Page 1

™

INSTRUCTION MANUAL

Wingspan: 71.5 in [1815 mm]

2

Wing Area: 836 in

Wing Loading: 27−30 oz /ft

[53.9 dm2]

2

[82−92 g/dm2]

Length: 73 in [1855 mm]

WARRANTY

Great Planes Model Manufacturing® Co. guarantees this kit to

be free from defects in both material and workmanship at the

date of purchase. This warranty does not cover any component

parts damaged by use or modification. In no case shall Great

Planes’ liability exceed the original cost of the purchased kit.

Further, Great Planes reserves the right to change or modify this

warranty without notice.

In that Great Planes has no control over the final assembly or

material used for final assembly, no liability shall be assumed nor

accepted for any damage resulting from the use by the user of

the final user-assembled product. By the act of using the

user-assembled product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated

with the use of this product, the buyer is advised to return

Weight: 9.75− 10.75 lb

[4420 −4870 g]

Radio: 4– 6 channel

SPECIFICATIONS

Engine: 1.20 cu in [20cc] 2-stroke glow,

1.55 cu in [25cc] 4-stroke glow,

Rimfire 1.20 Brushless

electric

this kit immediately in new and unused condition to the

place of purchase.

To make a warranty claim send the defective part or item to

Hobby Services at the address below:

Hobby Services

3002 N. Apollo Dr. Suite 1

Champaign IL 61822 USA

Include a letter stating your name, return shipping address, as

much contact information as possible (daytime telephone

number, fax number, e-mail address), a detailed description of

the problem and a photocopy of the purchase receipt. Upon

receipt of the package the problem will be evaluated as quickly

as possible.

READ THROUGH THIS MANUAL BEFORE STARTING CONSTRUCTION. IT CONTAINS IMPORTANT

INSTRUCTIONS AND WARNINGS CONCERNING THE ASSEMBLY AND USE OF THIS MODEL.

© 2014 Great Planes Model Mfg. A subsidiary of Hobbico, Inc.

Champaign, Illinois

(217) 398-8970, Ext 5

airsupport@greatplanes.com

GPMA1232

Page 2

TABLE OF CONTENTS

INTRODUCTION

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . 3

ADDITIONAL ITEMS REQUIRED. . . . . . . . . . . . . . . . . . . 3

Engine Recommendations. . . . . . . . . . . . . . . . . . . . . . 3

Brushless Electric Motor . . . . . . . . . . . . . . . . . . . . . . . 3

Radio Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ADHESIVES, HARDWARE & OTHER ACCESSORIES. . 4

KIT INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ORDERING REPLACEMENT PARTS . . . . . . . . . . . . . . . 5

KIT CONTENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ASSEMBLE THE WINGS . . . . . . . . . . . . . . . . . . . . . . . . . 6

ASSEMBLE THE FUSELAGE . . . . . . . . . . . . . . . . . . . . .8

Mount the Landing Gear . . . . . . . . . . . . . . . . . . . . . . . 8

Prepare the Fuselage for Mounting

the Engine (or Electric Motor) . . . . . . . . . . . . . . . . . . . 9

Mount a Glow Engine. . . . . . . . . . . . . . . . . . . . . . . . . 10

Hook Up the Throttle . . . . . . . . . . . . . . . . . . . . . . . . . 11

Install the Fuel Tank. . . . . . . . . . . . . . . . . . . . . . . . . . 11

Mount an Electric Motor . . . . . . . . . . . . . . . . . . . . . . . 12

Cut the Cowl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Mount the Cowl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Mounting the Cowl with Wood Screws . . . . . . . . . . . 21

Finish the Cowl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Hook Up the Rudder and Elevators . . . . . . . . . . . . . . 22

FINAL ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Set the C.G. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Balance the Model Laterally . . . . . . . . . . . . . . . . . . . 25

Set the Control Throws . . . . . . . . . . . . . . . . . . . . . . . 25

PREFLIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Identify Your Model . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Ground Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Range Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

ENGINE /MOTOR SAFETY PRECAUTIONS . . . . . . . . . 26

AMA SAFETY CODE (excerpts) . . . . . . . . . . . . . . . . . . . 27

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Radio Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

CHECK LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

FLYING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

OPTIONAL WOOD/FRP EP MOTOR MOUNT BOX . . . 28

ENGINE CUTOUT TEMPLATE FOR O.S. 1.55FS-a . . . 31

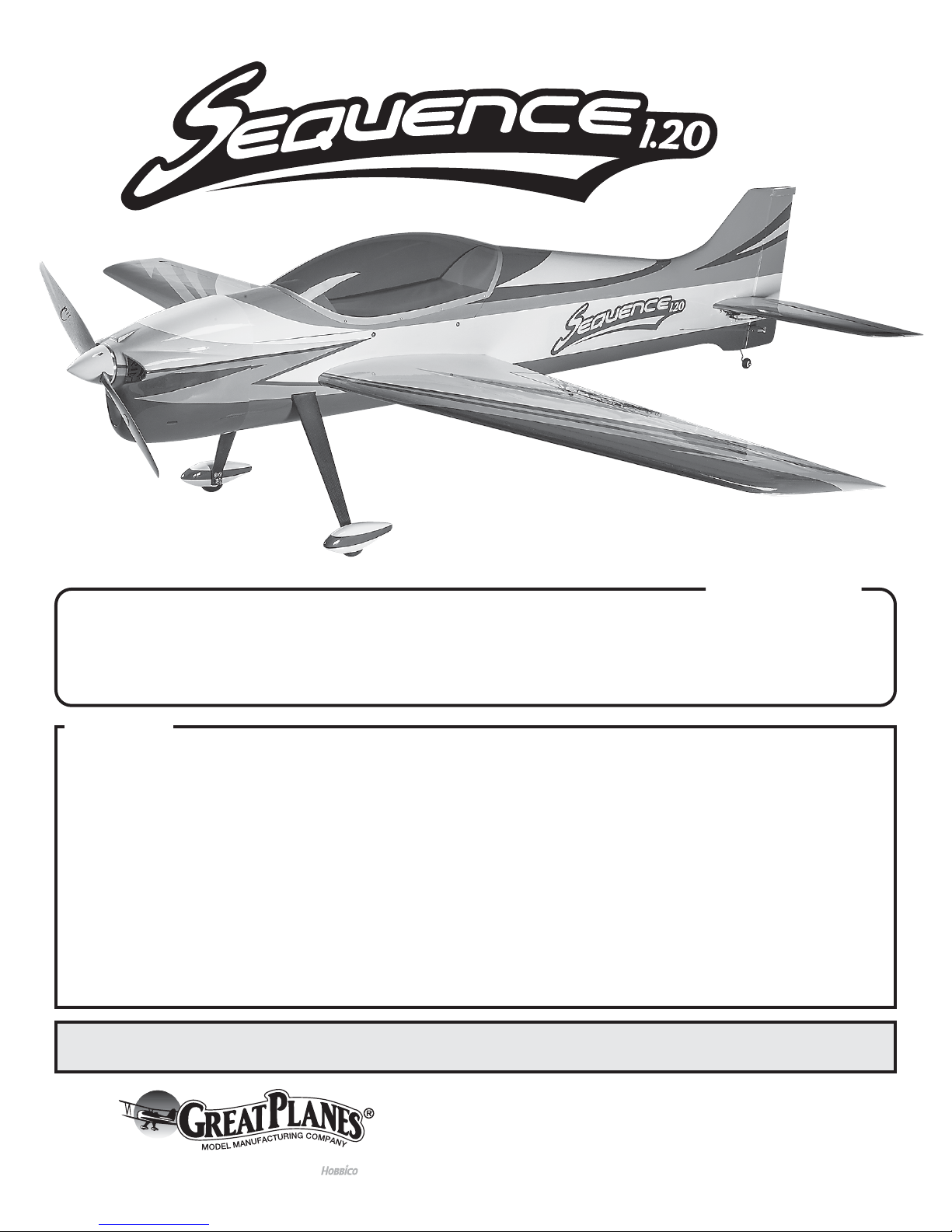

Congratulations and thank you for purchasing the Great Planes

Sequence 1.20 ARF! The Sequence may not have all of the

frills of your exclusive, composite pattern plane, but it’s still

a contender at a fraction of the price. And the Sequence’s

simplicity makes it the perfect entry for beginner/intermediate

pattern pilots or a great practice/backup ship for experienced

pilots. And while we’re at it, the Sequence is a great all-around

sport plane too!

NOTE: An optional wood motor mount for brushless electric

motors is available separately (GPMA4382). This mount allows

outrunners to be “front mounted” and has provisions for geared

inrunners. Full instructions for assembly and mounting are in

the back of the manual on page 28.

For the latest technical updates or manual corrections to

the Sequence 1.20 ARF visit the Great Planes web site at

greatplanes.com. Open the “Airplanes” link, then select the

Sequence 1.20 ARF. If there is new technical information or

changes to this model a “tech notice” box will appear in the

upper left corner of the page.

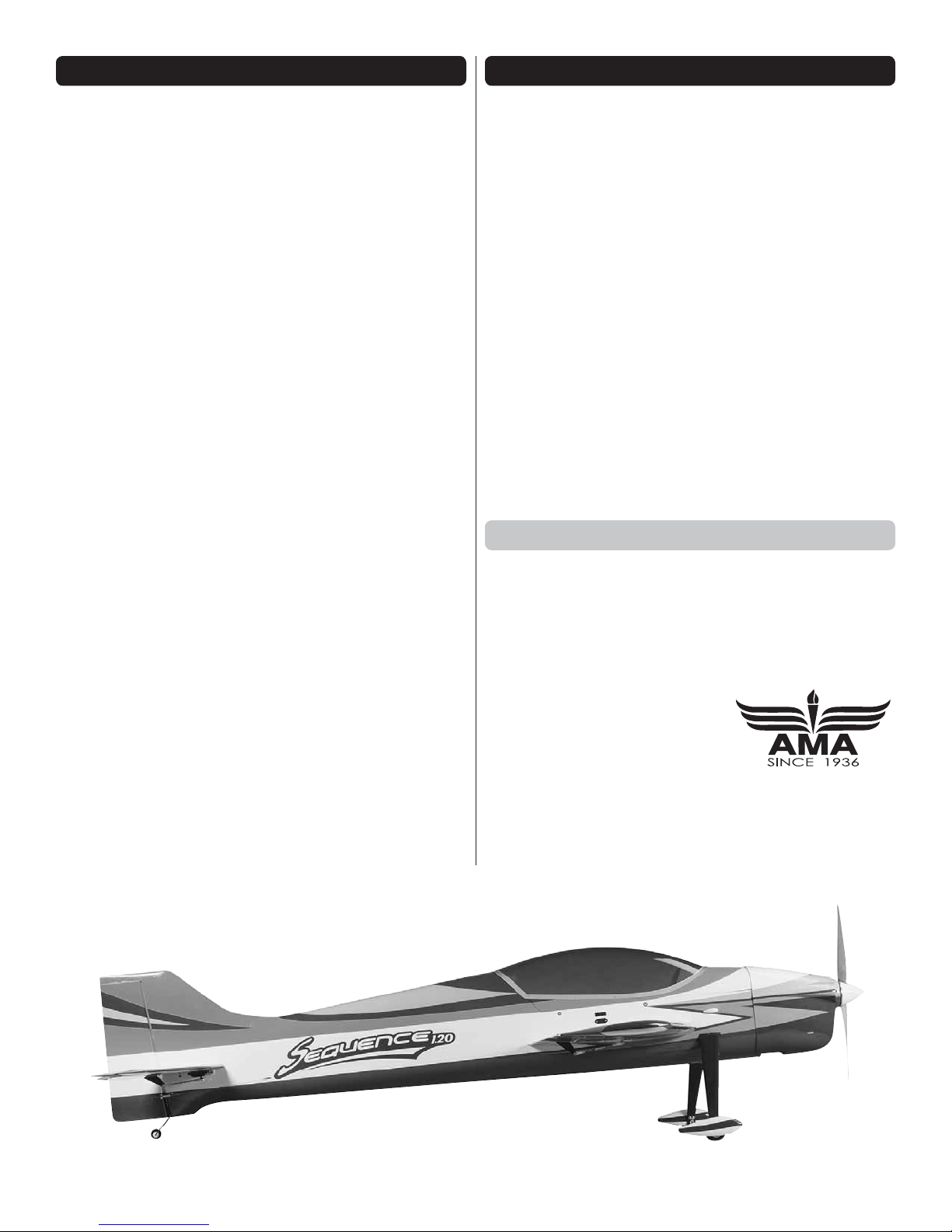

Academy of Model Aeronautics

If you are not already a member of the AMA, please join! The

AMA is the governing body of model aviation and membership

provides liability insurance coverage, protects modelers’ rights

and interests and is required to fl y at most R/C sites.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Tele. (800) 435-9262

Fax (765) 741-0057

modelaircraft.org

IMPORTANT!!! Two of the most important things you can

do to preserve the radio controlled aircraft hobby are to avoid

fl ying near full-scale aircraft and avoid fl ying near or over

groups of people.

