Page 1

KAYENNE

VIDEO PRODUCTION CENTER

Installation Planning Guide

071869003

AUGUST 2011

Page 2

CERTIFICATE

Certificate Number: 510040.001

The Quality System of:

Grass Valley USA, LLC and its Grass Valley Affiliates

Headquarters:

400 Providence Mine Road

Nevada City, CA 95945

United States

15655 SW Greystone Ct.

Beaverton, OR 97006

United States

Brunnenweg 9

D-64331 Weiterstadt

Germany

Kapittelweg 10

4827 HG Breda

The Nederlands

2300 So. Decker Lake Blvd.

Salt Lake City, UT 84119

United States

Including its implementation, meets the requirements of the standard:

ISO 9001:2008

Scope:

The design, manufacture and support of video and audio hardware and software products and related

systems.

This Certificate is valid until: June 14, 2012

This Certificate is valid as of: December 23, 2010

Certified for the first time: June 14, 2000

H. Pierre Sallé

President

KEMA-Registered Quality

The method of operation for quality certification is defined in the KEMA General Terms And Conditions For

Quality And Environmental Management Systems Certifications. Integral publication of this certificate is allowed.

KEMA-Registered Quality, Inc.

4377 County Line Road

Chalfont, PA 18914

Ph: (215)997-4519

Fax: (215)997-3809

CRT 001 042108

ccredited By:

ANAB

A

Page 3

KAYENNE

VIDEO PRODUCTION CENTER

Installation Planning Guide

071869003

AUGUST 2011

Page 4

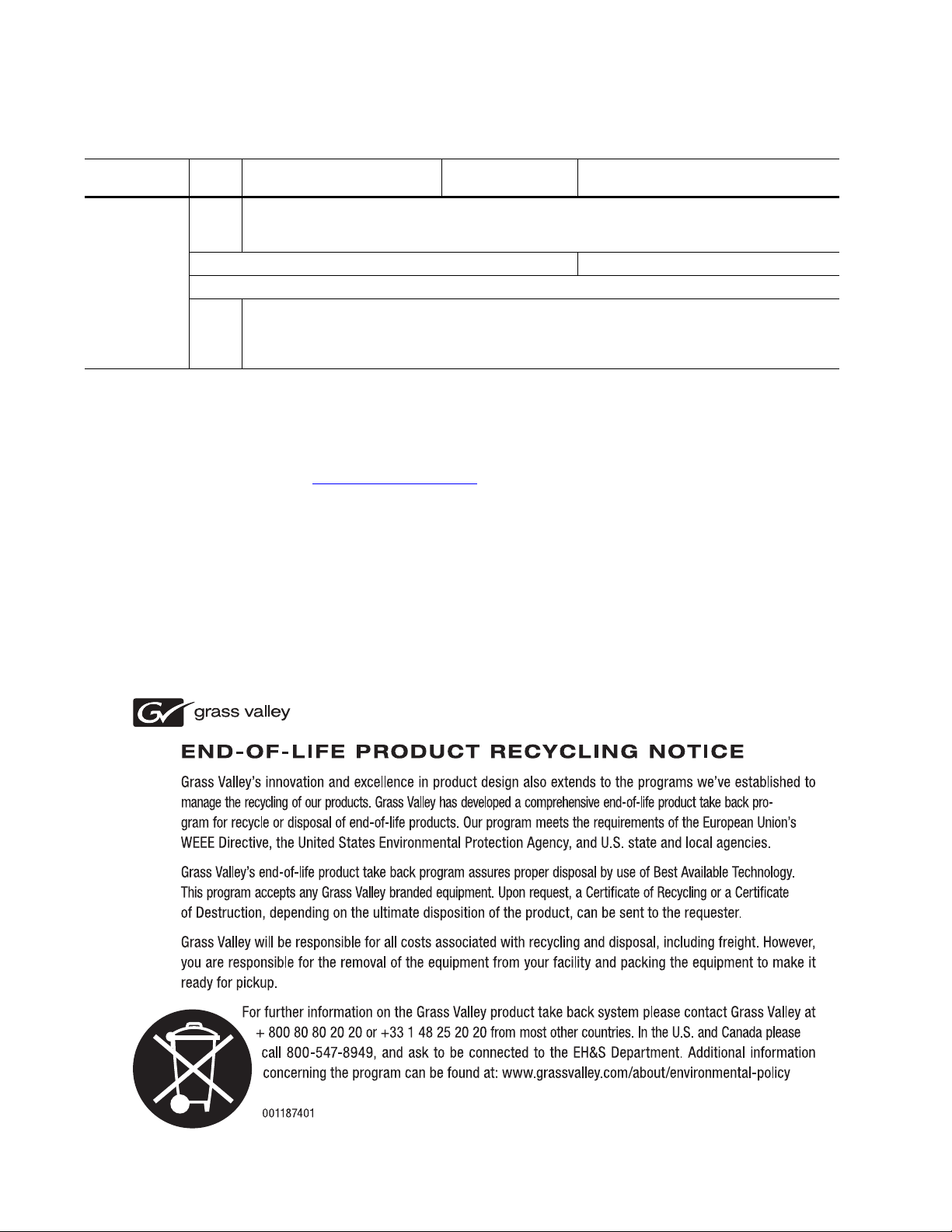

Contacting Grass Valley

International

Support Centers

Local Support

Centers

(available

during normal

business hours)

France

24 x 7

Australia and New Zealand: +61 1300 721 495 Central/South America: +55 11 5509 3443

Middle East: +971 4 299 64 40 Near East and Africa: +800 8080 2020 or +33 1 48 25 20 20

Europe

+800 8080 2020 or +33 1 48 25 20 20

Hong Kong, Taiwan, Korea, Macau: +852 2531 3058 Indian Subcontinent: +91 22 24933476

Asia

Southeast Asia/Malaysia: +603 7805 3884 Southeast Asia/Singapore: +65 6379 1313

China: +861 0660 159 450 Japan: +81 3 5484 6868

Belarus, Russia, Tadzikistan, Ukraine, Uzbekistan: +7 095 2580924 225 Switzerland: +41 1 487 80 02

S. Europe/Italy-Roma: +39 06 87 20 35 28 -Milan: +39 02 48 41 46 58 S. Europe/Spain: +34 91 512 03 50

Benelux/Belgium: +32 (0) 2 334 90 30 Benelux/Netherlands: +31 (0) 35 62 38 42 1 N. Europe: +45 45 96 88 70

Germany, Austria, Eastern Europe: +49 6150 104 444 UK, Ireland, Israel: +44 118 923 0499

Copyright © Grass Valley USA, LLC. All rights reserved.

This product may be covered by one or more U.S. and foreign patents.

United States/Canada

24 x 7

+1 800 547 8949 or +1 530 478 4148

Grass Valley Web Site

The www.grassvalley.com web site offers the following:

Online User Documentation — Current versions of product catalogs, brochures,

data sheets, ordering guides, planning guides, manuals, and release notes

in .pdf format can be downloaded.

FAQ Database — Solutions to problems and troubleshooting efforts can be

found by searching our Frequently Asked Questions (FAQ) database.

Software Downloads — Download software updates, drivers, and patches.

4 KAYENNE — Installation Planning Guide

Page 5

Contents

Section 1 — Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Section 2 — Kayenne Control Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Kayenne Video Processor Frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Kayenne Control Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Multiple Suites and Control Surfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Flat or Curved Control Panel Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Control Panel Stripes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Control Panel Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Touch Screen Menu Panel and PC Menu Control . . . . . . . . . . . . . . . . . . . . . . . . 13

Panel Control Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Redundant Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Supported Control Protocols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Control Panel Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Support Structure Assembly Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Control Panel Variations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Control Panel Cooling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Truck and High Vibration Environment Considerations . . . . . . . . . . . . . . . . . . 16

4-ME 35 Control Panel, Curved Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4-ME 35 Control Panel, Flat Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4-ME 25 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3-ME 35 Control Panel, Curved Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3-ME 35 Control Panel, Flat Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3-ME 25 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2-ME 35 Control Panel, Curved Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2-ME 35 Control Panel, Flat Assembly with Local Aux. . . . . . . . . . . . . . . . . . . . 29

2-ME 35 Control Panel, Flat without Local Aux . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2-ME 25 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

1-ME 15 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Separately Mounted Local Aux Stripe (35 & 25 Models) . . . . . . . . . . . . . . . . . . 34

Control Panel Stripe-PCU Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Touch Screen Menu Panel Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Menu Panel Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Menu Panel Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Menu Panel Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Menu Panel Articulated Arm Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Additional Kayenne Menu Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Touch Screen Menu Panel Using PCU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Touch Screen Menu Panel Using PC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Menu Application on PC (Keyboard & Mouse) . . . . . . . . . . . . . . . . . . . . . . . . 38

KAYENNE — Installation Planning Guide 5

Page 6

Contents

Section 3 — Kayenne Frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

General Rack Mounting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Weight Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Cooling Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Power Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

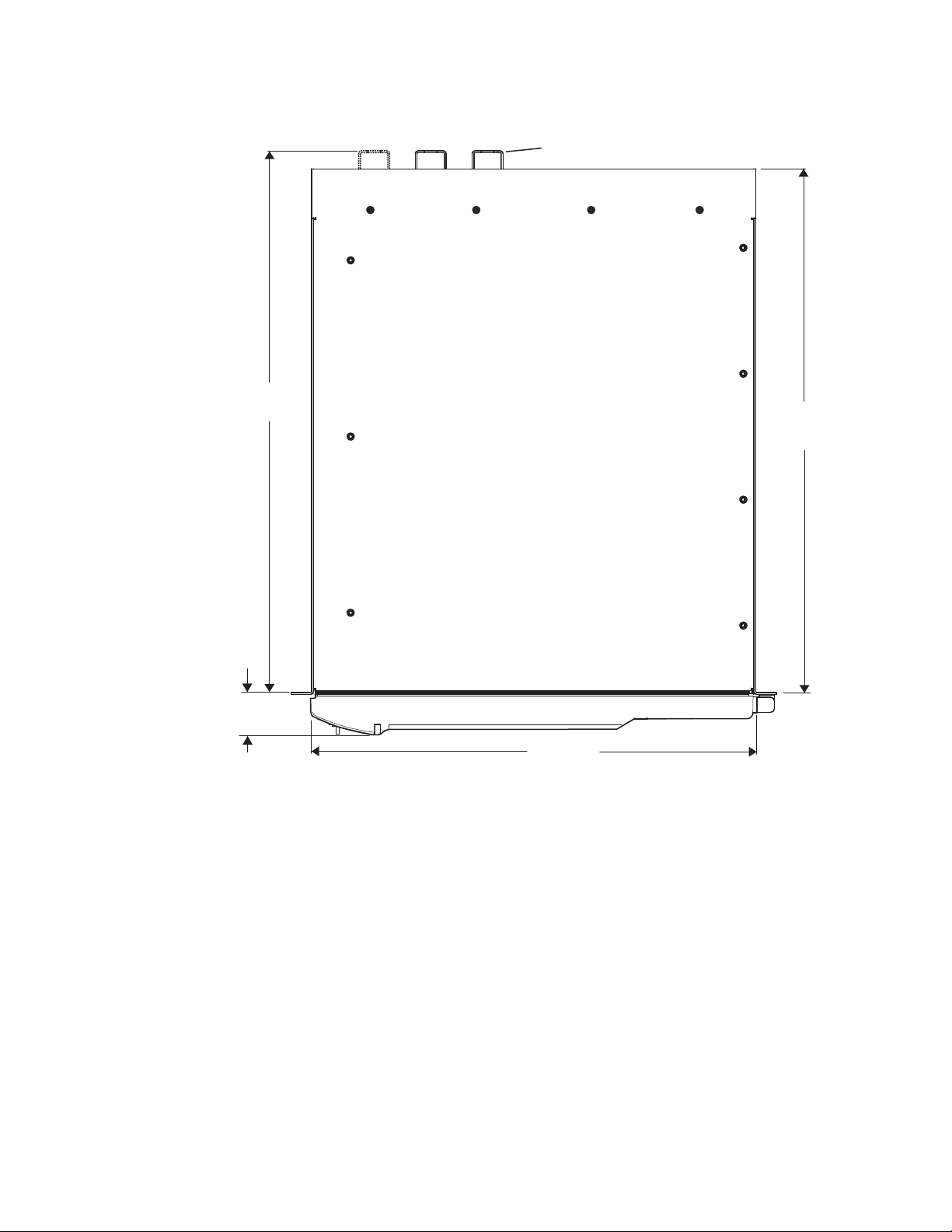

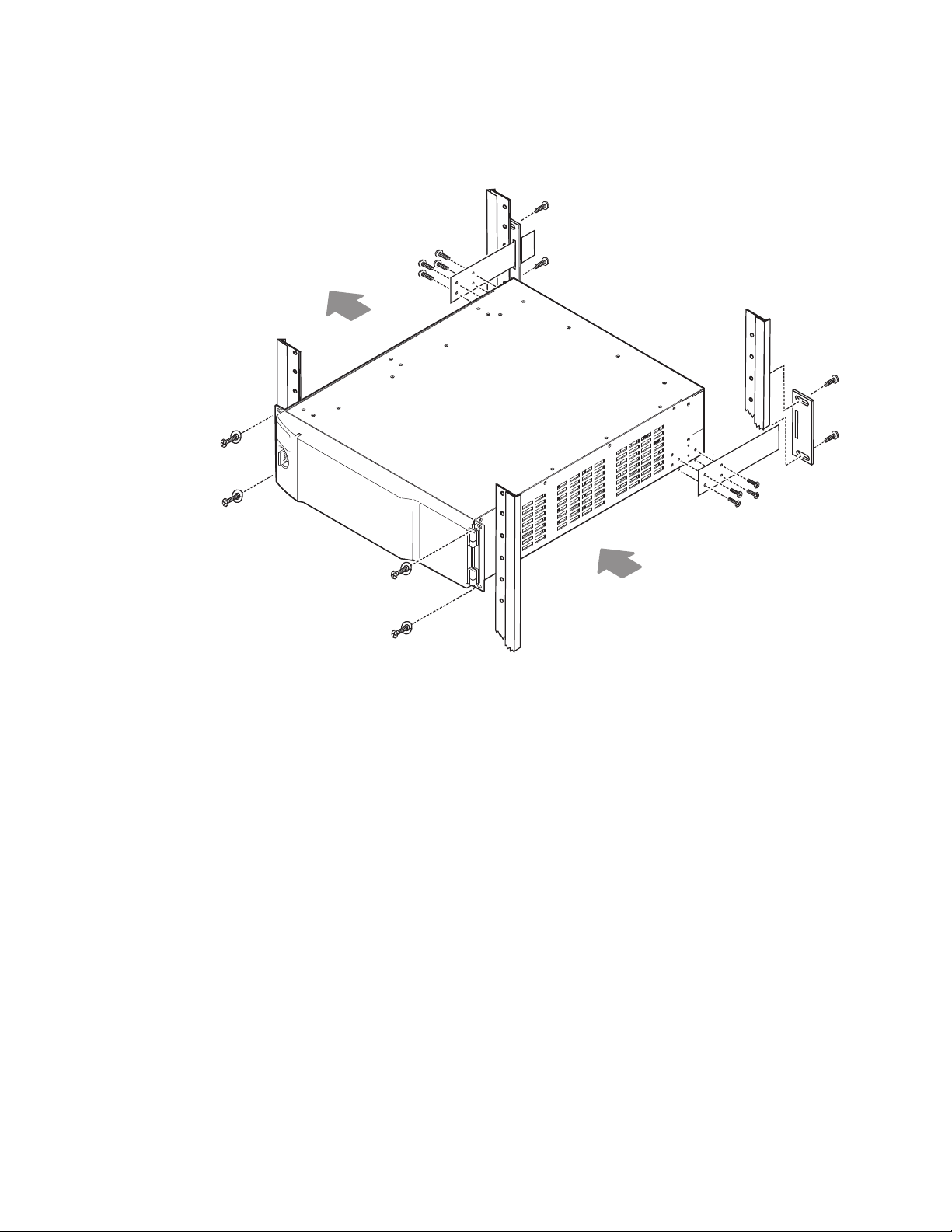

Kayenne 8-RU Video Processor Frame Installation . . . . . . . . . . . . . . . . . . . . . . . . 40

8-RU Frame Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8-RU Frame Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Door Removal Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8-RU Frame Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8-RU Frame Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

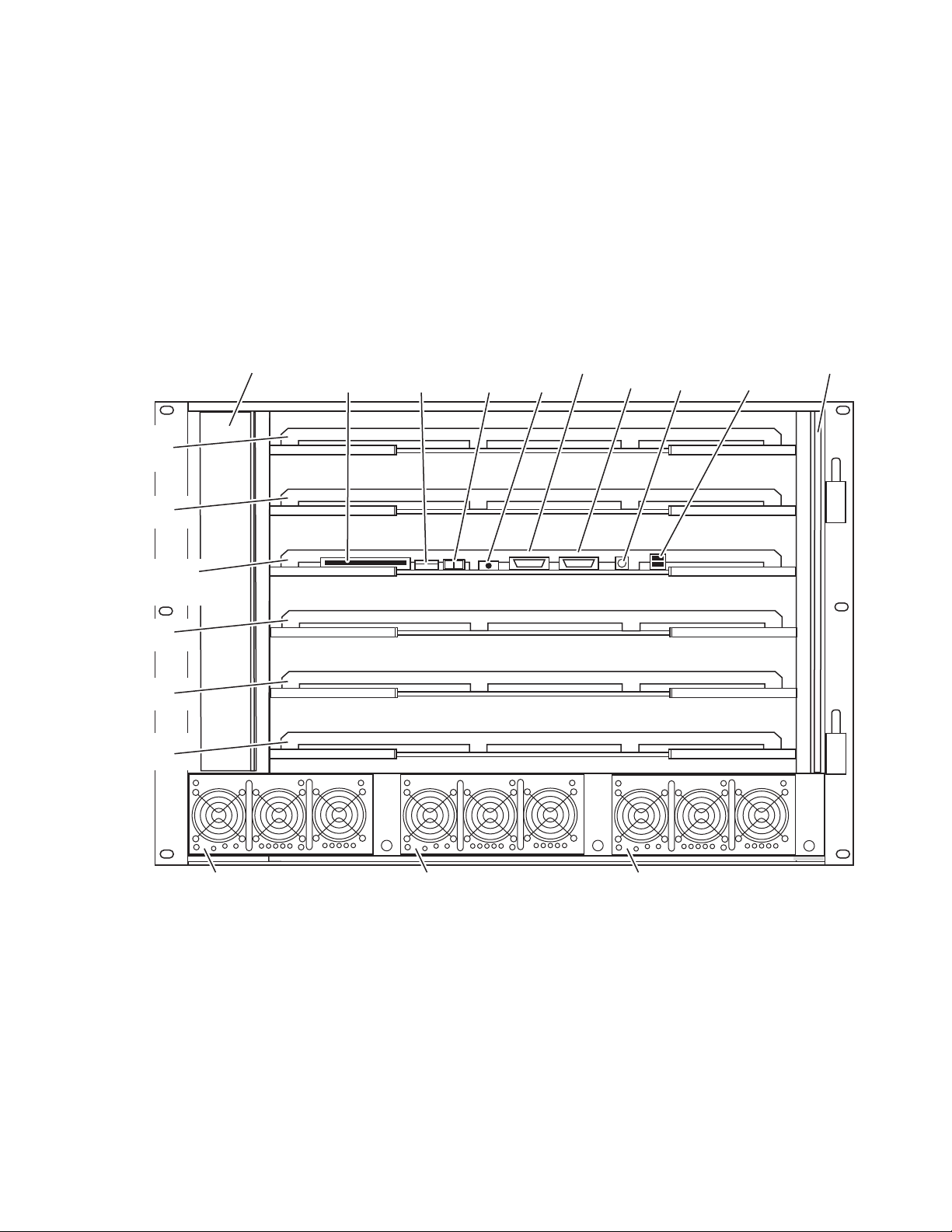

Kayenne 4-RU Video Processor Frame Installation . . . . . . . . . . . . . . . . . . . . . . . . 45

4-RU Frame Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4-RU Frame Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Door Removal Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4-RU Frame Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4-RU Frame Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

