Page 1

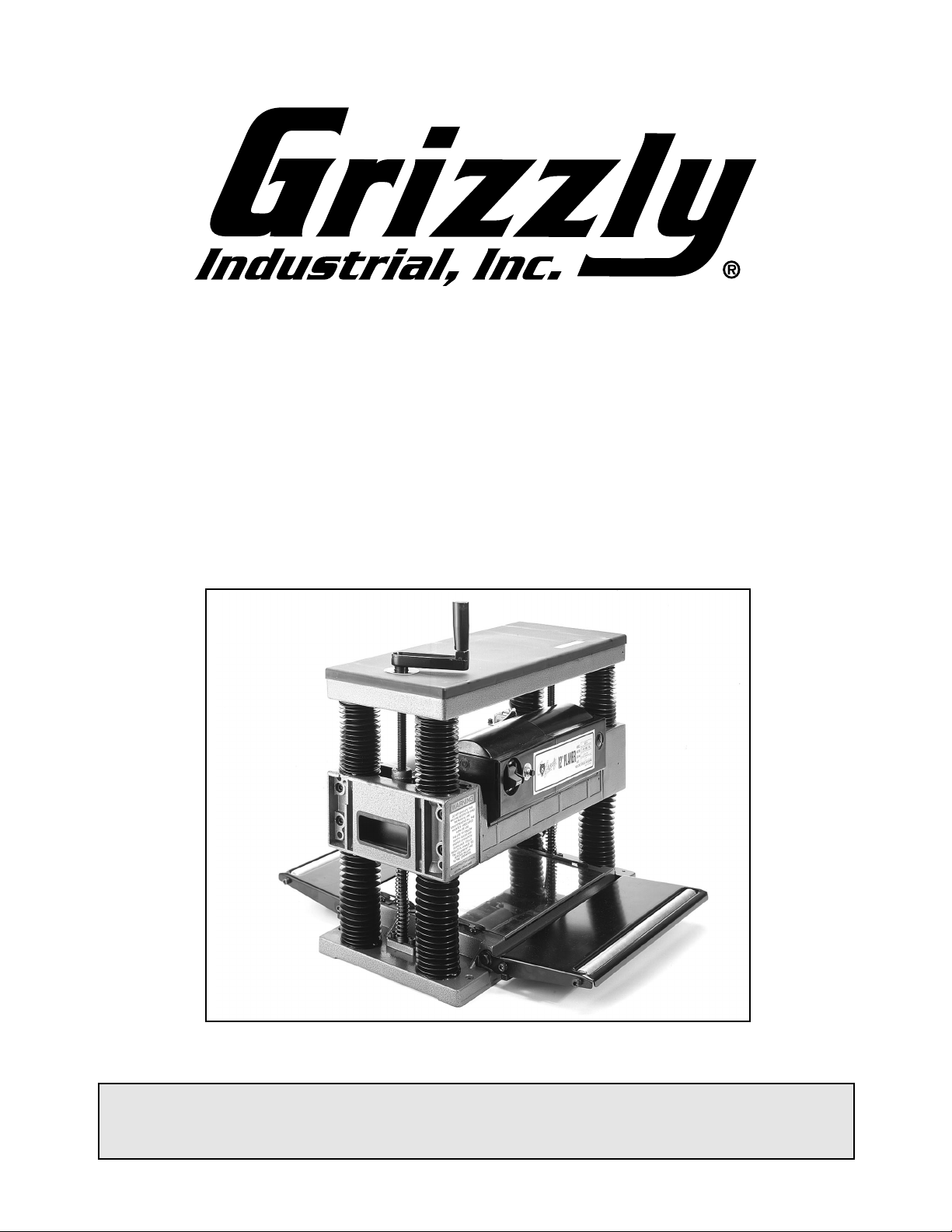

12'' PORTABLE PLANER

MODEL G1017

INSTRUCTION MANUAL

COPYRIGHT © 1991 BY GRIZZLY INDUSTRIAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

REVISED APRIL, 1999 PRINTED IN U.S.A.

Page 2

-2- G1017 12'' Portable Planer

Table Of Contents

PAGE

1. SAFETY

SAFETY INSTRUCTIONS FOR POWER TOOLS..................................................3-4

ADDITIONAL SAFETY INSTRUCTIONS FOR PORTABLE PLANERS....................5

2. CIRCUIT REQUIREMENTS

110V OPERATION ....................................................................................................6

GROUNDING ............................................................................................................6

3. GENERAL INFORMATION

COMMENTARY........................................................................................................ 7

UNPACKING..............................................................................................................8

PIECE INVENTORY ..................................................................................................8

CLEAN UP ................................................................................................................9

SITE CONSIDERATIONS..........................................................................................9

4. ASSEMBLY

CHIP DEFLECTOR..................................................................................................10

HANDLE ASSEMBLY ..............................................................................................10

WOOD BASE ..........................................................................................................10

5. CONTROLS

ON/OFF SWITCH....................................................................................................11

RESET BUTTON ....................................................................................................11

DEPTH OF CUT......................................................................................................11

6. ADJUSTMENTS

EXTENSION WINGS ..............................................................................................12

FEED ROLLERS......................................................................................................12

PARALLELISM....................................................................................................13-14

KNIFE SETTING ................................................................................................14-15

7. OPERATIONS

TEST RUN ..............................................................................................................16

PLANING TIPS........................................................................................................16

WOOD TYPES ........................................................................................................17

WOOD CHARACTERISTICS ............................................................................17-18

8. MAINTENANCE

GENERAL ................................................................................................................19

LUBRICATION ........................................................................................................19

KNIFE SHARPENING ............................................................................................19

MOTOR ....................................................................................................................20

V-BELT ....................................................................................................................20

FEED ROLLERS......................................................................................................21

9. CLOSURE ....................................................................................................................22

Page 3

G1017 12'' Portable Planer -3-

Safety Instructions For Power Tools

SECTION 1: SAFETY

5. KEEP CHILDREN AND VISITORS AW AY.

All children and visitors should be kept a

safe distance from work area.

