Page 1

10" TABLE SAW

MODEL G1022SM, G1022Z, G1022ZF, G1022ZFX, G1022PRO

INSTRUCTION MANUAL

COPYRIGHT © MARCH, 2002 BY GRIZZLY INDUSTRIAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

PRINTED IN TAIWAN.

DISCONTINUED MACHINE MANUAL DISCLAIMER

THE INFORMATION IN THIS MANUAL REPRESENTS THE LAST CONFIGURATION OF THE MACHINE BEFORE IT WAS DISCONTINUED. MACHINE CONFIG-

URATIONS MAY HAVE CHANGED AS PRODUCT IMPROVEMENTS WERE INCORPORATED. IF YOU OWN AN EARLIER VERSION OF THE MACHINE, THIS

MANUAL MAY NOT EXACTLY DEPICT YOUR MACHINE . CONTACT CUSTOMER SERVICE IF YOU HAVE ANY QUESTIONS ABOUT DIFFERENCES. PREVI-

OUS VERSIONS ARE NOT AVAILABLE ONLINE.

G1022ZF

&

G1022ZFX

G1022PRO

G1022Z

G1022SM

Page 2

WARNING

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement, and other

masonry products.

• Arsenic and chromium from chemically treated

lumber.

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such

as those dust masks that are specially designed to filter out microscopic particles.

Page 3

Table Of Contents

PAGE

1. SAFETY

SAFETY RULES FOR ALL TOOLS..........................................................................................................2-3

ADDITIONAL SAFETY INSTRUCTIONS FOR TABLE SAWS ................................................................4-7

2. CIRCUIT REQUIREMENTS

110V OPERATION ......................................................................................................................................8

220V OPERATION ......................................................................................................................................9

GROUNDING ............................................................................................................................................10

EXTENSION CORDS ................................................................................................................................10

3. GENERAL INFORMATION

COMMENTARY ....................................................................................................................................11-12

UNPACKING ..............................................................................................................................................13

PIECE INVENTORY ..................................................................................................................................13

HARDWARE BAG CONTENTS ................................................................................................................14

HARDWARE RECOGNITION CHART ......................................................................................................15

CLEAN UP ................................................................................................................................................16

SITE CONSIDERATIONS..........................................................................................................................16

4. ASSEMBLY

BEGINNING ASSEMBLY ..........................................................................................................................17

STAND ..................................................................................................................................................17-18

HANDWHEELS ..........................................................................................................................................19

MOTOR ................................................................................................................................................19-21

WIRING ......................................................................................................................................................21

EXTENSION WINGS ................................................................................................................................22

FENCE RAILS ......................................................................................................................................22-23

FENCE ......................................................................................................................................................23

BLADE........................................................................................................................................................23

BLADE GUARD ....................................................................................................................................24-25

TABLE INSERT..........................................................................................................................................26

5. ADJUSTMENTS

G1022SM FENCE ................................................................................................................................27-29

G1022Z FENCE....................................................................................................................................29-30

BLADE PARALLELISM ........................................................................................................................31-32

45˚ & 90˚ POSITIVE STOPS ....................................................................................................................33

WORM GEAR ............................................................................................................................................34

MITER GAUGE ..........................................................................................................................................34

6. OPERATIONS

PRE-RUN CHECK ....................................................................................................................................35

TEST RUN ............................................................................................................................................35-36

BLADE SELECTION ............................................................................................................................36-37

CROSSCUTTING ................................................................................................................................37-38

RIPPING ....................................................................................................................................................38

DADO OPERATIONS ..........................................................................................................................39-40

RABBET OPERATIONS ......................................................................................................................40-41

7. MAINTENANCE

GENERAL ..................................................................................................................................................42

LUBRICATION ..........................................................................................................................................42

TABLE ........................................................................................................................................................42

V-BELT ......................................................................................................................................................42

WIRING DIAGRAMS ............................................................................................................................43-44

8. CLOSURE ......................................................................................................................................................45

G1022SM MACHINE DATA ......................................................................................................................46

G1022SM PART BREAKDOWNS AND PART LIST ............................................................................47-51

G1022Z MACHINE DATA ..........................................................................................................................52

G1022Z PART BREAKDOWNS AND PART LIST ..............................................................................53-57

G1022ZF/ZFX/PRO MACHINE DATA ......................................................................................................58

G1022ZF/ZFX/PRO PART BREAKDOWNS AND PART LIST ............................................................59-63

TROUBLESHOOTING GUIDE ..................................................................................................................64

PUSH STICK..............................................................................................................................................65

WARRANTY..........................................................................................................................................67-69

Page 4

-2- G1022 Series Contractor Saws

SECTION 1: SAFETY

Safety Instructions For Power Tools

5. KEEP CHILDREN AND VISITORS

AWAY. All children and visitors should be

kept a safe distance from work area.

6. MAKE WORKSHOP CHILD PROOF with

padlocks, master switches, or by removing

starter keys.

7. DO NOT FORCE TOOL. It will do the job

better and safer at the rate for which it was

designed.

8. USE RIGHT TOOL. Do not force tool or

attachment to do a job for which it was not

designed.

1. KEEP GUARDS IN PLACE and in working

order.

2. REMOVE ADJUSTING KEYS AND

WRENCHES. Form habit of checking to

see that keys and adjusting wrenches are

removed from tool before turning on.

3. KEEP WORK AREA CLEAN. Cluttered

areas and benches invite accidents.

4. DO NOT USE IN DANGEROUS ENVIRONMENT. Do not use power tools in

damp or wet locations, or where any flammable or noxious fumes may exist. Keep

work area well lighted.

For Your Own Safety Read Instruction

Manual Before Operating This Equipment

Indicates an imminently hazardous situation which, if not avoided,

WILL result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

COULD result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

MAY result in minor or moderate injury. It may also be used to alert

against unsafe practices.

This symbol is used to alert the user to useful information about

proper operation of the equipment.

The purpose of safety symbols is to attract your attention to possible hazardous conditions. This

manual uses a series of symbols and signal words which are intended to convey the level of

importance of the safety messages. The progression of symbols is described below. Remember

that safety messages by themselves do not eliminate danger and are not a substitute for proper

accident prevention measures.

NOTICE

Page 5

G1022 Series Contractor Saws -3-

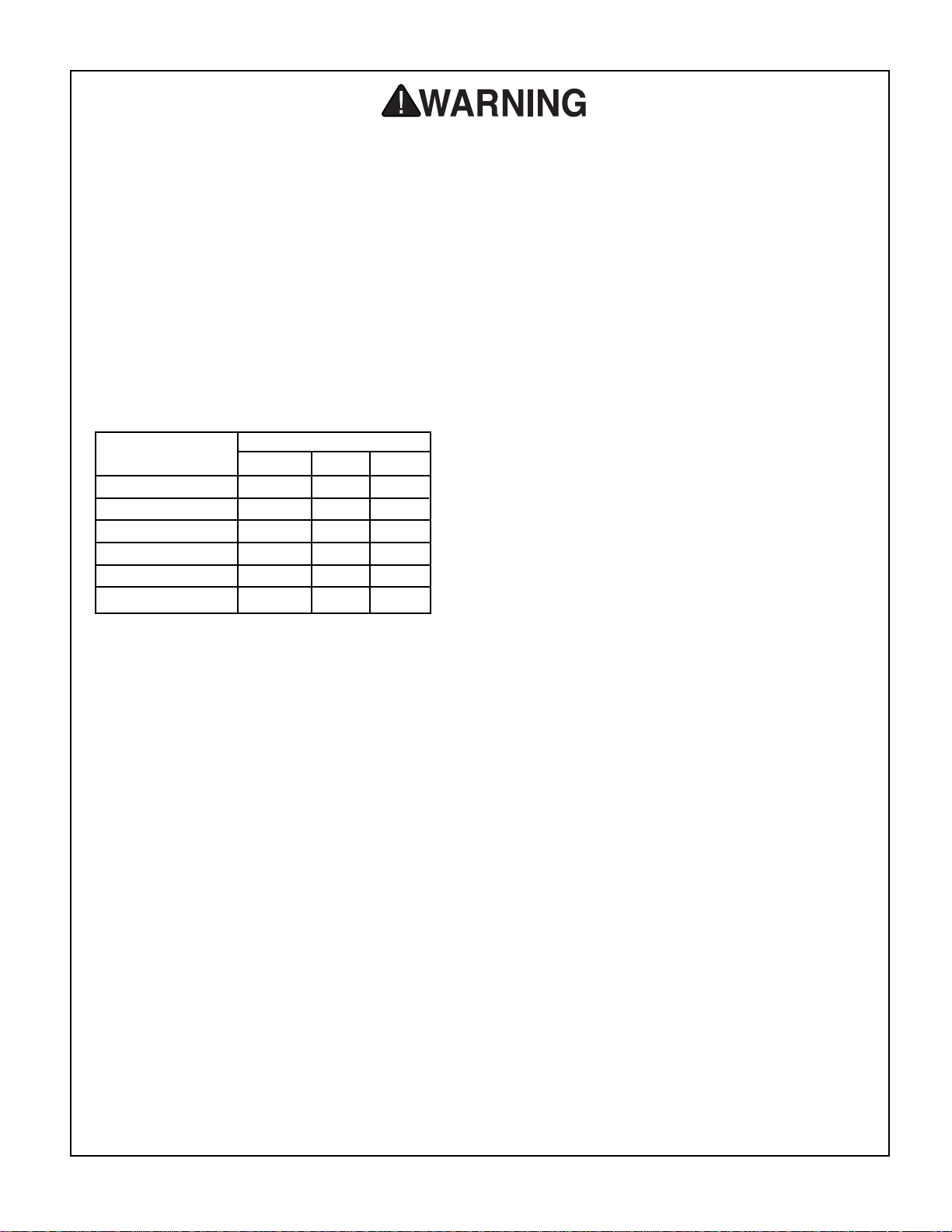

9. USE PROPER EXTENSION CORD. Make

sure your extension cord is in good condition. Conductor size should be in accordance with the chart below. The amperage

rating should be listed on the motor or tool

nameplate. An undersized cord will cause a

drop in line voltage resulting in loss of power

and overheating. Your extension cord must

also contain a ground wire and plug pin.

Always repair or replace extension cords if

they become damaged.