2

Page 3

SAFETY PRECAUTIONS

ADDITIONAL ITEMS REQUIRED

Protect Your Model, Yourself & Others…

Follow These Important Safety Precautions

1. Your Sequence 1.20 ARF should not be considered a toy,

but rather a sophisticated, working model that functions very

much like a full-size airplane. Because of its performance

capabilities, the Sequence, if not assembled and operated

correctly, could possibly cause injury to yourself or spectators

and damage to property.

2. You must assemble the model according to the instructions.

Do not alter or modify the model, as doing so may result in an

unsafe or unfl yable model. In a few cases the instructions may

differ slightly from the photos. In those instances the written

instructions should be considered as correct.

3. You must take time to build straight, true and strong.

4. You must use an R/C radio system that is in good condition,

a correctly sized engine, and other components as specifi ed

in this instruction manual. All components must be correctly

installed so that the model operates correctly on the ground

and in the air. You must check the operation of the model and

all components before every fl ight.

5. If you are not an experienced pilot or have not fl own this type

of model before, we recommend that you get the assistance

of an experienced pilot in your R/C club for your fi rst fl ights.

If you’re not a member of a club, your local hobby shop has

information about clubs in your area whose membership

includes experienced pilots.

6. While this kit has been fl ight tested to exceed normal use,

if the plane will be used for extremely high stress fl ying, such

as racing, or if an engine larger than one in the recommended

range is used, the modeler is responsible for taking steps to

reinforce the high stress points and/or substituting hardware

more suitable for the increased stress.

Engine Recommendations

The glow engine sizes are straightforward and as printed

on the cover. You cannot get any simpler than with the O.S.

1.20AX 2-stroke. If a 4-stroke is preferred, the O.S. 1.55FS-a

provides gobs of “grunt” to get you through all the advanced

pattern maneuvers. Both engines may use the standard O.S.

muffl ers that come with them.

Propellers: On the O.S. 1.20AX we preferred the APC 16

x 8 propeller (APCQ1608). With the O.S. 1.55FS-a the APC

17 x 8 (APCQ1710) was preferred.

OTHER ACCESSORIES IF USING A GLOW ENGINE:

❍ 1/4" [6.4mm] R/C foam rubber (HCAQ1000)

❍ 3' [900mm] standard silicone fuel tubing (GPMQ4131)

❍ Great Planes Dead Center Hole Locator (GPMR8130)

❍ 8-32 tap and drill set (GPMR8103)

Brushless Electric Motor

The 50-65-450kV RimFire 1.20 powered by a 5,000mAh 6S

battery and APC 17 x 8E propeller fl ies the Sequence 1.20

nicely. With throttle management the Sequence completes the

Intermediate pattern sequence with a little time to spare. This

combination puts out approximately 1900 watts @ 7,700rpm,

85A (static ground readings of a newly-charged battery). Infl ight, the maximum current draw during full-throttle bursts

will be approximately 72A with an average current draw of

around 40A when using the throttle judiciously. 72A is above

the motor’s 50A constant current limit (but under its 80A surge

limit), so full-throttle may be used only in bursts. Always use

a Watt meter to verify the current your setup is drawing. (See

more about motor setup on page 25.)

7. WARNING: The cowl, landing gear and wheel pants included

in this kit are made of fi berglass, the fi bers of which may cause

eye, skin and respiratory tract irritation. Never blow into a

part (wheel pant, cowl) to remove fi berglass dust, as the dust

will blow back into your eyes. Always wear safety goggles, a

particle mask and rubber gloves when grinding, drilling and

sanding fi berglass parts. Vacuum the parts and the work area

thoroughly after working with fi berglass parts.

We, as the kit manufacturer, provide you with a top quality,

thoroughly tested kit and instructions, but ultimately the

quality and fl yability of your fi nished model depends

on how you build it; therefore, we cannot in any way

guarantee the performance of your completed model,

and no representations are expressed or implied as to the

performance or safety of your completed model.

Remember: Take your time and follow the instructions to

end up with a well-built model that is straight and true.

FOLLOWING ARE THE ITEMS REQUIRED TO

OUTFIT YOUR SEQUENCE WITH THE RIMFIRE 1.20:

❍ ElectriFly RimFire 1.20 brushless motor (GPMG4770)

❍ Great Planes brushless motor mount for large motors

(GPMG1260) OR optional wood motor mount box

(GPMA4282 illustrated on page 28)

❍ Great Planes Silver Series 80A Brushless ESC

(GPMM1860)

❍ FlightPower Pro 50 6S (22.2V) 5000mAh 50C LiPo

(FPWP5103) OR FlightPower EON-X 30 6S (22.2V)

5000mAh 30C LiPo (FPWP6702) OR (2) FlightPower

EON-X 30 3S (11.7V) 5000mAh 30C LiPo (FPWP6698)

and ElectriFly series adapter (GPMM3143)

NOTE: See LiPo Battery Charger Requirements on page

4 to help you decide on a battery.

❍ Great Planes 6mm male/4mm female bullet adapters

(GPMM3119) OR Great Planes 4mm female bullet

connectors (GPMM3115) and 3/16" [5mm] heat shrink

tubing (GPMM1056)

3

Page 4

❍ Great Planes adhesive-back Velcro (GPMQ4480)

11/16"

[18mm]

❍ Electrifl y Powermatch Power Meter Balancer (GPMM3220)

IMPORTANT:

adapter plugs, refer to the Battery Precautions on page 12.

OPTIONAL:

If using the GPMG1260 brushless motor mount for large

motors, it is suggested to replace the Phillips screws and

thin washers that come with the mount with socket-head cap

screws and regular washers (see page 13):

❍ 3 x 8mm socket-head cap screws (DTXC8640)

❍ 3mm fl at washers (DUBQ3307)

A 2.0mm precision-machined hex driver (DTXR0289) is also

suggested for securely tightening the set screws in the collar

on the shaft of the RimFire 1.20

The preferred propeller for the RimFire 1.20 on 6S is either

the APC 17 x 8E (APCQ4018) or the Xoar 17 x 8 Electric

Series propeller (XOAQ4073).

Note: The battery wires from the ESC will have to be extended

to reach the battery. See page 14 for more details. Following

are the items that will be required:

❍ 2’ Deans 12 gauge silicone wire (WSDC1000)

❍ Deans Ultra Plug™ set (WSDM3001)

❍ Electrical solder, soldering fl ux, soldering iron

LIPO BATTERY CHARGER REQUIREMENTS

A LiPo-compatible battery charger with cell balancing is required.

When shopping for a charger (if you don’t already have one)

select a charger (and DC power supply if required) capable

of enough power (Watts) to charge your batteries within an

acceptable time—usually one hour. Once you calculate the Watts

required add in a factor of 20% for loss from normal ineffi ciency:

To fi nd out how many Watts are required to charge a 6S,

5,000mAh battery, fi rst multiply the number of cells (6) times

the Voltage of a fully-charged LiPo cell (4.2V):

Then multiply the Voltage of the fully-charged pack by the

pack’s capacity in Amps:

Finally, increase the Watts needed from a charger by a factor

of 20%:

126 Watts x .2 = 25W + 126W = approximately 150 Watts.

You will need a charger capable of approximately 150 Watts

to charge a 6S 5000mAh battery in about one hour.

If you use two 5000mAh 3S batteries connected in series

with a series adapter you will need a charger capable of

approximately 75 Watts (3 x 4.2 x 5 = 63 + (63 x .2) = 75W).

But then you will have to charge each battery separately

(unless you purchase a charger with multiple charging ports).

If your charger is not capable of the Watts required you should still

be able to charge the battery, except it will take more than one hour.

Before connecting multiple battery packs with

6 x 4.2V = 25.2V

25.2V x 5A = 126 Watts

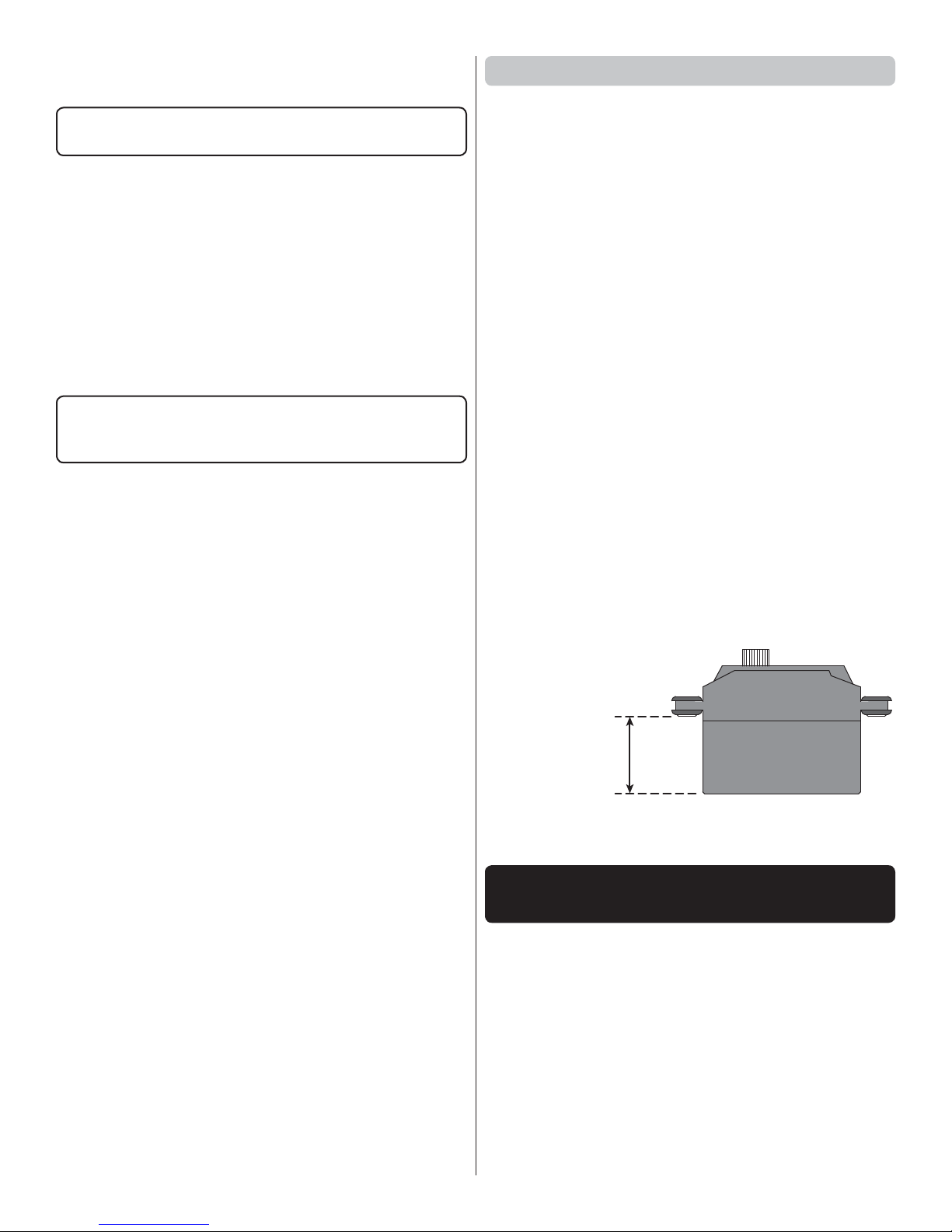

Radio Equipment

The Sequence can be fl own with as few as four channels, but

the ailerons will have to be connected to the same channel

in the receiver via a dual servo connector (FUTM4130 for

Futaba) and the elevator servos will have to be connected to

the same channel via a servo reverser (FUTM4150). If fl ying

with six channels, the ailerons and elevators can be linked

electronically through the programming in the transmitter to

allow for unlimited mixing/fi ne-tuning options.

