Page 1

50CC-65CC BRUSHLESS

OUTRUNNER MOTOR

Thanks for purchasing the ElectriFly RimFire

Motor! In order to complete your power system you will need to select

the correct LiPo batteries, propeller, ESC, and motor mount. The

following instruction manual will explain what you will need to

complete your new RimFire power system.

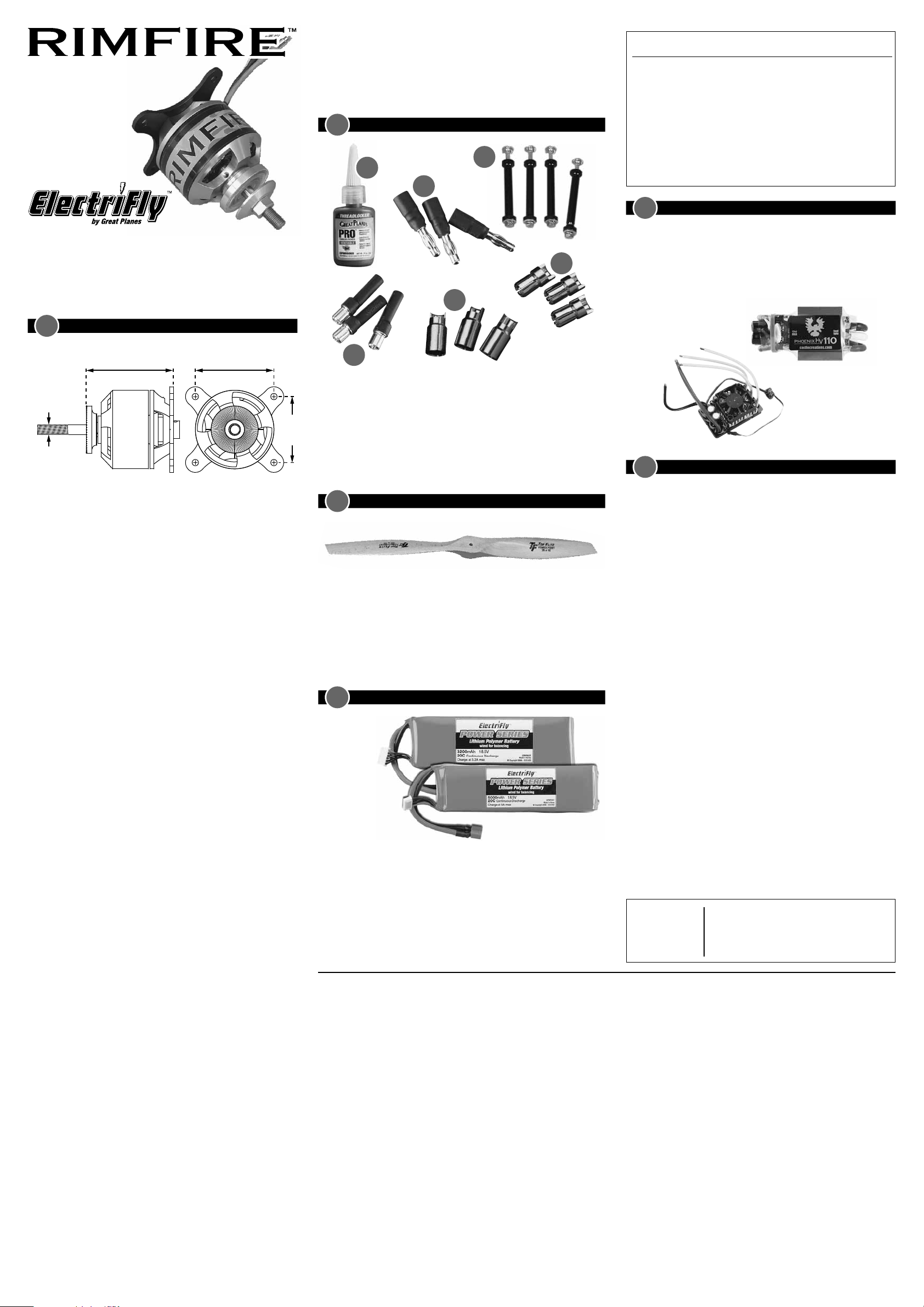

MOTOR

1

87.3mm (50cc)

97.3mm (65cc)

™

50cc-65cc Brushless

80mm

the current in check. If a higher voltage battery is replaced by a lower voltage battery, the size of the propeller can be increased to keep the motor at

its rated current.

