Page 1

HHuunntteerr’’ss MMeeaatt CCuuttttiinngg BBaannddssaaww

-- 11 --

HUNTER’S MEAT CUTTING SAW

MODEL G1016

INSTRUCTION MANUAL

COPYRIGHT © 1995 BY GRIZZLY IMPORTS, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY IMPORTS, INC.

JULY, 1995. PRINTED IN USA

DISCONTINUED MACHINE MANUAL DISCLAIMER

THE INFORMATION IN THIS MANUAL REPRESENTS THE LAST CONFIGURATION OF THE MACHINE BEFORE IT WAS DISCONTINUED.

MACHINE CONFIGURATIONS MAY HAVE CHANGED AS PRODUCT IMPROVEMENTS WERE INCORPORATED. IF YOU OWN AN EARLIER VER-

SION OF THE MACHINE, THIS MANUAL MAY NOT EXACTLY DEPICT YOUR MACHINE . CONTACT CUSTOMER SERVICE IF YOU HAVE ANY

QUESTIONS ABOUT DIFFERENCES. PREVIOUS VERSIONS ARE NOT AVAILABLE ONLINE.

IMPORTS, INC.

Page 2

Table of Contents

PAGE

I. Introduction..........................................................................................................1

II. Safety Rules for all Tools ................................................................................2

III. Electrical Requirements ..................................................................................4

A. Circuit Loading..........................................................................................................4

B. Grounding ................................................................................................................4

C. General Information..................................................................................................4

D. Word of Caution ......................................................................................................4

IV. Site Planning........................................................................................................5

A. Working Clearances ................................................................................................5

B. Lighting and Outlets ................................................................................................5

V. Unpacking ............................................................................................................5

VI. Piece Inventory ..................................................................................................6

VII. Assembly ..............................................................................................................7

A. Stand ........................................................................................................................7

B. Motor ........................................................................................................................8

C. Bandsaw Unit ..........................................................................................................8

D. Pulleys and V-Belt ....................................................................................................9

E. Table ......................................................................................................................10

F. Fence and Guards..................................................................................................10

G. Meat Grinder ..........................................................................................................11

H. Stand Enclosures ..................................................................................................11

- i - Hunters Meat Cutting

Bandsaw

Page 3

Table of Contents

PAGE

VIII. Adjustments ......................................................................................................12

A. Blade Tension ......................................................................................................12

B. Tracking ..................................................................................................................13

C. Guide Blocks ..........................................................................................................14

D. Support Bearings....................................................................................................15

E. Blade Removal and Replacement ..........................................................................16

F. Blade Guard ..........................................................................................................16

IX. Safety Rules for Bandsaws ..........................................................................17

X. Operations ..........................................................................................................18

A. General ..................................................................................................................18

B. Test Run ................................................................................................................18

C. Cutting Procedures ................................................................................................18

D. Meat Grinder ..........................................................................................................18

XI. Cleaning ..............................................................................................................19

XII. Maintenance ......................................................................................................20

A. Lubrication ..............................................................................................................20

B. Miscellaneous ........................................................................................................20

XIII. Troubleshooting................................................................................................21

XIV. Machine Data ....................................................................................................22

XV. Main Parts Diagram ........................................................................................23

XVI. Meat Grinder Parts Diagram ........................................................................24

XVII. Stand Parts Diagram ......................................................................................25

XVIII.Parts List ............................................................................................................26

XIX. Warranty and Returns ................................................................BACK COVER

- ii - Hunters Meat Cutting

Bandsaw

Page 4

We are proud to offer the Hunter’s Meat

Cutting Bandsaw. When used according to

the guidelines stated in this manual, you can

expect years of trouble-free, enjoyable operation and experience proof of our commitment

to customer satisfaction.

The saw features a sheet steel body, easy to

clean stainless steel table, and a 10

1

/4" cutting

height. It comes equipped with a 1720 RPM, 1

HP motor.

We are also pleased to provide this manual

with your saw. It was written to guide you

through assembly, review safety considerations, and cover general operating procedures. It represents our latest effort to produce the best documentation possible. If you

have any criticisms that you feel we should

pay attention to in our next printing, please

write to the customer service address listed

on your catalog: attn: Manager, Technical

Documentation.

Most importantly, we stand behind our

machines. If you have any service questions

or parts requests, please call or write us at the

appropriate customer service location listed

on your catalog.

To operate this or any power tool safely and

efficiently, it is essential to become as familiar

with its characteristics as possible. Take as

much time as necessary to become acquainted with your saw. The time you invest before

you begin to use your machine will be time

well spent. Also, read all of the safety procedures. If you do not understand something

about this machine, DO NOT operate it.

The specifications, drawings, and photographs illustrated in this manual represent

the Hunter’s Meat Cutting Bandaw as supplied when the manual was prepared.

However, owing to our policy of continuous

improvement, changes may be made at any

Hunter’s Meat Cutting Bandsaw - 1 -

time with no obligation on our part. Whenever

possible, though, we send manual updates to

all owners of a particular tool or machine.

Should you receive one, we urge you to insert

the new information with the old and keep it

for reference.

The information in this manual has been

obtained from sources we believe to be reliable and as up-to-date as possible. We have

included some important safety measures

which we believe to be essential for safe operation. While most safety measures are generally universal, we remind you that each work

area is different and safety rules should be

considered as they apply to your specific situ-

ation. Also – please read the entire manual

before attempting to operate your saw.

We recommend that you keep a copy of our

current catalog for complete information

regarding our warranty and return policy.

Should you need additional technical information relating to this machine, or if you need

general assistance or parts, please contact

the customer service department.

We also believe additional information

sources are very important for reaping the full

potential of this machine. Consulting with your

local butcher would be a good place to start.

WARNING! This saw is dangerous. Use the

tool with respect and caution to lessen the

possibility of mechanical damage or injury. If

normal safety precautions are overlooked or

ignored, injury to the operator or others in the

area is likely.

This bandsaw was specifically designed for

meat cutting. Modifications or improper use

of this tool will void the warranty. If you are

confused about any aspect of this machine,

DO NOT use it until you have resolved any

questions you have.

I. Introduction

End of Section

Page 5

II. Safety Rules for all Tools

- 2 - Hunters Meat Cutting Bandsaw

1. KNOW YOUR POWER TOOL. Read

the owner’s manual carefully. Learn the

tool’s applications and limitations, as well

as its hazards.

2. KEEP ALL GUARDS IN PLACE and

in working order.

3. GROUND ALL TOOLS. If an adapter

is used to accommodate a two-prong

receptacle, the adapter plug must be

attached to a known ground. Never

remove the grounding prong.

4. REMOVE ADJUSTING KEYS AND

WRENCHES. Make it a habit to check

that keys and wrenches are removed

from the machine before turning it on.