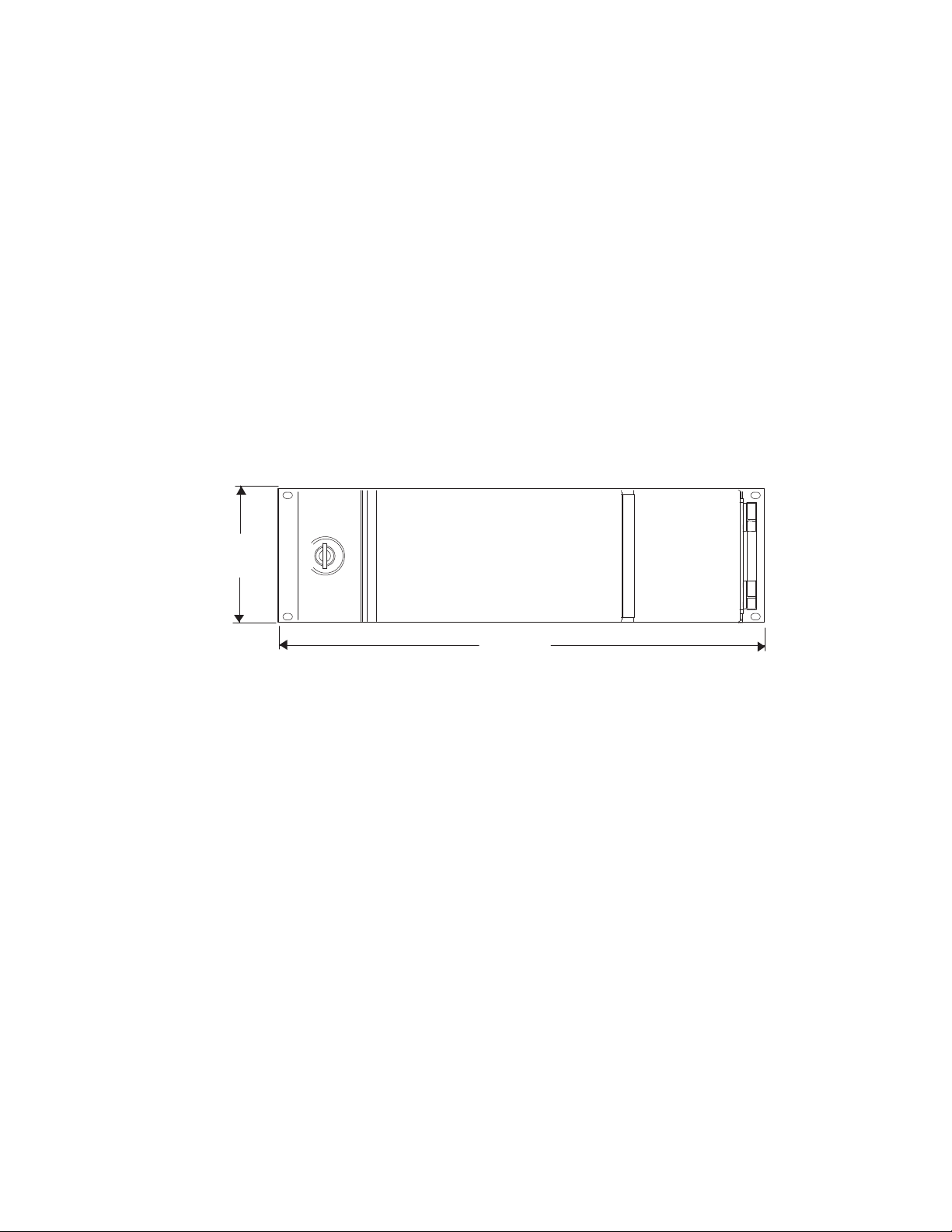

Panel Control Unit (PCU) Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

PCU Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

PCU Frame Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Door Removal Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

PCU Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

PCU Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Section 4 — System Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Network Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Suites and Control Surfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Customer Supplied Ethernet Routers and Switches . . . . . . . . . . . . . . . . . . . . 56

Factory Default Network Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Control Surface Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

ME and Local Aux Stripe Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Satellite Panel Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

PCU Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Internal Cabling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Touch Screen Menu Panels (Used with PCU) . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Video Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

MatchDef and SetDef Format Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Reference Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Video Processor Frame GPI/Tally Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

GPI and Tally Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

GPI Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Tally/GPI Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

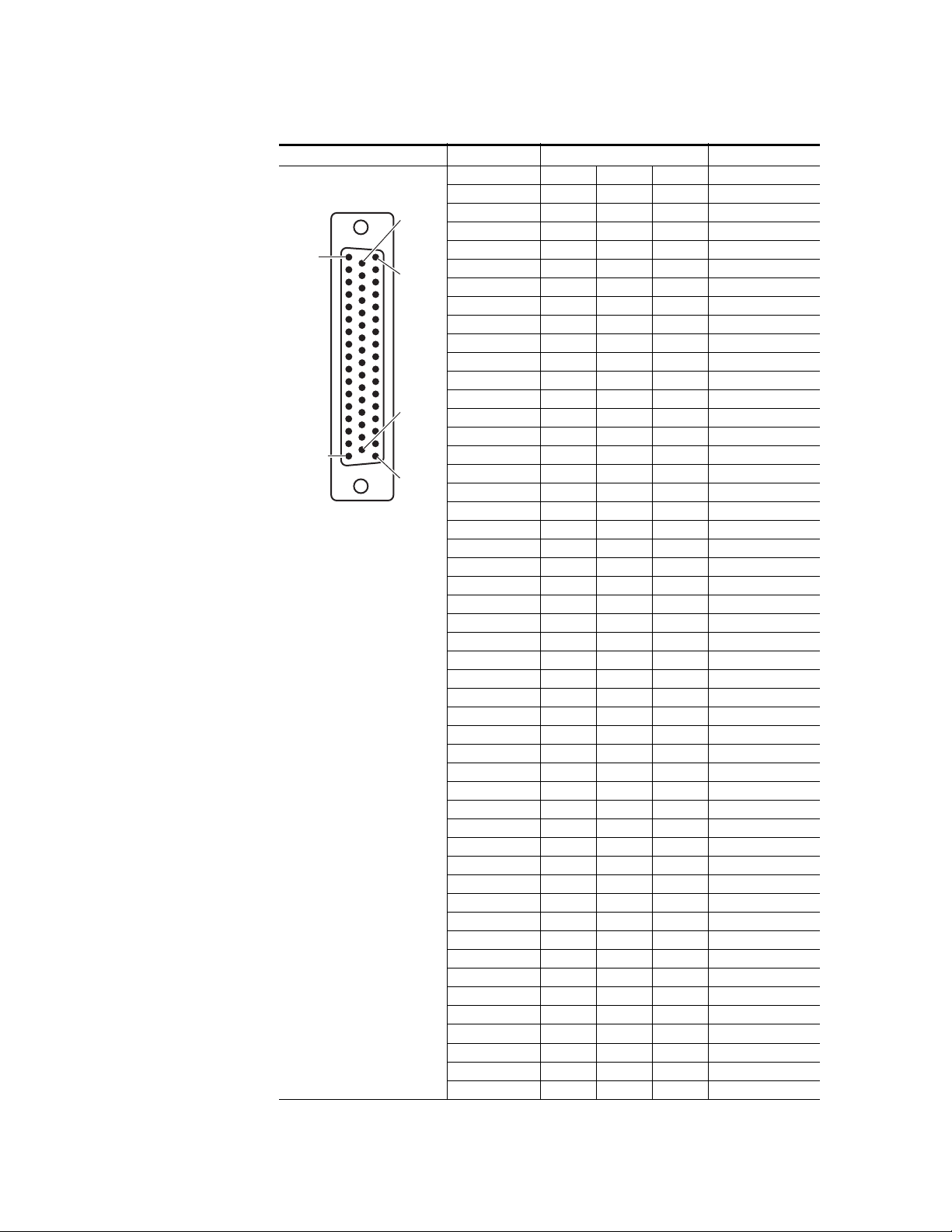

Pin Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

RS-422/485 Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

RS-232 Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4-RU and 8-RU Frame (GPI In 1-8, Tally 1-24, GPI Out 1-8) . . . . . . . . . . . . . . . 67

4-RU and 8-RU Frame (GPI In 9-16, Tally 25 - 48, GPI Out 9-16) . . . . . . . . . . . 68

8-RU Frame (GPI In 17-24, Tally 49 - 72, GPI Out 17-24) . . . . . . . . . . . . . . . . . . 69

8-RU Frame (GPI In 25-32, Tally 73 - 96, GPI Out 25 - 32) . . . . . . . . . . . . . . . . . 70

6 KAYENNE — Installation Planning Guide

Page 7

Appendix A — Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Contents

KAYENNE — Installation Planning Guide 7

Page 8

Contents

8 KAYENNE — Installation Planning Guide

Page 9

Introduction

Kayenne 8-RU

Video Processor Frame

Kayenne 4-RU

Video Processor Frame

Note For reader convenience this identical Section 1 is included at the beginning

Overview

The Grass Valley Kayenne family of multi-format digital production

switchers provides powerful, ground-breaking features designed to meet

the widest range of requirements for live studio, mobile, and post-produc

tion applications. Available in configurations ranging from 1.5-ME to

4.5-MEs, Kayenne systems combine features and functionality available in

the current Grass Valley Kalypso, KayakHD, and XtenDD switchers along

with additional capabilities previously unavailable in any video produc

tion switcher from any manufacturer. A wide variety of possible Kayenne

system configurations exist to meet different customer requirements.

Section 1

of each Kayenne manual. If you are already familiar with this material you can

skip to the next section.

-

-

Kayenne Video Processor Frames

KAYENNE — Installation Planning Guide 9

The Kayenne Video Processor Frame is available in two sizes. The 8-RU full

size frame supports up to 4.5 ME systems. The 4-RU compact frame sup

ports 1.5-ME through 2.5-ME Kayenne systems (Figure 1). The number of

licensed boards present in the Kayenne frame determines the number of

MEs available, as well as the number of video inputs, outputs, GPIOs and

Relay Tallies.

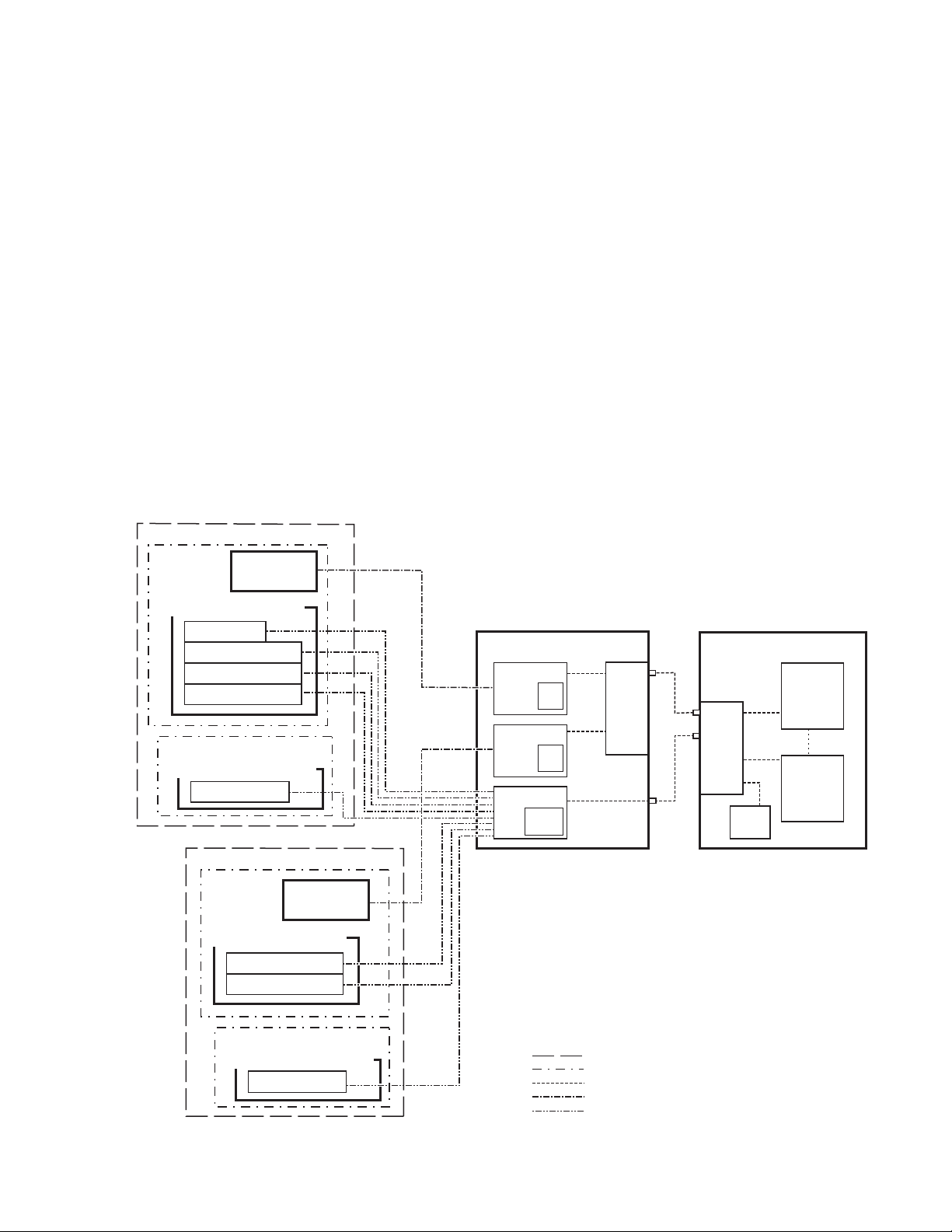

Figure 1. Kayenne Video Processor Frames

-

Page 10

Section 1 — Introduction

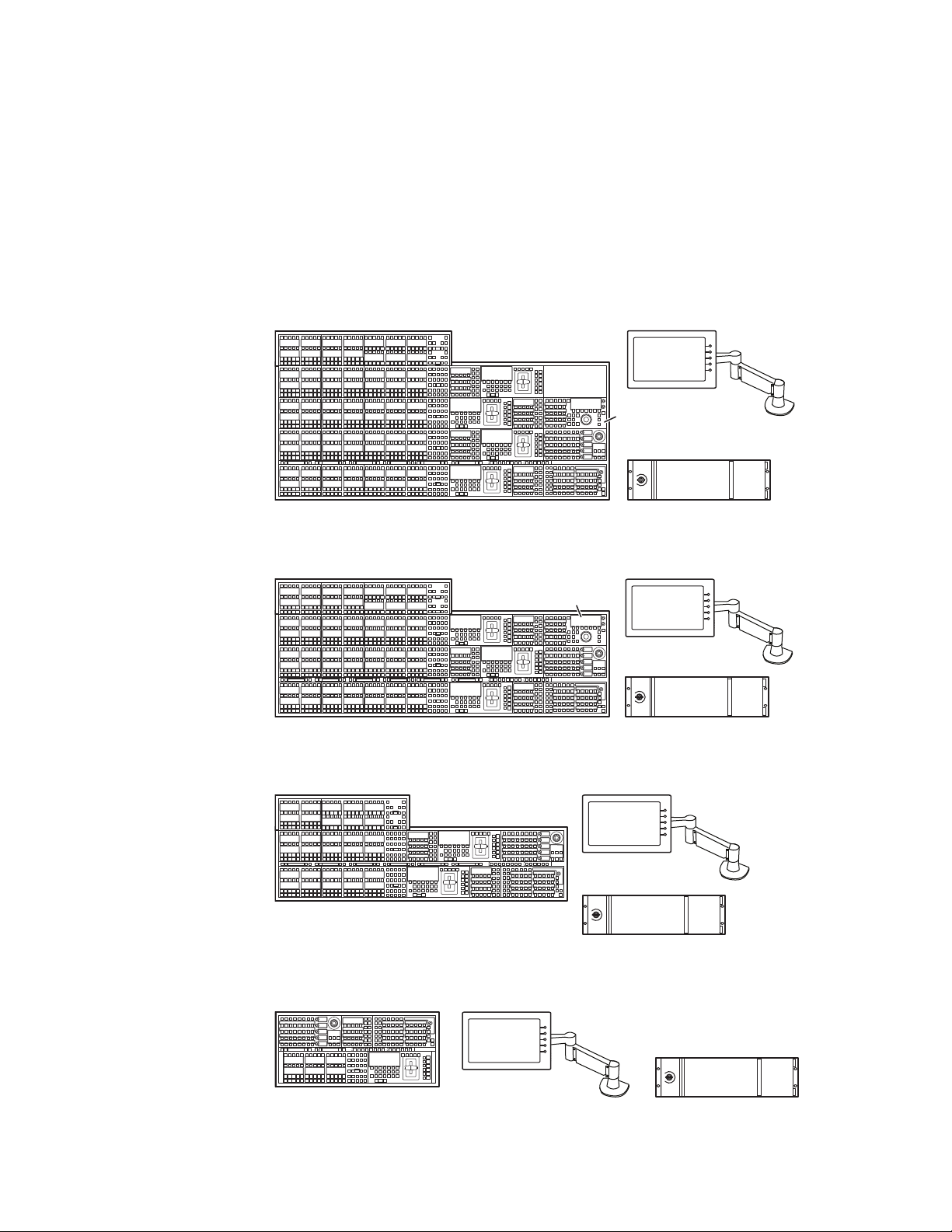

4-ME 35 Control Panel Menu Panel

Menu Panel

Articulated

Arm

8623266_01

Panel Control Unit (PCU)

Optional Device

Control Module

Optional

Module

Menu Panel

Menu Panel

Articulated

Arm

8623266_02

Panel Control Unit (PCU)

3-ME 35 Control Panel

Optional Device

Control Module

Menu Panel

Menu Panel

Articulated

Arm

8623266_03

Panel Control Unit (PCU)

2-ME 25 Control Panel

Menu Panel

Menu Panel

Articulated

Arm

8623266_04

Panel Control Unit (PCU)

1-ME 15 Control Panel

Kayenne Control Surfaces

A Kayenne control surface typically consists of a Control Panel, a Menu

Panel with an included articulated support arm, a Panel Control Unit

(PCU) frame, and optional Satellite Panels. This control surface has an

innovative modular design. Representative Kayenne control surfaces are

shown in the following illustrations.

Figure 2. Kayenne 4-ME 35 Control Surface

Figure 3. Kayenne 3-ME 35 Control Surface

Figure 4. Kayenne 2-ME 25 Control Surface

Figure 5. Kayenne 1-ME 15 Control Surface

10 KAYENNE — Installation Planning Guide

Page 11

The modular design and use of a separate PCU supports the hot-replace-

Flat Control Panel AssemblyCurved Control Panel Assembly

ment of individual Control Panel components, if necessary, while the rest

of the system remains operational.

Multiple Suites and Control Surfaces

A Kayenne system can be subdivided into two suites, if desired, each of

which can have two control surfaces. Hardware resources in the Video Pro

cessor Frame can be assigned to an individual suite during configuration,

essentially creating two separate switchers from one Kayenne system. A

Kayenne PCU can support two control surfaces using its eight available

ports.

Flat or Curved Control Panel Orientation

The main Kayenne Control Panel supports different physical orientations.

Besides a conventional flat surface, a special support design permits a

curved working surface, where the MEs progressively tilt for improved

ergonomics (

Figure 6).