Pattern fl yers typically prefer digital servos. Powering the

servos from a 6V receiver battery is also in-line with current

pattern practices, but make certain the servos you chose

are compatible with 6 Volts. Following are the recommended

Futaba servos with the associated servo extensions illustrated

in the manual—if setting up your model differently, different

extensions may be required:

❍ Rudder: S9155 (FUTM0215)

❍ Elevators (2): S9650 (FUTM0260) (2 pcs. 36" [915mm]

servo extension—TACM2726)

❍ Ailerons (2): S9252 (FUTM0222) (4 pcs. 6" [150mm]

servo extension—TACM2701)

❍ Throttle (for glow): S3102 (FUTM0034) (12" [305mm]

servo extension—TACM2711)

❍ HydriMax 1600mAh 6.0V NiMH (HCAM6342) or 2000mAh

6.0V NiMH (HCAM6351) receiver battery

❍ Futaba Switch Harness (FUTM4370)

❍ Great Planes 3"[75mm] double-sided servo arm (for the

rudder servo, GPMM1165)

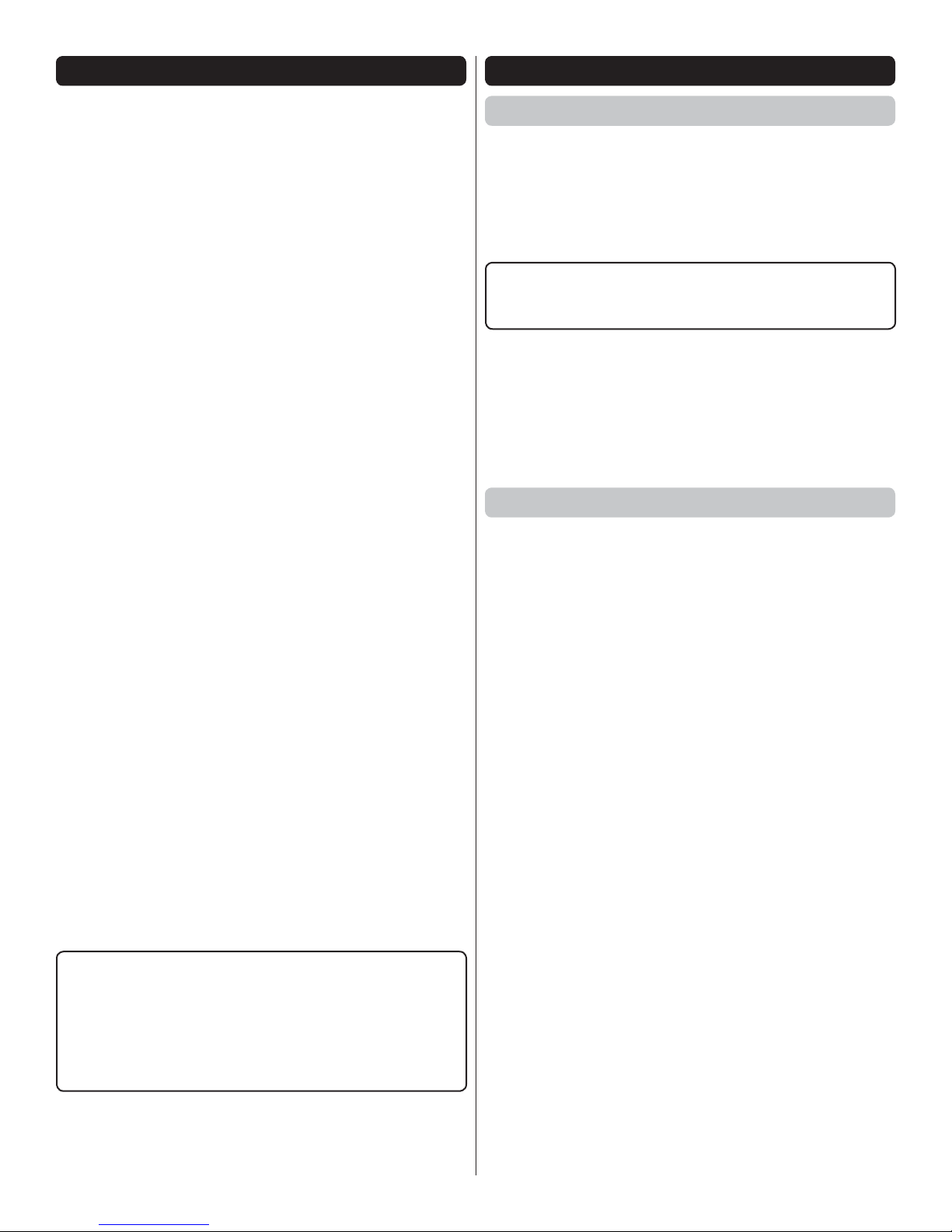

NOTE:

The elevator

servos must

measure no

more than 11/16"

[18mm] from

the bottom up

to the mounting

grommets in order to fi t in the horizontal stabilizers. Taller

servos will require shimming to fi t.

ADHESIVES, HARDWARE AND

OTHER ACCESSORIES

Other than common hobby tools here is a list of the rest of

the items required:

❍ 1/2 oz. [15g] Thin Pro CA (GPMR6001)

❍ 1/2 oz. [15g] Medium Pro CA+ (GPMR6007)

❍ 2 oz. [57g] spray CA activator (GPMR6035)

❍ Threadlocker thread locking cement (GPMR6060)

❍ 2-1/2" spinner (GPMQ4770)

❍ 8mm Propeller Reamer (for O.S. engines or RimFire

1.20 brushless motor) (GPMQ5007)

❍ Drills bits: 1/16" [1.6mm], 3/32" [2.4mm], 1/8" [3.2mm],

7/32" [5.6mm], 7/64" [2.8mm]

4

Page 5

A Robart Super Stand II (ROBP1402) is also indispensable

for working on your Sequence 1.20.

Following are the MonoKote colors used on the Sequence

1.20 should repairs or patches ever be required.

White (TOPQ0204) Sky Blue (TOPQ0206)

Orange (TOPQ0202) Sapphire Blue (TOPQ0226)

Pink (TOPQ0215) Matte Dove Gray (TOPQ0511)

KIT INSPECTION

Before starting to build, take an inventory of this kit to make

sure it is complete, and inspect the parts to make sure they

are of acceptable quality. If any parts are missing or are not

of acceptable quality, or if you need assistance with assembly,

contact Product Support. When reporting defective or missing

parts, use the part names exactly as they are written in the

Kit Contents list.

Great Planes Product Support

3002 N Apollo Drive, Suite 1 Ph: (217) 398-8970, ext. 5

Champaign, IL 61822 Fax: (217) 398-7721

E-mail: airsupport@greatplanes.com

ORDERING REPLACEMENT PARTS

Replacement parts for the Great Planes Sequence 1.20 ARF

are available using the order numbers in the Replacement

Parts List that follows. The fastest, most economical service

can be provided by your hobby dealer or mail-order company.

To locate a hobby dealer, visit the Great Planes web site at

greatplanes.com. Choose “Where to Buy” at the upper right

side of the page. Follow the instructions provided on the page

to locate a U.S., Canadian or International dealer.

Parts may also be ordered directly from Hobby Services by

calling (217) 398-0007, or via facsimile at (217) 398-7721, but

full retail prices and shipping and handling charges will apply.

Illinois and Nevada residents will also be charged sales tax. If

ordering via fax, include a Visa® or MasterCard® number and

expiration date for payment.

Mail parts orders Hobby Services

and payments by 3002 N Apollo Drive, Suite 1

personal check to: Champaign IL 61822

Be certain to specify the order number exactly as listed in the

Replacement Parts List. Payment by credit card or personal

check only; no C.O.D.

If additional assistance is required for any reason contact

Product Support by e-mail at productsupport@greatplanes.

com, or by telephone at (217) 398-8970.

REPLACEMENT PARTS LIST

Order No. Description

GPMA4370

GPMA4371

GPMA4372

GPMA4373

GPMA4374

GPMA4375

GPMA4376

FUSELAGE

WING

STABLIZER

RUDDER

CANOPY/HATCH

COWL

LANDING GEAR

Order No. Description

GPMA4377

GPMA4378

GPMA4379

GPMA4380

GPMA4381

GPMA4382

WHEEL PANTS

WING TUBE

STABILIZER TUBE

DECALS

WING BOLTS (2)

