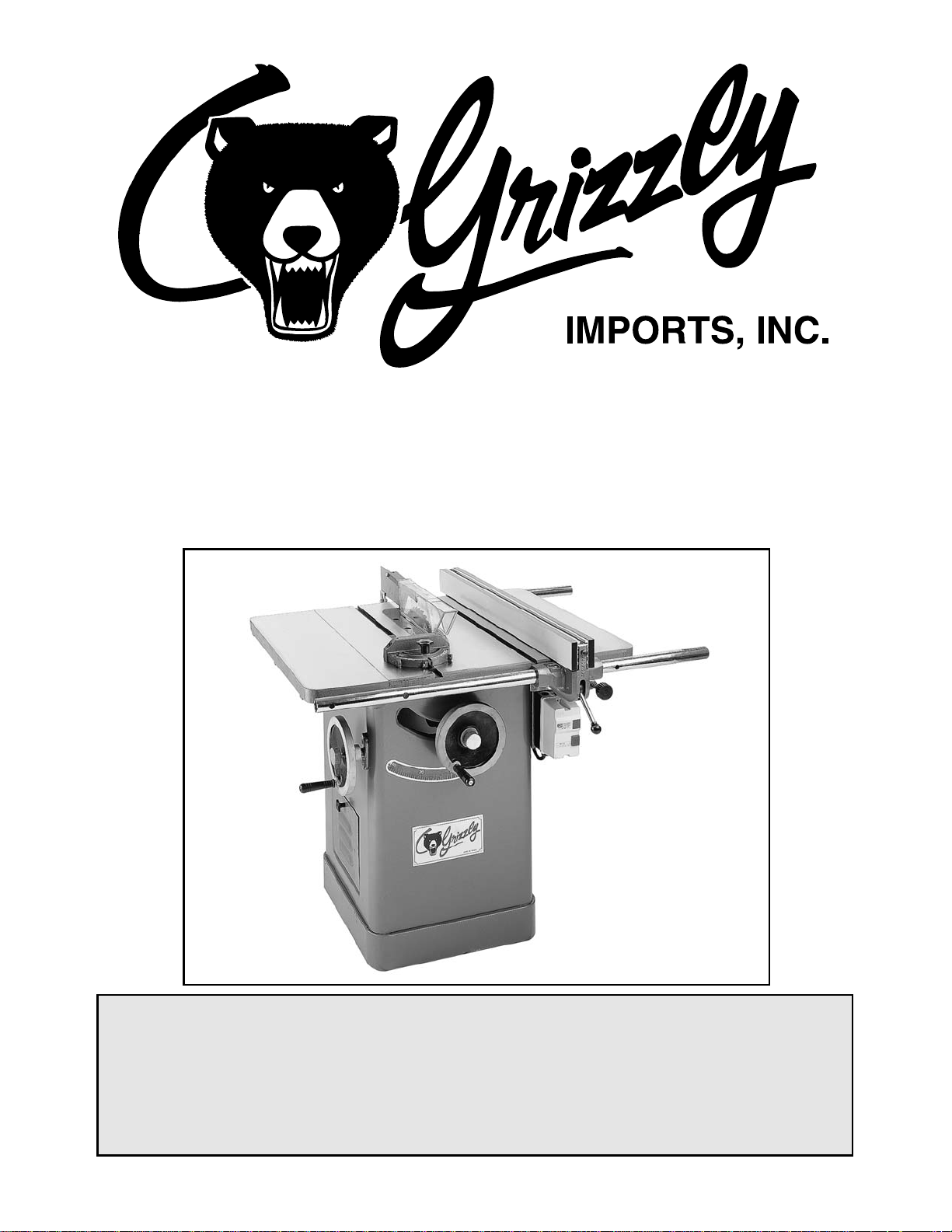

10" HEAVY-DUTY TABLE SAW

MODEL G1023

INSTRUCTION MANUAL

COPYRIGHT © 1990 BY GRIZZLY IMPORTS, INC REG #TX 3 170 579

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY IMPORTS, INC.

APRIL, 1997. PRINTED IN TAIWAN

DISCONTINUED MACHINE MANUAL DISCLAIMER

THE INFORMATION IN THIS MANUAL REPRESENTS THE LAST CONFIGURATION OF THE MACHINE BEFORE IT WAS DISCONTINUED.

MACHINE CONFIGURATIONS MAY HAVE CHANGED AS PRODUCT IMPROVEMENTS WERE INCORPORATED. IF YOU OWN AN EARLIER VER-

SION OF THE MACHINE, THIS MANUAL MAY NOT EXACTLY DEPICT YOUR MACHINE . CONTACT CUSTOMER SERVICE IF YOU HAVE ANY

QUESTIONS ABOUT DIFFERENCES. PREVIOUS VERSIONS ARE NOT AVAILABLE ONLINE.

Page 2

G1023 Heavy-Duty Table Saw -1-

Table Of Contents

PAGE

1. SAFETY INSTRUCTIONS ........................................................................................2

SAFETY INSTRUCTIONS FOR POWER TOOLS ..............................................2

ADDITIONAL SAFETY INSTRUCTIONS FOR TABLE SAWS ............................3

2. GENERAL INFORMATION ......................................................................................4

UNPACKING ........................................................................................................5

PIECE INVENTORY ............................................................................................5

CLEAN UP............................................................................................................6

SITE CONSIDERATIONS ..................................................................................6

CIRCUIT REQUIREMENTS ................................................................................7

GROUNDING ......................................................................................................7

3. ASSEMBLY .............................................................................................................. 8

BEGINNING ASSEMBLY ....................................................................................8

HAND WHEELS ..................................................................................................8

SWITCH ..............................................................................................................9

EXTENSION WINGS ......................................................................................9-10

GUARD SUPPORT SHAFT ..............................................................................10

BLADE................................................................................................................11

BLADE GUARD ............................................................................................11-12

FENCE RAILS....................................................................................................12

FENCE ..............................................................................................................13

TABLE INSERTS ..........................................................................................13-14

4. ADJUSTMENTS .................................................................................................... 15

MITER TO BLADE ............................................................................................15

90˚ POSITIVE STOP..........................................................................................16

45˚ POSITIVE STOP..........................................................................................17

ANGLE POINTER ..............................................................................................18

MITER GAUGE ..................................................................................................18

FENCE ..........................................................................................................19-20

BLADE ALIGNMENT..........................................................................................20

5. OPERATIONS ........................................................................................................ 21

PRE-RUN CHECK..............................................................................................21

TEST RUN..........................................................................................................21

BLADE SELECTION ....................................................................................22-23

CROSSCUTTING ..............................................................................................23

RIPPING ............................................................................................................24

6. MAINTENANCE ......................................................................................................25

TABLE AND WINGS ..........................................................................................25

V-BELT..........................................................................................................25-26

LUBRICATION ..................................................................................................26

7. CLOSURE................................................................................................................27

PARTS BREAKDOWNS AND LISTS............................................................28-33

MACHINE DATA ................................................................................................34

TROUBLESHOOTING ......................................................................................35

WARRANTY AND RETURNS............................................................................36

-STICK PATTERN..............................................................................................37

Page 3

-2- G1023 Heavy-Duty Table Saw

1. Wear eye protection.

2. Use saw-blade guard and spreader for every

operation for which it can be used, including

all through sawing.

3. Keep hands out of the line of saw blade.

4. Use a push-stick when required.

5. Pay particular attention to instructions on

reducing risk of kickback.

6. Do not perform any operation freehand.

7. Never reach around or over saw blade.

WARNING: For Your Own Safety Read

Instruction Manual Before Operating Saw

Safety Instructions For Power Tools

These safety rules cannot cover every situation in a woodshop. Consider your conditions when setting up

or operating your table saw.

9. USE PROPER EXTENSION CORD. Make

sure your extension cord is in good condition. When using an extension cord, be sure

it is rated Hard Service (grade S) or better.

Conductor size must be 16 A.W.G. for cords

up to 100 feet in length. An undersized cord

will cause a drop in line voltage resulting in

loss of power and overheating. Your extension cord must also contain a ground wire

and plug pin. Always repair or replace

extension cords if they become damaged.

Minimum Gage for extension cord:

16 A.W.G. 50ft

16 A.W.G. 100ft

14 A.W.G. 200ft

12 A.W.G. 300ft

10. WEAR PROPER APPAREL Do not wear

loose clothing, gloves, neckties, rings,

bracelets, or other jewelry which may get

caught in moving parts. Non-slip footwear is

recommended. Wear protective hair covering

to contain long hair.