Kayenne Control Surfaces

-

Figure 6. Curved and Flat Control Surface Installations

KAYENNE — Installation Planning Guide 11

Page 12

Section 1 — Introduction

Hold

Hold

A

Hold

BU1U2

Hold

Far

Key

Split

Rules

Hold

EMEM

Sec

Aux

Pri

Key

3

Key

1

Macro

Key

5

Key

4

Key

2

RtrKeKey

6

EMEM

Macroro

Rev

Rwd

Run

Tr

ans

Rate

Auto

Run

Pa

nel

Mem

Menu

Mix

Transns

PVW

Tr

ans

Rate

EMEM

Runun

Ptntn

Limit

Pst

BLK

Key

1

Key

2

Key

3

Key

4

Key

5

Key

6

Key1

Cut

Key2

Cut

Key4

Cut

Key3

Cut

Key6

Cut

Key5

Cut

Key1

Auto

Key2

Auto

Key3

Auto

Key4

Auto

Key6

Auto

Cut

Auto

Key5

Auto

Userer5Userer

6

Userer4W

ipe2W

ipe

1

Userer3Userer2Userer

1

Key

Prior

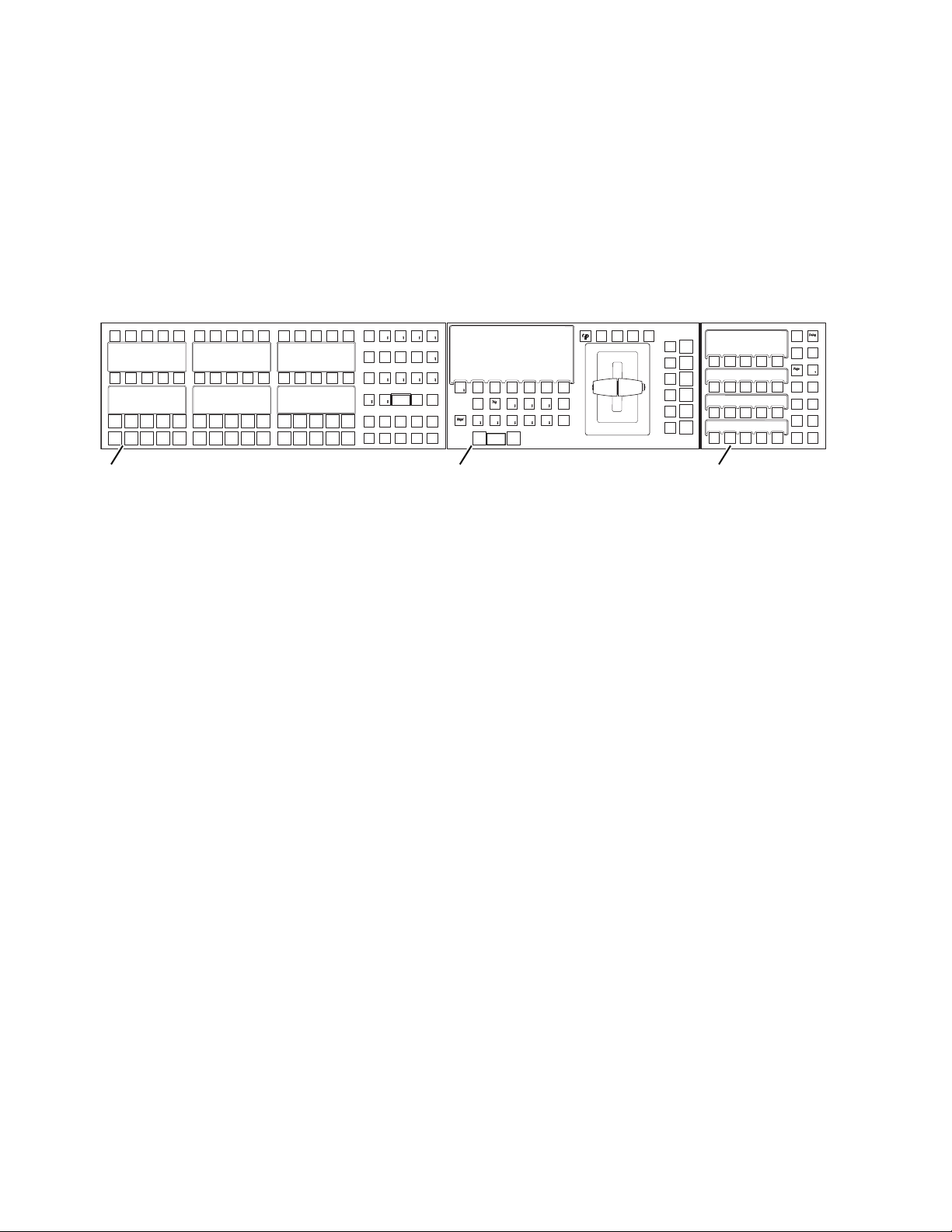

Control Panel Stripes

The main Kayenne Control Panel is organized into from one to five Stripes.

Each Stripe consists of a tray and its complement of drop-in modules. An

ME Stripe has a module for Source Selection, Transition, and individual

E-MEM control (Figure 7). Additional Master E-MEM, Machine Control,

Multi-Function, and Local Aux modules are populated to complete the

control surface functionality.

Figure 7. Portion of Control Panel ME Stripe

Key

Key

Hold

Key

Spl

Hold

Hold

Hold

Source Module (35, 25, or 15) Local E-MEM ModuleTransition Module

Key

Macro

Far

Key

Key

Rules

Sec

Hold

Key

EMEM

Key

ipe

ipe

Cut

ans

EMEM

Lim

Key

Key

Key

Key

Auto

Ke

Ke

Auto

Cut

Ke

Ke

Auto

Cut

Ke

Ke

Auto

Cut

Ke

Ke

Auto

Cut

Ke

Ke

Auto

Cut

Ke

Ke

Auto

Cut

EMEM

ans

nel

Rate

Mem

Me

Ma

Run

Rev

Rwd

Run

8623266_54

Control Panel Modules

The following Kayenne modules are available:

• KAYN-PNL-TRM - Transition Module

• KAYN-PNL-LEM - Local E-MEM Module

• KAYN-PNL-MEM - Master E-MEM Module

• KAYN-PNL-MFM - Multi-Function Module

• KAYN-PNL-SRC-35, 25, 15 - Source Module, available in 35, 25, and 15

button widths.

Note 15 button widths are only available with 1-ME Control Panels.

• KAYN-PNL-AUX-35, 25 - Local Aux Module, available in 35 and 25

button widths.

• KAYN-PNL-BAR-35, 15 - System Bar, available in two sizes to match

various Control Panel widths.

• KAYN-PNL-DCM - Device Control Module, available as an option for

3 and 4-ME panels and as a satellite panel module.

12 KAYENNE — Installation Planning Guide

Page 13

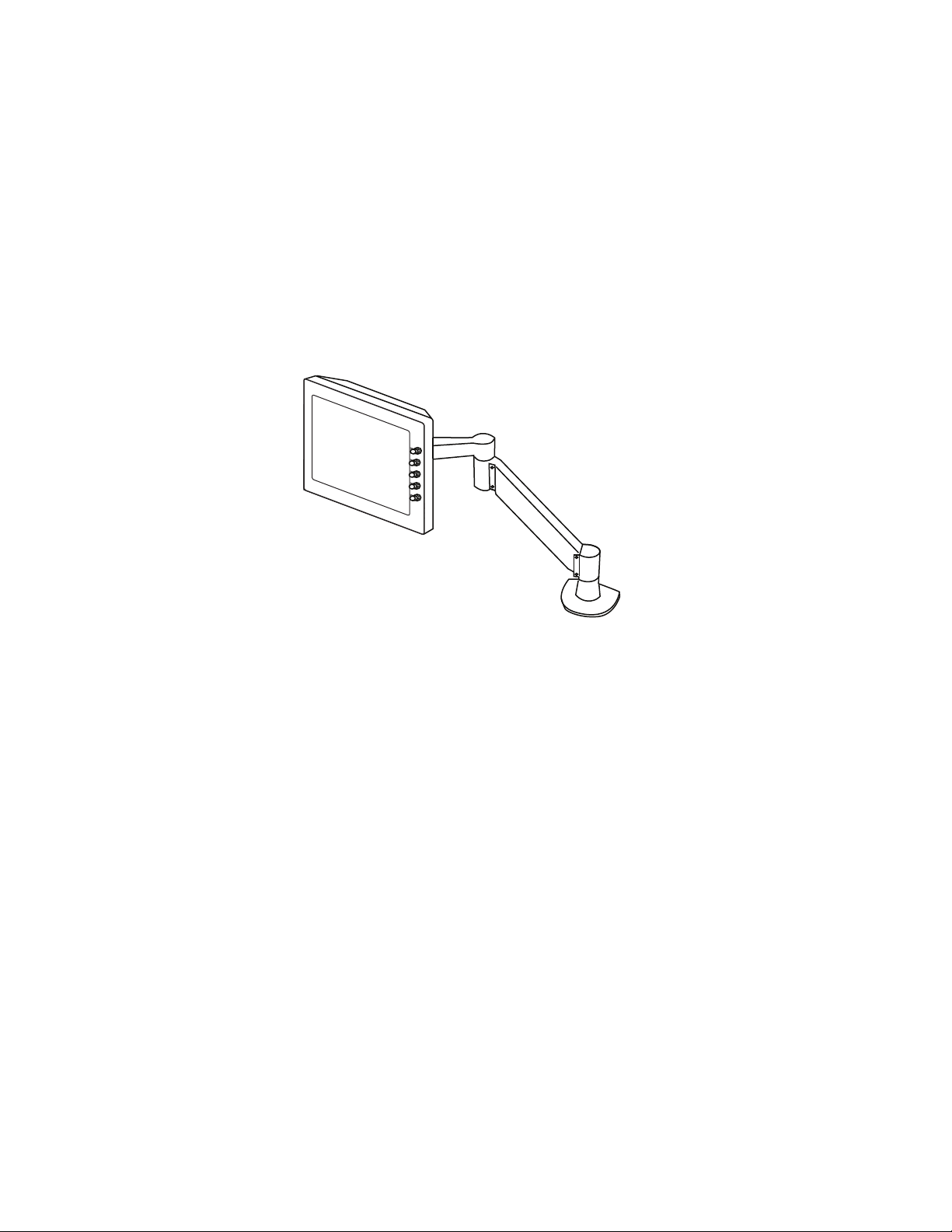

Touch Screen Menu Panel and PC Menu Control

Each Kayenne control surface includes a Menu Panel that features a wide

format 15 in. touch screen display. An articulated arm is also included,

offering a wide variety of installation options (Figure 8). The Menu Panel

has a standard VESA-75 hole pattern and M4 threads, compatible with this

and many other mounting devices.

The Menu Panel has four USB ports, two on the right side edge of the panel

and two on the back for keyboard and mouse (wired or wireless are sup

ported).

Figure 8. Menu Panel with Articulated Arm

Kayenne Control Surfaces

-

8623266_05

An additional touch screen Kayenne Menu Panel is available as an option

(additional Menu Controller Board is required in the PCU).

It is also possible to run the Kayenne Menu application on a standard PC,

permitting mouse and keyboard control from a laptop, or remote control

from any location on the network.

Panel Control Unit

The Kayenne Control Panel and Menu Panel(s) are powered from a separate rack mount Panel Control Unit (PCU). Control surface processing and

communications are handled by this unit. The PCU eliminates the need for

cooling fans in the Control Panel and Menu Panels, making for quiet

system operation.

KAYENNE — Installation Planning Guide 13

Page 14

Section 1 — Introduction

Redundant Power Supplies

Optional built-in redundant power supplies are available for the Kayenne

4-RU and 8-RU Frames. An additional redundant power supply is stan

dard with the Kayenne PCU.

Supported Control Protocols

All Kayenne systems support the following control interfaces and types of

external devices:

• Serial control of VTR/DDR (BVW, AMP, and Odetics protocols),

• Ethernet control of DDR channels (AMP protocol),

• Peripheral Bus II protocol,

• Tally (Contact Closure and Serial),

• GPI Inputs and Outputs,

-

• Routing Control Systems (Jupiter, Encore, SMS-7000, and third party

routers), and

• Grass Valley Editor protocol.

14 KAYENNE — Installation Planning Guide

Page 15

Section 2

Kayenne Control Surfaces

Overview

A typical Kayenne control surface has a modular Control Panel, a Menu

Panel, and is driven by a Panel Control Unit (PCU) frame. Additional Menu

Panels and Satellite Panels are available as options.

A Control Panel consists of system operation modules, which mount into

trays, which are in turn held in place by a Control Panel support structure.

One Control Panel tray filled with modules is called a Stripe. Various

numbers and types of modules and trays can be combined to create a wide

variety of control surface functionality.

The Control Panel and Menu Panel’s processing electronics are located in

the PCU. The Stripes and Menu Panels are connected to the PCU via multipin cables that carry power and communication signals.

Kayenne Control Panels ship to the customer as boxed Stripes, which are

assembled with the support structure on site. You will need to know what

Control Panel configuration(s) you intend to use at your facility in order to

plan your installation effectively.

The Kayenne Control Panel support kit uses 30mm series components

sourced from Bosch Rexroth.

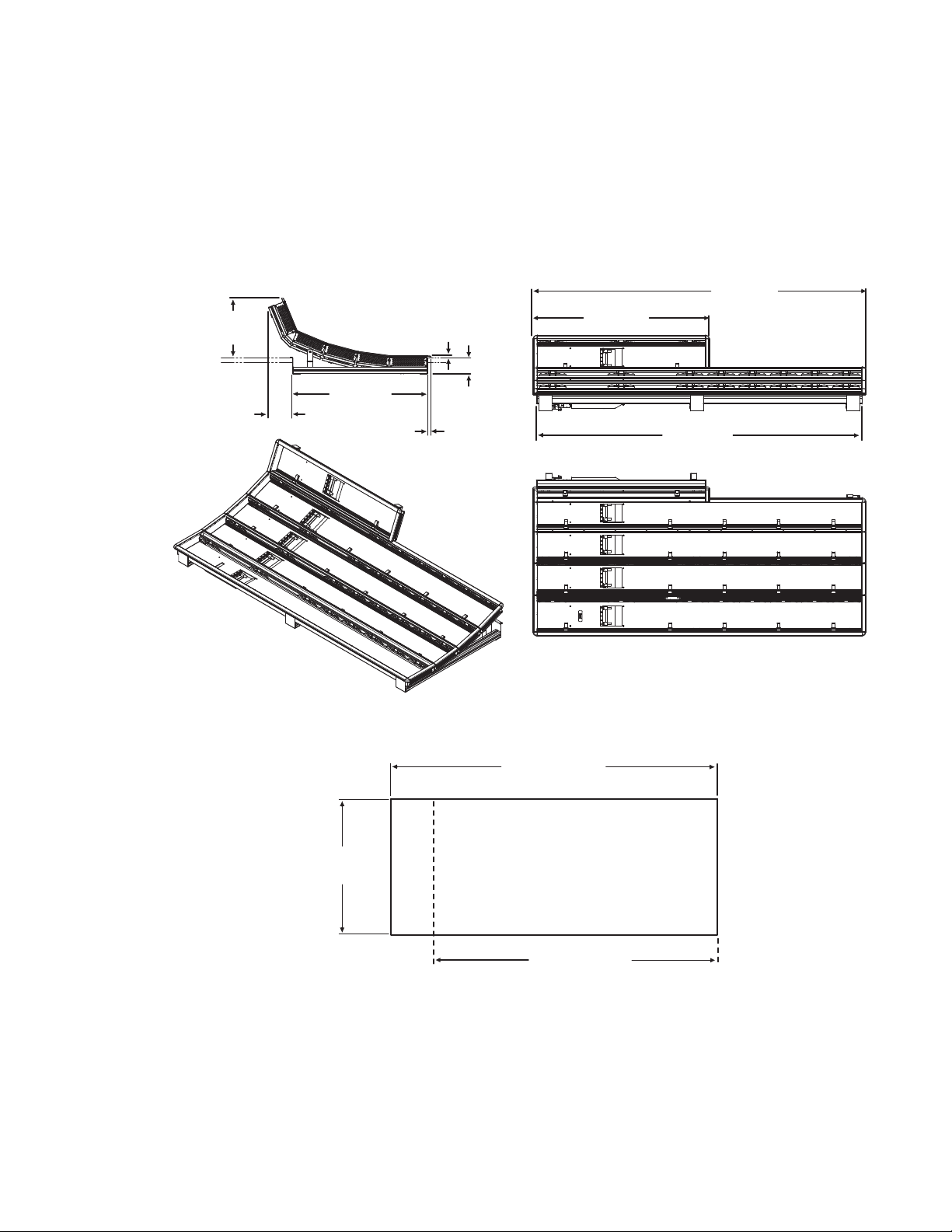

Control Panel Assembly

Support Structure Assembly Required

CAUTION Assembly of the Control Panel support structure is nontrivial. Do not attempt

assembly without first reading the detailed instructions in the separate

Kayenne Installation & Service Manual.

If you purchased commissioning with your Kayenne system, assembly of

the Control Panel support is included as part of the commissioning.

KAYENNE — Installation Planning Guide 15

Page 16

Section 2 — Kayenne Control Surfaces

If you did not purchase commissioning, but would like to reconsider the

option, contact Grass Valley Customer Support.

Control Panel Variations

Seven basic Control Panel assemblies are considered standard: 4-ME 35,

4-ME 25, 3-ME 35, 3-ME 25, 2-ME 35, 2-ME 25, and 1-ME 15. Each assembly

name identifies the number of MEs present and the number of source

selector buttons in each ME.

Two Control Panel Assembly orientations are possible, flat and curved. The

curved panel provides improved operator ergonomics. This orientation

raises the Control Panel height, so visibility of a monitor wall should be

considered prior to installation. An assembled Control Panel can be oper

ated from a tabletop, or it can be installed into a cutout.

The Local Aux Stripe can be connected to the Control Panel support structure at a 45 degree angle, or it can be mounted separately in its own backsplash cutout.

-

The following diagrams show some standard Control Panel assemblies. It

is also possible to create different Control Panel assemblies (for example, a

2-ME 35), since the parts are interchangeable. Specific information for nonstandard configurations is not included in this document.

Control Panel Cooling

The Kayenne Control Panel is externally powered and does not have

internal cooling fans. Electronics in the panel are convection cooled and

require free air movement. Do not install the panel into a sealed space.

CAUTION If the panel is mounted in a counter-top, do not enclose the

lower portion of the cutout. Leave the bottom open to allow

passive air movement.

Truck and High Vibration Environment Considerations

The Kayenne Control Panel has several bolt and screw tightened components. In high vibration environments these attachments could loosen over

time. Loctite Blue 242 or equivalent thread locking compound is recom

mended for these environments. This compound is designed to lock

threaded components together during assembly, but permits them to be

loosened if necessary later using hand tools.

-

During Control Panel assembly, apply a drop of the locking compound to

the ends of the threads of the support beam bolts, to the screws connecting

the cutout lip brackets to the support beams, and to the bolts attaching the

16 KAYENNE — Installation Planning Guide

Page 17

trays to the support beams. Make sure the locking compound is present

1533.7 mm

60.4 in.

8623266_12

813.5 mm

32.0 in.

1501.5 mm

59.1 in.

622.8 mm

24.5 in.

109.2 mm

4.3 in. 14.3 mm

0.6 in.

275.0 mm

10.8 in.

10.3 mm

0.4 in.

74.0 mm

2.9 in.

where the thread interfaces to each bolt or beam.