Another possibility to fine tune the power system’s performance is to use

another motor with higher kV to increase the current or a lower kV to lower

the current.

ACCESSORIES

2

B

A

C

E

F

D

Items not shown

actual size.

Stock # Voltage Capacity Weight

GPMP0540 7.4V (2S) 3350mAh oz (188g)

GPMP0541 11.1V (3S) 3350mAh oz (275g)

GPMP0542 14.8V (4S) 3350mAh oz (347g)

GPMP0543 18.5V (5S) 3350mAh oz (435g)

GPMP0560 7.4V (2S) 5300mAh oz (291g)

GPMP0561 11.1V (3S) 5300mAh oz (426g)

GPMP0562 14.8V (4S) 5300mAh oz (555g)

GPMP0563 18.5V (5S) 5300mAh oz (697g)

ELECTRONIC SPEED CONTROL (ESC)

5

The following brushless electronic speed controls are compatible with

these motors.

ElectriFly Silver Series 80A Brushless ESC High-Volt (GPMM1860)

ElectriFly Silver Series 100A Brushless ESC High-Volt (GPMM1870)

Castle Creations Phoenix

110 High-Volt Brushless

ESC (CSEM2018)

6.6

9.7

12.2

15.3

10.3

15.4

19.6

24.6

Type

25C LiPo

25C LiPo

25C LiPo

25C LiPo

25C LiPo

25C LiPo

25C LiPo

25C LiPo

Thread Pitch:

r

1.25mm

10

10mm

RimFire 50cc (80-75-230) (GPMG4800)

Motor Output Shaft Size: 10mm

Motor Diameter: 80mm [3.14”]

Motor Can Length: 75mm [3.0”]

Mounting Space Length: 87.3mm [3.44”]

Weight: 1250g [44.1oz]

Input Voltage: 33.3-55.5V (9-15S LiPo)

Max Continuous Current: 110A (at 12S)

Max Continuous Power: 5000W

Max Surge Current: 135A (at 12S)

Max Surge Power: 6500W

Prop Range: 22x8 to 26x10 glow/gas prop

Sport Aircraft Weight: 12.7kg [28lbs] [460oz]

3D Aircraft Weight: 8.17kg [18lbs] [288oz]

RimFire 65cc (80-85-160) (GPMG4805)

Motor Output Shaft Size: 10mm

Motor Diameter: 80mm [3.14”]

Motor Can Length: 85mm [3.35”]

Mounting Space Length: 97.3mm [3.83”]

Weight: 1480g [52.2oz]

Input Voltage: 33.3-55.5V (9-15S LiPo)

Max Continuous Current: 135A (at 12S)

Max Continuous Power: 7500W

Max Surge Current: 150A (at 12S)

Max Surge Power: 8400W

Prop Range: 22x10 to 26x12 glow/gas prop

Sport Aircraft Weight: 19.7kg [42lbs] [665oz]

3D Aircraft Weight: 11.79kg [26lbs] [416oz]

Understanding Motors

kV (rpm/volt): This is a number that gets thrown around quite a bit

when talking electrics and it is important to know what it is. kV is the

number of rpm a motor will spin per each volt applied (rpm/volt)

under no load.

This means that basically a motor that has a kV of 1000 when

connected to a 12V battery will try to spin at 12,000rpm (1000x12)

under no load. Likewise a 3500kV motor will try to spin at 42,000rpm

(3500x12) under no load.

When a propeller is attached to the motor, the motor will try to spin

the prop at the rated kV. Depending on the diameter and pitch of the

propeller (the larger the diameter or higher the pitch, the harder it is

for the motor to spin), the motor’s current draw increases as the load

increases and decreases as the load decreases. There are meters

available from your hobby dealer that measure current and voltage.