5. KEEP WORK AREA CLEAN.

Cluttered areas and benches invite accidents.

6. AVOID DANGEROUS ENVIRONMENTS. Keep your work area well

lighted.

7. KEEP CHILDREN AND VISITORS

AWAY. All children and visitors should

be kept a safe distance away from your

work area.

8. MAKE WORK AREA CHILDPROOF with padlocks, master switches,

or by removing starter keys.

9. DO NOT FORCE TOOL. Tools work

better and more safely when they are

allowed to work at their own speed.

10. USE THE RIGHT TOOL. Do not use a

tool or an attachment to do a job that it

was not intended to perform.

11. WEAR PROPER APPAREL. Do not

wear loose clothing, gloves, neckties, or

jewelry that might get caught in moving

parts. Non-slip footwear is also recommended. Wear a hat or other protective

head wear if your hair is long.

12. USE SAFETY GLASSES AND EAR

PROTECTION.

13. DO NOT OVERREACH. Keep proper

footing and balance at all times.

14. MAINTAIN TOOLS IN TOP CONDITION. Keep tools sharp and clean for

best and safest performance. Follow

instructions for lubricating and changing

accessories.

15. DISCONNECT TOOLS FROM

POWER before servicing and when

changing accessories.

16. USE ONLY RECOMMENDED

ACCESSORIES. Consult the current

catalog for recommended accessories.

Using improper accessories may be hazardous.

17. AVOID ACCIDENTAL STARTING.

Make sure the switch is in the “OFF” position before plugging in the cord.

Page 6

II. Safety Rules for all Tools

Hunter’s Meat Cutting Bandsaw - 3 -

18. NEVER STAND OR LEAN ON

TOOL. Serious injury could occur if the

tool is tipped or if the cutting edge is accidentally contacted.

19. CHECK DAMAGED PARTS. Before

further use of the tool, any part or guard

that is damaged should be promptly

repaired or replaced. Do not operate the

machine until you are certain that it is in

perfect running condition. Failure to follow this precaution could result in further

mechanical damage and operator injury.

20. DO NOT WORK IN HASTE or operate machine if you are mentally or physically fatigued.

21. NEVER LEAVE THE TOOL RUNNING UNATTENDED - TURN

POWER OFF. Do not leave the tool until

it comes to a full stop.

22. DO NOT OPERATE THE TOOL

UNDER THE INFLUENCE OF

DRUGS, ALCOHOL, OR MEDICATION. Never operate machinery when

overly fatigued.

23. IF THERE IS SOMETHING YOU

DO NOT KNOW OR UNDERSTAND

ABOUT THIS MACHINE, DO NOT

OPERATE IT! Ask for help first.

Confusion is dangerous.

24. BAD HABITS ARE DANGEROUS.

Review all safety procedures often.

These safety rules, while expansive, may not

cover every situation. Please consider your

unique conditions when setting up and using

your saw.

More safety rules are reviewed in Section

IX.

Remember:

Safety First!

End of Section

Page 7

- 4 - Hunters Meat Cutting

Bandsaw

If you are unsure about connecting your

bandsaw, don’t take chances: consult the

service dept or a licensed electrician.

EXTENSION CORDS: If used, extension

cords must be rated hard service – grade S –

or better. Conductor size must be 12 AWG for

cords up to 50 feet in length. Your extension

cord must also contain a ground wire and plug

pin. Repair or replace extension cords if they

become damaged.

C. Word of Caution

In this section we have covered some basic

electrical requirements for the safe operation

of your bandsaw. As with the safety rules in

the preceding section, these requirements are

not necessarily comprehensive. Further, you

must be sure that your particular electrical

configuration complies with local and state

codes. The best ways to ensure compliance

are to check with your local municipality or

licensed electrician.

A. Circuit Loading

The motor will safely draw about 12 amps at

110V under load. If you operate the bandsaw

on any circuit that is already close to its

capacity, it might blow a fuse or trip a circuit

breaker. However, if an unusual load does not

exist, and power failure still occurs, have the

circuit inspected by a qualified electrician.

CIRCUIT BREAKERS/FUSES: A 15 amp

circuit breaker or fuse should be used for a

110V undedicated circuit. The general rule is

to use the lightest breaker or fuse that will

hold under regular loads. Circuit breakers or

fuses that are rated higher may not adequately protect the motor.

B. Grounding

This machine must be electrically

grounded. We have furnished the bandsaw

with a plug suitable for use with a grounded,

domestic 110V circuit.

Please verify that any circuit you intend to use

is actually grounded. If the circuit is not

grounded, it will be necessary to run a separate 12 AWG copper grounding wire from the

machine frame to a grounding terminal in your

electric service panel. Consult with a licensed

electrician if you are unsure about machine

grounding.

III. Electrical Service Requirements

When placing the bandsaw in your work area,

three considerations should be addressed;

electrical service requirements, working clearances, and lighting and outlets. We’ll look at

the first consideration now and leave the other

two for the next section.

The bandsaw has a 1 HP motor which is ready

for 110V, single phase operation.

You must wire the motor to the switch.

End of Section

Page 8

V. UnpackingIV. Site Planning

Hunter’s Meat Cutting Bandsaw - 5 -

The bandsaw is shipped from the factory in a

carefully packed carton. If you find the

machine to be damaged after you’ve signed

for delivery and the truck and driver are

already gone, you will need to file a freight

claim with the carrier. Save the containers and

all packing materials for inspection by the carrier or their agent. Without the packing materials, filing a freight claim can be difficult. If you

need advice regarding this situation, please

call us immediately.

Caution: The meat cutting saw is a HEAVY

machine (106 lbs. shipping weight). DO NOT

over-exert yourself while unpacking or moving

your machine – get assistance. In the event

that your bandsaw must be moved up or down

a flight of stairs, be sure that the stairs are

capable of supporting the combined weight of

people and the machine.

When you are completely satisfied with the

condition of your shipment, you should inventory its parts.

A. Working Clearances

Be sure that there is plenty of room around

your saw before cutting. Relocate any items

that risk contamination and cannot be easily

washed. Allow yourself sufficient room to run

your saw IN ANY FORESEEABLE OPER-

ATION.

B. Lighting and Outlets

Lighting should be bright enough to eliminate

shadow and prevent eye strain. Electrical circuits should be dedicated or large enough to

handle combined motor amp loads. Outlets

should be located near the machine so power

or extension cords are not obstructing hightraffic areas. Be sure to observe local electrical codes for proper installation of new lighting, outlets, or circuits.