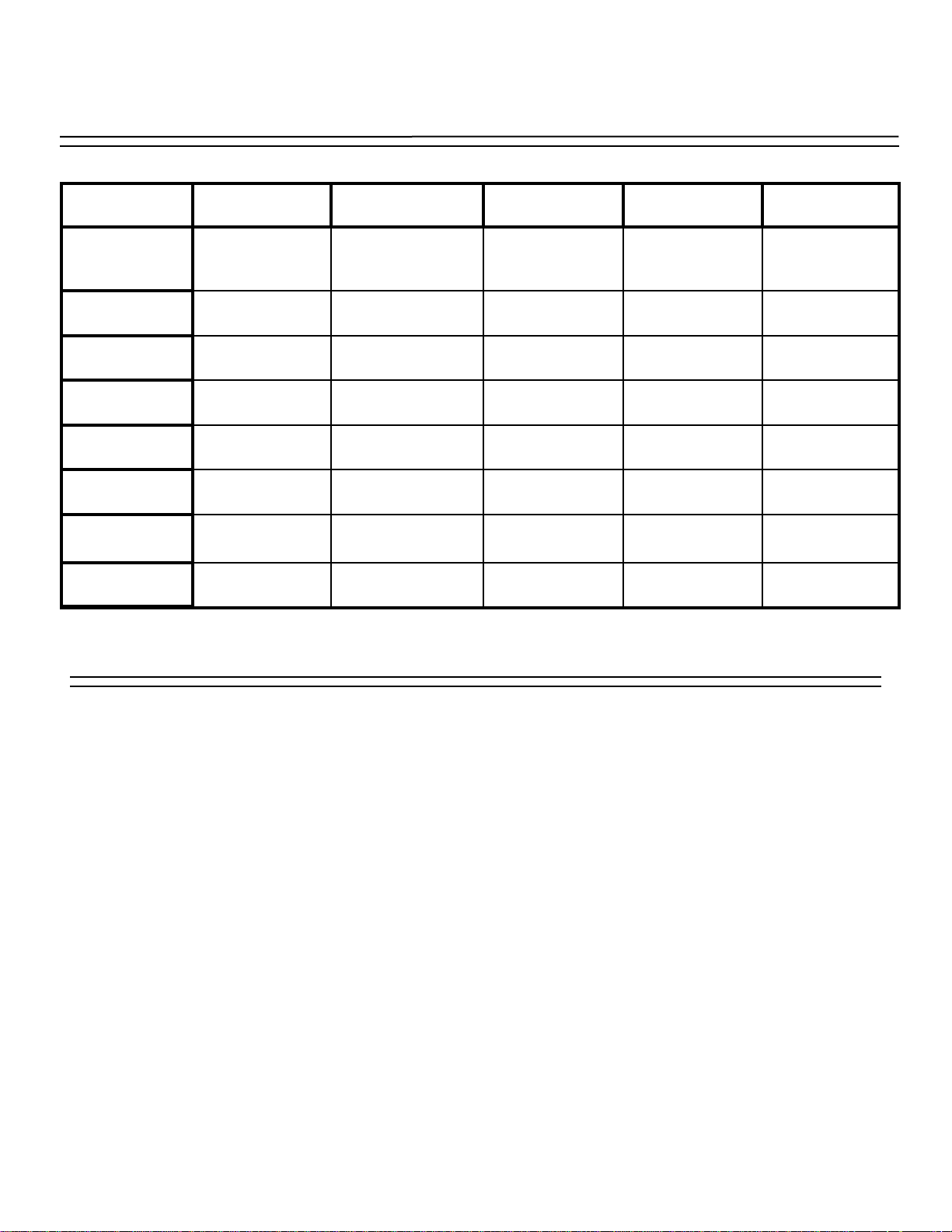

Minimum Gauge for Extension Cords

10. WEAR PROPER APPAREL. Do not wear

loose clothing, gloves, neckties, rings,

bracelets, or other jewelry which may get

caught in moving parts. Non-slip footwear is

recommended. Wear protective hair covering to contain long hair.

11. ALWAYS USE SAFETY GLASSES. Also use

face or dust mask if cutting operation is dusty.

Everyday eyeglasses only have impact resistant lenses, they are NOT safety glasses.

12. SECURE WORK. Use clamps or a vise to hold

work when practical. It’s safer than using your

hand and frees both hands to operate tool.

13. DO NOT OVER-REACH. Keep proper foot-

ing and balance at all times.

14. MAINTAIN TOOLS WITH CARE. Keep

tools sharp and clean for best and safest

performance. Follow instructions for lubricating and changing accessories.

15. USE RECOMMENDED ACCESSORIES.

Consult the owner’s manual for recommended accessories. The use of improper

accessories may cause risk of injury.

LENGTH

AMP RATING 25ft 50ft 100ft

0-6 18 16 16

7-10 18 16 14

11-12 16 16 14

13-16 14 12 12

17-20 12 12 10

21-30 10 10 No

Safety Instructions For Power Tools

16. REDUCE THE RISK OF UNINTENTIONAL STARTING. On machines with mag-

netic contact starting switches there is a

risk of starting if the machine is bumped or

jarred. Always disconnect from power

source before adjusting or servicing. Make

sure switch is in OFF position before reconnecting.

17. MANY WOODWORKING TOOLS CAN

“KICKBACK” THE WORKPIECE toward

the operator if not handled properly. Know

what conditions can create “kickback” and

know how to avoid them.

18. CHECK DAMAGED PARTS. Before fur-

ther use of the tool, a guard or other part

that is damaged should be carefully

checked to determine that it will operate

properly and perform its intended function.

Check for alignment of moving parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that

may affect its operation. A guard or other

part that is damaged should be properly

repaired or replaced.

19. NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Do not

leave tool until it comes to a complete stop.

20. NEVER OPERATE A MACHINE WHEN

TIRED, OR UNDER THE INFLUENCE OF

DRUGS OR ALCOHOL. Full mental alert-

ness is required at all times when running

a machine.

21. NEVER ALLOW UNSUPERVISED OR

INEXPERIENCED PERSONNEL TO

OPERATE THE MACHINE. Make sure

any instructions you give in regards to

machine operation are approved, correct,

safe, and clearly understood.

22. IF AT ANY TIME YOU ARE EXPERIENCING DIFFICULTIES performing the intend-

ed operation, stop using the machine!

Then contact our service department or

ask a qualified expert how the operation

should be performed.

Page 6

-4- G1022 Series Contractor Saws

Additional Safety Instructions For Table Saws

1. ALWAYS use blade guard, splitter and

anti-kickback fingers on all ''through-sawing'' operations. Through-sawing operations are those when the blade cuts completely through the workpiece as in ripping

or crosscutting.

2. AVOID KICKBACKS. A condition in which

a piece of wood is thrown back towards an

operator at a high rate of speed. If you do

not have a complete understanding of how

kickback occurs, or how to prevent it, DO

NOT operate this table saw.

3. NEVER reach behind or over the blade

with either hand for any reason.

4. ALWAYS use a push stick for ripping nar-

row stock.

5. NEVER perform any operation ''free-

hand,'' which means using only your hands

to support or guide the workpiece. Always

use either the fence or the miter gauge to

position and guide the work.

6. NEVER stand or have any part of your

body in line with the path of the saw blade.

7. ALWAYS hold the work firmly against the

miter gauge or fence and hold the work

firmly against the table.

8. MOVE the rip fence out of the way when

crosscutting.

9. NEVER use the miter gauge and rip fence

at the same time.

10. NEVER attempt to free a stalled saw blade

without first turning the saw OFF.

11. PROVIDE adequate support to the rear

and sides of the saw table for wide or long

workpieces.

12. AVOID awkward operations and hand

positions where a sudden slip could cause

your hand to move into the blade.

13. IF AT ANY TIME YOU ARE EXPERIENCING DIFFICULTIES performing the intend-

ed operation, stop using the machine!

Then contact our service department or

ask a qualified expert how the operation

should be performed.

14. ALWAYS LOWER OR REMOVE SAW

BLADE WHEN NOT IN USE.

15. NEVER USE A DAMAGED SAW BLADE

OR ONE THAT HAS BEEN DROPPED.

16. USE GREAT CARE WHEN CUTTING

WITH A DADO BLADE. There is a high

degree of risk involved with any dado operation. Slight movement of the stock away

from the fence will cause kickback.

No list of safety guidelines can be complete. Every shop environment is different.

Always consider safety first, as it applies to

your individual working conditions. Use

this and other machinery with caution and

respect. Failure to follow guidelines could

result in serious personal injury, damage to

equipment or poor work results.

Page 7

G1022 Series Contractor Saws -5-

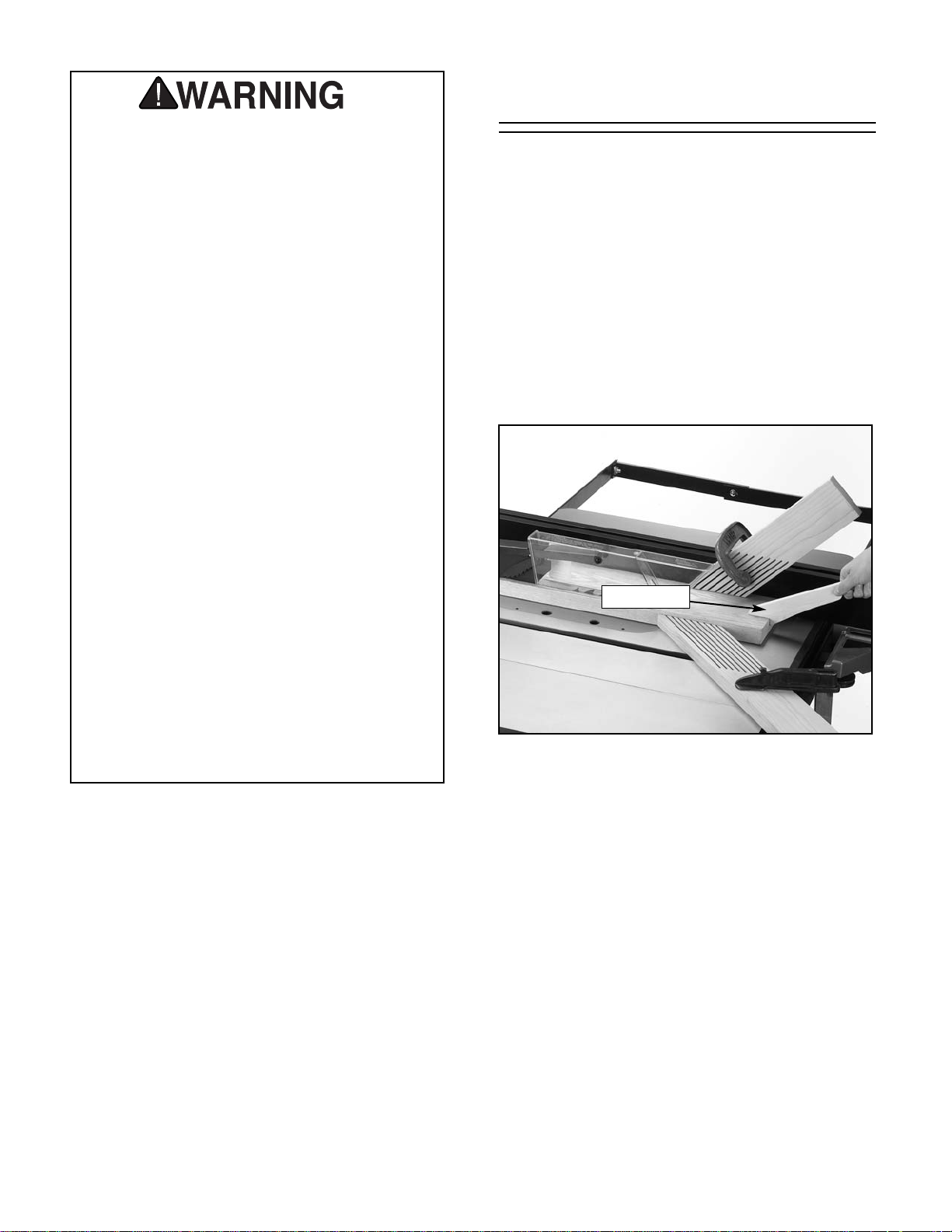

Push Sticks

The use of push sticks, particularly when cutting

small or narrow workpieces, provides a double

benefit for saw operators. The push stick provides added leverage, enabling the operator to

keep the workpiece firmly supported against the

fence and table. At the same time, the push stick

keeps the operator’s hand safely away from the

rotation of the saw blade as shown in Figure 1.

See the template on Page 62 of the manual for

construction details, or purchase one from the

Grizzly catalog.