6. MAKE WORK SHOP CHILD PROOF with

padlocks, master switches, or by removing

starter keys.

7. DON’T FORCE TOOL. It will do the job

better and safer at the rate for which it was

designed.

8. USE RIGHT TOOL. Don’t force tool or

attachment to do a job for which it was not

designed.

1. KEEP GUARDS IN PLACE and in working

order.

2. REMOVE ADJUSTING KEYS AND

WRENCHES. Form habit of checking to

see that keys and adjusting wrenches are

removed from tool before turning on.

3. KEEP WORK AREA CLEAN. Cluttered

areas and benches invite accidents.

4. DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use power tools in damp or

wet locations, or where any flammable or

noxious fumes may exist. Keep work area

well lighted.

For Your Own Safety Read Instruction

Manual Before Operating This Equipment

Indicates an imminently hazardous situation which, if not

avoided, WILL result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, COULD

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, MA

Y result in minor or moderate injury. It may also be

used to alert against unsafe practices.

This symbol is used to alert the user to useful information

about proper operation of the equipment.

The purpose of safety symbols is to attract your attention to possible hazar dous conditions.This

manual uses a series of symbols and signal words which are intended to convey the level of

importance of the safety messages.The progression of symbols is described below. Remember

that safety messages by themselves do not eliminate danger and are not a substitute for proper accident prevention measures.

NOTICE

Page 4

-4- G1017 12'' Portable Planer

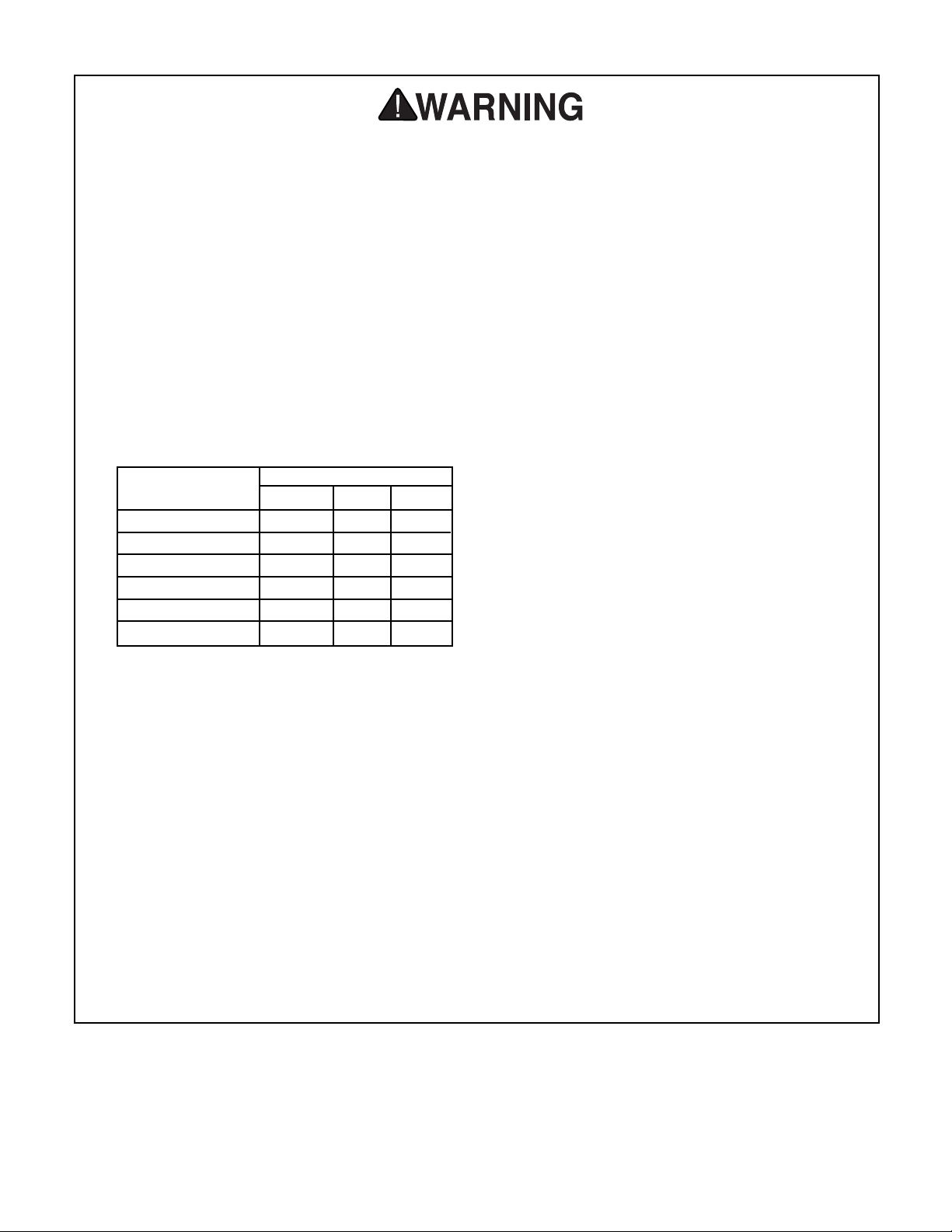

9. USE PROPER EXTENSION CORD. Make

sure your extension cord is in good condition. Conductor size should be in accordance with the chart below.The amperage

rating should be listed on the motor or tool

nameplate.An undersized cord will cause a

drop in line voltage resulting in loss of

power and ov erheating.Your extension cord

must also contain a ground wire and plug

pin. Always repair or replace extension

cords if they become damaged.

Minimum Gauge for Extension Cords

10. WEAR PROPER APPAREL. Do not wear

loose clothing, gloves, neckties, rings,

bracelets, or other jewelry which may get

caught in moving parts. Non-slip footwear

is recommended.Wear protective hair covering to contain long hair.

11. ALWAYS USE SAFETY GLASSES. Also

use face or dust mask if cutting operation is

dusty. Everyday eyeglasses only have

impact resistant lenses, they are NOT safety glasses.

12. SECURE WORK. Use clamps or a vise to

hold work when practical. It’s safer than

using your hand and frees both hands to

operate tool.