MOTOR MOUNT

BOX PARTS SET

2 2

4

8

5

6

7

12

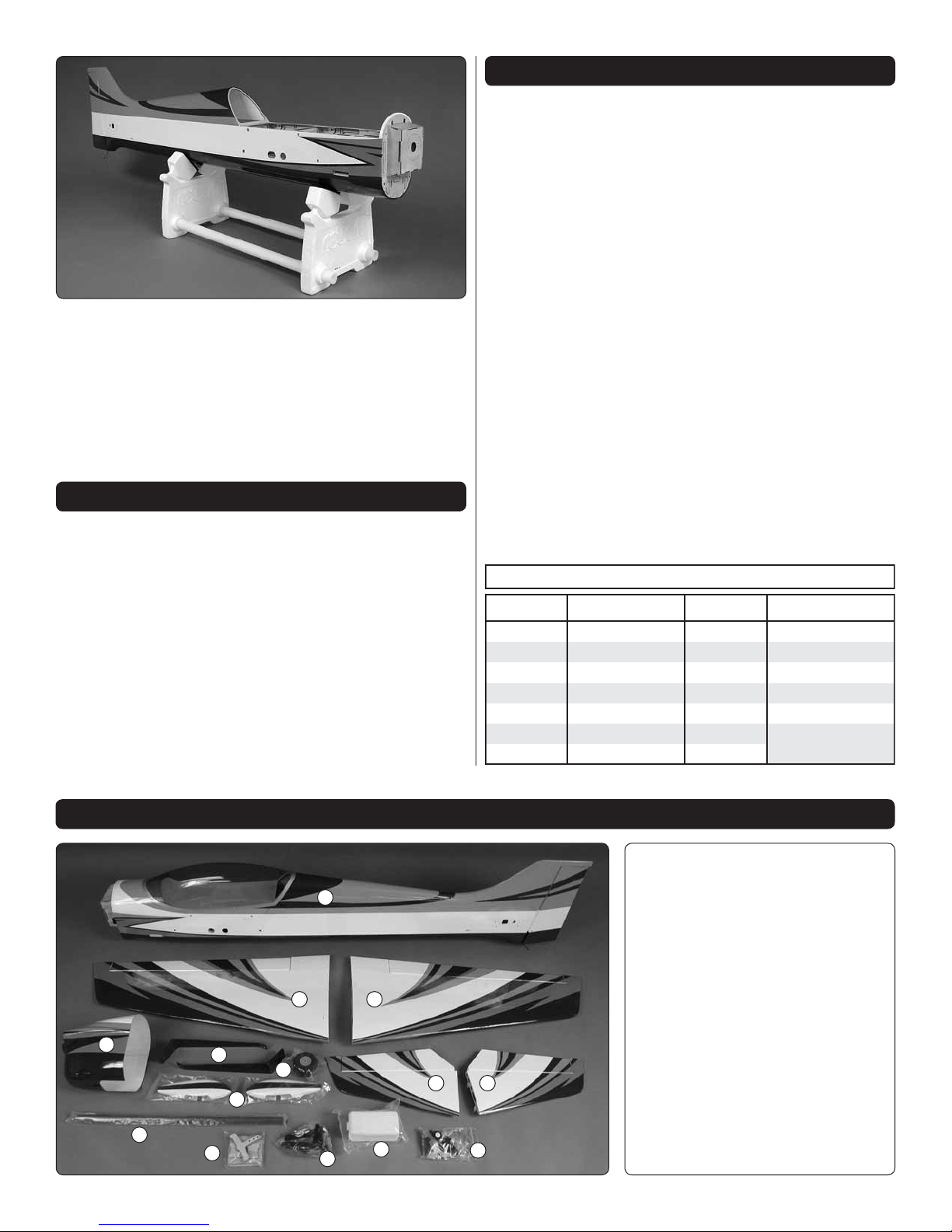

KIT CONTENTS

Kit Contents

1.

1

33

11

10

9

5

Fuselage

2.

Wing Halves

3.

Horizontal Stab Halves

4.

Cowl

5.

Main Landing Gear

6.

Main Wheels

7.

Wheel Pants

8.

Wing Tube

9.

Tailwheel Hardware

10.

Fuel Tank

11.

Glow Engine Mount

12.

ESC Mount Set

Page 6

ASSEMBLE THE WINGS

4. Use thin CA followed by a small fi llet of medium CA to

❏

reinforce the servo mounting blocks to the hatch covers.

1. Pull hard on the ailerons to test the hinges. Inspect the

❏

hinges to be sure enough glue has been used. Add a few

drops of thin CA to any hinges that look dry. Note: CA “fogging”

deposited on the covering can be cleaned with CA debonder.

2. Remove the aileron hatch covers and use naphtha

❏

(lighter fl uid) or commercially-available sticker removal

fl uid to wipe away any glue left from the tape that held on

the hatches.

5.

With the servos plugged in and the radio turned on, use

❏

the plastic servo arm gauge to fi nd the servo arms that will

align with the gauge as shown. (This will allow the servo arms

to be perpendicular to the pushrods.) Cut the other arms off.

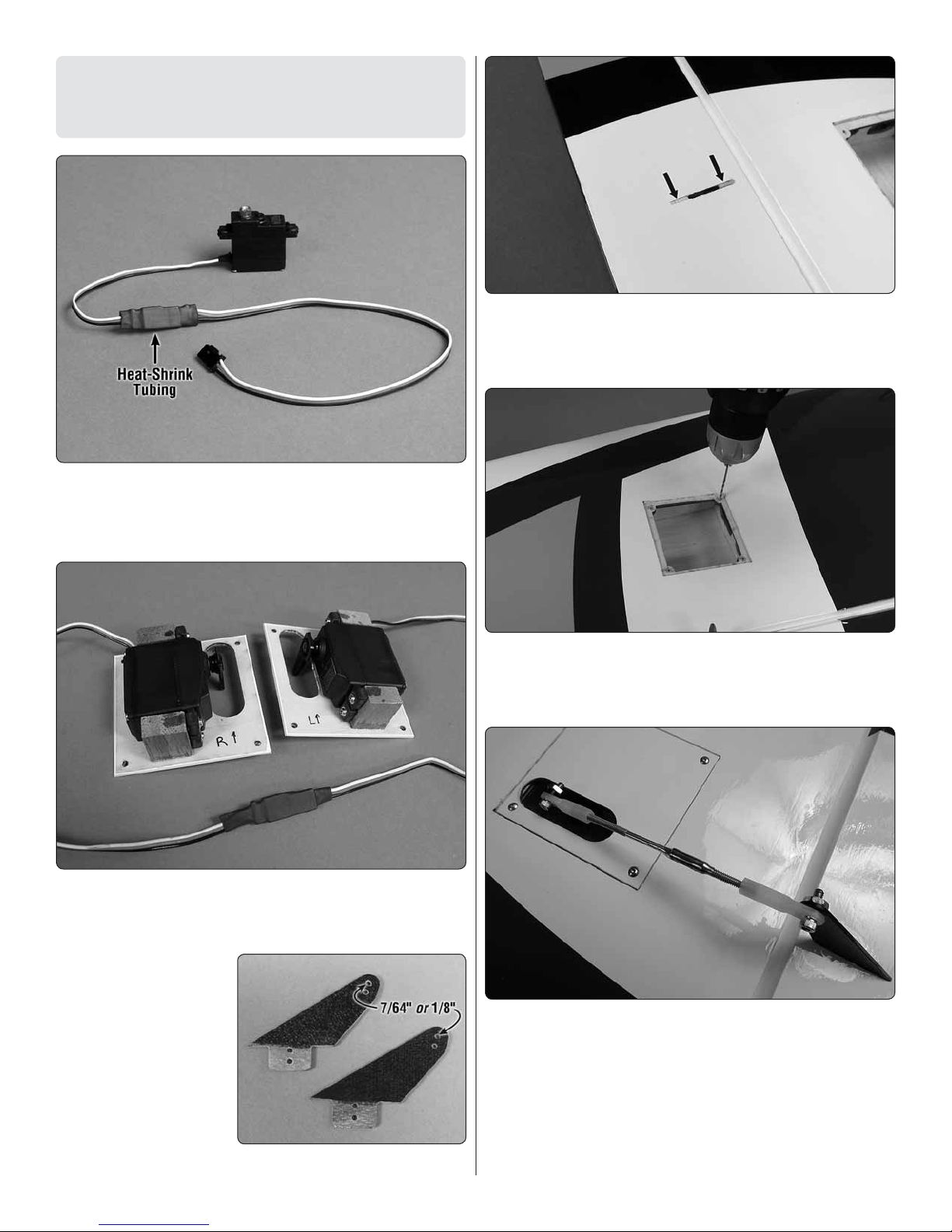

6.

If using the included Great

❏

Planes 4-40 ball links, enlarge the

holes in the servo arms with a 7/64"

or 1/8" [2.8mm or 3.2mm] drill.

7/64" or 1/8"

[2.8mm–3.2mm]

3. Refer to the “How to Tighten Covering on ARF Models”

❏

sheet and remove wrinkles and bond the covering to the

wings. You can go over the whole model now, or just start

with the wings and get to the rest of the model later.

7. Temporarily mount the aileron servos to the mounting

❏

blocks by drilling 1/16" [1.6mm] holes for the screws.

Remove the screws and servos. Use a few drops of thin

CA to harden the screw holes. Allow the CA to harden before

remounting the servos.

6

Page 7

NOTE: Every time wood screws are used throughout

the rest of assembly always perform this procedure of

installing and removing the screws, then hardening the

holes with thin CA.

8. Add a 6" [150mm] servo extension to each aileron

❏

servo. Secure the connections with 1-1/2" [40mm] pieces of

the included heat shrink tubing as shown. Use a heat gun to

shrink the tubing.

11. Cut and remove the covering from around the base

❏

of the horns.

12. Securely glue the horns in to position with CA.

❏

9. Mount the servos to the hatches—be certain the servo

❏

arm screws are in place. If you used metal-gear servos, use

a small drop of threadlocker on the threads.

10.

❏

Same as was done for the

4-40 ball links, enlarge

Roughen the tabs

on two of the included,

fi berglass control horns.

servo arms, if using the

included Great Planes

the holes. Without any

glue, test fi t the horns

into the slots—be certain

the horns fi t all the way

down and make any adjustments for a proper fi t

.

13. Drill out the screw holes in the hatch cover frame with

❏

a 1/16" [1.6mm] drill.

Refer to this photo while hooking up the ailerons:

14. Guide the aileron servo wires out the end of the wing

❏

and mount the hatch covers with four #2 x 3/8" [9.5mm]

button-head screws—do not use a ball-end hex wrench.

Use a quality, machine-ground hex driver. If you don’t have

a good hex driver you could replace the included buttonheat screws with Phillips screws and washers (not included)

instead. Don’t forget to temporarily remove the hatch covers,

harden the screw holes with thin CA and allow to harden

before remounting the hatches.

7

Page 8

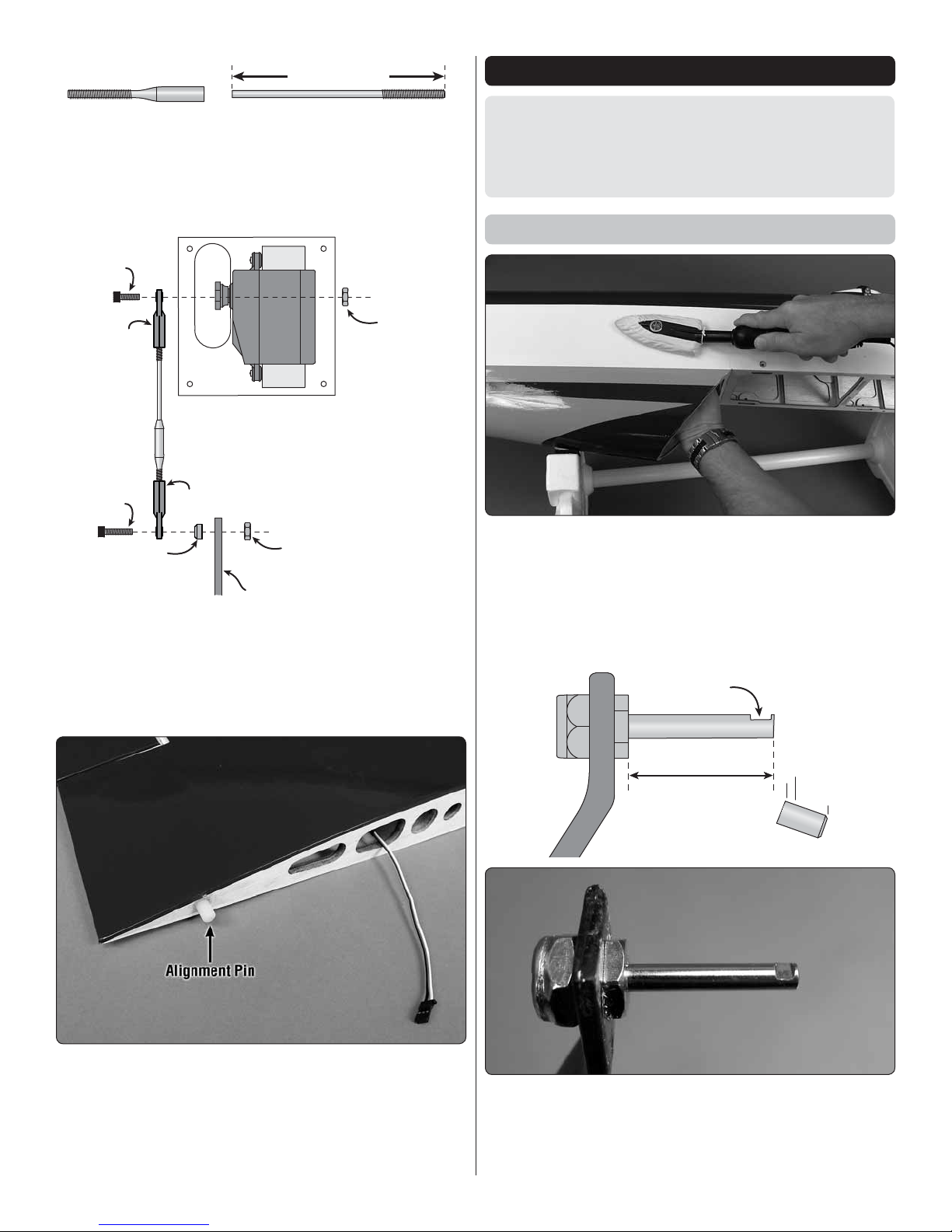

Threaded Coupler

4-40 Pushrod

2-1/4" [57mm]

15. Make the aileron pushrod from a 4-40 x 4-1/2" [115mm]

4-40x 3/8"

SHCS

4-40x 1/2"

SHCS

4-40 Ball Link

Aileron Horn

4-40 Nut

(Use threadlock)

4-40 Nut

(Use threadlock)

4-40 Ball Link

Stand-Off

(optional)

Flat spot

1" [25mm]

❏

pushrod cut to a length of 2-1/4" [57mm]. Clean the pushrod

with denatured alcohol, scuff the end with sandpaper, then

silver solder on a 4-40 threaded coupler.