Because every motor has a maximum current it can take based on its

design and cooling ability, the maximum size of propeller that can be

used with each motor can be determined. Use a propeller that’s too

large and the motor will spin at a much lower rpm than its rated kV,

causing it to draw a lot of current and overheat. If the propeller/fan is

too small, it will require little effort (current) to turn the prop at the

rated kV.

Ideally the motor should be matched with a propeller that causes

the motor to draw 80-100% of its rated maximum constant

current. Once a power system is set up, it can be fine-tuned by

adjusting the propeller size and measuring the amount of current

the motor is drawing.

Please note that the kV of a motor does not change with voltage, but

if a higher voltage is applied to the motor, it will try to spin the same

propeller at a higher rpm. This will cause the motor to draw more

current and possibly exceed the maximum rated current of the motor.

So, if a battery with lower voltage is replaced with one with a higher

voltage, it is recommended that a smaller propeller be used to keep

A Great Planes® Pro™ Thread Locking Compound (GPMR6060)

B Standoff Brushless Motor Mount XX-Large (GPMG1275)

C 4mm/6mm Female Bullet Adapter (GPMM3118)

67mm

D 6mm/4mm Female Bullet Adapter (GPMM3119)

E 6mm Bullet Connector Male (GPMM3116)

F 6mm Bullet Connector Female (GPMM3117)

PROPELLERS

3

Because of the high torque of this motor and its ability to spin at high rpm,

we recommend against using electric-only propellers. Below is a listing

of a few of the recommended props.

™

TOPQ5260 22x10 Power Point

TOPQ5270 24x10 Power Point ZINQ2014 26x10 Zinger Prop

ZINQ1403 20x10 Pro-Zinger ZINQ2017 26x12 Zinger Prop

ZINQ1603 22x10 Pro-Zinger

LI-POLY BATTERIES (LIPO)

4

ZINQ1803 24x10 Pro-Zinger

Number of Cells

Batteries can be connected in series (S) or in parallel (P). A LiPo battery

is advertised by voltage and capacity where each cell carries 3.7 volts. A

4S LiPo battery would be 4 x 3.7V or 14.8V. The capacity is listed in milliamp hours or mAh, so a 5300mAh battery can discharge a maximum of

5300 milliamp-hours or 5.3 amp-hours. Please also be aware of the

battery’s discharge current delivery capability, or C-rating. A 25C,

5300mAh battery will deliver 132.5A of current regardless of voltage.

For the most up-to-date list of LiPo batteries, check out the ElectriFly web

site at: www.electrifly.com

Kontronik™ Power Jazz

63V Brushless ESC

120A (KONM3140)

DETERMINE WHAT YOU NEED TO BUILD YOUR POWER SYSTEM

6

If you know the approximate weight of your airplane, including the

motor and battery, and the performance you want from it, answer the

questions below to determine the correct power system for your

plane. You may need to make more than one calculation using

different motors and battery combinations. See the battery section for

some of the battery weights for the suggested batteries.

1. Perform the following calculation to determine the wattage

required:

If you expect trainer-like performance, then multiply 75 x

•

Airplane Weight (lbs)

If you expect aerobatic or high speed performance then

•

multiply 100 x Airplane Weight (lbs)

If you expect 3D or extreme performance multiply 150 x

•

Airplane Weight (lbs)

2. The number you get is the minimum wattage you will need for your

plane to perform as you wish.

3. Select a LiPo battery voltage within the recommended range of the

motor. Keep in mind that voltage affects prop size (lower volts

require bigger props). 12S is a good reference point to start at. See

“Sample Power Systems” in this manual.

4. Divide the minimum wattage that you came up with by the voltage

you selected. This will give you the current you should expect.

5. Determine the battery capacity needed based on the current draw of

your system and your desired flight time. Be sure to select batteries

with the proper C-rating that can deliver the current you need.

6. Determine the ESC you need based on the system current draw.

See the ESC section for recommended ESCs.

In addition to this procedure, you can also visit the Great Planes

ElectriFly web site for descriptions of the power systems recommended

for our line of electric and glow airplanes as well as more detailed

explanation on the subject.