4-ME 35 Control Panel, Curved Assembly

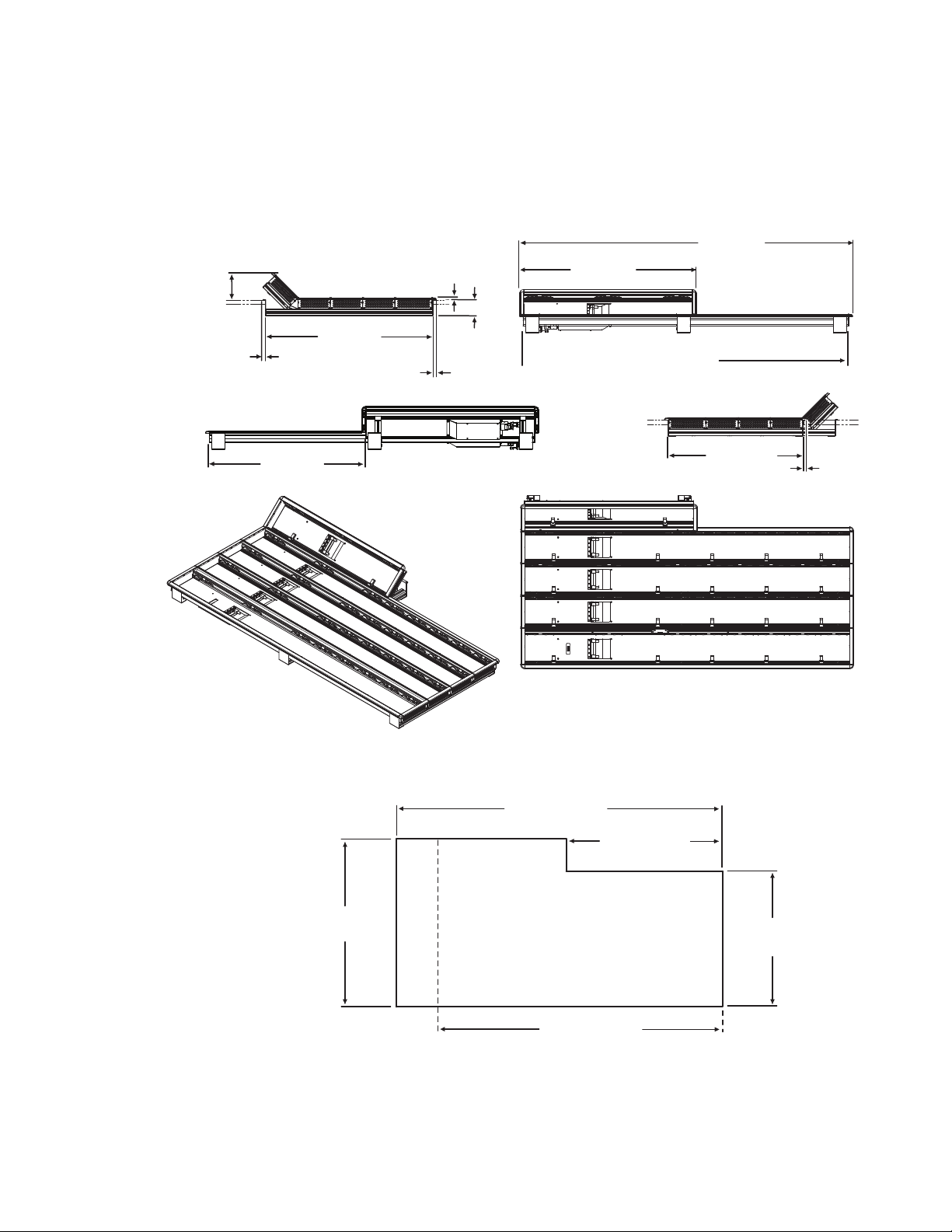

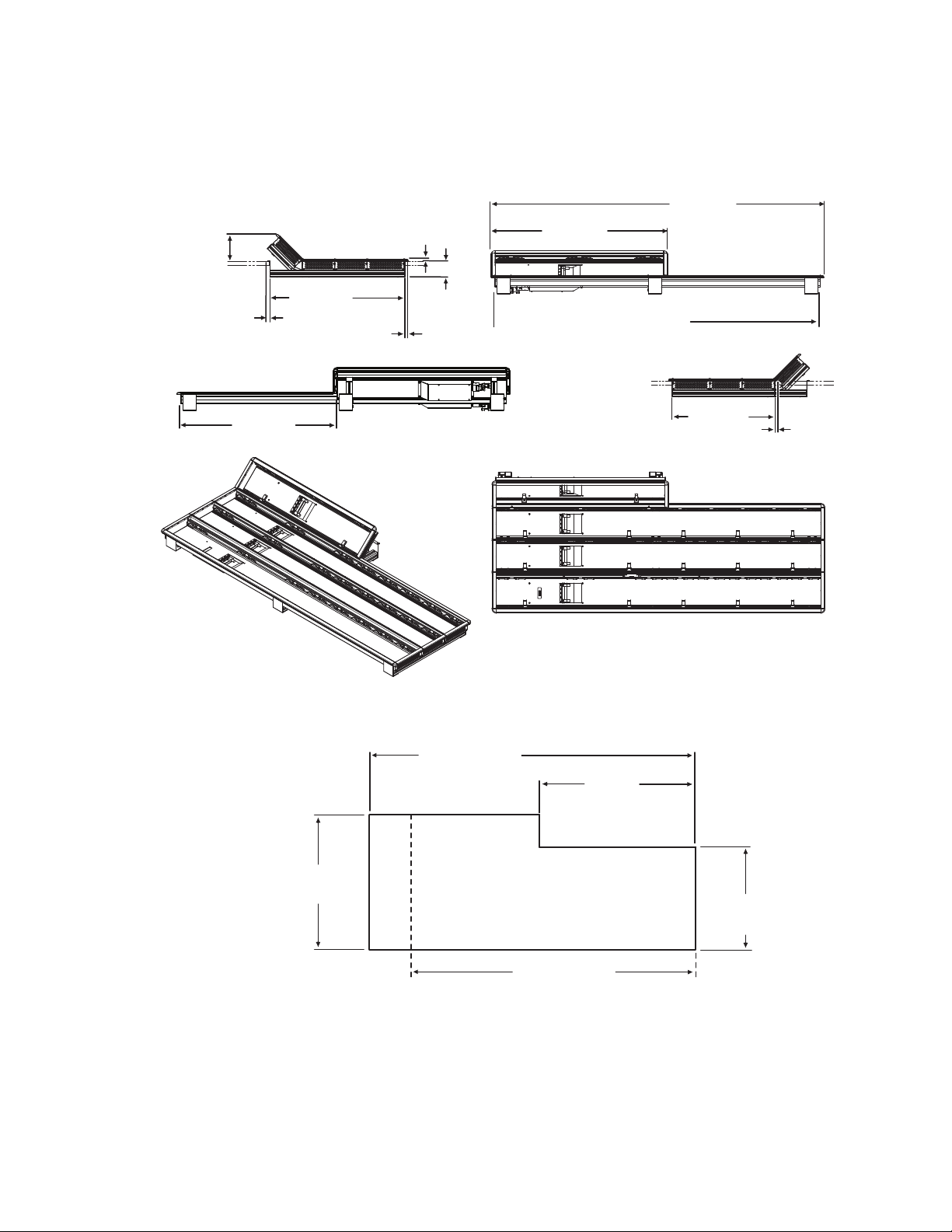

Figure 9. 4-ME 35 Control Panel Dimensions, Curved Installation

Control Panel Assembly

Figure 10. 4-ME Control Panel Cutout Dimensions, Curved Installation

4-ME 35 Panel Cutout

1503.5 +/-1 mm

59.2 +/-.04 in.

1311.5 +/-1 mm

51.6 +/-.04 in.

4-ME 25 Panel Cutout

625 +/-1 mm

24.6 +/-.04 i

n.

4-ME Panel Curved Install Cutout

8623266_14

KAYENNE — Installation Planning Guide 17

Page 18

Section 2 — Kayenne Control Surfaces

855 7 2700

855 7 2700

855 7 2700

8557 27 80

8557 2780

8557 27 80

8557 2 710

8557 27 10

8557 27 10

855 7 2710

8557 2 710

8557 2710

8557 27 10

855 7 2710

8557 27 10

8557 2710

855 7 2710

8620 3 170

862 0 3170

8620 31 70

855 7 2890

855 7 2890

855 7 2890

8557 28 90

855 7 2890

855 7 2890

B

DETAIL B

A

DETAIL A

8557 2830

8557 28 30

8557 2820

8557 2 820

855 7 2720

850 0 4420

6x

862 0 3200

6x

850 0 442 0

4x

855 7 2810

855 7 2860

862 0 3180

862 0 3180

850 0 7620

850 0 7620

862 0 3180

4x

8500 6460

4x

8620 3180

4x

8500 6460

4x

8620 3 180

4x

8500 6460

4x

850 0 6460

2x

850 0 6460

2x

850 0 6460

2x

862 0 3180

2x

862 0 3180

2x

855 7 2860

8620 3180

862 0 3180

8500 7620

850 0 7620

C

DETAIL C

8500 4 420

862 0 3200

862 0 3200

8500 44 20

8620 3180

862 0 3180

8620 3200

850 0 4420

862 0 3200

850 0 442 0

862 0 3180

2x

855 7 2810

855 7 2800

8500 4420

4x

862 0 3200

4x

862 0 3200

4x

855 7 2800

8622 5420

5x

862 2 5410

5x

8623266_13_r2

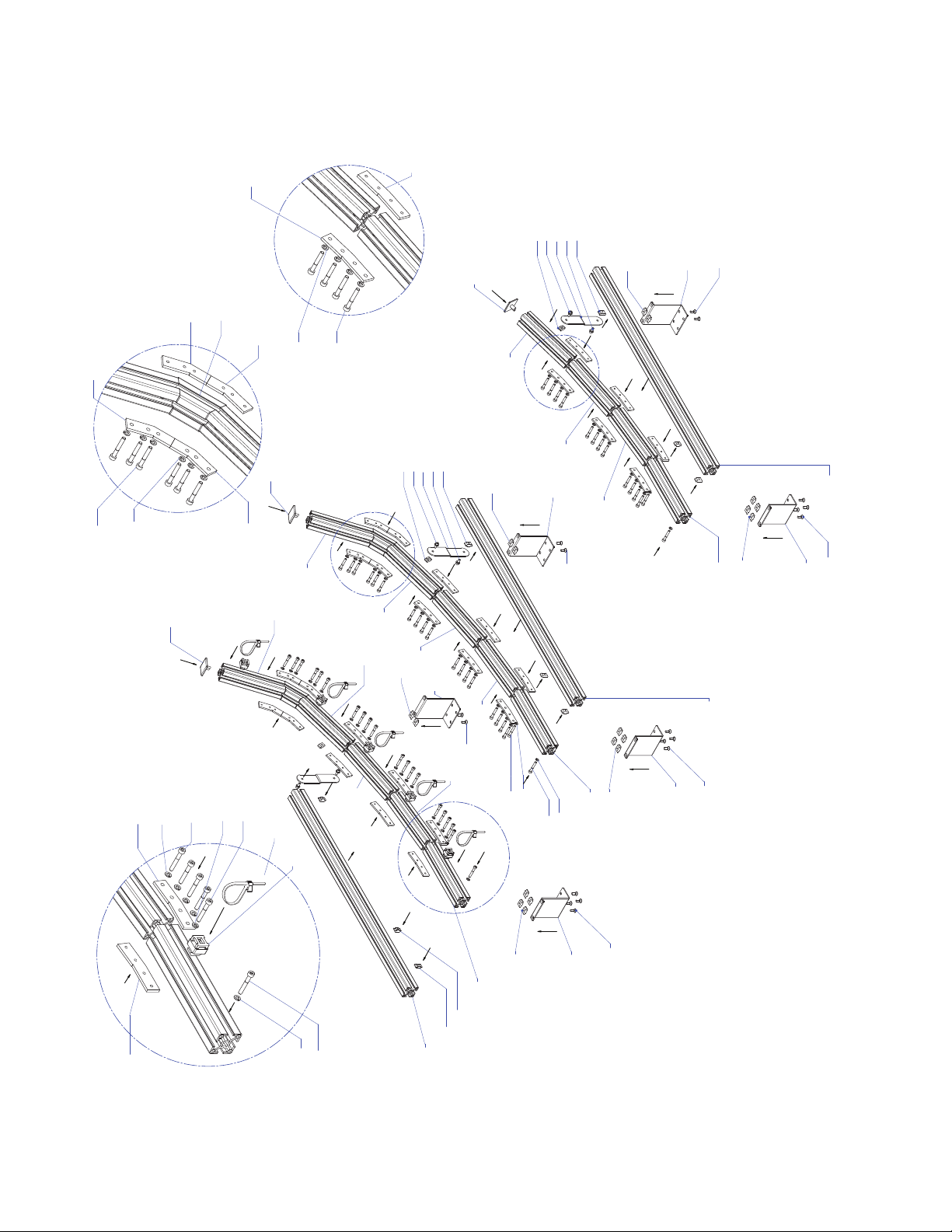

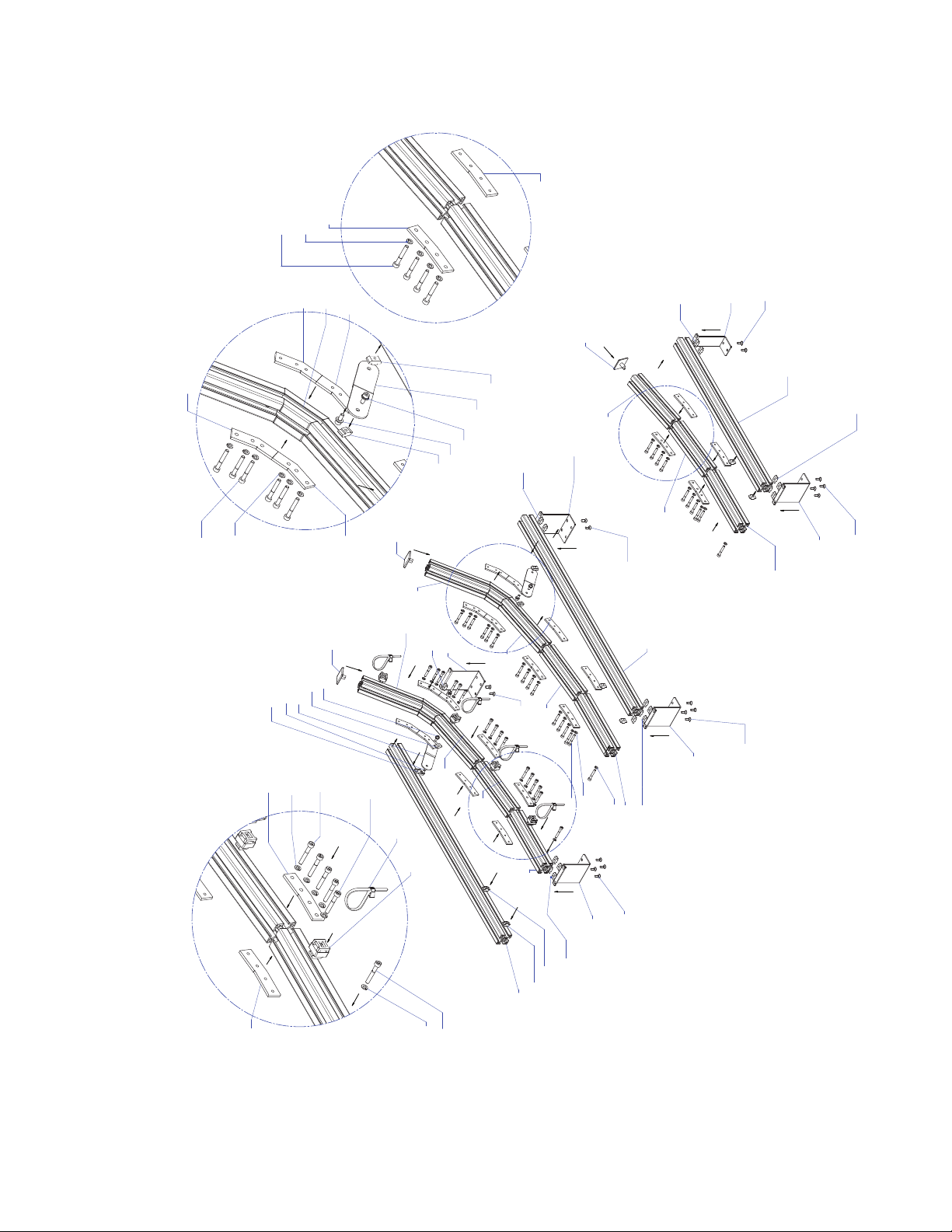

Figure 11. 4-ME Support Structure, Curved Installation

18 KAYENNE — Installation Planning Guide

Page 19

4-ME 35 Control Panel, Flat Assembly

1501.5 mm

59.1 in.

622.8 mm

24.5 in.

1533.7 mm

60.4 in.

813.5 mm

32.0 in.

771.5 mm

30.4 in.

10.4 mm

0.4 in.

14.1 mm

0.6 in.

124.0 mm

4.9 in.

10.3 mm

0.4 in.

74.0 mm

2.9 in.

720.0 mm

28.3 in.

14.3 mm

0.6 in.

8623266_17

Note Read through the entire procedure before you begin actual assembly.

Figure 12. 4-ME 35 Control Panel Dimensions, Flat Installation

Control Panel Assembly

Figure 13. 4-ME Control Panel Cutout Dimensions, Flat Installation

773.5 +/-1 mm

30.5 +/-.04 in.

4-ME 35 Panel Cutout

4-ME Panel Flat Install Cutout

1503.5 +/-1 mm

59.2 +/-.04 in.

28.3 in. +0-.04 in.

1311.5 +/-1 mm

51.6 +/-.04 in.

4-ME 25 Panel Cutout

720 +0-1 mm

625 +/-1 mm

24.6 +/-.04 in.

8623266_16

KAYENNE — Installation Planning Guide 19

Page 20

Section 2 — Kayenne Control Surfaces

8557 2780

8557 2710

8557 2710

8557 2890

8557 2890

8620 3180

2x

8500 6460

2x

8622 5410

5x

8622 5420

5x

855 7 2890

8620 3180

2x

8500 6460

2x

8557 2890

862 0 3180

2x

8500 6460

2x

855 7 2790

8557 2790

855 7 2890

862 0 3180

2x

8500 6460

2x

8557 2890

862 0 3180

2x

850 0 6460

2x

A

DE T A IL A

855 7 2720

8557 2830

855 7 2830

855 7 2820

8557 2820

8500 4420

6x

862 0 3200

6x

8620 3200

2x

850 0 442 0

2x

862 0 3180

2x

8620 3170

862 0 3180

2x

850 0 6460

2x

8620 3170

862 0 3170

862 0 3170

862 0 3170

855 7 2710

B

DETAIL B

855 7 2710

855 7 2720

8557 2710

855 7 2830

855 7 2830

855 7 2820

855 7 2820

862 0 3200

6x

8500 4420

6x

Figure 14. 4-ME Support Structure, Flat Installation

20 KAYENNE — Installation Planning Guide

Page 21

4-ME 25 Control Panel

Control panels with 25 source selection buttons are narrower in width, but

otherwise have the same dimensions as 35 source button models.

Figure 15. 4-ME 25 Control Panel Dimensions

275.0 mm

10.8 in.

124.0 mm

4.9 in.

4-ME 25 Curved Installation

1341.7 mm

621.5 mm

24.5 in.

4-ME 25 Flat Installation

1309.5 mm

52.8 in.

51.6 in.

Control Panel Assembly

8623266_32

KAYENNE — Installation Planning Guide 21

Page 22

Section 2 — Kayenne Control Surfaces

8623266_19

1533.7 mm

60.4 in.

813.5 mm

32.0 in.

1501.5 mm

59.1 in.

622.8 mm

24.5 in.

14.8 mm

0.6 in.

14.3 mm

0.6 in.

208.0 mm

8.2 in.

10.3 mm

0.4 in.

74.0 mm

2.9 in.

720.0 mm

28.3 in.

474.1 mm

18.7 in.

13.9 mm

0.5 in.