End of Section

End of Section

Page 9

VI. Piece Inventory

- 6 - Hunters Meat Cutting

Bandsaw

With all the parts removed from the

container, you should have:

• Bandsaw Unit with Blade

• Motor

• Motor Pulley

• V-Belt

• Table

• Fence

• Column Guard

• Blade Guard

• Table & Guard Knobs (13)

• Stand Parts (5)

• Stand Enclosures (2)

• Motor Mounting Brackets (2)

• Meat Grinder

• Plastic Pestle

• Casing Tube

• Fasteners

If anything is missing, call or write the customer service department. If anything is damaged, please follow the procedures described

in Section V above.

Below is a list of fasteners required to assemble your bandsaw. If any standard hardware is

missing (e.g., a nut or bolt), we will be happy

to replace it, but it would be quicker to buy

replacements from your local hardware store.

However, if an unusual amount of fasteners or

proprietary parts are missing, please let us

know. A full parts list and breakdown can be

found toward the end of this manual.

QTY.

22

30

34

4

4

3

4

DESCRIPTION

5

/16

" - 18 x

5

/8

" Carriage Bolts

5

/16" - 18 Hex Nuts

5

/16" Flat Washers

Foot Assemblies

5

/16" - 18 x 3/4" Hex Bolts

3

/8" - 16 Threaded Studs

90° Brackets

LOCA

TION

Stand

Stand

Stand

Stand

Motor

Stand/Bandsaw Body

Stand

End of Section

Figure 1 shows the bolt bag contents.

Page 10

A. Stand

Note: All die-cut metal parts have a sharp

edge (called “flashing”) on them after they are

formed. This is removed at the factory.

Sometimes, though, a bit of flashing might

escape inspection. Please examine the edges

of all die-cut metal parts before handling

them.

TOOLS REQUIRED: Common hand tools

are necessary to assemble this machine. You

will need a set of open ended metric and standard wrenches and a Phillips head screwdriver.

VII. Assembly

Hunter’s Meat Cutting Bandsaw - 7 -

1. Flip the top of the stand upside down and

place it on your benchtop.

2. Attach the sides using the carriage bolts,

washers, and nuts provided. Mount the

stand front (the side with the switch) so it

is on the same side as the rectangular

hole in the stand top. Figure 2. Do not

fully tighten the nuts.

3. Mount the braces between the front and

back panels. Use carriage bolts, washers, and nuts provided. Tighten partially.

4. Press the 90° brackets onto the bottom

corners of the stand. These are stiffeners.

Primary Motor

Bracket

Motor

Motor Pulley

Rubber Foot

90° Bracket

Aux. Motor Bracket

Left Brace

Back

Front

Right Brace

Switch

Stand Top Hole

1

st

page of 5 page section

Figure 2 shows the stand/motor assembly completed.

Page 11

- 8 - Hunters Meat Cutting

Bandsaw

7. If the stand is wobbly, check your floor

first. If the floor is level, loosen the bolts

and wiggle the stand until it rests firmly on

the floor. Re-tighten the bolts.

C. Bandsaw Unit

1. Lift the bandsaw onto the stand. The front

of the saw must be on the same side as

the switch.

2. Attach the bandsaw to the stand with the

three (3) threaded studs. Screw them up

through the stand top and into the welded

nuts on the base of the bandsaw. Figure

3. It may be necessary to shift the bandsaw slightly to get the studs lined up right.

3. Feed the short electrical cord through the

plastic wire clamp in the motor junction

box. Connect the wire according to the

wire diagram insert included with this

manual. Tighten the wire clamp. DO

NOT over-tighten – the plastic threads

may strip.

4. The longer cord from the base of the saw

is the power cord. It is prefitted with a

110V grounded plug. NEVER

REMOVE THE GROUNDING

PRONG!

VII. Assembly

Figure 3 shows the stud mounting locations.

Threaded Stud

5. Install the rubber feet. They should go

through the 90° brackets first and then

through the sides. Tighten securely.

B. Motor

1. Secure the auxiliary motor bracket to the

stand top. Use carriage bolts, nuts, and

washers. Figure 2.

2. Fasten the primary motor bracket to the

left brace and the auxiliary motor bracket.

Use carriage bolts, nuts, and washers.

Do not fully tighten.

3. Mount the motor to the primary motor

bracket using the hex bolts, nuts, and

washers provided. Do not fully tighten.

4. Press the motor pulley over the motor

shaft and insert the key in the keyway.

Position the pulley so its V-groove is

roughly centered over the rectangular

slot in the stand top. Tolerances are tight:

you may need to sand the key or the keyways slightly. Tighten the setscrew.

5. Now that the motor is mounted, tighten all

the stand bolts but leave the motor bolts

loose.

6. Flip the stand/motor assembly right side

up on the floor. Hold the motor so it does

not slide when you tip the stand over.

Welded Nuts

2

nd

page of 5 page section

Page 12

VII. Assembly

Hunter’s Meat Cutting Bandsaw - 9 -

1"

Driven Pulley

Motor Pulley

Figure 4 shows the V-Belt installed correctly.

D. Pulleys and V-Belt

Pulley alignment and proper V-Belt tension

are crucial to increased belt life and optimal

power transmission from motor to blade.

The motor pulley should already be centered

under the slot in the stand top. Shift the driven

pulley so it lines up with the motor pulley.

To align the driven pulley (Figure 4):

1. Loosen the setscrew on the back of the

driven pulley.

2. Grasp the pulley on the top and bottom.

Shift it along its shaft to line up the Vgrooves on both pulleys. Use sight to

judge their vertical alignment.

3. Tighten the setscrew on the driven pulley.

To install and properly tension the V-

Belt:

1. Push the motor up to the top of its slots.

2. While holding the motor in place, slip the

V-Belt into the grooves in the pulleys.

3. Slide the motor down until the V-Belt is

properly tensioned. You should be able to

deflect the belt about 1" at the midpoint.

Use moderate finger pressure. Figure 5.

4. Check that the motor pulley is still in line

with the driven pulley. The motor will

have a tendency to twist slightly when it is

moved. This will push the pulleys out of

alignment and twist the V-Belt. Check

and adjust motor position if twisting

occurs.

5. Tighten the motor mounting bolts.

When cleaning (Section XI), you will need

to take off and put on the V-Belt. This can be

done without adjusting the position of either

pulley. UNPLUG THE MACHINE FIRST!

To remove the V-Belt, pull it laterally from

the back of the motor pulley and roll the pulleys forward. The belt will pop off. Figure 4.

To replace the V-Belt, loop it over the

motor pulley and as much of the driven pulley

as possible. Roll the pulleys forward and the

V-belt will slip into the grooves, just like a bicycle chain on its sprockets.

Figure 5 shows proper V-Belt deflection.

Driven Pulley

V-Belt

Pull Here to

Remove

3

rd

page of 5 page section

Page 13

- 10 - Hunters Meat Cutting

Bandsaw

E. Table

Before installing the table and

guards, peel off the blue, protective

plastic.