ASSEMBLE THE FUSELAGE

CAUTION: The turtledeck and fuselage bottom of the

Sequence 1.20 are made from balsa-covered foam.

Some solvents and adhesives will attack the foam, so use

care—especially when using CA which will defi nitely “eat”

into the foam.

Mount the Landing Gear

❏ 16. Connect the aileron horn to the servo arm with the

hardware shown in the illustration—the stand-off on the

aileron horn is optional and not used with the servos shown,

but if your servo spacing is different the standoffs may be

used to keep the pushrod perpendicular to the aileron horn.

Be sure to use threadlocker on the nuts.

1. If you haven’t yet done so, use a covering iron with a

❏

cover sock to go over the fuselage to remove any wrinkles

and bond the covering to the airframe—remember to support

the inside of the sheeting where possible.

2. Test-fi t the main landing gear legs in the fuselage to

❏

distinguish the left from the right and mark them as such.

17. Glue a large alignment pin into the end of each wing.

❏

3. Mount 5/32" [4mm] axles to the main landing gear with

❏

the large lock nuts and threadlocker. Use a rotary tool with a

fi ber-reinforced cutoff wheel to accurately cut the axles to a

length of 1" [25mm], as shown in the illustration. Grind or fi le

a fl at spot on the end of both axles.

8

Page 9

Fiberglass

Wheel Pant

4-40x3/8" [10mm] Phillips

and #4 Flat Washers

5-32" [4mm]

Wheel Collar

#6 Washers

(as spacers) 6-32" Set Screw

4. Mount the wheels and wheel pants as shown—don’t

Vertical Tick Marks

Horizontal

Tick Marks

Angled

Tick Marks

Angled

Tick Marks

❏

forget to use threadlocker on all the screws.

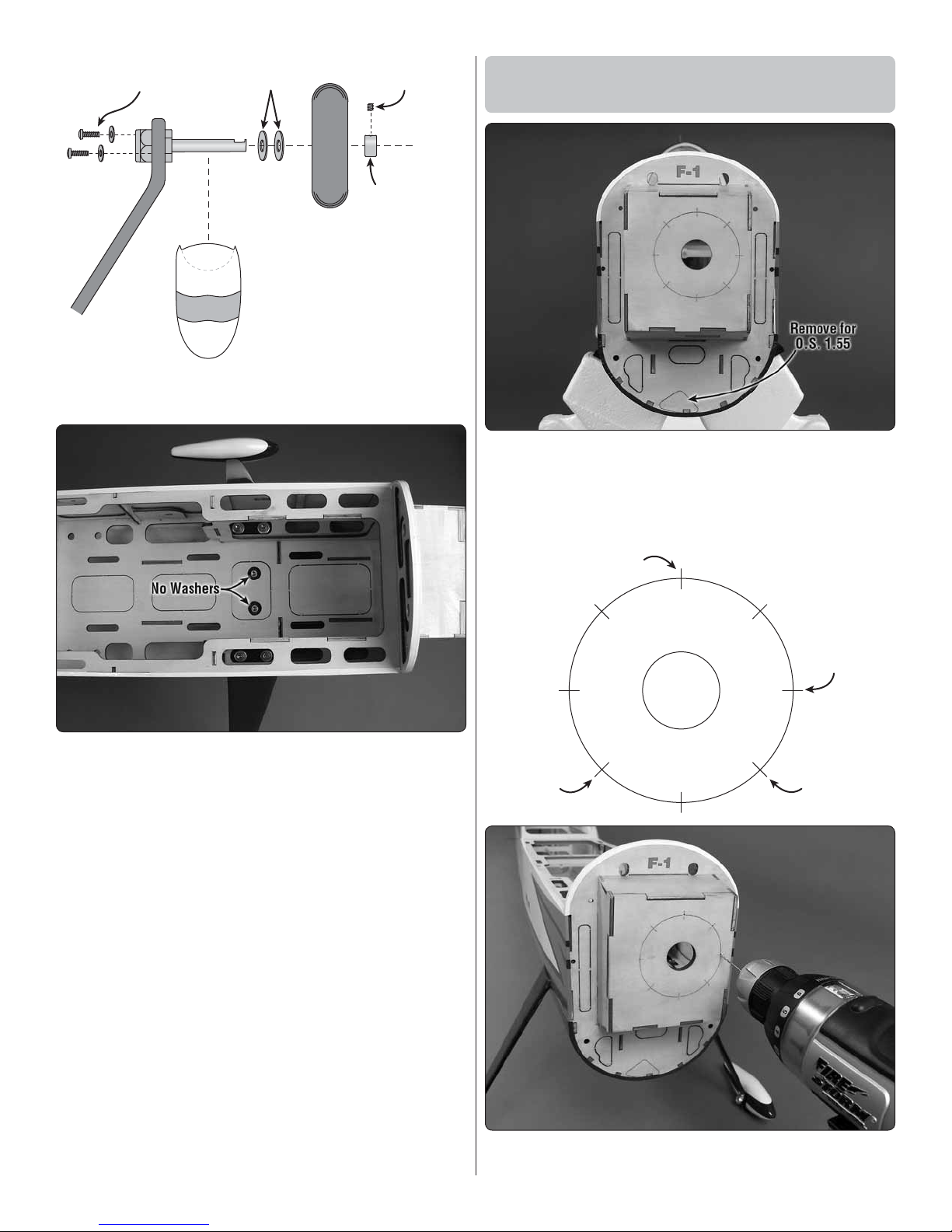

Prepare the Fuselage for Mounting

the Engine (or Electric Motor)

1. If using the O.S. 1.55 FS-a, remove the bottom cutout

❏

for the muffl er. If using a brushless electric motor, remove all

the other cutouts instead. Use epoxy to seal the MonoKote

around F-1, the seams around the cutouts not removed and

the edges of the cutouts you did remove.

5. Mount the main landing gear in the fuselage with

❏

#8 x 1/2" [13mm] SHCS (socket-head cap screws), #8

lock washers and fl at washers—note that the inner screw

on each gear leg uses no washers so the heads will not

protrude too much above the fuel tank/battery plate. As you

have been doing all along, be certain to use threadlocker on

all the screws.

6. Mount the tail wheel with a 3/32" [2.4mm] wheel collar

❏

and a 4-40 set screw and threadlocker.

2. If mounting a glow engine drill 1/16" [1.6mm] pilot

❏

holes through the fi rewall at the four horizontal and vertical

9

Page 10

tick marks. If mounting the Great Planes Brushless Motor

Mount for Large Motors drill the holes through the fi rewall

at the four angled tick marks. If mounting the optional wood

motor mount box, refer to the instructions on page 28 and

assemble/mount the box as illustrated.

3. Enlarge the holes with a 7/32" [5.6mm] drill to

❏

accommodate the 8-32 blind nuts. Draw the blind nuts into

the back of the fi rewall with a #8 SHCS (socket-head cap

screw) and washers.

Mount a Glow Engine

Refer to this photo for the following two steps.

1. Temporarily mount the included engine mount to the

❏

fi rewall with four 8-32 x 1" [25mm] SHCS, #8 lock washers

and fl at washers. Clamp your engine to the mount so the

drive washer will be 6-7/16" [164mm] from the fi rewall.

2. Mark the engine mounting bolt holes with a Great

❏

Planes Dead Center Hole Locator (GPMR8130).

4. If you will be mounting the cowl with the optional cowl

❏

ring, drill 1/8" [3.2mm] holes 3/8" [9.5mm] deep into the

fuselage sides through the two laser-cut holes in F-1. (If

you’re not certain how you will mount the cowl, read ahead

about what’s involved to help you decide.)

If mounting an electric brushless motor skip ahead to

“Mount an Electric Motor” on page 13.

3. Take the mount off the fi rewall and drill #29 (or 9/64"

❏

[3.6mm]) holes at the marks. Tap 8-32 threads into the

holes—a variable speed hand drill makes tapping the

threads fast and easy!

4. Fasten the engine mount back onto the fi rewall and bolt

❏

the engine to the mount with four 8-32 x 1" [25mm] SHCS

and #8 lock washers.

10

Page 11

Hook Up the Throttle

“Hook” side

11" [280mm]

“Loop” side

9" [230mm]

Overlap

5" [130mm]

Velcro Fuel Tank Strap

1. Refer to following photos to see which of the two throttle

❏

servo mounting locations will work best for your engine. Cut

the side or bottom servo mount hole from the location you

will use.

2. Connect a 12" [305mm] servo extension to your throttle

❏

servo and secure the connection with another piece of shrink

tubing.

Install the Fuel Tank

1. Prepare the stopper assembly as shown. Insert the

❏

stopper into the tank and tighten the screw.

3. Mount the throttle servo and hook up the throttle using

❏

the hardware shown in the photo. (It’s not necessary to

mount the muffl er yet, but it’s shown in the photo so you can

see how it fi ts and where to position the exhaust).

2. Make the fuel tank strap from the included Velcro strip

❏

as shown.

3. Install the strap in the fuselage in the location you will

❏

be mounting the tank—it may be necessary to temporarily

punch out one of the lightening holes to install the strap, then

glue the piece back in.

11

Page 12

Mount an Electric Motor

This is a SERIES battery adapter

that connects two batteries in series.

(3-Cell) 3200 mAh

(2-Cell) 3200 mAh

11.1V

7. 4 V

These are two 3200mAh batteries (one 11.1V and the

other 7.4V). When joined in SERIES, the result will be

a 18.5V, 3200 mAh battery.

This is a PARALLEL battery adapter that

connects two batteries in parallel.

(3-Cell) 1500 mAh

(3-Cell) 1500 mAh

11.1V

11.1V

These two 1500mAh batteries (both 11.1V) are being

joined in PARALLEL. The result will be one 11.1V,

3000mAh battery.

Before mounting the motor and setting up the ESC and

battery, read the following important battery precautions:

IMPORTANT: If using multiple battery packs that are connected

with an adapter, never charge the batteries together through

the adapter. Always charge each battery pack separately.

Charge the batteries, then read the following precautions on

how to connect multiple packs for fl ying the model:

Battery Precautions:

There are two ways to connect multiple battery packs: In

Series and in Parallel.