11. ALWAYS USE SAFETY GLASSES. Also

use face or dust mask if cutting operation is

dusty. Everyday eyeglasses only have

impact resistant lenses, they are NOT safety

glasses.

1. KEEP GUARDS IN PLACE and in working

order.

2. REMOVE ADJUSTING KEYS AND

WRENCHES. Form habit of checking to see

that keys and adjusting wrenches are

removed from tool before turning on.

3. KEEP WORK AREA CLEAN. Cluttered

areas and benches invite accidents.

4. DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use power tools in damp or

wet locations, or expose them to rain. Keep

work area well lighted.

5. KEEP CHILDREN AWAY. All visitors

should be kept a safe distance from work

area.

6. MAKE WORK SHOP KID PROOF with

padlocks, master switches, or by removing

starter keys.

7. DON’T FORCE TOOL. It will do the job bet-

ter and safer at the rate for which it was

designed.

8. USE RIGHT TOOL. Don’t force tool or

attachment to do a job for which it was not

designed.

SECTION 1: SAFETY

Page 4

G1023 Heavy-Duty Table Saw -3-

Additional Safety Instructions For Table Saws

1. ALWAYS use guard, splitter and anti-kick-

back fingers on all ''through-sawing'' operations. Through-sawing operations are those

when the blade cuts completely through the

work- piece as in ripping or cross cutting.

2. ALWAYS hold the work firmly against the

miter gauge or fence.

3. ALWAYS use a push-stick for ripping nar-

row stock. Refer to ripping applications on

Page 23 of this manual, and Page 37 where

push- stick use is covered in detail.

4. NEVER perform any operation ''free-hand''

which means using only your hands to support or guide the workpiece. Always use

either the fence or the miter gauge to position and guide the work.

5. NEVER stand or have any part of your body

in line with the path of the saw blade.

6. NEVER reach behind or over the blade with

either hand for any reason.

7. MOVE the rip fence out of the way when

cross cutting.

8. NEVER use the fence as a cut-off gauge

when cross cutting.

9. NEVER attempt to free a stalled saw blade

without first turning the saw OFF.

10. PROVIDE adequate support to the rear and

sides of the saw table for wide or long workpieces.

11. AVOID KICKBACKS (work thrown back

toward you) by keeping blade sharp, keeping rip fence parallel to the saw blade, keeping splitter and anti-kickback fingers and

guard in place and operating, by not releasing work before it is pushed all the way past

the saw blade, and by not ripping work that

is twisted or warped or does not have a

straight edge to guide along the fence.

12. AVOID awkward operations and hand posi-

tions where a sudden slip could cause your

hand to move into the blade.

17. USE RECOMMENDED ACCESSORIES.

Consult the owner’s manual for recommended accessories. The use of improper accessories may cause risk of injury.

18. CHECK DAMAGED PARTS. Before further

use of the tool, a guard or other part that is

damaged should be carefully checked to

determine that it will operate properly and

perform its intended function - check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any

other conditions that may affect its operation.

A guard or other part that is damaged should

be properly repaired or replaced.

19. DIRECTION OF FEED. Feed work into a

blade or cutter against the direction of rotation of the blade or cutter only.

20. NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don’t leave

tool until it comes to a complete stop.

12. SECURE WORK. Use clamps or a vise to

hold work when practical. It’s safer than

using your hand and frees both hands to

operate tool.

13. DON’T OVERREACH. Keep proper footing

and balance at all times.

14. MAINTAIN TOOLS WITH CARE. Keep tools

sharp and clean for best and safest performance. Follow instructions for lubricating and

changing accessories.

15. DISCONNECT TOOLS before servicing and

changing accessories, such as blades, bits,

cutters, and the like.

16. REDUCE THE RISK OF UNINTENTIONAL

STARTING. Make sure switch is in off posi-

tion before plugging in.

Page 5

-4- G1023 Heavy-Duty Table Saw

Grizzly Imports, Inc. is proud to offer the Model

G1023 10" Heavy-Duty Table Saw. This model

G1023 is a part of Grizzly’s growing family of fine

woodworking and metalworking machinery.

When used according to the guidelines stated in

this manual, you can expect years of trouble-free,

enjoyable operation.

The Model G1023 is a cabinet-type table saw

intended for heavy-duty professional use. This

saw is equipped with cast-iron extension wings,

regular and dado blade table inserts, table TSlots, cast iron miter gauge, a rip fence and a

blade guard. The heart of the saw is a powerful 3

H.P., 3450 rpm, capacitor start motor with magnetic push-button switch. All running parts operate on shielded ball bearings and require no

maintenance for the life of the bearings. We also

offer many accessories for this table saw including blades, extension rails outfeed rollers and a

mobile base. Please refer to our current catalog

for prices and ordering information.

We are also pleased to provide this manual with

the Model G1023. It was written to guide you

through assembly, review safety considerations,

and cover general operating procedures. It represents our latest effort to produce the best documentation possible. If you have any criticisms that

you feel we should address in our next printing,

please write to us at the Bellingham, WA address

at the end of this section.

SECTION 2: GENERAL INFORMATION

Most important, we stand behind our machines.

We have an excellent service departments at

your disposal should the need arise. If you have

any service questions or parts requests, please

call or write to us at the location listed below.

Grizzly Industrial, Inc.

1203 Lycoming Mall Circle

Muncy, PA 17756

Phone:(570) 546-9663

Fax:(800) 438-5901

E-Mail: techsupport@grizzly.com

Web Site: http://www.grizzly.com

To comment on this manual write to:

Grizzly Imports, Inc.

C

⁄O Technical Documentation

P.O. Box 2069

Bellingham, WA 98227

To operate this or any power tool safely and efficiently, it is essential to become as familiar with it

as possible. The time you invest before you begin

to use your Model G1023 will be time well spent.

DO NOT operate this machine until you are com-

pletely familiar with the contents of this manual.

Page 6

G1023 Heavy-Duty Table Saw -5-

Unpacking

The Model G1023 is shipped from the manufacturer in a carefully packed carton. If you discover

the machine is damaged after you’ve signed for

delivery, please call Customer Service immedi-

ately for advice.

Save the containers and all packing materials for

possible inspection by the carrier or its agent.

Otherwise filing a freight claim can be difficult.

Caution: The Model G1023 is a heavy machine

(425 lbs. shipping weight). DO NOT over-exert

yourself while unpacking or moving your machine

– get assistance. In the event that your table saw

must be moved up or down a flight of stairs, be

sure that the stairs are capable of supporting the

combined weight of people and the machine.

When you are completely satisfied with the condition of your shipment, you should inventory its

parts.

Piece Inventory

After all the parts have been removed from the

carton, you should have:

• Table Saw Unit

• Miter Gauge

• Extension Wings (2)

• Fence Rails

• Adhesive Scale For Fence

• Fence Assembly

• Splitter/Guard Assembly

• Bolt Bag

Contents of bolt bag:

3

⁄8" - 16 x 1 1⁄4" Hex Bolts (6)

3

⁄8" Lock Washers (6)

3

⁄8" - 16 x 1" Cap Screws (4)

Hex Nuts

3

⁄8"-16 (4)

3

⁄8

" Flat Washers(4)

In the event that any non-proprietary parts are

missing (e.g. a nut or a washer), we would be

glad to replace them, or, for the sake of expediency, replacements can be obtained at your local

hardware store.

Page 7

-6- G1023 Heavy-Duty Table Saw

Clean up

The table and other unpainted parts of the Model

G1023 are coated with a waxy oil that protects

them from corrosion during shipment. Remove

the protective coating with mineral spirits and

paper towels. Do not use gasoline or other petroleum based solvents because of their extremely

low flash points. Do not use chlorine-based solvents – if you happen to splash some onto a

painted surface, you’ll ruin the finish.

WARNING!

Follow the safety rules listed below when

working with solvents:

1. Read and follow all directions and warnings

on the solvent label.

2. Work only in a well ventilated area.

3. Do not work near any type of open flame

(e.g., pilot lights, kerosene heaters, and so

on).

4. DO NOT smoke while working with flamma-

ble material.

5. Paper towels from the cleaning process are

extremely combustible. Dispose of waste

towels so they do not create a fire hazard.

Site Considerations

1. Floor Load: Your Model G1023 Table Saw

represents a large weight load in a small

footprint. Most commercial floors are suitable

for the Model G1023. Some residential floors

may require additional bracing to support

both machine and operator.