LENGTH

AMP RATING 25ft 50ft 100ft

0-6 18 16 16

7-10 18 16 14

11-12 16 16 14

13-16 14 12 12

17-20 12 12 10

21-30 10 10 No

Safety Instructions For Power Tools

13. DON’T O VERREACH. Keep proper footing

and balance at all times.

14. MAINTAIN TOOLS WITH CARE. Keep

tools sharp and clean for best and safest

performance. Follow instructions for lubricating and changing accessories.

15. DISCONNECT TOOLS before servicing

and changing accessories, such as blades,

bits, cutters, and the like.

16. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure switch is in off

position before plugging in.

17. USE RECOMMENDED ACCESSORIES.

Consult the owner’s manual for recommended accessories. The use of improper

accessories may cause risk of injury.

18. CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part

that is damaged should be carefully

checked to determine that it will operate

properly and perform its intended function.

Check for alignment of moving parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that

may affect its operation. A guard or other

part that is damaged should be properly

repaired or replaced.

19. NEVER LEAVE TOOL RUNNING UNATTENDED.TURN POWER OFF. Don’t leave

tool until it comes to a complete stop.

Page 5

G1017 12'' Portable Planer -5-

Additional Safety Instructions For The

Portable Planer

6. Position yourself so as not to get caught

(pinned) between the lumber and another

obstruction during the planing operation.

Also, ensure that there is sufficient clearance for the material being fed.

7. Keep hands and fingers away from moving

parts and away from the infeed and outfeed

section of the planer. Do not reach into the

machine at any time for any reason without

first turning the switch off, pulling the electrical plug and after the machine has come

to a full stop.

8. Any glued-up stock must be completely set

up and dry before planing.

9. Never leave the planer running unattended.

10. Habits – good and bad – are hard to break.

Develop good habits in your shop and safety will become second-nature to you.

1. Ensure that the machine is firmly secured

to a bench or the floor before use.

2. Always be aware of the condition of the

wood you are planing.Pa y particular attention to knots, splits, and other potential

areas where the grain may be getting

ready to separate.

3. Perform machine inspection and maintenance services promptly when called for.

4. Make sure the planer knives are sharp,

balanced, and set correctly and securely.

Operate planer only with both knives in the

cutterhead.

5. Do not plane any man-made composites

such as plywood, hardboard, particle

board, fiber board, flake board, fiberglass

and/or any other material other than solid,

natural wood fiber.

Operating this equipment has the potential

to propel debris into the air which can

cause eye injury. Always wear safety glasses or goggles when operating equipment.

Everyday glasses or reading glasses only

have impact resistant lenses, they are not

safety glasses. Be certain the safety glasses you wear meet the appropriate standards of the American National Standards

Institute (ANSI).

Like all power tools, there is danger associated with the Model G1017 Portable Planer.

Accidents are frequently caused by lack of

familiarity or failure to pay attention. Use

this tool with respect and caution to lessen

the possibility of operator injury. If normal

safety precautions are overlooked or

ignored, serious personal injury may occur.

Page 6

G1017 12'' Portable Planer

G1017 12'' Portable Planer

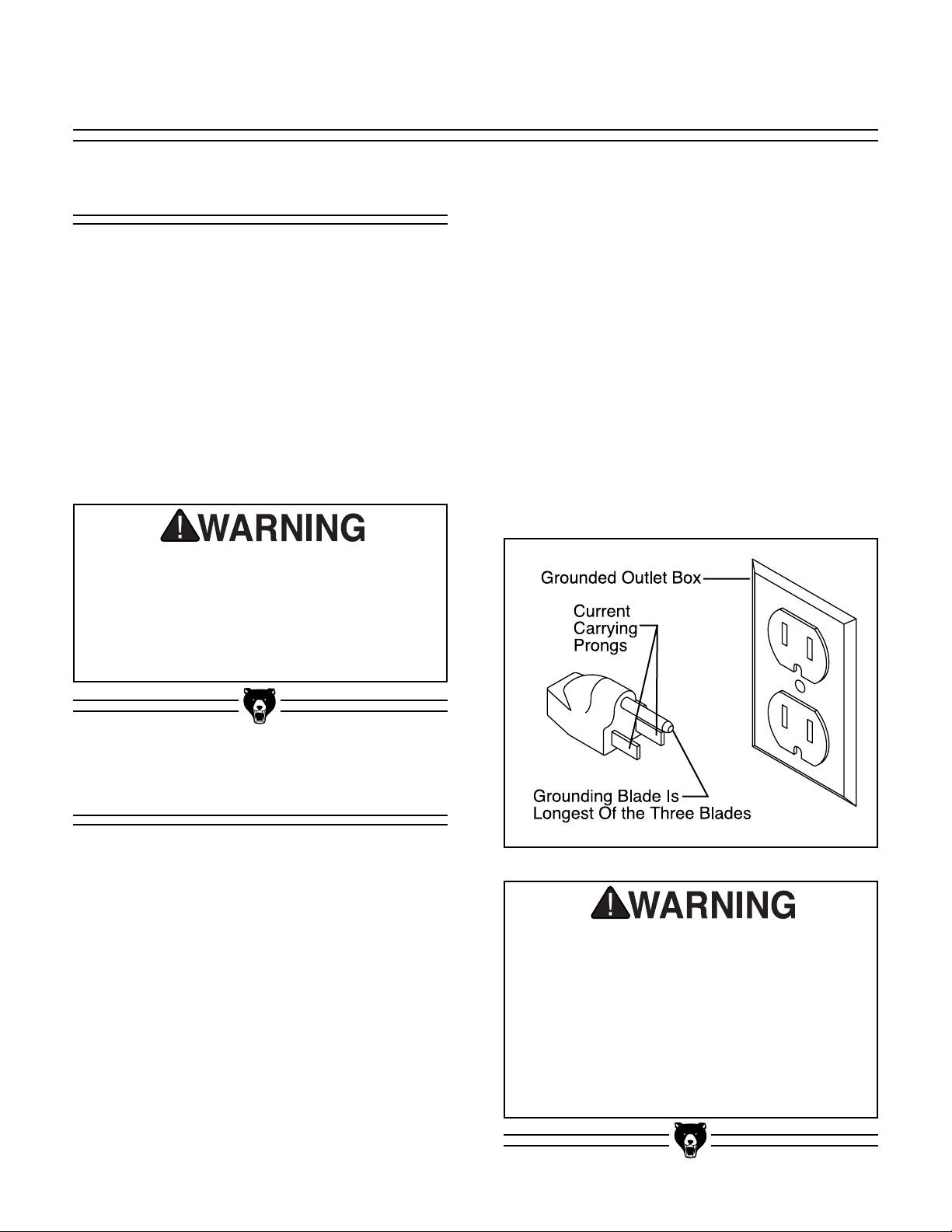

Figure 1. Typical 3-prong plug and outlet.