Slide the table on at a 45° angle. Figure 6.

Lower the table so the notch goes around the

column. When it is in its final position, secure

it to the bandsaw body using the black knobs

provided.

F. Fence & Guards

Fence:

Install the fence so the vertical portion is facing the blade. Figure 7. Secure it to the table

and bandsaw body with the black knobs.

Column Guard:

Attach the column guard to the vertical column. Use the black knobs. Figure 7.

Upper Wheel Guard:

Attach the upper wheel guard to the vertical

column using a black knob. Figure 7.

Blade Guard:

Using the last 2 black knobs, secure the blade

guard to the upper wheel guard. You may

need to place washers behind the heads of

the knobs so the threaded ends do not touch

the blade. Extra washers are not provided.

Figure 7.

VII. Assembly

Figure 6 shows how to install the table.

Figure 7 shows the fence, guards, and table installed

correctly.

Notch

Blade Slot

Column

Column

Guard

Fence

Upper Wheel Guard

Blade Guard

Table

4

th

page of 5 page section

Page 14

Hunter’s Meat Cutting Bandsaw - 11 -

G. Meat Grinder

To install the meat grinder (Figure 8):

1. Loosen the mounting bolt at the base of

the meat grinder.

2. Line up the tang on the saw with the slot

on the grinder (similar to a flat head

screwdriver and a screw).

3. Push the meat grinder on the aluminum

holder. Some twisting and turning may be

necessary to slide it on; it is a tight fit.

4. Put the die in place and screw down the

lock. Re-tighten the mounting bolt.

If you don’t intend to grind meat, don’t

leave the grinder on the bandsaw. Meat

juices are its lubrication and running dry

will cause excessive wear.

H. Stand Enclosures

To install the stand enclosures:

1. Attach 6 plastic tabs to each plastic

enclosure using the screws provided.

Tighten them so they can still be turned

by hand, without further adjustment with

a screwdriver. Figure 9.

2. Position each stand enclosure as shown

in Figure 9. Turn the plastic tabs so

they keep the enclosures in place.

VII. Assembly

Figure 8 shows the meat grinder installed with the

casing tube in place.

Figure 9 shows a stand enclosure in place.

Stand Enclosure

Casing Tube

Pestle

Meat Grinder

Plastic Tab

Lock

5

th

page of 5 page section

End of Section

Page 15

- 12 - Hunters Meat Cutting

Bandsaw

A. Blade Tension

To check blade tension:

1. Turn off the power and unplug the saw.

2. Remove the upper wheel guard by

removing the black plastic knob. The

blade guard will come off with it.

3. Lower the guide post so it is not in the

way when testing the tension. This is

done by loosening the guide post secur-

ing knob. Figure 11. Do not let the

post and attached guide assembly

drop. There is no spring attached.

Damage could occur.

4. Press on the face of the blade with your

thumb. Figure 10.

5. The blade should flex about

1

/2

" with mod-

erate pressure.

If the blade flexes too much or too little, you

will experience problems with blade life and/or

cutting efficiency.

To adjust the blade tension:

1. Turn the tension adjustment bolt until the

blade appears properly tensioned.

Figure 11.

2. Check the blade tension again.

The pressure that the blade puts on the tension bolt acts to keep it in place. The tension

should stay relatively constant. But if you find

that the blade will not keep proper tension,

consider adding a jam nut to the bottom of the

tension bolt. This will act as a supplementary

lock.

If the tension seems correct, make the other

adjustments to the saw and test run it. If the

blade does not cut properly, the tension may

be incorrect. Re-adjust tension.

VIII. Adjustments

Guide Post

Securing Knob

Tension

Adjustment

Bolt

Figure 10 shows how to test the blade tension.

Figure 11 shows the tension adjustment bolt and the

guide post securing knob locations.

1

st

page of 5 page section

Page 16

Hunter’s Meat Cutting Bandsaw - 13 -

To CHECK tracking:

1. Turn the power off and unplug the saw.

2. Spin the wheels through several com-

plete rotations. Watch the position of the

blade on the wheels.

3. The blade will move back and forth on

the wheels very slightly. It may also ride

closer to the back of the wheels than the

front or vice versa. This is acceptable for

a meat cutting saw. However, if the blade

moves back and forth on the wheels

erratically or falls off completely, you

must adjust the tracking.

To ADJUST tracking:

Tracking is adjusted by altering the position of

the setscrews behind the upper wheel. Adjust

only the upper and lower setscrews. Do

not adjust the setscrews on the sides.

Figure 12.

1. Disconnect the bandsaw from the power

source and adjust the upper guide blocks

away from the blade. See Section

VIII.C.

2. Decrease the tension slightly before

adjusting tracking. Tracking adjustment

will automatically increase the tension.

See Section VIII.A.

3. If you need to push the top of the upper

wheel toward the front of the saw, loosen

the lower setscrew first and then tighten

the upper setscrew.

4. If you need to push the bottom of the

upper wheel toward the front of the saw,

loosen the upper setscrew first and then

tighten the lower setscrew.

Pushing the top or bottom of the upper wheel

toward the front of the saw will correct any

tracking irregularities. You must loosen the

opposing setscrew before tightening the

setscrew that pushes the wheel the way

you want. Otherwise, you’ll put tremendous pressure on the threads and may

strip them out.

VIII. Adjustments

Figure 12 shows the tracking adjustment screws. Do

not attempt to adjust the horizontally opposed

screws.

DO NOT

ADJUST!

DO NOT

ADJUST!

Adjustment Screw

Adjustment Screw

B. Tracking

Alignment of the blade on the wheels, or

tracking, is important for cutting efficiency.

Also, blade life will be extended and your cuts

will be more predictable.

2

nd

page of 5 page section

Page 17

- 14 - Hunters Meat Cutting

Bandsaw

VIII. Adjustments

Figure 13 shows a closeup of the upper guide

assembly.

To adjust the lower guide tabs

(Figure 14):

1. Remove the table.

2. Note whether the blade touches the fixed

plate: it should not. If it does, loosen the

nuts that hold the fixed plate in place and

position it so the blade is centered in the

slot in the fixed plate. Re-tighten the nuts.

3. Loosen the screws that hold the guide

tabs in place.

4. Adjust the guide tabs so they are about

1

/64" behind the gullet line (the low points)

of the blade and 0.004" from the sides of

the blade. This is about the same thickness as a piece of typing paper.

5. Re-tighten the screws to secure the tabs.

To adjust the upper guide blocks

(Figure 13):

1. Check the position of the guide blocks in

relation to the blade. They should be

approximately

1

/64" behind the gullet line

(the low points) of the blade.