2. Working Clearances: Consider existing and

anticipated needs, size of material to be

processed through each machine, and

space for auxiliary stands, work tables or

other machinery when establishing a location for your Table Saw.

3. Lighting and Outlets: Lighting should be

bright enough to eliminate shadow and prevent eye strain. Electrical circuits should be

dedicated or large enough to handle amperage requirements. Outlets should be located

near each machine so power or extension

cords are clear of high-traffic areas. Observe

local electrical codes for proper installation

of new lighting, outlets, or circuits.

Page 8

G1023 Heavy-Duty Table Saw -7-

Circuit Requirements

The Model G1023 Table Saw has one 3 HP

motor. It has been pre-wired to operate at 220V,

single phase operation and cannot be operated

at 110V. The Model G1023 motor will safely draw

about 18 amps at 220V. If you operate the table

saw on any circuit that is already close to its

capacity, it might blow a fuse or trip a circuit

breaker. However, if an unusual load does not

exist, and power failure still occurs, have the circuit inspected by a qualified electrician.

Circuit breakers/fuses: A 30 amp circuit break-

er or fuse should be used with a 220V dedicated

circuit. The general rule is to use the lightest

breaker or fuse that will hold under regular loads.

Circuit breakers or fuses that are rated higher

may not adequately protect the motor.

The Model G1023 is not equipped with a plug. It

will be necessary to connect a plug that is suit-

able for your 220V receptacle. Figure 1.

This equipment must be grounded. Please

ensure that the Model G1023 is continuously

grounded from the motor to the machine frame

and then to a known ground. Verify that any existing electrical outlet and circuit you intend to plug

into is actually grounded. If it is not, it will be necessary to run a separate 12 A.W.G. copper

grounding wire from the outlet to a known ground.

Under no circumstances should the grounding

pin from any three-pronged plug be removed.

CAUTION: Be sure that your particular electrical

configuration complies with local and state codes.

The best way to ensure compliance is to check

with your local municipality or licensed electrician.

Grounding

Figure 1.

Page 9

-8- G1023 Heavy-Duty Table Saw

Beginning Assembly

Most of your Model G1023 Table Saw has been

assembled at the factory, but some parts must be

assembled or installed after delivery. We have

organized the assembly process into steps.

Please follow along in the order presented here.

Note: All die-cut metal parts have a sharp edge

(called “flashing”) on them after they are formed.

This is removed at the factory. Sometimes,

though, a bit of flashing might escape inspection.

Please examine the edges of all metal parts

before handling them.

TOOLS REQUIRED: A high quality square and

long straightedge plus common hand tools are

necessary to assemble this machine. You will

need a set of open and closed ended metric

wrenches, a flat tipped screwdriver, Phillips

screwdriver, dead blow hammer, and a 6" or 8"

adjustable wrench.

Hand Wheels

The handle on the arbor tilting hand wheel has

been installed backward for shipping.

Unscrew it and then reinstall it in the correct posi-

tion. Figure 2.

SECTION 3: ASSEMBLY

Figure 2.

Page 10

G1023 Heavy-Duty Table Saw -9-

Figure 3.

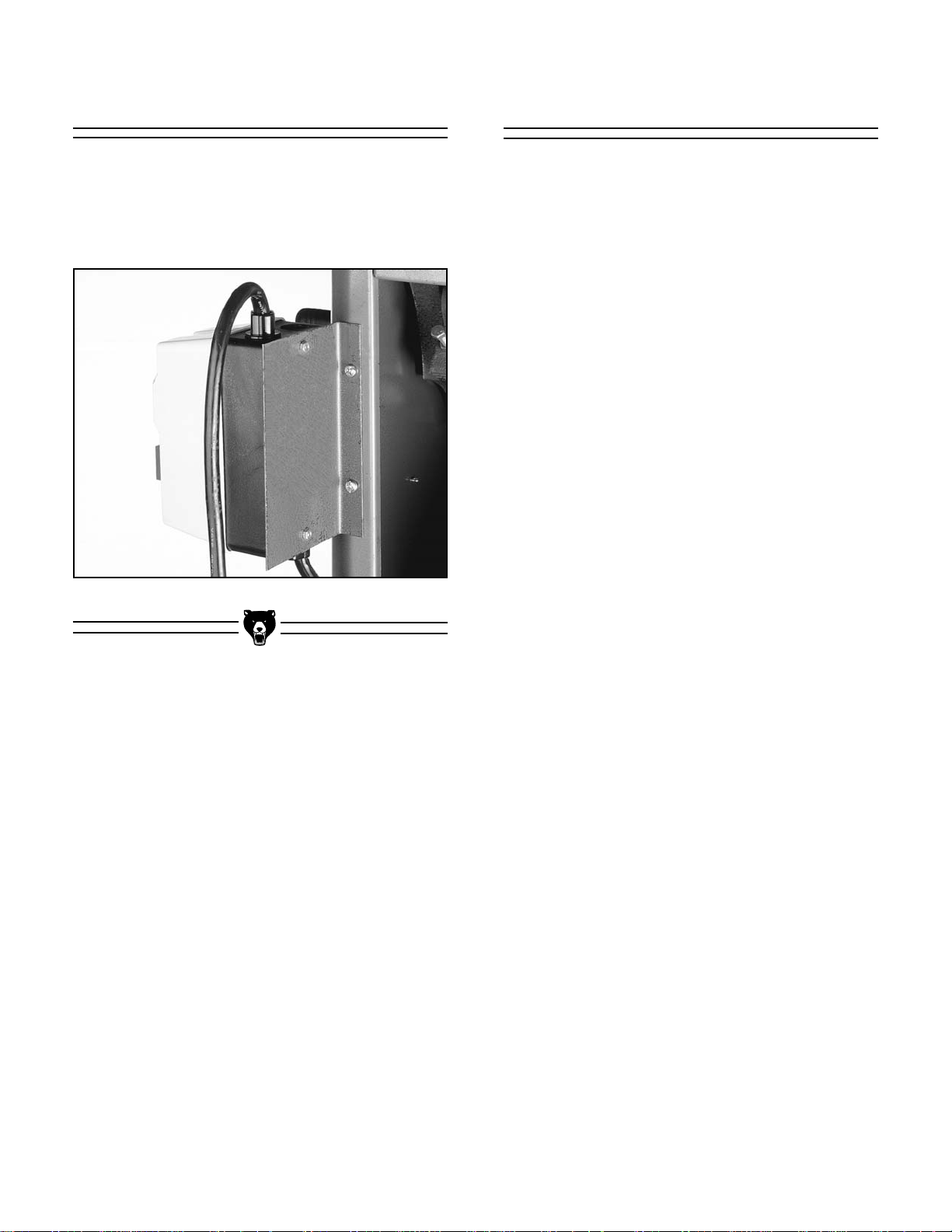

Switch

The magnetic switch comes prewired to the

motor. However, you must mount the switch to

the table saw body before it can be used. A

bracket with screws to attach it is provided.

Figure 3.

Extension Wings

Inspect the extension wings for burrs or foreign

material that may inhibit assembly. The mating

edges of the wings and table must be clean,

smooth, and flat. Use a wire brush or file if necessary to clean up the edges. It is possible to

attach the extension wings to the table by yourself, but it is easier if someone else holds the

wing in place while you insert the bolts.

1. Attach each wing to the table using the six

3

⁄8" - 16 x 1 1⁄4" Hex Head Bolts and 3⁄8" Flat

Washers provided. Get the wings reasonably flush with the table. Do not tighten the

bolts.

2. Align the top of the wing flush with the table

top directly above the front bolt and tighten

the front bolt. The front surface of the extension wing should also be flush with the front

surface of the table.

3. Raise or lower the rear of the extension wing

until the middle of the wing is flush with the

table top. Tighten the middle bolt.

4. Raise or lower the rear of the wing until the

wing and table are flush. Tighten the bolt.

Any adjustment at this point should be very

slight.

5. Re-check flushness at the front bolt and re-

adjust if necessary.

6. Repeat steps 2-4 for the other extension

wing.

7. Now, check the alignment of the table and

both wings with a straight edge. The straightedge should run flat across both wings and

the table top. Figure 4. If the straightedge

contacts both wings and the table evenly,

you are finished with this section. If it does

not, continue to step 8.

Page 11

Figure 5.

-10- G1023 Heavy-Duty Table Saw

8. If the wing tilts down, remove the wing and

stick layers of masking tape under each bolt

near the bottom edge. Re-install the wing

and check the flushness again.

9. If the wing tilts up, remove the wing and stick

layers of masking tape over each bolt near

the top edge. Re-install the wing and check

the flushness again. Figure 5.