is necessary, do not connect the equipment

grounding conductor to a live terminal.

Under no circumstances should the grounding pin

from any three-pronged plug be removed.If it will

not fit the outlet, have the proper outlet installed

by a qualified electrician.

Check with a qualified electrician or one of our

service personnel if the grounding instructions

are not completely understood, or if in doubt as to

whether the tool is properly grounded.Use only 3wire extension cords that hav e 3-prong g rounding

type plugs and 3-hole receptacles that accept the

tool’s plug.See FIgure 1.

Repair or replace damaged or worn cord immediately.

110V Operation

The G1017 planer operates on 110 volts. Under

normal use, the motor draws approximately 16

amps at 110V. We recommend a 20 amp circuit

breaker for 110V. This should be satisfactory for

normal use, while providing enough protection

against motor damage caused by power surges.

Grizzly recommends that the circuit you use

should be dedicated, (i.e., the G1017 should provide the only draw from that circuit). If frequent

circuit failures occur when using the planer, contact our service depar tment or your local electrical contractor.

Grounding

In the event of a malfunction or breakdown,

grounding provides a path of least resistance for

electric current to reduce the risk of electric

shock.This tool is equipped with an electric cord

having an equipment-grounding conductor and a

grounding plug.The plug must be plugged into a

matching outlet that is properly installed and

grounded in accordance with all local codes and

ordinances.

Improper connections of the electrical-grounding

conductor can result in risk of electric shock.The

conductor with green or green and yellow striped

insulation is the electrical-grounding conductor.If

repair or replacement of the electric cord or plug

SECTION 2: CIRCUIT REQUIREMENTS

Be sure that your particular electrical configuration complies with local and state

codes. The best way to ensure compliance

is to check with your local municipality or

licensed electrician. Serious personal injury

may occur.

This equipment must be grounded. Verify

that any existing electrical outlet and circuit

you intend to plug into is actually grounded.

If it is not, it will be necessary to run a separate 12 A.W.G. copper grounding wire from

the outlet to a known ground. Under no circumstances should the grounding pin from

any three-pronged plug be removed.

Serious personal injury may occur.

Page 7

G1017 12'' Portable Planer -7-

Commentary

Grizzly Industrial, Inc. is proud to offer the Model

G1017 12" Portable Planer. This planer is a par t

of Grizzly’s growing family of fine machinery.

When used according to the guidelines described

in this manual, you can expect years of troublefree, enjoyable operation and proof of Grizzly’s

commitment to customer satisfaction.

The Model G1017 is a wood planer designed for

portable or small shop use.This planer features a

2 HP motor, four steel column supports for

increased strength, chain-driven feed rollers,

extension wings, and a direct reading thickness

gauge.

We are also pleased to provide this manual with

the G1017. It was written to guide you through

assembly, review safety considerations, and

cover general operating procedures.It represents

our latest effort to produce the best documentation possible. If you have any criticisms that you

feel we should pay attention to in our next printing, please write to us at the address below:

Grizzly Industrial, Inc.

C

/O Technical Documentation

P.O. Box 2069

Bellingham, WA 98227-2069

Most importantly, we stand behind our machines.

We have excellent regional service departments

at your disposal, should the need arise. If, after

reviewing this manual carefully, you hav e an y service questions or parts requests, please call or

write us at the location listed below.

Grizzly Industrial, Inc.

2406 Reach Road

Williamsport, PA 17701

Phone: 1-570-326-3806

FAX: 1-800-438-5901

E-Mail: techsupport@grizzlyindustr ial.com

Web Site:http://www.grizzlyindustrial.com

SECTION 3: GENERAL INFORMATION

The specifications, drawings, and photographs

illustrated in this manual represent the Model

G1017 as supplied when the manual was prepared. However, owing to Grizzly’s policy of continuous improvement, changes may be made at

any time with no obligation on the part of Grizzly.

Whenever possible, though, we send manual

updates to all owners of a particular tool or

machine.Should you receive one, we urge you to

insert the new information with the old and keep

it for reference.

To operate this, or any power tool, safely and

efficiently, it is essential to become as familiar

with its characteristics as possible. The time

you invest before you begin to use your Model

G1017 will be time well spent.DO NOT operate

this machine until you are completely familiar

with the contents of this manual.Make sure you

read and understand all of the safety procedures.If you do not understand something, DO

NOT operate the machine.

Page 8

-8- G1017 12'' Portable Planer

Unpacking

The Model G1017 12'' Planer is shipped from the

manufacturer in a carefully packed carton. If you

discover the machine is damaged after you’ve

signed for delivery,

please call Customer Service

immediately for advice.

Save the containers and all packing materials for

possible inspection by the carrier or its agent.

Otherwise filing a freight claim can be difficult.

Piece Inventory

After all the parts have been removed from the

carton, you should have:

• Manual

• Planer

• Chip Deflector

• Handle

• 8-10 mm Wrench

• 12-14 mm Wrench

• Allen

®

Wrenches 3, 4, 5 & 6mm

• Combination Screw Driver

• Knife Gauge

• Hardware

Lag Bolts

5

⁄16" x 13⁄4" 4

Washers

3

⁄8"4

In the event that any non-proprietary parts are

missing (e.g.a nut or a washer), we would be glad

to replace them, or, for the sake of expediency,

replacements can be obtained at your local hardware store.