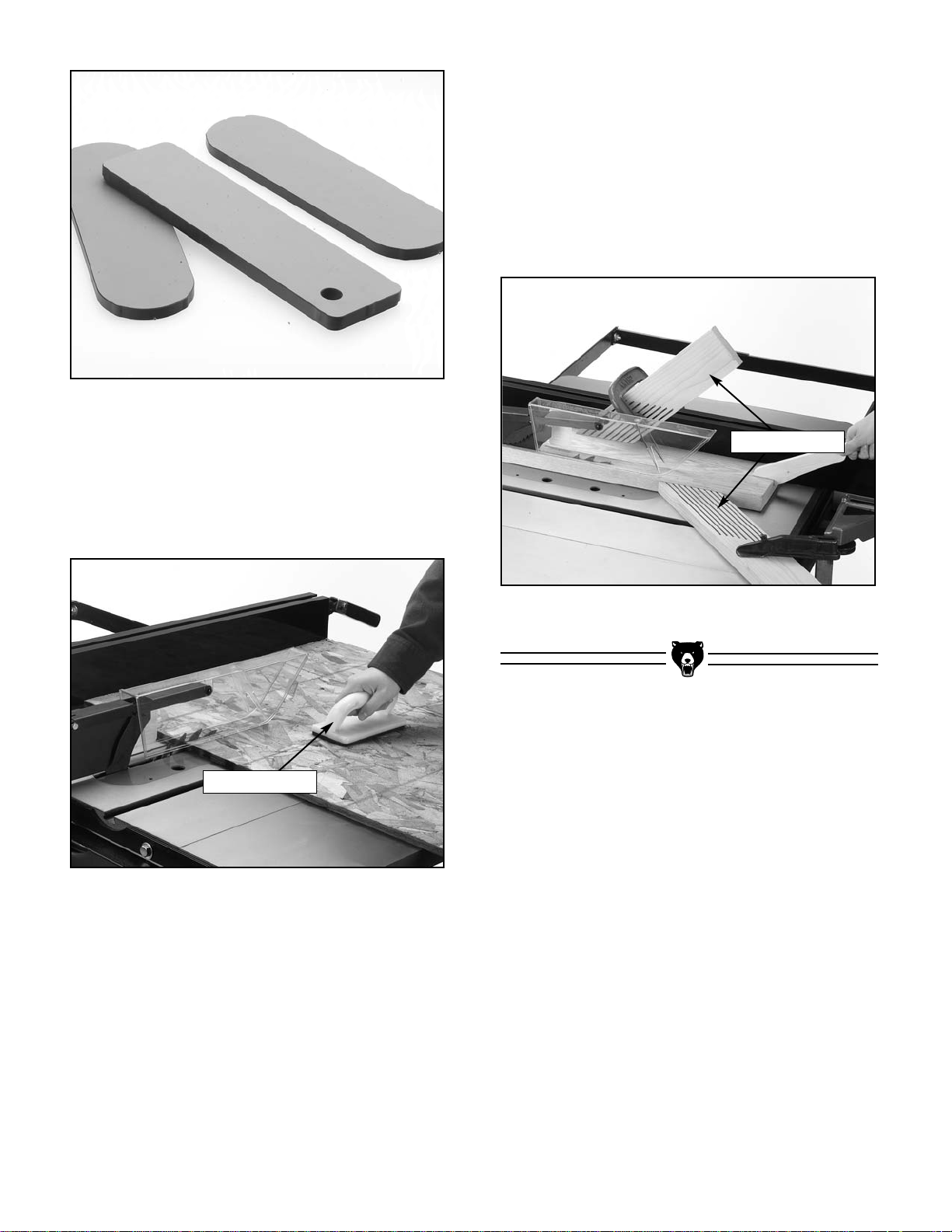

Zero Clearance Table Inserts

Ideal for use when ripping thin strips or making

bevel cuts, these prevent tearout and jammed

blades by supporting material close to the blade.

Use the standard table insert as a template when

creating additional inserts from wood or plywood.

Blade slot inserts can be custom cut for specific

blade angles by raising the running blade into an

uncut insert at the angle you desire. Be sure to

make an additional slot for the blade splitter. We

also carry a wide selection of table inserts shown

in Figure 2 in the Grizzly catalog. Be sure to hold

the insert firmly in place with a piece of wood

when creating slots. Never hold the table insert

with your hand while cutting new slots.

Safety Accessories

Statistics prove that most common accidents among table saw users can be

linked to kickback. Kickback is typically

defined as the high-speed expulsion of

stock from the table saw toward its operator. In addition to the danger of the operator or others in the area being struck by

the flying stock, it is often the case that

the operator’s hands are forced into the

blade during the kickback. The following

can help minimize kickbacks.

1. Use your blade guard and splitter.

2. Never for any reason place your hand

behind the blade. Should kickback

occur, your hand will be pulled into the

blade.

3. Inspect splitter for alignment between it

and your blade.

4. Never use the fence as a guide for crosscutting.

5. Never attempt freehand cuts.

6. Use a push stick or featherboard to

maintain control of your workpiece.

7. Feed cuts through to completion.

8. Stand to the side when ripping.

9. Ensure your fence and miter slot are parallel to the blade.

If you do not have a clear understanding of

kickback and how it occurs, do not operate

this table saw.

Figure 1. Push Stick.

Push Stick

Page 8

-6- G1022 Series Contractor Saws

Push Paddles

Push paddles provide added leverage and support when ripping or crosscutting wide work-

pieces as shown in Figure 3. We offer a number

of push paddles in the Grizzly catalog.

Featherboards

Easily made from scrap stock, featherboards

provide an added degree of protection against

kickback as shown in Figure 4. To make a

featherboard, cut a 30-40° angle at one end of

the board and make a number of end cuts at

approximately

1

⁄4" apart and 2" to 3" deep. We

also offer a number of featherboards in the

Grizzly catalog.

Figure 2. Zero Clearance Table Inserts.

Figure 3. Push Paddles.

Figure 4. Featherboards.

Push Paddles

Featherboards

Page 9

G1022 Series Contractor Saws -7-

Common Definitions, Terms and Phrases

The following is a list of common definitions, terms and phrases used throughout this manual as they relate

to this table saw and woodworking in general. It is important that you read and become familiar with them

before assembling, adjusting or operating this machine. Your safety is VERY important to us at Grizzly!

Arbor: Metal shaft extending from the drive

mechanism, to which the cutting blade is

attached.

Bevel Edge Cut: Tilting the saw arbor and blade

to an angle between 0° and 45° to perform an

angled cutting operation.

Blade Guard: Metal or plastic mechanism that

mounts over the saw blade to prevent accidental contact with the cutting edge.

Crosscut: Table saw operation in which the miter

gauge is used to cut across the grain of a piece

of wood.

Dado Blade: Blade or set of blades that attach to

the arbor and are used for cutting grooves and

rabbets.

Dado Cut: Table saw operation that uses a dado

blade to cut a flat bottomed groove into the

face of wood stock.

Featherboard: Safety device used to keep a

board against the rip fence or table. Allows

operator to keep hands away from the saw

blade.

Kerf: The resulting cut or gap made by a saw

blade.

Kickback: A condition in which the wood is

thrown back towards an operator at a high rate

of speed.

Miter Gauge: A component that controls the

wood stock movement while performing a

crosscut. Allows for variation of angle cuts

such as miter cuts used on a picture frame.

Moulding Head: A cutterhead attached to the

arbor. Accepts interchangeable moulding

knives for profile cutting. We DO NOT recommend the use of a moulding head as they

require advanced skills in their operation.

Parallel: Being an equal distance apart at every

point. i.e. the rip fence face is parallel to the

side face of the saw blade.

Non-Thru Cut: A sawing operation that requires

the removal of the blade guard and splitter.

Dado and rabbet cuts are considered NonThru Cuts because the blade does not protrude above the top face of the wood stock.

Always remember to reinstall the blade guard

and splitter after performing a non-thru cut.

Perpendicular: Intersecting and forming right

angles; at right angles to the vertical and horizontal planes. i.e. the blade is perpendicular to

the table surface.

Push Paddle: Safety aid used to push a piece of

wood stock through a cutting operation.

Push Stick: Safety aid used to push a piece of

wood stock through a cutting operation.

Usually used when rip cutting.

Rabbet: Cutting operation that creates an L-

shaped channel along the edge of wood stock.

Splitter: Metal plate attached to the back of the

blade guard that maintains the kerf opening in

the wood when performing a cutting operation.

Standard Kerf:

1

⁄8" gap made with a standard

blade.

Straightedge: A tool used to check the flatness,

parallelness, or consistency of a surface(s).

Thru-Sawing: A sawing operation where the

wood stock thickness is completely sawn

through. Proper blade height usually allows

1

⁄4"

of the top of the blade to extend above the

wood stock.

Thin Kerf:

3

⁄32" gap made with a thin kerf blade.

Rip Cut: A cut made along grain of the wood.

Sacrificial Fence: A piece of wood attached to

the face of the rip fence that is designed to

extend the fence face away from the metal portion of the fence. Used primarily when making

rabbet cuts with a dado blade.

Page 10

-8- G1022 Series Contractor Saws

SECTION 2: CIRCUIT REQUIREMENTS

110V Operation

The Model G1022SM, Z and ZF motors are

prewired to operate at 110V. See Figure 5 for a

typical 110V installation.

G1022SM and G1022Z:

Under normal 110V use, the Models G1022SM

and Z motors draw approximately 16 amps. We

recommend a 20 amp circuit breaker or a 20 amp

slow-blow fuse.

G1022ZF:

Under normal 110V use, the Model G1022ZF

motor draws approximately 17 amps. We recommend a 20 amp circuit breaker or a 20 amp slowblow fuse.

The circuit you use should be dedicated, (i.e., the

machine should provide the only draw from that

circuit). If frequent circuit failures occur when

using this machine, contact our Service

Department or your local electrical contractor.

Because of the high amperage draw of the Model

G1022 Series when wired for 110V, standard

household circuit wiring may not be of a large

enough gauge. A qualified electrician may need to

install a new circuit with wires capable of handling

a 20 amperage draw. Do not attempt to modify an

existing circuit by replacing the circuit breaker

with one rated for a higher amperage.

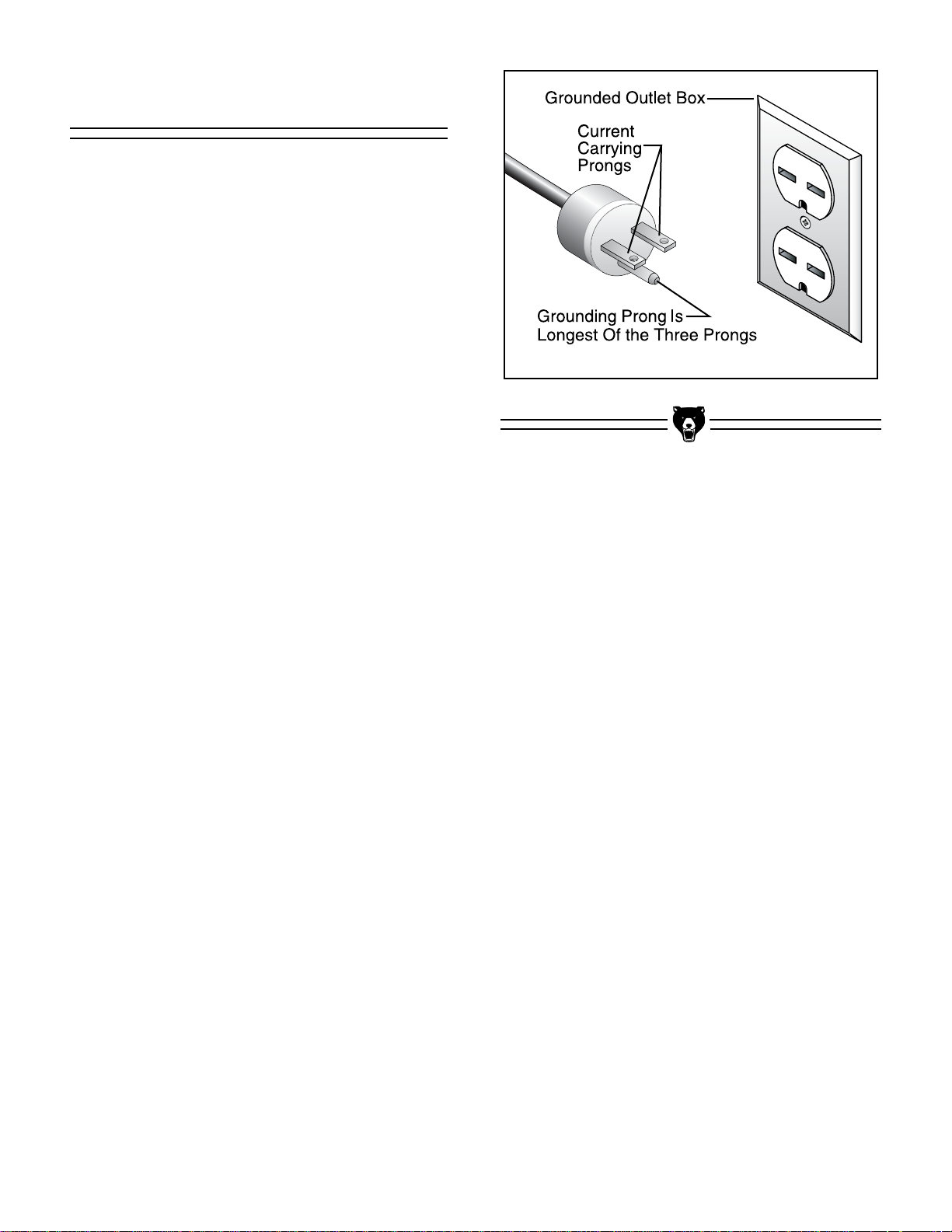

Figure 5. Typical 110V 3-prong plug and outlet.