Masking Tape

Figure 4.

Guard Support Shaft

Install the guard support shaft before installing

the blade. This will eliminate the risk of accidentally touching the sharp edges of the blade while

working inside the saw cabinet.

1. Push the threaded end of the shaft through

the hole in the back of the saw until the

shoulder on the shaft stops it.

2. Secure the shaft with the hex nut provided.

Figure 6.

Figure 6.

Page 12

G1023 Heavy-Duty Table Saw -11-

Figure 7.

Blade

The Model G1023 is not supplied with a blade.

For a selection of blades, including dado sets,

refer to the Grizzly catalog for selection, price and

ordering information. To install the blade:

1. Remove the arbor nut and outside arbor

flange from inside the blade cavity. Figure 7.

The arbor nut and arbor are left hand threaded.

2. Slide the saw blade over the arbor. Ensure

that the blade teeth point toward you when

standing at the front of the saw.

3. Use the arbor wrench provided with the saw

to tighten the arbor nut and secure the blade.

Wedge a block of wood in the teeth to keep

the blade from turning when tightening the

nut. Be sure the arbor flanges are on either

side of the blade.

4. When removing the blade, use the same

block of wood to wedge the blade and the

nut will come off easily.

2. Set a combination square against the face of

the guard. Slightly rotate the rear bracket to

adjust the face of the blade guard perpendic-

ular to the table top. Figure 9.

Figure 8.

Figure 9.

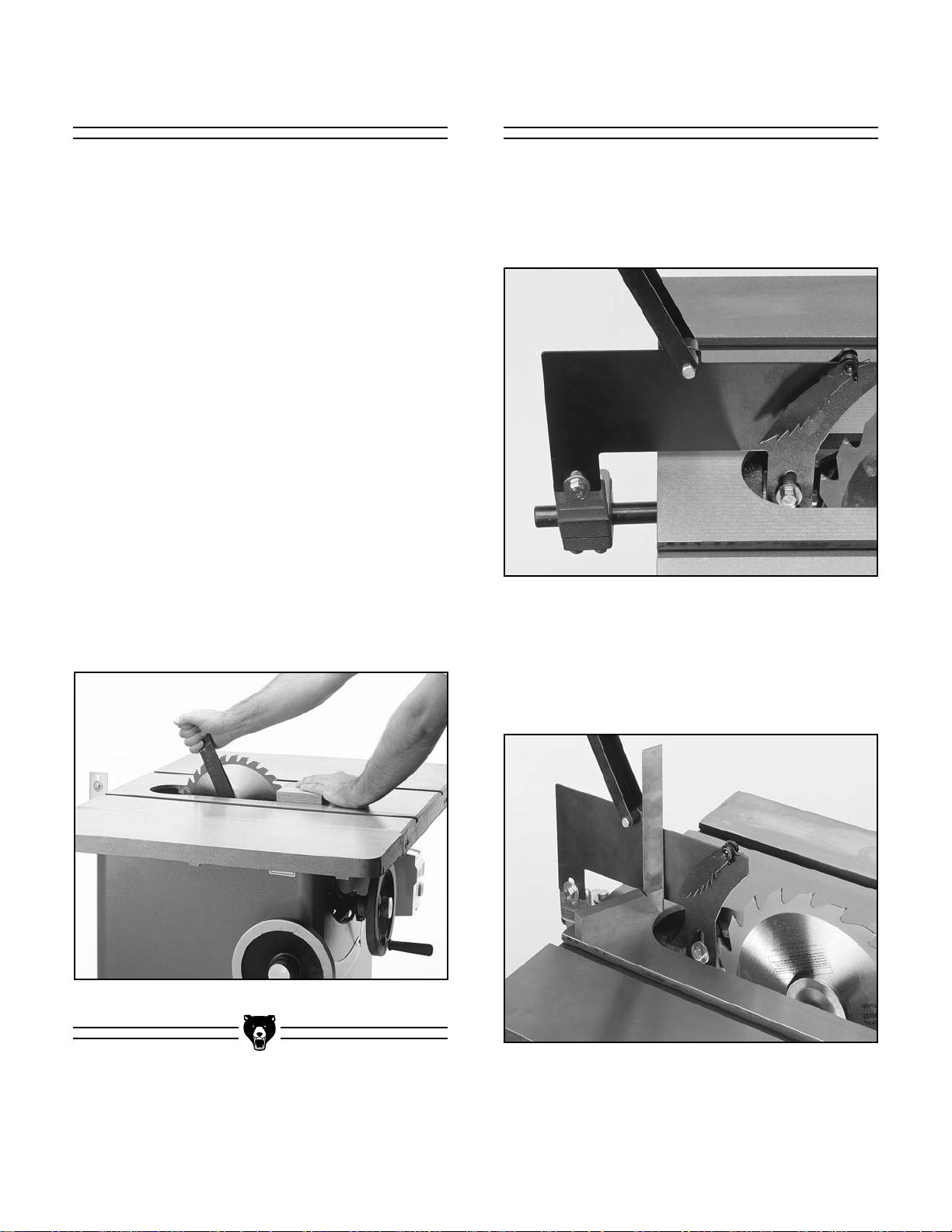

Blade Guard

1. Slip the blade guard/splitter over the mount-

ing bolts. Figure 8. The washers should be

between the bolt head and the slots. Tighten

the bolts to secure the blade guard/splitter.

Page 13

Figure 11.

-12- G1023 Heavy-Duty Table Saw

4. Recheck guard alignment to the blade and to

the table top. Adjust as necessary and tighten down all the bolts before use.

3. Next, set a straightedge against the face of

the saw blade and the blade guard. Figure

10. Loosen and adjust the rear blade guard

bracket to set the alignment at the rear, then

add washers as necessary between the splitter and the front mounting bracket to gain

adjustment in the front.

Figure 10.

Fence Rails

The rails should extend to the right of the saw and

are attached to the table top with cap screws and

dished spacers. The rails come packed in a separate box. To mount the rails:

1. Attach the front and rear rails to the drilled

and tapped holes on each extension wing.

Figure 11. Be sure that the rail with the

scale is mounted on the front side of the

machine, with the markings facing up.

2. Insert the round, plastic plugs into the ends

of each rail.

Page 14

G1023 Heavy-Duty Table Saw -13-

Figure 13.

Table Inserts

Your table saw comes with two table inserts. One

is for standard blades and the other is for dado

blades. Figure 13.

Fence

To mount the fence:

1. Thread the plastic knob onto the lock handle.

2. Set the lock handle in the up position and

slide the fence over the front and rear rails.

Figure 12.

3. The fence will require further adjustments

covered in Section 3, page 19-20.

Figure 12.

Page 15

-14- G1023 Heavy-Duty Table Saw

Figure 15.

Figure 14.

1. Install the table insert by putting your fingers

into the finger holes of the insert and lifting

the front to install it as shown in Figure 14.

There is a small pin at the back of the insert

which fits into a hole in the back edge of the

blade cavity. Note: The blade will not be

exactly centered in the insert slot. This is

normal. This positioning allows the blade to

tilt a full 45° without hitting the insert.

2. Make the insert flush with the table top by

adjusting the four setscrews in the insert.

Check flushness with a straight edge. Figure

15.

3. A drop of glue or Loctite

®

on the threads of

the setscrews will keep the setting from

changing.

4. If the blade hits the edge of the insert when

raised, the blade is out of alignment. See

Section 3 page 19.

Page 16

G1023 Heavy-Duty Table Saw -15-

Figure 18.

Figure 16.

Figure 17.

Table Mount Holes

5. The difference between distance A and dis-

tance B must be equal to or less than

1

⁄64".

6. If the difference is greater than

1

⁄64", loosen

the four (4) table mounting bolts and adjust

the table slightly. Figure 18. Repeat steps 1-

5 until satisfactory. Do not forget to tighten

the table mounting bolts when finished.

Miter Slot to Blade

SECTION 4: ADJUSTMENTS

Your table saw will give the best results if the

miter slot and rip fence are adjusted parallel to

the blade. If they are not exactly parallel, your

cuts and finished work will be lower in quality.

Take the time to adjust your table saw properly. A

few minutes now will be time well spent.

CAUTION: Ensure that the table saw is

unplugged from its power source before making

any adjustments. To check and adjust parallelism

between miter slot and blade:

1. Use a piece of tape to mark the blade in the

gullet between two (2) teeth closest to the

table.