4. Mount the fuel tank with a piece of 1/4" [6.4mm] R/C

❏

foam underneath and securely tighten the strap.

5. Connect the fuel lines (not included) to the engine. A

❏

plastic fuel line plug is included for plugging the fi ll line after

fueling.

Proceed to “CUT THE COWL” on page 16.

1. Connecting batteries in “Series” means to connect the

+’s to the –’s and the –’s to the +’s. This combines the

battery’s Voltages, but the capacity remains the same.

2. Connecting batteries in “Parallel” means to connect

the +’s to the +’s and the -’s to the -’s. This combines the

battery’s capacities, but the Voltage remains the same.

12

Page 13

PARALLEL

adapter

(2-Cell)

(3-Cell)

11.1V

7. 4 V

NEVER connect battery packs with different Voltages in

(3-Cell) 3200mAh

11.1V

(3-Cell) 1250mAh

11.1V

SERIES

adapter

Parallel– only combine in Series. Otherwise, the batteries

will try to “equalize” with the larger one trying to “charge”

the smaller one, thus causing heat and likely a fi re.

from the collar on the end of the RimFire 1.20 motor shaft.

Then, reinstall them with threadlocker and securely retighten.

Refer to this photo while mounting the motor and ESC.

3. Mount the motor to the mount. Adjust the mount and

❏

tighten the bolts so the base of the prop adapter will be 6-3/8"

[162mm] from the fi rewall.

Also NEVER connect battery packs with different capacities

in Series or in Parallel.

1. The Great Planes Large Brushless Motor Mount comes

❏

with Phillips motor mounting screws and thin washers, but

some modelers prefer socket-head cap screws and regular,

thicker washers. If so, substitute the Phillips screws with

3x8mm screws (DTXC8640) and 3mm or #4 washers.

2. Use a 2.0mm hex wrench to remove the set screws

❏

4. If using the Great Planes ElectriFly 80A ESC, install

❏

Great Planes 6mm male/4mm female bullet adapters

(GPMM3119) on the motor wires, or remove the 6mm female

bullet connectors from the ESC and solder on 4mm female

bullet connectors (GPMM3115) instead.

5. If you soldered on 4mm connectors, cover the

❏

connectors with 3/16" [5mm] heat shrink tubing (GPMM1056).

6. Assemble and mount the plywood ESC mount to the

❏

motor mount with four 4-40 x 1/2" [13mm] SHCS, #4 fl at

washers and 4-40 nuts with threadlocker. Mount the motor

mount with the motor to the fi rewall with four 8-32 x 1/2" [13mm]

13

Page 14

SHCS, #8 lock washers and fl at washers and threadlocker.

7. Before mounting the ESC consider the options for

❏

connecting the battery. First, the wires coming from the ESC

are probably not long enough to reach the battery, so an

extension of some sort may have to be made. And if using two

3S LiPo packs connected in series (as illustrated here in the

manual), a Series Deans Ultra 2 to 1 Adapter (GPMM3143)

will also be required. (If using a single 6S battery pack no

adapter will be required.)

The easiest way to get the ESC wires to reach the battery is to

make a plug-in extension with a Deans connector on both ends.

How to Make an Externally-Accessible Arming Plug:

A.

First, you’ll need a

❏

short metal tab to bridge the

tabs across a Deans male

Ultra Plug. A tab extracted

from another male or female

plug works perfectly for this.

B. Cut the tab to length and make a 90° bend on one

❏

end. Solder the tab across the tabs on the plug. Hint: Plug

the arming plug into a female plug to serve as a heat sink

and to make it easier to hold in a vice for soldering.

C. Trim the edges around

❏

the Deans plug as shown.

Glue together the plastic

pieces of the frame for the

plug and test-fi t the plug

into the frame. Make any

adjustments necessary and

glue the assembly together

with CA.

Or, additional wire could simply be soldered directly onto the

ESC.

Finally, an external motor arming plug could be incorporated

with the necessary wiring and receptacle plug soldered to

the ESC. With an arming plug you’ll never have to handle the

airplane while the motor is armed—you can simply install

and connect the battery, mount the canopy hatch, then insert

the arming plug right before you fl y!

D. Apply auto body fi ller to the frame and allow to

❏

partially harden. While the fi ller is still “rubbery” use a

hobby knife to roughly carve it to a teardrop shape.

E. After the body fi ller

❏

has hardened use coarse

sandpaper to sand to the

fi nal profi le.

F.

Use a small rod or

❏

dowel wrapped with mediumgrit sandpaper to cut the

depressions into the sides of

the plug so you can grip it.

G. Prime, sand, then

❏

paint—just about any kind

of paint will work, but we

used enamel spray paint.

14

Page 15

8. Once you’ve made the arming plug, decide which of

❏

the three precut locations in the fuselage side you will use

for mounting a Deans female Ultra Plug to serve as the

receptacle. Solder the plug in-line between one of battery

leads. Solder on any additional wire so the battery and ESC

will reach.

9. Mount the ESC to the ESC mount with three #4 x 1/2"

❏

Phillips screws and #4 fl at washers. After mounting the ESC,

temporarily remove the screws, harden the holes with a few

drops of thin CA, allow to harden, then remount the ESC.

10. If using the arming plug, carefully cut the covering

❏

from the side of the fuselage over the location you will use for

the receptacle. Securely glue the receptacle plug into place

with the plywood doubler.

11. Make battery straps from the included Velcro strips

❏

and guide them in and out of the slots in the battery fl oor

(the rear strap can be reached with your fi ngers under the

rear of the fl oor, but the front strap will require a piece of

wire to pull it up through). Apply strips of the rougher, “hook”

side of Great Planes adhesive Velcro to the battery fl oor and

apply strips of the softer, “loop” side to the batteries. Then

test mount the battery into position just to see how it all fi ts.

15

Page 16

Cut the Cowl

If going electric the cowl probably doesn’t need to be cut—just

skip ahead to “Mount the Cowl” on page 18. But if using a glow

engine the cowl must be cut to fi t over the head and cylinder. If

using an O.S. 1.55FS-a you’re in luck because we’ve provided

a template that can be used as a guide. If installing a different

engine you’ll have to fi gure out where to make the cut yourself.

Some modelers dread this process, but you can make it easier

and achieve great results by proceeding slowly and using

the proper tools. The best way is to cut in small increments,

fi tting and marking the cowl as you go. When you zero-in on

the fi nal shape of the cutout you can position the cowl more

accurately until you can make the fi nal cuts.

template aligns with the bottom of the cowl “cheek” and the

back of the template aligns with the back of the cowl. Use a

fi ne-point felt-tip pen to mark the cutout directly onto the cowl.

With or without a template, the most important thing is to have

the proper tools. It cannot be over emphasized how helpful a

Dremel carbide grout removal bit and a Dremel sanding drum

are for cutting a fi berglass cowl—these can be found at most

hardware and home-improvement stores. Initial cuts go easy,

fast and accurate with the carbide bit. Then, the rough edges

can be smoothed and rounded with the sanding drum. The 1/16"

carbide cutter and 1/4" sanding drum are absolutely a MUST,

but the 1/8" cutter and 1/2" sanding drum come in handy too:

1. The cowl will be easier to start fi tting if you can remove

❏

the head from your 2-stroke engine or remove the valve

cover from your 4-stroke engine. Also leave the muffl er off

the engine for now.

3. If not using the template you will have to determine

❏

where to mark and cut the cowl yourself. Position the cowl as

far over the engine as it will go. Use a lead pencil to mark the

inside of the cowl where it needs to be cut to clear whatever

part of the engine is in the way.

It’s time for cutting. Work in a well-ventilated area and

always wear protective gear including goggles or glasses,

hearing protection and an appropriate breathing fi lteration.

Also do your self a favor and wear a long sleeve shirt to

protect your arms from itchy fi bers that get into the air.

4. Use one of the grout removal bits to start cutting the cowl.

❏

If you’ve marked the cut with the template, cut approximately

1/8" [3mm] inside the lines. If you didn’t use the template, cut

where you made your fi rst marks. Note: The grout removal

bits work best and cut most accurately with the speed of your

rotary tool turned all the way up to full rpm.

2.

If using the O.S. 1.55FS-a, cut the template from the

❏

back of the manual and tape it into the cowl. The top of the

16

Page 17

5. Test fi t the cowl and see where it needs to be cut next.

❏

Mark the inside again if necessary, or switch to a fi ne-point

felt-pen to mark the outside. Remove the cowl and continue

to cut in small increments.

6. Proceed slowly continuing to fi t, mark and cut the cowl

❏

in small increments until you can get it over the engine—

as you really “zero-in” on the cutout, switch to the sanding

drum. When you’re really close, install the spinner back plate

for aligning the front of the cowl. Replace the head or valve

cover onto the engine and continue to adjust the cutout

accordingly. Don’t worry about perfecting the cutout yet—for

now just make the cutout large enough to fi t over the engine

as closely as possible. The fi nal cutout will be perfected after

the cowl has actually been mounted to the fuselage.

17

Page 18

Mount the Cowl

Now that you can get the cowl to fi t over the engine it is

time to determine how the cowl will be mounted. There are

two options: You can use the standard wood screws from

the outside, or use the optional cowl ring. Review the cowl

fi tting process to decide which way you prefer. The cowl ring

requires fabrication of an extended ball-end hex driver, but

the installation is “cleaner” and more durable as there will be

no external screws.

METHOD 1: Mounting the Cowl with the Cowl Ring

Now let’s get back to the cowl ring…

1. Round both ends of the included 1/8" [3.2mm]

❏

hardwood dowel and cut it in half. Glue the dowels into the

cowl ring with 1/4" [6.4mm] protruding from one side—this

will now be the back.

If using the cowl ring, fi rst make an extended hex driver…

A. Use a Dremel with a fi ber-reinforced cutoff wheel to

❏

cut a Great Planes 3/32" Hex driver ball wrench in half. Then

cut a 4" [100mm] section from a 4-40 (.095") pushrod wire.

B. Grind 1/2" [13mm] of the joining ends of the hex

❏

driver so the included brass tube couplers will fi t over the

ends. Then use coarse sandpaper to roughen both ends

of the pushrod wire.

C. Use silver solder with plenty of acid fl ux (that comes

❏

with silver solder) to join the pushrod wire between the

ends of the hexdriver with the brass tubes. The key to a

good soldering job is fi rst to tin the ends of the hex driver

and the pushrod wire—for the hex driver this requires

continually heating the ends and quenching them in fl ux.

After doing this several times the ends of the hex driver will

be thoroughly tinned and ready for joining.

D. After all the soldering is done use a small paper

❏

towel square dampened with acid fl ux to clean residual

fl ux from the wrench. Then follow with steel wool and a

thin coat of oil.

2. Press two 4-40 blind nuts into the front of the top two

❏

holes in the cowl ring.

3. Use the remainder of the 4-40 pushrod you used for

❏

extending the hex driver to pull two 4-40 blind nuts into the

back of the bottom two holes in F-1. Use a 4-40 screw with

washers to draw the blind nuts tightly all the way in. Carefully

add a few drops of thin CA around the blind nuts so they will

not pop out.

18

Page 19

6. Once satisfi ed with the fi t of the cowl ring, re mount it to

❏

the fuselage with the screws.

7. Use coarse sandpaper to roughen the cowl all the way

❏

around the inside so glue will adhere. “Prime” the inside of

the cowl with a few squirts of CA accelerator to keep the CA

from leaking around the cowl ring inadvertently gluing it to

the fuselage.

4. Temporarily fasten the cowl ring to F-1 with four 4-40 x

❏

1/2" [13mm] SHCS and fl at washers—now you can test out

your new extended hex driver!