2. If the guide blocks are in the correct position, go on to step 3. If the guide blocks

are out of alignment, you can alter the

position of the guide post and guide

blocks.

a. Loosen the guide post securing knob

and remove the entire upper guide

post assembly.

b. Remove the bolts that anchor the

guide post bracket to the frame.

c. Add or remove washers between the

bracket and the frame to adjust the

position of the guide post and the

guide blocks. This will correct the position of the guide blocks.

3. Now, loosen the thumbscrews holding

the guide blocks in place.

4. Adjust the blocks to about 0.004" from

the blade. This is about the same thickness as a piece of typing paper.

5. Re-tighten the thumbscrews.

C. Guide Blocks

The guide blocks ensure that the blade is not

pushed too far laterally. The upper guide

blocks are similar to those found on wood cutting bandsaws. The lower guides are steel

tabs that can be adjusted to a specific distance from the blade.

Thumbscrews

Guide Post

Guide Block

Blade

Support Bearing

Support

Bearing Shaft

3

rd

page of 5 page section

Page 18

Hunter’s Meat Cutting Bandsaw - 15 -

VIII. Adjustments

To adjust the lower support bearing

(Figure 14):

1. Loosen the nut that holds the lower sup-

port bearing in place.

2. Position the bearing to approximately

1

/64"

behind the blade.

3. Re-tighten the nut that holds the bearing

in place.

To adjust the upper support bearing

(Figure 13):

1. Loosen the thumbscrew securing the

upper support bearing shaft.

2. Position the bearing to approximately

1

/64"

behind the blade.

3. Re-tighten the thumbscrew.

D. Support Bearings

The support bearings back-up the blade during sawing. The upper support bearing is

located just above the guide blocks. Figure

13. The lower support bearing is perpendicular (90°) to the upper bearing, but it should be

adjusted similarly.

Figure 14 shows a closeup of the lower guide assembly.

Guide Tab

Fixed Plate

Support Bearing

Guide Tab

Support Bearing Nut

4

th

page of 5 page section

Page 19

- 16 - Hunters Meat Cutting Bandsaw

VIII. Adjustments

F. Blade Guard

Warning: The blade guard must cover all of

the blade above the upper blade guide

assembly. It is very dangerous to leave

unused portions of the blade exposed.

To adjust the blade guard:

1. Loosen the two black knobs that secure

the blade guard to the upper wheel

guard. Figure 15.

2. Slide the blade guard so it almost touch-

es the blade guide assembly.

3. Re-tighten the mounting knobs.

E. Blade Removal and

Replacement

To remove a blade:

1. Turn off the power and unplug the

machine.

2. Remove the table and V-Belt. See

Section VII.D.

3. Loosen and remove the tension adjust-

ment bolt. Lower the upper wheel mounting arm.

4. Slip the blade off the wheels and pull it

out.

To install a blade:

1. Turn off the power and unplug the

machine. Remove the table and V-Belt.

2. Unscrew the tension adjustment bolt.

3. Lower the upper wheel mounting arm.

4. Slip the blade over both the lower and

upper wheels.

5. Carefully lift the upper wheel mounting

arm and engage the tension adjustment

bolt into the welded nut.

6. Tighten the tension adjustment bolt until

the blade is correctly tensioned. Check

according to Section VIII.A. Check

tracking as well. See Section VIII.B.

The teeth must point toward the front of

the saw and downward. If you cannot orient the blade so the teeth are in the cutting

position, the blade is inside out. Remove

the blade, twist it inside out, and replace it.

Be sure to check for correct tension and

tracking.

Blade

Guard

Figure 15 shows the blade guard in proper position.

Blade Guide

Assembly

Upper Wheel

Guard

Blade

Guard

Knobs

End of Section

5

th

page of 5 page section

Page 20

Hunter’s Meat Cutting Bandsaw - 17 -

1. Ensure that the machine sits firmly on the

floor before use. Any “wobbles” must be

corrected before operation.

2. ALWAYS wear eye protection while

operating this bandsaw. All safety equipment must be ANSI approved.

3. NEVER attempt to operate your band-

saw with dull or badly worn blades. Dull

blades require more effort to use and are

difficult to control. Cracked blades will

snap and flail dangerously in the saw during operation. Inspect blades before each

use.

4. This machine is not designed to cut any

material other than meat and bone.

5. All inspections, adjustments, and mainte-

nance are to be done with the power off

and the plug pulled from the outlet. Wait

for all moving parts to come to a complete stop.

6. DO NOT operate this bandsaw without

wheel and blade guards in place.

7. DO NOT stick your fingers into the meat

grinder

8. NEVER position body parts in line with

the cut.

9. ALWAYS stand in front (the meat

grinder is at the back and the blade teeth

point toward the front) of the bandsaw

when feeding meat.

10. Cuts should always be fully supported by

the table or some type of support fixture.

11. Blade should run at full speed before

beginning a cut.

12. When replacing blades, make sure teeth

face down toward the table. The force of

the cut is always down.

13. Make sure the blade has proper tension.

See Section VIII.A.

14. DO NOT manually stop or slow blade

after turning the saw off.

15. DO NOT operate the bandsaw at excessively low temperatures. Blades can

break easier if operated at cold temperatures.

16. NEVER leave the bandsaw running

unattended.

IX. Safety Rules for Bandsaws

This tool will injure you if you use it in a reckless manner. If you are unfamiliar with the

operating and safety procedures for this

machine, DO NOT use it. Injury prevention

begins before the machine is turned on.

Please read and observe all safety items

addressed in this manual.

We have already discussed general safety

rules for all power tools. At this point we wish

to review some additional safety items relating

specifically to bandsaw operation.

End of Section

Page 21

- 18 - Hunters Meat Cutting Bandsaw

A. General

1. Use a sharp, high-quality blade.

2. Use the right blade for the job.

Your saw comes equipped with a “bonein” blade - which means it can cut both

meat and bone. Do not use a “boneless”

blade if planning to cut through bone.

3. Partially frozen meat is easier to cut than

meat at room temperature. At room temp,

the meat is so soft that it will tend to plug

the grinder and blade.

4. Allow the saw to cut. Don’t force

the meat into the blade. Feed the

blade with even pressure at a moderate

speed.

5. Maintain your bandsaw in top

condition. See Section XII of this

manual for maintenance procedures.

B. Test Run

1. Completely assemble the bandsaw and

perform all adjustment procedures.

2. Check that all fasteners are tight.

3. Make sure that the saw is properly wired

for the voltage you intend to use.

4. Turn on the machine. Be ready to turn it

off immediately if there is any sign of malfunction.

5. If everything is normal, proceed to Part

C and begin cutting.