Page 11

G1022 Series Contractor Saws -9-

220V Operation

G1022ZFX and G1022PRO:

The motors supplied with the Models G1022ZFX

and G1022PRO are prewired to operate at 220V.

The Models G1022ZFX and G1022PRO are not

supplied with a plug; therefore, a suitable 220V

plug must be wired in. When operating at 220V,

we recommend using a NEMA-style 6-15 plug

and outlet as shown in Figure 6A. You may also

“hard-wire” the machine directly to your panel,

provided you place a disconnect switch near the

machine. Check the electrical codes in your area

for specifics on wiring requirements.

Under normal use, the motor draws approximately 13 amps at 220V. We recommend a 15 amp circuit breaker for 220V operation. This should be

satisfactory for normal use while providing

enough protection against circuit damage caused

by power surges. Always check to see if your current wires are capable of handling a 15 amp load.

If you are unsure, consult the advice of a qualified

electrician. Do not attempt to modify an existing

circuit by replacing the circuit breaker with one

rated for a higher amperage.

Figure 6A. Typical 220V 3-prong plug and outlet.

Page 12

-10- G1022 Series Contractor Saws

We do not recommend the use of extension cords

with 220V equipment. It is much better to arrange

the placement of your equipment and the installed

wiring to eliminate the need for extension cords.

Should it be necessary to use an extension, make

sure the cord is rated Hard Service (grade S) or

better. Refer to the chart in Section 1: Safety

Instructions to determine the minimum gauge for

the extension cord when using either 110V or

220V. The extension cord must also contain a

ground wire and plug pin. Always repair or replace

extension cords when they become worn or damaged.

We have covered some basic electrical

requirements for the safe operation of your

machine. These requirements are not necessarily comprehensive. You must be sure

that your particular electrical configuration

complies with local and state codes.

Ensure compliance by checking with your

local municipality or a licensed electrician.

Grounding Extension Cords

In the event of an electrical short, grounding provides electric current a path of least resistance to

reduce the risk of electrical shock. This tool is

equipped with an electric cord having an equipment-grounding conductor which must be properly connected to a grounding plug. The plug must

be plugged into a matching outlet that is properly

installed and grounded in accordance with all

local codes and ordinances.

Improper connections of the electrical-grounding

conductor can result in risk of electric shock. The

conductor with green or green and yellow striped

insulation is the electrical-grounding conductor. If

repair or replacement of the electric cord or plug

is necessary, do not connect the equipment

grounding conductor to a live terminal.

This equipment must be

grounded. Verify that any

existing electrical outlet

and circuit you intend to

plug into is actually

grounded. Under no circumstances should the

grounding pin from any

three-pronged plug be

removed. Serious injury

may occur.

Page 13

G1022 Series Contractor Saws -11-

SECTION 3: INTRODUCTION

We are proud to offer the Model G1022 Series

Table Saws. The Model G1022 Series is part of a

growing Grizzly family of fine woodworking

machinery. When used according to the guidelines set forth in this manual, you can expect

years of trouble-free, enjoyable operation and

proof of Grizzly’s commitment to customer satisfaction.

The Model G1022 Series comes in 5 different versions. The differences are listed on the chart at

the beginning of this manual. The SM, Z, ZF, ZFX

and PRO are all 10" heavy-duty table saws

designed for a wide variety of cutting applications.

They feature ball bearing arbors on a worm gear

mechanism, precision-ground cast iron tables

(except the Model G1022SM), sturdy steel

stands, standard and dado inserts and a miter

gauge.

We also offer many accessories for the table

saws including blades, extension rails, outfeed

rollers and a mobile base. Please refer to our current catalog for prices and ordering information.

We are also pleased to provide this manual with

the Model G1022 Series. It was written to guide

you through assembly, review safety considerations, and cover general operating procedures. It

represents our effort to produce the best documentation possible. If you have any comments

regarding this manual, please write to us at the

address below:

Grizzly Industrial, Inc.

C

/

O Technical Documentation

P.O. Box 2069

Bellingham, WA 98227-2069

Commentary

Item G1022SM G1022Z G1022ZF G1022ZFX G1022PRO

Extension

Wings

Rip Fence

Miter Gauge

Motor

Pre-Wired

Switch

Weight

Dust Port

Sheet Metal

Standard

Standard

1.5 H.P.-110/220V

110V

Body Mounted

220 lbs

-

Cast Iron

Shop Fox

®

Classic

Adjustable Slot

2H.P.-110/220V

220V

Rail Mounted

340 lbs

4" Port

Cast Iron

T-Slot Fence

Standard Orange

1.5 H.P.-110/220V

110V

Body Mounted

250 lbs

-

Cast Iron

Shop Fox

®

Adjustable Slot

1.5 H.P.-110/220V

110V

Rail Mounted

290 lbs

4" Port

Cast Iron

Shop Fox

®

Adjustable Slot

2 H.P.-110/220V

220V

Rail Mounted

290 lbs

4" Port

Page 14

-12- G1022 Series Contractor Saws

Most importantly, we stand behind our machines.

If you have any service questions or parts

requests, please call or write us at the location

listed below:

Grizzly Industrial, Inc.

1203 Lycoming Mall Circle

Muncy, PA 17756

Phone: (570) 546-9663

Fax: (800) 438-5901

E-Mail: techsupport@grizzly.com

Web Site: http://www.grizzly.com

The specifications, drawings, and photographs

illustrated in this manual represent the Model

G1022 Series as supplied when the manual was

prepared. However, owing to Grizzly’s policy of

continuous improvement, changes may be made

at any time with no obligation on the part of

Grizzly. Whenever possible, though, we send

manual updates to all owners of a particular tool

or machine. Should you receive one, we urge you

to insert the new information with the old and keep

it for reference.

Read the manual before

assembly and operation. Become familiar

with the machine and its

operation before beginning any work. Serious

personal injury may

result if safety or operational information is not

understood or followed.

Page 15

G1022 Series Contractor Saws -13-

Unpacking

If moving this machine

up or down stairs, the

machine must be dismantled and moved in

smaller pieces. Make

sure floor and stair

structures are capable of

supporting the combined weight of the

machine parts and the

people moving them.

The Model G1022 Series is shipped from the

manufacturer in a carefully packed carton. If you

discover the machine is damaged after you have

signed for delivery, immediately call Customer

Service for advice.

When you are completely satisfied with the condition of your shipment, you should inventory its

parts.

The Model G1022 Series

represents a heavy load.

Seek assistance before

beginning assembly.

Some metal parts may

have sharp edges on

them after they are

formed. Please examine

the edges of all metal

parts before handling

them. Failure to do so

could result in injury.

Piece Inventory

After all the parts have been removed from the carton, you should have:

1. Stand Components

2. Extension Wings (2)

3. V-Belt

4. Motor with Pulley

5. Motor Bracket

6. Motor Mount Plate

7. Table Saw Unit

8. Handwheels (2)

9. Arbor Wrench

10. Dado Insert

11. Standard Insert

12. Miter Gauge

14. Blade Guard

15. Blade Guard Bracket

16. Hardware Bags (5)

17. V-Belt Guard and Mounting Hardware

18. V-Belt Guard Bracket

19. Fence Unit (Separate Box W/ZF, ZFX and Pro)

20. Fence Rails (Separate Box)

Figure 6B. (G1022 Layout) Rip fence, rails and

extension wings will vary depending on model.

20

19

2

8

18

4

12

10

11

9

15

3

6

17

14

16

5

7

1

Page 16

-14- G1022 Series Contractor Saws

Hardware Contents

Qty Description

8 Special Rail Bolt (SM & Z)

8 Fence Rail Spacer (SM & Z)

4Flat Washer M10 (SM & Z)

4Hex Nut M10-1.5 (SM & Z)

4 Fence Rail Plug (SM & Z)

6 Flat Washer M10 x M4 Thick

6 Hex Bolt M10-1.5 x 25

2 Hand Wheel Knob

Guide Rail & Extension Wing Hardware Bag

Qty Description

1 Hex Bolt

1

⁄4"-20 x 2"

1 Flat Washer

1

⁄

4"

1Sleeve

1Wing Nut

1

⁄4"-20

1 Plastic Belt Guard

Plastic Belt Guard Hardware Bag

Qty Description

4 Hex Bolt M8-1.25 x 25

8 Flat Washer M8

4 Hex Nut M8-1.25

Motor Mount Hardware Bag

Qty Description

40 Carriage Bolt M8-1.25 x 16

4 Hex Bolt M8-1.25 x 19

48 Flat Washer M8

44 Hex Nut M8-1.25

4 Hex Bolt M10-1.5 x 20

4 Hex Nut M10-1.5

4 Flat Washer M10

4 Plastic Foot

4 Hex Bolt #10-24 x

3

⁄8" (ZX, ZFX, PRO)

4 Hex Nut #10-24 (ZX, ZFX, PRO)

4 Lock Washer #10 (ZX, ZFX, PRO)

Floor Stand Hardware Bag

In the event that any nonproprietary parts are

missing (e.g. a nut or a washer), we would be

glad to replace them, or for the sake of expediency, replacements can be obtained at your local

hardware store.