The G1017 is a heavy machine (85 lbs. shipping weight). DO NOT over-exert yourself

while unpacking or moving your machine –

get assistance. In the event that your planer

must be moved up or down a flight of stair s,

be sure that the stairs are capable of supporting the combined weight of people and

the machine. Serious personal injury may

occur.

When you are completely satisfied with the condition of your shipment, you should inventory its

parts.

Page 9

G1017 12'' Portable Planer -9-

Clean up Site Considerations

The Model G1017 is designed to be portable.

There are handles on both sides of the planer to

aid in lifting and moving. Before moving the planer, fold the depth control handle down, the extension wings up and ensure that the power cord is

disconnected.

1. Working Clearances: Consider existing

and anticipated needs, size of material to

be processed through each machine, and

space for auxiliary stands, work tables or

other machinery when establishing a location for your planer.

2. Lighting and Outlets: Lighting should be

bright enough to eliminate shadow and prevent eye strain. Electr ical circuits should be

dedicated or large enough to handle

amperage requirements. Outlets should be

located near each machine so power or

extension cords are clear of high-traffic

areas. Observe local electrical codes for

proper installation of new lighting, outlets,

or circuits.

The cutterhead knives on the G1017 planer

are extremely sharp. Merely brushing your

finger along the edge can result in a severe

cut.Take e xtreme caution when doing any of

the adjustments involving the cutterhead

knives. Wear thick gloves anytime it is necessary to manually rotate the cutterhead

assembly.

The unpainted surfaces are coated with a waxy

oil to protect it from corrosion during shipment.

Remove this protective coating with a solvent

cleaner or citrus-based degreaser. Avoid chlorine-based solvents as they may damage painted

surfaces should they come in contact.Always follow the usage instructions on the product you

choose for clean up.

Many of the solvents commonly used to

clean machinery can be highly flammable,

and toxic when inhaled or ingested. Always

work in well-ventilated areas far from potential ignition sources when dealing with solvents. Use care when disposing of waste

rags and towels to be sure they do not create fire or environmental hazards. Keep

children and animals safely away when

cleaning and assembling this machine.

Do not use gasoline or other petroleumbased solvents to remove this protective

coating.These products generally have low

flash points which makes them extremely

flammable. A risk of explosion and burning

exists if these products are used. Serious

personal injury may occur.

Page 10

-10- G1017 12'' Portable Planer

SECTION 4: ASSEMBLY

Wooden Base

The wooden base yields greater stability and

enables the planer to be fastened to a sturdy

bench or floor when planing long stock. To construct the wooden base pieces:

1. Mill two pieces of wood 17'' (L) x 2'' (W) x 2''

(H).Do not use planer for constructing base

pieces until it is checked out and adjustments have been made as required.

2. Layout the two planer mounting hole locations on each piece.

3. Predrill mounting holes and mount the planer using four

5

⁄16'' lag bolts and washers pro-

vided. See Figure 3.

Alternatively, the planer can be directly mounted

to a bench or table top, or to a Shop Fox

®

Deluxe

Tool Table utilizing these same mounting holes,

using the appropriate fasteners.

Figure 3. Mounting planer to wooden base.

Chip Deflector

Handle Assembly

For your safety and proper machine operation,

ensure that the chip deflector is secured before

use. The chip deflector directs wood chips away

from the cutterhead during operation and covers

the cutterhead and feed rollers for operator safety. To secure the chip deflector :

1. Remove the two socket head cap screws at

the rear of the planer.

2. Set chip deflector in place and replace the

two socket head cap screws.See Figure 2.

Figure 2. Chip deflector mounting screws.

Attach the handle assembly to the shaft protruding out of the top of the planer. Align the handle

with the notch, and tighten the M6-1 x 10mm cap

screw. Do not over tighten.

Page 11

G1017 12'' Portable Planer -11-

SECTION 5: CONTROLS

On-Off Switch

The on-off switch is located on the front of the

planer. See Figure 4.The switch has a ke y which,

when removed, allows the switch to be locked in

the “off” position. To access the locking feature,

push the switch to the “off” position and pull the

switch key out.

Figure 4. Location of switch and reset button.

Reset Button

The G1017 Planer comes equipped with a thermal overload protection switch inside the motor.

To reset the switch, turn off the on-off switch, wait

a few seconds and then depress the reset b utton.

See Figure 4. If the reset button does not stay

depressed, wait longer before resetting.

Reset Button

Depth Of Cut

The planing depth is controlled by the crank handle on top of the planer.To extend the handle up

for operation, pull out on the handle while folding

it up.Turning the handle clockwise raises the cutterhead and counter-clockwise lowers the cutterhead. See Figure 5. Depth of cut is read directly

from the inch/millimeter scale located on the top,

right side of the planer. The minimum reading is

1

⁄16'' (1 mm).One complete turn of the handle rais-

es or lowers the cutterhead approximately

1

⁄16''

(1mm). The range of material thickness that can

be planed is

1

⁄4'' - 5'' (5mm - 127mm).

Figure 5. Depth of cut adjustment handle.

Page 12

-12- G1017 12'' Portable Planer

Figure 6. Aligning extension wings.

SECTION 6: ADJUSTMENTS

Extension Wings

Your planer is equipped with front and rear extension wings.Each wing folds up for machine mobility and down for machine operation. To check

alignment, lay a straightedge across the bed and

wings. See Figure 6.

If adjustment is necessary, proceed as follows:

1. Use the 10mm wrench and loosen the locking nuts and set bolts underneath each

extension wing.

2. Hold a straightedge across the bed and

wing and turn the setscrews so the end of

the wing moves back into the same plane

as the planer bed.

3. Move the straightedge to the other side of

the bed and repeat step two. Re-check to

ensure consistency from side to side.

Without turning the set bolts, tighten the

lock nuts.

4. To adjust the second wing, repeat steps

one through three above.