X. Operations

This bandsaw will make home butchering a

simple process. Below is a discussion of possible applications for this saw. Consult your

local butcher shop if you are interested in cutting specific types of steaks or chops.

C. Cutting Procedures

1. Determine the steak thickness you want.

2. Position the fence according to steak

thickness. If not using the fence, remove

it completely. Removing the fence means

one less item to clean.

3. Adjust the upper blade guide assembly

so it is

1

/4" from the top of your meat.

Adjust the blade guard so it covers any

unused portion of the blade.

4. Set up a large bowl or container to place

your steaks as they are cut. Package

them when you are finished cutting.

5. Power up and let the saw reach full

speed.

6. Feed your meat into the blade slowly and

evenly. Do not allow your fingers to

come close to the blade. Retrieve your

steaks and put them in your bowl or container.

D. Meat Grinder

The meat grinder operates simultaneously

with the blade. As you are cutting steaks, any

extra pieces can be put into the meat grinder.

If you are using the grinder only, remove the

blade to decrease the hazards.

Optional dies (parts #33A and #33B) are available for a small fee. Consult the parts list and

service department for more information.

You can also make sausages by putting

sausage casing over the casing tube and forcing the meat into it. Consult your butcher for

further instructions about making sausage.

End of Section

Page 22

Your meat cutting band-

saw MUST be thoroughly

cleaned after each use!

Bacterial infection is a major concern when

working with raw meat. Your meat cutting

bandsaw must be thoroughly cleaned with

antibacterial soap and water or bleach and

water after each use.

Fortunately, your saw was designed with

these requirements in mind. A thorough cleaning can be performed relatively easily.

To clean your bandsaw:

1. Turn the power off and unplug the saw.

2. Remove the table, fence, upper wheel

guard with blade guard, and column

guard. Wash them thoroughly.

3. Pull the V-Belt off the pulleys (Section

VII.D.) and clean it. Use soap and

water only.

4. Unscrew the threaded studs that anchor

the saw to the stand and remove the saw.

The motor is not sealed. Do not allow

water to contact it. Take the saw to a

place where you can thoroughly hose off

any meat remnants and do so.

5. Thoroughly wash the saw with antibacterial soap or bleach. Do not forget to clean

the blade. Soap is cheap, lather it up.

6. Rinse the saw off with the hose and dry it.

Some parts, such as the blade, will rust if

not dried completely. Wiping the blade

with vegetable oil will help to retard rust.

Hunter’s Meat Cutting Bandsaw - 19 -

7. Remove the enclosures from the sides of

the stand. Clean out any spots that have

been contacted by meat. Pay particular

attention to the motor pulley. Be careful

not to let water get down into the motor.

8. Re-assemble the bandsaw in the oppo-

site order it was taken apart.

Do not neglect to clean your saw immediately

after use. By cleaning it immediately, you will

avoid bacteria, rust, stinky, rotten meat

chunks, and a host of other problems.

To clean the meat grinder:

Remove the meat grinder from the saw by

loosening the mounting bolt and pulling the

grinder off. Completely disassemble the

grinder and clean it with antibacterial soap

and water or bleach and water. When reassembling, be sure to orient the blade correctly. The grinder will not grind effectively if

the grinder blade is fitted backward. When the

meat exits the auger, it should contact the flat,

sharp side of the grinder blade – not the

round, blunt side. Figure 16.

XI. Cleaning

Figure 16 shows the meat grinder disassembled for

cleaning.

Auger

Blade

Die

Casing

Tube

Lock

Mounting Bolt

Meat Pusher

Grinder Body

End of Section

Page 23

- 20 - Hunters Meat Cutting

Bandsaw

Since the moving parts on this machine run

on shielded ball bearings, you will find that

there is very little in the line of routine maintenance outside of cleaning (See Section XI).

However, “little maintenance” does not imply

“no maintenance." This section will cover a

few simple but crucial steps for the proper

maintenance of your bandsaw.

A. Lubrication

Shielded and pre-lubricated ball bearings

require no extra lubrication for the life of the

bearings. All bearings are standard sizes. If

they wear out, replacements can be easily

purchased from our parts department or bearing supply stores.

As for other items on this machine, such as

adjustment controls, an occasional “shot” of

light oil is just about all that is necessary.

Before applying, however, wipe off any debris

with a clean cloth or towel and spray on the

lubricant. Ensure that oil does not get on the

pulleys or V-Belts because it could cause belt

deterioration and slipping. Wipe off any spray

that gets on the blade, meat grinder, or any

stainless steel cutting surfaces.

XII. Maintenance

B. Miscellaneous

Always be aware of the condition of your

bandsaw before using it. Routinely check the

condition of the following items and repair or

replace as necessary.

1. Loose mounting bolts.

2. Worn switch.

3. Worn or damaged blade.

4. Worn or damaged support bearings or

guide blocks.

5. Worn or damaged V-Belt.

6. Any other condition that may affect safe

operation of this machine.