Page 17

G1022 Series Contractor Saws -15-

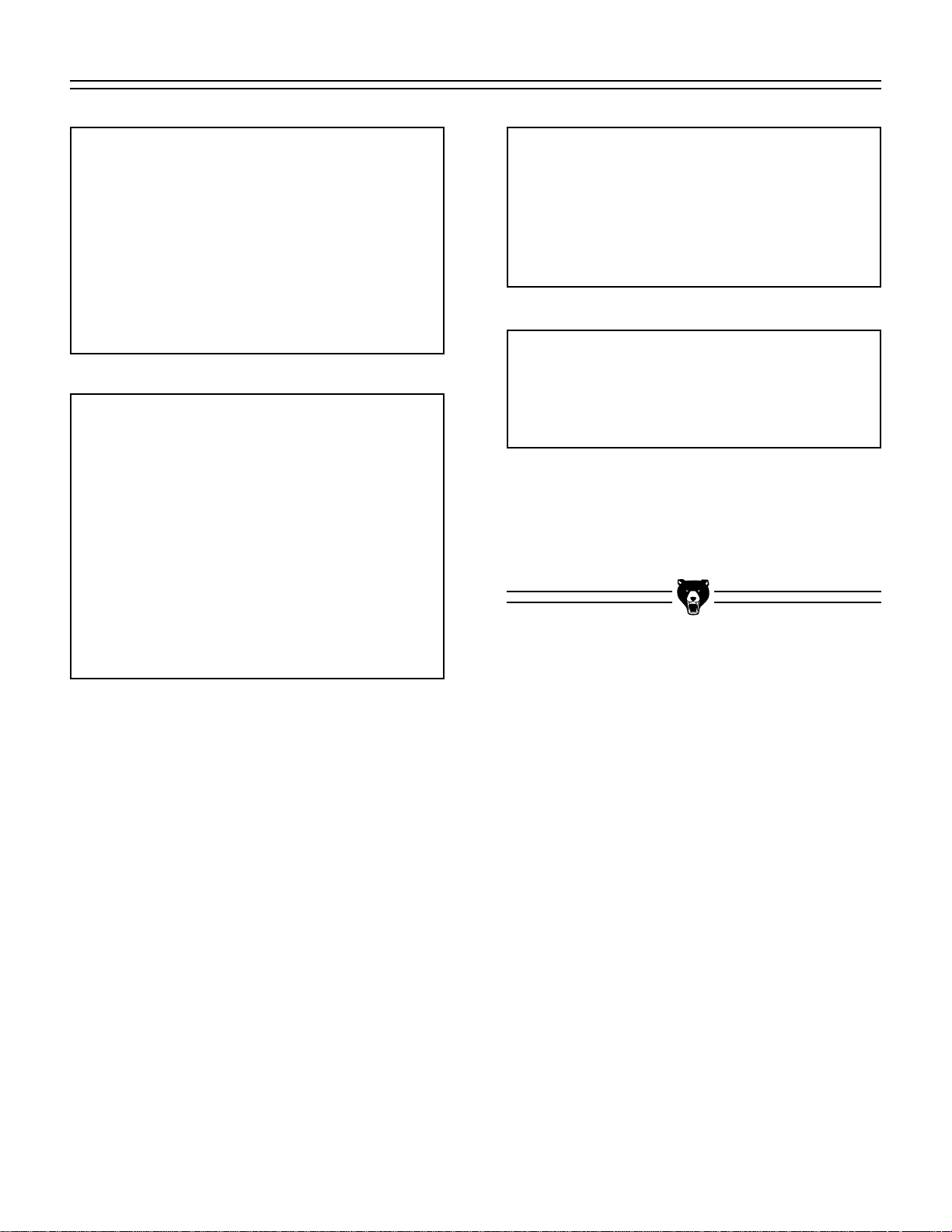

Hardware Recognition Chart

Use this chart to match up

hardware pieces during the

assembly process!

#

10

Lock

Nut

Wing

Nut

S

A

W

D

I

A

R

E

H

M

E

T

⁄8''

E

R

5

1

⁄4''

5

⁄16''

3

⁄8''

7

⁄16''

1

⁄2''

5

⁄8''

MEASURE BOLT DIAMETER BY PLACING INSIDE CIRCLE

4mm

6mm

8mm

10mm

12mm

LINES ARE 1MM APART

16mm

Thumb

Screw

Cap

Screw

Setscrew

Washer

5mm

10mm

15mm

20mm

25mm

30mm

35mm

40mm

45mm

50mm

55mm

60mm

65mm

70mm

75mm

Phillips

Head

Screw

Carriage

Bolt

Hex

Head

Bolt

Lock

Washer

1

⁄4''

3

⁄8''

1

⁄2''

5

⁄8''

⁄16'' INCH APART

1

LINES ARE

Countersunk

Phillips

Head

Screw

Flange

Bolt

Phillips

Head

Hex

Bolt

Hex

Nut

5

⁄16''

7

⁄16''

9

⁄16''

3

⁄4''

7

⁄8''

1''

11⁄4''

1

⁄2''

1

3

⁄4''

1

2

1

⁄4''

2

1

⁄2''

2

3

⁄4''

2

3

Slotted

Screw

E

H

S

A

W

Button

Head

Screw

Phillips

A

H

S

W

E

Head

Sheet

Metal

Screw

S

D

I

A

M

R

S

A

S

H

W

H

A

E

S

A

E

W

R

E

H

12mm

W

R

10mm

D

8mm

E

T

E

R

D

I

A

R

M

E

E

H

T

S

E

A

R

W

D

I

A

M

4mm

E

T

E

R

D

I

A

R

M

E

A

W

6mm

E

T

E

R

H

S

I

A

M

E

T

E

R

WASHERS ARE MEASURED BY THE INSIDE DIAMETER

D

I

A

R

M

E

T

⁄16''

1

⁄2''

R

7

R

E

A

W

H

S

D

D

⁄16''

3

R

E

A

H

S

E

I

⁄8''

5

A

A

I

D

D

⁄16''

W

R

1

⁄4''

W

E

H

S

A

#

M

A

M

I

A

I

D

R

W

10

E

R

E

T

E

R

E

T

E

R

M

E

T

E

R

A

M

E

T

E

R

I

A

M

E

T

E

R

D

I

A

M

E

T

E

R

9

R

E

H

A

W

H

S

Page 18

-16G1022 Series Contractor Saws

Clean Up

The unpainted surfaces are coated with a waxy oil

to protect them from corrosion during shipment.

Remove this protective coating with a solvent

cleaner or citrus-based degreaser such as

Grizzly’s G7895 Degreaser. Avoid chlorine-based

solvents as they may damage painted surfaces

should they come in contact. Always follow the

usage instructions on the product you choose for

clean up.

Do not smoke while using

solvents. A risk of explosion or fire exists and may

result in serious personal

injury.

Do not use gasoline or

other petroleum-based

solvents. They have low

flash points which make

them extremely flammable. A risk of explosion

and burning exists if

these products are

used. Serious personal

injury may occur if this

warning is ignored.

Many of the solvents

commonly used to clean

machinery can be toxic

when inhaled or ingested. Always work in wellventilated areas far from

potential ignition sources

when dealing with solvents. Use care when disposing of waste rags and

towels to be sure they do

not create fire or environmental hazards.

Site Considerations

FLOOR LOAD

Your Model G1022 Series represents a medium

load in a small footprint. Most commercial or

home shop floors should be sufficient to carry the

weight of the Model G1022 Series. If you question

the strength of your floor, you can opt to reinforce

it.

WORKING CLEARANCES

Working clearances can be thought of as the distances between machines and obstacles that

allow safe operation of every machine without limitation. Consider existing and anticipated machine

needs, size of material to be processed through

each machine, and space for auxiliary stands

and/or work tables. Also, consider the relative

position of each machine to one another for efficient material handling. Be sure to allow yourself

sufficient room to safely run your machines in any

foreseeable operation and keep dust collection

hoses off the floor and out of the way.

LIGHTING AND OUTLETS

Lighting should be bright enough to eliminate

shadows and prevent eye strain. Electrical circuits

should be dedicated or large enough to handle

combined motor amp loads. Outlets should be

located near each machine so power or extension

cords are not obstructing high-traffic areas. Be

sure to observe local electrical codes for proper

installation of new lighting, outlets, or circuits.

Make your shop “child

safe.” Ensure that your

workplace is inaccessible

to youngsters by closing

and locking all entrances

when you are away. Never

allow visitors in your shop

when assembling, adjusting or operating equipment.

Page 19

G1022 Series Contractor Saws

-17-

SECTION 4: ASSEMBLY

Beginning Assembly

Stand Assembly

Most of your Model G1022 Series has been

assembled at the factory, but some parts must be

assembled or installed after delivery. We have

organized the assembly process into steps.

Please follow along in the order presented here.

TOOLS REQUIRED: High quality square and

straightedge, metric Allen

®

wrench set, flat screw-

driver, Phillips

®

screwdriver, dead blow hammer

and a 6" or 8" adjustable wrench.

Disconnect power to the

machine when performing any maintenance,

assembly or adjustments. Failure to do this

may result in serious

personal injury.

Keep loose clothing

rolled up and out of the

way of machinery and

keep hair pulled back.

Wear safety glasses during the entire assembly

process. Failure to comply may result in serious

personal injury.

Some metal parts may

have sharp edges on

them after they are

formed. Please examine

the edges of all metal

parts before handling

them. Failure to do so

could result in injury.

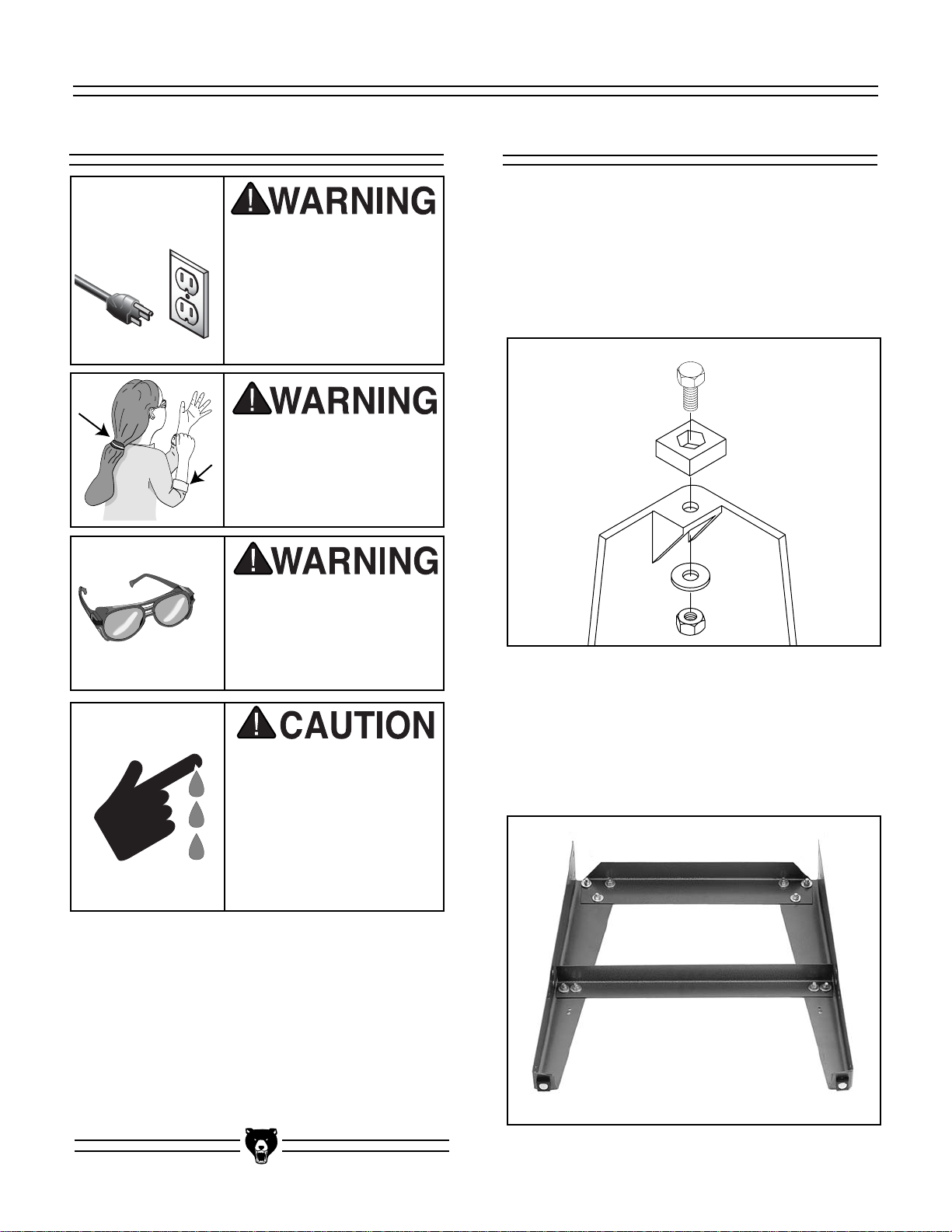

Figure 7. Installing the rubber feet.