3-ME 35 Control Panel, Curved Assembly

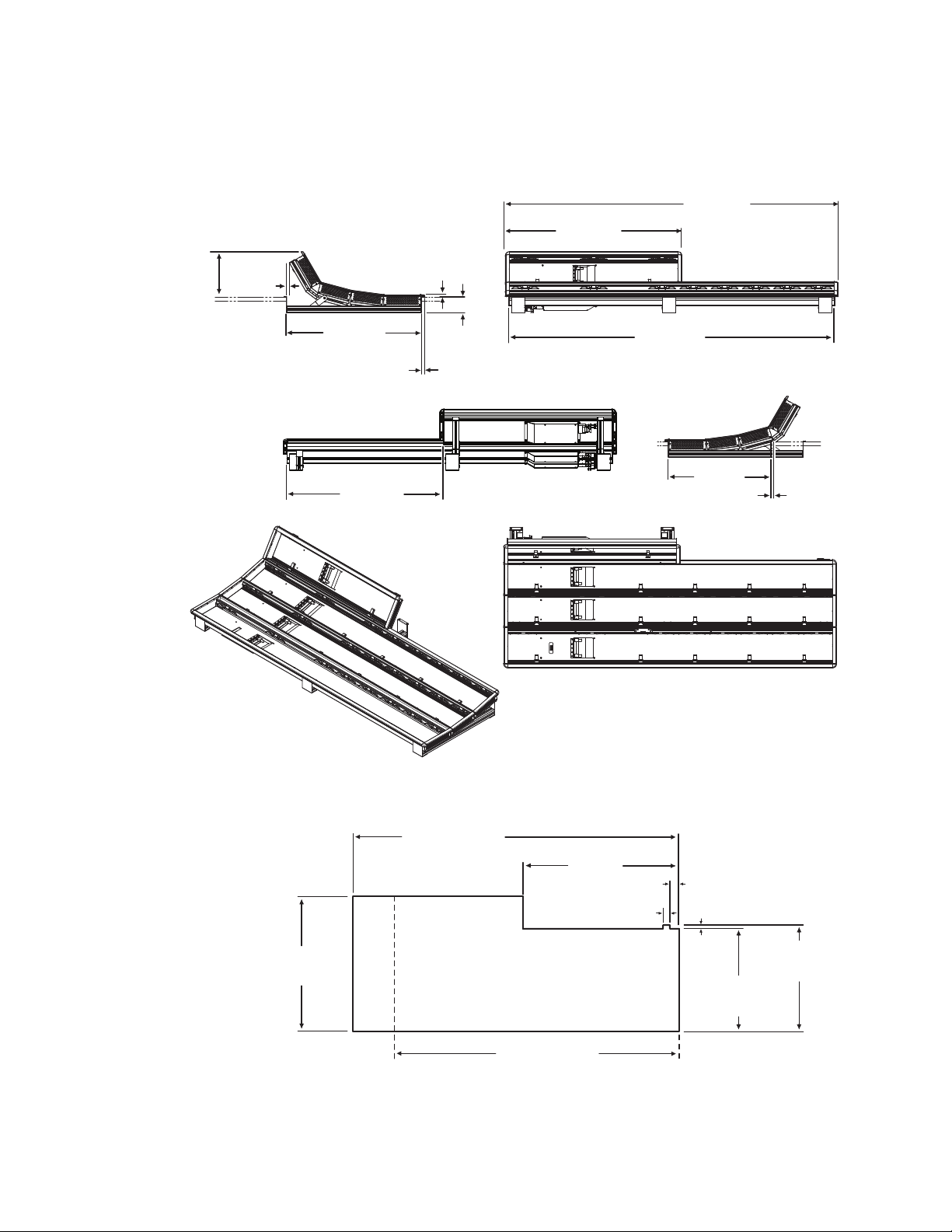

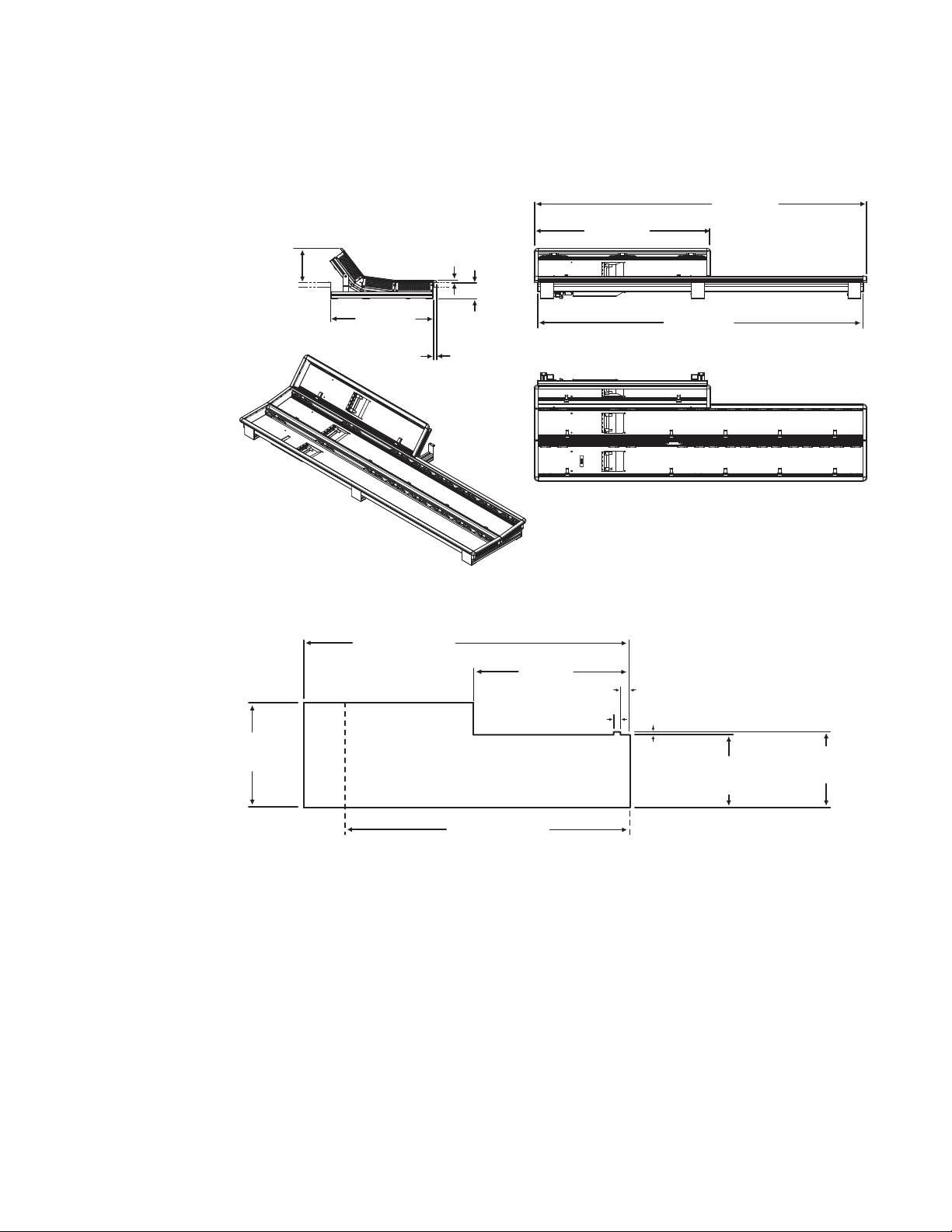

Figure 16. 3-ME 35 Control Panel Dimensions, Curved Installation

Figure 17. 3-ME Control Panel Cutout Dimensions, Curved Installation

3-ME 35 Panel Cutout

625.0 +/-1 mm

24.6 +/-.04 in.

1503.5 +/-1 mm

59.2 +/-.04 in.

3-ME Panel Curved Install Cutout

720 mm

28.3 in.

32.0 +2 -0 mm

1.3 +.08 in. -0 in.

1311.5 +/- 1 mm

51.6 +/- .04 in.

3-ME 25 Panel Cutout

42.5 +/-1 mm

1.7 +/-.04

15 mm

.60 in.

476.0 +/-1 mm

18.7 +/-.04 in.

491.0 +/-1 mm

19.3 +/-.04 in.

8623266_19_r1

22 KAYENNE — Installation Planning Guide

Page 23

Control Panel Assembly

855 7 2700

855 7 2700

8557 2700

8557 2780

8557 2710

8557 2 710

8557 2710

8557 27 10

8557 2710

8557 27 10

8557 2710

855 7 2710

862 0 3170

8620 3 170

8620 3170

855 7 2890

8557 2890

855 7 2890

855 7 2850

8557 2890

8557 28 90

B

DETAIL B

A

DETAIL A

8557 2830

8557 2830

8557 2 820

855 7 2820

855 7 2720

850 0 442 0

6x

8620 3200

6x

8620 31 80

4x

8500 6 460

4x

862 0 3180

4x

8620 31 80

4x

8500 6460

4x

850 0 6460

2x

8500 6460

2x

850 0 6460

2x

8620 3180

2x

862 0 3180

2x

C

DE T AIL C

8500 4420

8620 3200

862 0 3200

8620 31 80

8620 3 180

850 0 442 0

8620 3200

8500 4420

8620 3 180

2x

855 7 2810

8557 2800

8500 4420

4x

862 0 3200

4x

8622 54 20

4x

862 2 5410

4x

8557 2770

850 0 442 0

8x

8620 32 00

8x

8557 28 00

855 7 2810

85 57 27 80

8620 3180

850 0 7620

8557 28 60

8500 76 20

862 0 3180

862 0 3180

4x

8620 31 80

8500 76 20

855 7 2860

862 0 3180

8500 7620

8623266_20_r2

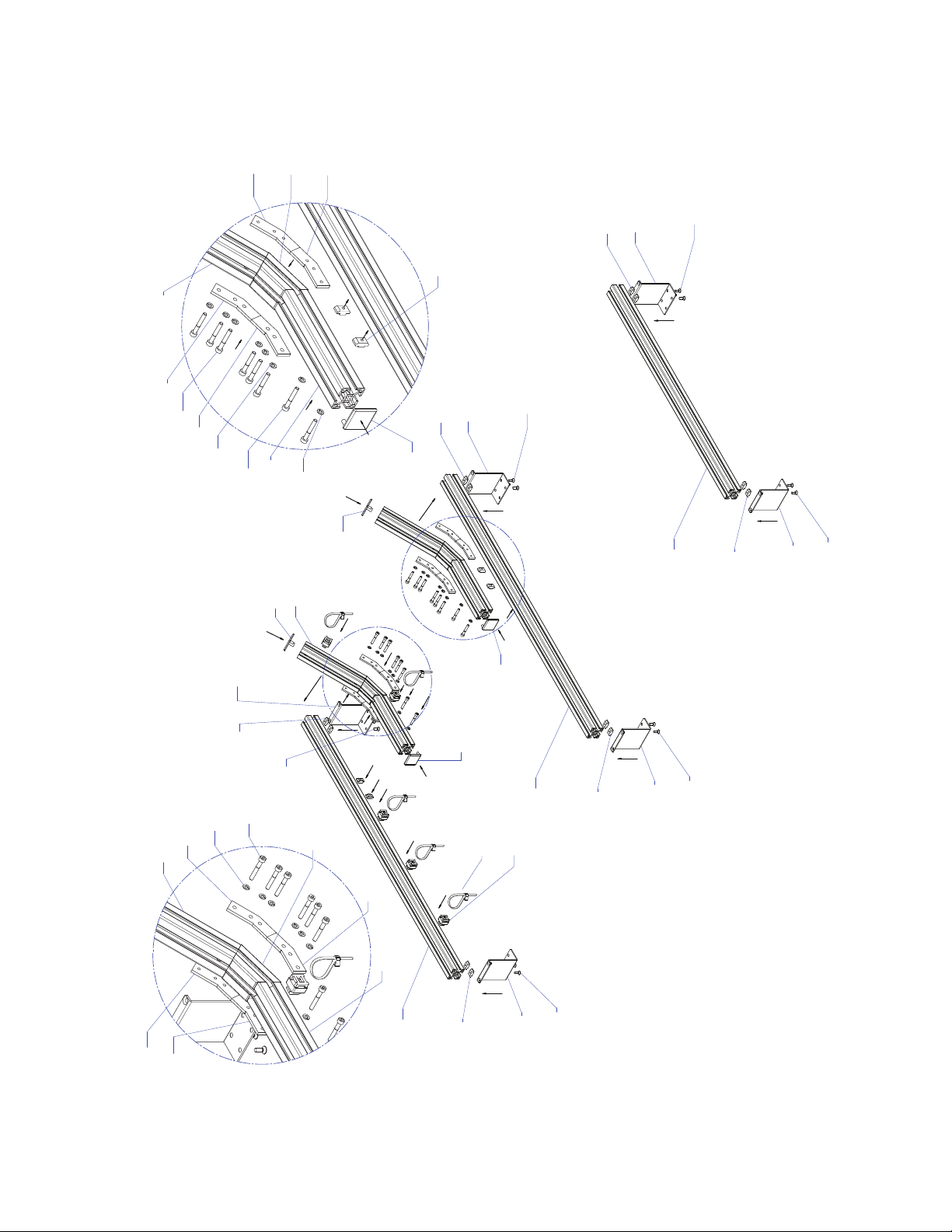

Figure 18. 3-ME Support Structure, Curved Installation

KAYENNE — Installation Planning Guide 23

Page 24

Section 2 — Kayenne Control Surfaces

3-ME Panel Flat Install Cutout

476.0 +/-1 mm

18.7 +/-.04 in.

3-ME 35 Panel Cutout

1503.5 +/-1 mm

59.2 +/-.04 in.

1311.5 +/- 1 mm

51.6 +/- .04 in.

3-ME 25 Panel Cutout

720 mm

28.3 in.

625.0 +/-1 mm

24.6 +/-.04 in.

3-ME 35 Control Panel, Flat Assembly

Figure 19. 3-ME 35 Control Panel Dimensions, Flat Installation

124.0 mm

4.9 in.

10.3 mm

0.4 in.

813.5 mm

32.0 in.

1533.7 mm

60.4 in.

10.2 mm

0.4 in.

720.0 mm

622.8 mm

24.5 in.

14.4 mm

0.6 in.

28.3 in.

Figure 20. 3-ME Control Panel Cutout Dimensions, Flat Installation

74.0 mm

2.9 in.

1501.5 mm

59.1 in.

474.1 mm

18.7 in.

13.9 mm

0.55 in.

8623266_55

24 KAYENNE — Installation Planning Guide

Page 25

Figure 21. 3-ME Support Structure, Flat Installation

855 7 2770

8557 2710

8557 2 710

8557 28 90

8557 2890

862 0 3180

2x

8500 64 60

2x

862 2 5410

4x

8622 5420

4x

855 7 2890

8620 3180

2x

8500 6 460

2x

8557 28 90

862 0 3180

2x

8500 6 460

2x

855 7 2780

8557 2 780

855 7 2890

862 0 3180

2x

850 0 6460

2x

8557 28 90

8620 3 180

2x

850 0 6460

2x

A

DETAIL A

8557 2720

855 7 2830

8557 2830

855 7 2820

8557 2820

850 0 442 0

6x

862 0 3200

6x

862 0 3200

2x

862 0 3180

2x

850 0 6460

2x

8620 3170

8620 3170

862 0 3170

8620 3 170

8557 2 710

B

DETAIL B

855 7 2710

8557 2720

8557 27 10

8557 28 30

855 7 2830

8557 2820

8

557 2820

862 0 3200

6x

8500 4420

6x

8623266_57_r2

Control Panel Assembly

KAYENNE — Installation Planning Guide 25

Page 26

Section 2 — Kayenne Control Surfaces

1341.7 mm

52.8 in.

621.5 mm

24.5 in.

3-ME 25 Flat Installation

1309.5 mm

51.6 in.

124.0 mm

4.9 in.

208.0 mm

8.2 in.

3-ME 25 Curved Installation

3-ME 25 Control Panel

Control panels with 25 source selection buttons are narrower in width, but

otherwise have the same dimensions as 35 source button models.

Figure 22. 4-ME 25 Control Panel Dimensions

26 KAYENNE — Installation Planning Guide

Page 27

2-ME 35 Control Panel, Curved Assembly

8623266_24

1533.7 mm

60.4 in.

813.5 mm

32.0 in.

1501.5 mm

59.1 in.

474.1 mm

18.7in.

14.3 mm

0.6 in.

158.0 mm

6.2 in.

10.3 mm

0.4 in.

74.0 mm

2.9 in.

2-ME Panel Curved Install Cutout

330.5 +/-1 mm

13.0 +/-.04 in.

340.5 +/-1 mm

13.4 +/-.04 in.

32.0 +2 -0 mm

1.3 +.08 in. -0 in.

42.5 +/-1 mm

1.7 +/-.04

2-ME 35 Panel Cutout

1503.5 +/-1 mm

59.2 +/-.04 in.

1311.5 +/- 1 mm

51.6 +/- .04 in.

2-ME 25 Panel Cutout

720 mm

28.3 in.

476.0 +/-1 mm

18.7 +/-.04 in.

10 mm

.40 in.

Figure 23. 2-ME 35 Control Panel Dimensions, Curved Installation

Control Panel Assembly

Figure 24. 2-ME Control Panel Cutout Dimensions, Curved Installation

KAYENNE — Installation Planning Guide 27

Page 28

Section 2 — Kayenne Control Surfaces

A

DETAIL A

B

DETAIL B

C

DETAIL C

855 7 2710

862 0 3170

8557 2890

855 7 2850

8500 6460

4x

850 0 6460

2x

862 0 3180

2x

8557 27 60

8620 3 180

4x

8620 32 00

2x

850 0 442 0

2x

8620 3180

2x

8557 2700

850 0 442 0

8x

862 0 3200

8x

8557 28 00

8557 2810

8557 2 890

855 7 2850

8620 3 180

4x

850 0 6460

4x

8500 6 460

2x

8620 3 180

2x

855 7 2770

8620 32 00

2x

8500 4420

2x

8620 3180

2x

8557 2700

855 7 2830

8557 2830

855 7 2820

855 7 2820

8557 2720

850 0 442 0

6x

862 0 3200

6x

8620 3180

850 0 7620

8557 2 860

8500 7620

8620 3180

8557 2 700

8557 27 80

855 7 2710

855 7 2710

8557 2720

8620 31 70

862 0 3170

8557 2 890

8620 3 180

4x

8620 3 180

8620 3 180

8620 3180

4x

8620 3 170

8622 5420

3x

8622 5410

3x

8500 7620

8557 28 60

8500 76 20

862 0 3180

8620 3180

Figure 25. 2-ME Support Structure, Curved Installation

28 KAYENNE — Installation Planning Guide

Page 29

2-ME 35 Control Panel, Flat Assembly with Local Aux

8623266_58

1533.6 mm

60.4 in.

813.5 mm

32.0 in.

1501.5 mm

59.1 in.

474.1 mm

18.7in.

14.3 mm

0.6 in.

124.0 mm

4.9 in.

10.3 mm

0.4 in.

74.0 mm

2.9 in.

10 mm

0.4 in.

2-ME Panel Flat Install Cutout

327.5 +/-1 mm

12.9 +/-.04 in.

2-ME 35 Panel Cutout

1503.5 +/-1 mm

59.2 +/-.04 in.

1311.5 +/- 1 mm

51.6 +/- .04 in.

2-ME 25 Panel Cutout

720 mm

28.3 in.

476.5 +/-1 mm

18.8 +/-.04 in.

Figure 26. 2-ME 35 Control Panel Dimensions, Flat Installation

Control Panel Assembly

Figure 27. 2-ME Control Panel Cutout Dimensions, Flat Installation

KAYENNE — Installation Planning Guide 29

Page 30

Section 2 — Kayenne Control Surfaces

Figure 28. 2-ME Support Structure, Flat Installation

855 7 2830

855 7 2830

DE T AIL B

8557 27 70

862 0 3180

2x

855 7 2850

8557 27 10

855 7 2710

8500 6460

2x

8557 2 820

855 7 2720

8557 28 20

850 0 442 0

6x

8620 3 200

6x

B

8620 3 180

2x

855 7 2850

862 0 3170

855 7 2710

8620 3 170

8500 4420

8620 3 200

2x

8620 3 200

855 7 2820

6x

6x

8557 2820

8620 31 80

2x

855 7 2890

8557 2720

855 7 2710

8557 2830

DETAIL A

8500 64 60

2x

8622 5410

4x

8622 54 20

4x

8620 3180

2x

8557 2850

850 0 6460

2x

862 0 3170

A

855 7 2770

855 7 2760

862 0 3180

2x

8557 2850

850 0 6460

8500 6460

2x

8620 3 180

2x

850 0 6460

2x

855 7 2850

2x

8623266_60_r2

30 KAYENNE — Installation Planning Guide

Page 31

2-ME 35 Control Panel, Flat without Local Aux

8623266_21

1501.5 mm

59.1 in.

1533.7 mm

60.4 in.

325.4 mm

12.8 in.

10.3 mm

0.4 in.

74.0 mm

2.9 in.

15.2 mm

0.60 in.

15.8 mm

0.62 in.

8557 28 50

862 2 5420

2x

862 2 5410

2x

8557 2850

8557 2760

8620 3180

2x

862 0 3180

2x

8500 64 60

2x

8500 64 60

2x

72850

8557 2850

8557 2760

8620 3180

2x

850 0 6460

2x

8620 3180

2x

850 0 6460

2x

8623266_23_r1

855

8557 2 850

8620 3 180

2x

8500 6 460

2x

8557 28 50

855 7 2760

862 0 3180

2x

850 0 6460

2x

Figure 29. 2-ME 35 Control Panel Dimensions, Flat Installation

Control Panel Assembly

Figure 30. 2-ME Control Panel Cutout Dimensions, Flat Installation

2-ME 35 Panel Cutout

1503.5 +/-1 mm

59.2 +/-.04 in.

327.5 +/-1 mm

12.9 +/-.04 in.

2-ME Panel Flat Install Cutout

(Local Aux Installed Separately)

1311.5 +/-1 mm

51.6 +/-.04 in.

2-ME 25 Panel Cutout

8623266_22

Figure 31. 2-ME Support Structure, Flat Installation, w/o Local Aux Stripe

KAYENNE — Installation Planning Guide 31

Page 32

Section 2 — Kayenne Control Surfaces

1341.7 mm

52.8 in.

621.5 mm

24.5 in.

2-ME 25 Flat Installation

1309.5 mm

51.6 in.

124.0 mm

4.9 in.

158.0 mm

6.2 in.

2-ME 25 Curved Installation

2-ME 25 Control Panel

Control panels with 25 source selection buttons are narrower in width, but

otherwise have the same dimensions as 35 source button models.

Figure 32. 2-ME 25 Control Panel Dimensions

32 KAYENNE — Installation Planning Guide

Page 33

1-ME 15 Control Panel

327.5 +/-1 mm

12.9 +/-.04 in.

8623266_28

728 +/-1 mm

28.7 +/-.04 in.