RECOMMENDED

SETUP

RimFire

50cc

RimFire

65cc

12S 5300mAh 25C LiPo, 120A ESC,

22r8 glow/gas prop

12S 5300mAh 25C LiPo, 120A ESC,

24r8 glow/gas prop

Page 2

INSTALL YOUR MOTOR

7

1) If you will

mount your motor

directly to the

firewall or if you

will use the Great

Planes 80mm

Motor Standoff

Motor Mount set,

cut out the

mounting template in this manual and mount it

to your firewall using tape or a spray adhesive. Align the template

crosshairs with the centering marks provided on the firewall. Drill four

9/32” [7.1mm] mounting holes.

2) Remove the

four countersunk

screws holding the

X-mount to the

motor and reinstall

them using thread

locking compound. Remove

the set screws

from the wheel

collar, the rear

case, and the front

case and reinstall them using thread locking compound.

3) Determine the mounting space required by your model – this is

usually found during the engine/motor installation steps in your

model’s instruction manual. Subtract the mounting space of the

motor from the total required mounting space. For example, if the

mounting space is 184mm [7-1/4”] and we want to mount the 50cc

RimFire which itself has a mounting space of 87.3mm [3.44”]:

184mm - 87.3mm = 96.7mm

4) Using a Great Planes

XX-Large Standoff

Brushless Motor Mount

set (sold separately,

GPMG1275), combine

standoffs to achieve the

dimension you came up

with. You may not get

the exact dimension

with the standoffs, so

check to see if your cowl

or balance condition will

allow you to increase or

decrease this dimension. The standoffs shown in the photo above

combine to make a 100mm standoff dimension.

5) Select good

quality 1/4-20 bolts

that are long enough

to fully engage all of

the threads of your

blind nuts, or use

the bolts included

with the standoff kit.

We used 5” [127mm]

long bolts for this

example. Attach your

motor to the firewall using flat washers, lock washers, and thread

locking compound.

INSTALL THE BRUSHLESS ESC

8

1) Make sure that the ESC you have selected has the proper 6mm female

bullet connectors attached to the three motor leads. If it does not, this

motor is supplied with 6mm female bullet connectors. These are fitted to

the male bullet connectors on the motor leads. Slide them off and solder

them to your ESC motor leads. Insulate the bare connector body with

some heat-shrink tubing. The heat shrink on the motor wires and the

ESC wires must completely cover the gold connectors. If the bare

connectors touch each other while power is supplied to the motor,

permanent damage to the ESC/motor may result. Note: DO NOT try to

remotely mount your ESC by extending the motor lead wires. This will

adversely affect motor timing.

2) Attach the ESC you have selected to your model in the location suggested

by the manufacturer. If your model does not come with mounting

equipment for an ESC, fit your ESC to a place where it will receive adequate

airflow. Make sure that airflow is directed over the cooling fins of the ESC

and that air has a path to exit from the model.

3) Attach a suitable battery lead connector from your ESC to your battery.

For safety reasons, you may want to build an arming switch which will

allow you to quickly and safely arm and disarm your motor without

opening or removing any hatch. Keep all leads as short as possible to

reduce resistance, and well insulated to eliminate short-circuits.

4) Connect the three motor leads from the ESC to the motor. Check to see

that the motor rotates in the correct direction. Swap the position of any

two motor leads to reverse the rotation of the motor.

RIMFIRE MOTOR MAINTENANCE

9

RimFire brushless motors require virtually no maintenance. There are no

brushes to wear out and replace. The precision bearings have a very long

service life and should last a very long time. The internal parts of the motor

should not require any cleaning. The only thing that needs to be checked

is to make sure all the screws and set screws remain tight.

IMPORTANT PRECAUTIONS

10

• Once the battery is connected to the ESC, stay clear of the motor and

prop.

• DO NOT apply an input voltage that exceeds the maximum specification

of each motor.

• DO NOT apply currents to the motor that exceed the maximum

specifications of each motor.

• DO NOT allow the input connectors to accidentally touch each other while

power is applied to the motor. Make sure all input connections are

insulated electrically.

• DO NOT allow water or moisture to enter the motor, as it can cause

permanent damage to the motor and possibly short out the

attached ESC.