The Model G1022 Series is supplied with a

heavy-duty stand. To assemble the stand:

1. Fasten the plastic feet to all four legs using

the M10-1.5 x 25 hex bolts, 10MM flat washers and M10-1.5 hex nuts as shown in

Figure 7.

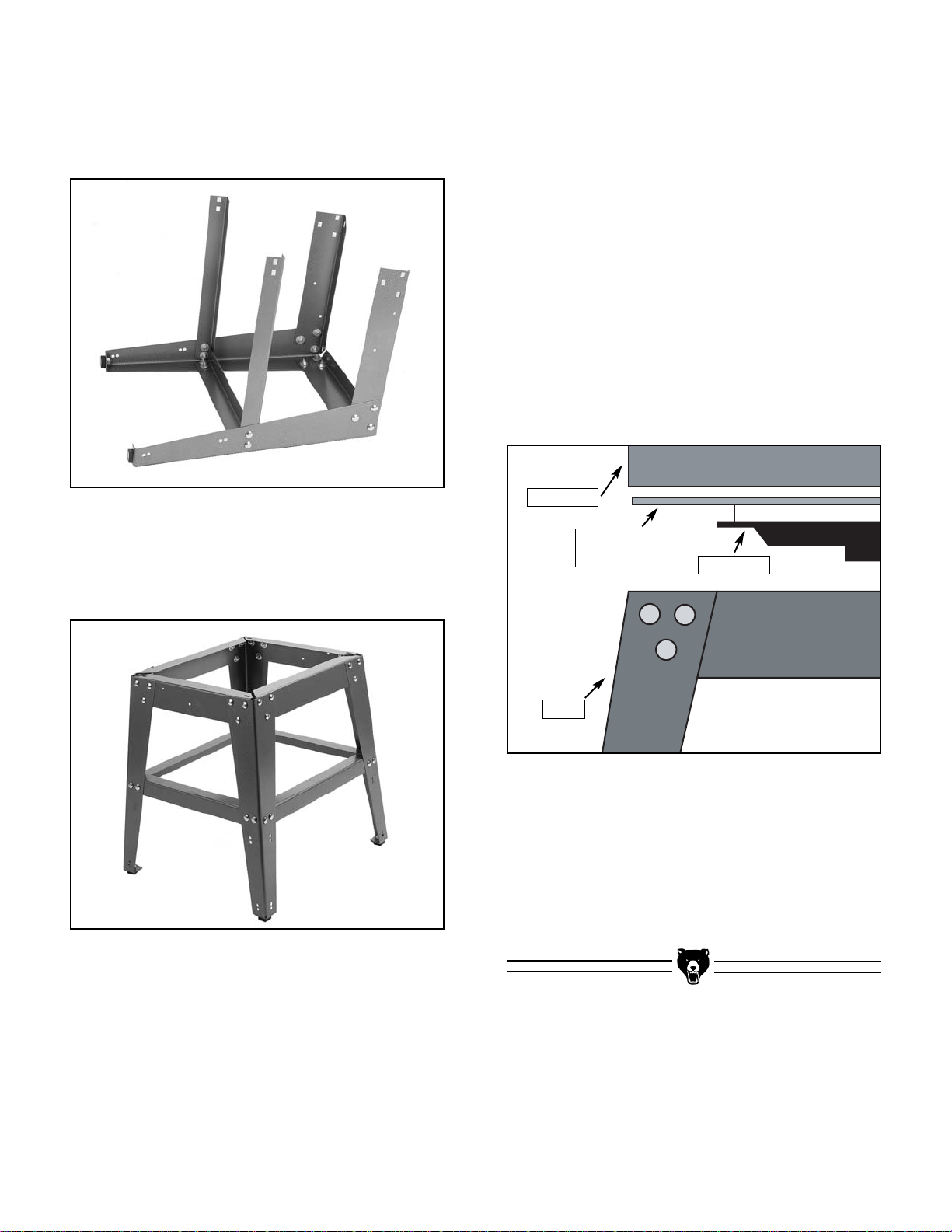

2. Locate the long upper and lower side braces

(2 each) and bolt to the legs using the M8-

1.25 x 16 carriage bolts, 8MM flat washers

and M8-1.25 hex nuts as shown in Figure 8.

Do not tighten any stand bolts at this time.

Figure 8. Assembled side panel.

!

Page 20

-18- G1022 Series Contractor Saws

Figure 9. Assembled stand section.

3. Attach the short upper and lower side braces

to one of the assembled side panels. Use the

M8 - 1.25 x 16 carriage bolts, 8MM flat washers and M8-1.25 hex nuts as shown in

Figure 9.

6. Note the location of the mounting holes on

the top of the stand. Turn the table saw body

upside-down and place the dust hood and

adapter assembly over the bottom of the

table saw body with the dust port flange

pointed up.

All Models:

7. Align the holes at the four corners. Place the

assembled stand upside down on the table

saw body, and line up its mounting holes.

Make certain the side of the stand with the “Z

Series” label, if applicable, is on the front side

of the machine (the side with the Grizzly label

and angle scale). Secure with M8-1.25 x 19

hex bolts, 8MM flat washers and M8-1.25

hex nuts, with the dust port sandwiched

between as shown in Figure 11.

4. Bolt the other side panel to the upper and

lower braces using the M8-1.25 x 16 carriage bolts, 8MM flat washers and M8-1.25

hex nuts as shown in Figure 10.

G1022ZF and ZFX:

5. Take the black plastic dust hood with the 4"

port and align it with the opening in the

adapter. The bolt holes on each of the four

corners should line up. Using 10-24 x

3

⁄

8"

bolts, 10-24 nuts and 3⁄16" lock washers to

secure the hood to the adapter.

Figure 10. Stand completely assembled.

Figure 11. Attaching the stand to the saw base.

8. With the help of a second person, flip the

entire table saw unit right side-up and move

it into its working position. Level the stand by

checking all sides for symmetry. Measure

diagonally from top to bottom and adjust the

stand so both diagonals are equal. Tighten

all of the stand bolts.

Stand

Dust Hood

Saw Body

Dust Hood

Adapter

Page 21

G1022 Series Contractor Saws -19-

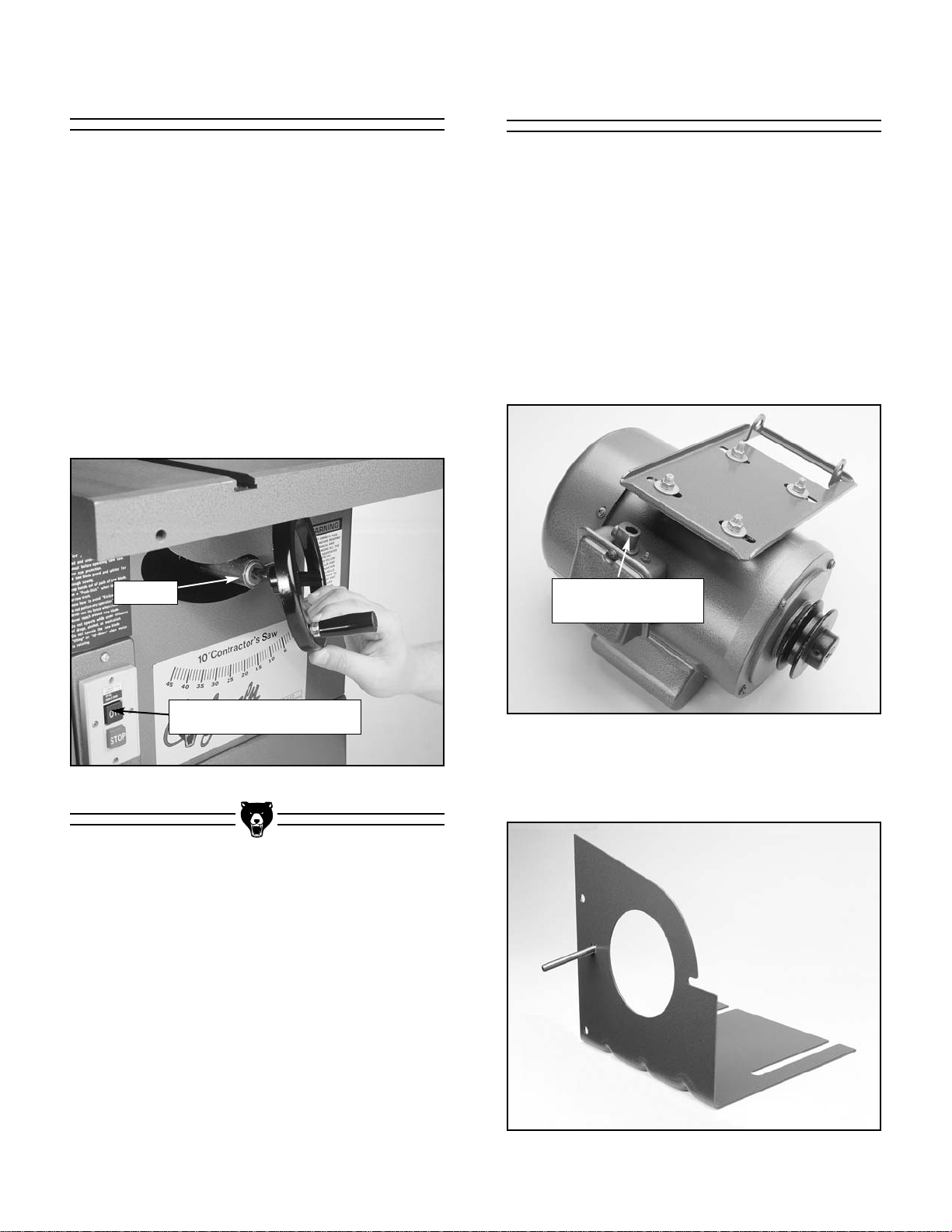

Figure 13. Attaching the motor plate.

The following pictures show the motor and V-belt

included with the Model G1022SM and Z. The

motor and belt included with the Model G1022ZF,

ZFX and PRO will look slightly different but will

assemble in the same manner as shown.

To mount the motor:

1. Turn the motor upside down and attach the

motor plate using M8-1.25 x 25 hex bolts,

8MM flat washers and M8-1.25 hex nuts as

shown in Figure 13. Finger-tighten only.

Motor

Figure 12. Mounting the handwheels.

To mount the handwheels:

1. Position a handwheel over the arbor raising

shaft on the front of the saw. Be sure it fits

completely over the shaft. The slots in the

handwheel hole will engage with the roll pin

on the shaft as shown in Figure 12.

2. Position the other handwheel similarly on the

blade tilting shaft located at the side of the

saw.

3. Screw the black plastic lock knobs onto the

ends of the shafts to lock the handwheels in

place.

Handwheels

Roll Pin

Figure 14. Attaching pulley guard bracket.

2. Insert the

1

⁄4''-20 x 2'' hex bolt through the

hole in the pulley guard bracket as shown in

Figure 14.

Body mounted switch on

G1022SM and Z only

Note: Motor comes

pre-wired.

Page 22

-20- G1022 Series Contractor Saws

3. Set the motor on end and slip the pulley

guard bracket between the base of the motor

and the motor plate. Tighten one of the four

mounting bolts. Leave the other three loose

as shown in Figure 15.

Figure 15. Installing pulley guard.

Figure 16. Installing the motor mount bracket.