2. Use a steel rule to measure the distance

from the mark on the blade to the edge of the

miter slot. Figure 16.

3. Rotate the blade 180°.

4. Measure the distance from the mark on the

blade to the edge of the miter slot. Figure

17.

Page 17

-16- G1023 Heavy-Duty Table Saw

Figure 21.

90° Stop Bolt

Jam Nut

Front

Trunnion

Geared

Trunnion

5. Loosen the jam nut and thread the stop bolt

in or out not more than a half turn. Figure 21.

6. Tighten the jam nut and tilt the blade back to

90°. Check the angle of the blade with the

square.

7. Repeat steps 3-6 as necessary.

90˚ Positive Stop

Your table saw will be easier to use and produce

more predictable results if it is adjusted correctly.

Next to parallelism, the 90° positive stop is perhaps the most important adjustment point on the

saw. To adjust the 90° positive stop bolt:

1. Turn the arbor tilting handwheel (the one on

the left side of the saw) until the 90° positive

stop limits movement.

2. Check the angle of the blade to the table with

a high quality square. Figure 19. If the blade

is 90° to the table, you are finished. If the

blade is not exactly 90° to the table, proceed

to the next steps.

3. Angle the blade toward 45° to allow access

to the stop bolt.

4. Locate the stop bolt on the geared trunnion

inside the cabinet. Figures 20.

Figure 19.

Figure 20. Location for 90˚ positive stop.

Page 18

G1023 Heavy-Duty Table Saw -17-

Figure 23.

5. Loosen the jam nut behind the 45° stop bolt.

Tighten or loosen the stop bolt to adjust the

stopping position of the arbor. Tighten the

jam nut.

6. Tilt the blade until the 45° stop bolt prohibits

movement. Check the angle of the blade.

7. Repeat steps 3-6 as necessary.

45° Stop Bolt

45˚ Positive Stop

To adjust the 45° positive stop bolt:

1. Turn the arbor tilting handwheel (the one on

the left side of the saw) until the 45° positive

stop limits movement.

2. Check the angle of the blade to the table with

a high quality angle gauge. Figure 22. If the

blade is 45° to the table, you are finished. If

the blade is not exactly 45° to the table, proceed to the steps below.

3. Angle the blade toward 90° to allow access

to the stop bolt.

4. Locate the stop bolt on the geared trunnion

inside the cabinet. It is accessed through the

hole in the side of the cabinet behind the

blade height hand wheel. Figure 23.

Figure 22.

Jam

Page 19

-18- G1023 Heavy-Duty Table Saw

Figure 24.

Angle Pointer

Angle Pointer

Once the positive stops have been set, the angle

pointer will require adjusting. To adjust the angle

pointer:

1. The angle pointer is located behind the arbor

height hand wheel. Figure 24. (hand wheel

removed for clarity)

2. Turn the arbor tilting hand wheel until it stops

on the 90° positive stop.

3. Loosen the pointer and set it to ''0'' on scale.

Tighten the screw.

4. Turn the arbor tilting hand wheel until it stops

on the 45° stop.

5. If the pointer is set on 45˚, skip to the next

adjustment. If it does not point to 45°, repeat

steps 2-4 until the pointer is adjusted cor-

rectly.

Miter Gauge

To adjust the miter gauge so it is perpendicular to

the saw blade:

1. Loosen the lock knob on the miter gauge and

place a square against the face of the miter

body and the blade.

2. Adjust the miter body until there is no space

between the square and the blade. Tighten

the lock knob.

3. With the stop link in the up position, loosen

the jam nut and adjust the stop screw until it

is seated against the stop link. Figure 25.

4. Now loosen the setscrew on the left front

side of the miter bar, adjust the pointer to 90˚

and retighten the setscrew.

5. To adjust to 45˚, follow steps 1-4 using an

adjustable square set to 45˚.

6. After rotating the miter body from 45˚ to 90˚

and back a few times, double check your

adjustments at both angles to assure that

you have accurately set your miter gauge.

Figure 25.

Jam Nut

Stop Screw

Stop Link

Page 20

G1023 Heavy-Duty Table Saw -19-

Figure 26.

Figure 27.

Fence

The fence must engage and square up on the

front rail before the rear clamp engages the back

rail. In essence, the rear clamp should act as a

secondary mechanism for maintaining fence

position. When adjusted correctly, the lever lock

should only begin to apply pressure on the back

rail over the last one third of its stroke. To adjust

the fence:

1. First, make sure the front clamp is engaging

the front tube with the lock handle at one half

its throw. If the front clamp requires adjust-

ment, loosen the check nut. Figure 26. Turn

the adjusting bolt in if the front clamp is too

far from the tube, out if it is too close.

2. Now slide the fence along the rail until it is

aligned with the edge of the miter slot. Lock

the fence down.

3. With the fence in the locked position, loosen

the rear lock adjustment (the slotted screw

on the front of the fence) until the rear locking lever ceases to engage the rear rail.

Figure 27.

Jam nu

t

Adjusting

bolt

Rear lock adjustment

4. Loosen the adjustment bolts at the top of the

fence. Figure 28. move the straight portion

of the fence until it is parallel with the miter

slot from front to back. Tighten the bolts.

Figure 28.

Page 21

-20- G1023 Heavy-Duty Table Saw

Figure 29.

5. Loosen the locking lever until it is approxi-

mately two-thirds engaged. Tighten the rear

adjusting screw until the rear clamp just

touches the back rail.

6. Loosen the locking lever and slide the fence

along the rail. Return the fence to its position

at the edge of the miter slot and slowly apply

pressure to the lever. If adjustments are correct, the fence should square itself before

the rear clamp engages. If the rear clamp

engages before the fence is squared, loosen

the screw one quarter turn and re-test.

7. Once the fence is adjusted, check the pointer and adjust if necessary. Figure 29.

Figure 30.

Blade Adjustment Bolt

Geared Bearing Housing

Blade Alignment

The blade position can be adjusted slightly in

case it contacts the table insert when raised. To

adjust the blade position:

1. Remove the table and wings and set them

aside.

2. Loosen the blade adjustment bolt. Figure

30.

3. Shift the geared bearing housing in the

appropriate direction. WARNING: This

adjustment should not exceed

1

⁄16". Over

adjustment will cause the blade to hit internal

parts of the saw.

4. Place the blade on the arbor and finger tight-

en the arbor nut. Check that the blade does

not contact any internal parts.

5. Replace the table, wings, and insert. Tighten

securely.

6. If the blade is still touching the insert, repeat

steps 1-6. CHECK ALL OTHER ADJUST-

MENTS.

Page 22

G1023 Heavy-Duty Table Saw -21-

Pre-Run Check

Before you begin to use your model G1023 Table

Saw, you should give it a thorough inspection.

While making your inspection, ask yourself the

following questions:

1. Are all the fasteners tight?

2. Is the blade mounted correctly and securely?

3. Is the saw stable?

4. Is it wired properly?

5. Is your electrical system properly config-

ured?

6. Have you checked your material for obvious

defects?

7. Are the V-belts properly tensioned and the

pulleys properly aligned?

8. Is the guard assembly installed and function-

al?

Test run

The table saw is one of the most valuable tools in

the woodshop because it performs its duties so

well. It is primarily intended to rip and crosscut

and we will describe those operations in the following sections. For other uses, we suggest consulting a book dedicated to the table saw. Many

are available through the Grizzly catalog.

1. Face the table saw and stand to the left of

the blade path.

2. With one finger on the “Start” button and one

finger on the “Stop” button, turn the saw on.

Be ready to turn it off in case of mishap.

3. Watch and listen to the saw. Note whether

there are any unusual sounds or excessive

vibrations.

4. If ANYTHING appears abnormal, immedi-

ately turn off the saw and fix the problem. If

a problem exists that is beyond the scope of

this manual, call the appropriate service

department.

5. If the saw is behaving normally, turn it off and

prepare to make a cut according to the

instructions outlined in the following sections.

SECTION 5: OPERATIONS

Page 23

-22- G1023 Heavy-Duty Table Saw

3. Combination Blade: Used for cutting with

and across the grain. A compromise

between a rip blade and a cross-cut blade, a

combination blade will typically have

between 40-80 teeth, an alternate top bevel

and flat or alternate top bevel and raker

tooth profile. The teeth are arranged in

groups of five. The gullets are small and

shallow within the groups of five, simular to a

cross-cut blade, large and deep between the

groups, like a ripping blade. Figure 33.

Figure 33.

Blade Selection

Choosing the correct blade for the job is essential

for the safe and efficient use of your table saw.