Feed Rollers

The infeed and outfeed rollers are made of high

quality rubber and provide effectiv e gripping pressure during operation. The delivery speed is 26

FPM (8 MPM).The infeed and outf eed roller pressure was pre-set at the factory and requires no

adjustment.

Make sure the G1017 is unplugged or disconnected from the power source and moving parts have come to a complete stop

before investigating any problems or performing any maintenance or adjustments.

Serious personal injury may occur.

The cutterhead knives on the G1017 planer

are extremely sharp. Merely brushing your

finger along the edge can result in a severe

cut.Take e xtreme caution when doing any of

the adjustments involving the cutterhead

knives. Wear thick gloves anytime it is necessary to manually rotate the cutterhead

assembly.

Page 13

G1017 12'' Portable Planer -13-

Parallelism

Before leaving the factory, the planer cutterhead

was set parallel to the planer bed for even cutting.

However, periodic inspections should be done to

ensure accuracy, especially if the planer is jostled

during transport. To check parallelism between

the cutterhead and bed, switch planer off, wait for

moving parts to stop and proceed as follows:

1. Construct a hardwood gauge as shown in

Figure 7.

2. Raise the cutterhead so that the wood

gauge fits between the edge of the knife in

the cutterhead and the planer bed. Place

the gauge to one end of the cutterhead.

Adjust the crank handle so the knife edge

just makes contact with the gauge at its

lowest point. See Figure 8.

3. Shift the hardwood gauge to the other end

of the cutterhead without changing the

position of the cutterhead. If the block

begins to bind against the cutterhead as

you move to the opposite end, lower the

table and go back to step 2, starting at this

end instead.

4. Check to see if there is any gap between

the knife edge and the block at the other

end. The knife edge should just touch the

block all the way along the length of the

knife.

Figure 7. Hardwood gauge dimensions.

Figure 8. Using gauge to check cutterhead.

The cutterhead knives on the G1017 planer

are extremely sharp. Merely brushing your

finger along the edge can result in a severe

cut.Take e xtreme caution when doing any of

the adjustments involving the cutterhead

knives. Wear thick gloves anytime it is necessary to manually rotate the cutterhead

assembly.

45˚

.5''

3''

30˚

⁄8''

1

3

1

3

2

1

⁄8'' 11⁄2''

⁄8''

⁄2''

Page 14

-14- G1017 12'' Portable Planer

Knife Setting

The G1017 Planer is equipped with a 2 blade cutterhead.The blades are set by adjustable screws

and are locked in position by wedge type gibs.

Disconnect the power cord from the power source

before adjusting or removing the knives. To

remove the knives:

1. Lower cutterhead down to provide access

to knives from the top.

2. Remove chip deflector.

3. Use open-ended wrench to loosen the bolts

locking the gib and knife in place. Turn

clockwise to loosen knife.

4. Slide knife out of cutterhead and remove

gib. Use care when handling knives - they

are sharp!

5. Repeat steps three and four above to

remove second knife.

If there is any variation between one side and the

other, make adjustments as follows:

1. Remove the depth adjustment handle.

2. Loosen the six screws beneath the edge of

the head piece and remove the top cover.

3. Release the tension on the idler bracket by

loosening the Hex Bolt.

4. While maintaining the position of one of the

two end sprockets (A), lift the drive chain

and rotate the other sprocket to raise or

lower the cutterhead assembly in the

desired direction. See Figure 9. It is important that the designated fixed sprock et does

not move for consistent results.

5. Check parallelism between the knives and

bed. If both sides are parallel, secure the

chain and idler bracket into position.Set the

idler bracket so there is sufficient tension to

keep the chain in position on all sprockets.

6. Replace the top cover and depth adjustment handle.

Figure 9. Chain and sprocket adjustment.

AIdler Bracket

The cutterhead knives on the G1017 planer

are extremely sharp. Merely brushing your

finger along the edge can result in a severe

cut.Take e xtreme caution when doing any of

the adjustments involving the cutterhead

knives. Wear thick gloves anytime it is necessary to manually rotate the cutterhead

assembly.

Page 15

G1017 12'' Portable Planer -15-

To install and adjust the knives:

1. Turn leveling screws clockwise so the knife

will be set low in the cutterhead using the

socket head wrench provided.

2. Insert knife and loosened gib into the cutterhead. Ensure that the knife bevel side is

against cutterhead.

3. Position knife setting gauge on the cutterhead. See Figures 10 and 11.

4. While holding the knife setting gauge with

one hand, turn the leveling screw(s) counterclockwise, thus, raising the knife until the

knife edge just contacts the knife setting

gauge. Do this on both sides of the cutterhead. Repeat if necessary.

5. When the knife is correctly set in the cutterhead, tighten the gib bolts against the cutterhead using the open end wrench.

6. Repeat Steps 1 through 5 above to set the

second knife.

7. Check all gib bolts for tightness .Remember ,

when tightening gibs, turn bolts counterclockwise.

Figure 10. Knife gauge on cutterhead.

Figure 11. Side view of cutterhead and gauge.

The cutterhead knives on the G1017 planer

are extremely sharp. Merely brushing your

finger along the edge can result in a severe

cut.Take e xtreme caution when doing any of

the adjustments involving the cutterhead

knives. Wear thick gloves anytime it is necessary to manually rotate the cutterhead

assembly.

Page 16

-16- G1017 12'' Portable Planer

SECTION 7: OPERATIONS

Once assembly is complete and adjustments are

done to your satisfaction, y ou are ready to test the

machine. Make certain you have removed any

tools or gauges used in the adjustment or assembly process from the bed of the planer.

Turn on the power supply at the main panel.

Press the ON button. Make sure that your finger

is poised on the OFF button, just in case there’s

a problem. The planer should run smoothly, with

little or no vibration or rubbing noises. Strange or

unnatural noises should be investigated and corrected before operating the machine further.

If you cannot easily locate the source of an

unusual noise or vibration, feel free to contact our

service depar tment for help.

Test Run

• Inspect your lumber for twist or cup and sur-

face one face on a jointer if necessary.

• Scrape all glue off when planing laminated

stock.