1-ME 15 Panel Cutout

850 0 4960

6x

850 0 4420

6x

855 7 1480

855 7 1480

855 7 1480

855 7 3180

855 7 3180

850 06460

4x

850 06460

2x

850 06460

2x

862 0 3180

4x

862 0 3180

2x

862 0 3180

2x

8557 2 850

855 7 2850

855 7 2850

2x

855 7 2760

8557 2 760

855 7 3190

855 7 3190

855 7 1480

855 7 2550

855 7 2630

8557 3 150

w/ Silkscreen Kayenne Logo

855 7 3120

862 2 5420

2x

8622 5 410

2x

Figure 33. 1-ME 15 Control Panel Dimensions, Flat Installation

15.8 mm

0.62 in.

15.2 mm

0.60 in.

10.3 mm

0.4 in.

Control Panel Assembly

758.3 mm

29.9 in.

325.4 mm

12.8 in.

74.0 mm

2.9 in.

726.0 mm

28.6 in.

8623266_27

Figure 34. 1-ME 15 Control Panel Cutout Dimensions, Flat Installation

Figure 35. 1-ME Support Structure and Trim, Flat Installation

KAYENNE — Installation Planning Guide 33

Page 34

Section 2 — Kayenne Control Surfaces

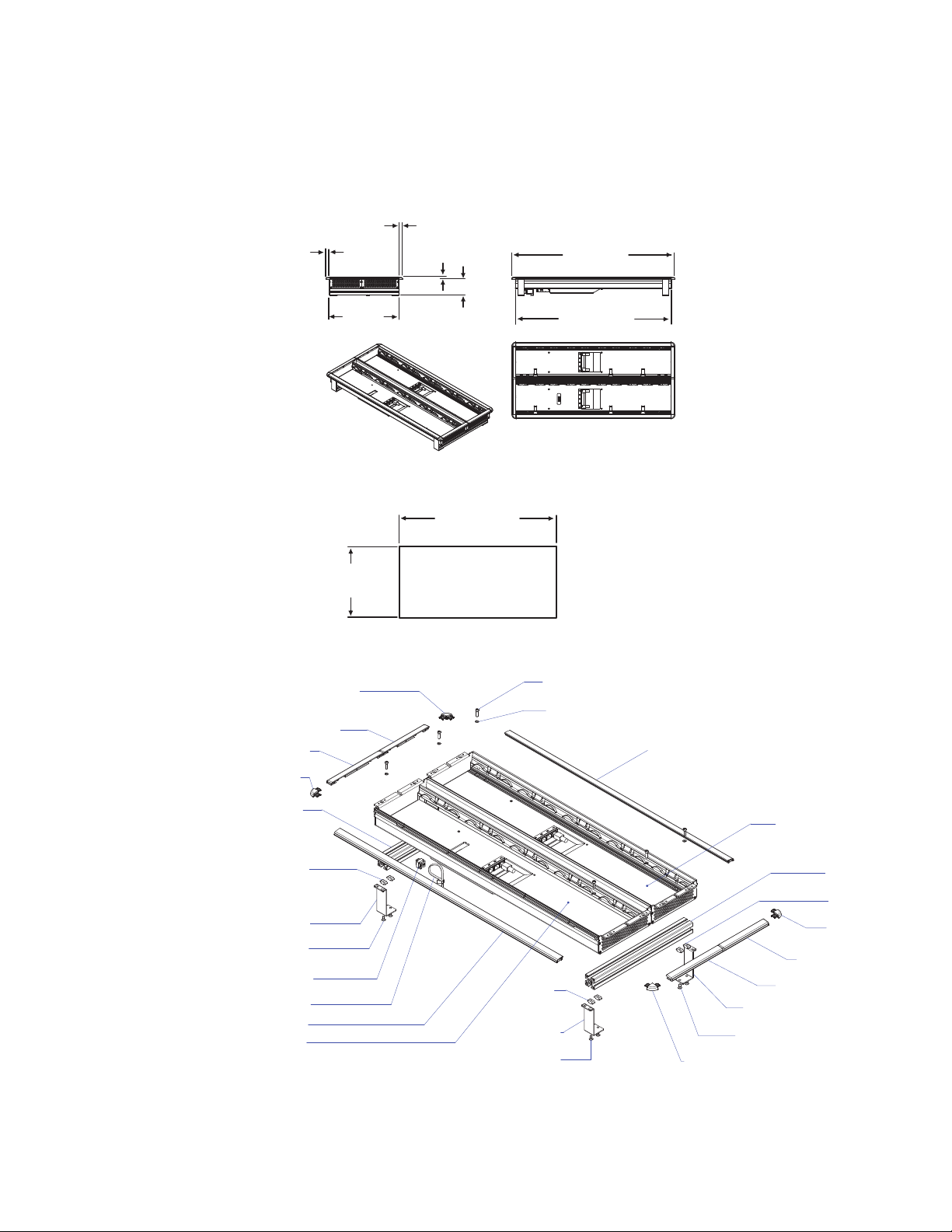

Separately Mounted Local Aux Stripe (35 & 25 Models)

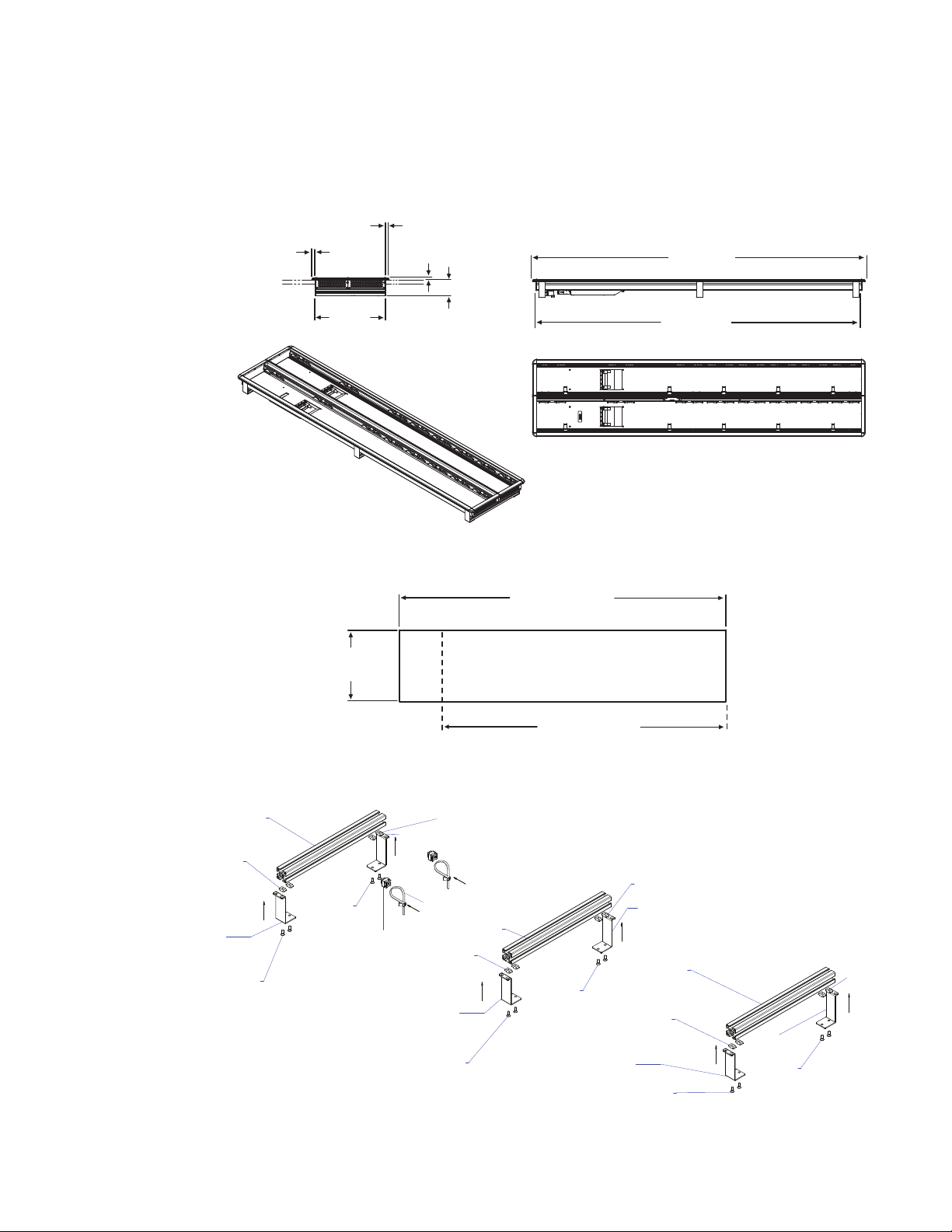

Figure 36. Local Aux Stripe Separate Installation Dimensions

15.2 mm

0.60 in.

154.7 mm

8623266_30

Figure 37. Local Aux Stripe Support Structure, Tray, and Trim

855 7 1480

855 7 3180

855 7 1480

855 7 3060 - 3 5 A UX B UT TON

855 7 3070 - 2 5 A UX B UT TON

855 7 2710

862 0 3180

6.1 in.

2x

10.3 mm

0.4 in.

15.8 mm

0.62 in.

74.0 mm

2.9 in.

Local Aux 35 Width

813.7 mm

32.0 in.

781.5 mm

30.8 in.

156.5 +/-1 mm

6.2+/-.04 in.

850 0 4960

4x

850 0 4420

4x

Local Aux 25 Width

621.7 mm

24.5 in.

589.5 mm

23.2 in.

Local Aux 35 Panel Cutout

783.5 +/-1 mm

30.8 +/-.04 in.

Aux Panel

Installed Separately

591.5 +/-1 mm

23.3 +/-.04 in.

Local Aux 25 Panel Cutout

35 AUX BUTT ON 25 AUX BUTT ON

855 7 3000

Silkscreen Kayenne Logo

855 7 3010

HOUSING CPL. AUX

855 7 258 0 - 35 A UX B UTT ON

855 7 259 0 - 25 A UX B UTT ON

855 7 2710

855 7 1480

855 7 2850

850 06460

2x

850 06460

2x

862 0 3180

2x

862 0 3180

2x

855 7 2850

855 7 2850

850 06460

2x

855 7 3180

855 7 1480

862 0 3180

2x

855 7 2850

850 06460

2x

8623266_31_r2

Control Panel Stripe-PCU Connections

Connectors on the outside bottom of the Stripe connect to the PCU, using a

special multi-pin cable that carries both power and communications.

CAUTION Do not connect or disconnect the multi-pin cables linking a Kayenne Control

Panel tray and PCU while the PCU is powered up. Damage to the Kayenne

equipment can result.

34 KAYENNE — Installation Planning Guide

Page 35

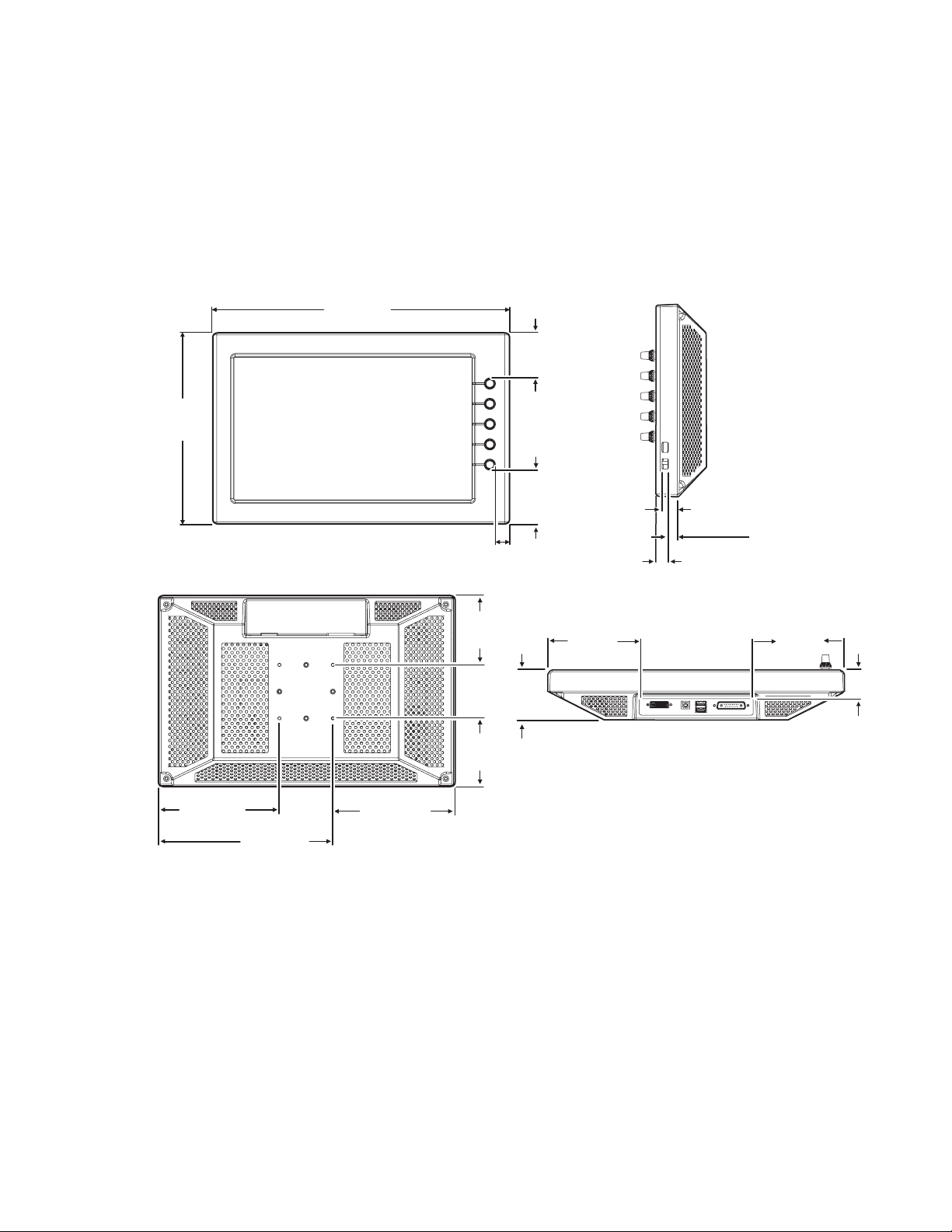

Touch Screen Menu Panel Installation

Front View

Rear View

Side View, Right

8623266_07

Bottom View

170.9 mm

6.73 in.

245.9 mm

9.68 in.

171.9 mm

6.77 in.

19.1 mm

.79 in.

76.2 mm

3.00 in.

417.8 mm

16.45 in.

270.0 mm

10.63 in.

64.1 mm

2.52 in.

129.4 mm

5.09 in.

8.4 mm

.33 in.

17.3 mm

.68 in.

12.7 mm

5.0 in.

97.5 mm

3.84 in.

97.5 mm

3.84 in.

128.4 mm

5.06 in.

70.6 mm

2.78 in.

40.6 mm

1.60 in.

Menu Panel Dimensions

Figure 38. Menu Panel Dimensions

Touch Screen Menu Panel Installation

Menu Panel Connectors

The Kayenne Menu Panel’s processor is located in the PCU. The Menu

Panel connects to the PCU with a special multi-pin cable that carries both

power and communications signals.

CAUTION Do not connect or disconnect the multi-pin cables linking a Kayenne Menu

Panel to the PCU while the PCU is powered up. Damage to the Kayenne equipment can result.

KAYENNE — Installation Planning Guide 35

Page 36

Section 2 — Kayenne Control Surfaces

Side View, Right

8623266_11

Bottom View

USB (2)

USB (2)

DVI-D USB Type B

Optional use with PC

PCU Connector

Figure 39. Menu Panel Connections

Menu Panel Cooling

CAUTION Do not install the Menu Panel into an enclosed space. Passive

air movement is required for cooling.

The Kayenne Menu Panel is externally powered and does not have internal

cooling fans. The electronics are convection cooled through perforations in

the rear of the Menu Panel chassis. Mounting the panel free-standing with

the articulated arm allows maximum air movement, and is the preferred

installation method. If an alternative method is used, ensure that all vents

are unobstructed and adequate airflow is available.

Menu Panel Articulated Arm Installation

The Kayenne Menu Panel has VESA 75 threads on the back that can be used

to mount the Menu Panel to the supplied articulated arm, or any VESA

compliant mounting system.

36 KAYENNE — Installation Planning Guide

Page 37

Touch Screen Menu Panel Installation

157 mm

6.18 in.

225.5 mm

8.88 in.

Max

vertical

range

454.7 mm

17.0 in.

Max

horizontal

range

685.8 mm

27.0 in.

114.3 mm

4.5 in.

438.2 mm

17.25 in.

387.4 mm

15.25 in.

195.3 mm

7.69 in.

79.4 mm

3.125 in.

S IDE VIEW

Vertical Range

TOP VIEW

Horizontal Range

TOP VIEW

Arm Folded

Figure 40. Articulated Arm Range of Motion Dimensions

The supplied articulated arm is equipped with a flex-mount system, permitting a variety of mounting options (table-top, wall mount, etc.). See the

documentation provided with the articulated arm for specific installation

instructions.

Additional Kayenne Menu Panels

Touch Screen Menu Panel Using PCU

An additional Touch Screen Menu Panel, available as an option, requires a

second Menu Panel processor board in the PCU. A multi-pin cable is pro

vided with the option to supply power and signals to the Menu Panel.

Touch Screen Menu Panel Using PC

A Touch Screen Menu Panel can be configured to operate without a PCU,

using a PC. Communication between the Menu Panel and the Kayenne

system is handled using the PC’s Ethernet connection. A special power

supply brick is required, which powers the Menu Panel through the PCU

connector.

-

KAYENNE — Installation Planning Guide 37

Page 38

Section 2 — Kayenne Control Surfaces

Menu Application on PC (Keyboard & Mouse)

The Kayenne menu application can also be run on a standard PC, permitting mouse and keyboard control from a nearby laptop, or remote control

of the Kayenne system from any location on the network. If a PC is used for

Kayenne Menu operation, the PC’s IP address must be set to a compatible

value to work with the rest of the Kayenne system.

38 KAYENNE — Installation Planning Guide

Page 39

Kayenne Frames

General Rack Mounting Instructions

Weight Distribution

Make sure that you mount the unit in the rack so that it is evenly balanced

to prevent damage to the frame and to avoid creating a hazardous condi

tion. Kayenne Frames (8-RU, 4-RU, and PCU) require rear rack support.

Section 3

-

Cooling Requirements

The maximum ambient temperature for a Kayenne chassis is 40-degrees C

(104-degrees F) monitored at the air intake. Installing the frame in a closed

or multi-unit rack assembly together with other units could increase the

maximum ambient temperature for this unit. If the unit is installed in a

rack, ventilation openings should not be blocked or otherwise covered.

Make sure you install the frame to allow for cooling airflow.

Power Connections

When connecting the unit to the supply circuit be sure that the supply

circuit of the rack is not overloaded. The unit must be well-grounded. The

safety ground is accomplished via the third wire in the AC line cord(s). The

rear panel ground lug is available for an optional ground.

All Kayenne Frame power supplies are 100V-240V AC +/-10% autorange,

power factor corrected. Each power supply has its own line IEC line cord.

Connecting each line cord to a separate AC circuit is recommended.