Ignoring this important step could result in damage to the saw and serious injury to the operator.

Documented below are the most common saw

blades and their uses.

1. Rip Blade: Used for cutting with the grain.

Typically, rip blades have between 20-30

teeth, a flat-top ground profile and large gul-

lets to allow for large chip removal. Figure

31.

2. Cross-cut Blade: Used for cutting across

the grain. Cross-cut blades have between

40-100 teeth, alternate top bevel or steep

alternate top bevel tooth profiles, small hook

angle and a shallow gullet. Figure 32.

Figure 31.

Figure 32.

Page 24

G1023 Heavy-Duty Table Saw -23-

Figure 34.

4. Plywood Blade: Used for cutting plywood or

veneers. A Plywood blade will have 80+

teeth, a steep alternate top bevel tooth pro-

file and very shallow gullet. Figure 34.

5. Thin-kerf: Most types of saw blades are

available in a thin-kerf style. Used primarily

to minimize stock wastage. It is recommended thin-kerf blades be used in conjunction

with a blade stabilizer to reduce blade wob-

ble. Note: Most blade guards/splitters are

thicker than most thin-kerf blades. Make

sure the stock will pass by the guard/splitter

before beginning a cut.

6. Dado Blades: There are two types of dado

blades: stack and wobble. Stack dadoes are

expensive and time consuming to set up but

leave a clean and smooth finish. Stack

dadoes are used for fine furniture and cabinet making. Wobble dadoes are inexpensive

and easy to set up, but leave a rough finish.

This section on Blade Selection is by no means

comprehensive. Always follow the saw blade

manufacturer's recommendations to assure safe

and efficient operation of your table saw.

Figure 36.

Crosscutting

Crosscutting means cutting across the grain of

the wood. In wood products without grain (i.e.

MDF, particleboard) it simply means cutting

across the width of the stock.

Crosscuts are made with the miter gauge. There

are two miter gauge slots in the table top. Use the

one that works best for the piece being crosscut.

To make a crosscut using the miter gauge:

1. Inspect the board for soundness. You do not

necessarily need a square edge to crosscut

with accuracy.

2. Move the rip fence completely out of the

way.

3. Turn on the saw and allow it to come to full

speed.

4. Hold the workpiece firmly against the face of

the miter gauge and ease it into the blade.

Figure 36.

5. Turn off the saw and allow the blade to come

to a full stop.

Page 25

-24- G1023 Heavy-Duty Table Saw

Ripping

Ripping means to cut with the grain of the wood.

In other materials such as MDF or plywood, ripping simply means to cut lengthwise. To rip a

board:

1. Inspect the board for soundness. You will

need a straight edge to rip with accuracy.

Your work piece may need to be jointed flat

before attempting to cut on the table saw.

2. Set rip fence to the desired distance from the

blade. IF YOU ARE MAKING NARROW

CUTS, USE A PUSH-STICK. It is unsafe to

put your hands close to the blade. A pushstick pattern has been included in this man-

ual on Page 37. Use them to hold the work-

piece against the table and fence and push

the workpiece fully. past the blade. When a

small width is to be ripped and a push-stick

cannot be safely put between the blade and

rip fence, rip a larger piece to obtain the

desired piece.

3. Turn on the saw and allow it to reach full

speed.

4. Place the trued edge of the board against the

rip fence.

Figure 35.

5. Feed the workpiece slowly and evenly into

the blade. Figure 35. STAND OUT OF THE

LINE OF POTENTIAL KICKBACK. HOLD

THE WORKPIECE FIRMLY AGAINST THE

FENCE AND TABLE. DO NOT ALLOW

YOUR FINGERS TO GET CLOSE TO THE

BLADE! DO NOT REACH OVER THE

BLADE TO OFF-LOAD THE WORKPIECE.

Page 26

G1023 Heavy-Duty Table Saw -25-

SECTION 6: MAINTENANCE

V-Belt

To ensure optimum power transmission from the

motor to the blade, the V-belts must be in good

condition and operate under proper tension.

When replacing V-belts, it is important to replace

all three at the same time-even if they do not all

appear worn. Even power transmission will be

ensured.

Belt tension should be checked at least every 3

months: more often if using the table saw intensively.

The V-belts are accessed through the cavity on

the right side of the saw. They link the arbor and

motor pulleys. To check V-belt tension:

1. Squeeze the center of each V-belt.

2. Note the amount of deflection. Deflection

should be approximately

3

⁄4". Figure 37.

Figure 37.

Keeping your table and wings slippery makes it

easier to slide your wood when making cuts. We

recommend the following types of products:

1. Carnauba wax. First clean the table top

thoroughly and apply a thin layer.

2. Talcum powder. Clean the table and sprin-

kle the table with it. Rub it in with a hard felt

pad such as a school blackboard eraser. The

talc will fill the pores of the iron and act as a

rust inhibitor.

3. Coat the table surface with any number of

cast iron table dressing sprays. These act as

a rust and friction inhibitor and are designed

especially for woodworking equipment.

Do not use paraffin or similar waxes because

they leave residues and create more friction

instead of less friction. Do not use silicon based

lubricants. They can rub off onto the wood and

prevent it from taking stains and finishes properly.

Table and Wings

Page 27

-26- G1023 Heavy-Duty Table Saw

Figure 39.

The shielded ball bearings in the motor and

throughout most of the model G1023 require no

further lubrication during their lifetime. When they

do wear out, replacements can be obtained

through the Grizzly Parts Department.

Your saw requires lubrication in several other

locations, however. Lubricate the areas indicated

below every 12 months.

1. Blade angling trunnions. These should be

lubricated with 6 or 7 drops of light machine

oil.

2. Blade height trunnion. This should also be

lubricated with 6 or 7 drops of light machine

oil.

3. The two (2) worm gears should be lubricat-

ed with a automotive wheel bearing grease.

The blade angle worm gear is not shown in

Figure 39.

These points can be reached by removing the

table. Check all adjustments when finished lubricating.

Lubrication

Figure 38.

Motor Mount Bolt

To adjust V-belt tension:

1. Loosen the motor mount bolt. Figure 38.

2. Shift the motor up or down to increase or

decrease the V-belt tension. Tighten the

motor mount bolt.

3. Check the V-belt tension again. Ensure that

the motor pulley and arbor pulley are lined

up.

To replace the V-belts:

1. Remove the blade.

2. Adjust the arbor so it is down all the way and

in the straight up position.

3. Loosen the motor mount bolt. Prop the motor

up with a board so the V-Belts stay loose on

the pulleys.

4. Pull off the old V-belts and replace them with

new ones. Have the number from the belt

ready when calling the service department

for replacements.

5. Remove the board and adjust the V-belt ten-

sion.

6. Tighten the motor mount bolt.

Page 28

G1023 Heavy-Duty Table Saw -27-

The following pages contain general machine

data, troubleshooting guide, parts diagram, parts

list and Warranty/Return information for your

Model G1023 Table Saw.

If you need parts or help in assembling your

machine, or if you need operational information,

we encourage you to call the appropriate regional Service Department. Our trained service technicians will be glad to help you.

If you have comments dealing specifically with

this manual, please write to our Bellingham,

Washington location using the address in the

Introduction. The specifications, drawings, and

photographs illustrated in this manual represent

the Model G1023 Table Saw as supplied when

the manual was prepared. However, due to

Grizzly’s policy of continuous improvement,

changes may be made at any time with no obligation on the part of Grizzly. Whenever possible,

though, we send manual updates to all owners of

a particular tool or machine. Should you receive

one, add the new information to this manual and

keep it for reference.

We have included some important safety measures that are essential to this machine’s operation. While most safety measures are generally

universal, Grizzly reminds you that each workshop is different and safety rules should be con-

sidered as they apply to your specific situation.

We recommend you keep a copy of our current

catalog for complete information regarding

Grizzly's warranty and return policy. If you need

additional technical information relating to this

machine, or if you need general assistance or

replacement parts, please contact the appropriate regional Service Department listed in the

introduction.

Additional information sources are necessary to

realize the full potential of this machine. Trade

journals, woodworking magazines, and your local

library are good places to start.

WARNING!

As with all power tools, there is danger associated with the Model G1023 Table Saw. Use the tool

with respect and caution to lessen the possibility

of mechanical damage or operator injury. If normal safety precautions are overlooked or ignored,

injury to the operator or others in the area is likely.