• Plane boards of equal thicknesses when

planing multiples.

• Remove only

1

⁄32'' to 1⁄16'' (.8mm to 1.6mm) of

material on each pass. Remove less material in each pass when planing wide or dense

stock.

• Support lumber on both ends.Get assistance

if planing long lumber, or use roller stands.

• Measure workpiece with calipers to get exact

results.

• Check surface of workpiece for any irregularities.

• Plane equal amounts on each side of the

board to reduce the chance of warpage.

• Use entire width of planer to wear knives

evenly.

• Surface wood with the grain.Never feed any

end cut or end grained wood through the

machine.

Planing Tips

Make sure the G1017 is unplugged or disconnected from the power source and moving parts have come to a complete stop

before investigating any problems or performing any maintenance or adjustments.

Serious personal injury may occur.

Page 17

G1017 12'' Portable Planer -17-

Figure 12. Common hardwood shear strengths.

The species of wood, as well as its condition,

have a dramatic effect on planing ability. The

harder the wood (as illustrated by its shear

strength), the more difficult it will be to plane.

Commonly used hardwoods and their associated

shear strengths are illustrated in Figure 12. High

shear means difficult planing.

Similarly, common softwood shear strengths are

displayed in Figure 13.

W ood T ypes

Type Shear (PSI)

Black Locust 2,480

Sugar Maple 2,330

Pecan Hickory 2,080

White Oak 2,000

White Ash 1,950

Black Cherry 1,700

American Elm 1,510

Black Waln ut 1,370

Red Alder 1,080

Basswood 980

Cottonwood 930

Increasing

Difficulty

Figure 13. Common softwood shear strengths.

Type Shear (PSI)

Western Larch 1,410

Tamarack 1,280

Douglas Fir 1,160

Alaska Cedar 1,130

Sitka Spruce 1,150

Sugar Pine 1,050

Cypress 1,000

Redwood (OG) 940

Red Cedar 860

White Pine 850

Balsam Fir 710

Increasing

Difficulty

Wood Characteristics

The species of wood, as well as condition, will

affect planing ability. The harder the wood, the

more difficult it will be to plane. We’ve included

below, a list of wood characteristics you may

encounter when planing. The following descriptions of defects will give you some possible

answers to problems you may encounter while

planing different materials. Possible solutions follow the descriptions.

Chipped Grain - usually a result of cutting

against the grain, or planing wood with knots or

excessive amount of cross grain. Chipped grain

can also be caused by dull knives.Often, chipped

grain can be avoided by taking shallow cuts. If

those options do not work, inspect your lumber

and determine if its grain pattern is causing the

problem. If the wood does not show substantial

crossgrain, inspect your knives for sharpness.

Fuzzy Grain - Usually caused by surfacing lumber with too high a moisture content. Sometimes

fuzzy grain is a characteristic of some woods,

such as basswood. Fuzzy grain can also be

caused by dull knives or an incorrect grinding

bevel.Check with a moisture meter. If moisture is

greater than 20%, sticker the wood and allow to

dry. Otherwise, inspect knife condition.

Glossy Surface - Usually caused by dull knives

taking shallow cuts at a slow feed speed.Surface

gloss will usually be accompanied by overheating. Often, lumber will be scorched and eventually, damage to knives will occur.

Snipe - Occurs when board ends have more

material removed than the rest of the board.

Usually caused when one or both of the bed

rollers are set too low. However, small amount of

snipe is inevitable. The best way to deal with

snipe is by planing lumber longer than your

intended work length and then cutting off the

excess after planing is completed.

Wavy Surface - Caused by poor knife height

adjustment, wavy surface appears when one

knife is taking deeper cuts than the rest of the

knives.Recheck or reset knife height to ±.001''.

Page 18

-18- G1017 12'' Portable Planer

Pitch & Glue Build-up - Glue and resin build-up

on the rollers and cutterhead will cause overheating by decreasing cutting sharpness while

increasing drag in the feed mechanism. The

result can include scorched lumber as well as

uneven knife marks and chatter.

Chip Marks or Indentations- Chip indentation or

chip bruising is the result of wood chips not being

thrown away from the cutterhead and out of the

dust chute. Instead they are carried around the

cutterhead, deposited on the planed surface and

crushed by the outfeed roller. Chip indentations

can be caused by a number of reasons, some of

which are:

1. The type of lumber being planed. Certain

species have a tendency to chip bruise.

2. A high moisture content (over 15%) and/or

surface moisture. Typically found in airdried stock where the surface is dry but the

inside needs a longer time to season.

3. An inefficient dust collection system without

enough suction capacity or an incorrectly

engineered and assembled system.

4. Dull knives.

5. Too much material being removed in one

pass.

6. Improper knife cutting angle.

Possible Solutions:

1. Lumber must be completely dry, preferably

kiln-dried (KD). Air-dried (AD) lumber must

be seasoned properly and have no surface moisture.Do not surface partially-airdried (PAD) lumber.

2. Make sure planer knives are sharp.

3. Use an adequate dust collection system,

one that uses relatively few turns and is as

air tight as possible.

4. Remove less material per pass.

5. Use a smaller cutting angle or a double

bevel grind (consult a reputable knife

grinder).

Notes

Page 19

G1017 12'' Portable Planer -19-

SECTION 8: MAINTENANCE

Lubrication

Since all bearings are shielded and permanently

lubricated, simply leave them alone until they

need to be replaced. Do not lubricate them.

As for other items on this machine, such as the

depth adjusting screw-threads, an occasional

“shot” of light oil is all that is necessary.

Regular periodic maintenance on your Model

G1017 Planer will ensure its optimum performance. Make a habit of inspecting your planer

each time you use it. Check for the following conditions and repair or replace when necessary.

General

Routinely check the condition of the following items and repair or replace as necessary:

• Loose mounting bolts, extension

wings, or handles, or excessive play

in the depth of cut adjustment.

• Worn switch.

• Worn or damaged cords or plugs.

• Dull or damaged cutterhead knives.

• Any condition that could hamper the

safe operation of the machine.

Serious personal injury may occur.