4. Locate the motor mount bracket. Loosen the

setscrew that holds the motor pivot rod in

place and remove the rod. Line up the hole

in the motor bracket with the hole in the

motor plate and insert the motor pivot rod

making sure the groove in the rod lines up

with the setscrew in the mount bracket as

shown in Figure 16. Tighten the setscrew.

Figure 17. Attaching motor to linking bars.

5. Turn the arbor tilting handwheel until the

arbor is set to 0°. Slide the motor assembly

onto the linking bars through the holes in the

motor bracket. Line up the setscrews with

the grooves on the linking bars and tighten

as shown in Figure 17.

Figure 18. Attaching the V-belt to the motor.

6. Lift the motor up and slip the V-belt over the

grooves in the pulleys. Slowly release the

motor, allowing its weight to add tension to

the V-Belt as shown in Figure 18.

Page 23

G1022 Series Contractor Saws -21-

Figure 19. Checking V-belt alignment.

7. Place a straightedge across the arbor pulley

and the motor pulley. The straightedge

should run across both pulleys evenly as

shown in Figure 19. Adjust the motor on its

mount until pulleys are aligned, then tighten

all the mounting bolts.

Figure 20. Attaching the pulley guard.

8. Slip the pulley cover spacer over the pulley

cover mounting bolt and fit the plastic pulley

cover in place. Secure it with the wing nut

provided as shown in Figure 20.

Wiring

G1022SM and G1022Z:

The ON/OFF switch, with attached power cord

and plug, is already mounted to the saw enclosure. Simply connect the quick disconnect on the

cord between the switch and motor.

G1022ZF, G1022ZFX and G1022PRO:

The ON/OFF switch on the ZF, ZFX and PRO

models mounts directly below the front fence rail.

1. Take the L-shaped bracket supplied and

position it below the front fence rail at the left

hand side of the machine. The shorter side

of the L has two holes which will align with

two holes in the fence rail. Use two Philip

®

head screws to attach the bracket. Thread

them in from underneath the rail so the

heads are not in the way of the fence travel.

2. Now attach the switch, using two Philips

®

head screws inserted through the back of the

bracket and into threaded inserts in the back

side of the switch box. Tighten these so the

switch box is secure.

3. Connect the quick disconnect on the cord

between the switch and motor.

Page 24

-22- G1022 Series Contractor Saws

Figure 21. Checking table to wing alignment.

4. Raise or lower the rear of the wing until the

wing and table are flush. Tighten the bolt.

5. Repeat Steps 2-4 for the other extension

wing.

6. Now, check the alignment of the table vs.

both wings. Your straightedge should run flat

across both wings and the table top. If the

straightedge contacts both the wings and the

table evenly, you may skip to the next sec-

tion. If it does not, continue to Step 7.

7. If the wings tilt down, apply layers of mask-

ing tape under each bolt near the bottom

edge of the wing.

8. If the wing tilts up, apply layers of masking

tape above each bolt near the top edge of

the wing.

9. Tighten bolts and adjust again as described

in Steps 2-4.

Fence Rails

The rails should extend to the right of the saw and

are attached to the table top with special bolts

and dished spacers. The rails come packed in a

separate box. To mount the rails:

1. The two center bolts for each rail thread

directly into the table top, and the outer two

bolts secure from the back side of the exten-

sion wing with hex nuts as shown in Figure

22. Be sure that the rail with the built-in mea-

suring rule is mounted on the front side of the

machine, with the markings facing up.

2. Insert the round, plastic plugs into the ends

of each rail.

The Model G1022SM and Z are supplied with

round rails, the Model G1022ZF and ZFX are

supplied with flat angular bar sections and the

Model G1022PRO is supplied with square tube

rails. This accommodates the standard fence for

the SM and Z models, the Shop Fox

®

fence for

the ZF and ZFX models and the Shop Fox

®

Classic fence for the PRO model. Please refer to

the Shop Fox

®

manuals for complete information

regarding the installation of the front and back

fence rails on the ZX, ZXF and PRO models.

Extension Wings

The Model G1022SM is supplied with sheet metal

extension wings, and the Models G1022Z, ZF,

ZFX and PRO include cast iron extension wings.

Installation and adjustment are the same for all

the models. To install the extension wings:

1. Attach each wing to the table using the

M10

- 1.50 x 25 hex bolts and 10MM flat washers

provided. Thread the center bolt in first, then

the front and back bolts. Get the wings reasonably flush with the table. Do not completely tighten the bolts.

2. Working front to back, align the front edge of

the extension wing with the edge of the table,

so they are flush, and tighten the front bolt.

3. Raise or lower the rear of the extension wing

until the middle of the wing is flush with the

table top and tighten the middle bolt as

shown in Figure 21.

G1022SM and G1022Z

Page 25

G1022 Series Contractor Saws -23-

Fence

1. Thread the plastic knob onto the lock handle.

2. Set the lock handle in the up position and

slide the fence over the front and rear rails as

shown in Figure 23.

3. The fence will require further adjustments, all

of which are covered in Adjustments

Section.

Figure 23. G1022SM fence shown.

Figure 24. Changing saw blade.

Blade

Please refer to our current catalog for a complete

selection of saw blades. To install the saw blade:

1. Unthread the arbor nut clockwise and

remove the outside flange from the arbor.

Note that there is a

3

⁄4'' diameter spacer on

the arbor shaft. Remove and discard it.

Remember the arbor nut is a left-handed

thread.

2. Install the saw blade onto the arbor. Ensure

that the blade teeth point toward you as you

stand at the front of the saw. Slide on the

flange and thread the arbor nut back on.

3. Use the arbor wrench provided with the saw

to tighten the arbor nut. Wedge a block of

wood in the teeth of the blade to keep it from

turning when tightening the nut as shown in

Figure 24.

Figure 22. Attaching fence rails.

G1022SM and G1022Z

Lock Handle

Disconnect power to the

machine when performing any maintenance,

assembly or adjustments. Failure to do this

may result in serious

personal injury.

!

Page 26

-24- G1022 Series Contractor Saws

Blade Guard

1. Screw the threaded end of the support shaft

into the hole in the back of the rear trunnion.

The check nut on the shaft will be used to

tighten the shaft in place as shown in Figure

25. Leave it loose for now.

2. Loosen the blade-guard mounting bolt locat-

ed just inside the table cut-out and the blade

guard mounting bolt on the end of the support shaft.

Figure 25. Installing blade guard.

3. Slip the slots at the bottom of the guard over

the two mounting bolts as shown in Figure

26. The washers should be between the bolt

head and the slots. Rotate the support shaft

to align the mounting bolts to the mounting

slots on the guard.

Figure 26. Blade guard components.

4. Tighten the mounting bolts to secure the

blade guard.

5. Using a machinist's or a combination square,

align the face of the splitter perpendicular to

the surface of the saw table as shown in

Figure 27. Rotate the support shaft slightly.

This will normally correct any minor misalignment.

Figure 27. Adjusting blade guard.

6. Next, set a straightedge against the face of

the saw blade and the blade guard/splitter as

shown in Figure 28. If the blade guard/split-

ter is properly aligned, please skip ahead to

the next section; otherwise, continue with the

next step.

The saw blade is extremely sharp. Use extra

care when handling the blade or working

near it. Serious injury is possible.

Blade Guard Mounting Bolts

Blade Guard

Support Shaft

Support Shaft

Page 27

G1022 Series Contractor Saws -25-

7. If the blade guard/splitter is to the right of the

blade as shown in Figure 29. simply add

washers between the splitter and front

mounting bracket, and adjust the rear splitter

support as shown in Figure 29.

Figure 29. Improper splitter/blade alignment.

Figure 30. Proper splitter/blade alignment.

8. Recheck guard alignment to the blade and to

the table top. Adjust as necessary and tighten all the bolts before use. If the blade guard

is properly aligned, please skip ahead to the

next section; otherwise, continue with the

next step.

9. If the splitter is positioned to the left of the

blade, alignment cannot be achieved by

washer placement. Adjustment of the front

support bracket is required as shown in

Figure 30. Loosen the adjustment screws

and move to the right.

10. Recheck guard alignment to the blade and to

the table top. Adjust as necessary and tighten down all the bolts before use.

11. Adjust the blade to 45° and raise and lower it

through the full range. Readjust blade to 90°

and raise and lower it through the full range.

There should be no contact between the

base and the table insert or any other part of

the saw. If there is, repeat Steps 1-10.

Figure 28. Checking alignment of blade guard.

Page 28

-26- G1022 Series Contractor Saws

Table Insert

The table insert provides access to the blade and

arbor when removed. When in place, the insert

provides support for materials being cut.

1. Disconnect the power cord from the outlet.

2. Ensure that all four setscrews are firmly in

contact with the table casting.

3. Using a 6mm hex wrench, raise or lower

each of the four setscrews until the insert is

flush with the table top as shown in

Figure

31

.

4. Now make sure the blade will not come into

contact with table insert. Position the blade at

90°, then raise and lower the blade through its

full range of motion. Also rotate the blade

while doing this, making sure that the blade

never contacts any part of the table insert. Do

the same with the blade in the 45° position.

Wear leather gloves while rotating the blade

to prevent being cut.

5. Be sure to review Section 5: Adjustments,

“Blade Parallelism,” before operating the

saw.

Disconnect power to the

machine when performing any maintenance,

assembly or adjustments. Failure to do this

may result in serious

personal injury.

Figure 31. Adjusting table insert height.

Setscrew

Allen

®

Wrench

Table Insert

!

Page 29

G1022 Series Contractor Saws -27-

SECTION 5: ADJUSTMENTS

Disconnect power to the

machine when performing any maintenance,

assembly or adjustments. Failure to do this

may result in serious

personal injury.

Wear safety glasses

during the entire adjustment process. Failure to

comply may result in

serious personal injury.

Keep loose clothing

rolled up and out of the

way of machinery and

keep hair pulled back.

Figure 32. Adjusting clamp mechanism.

G1022SM Fence

(The Model G1022ZF, ZFX and PRO use a Shop

Fox

®

fences. Please refer to the instruction man-

ual included with the Shop Fox

®

fences for com-

plete directions on adjusting.)

The fence must engage and square up on the

front rail before the rear clamp engages the back

rail. In essence, the rear clamp should act as a

secondary mechanism for maintaining fence

position. When adjusted correctly, the lever lock

should only begin to apply pressure on the back

rail over the last one-third of its stroke. To adjust

the fence:

1. First, make sure the front clamp is engaging

the front rail with the lock handle at one-half

of its throw. If the front clamp requires adjust-

ment, loosen the check nut shown in Figure

32. Turn the adjusting bolt clockwise if the

front clamp is too far from the rail, or counterclockwise if it is too close.

2. Now slide the fence along the rail until it is

aligned with the edge of the miter slot. Lock

the fence down.

Check Nut

Adjusting Bolt

!

Page 30

-28- G1022 Series Contractor Saws

Figure 33. Rear lock adjustment screw.

3. Loosen the rear lock adjustment, the slotted

screw on the front of the fence shown in

Figure 33, until the rear locking lever ceases

to engage the rear rail with the fence in the

locked position.

Rear Lock Adjustment

4. Loosen the adjustment bolts at the top of the

fence shown in Figure 34.Move the straight

portion of the fence until it is parallel with the

miter slot from front to back. Retighten the

bolts.

5. Loosen the locking lever until it is approxi-

mately two-thirds engaged. Tighten the rear

adjusting screw until the rear clamp barely

touches the back rail.

6. Loosen the locking lever and slide the fence

along the rail. Return the fence to its position

at the edge of the miter slot and slowly apply

pressure to the lever. If adjustments are correct, the fence should square itself before

the rear clamp engages. If the rear clamp

engages before the fence is squared, loosen

the screw one-quarter turn and retest.

Figure 34. Adjustment bolts for fence parallelism.