End of Section

Page 24

Hunter’s Meat Cutting Bandsaw - 21 -

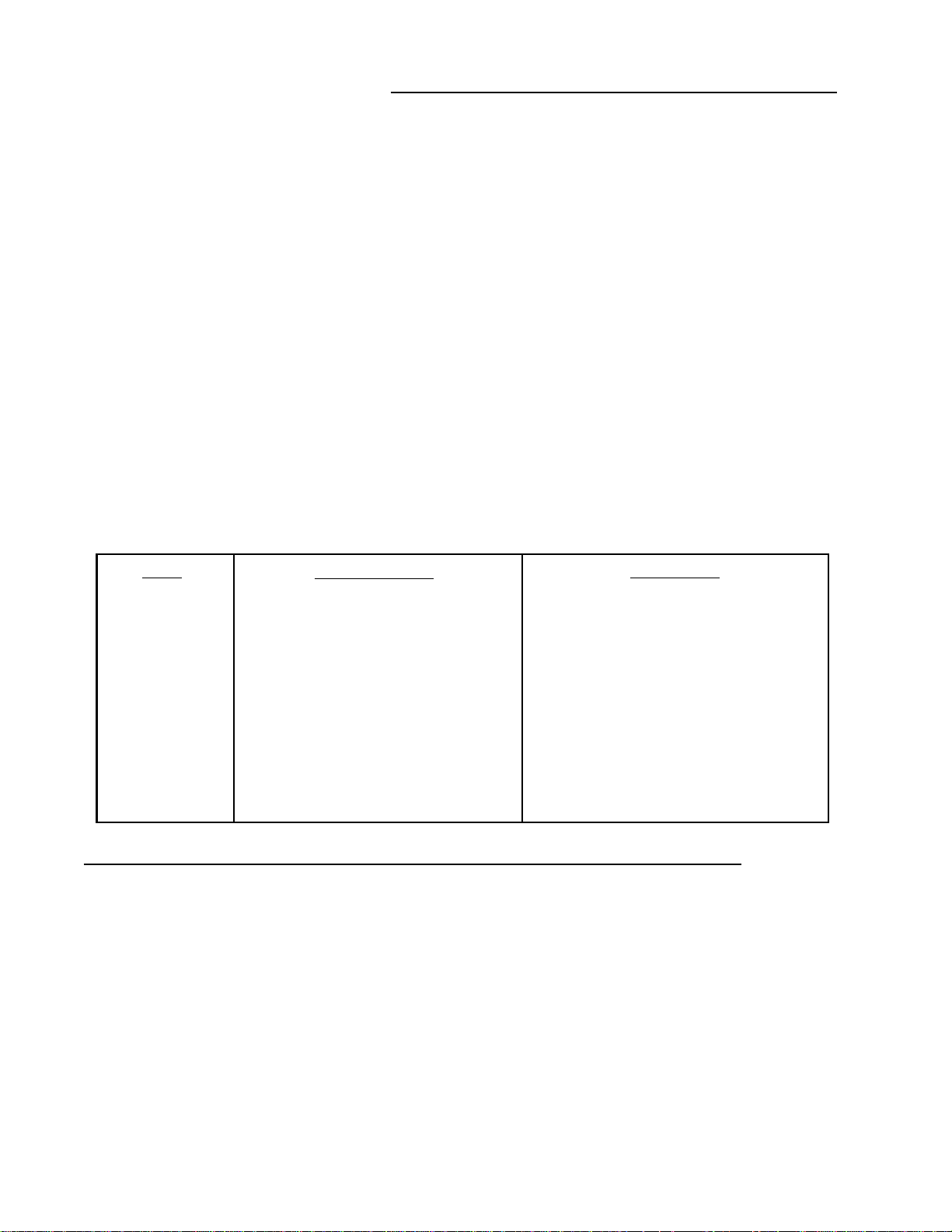

XIII. Troubleshooting

SYMPTOM

Motor will not start.

Motor will not start; fuses or

circuit breakers blow.

Motor fails to develop full

power (power output of

motor decreases rapidly

with decrease in voltage at

motor terminals).

Motor overheats.

Motor stalls (resulting in

blown fuses or tripped circuit).

Machine slows when using.

Blade does not run evenly

on wheels or runs off.

Blade slows when cutting.

Blade makes a squealing

noise, especially on start up.

CORRECTIVE ACTION

1. Check power line for proper voltage.

2. Inspect all lead connections on motor for loose or open

connections.

3. Check voltage at motor junction box.

4. Replace capacitor.

5. Contact customer service for further instructions.

1. Inspect cord or plug for damaged insulation and shorted

wires.

2. Inspect all connections on motor for loose or shorted terminals or worn insulation.

3. Install correct fuses or circuit breakers.

1. Reduce load on power line.

2. Increase wire sizes or reduce length of wire.

3. Request a power check from the power company.

1. Reduce load on motor.

2. Clean out motor to provide normal air circulation.

1. Inspect connections on motor for loose or shorted terminals or worn insulation.

2 Correct the low voltage conditions.

3. Install correct fuses or circuit breakers.

4. Reduce load on motor.

Feed slower.

Adjust tracking.

1. Tighten V-Belt.

2. Replace V-Belt.

POSSIBLE CAUSE

1. Low voltage.

2. Open circuit in motor or loose

connections.

3. Worn or defective switch.

4. Faulty starting capacitor.

5. Centrifugal switch out of adjustment.

1. Short circuit in line cord or plug.

2. Short circuit in motor or loose

connections.

3. Incorrect fuses or circuit breakers in power line.

1. Power line overloaded with

lights, appliances, and other

motors.

2. Undersized wires or circuits too

long.

3. General overloading of power

company facilities.

1. Motor overloaded.

2. Air circulation through the motor

restricted.

1. Short circuit in motor or loose

connections.

2. Low voltage.

3. Incorrect fuses or circuit breakers in power line.

4. Motor overloaded.

Applying too much pressure.

Tracking is not adjusted properly.

1. V-Belt loose.

2. V-Belt worn out.

Page 25

- 22 - Hunter’s Meat Cutting Bandsaw

XIV. Main Parts Diagram

38

72

39

43

44

71

39

79

42

57

40

35

36

57

79

53

70

64-1

60

63

53

64

49

51

55

59

65

66

60

61

63

62

2

3

50

3

52

3

13

75

11

12

77

48

78

73

58

1

4

57

56

24

21

81

46

3

11

57

17

3

13

8

8

18

5

12

68

19

19

6

13

3

3

25

26

6

46

23

3

80

46

A

Page 26

Hunter’s Meat Cutting Bandsaw - 23 -

XV. Meat Grinder Parts Diagram

34

74

33

76

22

20

32

14

A

29

21

33A

3

31

28

30

33B

OPTIONAL

Page 27

- 24 - Hunter’s Meat Cutting Bandsaw

XVI. Stand Parts Diagram

101

104

118

117

113

125

118

114

112

117

117

118

118

115

109

117

117

122

121

120

105

110

116

132

116

104

107

108

118

117

117

118

102

116

106

118

128

117

127

126

116

118

117

116

119

116

111

103

130

116

129

118

131

117

124

123

125

Page 28

Hunter’s Meat Cutting Bandsaw - 25 -

061 P1016061 BEARING GUIDE SHAFT

062 P6000 BEARING 6000-2RS

063 PR01M SNAP RING 10mm

064 P1016064 GUIDE BLOCK

64-1 P1016064-1 GUIDE BLOCK

065 PSS01M SETSCREW M6 - 1.0 x 10

066 P1016066 BLADE GUIDE COVER

068 P1016068 LOWER SHAFT MOUNT

070 P1016070 BLADE GUARD

071 PR21M SNAP RING 35mm

072 P1016072 FENCE

073 PN06 HEX NUT

1

/2" - 12

074 P1016074 CASING TUBE

075 P1016075 NAME PLATE

076 P1016076 PESTLE

077 PSS05M SETSCREW M5 - 0.8 x 10

078 PLW07 LOCK WASHER

1

/2"

079 PW02 FLAT WASHER

3

/8"

080 PLW01 LOCK WASHER

5

/16"

081 P1016081 DOOR LATCH ASSEMBLY

101 P1016101 TOP PANEL

102 P1016102 REAR PANEL

103 P1016103 FRONT PANEL

104 P1016104 BRACE

105 P1016105 MOTOR MOUNT PLATE

106 P1016106 AUXILIARY MOTOR BRACKET

107 P1016107 MOTOR 1HP

108 P1016108 CORD, MOTOR TO SWITCH

109 PSS02M SETSCREW M6 - 1.0 x 6

110 P1016110 STRAIN RELIEF

111 P1016111 POWER CORD

112 P1016112 SWITCH

113 PS03 PHLP HD SCREW 10 - 24 x 1"

114 PS06 PHLP HD SCREW 10 - 24 x

3

/8"