The Model G1023 Table Saw was specifically

designed for wood cutting operations. DO NOT

MODIFY THIS TABLE SAW OR USE IT FOR

ANYTHING OTHER THAN ITS STATED PURPOSE. Modifications or improper use of this

tool will void the warranty. If you are confused

about any aspect of this machine, DO NOT use it

until you have answered all your questions.

SECTION 7: CLOSURE

Page 29

-28- G1023 Heavy-Duty Table Saw

48A

83

82

84

80B

80-1

80-2

79

79

80-1

80-2

81

80D

77

76

78

75

74

73

62

19

20

21

22A

63

67

66

64

65

68

72

70

69

97

25

24

27

48

47

45

36

37A

35

38

44

41

43

42

37B

41

38

93

39

40

94

84

60

61

57

58

71

95

31

33

30

32

96

5

9

11

19

8

18

20

21

8

10

10

11

16

31

17

30

29

12

13

27

15

14

9

28

25

24

26

97

22A

23

52

50

51

55

23

54

43

89

85

53

85

86

7

1

4

6

2

5

98

56

99

3

87

90

91

88

92

Page 30

G1023 Heavy-Duty Table Saw -29-

001 P1023001 CABINET

002 P1023002 SCALE

003 P1023003 SELF TAPPING SCREW

004 P1023004 TRAP DOOR

005 PN02 HEX NUT

5

⁄16" - 18

006 P1023006 DOOR LATCH

007 P1023007 KNOB

008 P1023008 HAND WHEEL LOCK

009 P1023009 HANDLE

010 P1023010 HAND WHEEL

011 PSS04 SETSCREW

1

⁄4" - 20 x5⁄16"

012 P1023012 PHLP HD SCRW 10 - 24 x 2"

013 P1023013 POINTER BRACKET

014 PS27 PHLP HD SCRW

5

⁄16" - 18 x 1"

015 P1023015 POINTER

016 P1023016 FRONT TRUNNION

017 P1023017 PLATE

018 PS05 PHLP HD SCRW

5

⁄16" - 18 x 1"

019 PB16 HEX BOLT

3

⁄8" - 16 x 1 1/2"

020 PLW04 LOCK WASHER

3

⁄8"

021 PN08 HEX NUT

3

⁄8" - 16

22A PSS03 SETSCREW

1

⁄4" - 20 x3⁄8"

023 P1023023 WORM

024 P1023024 COLLAR

025 PSS05 SETSCREW

5

⁄16" - 18 x1⁄4"

026 P1023026 SHAFT

027 P1023027 PIN

028 PK01 KEY

3

⁄16" x 3⁄16" x 1 1⁄2"

029 P1023029 GEARED TRUNNION

030 PN02 HEX NUT

5

⁄16" - 18

031 PB03 HEX BOLT

5

⁄16" - 18 x 1"

032 P1023032 FLANGE

033 P1023033 SHAFT

035 P1023035 GEARED BEARING HOUSING

036 PB16 HEX BOLT

3

⁄8" - 16 x 1 1⁄2"

37A PLW04 LOCK WASHER

3

⁄8"

37B PK03 KEY

1

⁄4" x 1⁄4" x 2"

038 P6203 BEARING 6203 - 2RS

039 PR23M SNAP RING 40mm

040 P1023040 JAM NUT

5

⁄8" - 18

041 P1023041 COLLAR

042 P1023042 ARBOR PULLEY

043 PSS07 SETSCREW

1

⁄4" - 20 x1⁄2"

044 PK33M KEY 5 x 5 x 45mm

045 P1023045 BLADE ARBOR

047 P1023047 ARBOR FLANGE

048 P1023048 ARBOR NUT

48A P1023048A ARBOR WRENCH

49A PSS08 SETSCREW

5

⁄16" - 18 x 1⁄2"

050 P1023050 MOTOR FRAME SUPPORT

051 P1023051 CLIP

052 P1023052 PIVOT PIN

053 PB14 HEX BOLT

7

⁄16" - 20 x 3⁄4"

054 P1023054 V-BELTS, SET OF 3

055 P1023055 MOTOR PULLEY

056 P1023056 MOTOR 3 H.P.

057 PB28 HEX BOLT

5

⁄16" - 18 x 2 1⁄4"

058 PB03 HEX BOLT

5

⁄16" - 18 x 1"

060 PB07 HEX BOLT

5

⁄16" - 18 x 3⁄4"

061 PW07 FLAT WASHER

5

⁄16"

062 P1026062 SUPPORT BRACKET

063 P1023063 FLANGE CASTING

064 PRP03 ROLL PIN

5

⁄16" x5⁄8"

065 PSB14 CAP SCREW

3

⁄8" - 10 x 1"

066 PW02 FLAT WASHER

3

⁄8"

067 PK06 KEY

3

⁄16" x 3⁄16" x 1 9⁄16"

068 P1023068 SHAFT

069 PLN05 LOCK NUT

3

⁄4" - 16

070 P1023070 REAR TRUNNION

071 P1023040 JAM NUT

5

⁄8" - 18

072 P1023072 BLADE GUARD SUPPORT

073 PB03 HEX BOLT

5

⁄16" - 18 x 1"

074 P1023074 BLOCK

075 P1023075 BLOCK ANGLE

076 PW07 FLAT WASHER

5

⁄16

"

077 PB07 HEX BOLT

5

⁄16" - 18 x 3⁄4"

078 PB03 HEX BOLT

5

⁄16" - 18 x 1"

079 PSS07 SETSCREW

1

⁄4" - 20 x1⁄2"

80-1 P102380-1 SPRING CLIP

80-2 PS06 PHLP HD SCREW 10-24 x

3

⁄8''

80B P1023080B STD TABLE INSERT

80D P1023080D DADO INSERT

081 P1023081 TABLE

082 PLW05 LOCK WASHER

7

⁄16"

083 PB24 HEX BOLT

3

⁄8" - 16 x 1 1⁄4"

084 P1023084 EXT. WING

085 PW04 FLAT WASHER

7

⁄16"

086 PB14 HEX BOLT

7

⁄

16" - 20 x

3

⁄

4"

087 PSW01 SWITCH

088 P1023088 SWITCH MOUNT BRACKET

089 PK02M KEY 5 x 5 x 40mm

090 PS201-1 SWITCH COVER SCREW

091 PS07 PHLP HD SCR

1

⁄4" - 20 x3⁄8"

092 P1023092 LABEL

093 PSS02 SET SCREW

5

⁄16''-18 x3⁄8''

094 P1023094 SPRING

095 P1023095 BALL

096 P1023096 SET SCREW

097 P1023097 BRASS WASHER

098 P1023098 POWER CORD

099 P1023099 MOTOR CORD

REF# PART# DESCRIPTION

REF# PART# DESCRIPTION

Page 31

-30- G1023 Heavy-Duty Table Saw

412

401 P1023401 KNOB

402 P1023402 FLAT WASHER

1

⁄4"

403 P1023403 MITER GAUGE BODY

404 P1023404 MITER BAR

405 P1023405 SPECIAL WASHER

406 P1023406 FLAT HD SCREW

407 P1023407 HEX NUT

408 P1023408 SETSCREW

409 P1023409 SETSCREW

410 P1023410 STOP

411 P1023411 POINTER

412 P1023212 SCALE

413 P1023413 STUD

REF# PART# DESCRIPTION

REF# PART# DESCRIPTION

401

402

403

404

413

411

409

410

409

407

408

405

406

Page 32

G1023 Heavy-Duty Table Saw -31-

501

501 P1022174 GUARD

502 P1022171 HEX BOLT M6-1.0X40MM

503 PLN03M LOCK NUT M6-1.0

504 P1022162 SUPPORTING ARM

505 P1022173 PIVOT PIN

506 P1022175 RETAINER

507 P1022163 RETAINER

508 P1022176 SPRING

509 P1022167 SPACER

510 P1022073 SPLITTER

511 P1022164 PAWL

512 PRP20M ROLL PIN 4 X 22

513 P1022166 PIN

REF# PART# DESCRIPTION

REF# PART# DESCRIPTION

502

506

505

511

512

504

513

507

503

509

510

508

507

511

Page 33

28

23

24

25

38

34

33

32

35

30

31

29

1

24

23

7

25

26

27

10

8

9

11

24

25

23

37

35

40

19

3

13

5

4

6

20

39

17

18

14

16

15

12

23

Page 34

G1023 Heavy-Duty Table Saw -33-

601 P1022Z064 FENCE

602 PFH08M FLT HD SCREW

603 PW01M FLAT WASHER 8MM

604 PS05M PHLP HD SCREW M5-0.8 X 8

605 P1022Z037 POINTER

606 P1022042 SHAFT FOR CLAMP

607 P1022039 FRONT CLAMP

608 PSS03 SETSCREW

1

⁄4'' - 20 X 3⁄8''