5. View the cowl ring all the way around the fuselage to

❏

make sure it fi ts well and doesn’t protrude too far over the

edge—it should be pretty much even or extend no more than

approximately 1/64" [.4mm] over the sides of the fuselage.

Where necessary, use a fi ne-point ballpoint pen to mark

the back of the cowl ring where it extends too far over the

fuselage. Remove the cowl ring and sand as necessary.

8. Position the cowl with a #64 rubber band to hold it into

❏

position. Place the fuselage upside-down in your building

stand to get ready for gluing.

9. You’ll need the back plate of the spinner for aligning

❏

the front of the cowl, but it’s best to use the complete

spinner assembly which also usually requires the propeller.

If necessary, trim the propeller cutouts in the spinner cone to

fi t your propeller, and then mount the propeller and spinner.

19

Page 20

10. Medium CA will be used to glue the cowl to the cowl

❏

ring, but you’ll need an extended glue tip in order to reach

down inside. Pipettes and Tefl on tubing may be used, but we

used a length of micro pushrod tubing fi t over a CA tip.

11.

Double-check that the cowl is positioned precisely as

❏

you want it viewing it from all angles to make sure. The rubber

band should securely hold the cowl in position while gluing

.

14. Securely glue the back of the cowl ring with thin CA

❏

and the front of the cowl ring with medium CA.

15. If running a glow engine and the bottom cowl ring

❏

screws are not accessible through the air inlet in the front of

the cowl, cut a rounded slot on both sides of the cowl for the

hex driver. If the bottom two screws are accessible through

the inlet, the slots may not be necessary.

12. Use your extended glue tip to tack-glue the cowl to the

❏

ring with medium CA wherever you can reach—for now, the

cowl only needs to be tack-glued well enough to hold during

removal.

13. Once you’ve got the cowl glued to the cowl ring, use

❏

your extended hex driver to remove the cowl screws. Then,

take off the cowl.

Proceed to “Finish the Cowl” on page 22.

20

Page 21

METHOD 2: Mounting the Cowl with Wood Screws

Hard point

Hard point

In the following steps it may be helpful to have an

assistant drill the holes while you hold the cowl…

A. If using wood screws to fasten the cowl, mark

❏

the screw hole locations over the hard points under the

covering on both sides of the fuselage where shown.

D. Holding the cowl in position, use one of the templates

❏

as a guide to drill the fi rst 3/32" [2.4mm] hole through the

cowl into the fuselage.

E. Enlarge the hole in the cowl only with a 1/8" [3.2mm]

❏

drill. Mount the cowl to the fuselage through that fi rst screw

hole with a #4 x 1/2" [13mm] Phillips screw.

Don’t forget to put the 3/32" [2.4mm] drill bit back into

your drill before drilling the next hole.

B. Make four screw hole templates as shown from thin

❏

plastic or cardstock. Tape the templates to both sides of

the fuselage, aligning the holes in the templates over the

marks made over the hard points.

C. Fit the cowl into position. If you haven’t yet done so,

❏

trim the propeller cutouts in your spinner cone to fi t the

propeller, and then mount the propeller and spinner.

F. Holding the cowl in alignment again, drill the second

❏

3/32" [2.4mm] screw hole. Enlarge that hole in the cowl

only and insert the second screw.

G. Drill the two holes and mount the other side of the

❏

cowl to the fuselage the same way.

H. After all the holes have

❏

been drilled remove the cowl.

Use CA to glue the thin,

plastic bushings to the inside

of the cowl centered over the

holes.

I. Add a few drops of thin

❏

CA to each screw hole in the

fuselage and allow to harden.

21

Page 22

Finish the Cowl

Brass

Cable Swage

4-40x1/2"

SHCS

4-40 Nut

(Use threadlock)

4-40 Ball

Link

Stand-Off

Threaded

Cable Coupler

Great Planes

3" Double-Side

Servo Arm

Hook Up the Rudder and Elevators

1. Same as was done with the ailerons, give a good pull

❏

on the rudder and look at the hinges to make sure they are

all secure. Use thin CA to wet any hinges that look dry.

2. Making sure the trims and sub trims are centered, use

❏

your transmitter to center the rudder servo.

3. Enlarge the second-from-the-outer holes in a Great

❏

Planes 3" [150mm] double-side servo arm (GPMM1165)

with a 7/64" [2.8mm] drill. Mount the servo arm to the servo.

1. If using a glow engine, mount the muffl er and make any

❏

additional cuts necessary—you may have to cut through the

cowl ring, but this won’t weaken the cowl because the ring

will be braced by the fuselage when bolted into position.

2. Make any other cuts/holes necessary for the needle

❏

valve, glow plug and fueling lines.

3. Once all the cowl holes have been cut fi nal-sand the

❏

edges of all cuts with 320-grit or 400-grit sandpaper.

4. If using a glow engine, lightly coat the cowl ring with

❏

thinned epoxy or fuelproof paint.

4. Fit the aft rudder servo rail into position in the fuselage

❏

and adjust it to fi t the rudder servo. Securely glue the rail in

22

Page 23

place. Mount the rudder servo and hook up the rudder using

11/16"

[18mm]

the hardware shown—be certain to use threadlocker on all

the 4-40 nuts and don’t forget to harden the servo mounting

screw holes with thin CA. NOTE: Stand-offs are used under

the ball links on the servo arm, but are not required on the

rudder horn.

5. Pull on the elevators and inspect the hinges. Add thin

❏

CA to any hinges that look dry.

10. Fit both stabilizer halves to the fuselage with the

❏

aluminum joiner tube as you guide the servo wires down

through the fuselage—a long piece of wire with a hook bent

on the end works for pulling the wires.

11. Fasten the stabs to the fuselage with #2 x 3/8" [10mm]

❏

Phillips screws, #2 lock washers and fl at washers. Be certain

to use threadlocker on the threads.

6. If your elevator servos are higher than 11/16" [18mm]

❏

from the bottom of the grommets to the bottom of the servo,

they will need to be shimmed up in order not to interfere with

the sheeting on the top of the horizontal stabilizers.

❏ 7. Cut two more 4-40 pushrods to a length of 2" [50mm]

and solder on the threaded couplers to make the elevator

pushrods. Connect the elevators to the servos with the same

hardware as the ailerons—standoffs were not used under

the ball links on the servos, but were used on the elevator

horns. Be certain to use threadlocker on the nuts

8. Connect a 36" [910mm] servo extension to each

❏

elevator servo wire and secure the connections with 1-1/2"

[40mm] pieces of heat shrink tubing.

.

9. Glue a 1/8" [3.2mm] plastic dowel into each stab half.

❏

23

Page 24

FINAL ASSEMBLY

Set the C.G.

Determine where the model balances before mounting

the receiver battery. Then, mount the battery where

required to achieve the correct C.G.

1. With the exception of the receiver battery, receiver and

❏

on/off switch, the Sequence should otherwise be in readyto-fl y condition with everything else installed (including the

motor battery positioned in the approximate location shown

in previous photos if using an electric motor).

4. Use a Great Planes C.G. Machine or lift the model

❏

with your fi ngers at the balance point. Position the receiver

battery over the fuselage (and/or shift the motor battery) to

get the model to balance.

2. Mount the receiver battery to whichever of the two

❏

included plywood mounting plates fi ts best.

3. If you will be balancing the model with your fi ngers

❏

mark the recommended C.G. location and the forward and

aft C.G. on the top of the wing as shown.

Forward C.G. location 6" [150mm]

Recommended C.G. 6-3/4"

Aft C.G. location 7-1/2" [190mm]

[170mm]

5. Securely mount the receiver battery in the location

❏

required to get the desired C.G.; then, mount the receiver,

switch and an external charge receptacle using the included

plastic mounting plate for the Futaba mini switch and Ernst

charge receptacle. If using a different switch or charge

receptacle, cut the mounting through the side of the fuselage

holes as necessary.

6. Connect the servos to the receiver. Also connect a 6"

❏

[150mm] servo extension into each of the two channels you

will be using in the receiver for the ailerons. Use pieces of the

included small plastic tubing for mounting the Rx antennas.

7. IMPORTANT: Once the receiver battery and the rest of

❏

the radio components have been mounted, recheck the C.G.

Any small adjustments required can be made with Great

Planes stick-on lead weights (GPMQ4485).

24

Page 25

Balance the Model Laterally

These are the recommended control surface throws:

ELEVATOR

3/8"

[10mm]

7°

Up

3/8"

[10mm]

7°

Down

5/8"

[16mm]

11°

Up

5/8"

[16mm]

11°

Down

RUDDER

1-1/4"

[32mm]

13°

Right

1-1/4"

[32mm]

13°

Left

1-3/4"

[44mm]

19°

Right

1-3/4"

[44mm]

19°

Left

AILERONS

1/2"

[13mm]

9°

Up

1/2"

[13mm]

9°

Down

3/4"

[19mm]

13°

Up

3/4"

[19mm]

13°

Down

LOW RATE HIGH RATE

1. With the wing level, lift the model under the tail and by

❏

the propeller shaft. Do this several times.

2. If one wing always drops when you lift the model, it

❏

means that side is heavy. Balance the airplane by adding

weight to the other wing tip. An airplane that has been

laterally balanced will track better in fl ight and maintain

its heading better during maneuvers when the plane is

climbing.

Set the Control Throws

PREFLIGHT

Identify Your Model

Always attach your name, address, telephone number and

AMA number somewhere on or inside your model.

Ground Check

GLOW ENGINES:

Perform your usual checks and tune the engine so it idles

and runs smoothly at full-throttle and transitions reliably

between the two. With the engine running at full-throttle,

have an assistant hold the plane in different orientations

(including nose-up and inverted) to make certain the engine

continues to run smoothly and reliably.

ELECTRIC MOTORS:

Measure and set the throws according to the chart below.

The measurements are taken at the widest part (front-to-

back) of each surface. If the endpoints in your transmitter

programming require more than a 10% to 15% change to

get the required throws, relocate the pushrods on the control

horns or on the servo arms instead. Then, go back and

perfect the throws using the programming in the radio.

Whatever motor, battery, propeller and ESC you are running,

you should fi nd out what current and Watts your setup is

drawing before the fi rst fl ight. Once you have the data you can

compare it to the manufacturer’s specifi cations (or data from

other reliable sources) to make sure everything is operating

within its limits. Noting and recording the current and Watts

(and rpm) your system is making can also be used as a base

for comparison if experimenting with different propellers,

motors or batteries later.

There are a few ways to get this data. One way is to briefl y

run the motor on the ground with a “Watts Up” Watt meter

(RELP0100) connected in-line between the battery and

ESC. The Watt’s Up meter will display the current (Amps),

battery Voltage and Watts. Another way is to use on-board

data logging such as an Eagle Tree Systems ELogger (

ETRP8032) or logging in your ESC. The ELogger stores

data that can be downloaded and viewed on your personal

computer. Additionally, the ELogger can be used in-fl ight to

give you a constant and more accurate picture of what the

system is doing.

Although the static (non-fl ying) data will not be the same as

what it happening in the air, it can still be used as a reference:

For example, testing has shown that the RimFire 1.20 with an

25

Page 26

APC 17 x 8E propeller powered by a 5,000mAh 6S battery

draws about 80A, 1,750 Watts @ 7,500rpm (these are the

initial, static/non-fl ying readings using a fully charged battery).

And in-fl ight data from the ELogger shows that the average

current draw throughout a normal fl ight is about 40A with the

maximum current draw during full-throttle events about 72A.

Once you run your motor on the ground you can compare

your numbers to these as well as the current specifi cations

for the motor. The specifi ed limits for the RimFire 1.20 are

50A constant current and 80A surge current. Because the

setup we are using draws a maximum of 72A in the air, this

is within the specifi ed 50A constant/80A surge limit and is an

acceptable combination as long as full throttle is used only in

short bursts (say, during up-lines or on takeoff).