Adjustment Bolts

Figure 35. Attaching a sacrificial fence.

Tip: Attach a piece of

3

⁄4" thick hardwood to the

blade side of the fence as shown in Figure 35.

This will keep thin materials from wedging

between the fence and table, and will also protect

the fence from coming in contact with the blade

when dadoing or ripping thin stock. Remember to

adjust measurement scale on rail to compensate

for the thickness of the sacrificial fence.

Page 31

G1022 Series Contractor Saws -29-

Figure 36. Adjust measurement pointer.

7. Once the fence is adjusted, check the mea-

surement pointer shown in Figure 36 and

adjust if necessary.

Figure 36B. Adjusting clamp mechanism.

G1022Z Fence

(The Model G1022ZF, ZFX and PRO use a Shop

Fox

®

fence. Please refer to the instruction manu-

al included with the Shop Fox

®

fence for complete

directions on adjusting the fence.)

The fence must engage and square up on the

front rail before the rear clamp engages the back

rail. In essence, the rear clamp should act as a

secondary mechanism for maintaining fence

position. When adjusted correctly, the lever lock

should only begin to apply pressure on the back

rail over the last one-third of its stroke. To adjust

the fence:

1. First, make sure the front clamp is engaging

the front rail with the lock handle at one-half

of its throw. If the front clamp requires adjust-

ment, loosen the check nut shown in Figure

36B. Turn the adjusting bolt clockwise if the

front clamp is too far from the rail, counterclockwise if it is too close.

2. Now slide the fence along the rail until it is

aligned with the edge of the miter slot. Lock

the fence down.

Check Nut

Adjusting Bolt

Figure 37. Rear lock adjustment screw.

3. Loosen the rear lock adjustment, the slotted

screw on the front of the fence shown in

Figure 37, until the rear locking lever ceases

to engage the rear rail with the fence in the

locked position.

Rear Lock Adjustment

Measurement Pointer

Page 32

-30- G1022 Series Contractor Saws

4. Loosen the locking lever (Figure 38) until it

is approximately two-thirds engaged. Make

note of its position and lift it up all the way.

Tighten the rear adjustment screw until the

rear clamp is approximately

1

⁄16'' from the rail.

Move the lock handle back to its two-thirds

position. The rear clamp should just be

touching the rail. If it is too loose or too tight,

lift the handle and turn the adjusting screw in

small increments until the clamp is in its

proper location. NOTE: Do not turn the

adjustment screw unless the lock handle is

in the up position. Damage to the clamp

shoe will result if this step is not observed.

5. Loosen the locking lever and slide the fence

along the rail. Return the fence to its position

at the edge of the miter slot and slowly apply

pressure to the lever. If adjustments are correct, the fence should square itself before

the rear clamp engages. If the rear clamp

engages before the fence is squared, loosen

the screw one-quarter turn and retest.

Figure 38. Adjustment bolts for fence parallelism.

Figure 39. Attaching a sacrificial fence.

Figure 40. Adjust measurement pointer.

Tip – Attach a piece of

3

⁄4" thick hardwood to the

blade side of the fence shown in Figure 39. This

will keep thin materials from wedging between

the fence and table, and will also protect the

fence from coming in contact with the blade when

dadoing or ripping thin stock.

6. Once the fence is adjusted, check the measurement pointer shown in Figure 40, and

adjust if necessary.

Front Adjustment Screws

Measurement Pointer

Locking Lever

Page 33

G1022 Series Contractor Saws -31-

Blade Parallelism

Your table saw will give the best results if the

miter slot is parallel to the blade. If they are not

exactly parallel, your cuts and finished work will

be lower in quality. To check and adjust blade

parallelism:

1. Using an adjustable square, measure the

distance between the miter slot and the front

of your blade as shown in Figures 41 and

42.

Figure 42. 90° blade parallelism measurement.

Figure 41. 90° blade parallelism measurement.

Figure 43. Table/trunnion assembly.

2. Note the first measurement. Rotate the

blade 180° and move the square to the rear

of the blade. You may find it helpful to mark

your blade with a felt-tip pen (as a rotation

guide) at the point where the straightedge

and blade meet.

3. Compare the measurements. If the differ-

ence in measurements is less than 0.004",

your blade and table are in acceptable align-

ment move to Step 7. If the difference is

greater, you will need to adjust the trunnion

and table.

4. To adjust blade alignment, remove the

motor, wings and the upper half of the saw

from the stand. Place it upside down on 4 x

4 blocks to allow the saw blade to rotate

freely.

5. Remove the handwheels and the sheet

metal body. To maintain the trunnion assembly as one unit, place a bar clamp across the

entire trunnion assembly. The four trunnion

bolts (Figure 43) can now be loosened. This

will allow the trunnion assembly to be shifted

in order to change the alignment between

the blade and the miter slot.

6. Now measure the miter slot to the blade as

in Steps 1 and 2. Move the trunnion assem-

bly until proper alignment has been

obtained. Tighten the trunnion bolts and

remove the bar clamp.

Clamp Here

Clamp Here

Trunnion

Bolts

Trunnion

Bolts

#1 Shim Location

#3 Shim Location

#4 Shim Location

#2 Shim Location

Page 34

-32- G1022 Series Contractor Saws

7. Now check to see if the blade remains paral-

lel to the miter slot when tilted to 45°.

8. Tilt the blade to 45° and repeat Steps 1-5. If

the blade is still parallel to the miter slot, continue with the next section. Otherwise, continue with the next step.

9. If the blade was parallel to the miter slot at

90° but not at 45°, the trunnion will need to

be shimmed with metal shim stock. The

shims are placed between the trunnion corners and the table.

Figure 44A. 45°

blade parallelism measurement.

10. Refer to Figures 43, 44A, 44B and 45, for

shim placement. If the distance of A is shorter than B, shim(s) will need to be placed

under corners #1 and #2. If the distance of B

is shorter than A, shim(s) will need to be

placed under corners #3 and #4. Very thin

shim stock works well, just make sure they

are all the same thickness, and you put an

equal number under each of the two corners.

11. Tighten down one trunnion bolt a small

amount and then move on to each of the others, tightening each down the same amount.

Continue to rotate through the bolts, tightening them a little each time until they are all

secure.

12. Now recheck the blade to miter slot at 90°

and 45° by repeating Steps 1-3 and 8. If the

distance of A and B are equal to or less than

0.004" at both 90° and 45°, continue to the

next section. If the distances are still off by

more than 0.004", repeat Steps 4-12.

13. Once you feel you have the miter slot adjust-

ed to the blade, recheck all measurements

and be sure the table mounting bolts are

secure. Repeat Step 10 in “Blade

Guard/Splitter” instructions. Also, if you ever

loosen the trunnion in the future, be sure to

make note of shim placements and

reassemble exactly how it came apart.

Figure 45. 45°

blade parallelism measurement.

#1 Shim

#3 Shim

#4 Shim

#2 Shim

#1 Shim

#3 Shim

#4 Shim

#2 Shim

Figure 44B. Shim placement.

Page 35

G1022 Series Contractor Saws -33-

45° and 90° Stops

The Model G1022 Series is equipped with positive stops at 45° and 90°. When properly adjusted, they provide precise and dependable guides

for bevel adjustment. To set these stops:

1. Unplug the machine! Raise the saw blade

to its maximum height by turning the front

handwheel clockwise.

2. Set the saw blade at 90° to the table by turn-

ing the handwheel at the side of the machine

as far as it will go. Important: Do not force

the handwheels when setting the blade

height or bevel. If the handwheels offer resistance, do not continue turning until you

determine the source of the resistance.

3. Once your blade is set at 90° to the table,

place a machinist's square or speed square

against the blade and table surface, as

shown in Figure 46.

4. With the square in place, inspect for variation

between the blade and square.

5. If a gap exists at either the top or the bottom

of the square, loosen lock nut (A) and adjust-

ment bolt (B) indicated in Figure 47.

Figure 46. Checking blade angle to table.

6. Turn the handwheel until the blade and

square are flush from top to bottom.

7. Snug the adjustment screw and tighten the

lock nut. Recheck the blade with the square

to ensure that you have not over tightened

the screw.

8. Using the side handwheel, adjust the blade

bevel until you hit the 45° positive stop.

Check the bevel with your speed square or

an adjustable square set to 45°.

9. If variations exist, loosen the lock nut (C) and

adjust the stop bolt (D) (Figure 47) until your

blade and square match.

10. Tighten the lock nut and recheck the bevel

by adjusting the blade back to 90°, then back

to 45°. Correct again, if necessary.

Figure 47. 90° and 45° stop bolt adjustments.

C

D

B

A

Disconnect power to the

machine when performing any maintenance,

assembly or adjustments. Failure to do this

may result in serious

personal injury.

!

Page 36

-34G1022 Series Contractor Saws

Figure 48. Handwheel resistance adjustment.

Worm Gear

2. As you watch from below, twist the pointer

assembly at the front of the saw. As you turn

the pointer, you’ll see the worm gear move

toward and away from the teeth on the front

trunnion. Ideally, the worm gear should

mesh with the teeth without slop or excess

tightness. This process requires a bit of trial

and error.

3. Once you have found a degree of tightness

that you prefer, tighten the lock nut.

4. Loosen the setscrew (B) and pivot the point-

er back to zero. Retighten the setscrew.

Replace the handwheel.

The degree of resistance at the blade height

handwheel can be adjusted to compensate for

wear or for personal preference. To adjust:

1. Loosen the lock nut (A) shown in Figure 48.

This will allow the eccentric sleeve that surrounds the worm gear to turn. Although this

process can be done with the handwheel in

place, you may find it easier to remove it first.

A

B

Miter Gauge

Initial Step, Model G1022ZF and ZFX:

The ZF/ZFX miter gauge has two setscrews in

the miter slot bar which can be set to remove any

free play from the miter gauge when inserted in

the T-slot. Loosen or tighten the two setscrews

until the miter gauge slides freely back and forth,

but has no side-to-side movement.

Next step for all models:

1. Loosen the lock knob on the miter gauge and

place a square against the face of the miter

body and the blade.

2. Adjust the miter body until there is no space

between the square and the blade. Tighten

the lock knob.

3. With the stop link in the up position, loosen

the jam nut and adjust the stop screw shown

in Figure 49 until it is seated against the stop

link.

4. Now loosen the setscrew on the left front

side of the miter bar, adjust the pointer to 90˚

and retighten the setscrew.

5. To adjust to 45˚, follow Steps 1-4 using an

adjustable square set to 45˚.

6. After rotating the miter body from 45˚ to 90˚

and back a few times, double check your

adjustments at both angles to assure that

you have accurately set your miter gauge.

Figure 49. Miter gauge adjustment points.

Stop Link

Jam Nut

Stop Screw

Page 37

G1022 Series Contractor Saws

-35-

Pre-Run Check

Test Run

1. Face the table saw and stand to the left of

the blade path.

2. With one finger on the START button and

one finger on the STOP button, turn the saw

on. Be ready to turn it off in case of mishap.

3. Watch and listen to the saw. Note whether

there are any unusual sounds or excessive

vibrations.

SECTION 6: OPERATIONS

Before you begin to use your Model G1022

Series, you should give it a thorough inspection.

While making your inspection, ask yourself the

following questions:

1. Are all the fasteners tight?

2. Is the blade mounted correctly?

3. Is the saw stable?

4. Is it wired properly?

5. Is your electrical system properly config-

ured?

6. Have you checked your work piece for obvi-

ous defects?

7. Are the V-belts properly tensioned and the

pulleys properly aligned?

8. Is the guard assembly installed and func-

tional?

9. Have you checked the saw blade clearance

when it is adjusted to varying angles and

depths?

10. Have you read all warnings and directions

regarding the operation of this machine?

Disconnect power to the