KAYENNE — Installation Planning Guide 39

Page 40

Section 3 — Kayenne Frames

Kayenne 8-RU Video Processor Frame Installation

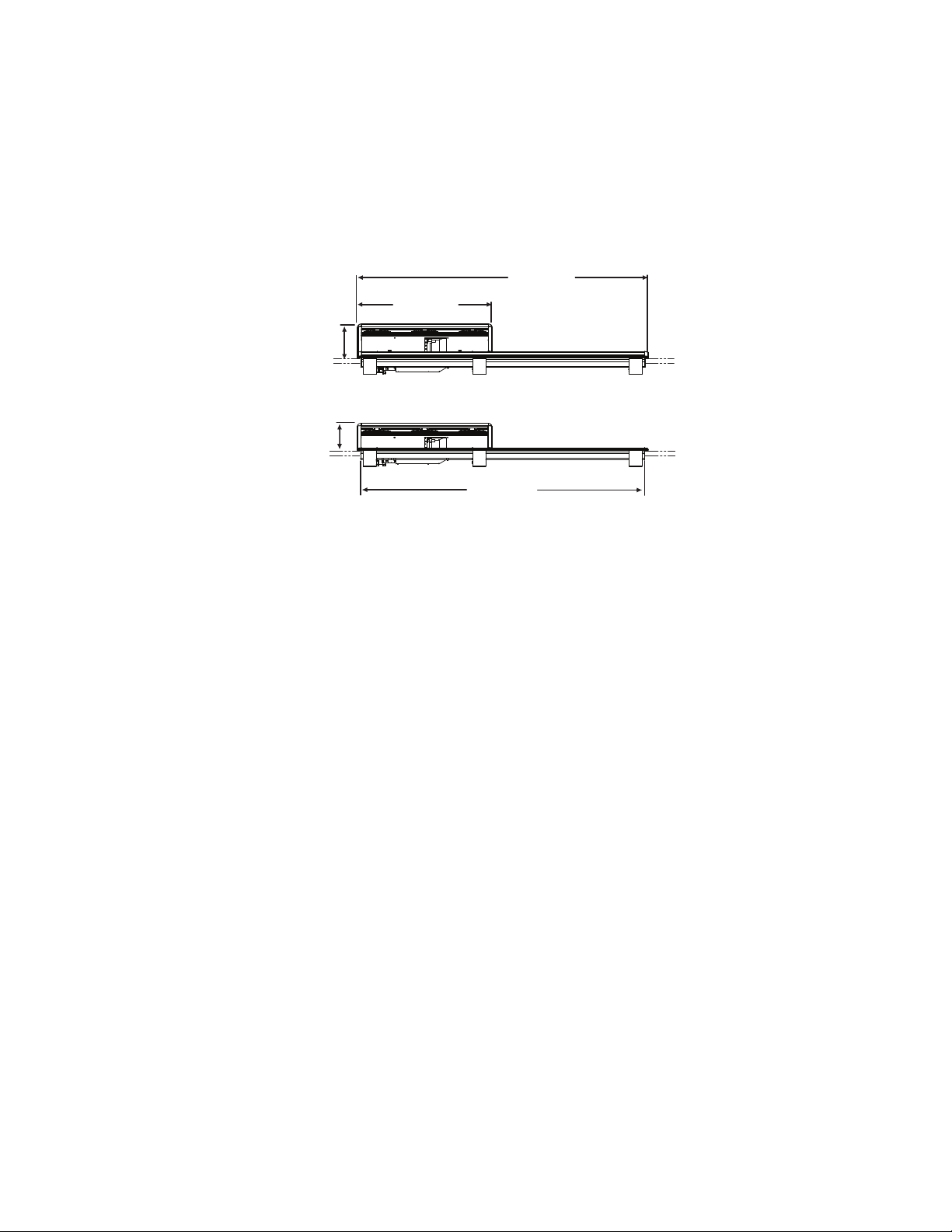

8-RU Frame Dimensions

Figure 41. Kayenne 8-RU Frame Dimensions (Front View)

483 mm

465 mm

18.31 in.

166 mm

6.5 in.

19.0 in.

178 mm

7.0 in.

355 mm

13.97 in.

8623266_93

40 KAYENNE — Installation Planning Guide

Page 41

Kayenne 8-RU Video Processor Frame Installation

523 mm

20.58 in.

541 mm

21.29 in.

AC Line Cord Retainers

(3 on 8-RU, 2 on 4-RU)

442 mm

17.4 in.

39.6 mm

1.56 in.

Figure 42. Kayenne 8-RU and 4-RU Frame Dimensions (Top View)

KAYENNE — Installation Planning Guide 41

Page 42

Section 3 — Kayenne Frames

8-RU Frame Rack Mounting

Figure 43. Kayenne 8-RU Frame Rack Mounting and Cooling Airflow

Air

Exhaust

CAUTION Kayenne Frames (8-RU, 4-RU, and PCU) installations require the use of the

provided rear rack supports.

Air intake holes exist on the right side of the frame (as you face the frame

front) and air exhaust holes are on the left. Make sure adequate ventilation

is provided for the Kayenne Frame. Do not block ventilation holes, which

could make the frame overheat.

Door Removal Clearance

CAUTION Mounting a Kayenne Frame in a rack immediately below equipment that

extends forward from the rack may not provide enough clearance to completely remove the Kayenne door.

8623266_53

Air

Intake

Rear Rack

Support

The Kayenne frame door should be able to be completely removed when

installed in a rack immediately below conventional flush mounted rack-ear

only equipment.

42 KAYENNE — Installation Planning Guide

Page 43

If the chassis is mounted immediately below equipment that extends

ON

OFF

ME A

ME B

ME C

ME D

eDPM

Controller

(and ME 50)

Fan Assembly Flash

Memory

Boot Mode

DIP Switch

Power

Switch

Reset

Button

USB

(not used)

Air Filter

Power Supply Unit 2 Power Supply Unit 3 (option)

RS-232 PS2

Keyboard

VGA

Power Supply Unit 1

8623266_43

forward from the rack (for example, under another Kayenne frame), extra

space must be reserved to be able to remove the front door. The door lifts

off its hinges vertically and for the 8-RU frames 23.7 mm (0.93-in.) of clear

ance is required to completely remove the door. A flush design 1 RU blank

filler panel can be used for clearance, if required.

8-RU Frame Connectors

Figure 44. Kayenne 8-RU Frame, Front View with Door Removed

Kayenne 8-RU Video Processor Frame Installation

-

KAYENNE — Installation Planning Guide 43

Page 44

Section 3 — Kayenne Frames

Video In

1 M/E: 1-24

2 M/E: 1-48

3 M/E: 1-72

4 M/E: 1-96

Figure 45. Kayenne 8-RU Frame, Backplane View

Video Out

1 M/E: 1-12

2 M/E: 1-24

3 M/E: 1-36

4 M/E: 1-48

GPI In/Out 1-8

Tally 1-24

SD Reference In

HD Reference In

Tri Level Sync

GPI In/Out 9-16

Tally 25-48

(2 M/E only)

LAN

(Internal Switch

with 4 Ports)

RS422/485

Serial Ports

(8)

Grounding Lug

(Not used with Kayenne) 100-240V AC

8-RU Frame Power Supplies

The 8-RU Kayenne Video Processor frame has two power supplies standard. A minimum of two supplies are needed for 8-RU frame operation.

An additional power supply is available as an option for redundancy. It

slides into the extra power supply slot in the chassis. When equipped with

the redundant power supply option, the frame will continue to operate

without interruption should a single power supply fail.

Redundant AC

Power Supply 3

(option)

100-240V AC

Power Supply 2

Power Supply 1

GPI In/Out 17-24

Tally 49-72

(3 M/E only)

GPI In/Out 25-32

Tally 73-96

(4 M/E only)

8623266_35

44 KAYENNE — Installation Planning Guide

Page 45

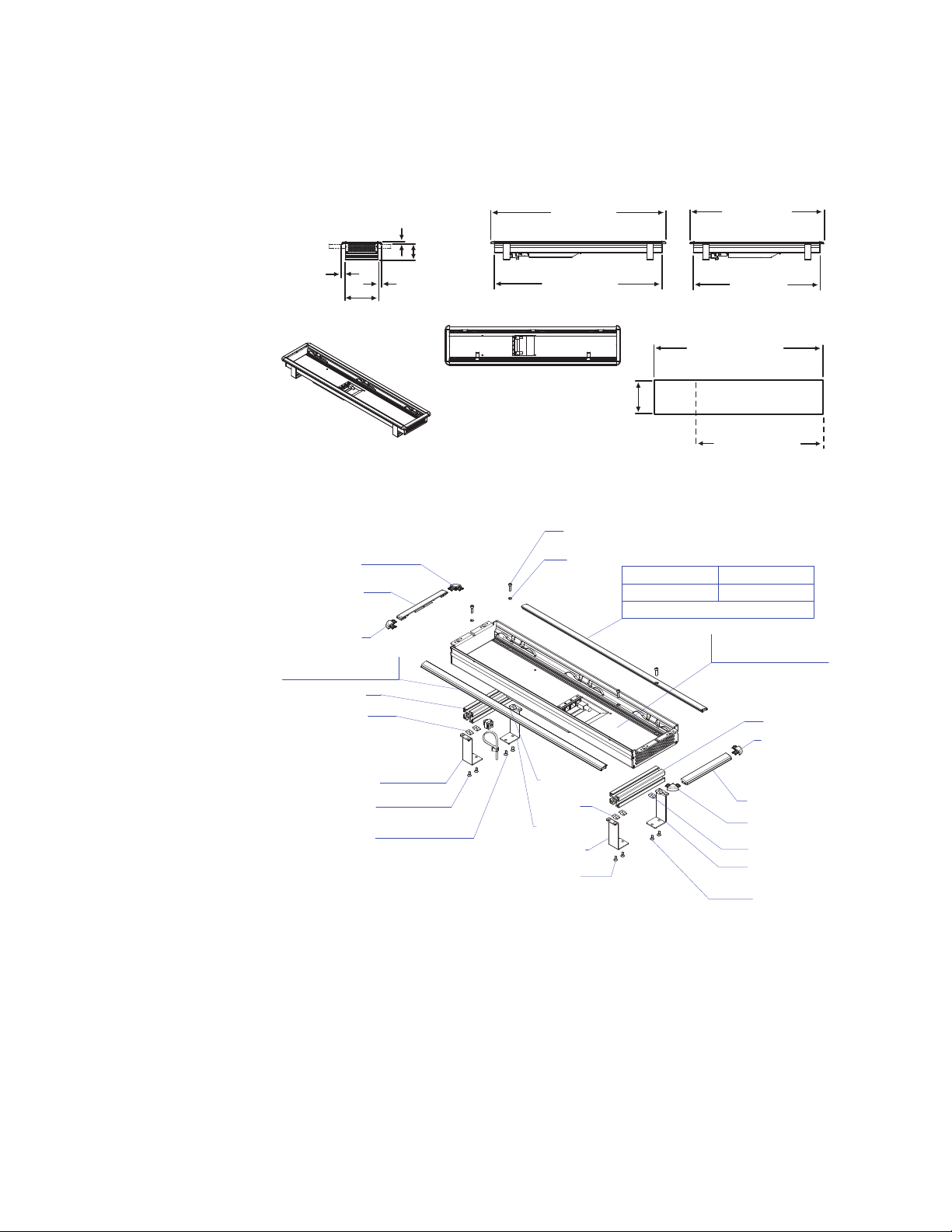

Kayenne 4-RU Video Processor Frame Installation

177 mm

6.97 in.

482 mm

19.0 in.

465 mm

18.31 in.

165 mm

6.5 in.

8623266_51

Kayenne 4-RU Video Processor Frame Installation

4-RU Frame Dimensions

Figure 46. Kayenne 4-RU Frame Dimensions (Front View)

The top view dimensions of the Kayenne 4-RU Frame are the same as the

8-RU Frame, except there are only two AC line cord retainers (see

on page 41).

Figure 42

KAYENNE — Installation Planning Guide 45

Page 46

Section 3 — Kayenne Frames

4-RU Frame Rack Mounting

Figure 47. Kayenne 4-RU Frame Rack Installation and Cooling Airflow

Air

Exhaust

CAUTION Kayenne Frame (8-RU, 4-RU, and PCU) installations require the use of the

provided rear rack supports.

Air intake holes exist on the right side of the frame (as you face the frame

front) and air exhaust holes are on the left. Make sure adequate ventilation

is provided for the Kayenne Frame. Do not block any ventilation holes,

which could make the frame overheat.

Door Removal Clearance

CAUTION Mounting a Kayenne Frame in a rack immediately below equipment that

extends forward from the rack may not provide enough clearance to completely remove the Kayenne door.

8623266_52

Air

Intake

Rear Rack

Support

The Kayenne frame door should be able to be completely removed when

installed in a rack immediately below conventional flush mounted rack-ear

only equipment.

If the chassis is mounted immediately below equipment that extends

forward from the rack (for example, under another Kayenne frame), extra

space must be reserved to be able to remove the front door. The door lifts

46 KAYENNE — Installation Planning Guide

Page 47

off its hinges vertically and for the 4-RU and PCU frames 7.7 mm (0.3 in.)

ON

OFF

Top Slot

ME A

Bottom Slot

ME B

Controller

(and ME 50)

USB

(not used)

Air Filter

Fan Assembly

Flash

Memory

Power

Switch

Reset

Button

RS-232

Power Supply Unit 1 Redundant Power Supply Unit 2 (option)

8623266_44

PS2

Keyboard

VGABoot Mode

DIP Switch

8623266_38

(Not used with Kayenne) 100-240V AC

Power Supply 1

Redundant AC

Power Supply 2

(option)

Grounding Lug

GPI In/Out 9-16

Tally 25-48

(2 M/E only)

GPI In/Out 1-8

Tally 1-24

HD Reference In

Tri Level Sync

Video Out

1 M/E: 1-12

2 M/E: 1-24

Video In

1 M/E: 1-24

2 M/E: 1-48

SD Reference In

LAN

(Internal Switch

with 4 Ports)

RS422/485

Serial Ports

(8)

of clearance is required to completely remove the door. A flush design 1 RU

blank filler panel can be used for clearance, if required.

4-RU Frame Connectors

Figure 48. Kayenne 4-RU Frame, Front View with Door Removed

Kayenne 4-RU Video Processor Frame Installation

Figure 49. Kayenne 4-RU Frame, Backplane View

KAYENNE — Installation Planning Guide 47

Page 48

Section 3 — Kayenne Frames

483 mm

19.0 in.

132.6 mm

5.22 in.

8623266_09

4-RU Frame Power Supplies

The 4-RU Kayenne Video Processor frame has one power supply standard.

An additional power supply is available as an option for redundancy. It

slides into the extra power supply slot in the chassis. When equipped with

the redundant power supply option, the frame will continue to operate

without interruption should a single power supply fail.

Panel Control Unit (PCU) Installation

PCU Dimensions

Figure 50. Panel Control Unit Dimension (Front View)

48 KAYENNE — Installation Planning Guide

Page 49

18.0 mm

0.71 in.

Panel Control Unit (PCU) Installation

Figure 51. Panel Control Unit Dimensions (Top View)

442.0 mm

17.4 in.

AC Line Cord Retainers

530.9 mm

20.90 in.

39.6 mm

1.56 in.

8623266_10

KAYENNE — Installation Planning Guide 49

Page 50

Section 3 — Kayenne Frames

PCU Frame Rack Mounting

Figure 52. Panel Control Unit Rack Installation and Cooling Airflow

Air

Exhaust

Rear Rack

Support

CAUTION Kayenne Frames (8-RU, 4-RU, and PCU) installations require the use of the

provided rear rack supports.

Air intake holes exist on the right side of the frame (as you face the frame

front) and air exhaust holes on the left. Make sure to provide adequate ven

tilation for the Kayenne Frame. Do not block any ventilation holes, which

can prevent cooling air from reaching the frame and cause it to overheat.

Door Removal Clearance

CAUTION Mounting a Kayenne Frame in a rack immediately below equipment that

extends forward from the rack may not provide enough clearance to completely remove the Kayenne door.

The Kayenne frame door should be able to be completely removed when

installed in a rack immediately below conventional flush mounted rack-ear

only equipment.

8621266_37

Air

Intake

-

If the chassis is mounted immediately below equipment that extends

forward from the rack (for example, under another Kayenne frame), extra

space must be reserved to be able to remove the front door. The door lifts

50 KAYENNE — Installation Planning Guide

Page 51

off its hinges vertically and for the 4-RU and PCU frames 7.7 mm (0.3-in.)

OFF

ON

100-240V AC

Power Supply 1

Redundant AC

Power Supply 2

USB (2)

Chassis

Fan

Panel Processor Menu Processor

Second Menu

Processor (Option)

AT

Keyboard

Compact

Flash

Panel

Reset

Menu

Reset

Status

Display &

Boot Switch

Serial Port

Com 1

VGA

Display

Power

Switch

Status

Display &

Boot Switch

Air

Filter

USB (2)

AT

Keyboard

Serial Port

Com 1

VGA

Display

RS 422/485

AC 1AC 2

PANELS

MENU

GPI

USB

2123456 7 81

USB

(Panel Processor)

GPI

(inactive)

Grounding Lug

LAN

(Internal Switch

with 6 Ports)

Panel

LAN

(Reserved LAN)

Menu

Panel 1

Panel Stripe

Connectors (8)

Menu

Panel 2

RS422/485

Serial Port

(Panel

Processor)

8623266_50

100-240V

AC Power 1

Redundant

AC Power 2

of clearance is required to completely remove the door. A flush design 1 RU

blank filler panel can be used for clearance, if required.

PCU Connectors

Figure 53. Panel Control Unit, Front View with Door Removed

Panel Control Unit (PCU) Installation

Figure 54. Panel Control Unit, Backplane View

CAUTION Do not connect or disconnect the multi-pin cables linking a PCU to a Menu

Panel or Control Panel Stripe while the PCU is powered up. Damage to the

Kayenne equipment can result.

KAYENNE — Installation Planning Guide 51

Page 52

Section 3 — Kayenne Frames

PCU Power Supplies

The Kayenne system uses a Panel Control Unit (PCU). This 3RU rackmount frame powers the Control Panel and Touch Screen Menu Panel(s),

and houses the processors for these devices. The PCU has one processor for

the Control Panel, and another processor for the standard Touch Screen

Menu Panel. An additional Menu Panel processor is available as an option.

The PCU has an internal Ethernet switch, used for Menu Panel processor

communications. Six Ethernet ports are available on the back. Two ports are

used internally for the Menu Panels. An additional Ethernet port is used for

Control Panel processor communications.

The Kayenne PCU frame has two power supplies standard. The frame will

continue to operate without interruption should a single power supply fail.

52 KAYENNE — Installation Planning Guide

Page 53

System Cabling

8623266_39_r2

Technical

Director’s

Laptop

CD-ROM

Drive

Disable Internet or

Wireless Connections

Isolate Kayenne System

from External Network

Ethernet

Serial Control

Custom Multi-Pin (Menu, 15m / 50ft max length)

Custom Multi-Pin (Panel, 15m / 50ft max length)

Maintenance Only (board front edge)

*

Internal

Control

Kayenne Video Processor

Frame

Video

Processor

CPU

Compact

Flash

Image

Store

CPU

RAM

Only

Ehternet Switch

1

2

3

4

5

6

7

8

Panel Main LAN

Panel Aux LAN

(not used)

Ehternet Switch

1

2

3

4

5

6

7

8

Kayenne PCU

Menu

CPU

Hard

Disk

Menu

CPU

(option)

Hard

Disk

Panel

CPU

Compact

Flash

Menu Panel

Kayenne Control Panel

Remote Aux Panel

Local Aux Stripe

ME Stripe

ME Stripe

ME Stripe

(Up to 8 Stripe Connections)

USB

RS-422/485

Facility LAN

Switch

Ethernet

Router

Remote Aux Panel

Clip Store

(Image Store Clips)

USB (2)*

Keyboard, VGA*

RS-232*

RS-422/485 (8)

GPI In/Out

Tally

Keyboard, VGA*

RS-232*

USB (2)*

USB (4)

RS-232*

USB (2)*

Keyboard, VGA*

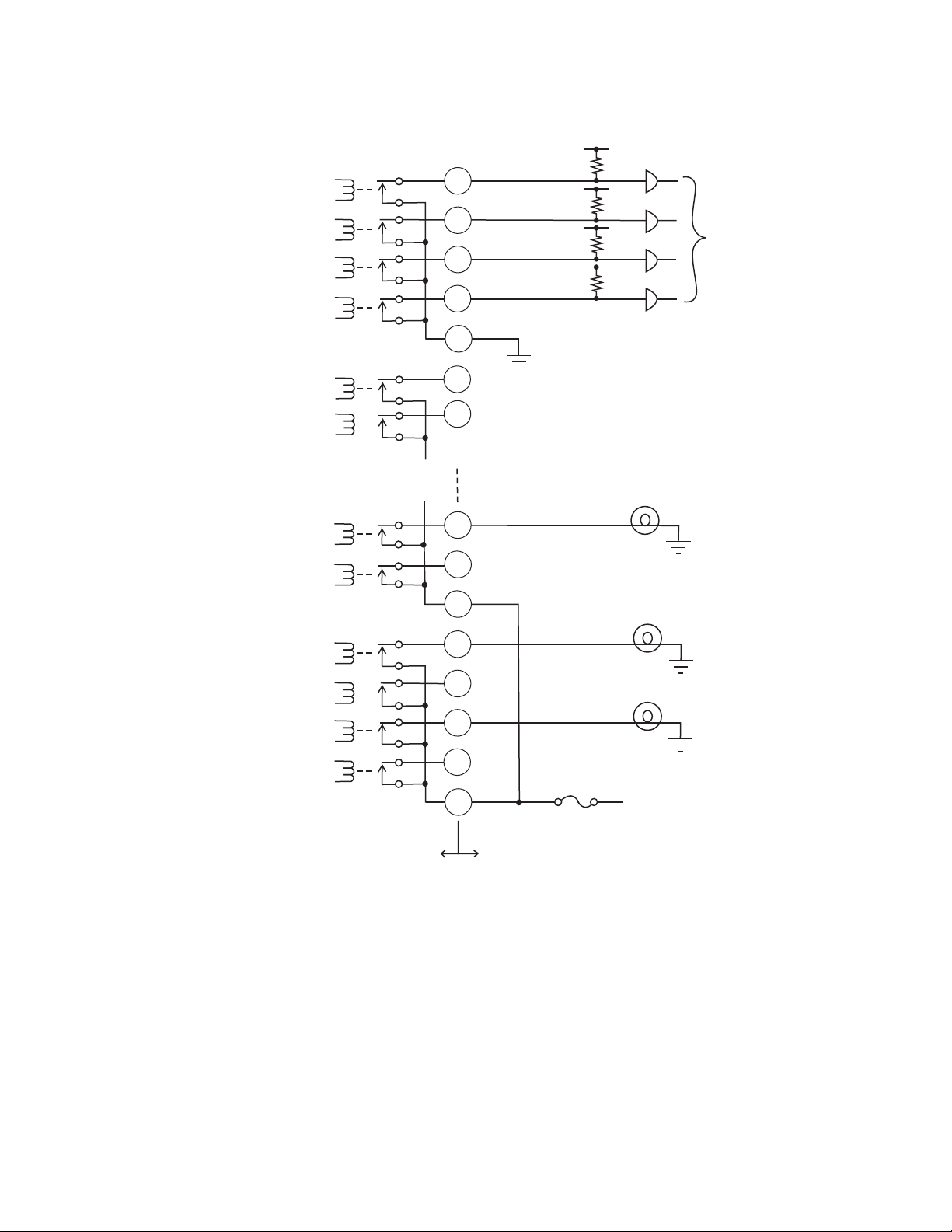

Overview

The Kayenne system uses Ethernet, serial, and USB connections. Custom

multi-pin cabling is also used to connect the Kayenne Panel Control Unit

(PCU) to Kayenne control surface and Menu Panel components. The

Kayenne Video Processor Frame and PCU each have built-in Ethernet

switches. Tally outputs and GPI I/O (General Purpose Interface Input/

Output) control is also available (

Figure 55. Kayenne System Communications Overview

Section 4

Figure 55).