• DO NOT cut the wires from the motor. The wires are part of the windings

and are coated with an insulating material and cannot be soldered

without removing the coating, which is very difficult. If you must remove

the bullet connectors, unsolder them.

• Allow the motor to cool after each flight.

• The motor shaft of the motor will rotate at very high rpm. DO NOT

attempt to touch the shaft while it is rotating. If setting up the motor/ESC

on the workbench, make sure the motor is securely attached and that

nothing is attached to the motor shaft BEFORE applying power.

• NEVER attempt to use a damaged motor (having mechanical or

electrical defects).

™

• Great Planes carries a complete line of Ammo

RimFire (outrunner style) brushless motors, gear drives, motor mounts,

prop adapters and speed controls. For a complete list of these products,

check out our web sites at:

www.greatplanes.com www.electrifly.com

or visit your nearest hobby shop that carries the full line of Great Planes

and ElectriFly products.

(inrunner style) and

BATTERY PRECAUTIONS

11

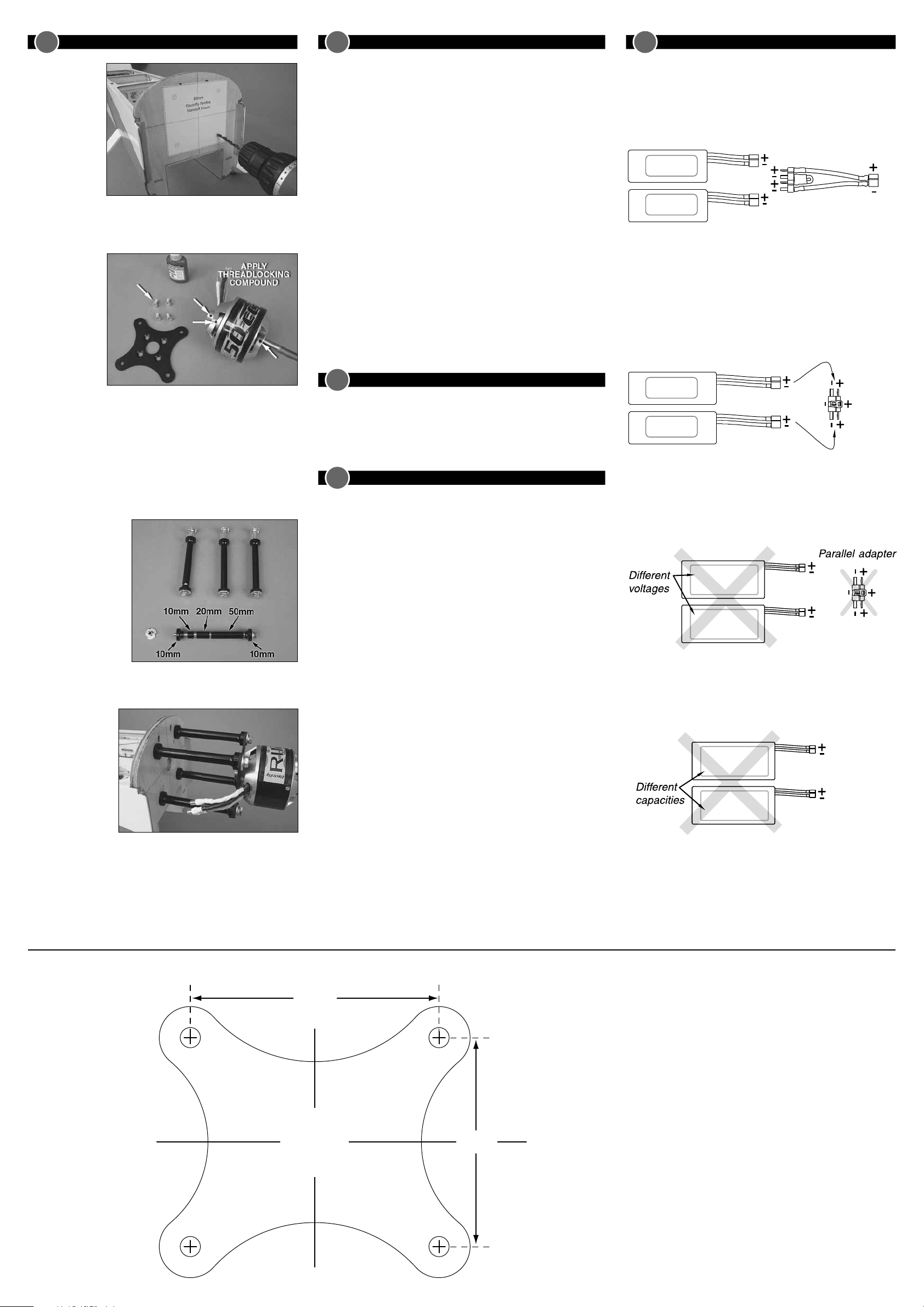

There are two ways to connect multiple battery packs: In Series and

in Parallel.

These are two 33500mAh batteries (one 11.1V

and the other 7.4V). When joined in SERIES,

the result will be a 18.5V, 3350 mAh battery.

11.1V (3-Cell)

3350mAh

7.4V (2-Cell)

3350mAh

1) Connecting batteries in “Series” means to connect the +’s to the –’s

and the –’s to the +’s. This combines the batteries’ voltages, but the

capacity remains the same.

OKAY

This is a SERIES battery

adapter (GPMM3143)

that connects two

batteries in series.

These two 3350mAh batteries (both 11.1V) are

being joined in PARALLEL. The result will be

one 11.1V, 6700mAh battery.

OKAY

11.1V (3-Cell)

3350mAh

11.1V (3-Cell)

3350mAh

This is a PARALLEL battery

adapter (GPMM3142) that

connects two batteries in parallel.