Knife Sharpening

Knife sharpness is one of the most important factors in getting good results with the planer.Knives

can be made to last a long time if care is taken in

checking the condition of the wood which is put

into the machine. The biggest problem will come

from wood with nails or other metal embedded.

This will nick or chip the knives and can require a

complete regrinding. Another wear factor is sand,

grit, or other dirt on the surface of the wood which

the knives have to cut through. At the speed the

cutterhead is rotating, these types of surface contamination can have a very abrasive effect.

This planer has knives with a grind angle of 50˚

which is a configuration which should suit most

general planing needs.The optimal grind or bevel

angle is a compromise between effective cutting

(the smaller the angle the better the cutting

action) and edge life where the larger the angle

the more the edge is supported, thus the longer it

will last.

For the best results it is best to hav e planer kniv es

sharpened by a professional sharpening service

which has the grinding and measurement equipment to assure that the knife cutting geometry is

maintained at optimum levels. It is a procedure

which requires some care and precision, otherwise a set of blades can be easily ruined. Knives

should always be ground as a set so they can be

properly matched. Unequal material removal can

result in an unbalanced cutterhead which can

affect not only planing surface quality but ultimately the life of the cutterhead bearings.

Please refer to Section 6 Adjustments - Knife

Setting for complete detail on the removal and

reinstallation of planer knives.

Page 20

-20- G1017 12'' Portable Planer

This motor is equipped with long life carbon

brushes.However, brush life expectancy is affected by motor loading. Planing very wide, dense

boards or cutting too deep will reduce brush life.

Check brushes after every ten to fifteen hours of

operation. See Figure 14. When the brushes are

worn down to

1

⁄4'' (6mm), it is time for replacement.When checking brushes, be sure to replace

each brush in the same position and the same

location that it came from. When replacing old

brushes, be sure to replace both brushes at the

same time.

Figure 14. Brush holder location.

V-Belt

The cutterhead is driven by a rubber V-belt located on the left side of the motor and cutterhead

assembly. The feed rollers are driven by a chain

on the right side of the motor and cutterhead

assembly. To inspect or remove the V-belt:

1. Lower the cutterhead assembly and lea v e a

gap along the front edge of 1

1

⁄2'' to the table.

2. Remove the Belt Guard Cover.

3. ''Roll off'' the old belt toward the side of the

elevation screw.

4. Loop the new belt so that it completely surrounds the motor pulley but with only half

the "vees" engaged. Start the lower portion

on the underside of the cutterhead pulley

and slowly rotate the motor pulley with your

free hand.

5. By pushing on the edge of the belt and

slowly turning the pulleys by hand, you can

force the belt over until all the "vees" of the

belt are in alignment with the "vees" on the

pulley.

6. Replace the belt guard.

Motor

Keep the motor as clean as possible.Prevent any

water, oil or wood chips from penetrating inside

the motor. Be sure to clean the machine after

every use. Do not use compressed air to remove

saw dust. Dust may be forced into normally protected parts which may cause damage to the

machine.

The bearings inside the motor are also shielded

and lubricated for the life of the bearing and

require no routine maintenance.

Page 21

G1017 12'' Portable Planer -21-

Feed Rollers

The feed rollers rotate in bushing blocks that are

spring-loaded. The feed rollers ride up on the

board so roller pressure is maintained. If chips or

sawdust build up between the bracket and bushing block, the amount of roller vertical travel will

be reduced. See Figure 15.

Routinely check and clean chips and sawdust

from between the bushing bloc ks and brac kets .To

depress the rollers so that chips and sawdust can

be easily removed:

1. Place a 5'' block of wood between one of

the feed rollers and the planer bed. Ensure

that the block of wood is not under the cutterhead.

2. Lower the cutterhead assembly down just

enough so that the roller pressure is off of

the two brackets.

3. Remove any trapped material from

between the roller assembly and bracket.

4. Raise the cutterhead assembly and remov e

the block of wood.

Repeat Steps 1 through 4 above to clean chips

and sawdust from the second feed roller.

Figure 15. Location of potential trapped sawdust.

Remove trapped sawdust from between

the bushing block and the bracket

Page 22

-22- G1017 12'' Portable Planer

The following pages contain parts diagrams / lists,

general machine data and Warranty/Return information for your Model G1017 12'' Planer.

If you need parts or help in assembling your

machine, or if you need operational information,

we encourage you to call our Service

Department. Our trained ser vice technicians will

be glad to help you.

If you have comments dealing specifically with

this manual, please write to our Bellingham,

Washington location using the address in the

General Information section. The specifications,

drawings, and photogr aphs illustrated in this manual represent the Model G1017 as supplied when

the manual was prepared. However, due to

Grizzly’s policy of continuous improvement,

changes may be made at any time with no obligation on the part of Grizzly. Whenever possible,

though, we send manual updates to all owners of

a particular tool or machine. Should you receive

one, add the new information to this manual and

keep it for reference.

We have included some important safety measures that are essential to this machine’s operation. While most safety measures are generally

universal, Grizzly reminds you that each workshop is different and safety rules should be considered

as they apply to your specific situation.

We recommend you keep a copy of our current

catalog for complete information regarding

Grizzly's warranty and return policy. If you need

additional technical information relating to this

machine, or if you need general assistance or

replacement parts, please contact the Service

Department listed in Section 3: General

Information.

Additional information sources are necessary to

realize the full potential of this machine. Trade

journals, woodworking magazines, and your local

library are good places to start.

SECTION 9: CLOSURE

As with all power tools, there is danger

associated with the Model G1017 12"

Portable Planer. Use the tool with respect

and caution to lessen the possibility of

mechanical damage or operator injury. If

normal safety precautions are overlooked

or ignored, serious personal injury may

occur.

The Model G1017 was specifically designed for

planing operations.DO NOT MODIFY AND/OR

USE THIS PLANER FOR ANY OTHER PURPOSE. Modifications or improper use of this

tool will void the warranty. If you are confused

about any aspect of this machine, DO NOT use

it until you have answered all your

questions.Serious injury may occur.

Loading...

Loading...