115 P1016115 MOTOR PULLEY

116 PCB02 CARRIAGE BOLT

5

/16" - 18 x1/2"

117 PW07 FLAT WASHER

5

/16"

118 PN02 HEX NUT

5

/16" - 18

119 PB03 HEX BOLT

5

/

16" - 18 x 1"

120 P1016120 SPECIAL BOLT

121 PB07 HEX BOLT

5

/16" - 18 x3/4"

122 PK23M KEY 5 x 5 x 25mm

123 P1016123 SCREW

125 P1016125 PLASTIC SIDE PANEL

126 P1016126 RUBBER FOOT

127 P1016127 KEEPER

128 P1016128 MOUNT BRACKET

129 P1016129 WIRE CLAMP

130 PN07 HEX NUT 10 - 24

131 PS01 PHLP HD SCREW 10 - 24 x

1

/2"

132 P1016132 SWITCH COVER

REF# PART# DESCRIPTION

XVII. Parts List

001 P1016001 CABINET BODY

002 PB09 HEX BOLT

5

/16" - 18 x1/2"

003 PW07 FLAT WASHER

5

/16"

004 P1016004 COVER

005 P1016005 LOWER WHEEL

006 P1016006 BEARING MOUNT

008 PSS04M SETSCREW M6 - 1.0 x 12

011 PB08M HEX BOLT M6 - 1.0 x 20

012 PN01M HEX NUT M6 - 1.0

013 PN02 HEX NUT

5

/16" - 18

014 PN01M HEX NUT M6 - 1.0

017 PVA53 V-BELT A-53

018 P1016018 PULLEY

019 P6204 BEARING 6204-2RS

020 PB08M HEX BOLT M6 - 1.0 x 20

021 P1016021 BRACKET

022 P1016022 GRINDER BODY

023 P6203 BEARING 6203-2RS

024 PR18M SNAP RING 17mm

025 PK01M KEY 5 x 5 x 22mm

026 P1016026 SHAFT

028 P1016028 CARR BOLT

5

/16" - 18 x 1 3/4"

029 P1016029 LOCK KNOB

030 P1016030 AUGER

031 P1016031 BUSHING

032 P1016032 BLADE

033 P1016033 DIE (8mm)

33A P1016033A DIE

33B P1016033B DIE

034 P1016034 LOCK

035 P1016035 TOP WHEEL COVER

036 PW06 FLAT WASHER

1

/4"

038 PR02M SNAP RING 14mm

039 P6202 BEARING 6202-2RS

040 PB08 HEX BOLT

3

/8"- 16 x 5

042 P1016042 UPPER WHEEL SHAFT

043 P1016043 TOP BLADE WHEEL

044 G1098 SEE CATALOG

046 PB07 HEX BOLT

5

/

16" - 18 x

3

/

4"

048 P1016048 GUIDE POST BRACKET

049 PS07 PHLP HD SCRW

1

/4" - 20 x 3/8"

050 P1016048 GUIDE POST BRACKET

051 PW06 FLAT WASHER

1

/4"

052 P608 BEARING 608-2RS

053 PB07 HEX BOLT

5

/16" - 18 x3/4"

055 P1016055 LOWER GUIDE

056 P1016056 TABLE

057 P1016057 KNOB

058 P1016058 LOCK KNOB

059 P1016059 GUIDE POST

060 P1016060 THUMB SCREW

REF# PART# DESCRIPTION

Page 29

- 26 - Hunters Meat Cutting Bandsaw

XVIII. Machine Data

HUNTER’S MEAT CUTTING SAW

Design Type ......................................................................................................2 Wheel Floor Model

Overall Dimensions:

Table ........................................................................................................................16" W x 13

3

/8" D

Stand............................................................................................................23

1

/2" H x 16" W x 18" D

Height ............................................................................................................................................58"

Height from Floor to Table ........................................................................................................34

1

/2"

Width of Unit..................................................................................................................................16"

Shipping Weight ....................................................................................................................106 lbs.

Cutting Capacity:

Left of Blade ................................................................................................................................9

3

/4"

Height ........................................................................................................................................10

1

/4"

Blade Speed ......................................................................................................................1125 FPM

Grinder Speed ......................................................................................................................45 RPM

Construction:

Table ..........................................................................................................................Stainless Steel

Wheels ................................................................................................................................Aluminum

Fence ............................................................................................................................Die Stamped

Wheel Covers ........................................................................................................Pre-Formed Steel

Guides....................................................................................Fiber Blocks with Thrust Ball Bearings

Motor:

Type..................................................................................................TEFC Capacitor Start Induction

Horsepower ................................................................................................................................1 HP

Phase/Cycle ........................................................................................................Single Phase/60 Hz

Voltage ......................................................................................................................................110V

Amps ............................................................................................................................................16A

RPM ............................................................................................................................................1720

Bearings ..........................................................................Shielded and Permanently Lubricated Ball

Switch ..................................................................................................................On/Off Mechanical

Features:

Includes Blade, Meat Grinder, and Casing Tube

Specifications, while deemed accurate, are not guaranteed.

Page 30

HHuunntteerr’’ss MMeeaatt CCuuttttiinngg BBaannddssaaww

-- 2277 --

Limited Warranty & Returns Policy

Grizzly Imports, Inc. warrants every product it sells for a period of 1 year to the original purchaser

from the date of purchase. This warranty does not apply to defects due directly or indirectly to misuse, abuse, negligence, accidents, repairs or alterations or lack of maintenance. This is Grizzly’s

sole written warranty and any and all warranties that may be implied by law, including any merchantability or fitness, for any particular purpose, are hereby limited to the duration of this written

warranty. We do not warrant or represent that the merchandise complies with the provisions of any

law or acts unless the manufacturer so warrants. In no event shall Grizzly’s liability under this warranty exceed the purchase price paid for the product and any legal actions brought against Grizzly

shall be tried in the State of Washington, County of Whatcom.

We shall in no event be liable for death, injuries to persons or property or for incidental, contingent,

special, or consequential damages arising from the use of our products.

To take advantage of this warranty, contact us by mail or phone and give us all the details. We will

then issue you a “Return Number” which must be clearly posted on the outside as well as the inside

of the carton. We will not accept any item back without this number. Proof of purchase must accompany the merchandise.

The manufacturers reserve the right to change specifications at any time because they constantly

strive to achieve better quality equipment. We make every effort to ensure that our products meet

high quality and durability standards and we hope you never need to use this warranty.

Loading...

Loading...