2) Connecting batteries in “Parallel” means to connect the +’s to the

+’s and the -’s to the -’s. This combines the batteries’ capacities, but

the voltage remains the same.

11.1V (3-Cell)

3350mAh

7.4V (3-Cell)

3350mAh

NEVER connect battery packs with different Voltages in Parallel–only

combine in Series. Otherwise, the batteries will try to “equalize” with

the larger one trying to “charge” the smaller one, thus causing heat

and likely a fire.

11.1V (3-Cell)

3350mAh

11.1V (3-Cell)

5300mAh

NO!!!

NO!!!

Also NEVER connect battery packs with different capacities in Series

or in Parallel.

Note: This mounting

pattern matches the

DLE-55 engine. An

optional mount that

matches the DA-50

engine is GPMG1214.

80mm

RIMFIRE 50cc & 65cc MOUNTING PATTERN

67mm

Entire Contents Copyright © 2009 GPMG4800/05Mnl

RimFire 50cc Accessory and Spare Parts

GPMM3116 6mm Gold Plated Bullet Cnnectors - Male (3)

GPMM3117 6mm Gold Plated Bullet Connectors - Female (3)

GPMQ4914 RimFire 50cc and 65cc Replacement Prop Drive

GPMG1212 RimFire Backplate Motor Mount for 50cc and 65cc Motors

GPMG1214 Optional DA50 RimFire Backplate Motor Mount for 50cc & 65cc Motors

GPMG1438 C-clip (10) for 10mm RimFire Motor Shafts

GPMG1462 Bearings (3) for RimFire 50cc and 65cc Motors

GPMG1424 Replacement Shaft Kit for RimFire 50cc

GPMG1275 Stand Off Brushless Motor Mount XX Large

RimFire 65cc Accessory and Spare Parts

GPMM3116 6mm Gold Plated Bullet Cnnectors - Male (3)

GPMM3117 6mm Gold Plated Bullet Connectors - Female (3)

GPMQ4914 RimFire 50cc and 65cc Replacement Prop Drive

GPMG1212 RimFire Backplate Motor Mount for 50cc and 65cc Motors

GPMG1214 Optional DA50 RimFire Backplate Motor Mount for 50cc & 65cc Motors

GPMG1438 C-clip (10) for 10mm RimFire Motor Shafts

GPMG1462 Bearings (3) for RimFire 50cc and 65cc Motors

GPMG1426 Replacement Shaft Kit for RimFire 65cc

GPMG1275 Stand Off Brushless Motor Mount XX Large

Loading...

Loading...