So, if you are using a RimFire 1.20 and your Watts-Up meter

tells you it is pulling around 80A on the ground, you will know

everything is working normally. However, if for some reason

you are not getting close to those numbers, you will know

something is wrong. It could be a greatly imbalanced propeller,

too large of a propeller, a damaged motor, defective wiring,

etc. Find and correct the problem before fl ying your Sequence.

CAUTION: Never run the motor on the ground for more

than a few seconds. Otherwise, you may overload the

motor, battery or ESC.

4,000mAh (used in fl ight) / 1,000 = 4 Ah / 6 minutes =

.67Amps/minute x 60 minutes = 40A.

The average, in-fl ight current draw was 40 Amps. Even

though we know the motor is drawing 72A during brief, full

throttle bursts, the average current draw over the duration of

the fl ight was only 40A so the motor and ESC are operating

comfortably within their limits.

Another calculation we can make is the percentage of charge

remaining in the battery. If 4,000mAh was used from a 5,000mAh

battery, 20% was remaining. This is generally accepted as a

safe reserve. Flying your LiPos down to no further than 20%

capacity is a good way to extend its life and performance.

Based on this information, you may want to start out setting

your fl ight timer to a conservative four or fi ve minutes. After

the fl ight note the exact fl ight time and the recharge capacity

in your log book. Calculate the percentage of charge that

was left in your battery and adjust your fl ight time accordingly.

Keep in mind that many variables can determine your infl ight current consumption such as how much you used fullthrottle, weather conditions, battery condition, etc. Due to

these variables it is always a good idea to calculate your

maximum fl ight time conservatively.

Range Check

Another smart thing you can do is record the fl ight time and

capacity used from the battery for each fl ight in a log book.

Record the fl ight time (from the timer on your transmitter or

other timer) immediately after each fl ight and record how

much mAh (capacity) went back into the battery read from

the display on your charger. (Number your fl ight packs so you

will be able to correlate each battery to each fl ight.) When

you know the fl ight time and recharge capacity (capacity

used for the fl ight) you can calculate valuable data indicating

how your motor is performing and whether or not your fl ight

time is too long or too short.

For the Sequence 1.20 for example, say we record a 6

minute fl ight. And back in the shop we record that the battery

took 4,000mAh to recharge. With these numbers we can

calculate the average, in-fl ight current draw:

Don’t forget to perform your usual ground range checks as

written in the instruction manual that came with your radio

system to be certain it is operating correctly.

ENGINE / MOTOR

SAFETY PRECAUTIONS

Failure to follow these safety precautions may result

in severe injury to yourself and others.

Keep all engine fuel in a safe place, away from high heat,

sparks or fl ames, as fuel is very fl ammable. Do not smoke

near the engine or fuel; and remember that engine exhaust

gives off a great deal of deadly carbon monoxide. Therefore

do not run the engine in a closed room or garage.

Get help from an experienced pilot when learning to operate

engines.

Use safety glasses when starting or running engines.

Do not run the engine in an area of loose gravel or sand; the

propeller may throw such material in your face or eyes.

Keep your face and body as well as all spectators away from the

plane of rotation of the propeller as you start and run the engine.

Keep these items away from the prop: loose clothing, shirt

sleeves, ties, scarfs, long hair or loose objects such as

pencils or screwdrivers that may fall out of shirt or jacket

pockets into the prop.

Use a “chicken stick” or electric starter to start the engine.

Do not use your fi ngers to fl ip the propeller. Make certain the

glow plug clip or connector is secure so that it will not pop off

or otherwise get into the running propeller.

26

Page 27

Make all engine adjustments from behind the rotating

propeller.

4) I will operate my model using only radio control frequencies

currently allowed by the Federal Communications Commission.

The engine gets hot! Do not touch it during or right after

operation. Make sure fuel lines are in good condition so fuel

will not leak onto a hot engine, causing a fi re.

To stop a glow engine, cut off the fuel supply by closing

off the fuel line or following the engine manufacturer’s

recommendations. Do not use hands, fi ngers or any other

body part to try to stop the engine. To stop a gasoline

powered engine an on/off switch should be connected to

the engine coil. Do not throw anything into the propeller of a

running engine.

AMA SAFETY CODE (excerpts)

Read and abide by the following excerpts from the Academy

of Model Aeronautics Safety Code. For the complete Safety

Code refer to Model Aviation magazine, the AMA web site or

the Code that came with your AMA license.

General

1) I will not fl y my model aircraft in sanctioned events, air shows,

or model fl ying demonstrations until it has been proven to be

airworthy by having been previously, successfully fl ight tested.

2) I will not fl y my model aircraft higher than approximately

400 feet within 3 miles of an airport without notifying the

airport operator. I will give right-of-way and avoid fl ying in the

proximity of full-scale aircraft. Where necessary, an observer

shall be utilized to supervise fl ying to avoid having models fl y

in the proximity of full-scale aircraft.

3) Where established, I will abide by the safety rules for the

fl ying site I use, and I will not willfully and deliberately fl y my

models in a careless, reckless and/or dangerous manner.

5) I will not fl y my model unless it is identifi ed with my name

and address or AMA number, on or in the model. Note: This

does not apply to models while being fl own indoors.

7) I will not operate models with pyrotechnics (any device that

explodes, burns, or propels a projectile of any kind).

Radio Control

1) I will have completed a successful radio equipment ground

check before the fi rst fl ight of a new or repaired model.

2) I will not fl y my model aircraft in the presence of spectators

until I become a qualified flier, unless assisted by an

experienced helper.

3) At all fl ying sites a straight or curved line(s) must be

established in front of which all fl ying takes place with the

other side for spectators. Only personnel involved with fl ying

the aircraft are allowed at or in the front of the fl ight line.

Intentional fl ying behind the fl ight line is prohibited.

5) I will not knowingly operate my model within three miles

of any pre-existing fl ying site except in accordance with

the frequency sharing agreement listed [in the complete

AMA Safety Code].

9) Under no circumstances may a pilot or other person touch

a powered model in fl ight; nor should any part of the model

other than the landing gear, intentionally touch the ground,

except while landing.

CHECK LIST

Perform these last-minute checks to make sure nothing has

been forgotten:

❏ 1. Confi rm that all controls respond in the correct direction

and the throws are set up according to the manual.

❏ 2. Make sure you have checked the C.G. as instructed.

❏ 3. Make sure the lock nuts are present on all the screws

that retain the pushrods to the servo arms and that

the screws that retain the servo arms are in place.

❏ 4. Be certain the battery and receiver are securely

mounted.

❏ 5. If using a radio system on 72 MHz, be certain to extend

the receiver antenna all the way down the antenna

tube in the fuselage.

❏ 6. Use threadlocking compound to secure all critical

fasteners including any servo screws that go into a

metal output shaft.

❏ 7. Add a drop of oil to the axles so the wheels will turn

freely.

❏ 8. Make sure all hinges are securely glued in place.

❏ 9. Reinforce holes for wood screws with thin CA where

appropriate.

❏ 10. Where appropriate, secure connections between servo

wires and Y-connectors or servo extensions, and the

connection between your battery pack and the on/off

switch with vinyl tape, heat shrink tubing or special

clips suitable for that purpose.

❏ 11. Make sure the fuel lines are connected and are not

kinked.

❏ 12. Balance the propellers (and spare propellers).

❏ 13. Place your name, address, AMA number and telephone

number on or inside your model.

❏ 14. Cycle your receiver battery pack (if necessary) and

make sure it is fully charged.

❏ 15. Range check your radio when you get to the fl ying

fi eld.

27

Page 28

FLYING

There are no particular fl ight characteristics about the

Sequence 1.20 that you need to be made aware of ahead of

time. The Sequence is a well-balanced, neutral fl ying plane

that will go wherever you point it. Simply fl y the Sequence

within your capabilities and take it easy for the fi rst couple of

fl ights to give your self time to become acclimated to it.

Have a ball!

But always stay in control

and fl y in a safe manner.

GOOD LUCK AND GREAT FLYING!

OPTIONAL WOOD/FRP

EP MOTOR MOUNT BOX

The wood/FRP (fi ber-reinforced plastic) motor mount box

may be used to “front-mount” a RimFire 1.20 brushless

motor (or other outrunners), or a geared inrunner.

2. Glue both backplate doublers to one side of the tabbed

backplate.

ITEMS REQUIRED:

❍ (4) M3 x 8 motor mounting screws for RimFire 1.20 or

suitable mounting screws for your motor

❍ (4ea) 4-40 blind nuts, 4-40 x 1/2" screws, #4 fl at washers

and lock washers

❍ Great Planes 8mm to 3/8-24 thread propeller adapter (for

RimFire 1.20, GPMQ4971)

1. Use medium-grit sandpaper to roughen both sides of the

FRP front bulkhead so glue will adhere. Glue the four blind

nut doublers to one side of the bulkhead as shown. Then

press 4-40 blind nuts into the doublers. If using a geared

inrunner that requires additional support, also press four

more 4-40 blind nuts into one side of the rear bulkhead. If

used, the rear motor mount may be custom fi t to your motor

and bolted to the rear bulkhead.

3.

Test fi t the sides, top, bottom, backplate assembly, rear

bulkhead and front bulkhead together—be certain the blind nuts

on the front bulkhead and the blind nuts (if used) on the rear

bulkhead are facing aft and the doublers on the tabbed back

plate are also on the back of the stack. Make any adjustments

necessary, and then securely glue the assembly together.

28

Page 29

4. Glue the front bulkhead doubler and the side doublers

5/16" [8mm]

9/16" [15mm]

1/8" [3.2mm]

to the assembly.

to drill 1/16 " [1.6mm] pilot holes through the FRP motor

mount plate. If using a different motor, mark, then drill holes

to fi t your motor. Hint: For perfection, fasten the template to

the mount with 4-40 screws and nuts.

5. Cut two 1" [25mm] pieces and two 2 " [50mm] pieces from

the included balsa triangle stock. Securely glue the triangle

stock pieces around the inside corners of the back plate.

6. If using a RimFire 1.20, use the included plywood RimFire

1.20 motor mount template (and a drill press if available)

7. Remove the plywood template, then enlarge the pilot holes

as illustrated for the RimFire 1.20.

8. If using an inrunner with a gearbox that requires additional

support, cut a hole in the rear motor mount to fi t to your

motor with whatever shock absorption preferred (usually fuel

tubing).

29

Page 30

9. Mount your motor to the motor mount plate—the RimFire

Cut Out

Drill:

7/32" [5.6mm]

1.20 uses four M3 x 8 screws. If also using the rear mount,

fasten it into the mount assembly with four 4-40 x 3/8 "

screws and washers. Test-mount the plate/motor assembly

to the box with four 4-40 x 3/4" screws, washers and lock

washers. Turn the motor by hand, making sure there is no

interference and everything turns free and smooth. Make

any adjustments necessary. Then, remove the mount plate/

motor assembly from the mounting box.

11. Key the mount tabs on the mounting box into the slots

in the fi rewall and fasten the mount with four 8-32 x 3/4 "

socket-head cap screws, #8 lock washers, fl at washers and

8-32 blind nuts. Mount the motor and ESC to the assembly.

12. Rejoin the assembly manual at Mount an Electric

Motor on page 13. Note: The spinner back plate will have

to be enlarged with a 3/8 " [9.5mm] drill for the Great Planes

propeller adapter.

10. Drill 7/32 " [5.6m] holes through the fi rewall at the four “+”

marks and cut the rest of the way through the four, partiallycut slots for the tabs on the motor mount.

30

Page 31

ENGINE CUTOUT TEMPLATE FOR

O.S. 1.55FS-a

31

Page 32

Loading...

Loading...