609 P1023609 CLAMP SHOE

610 P1022049 SPRING

611 PN02 HEX NUT

5

⁄16'' - 18

612 PB03 HEX BOLT

5

⁄16'' - 18 X 1''

613 P1022047 SHAFT BUSHING

614 P1022051 SPRING

615 P1022044-1 PINION W/ KNOB

616 P1022Z050 KNOB

617 P1023617 LOCK LEVER

618 P1022038 FENCE ADJUSTER

619 P1022040 ECCENTRIC

620 P1023620 SHAFT FOR ECCENTRIC

623 P1022023 PLUG

624 PSB26 CAP SCREW

3

⁄8''-16 X 11⁄2''

625 P1022025 FENCE RAIL SPACER

626 P1022163 SCREW

627 P1023627 FRONT RAIL

628 P1023628 REAR RAIL

629 P1022062 LOCK LINK

630 P1022060 CLAMP HOOK

631 P1022061 LEVER

632 P1022059 SPRING

633 P1022058 PIN

634 P1022057 BLOCK

635 P1023635 FACE BOARD

636 P1023636 FORMICA FACE

637 P1022Z186 SCALE

638 PFB08M FLAT HEAD SCREW

639 P1023639 SPACER

640 PSB30 CAP SCREW

5

⁄16''-18 X 1⁄2''

REF# PART# DESCRIPTION

Page 35

-34- G1023 Heavy-Duty Table Saw

MACHINE DATA

GRIZZLY MODEL G1023 TABLE SAW

Design Type......................................................................................................................10" Tilting Arbor

Maximum Diameter of Saw Blade ......................................................................................................10"

Diameter of Arbor..................................................................................................................................

5

⁄8"

Capacities:

Maximum Depth of Cut at 90° ........................................................................................................3

1

⁄8"

Maximum Depth of Cut at 45° ........................................................................................................2

1

⁄8"

Maximum Rip to Right of Blade (Standard)......................................................................................26"

Maximum Rip to Right of Blade (Optional) ......................................................................................46"

Maximum Rip to Left of Blade ..........................................................................................................11"

Distance Front of Table to Center of Blade......................................................................................17"

Table in Front of Blade at Maximum Cut..........................................................................................12"

Maximum Width of Dado ................................................................................................................

13

⁄16"

Overall Dimensions:

With Wings and Guide Bars ......................................................................................50" W x 31

5

⁄16" D

Weight (Shipping)......................................................................................................................425 lbs.

Construction:

Table ........................................................................................................................Ground Cast Iron

Stand ..........................................................................................................................Pre-formed Steel

Miter Gauge ............................................................................................................Cast Iron/Steel Bar

Trunnions ................................................................................................................................Cast Iron

Table:

Height ..............................................................................................................................................34"

Size................................................................................................................27

1

⁄8

" deep x 20

1

⁄8

" wide

Size w/Extension Wings ................................................................................27

1

⁄8" deep x 36 1⁄4" wide

Miter Gauge Groove Type ............................................................................................................T-slot

Spindle Bearings ........................................................................Shielded and Lubricated-For-Life/Ball

Motor:

Type ....................................................................................................TEFC Capacitor Start Induction

Horsepower....................................................................................................................................3 HP

Power Transfer ............................................................................................................Triple Belt Drive

Phase / Cycle ......................................................................................................Single Phase / 60 HZ

Voltage ..........................................................................................................................................220V

Amps ..............................................................................................................................................18 A

Motor RPM............................................................................................................................3450 RPM

Blade RPM............................................................................................................................4140 RPM

Bearings ..................................................................................Shielded and Lubricated-For-Life / Ball

Switch ................................................................................Magnetic with Thermal Overload Protector

Specifications, while deemed accurate, are not guaranteed.

Page 36

G1023 Heavy-Duty Table Saw -35-

SYMPTOM

Motor will not start.

Motor will not start; fuses or

circuit breakers blow.

Motor overheats.

Motor stalls (resulting in

blown fuses or tripped circuit).

Machine slows when operating.

Loud, repetitious noise coming from machine.

Blade is not square w/miter

slot or fence is not square to

blade.

Fence hits table top when

sliding on to the table.

Blade does not reach 90°.

Blade hits insert at 45°.

Blade won’t go beneath

table surface.

Hand wheels won’t turn.

POSSIBLE CAUSE

1. Low voltage.

2. Open circuit in motor or loose connections.

1. Short circuit in line cord or plug.

2. Short circuit in motor or loose connections.

3. Incorrect fuses or circuit breakers in

power line.

1. Motor overloaded.

2. Air circulation through the motor

restricted.

1. Short circuit in motor or loose connections.

2. Low voltage.

3. Incorrect fuses or circuit breakers in

power line.

4. Motor overloaded.

Applying too much pressure to workpiece.

1. Pulley setscrews or keys are missing

or loose.

2. Motor fan is hitting the cover.

3. V-belts are defective

1. Blade is warped.

2. Table top is not parallel to blade.

3. Fence is not parallel to blade.

1. Front rail is bolted too low on the

table.

2. Rear rail is bolted too low on the

table.

1. 90° stop bolt is out of adjustment.

2. Pointer bracket is hitting before the

blade reaches 90°.

1. Hole in insert is inadequate.

2. Table out of alignment.

3. Blade position is incorrect.

Table top too low.

1. Hand wheel key is inserted too far.

2. Bullets are wedged.

3. Roll pin or setscrew in worm gear is

contacting geared trunnion.

CORRECTIVE ACTION

1. Check power line for proper voltage.

2. Inspect all lead connections on motor for loose or open connections.

1. Inspect cord or plug for damaged insulation and shorted wires.

2. Inspect all connections on motor for loose or shorted terminals

or worn insulation.

3. Install correct fuses or circuit breakers.

1. Reduce load on motor.

2. Clean out motor to provide normal air circulation.

1. Inspect connections on motor for loose or shorted terminals or

worn insulation.

2 Correct the low voltage conditions.

3. Install correct fuses or circuit breakers.

4. Reduce load on motor.

Feed workpiece slower.

1. Inspect keys and setscrews. Replace or tighten if necessary.

2. Tighten fan or shim cover.

3. Replace V-belts. See Maintenance.

1. Replace blade.

2. Make table parallel to blade. See Adjustments.

3. Make fence parallel to blade. See Adjustments.

1. Raise front rail.

2. Raise rear rail.

1. Adjust 90° stop bolt. See Adjustments.

2. File down the right side of the pointer bracket until the blade

can reach 90°.

1. File or mill the hole in the insert.

2. Align table. See Adjustments.

3. Adjust blade position. See Adjustments.

Raise table top w/washers.

1. Remove hand wheel and adjust key.

2. Remove hand wheel and adjust bullets.

3. Inspect roll pins and setscrews in the worm gear. Tighten if

necessary.

TROUBLE SHOOTING GUIDE

Page 37

-36- G1023 Heavy-Duty Table Saw

Grizzly Imports, Inc. warrants every product it sells for a period of 1 year to the original purchaser from the

date of purchase. This warranty does not apply to defects due directly or indirectly to misuse, abuse, negligence, accidents, repairs or alterations or lack of maintenance. This is Grizzly’s sole written warranty and

any and all warranties that may be implied by law, including any merchantability or fitness, for any particular purpose, are hereby limited to the duration of this written warranty. We do not warrant or represent that

the merchandise complies with the provisions of any law or acts unless the manufacturer so warrants. In

no event shall Grizzly’s liability under this warranty exceed the purchase price paid for the product and any

legal actions brought against Grizzly shall be tried in the State of Washington, County of Whatcom.

We shall in no event be liable for death, injuries to persons or property or for incidental, contingent, special, or consequential damages arising from the use of our products.

To take advantage of this warranty, contact us by mail or phone and give us all the details. We will then

issue you a “Return Number’’, which must be clearly posted on the outside as well as the inside of the carton. We will not accept any item back without this number. Proof of purchase must accompany the merchandise.

The manufacturers reserve the right to change specifications at any time because they constantly strive to

achieve better quality equipment. We make every effort to ensure that our products meet high quality and

durability standards and we hope you never need to use this warranty.

Please feel free to write or call us if you have any questions about the machine or the manual.

Thank you again for your business and continued support. We hope to serve you again soon.

WARRANTY AND RETURNS

Loading...

Loading...