KAYENNE — Installation Planning Guide 53

CAUTION The facility network used for your Kayenne system (and other video produc-

tion equipment) should be kept separate from any external network, to

prevent network traffic from adversely affecting Kayenne system operation.

Kayenne system power is provided by power supplies built into the

Kayenne Video Processor Frame and Kayenne PCU. Power is routed to

Page 54

Section 4 — System Cabling

8623266_40_r1

Internal

Control

Kayenne Video Processor

Frame

Video

Processor

CPU

Image

Store

CPU

Ehternet Switch

1

2

3

4

5

6

7

8

Panel Main LAN

Panel Aux LAN

(reserved)

Ehternet Switch

1

2

3

4

5

6

7

8

Kayenne PCU

Menu

CPU

Menu

CPU

(option)

Panel

CPU

Two Cable PCU Frame Connection

Network Cabling

Kayenne control surface components and Menu Panels from the PCU

through the custom multi-pin cabling. Additional Frame and PCU power

supplies are available for redundancy.

Serial digital video and key input and output signals are connected to the

Kayenne Video Processor Frame. Specified MatchDef Input pair and

SetDef Output pair connectors on the Frame can be used for internal format

conversion (an optional feature). Separate Video Reference inputs are avail

able for HD and SD formats.

Network connections are required between the Kayenne Video Processor

Frame and the PCU. The PCU routes network communications to and from

the Control Panel Stripes and Menu Panels, using custom multi-pin cables.

The Ethernet switches built into the Kayenne Frame and PCU auto-detect

speed and polarity, and are 10/100/1000 Mbps capable. Either straightthrough or crossover Ethernet cabling can be used. Available Ethernet con

nectors may be connected to the Facility LAN or other devices, as needed.

However, should the Kayenne Frame or PCU power down, the internal

Ethernet switches will also power down, interrupting communication to

devices connected to that Frame’s or PCU’s internal Ethernet switches.

Only connect devices that are Kayenne system related.

-

-

54 KAYENNE — Installation Planning Guide

The use of two Ethernet cables to connect the PCU to the Frame is recommended (Figure 56).

Figure 56. PCU to Frame Network Connection Methods

The PCU Ethernet switch to Frame Ethernet switch cable connection is

used for Menu Panel communications. The second cable connects the Panel

PCU directly to the Frame’s Ethernet switch. Using two cables provides

additional Ethernet communications throughput (to support Image Store

file operations) and also offers redundancy. Because the Menu Panel and

Page 55

the Control Panel have independent cable connections, failure of one of

8623266_41_r2

Panel Main LAN

Ehternet Switch

1

2

3

4

5

6

7

8

Kayenne PCU

Menu

CPU

Hard

Disk

Menu

CPU

(option)

Hard

Disk

Panel

CPU

Compact

Flash

Menu Panel

Kayenne Control Panel

Local Aux Stripe

ME Stripe

ME Stripe

ME Stripe

Menu Panel

Kayenne Control Panel

ME Stripe

ME Stripe

Kayenne Satellite Panel

Satellite Stripe

Suite Boundary

Control Surface Boundary

Ethernet

Custom Multi-Pin (Menu, 15m / 50ft max length)

Custom Multi-Pin (Panel, 15m / 50ft max length)

Kayenne Satellite Panel

Satellite Stripe

Internal

Control

Kayenne Video Processor

Frame

Video

Processor

CPU

Image

Store

CPU

Ehternet Switch

1

2

3

4

5

6

7

8

Option

Slot

Kayenne Suite 2

Suite 2

Control Surface A

Suite 2

Control Surface B

Kayenne Suite 1

Suite 1

Control Surface A

Suite 1

Control Surface B

(Up to 8 Stripe Connections)

these cables will not completely disable the Kayenne system. Either the

Menu Panel or the Control Panel will remain operational after a single

network cable failure.

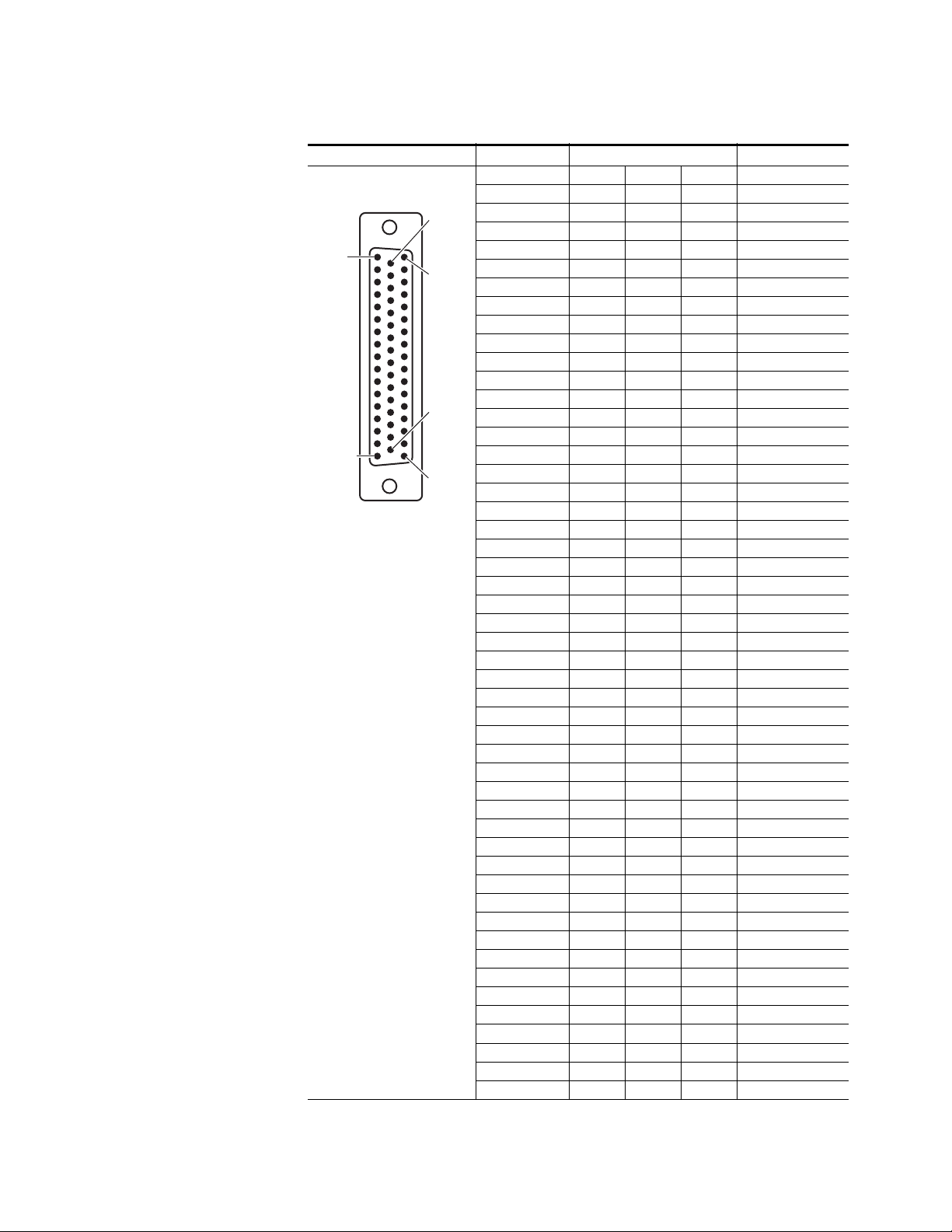

Suites and Control Surfaces

A Kayenne system can be divided into two suites. Kayenne system

resources (MEs, eDPMs, external devices, etc.) can be assigned to each

suite, creating two switchers with one Kayenne system. Each suite can be

subdivided into two control surfaces. Each control surface is intended for

use by a single operator. The Kayenne Control Panel system flexibility

permits locating these control surfaces in physically separate locations.

Custom multi-pin cable runs are limited to 15 meters (50 ft.) If this length is

sufficient, a single PCU can be used for an entire multi-suite Kayenne

system (

Figure 57. Two Suites with Two Control Surfaces Using One PCU

Figure 57).

Network Cabling

KAYENNE — Installation Planning Guide 55

Page 56

Section 4 — System Cabling

Using a second PCU, Kayenne suites can be located anywhere on the network, permitting system control from different rooms, floors, or even different buildings (Figure 58).

Figure 58. Two Suites Using Two PCUs

Kayenne Suite 1

Menu Panel

Kayenne Control Panel

Local Aux Stripe

ME Stripe

ME Stripe

ME Stripe

Kayenne Suite 2

Menu Panel

Kayenne Control Panel

Local Aux Stripe

ME Stripe

ME Stripe

ME Stripe

8623266_42_r2

Kayenne PCU 1

Menu

CPU

Menu

CPU

(option)

Panel Main LAN

Panel

CPU

Kayenne PCU 2

Menu

CPU

Menu

CPU

(option)

Panel

CPU

7

1

2

3

4

8

5

Ehternet Switch

6

7

8

Panel Main LAN

Ethernet

(100m / 300ft max single hop length,

unlimited distance using switches)

1

2

3

4

5

Ehternet Switch

6

Kayenne Video Processor

Frame

1

5

2

6

3

7

4

8

Ehternet Switch

Option

Slot

Suite Boundary

Ethernet

Custom Multi-Pin (Menu, 15m / 50ft max length)

Custom Multi-Pin (Panel, 15m / 50ft max length)

Video

Processor

CPU

Internal

Control

Image

Store

CPU

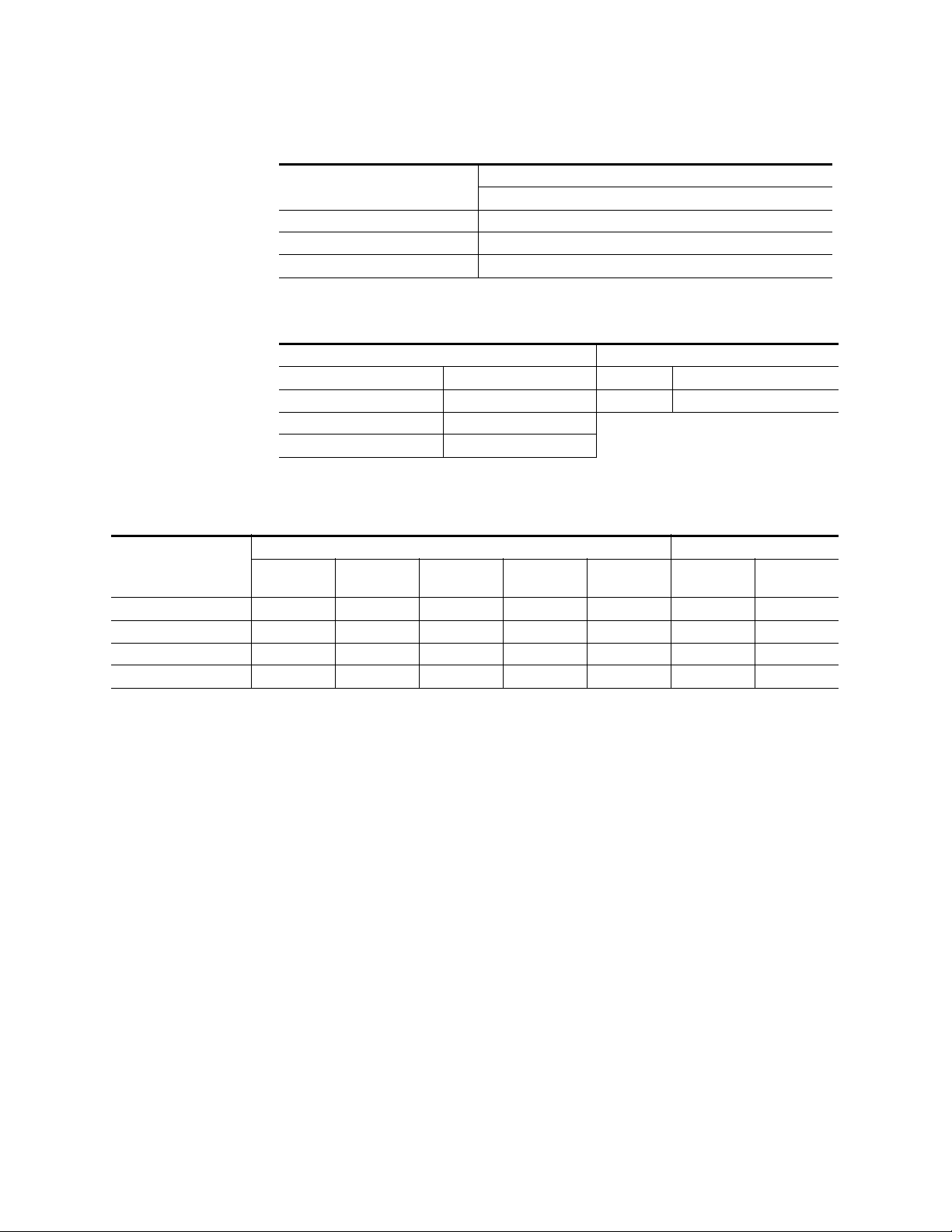

Customer Supplied Ethernet Routers and Switches

Existing facility Ethernet switches can be used in conjunction with a

Kayenne system. If connecting to a network area outside that used by the

Kayenne system, use of an appropriately configured Ethernet Router is

strongly advised. This reduces network traffic on the Kayenne network and

keeps it isolated. Any Ethernet switches added specifically for use with the

56 KAYENNE — Installation Planning Guide

Page 57

Network Cabling

Kayenne system should be 1000 Mbps capable for the most efficient operation (see Tab le 1).

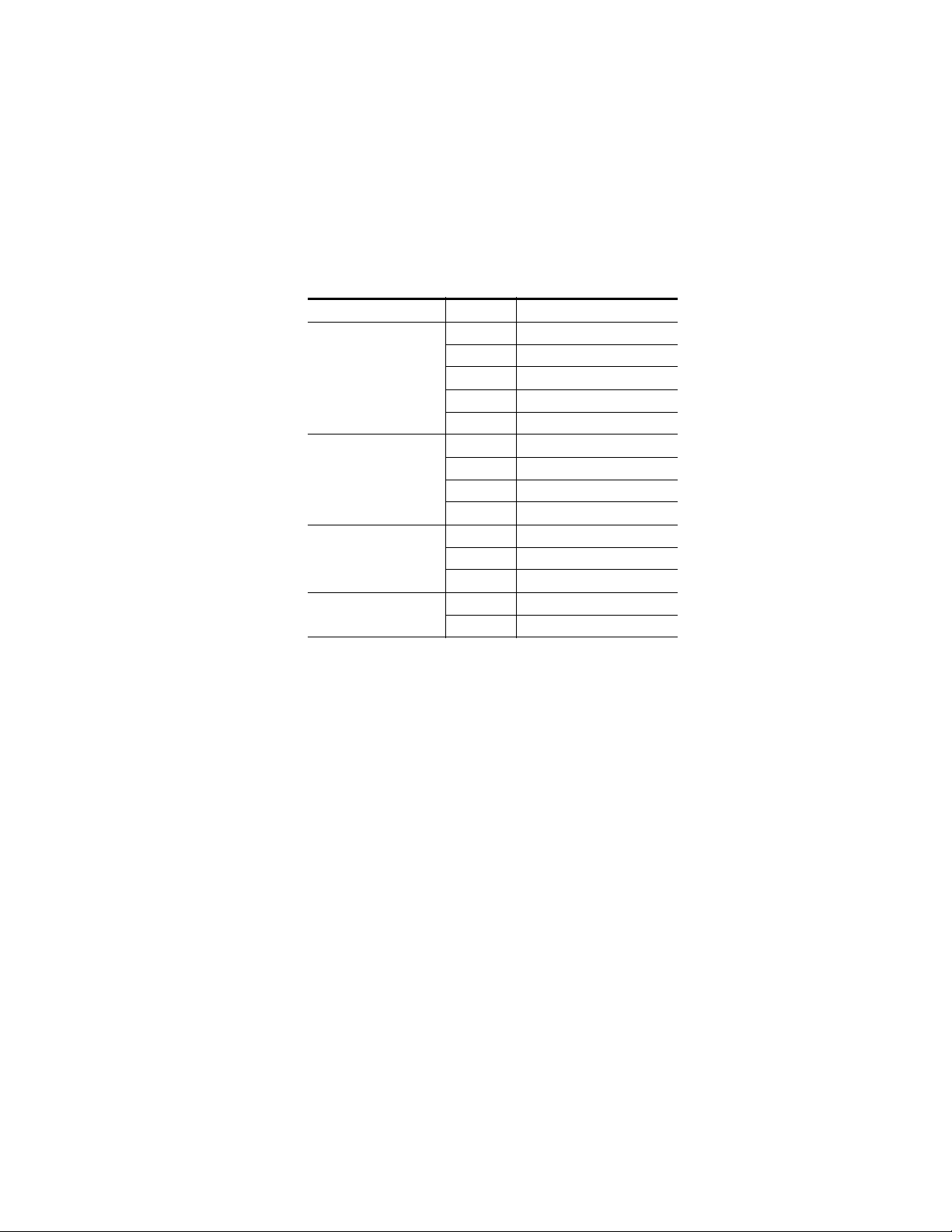

Table 1. Ethernet Specifications

10BaseT, 100BaseT, 1000BaseT compatible.

Typ e

Cables

Connectors

Length

Speed

Ports

Switch

Unmanaged

Managed

Category 5 cable, 8 conductor twisted pair.

The system will work at lower ratings with reduced performance.

1000BaseT components are highly recommended.

RJ-45 male connector at each end of cable.

100BaseT, 1000BaseT: 328 ft. (100 m) maximum.

10BaseT: 984 ft. (300 m) maximum.

Use additional switches to exceed maximum cable runs.

10/100/1000 Mbps

RJ-45 auto-negotiating 10/100/1000 Mbps; number of ports required

is dependent upon system size. Frame and PCU ports are capable of

1000 Mbps. Using a 1000 Mbps Ethernet switch enhances Image Store

transfer speeds.

Recommended. Configuration not required, but does not provide

remote monitoring capability.