Page 1

KayakDD-2™

DIGITAL PRODUCTION SWITCHER

Planning and Installation Manual

SOFTWARE VERSION 6.7.1

071829903

JUNE 2005

Page 2

KayakDD-2 Digital Production Switcher

Contacting Grass Valley

Region Voice Fax Address Web Site

North America (800) 547-8949

Support: 530-478-4148

Pacific Operations +852-2585-6688

Support: +852-2585-6579

U.K., Asia, Middle East +44 1753 218 777 +44 1753 218 757

France +33 1 45 29 73 00

Germany, Europe +49 6150 104 782 +49 6150 104 223

Copyright © Thomson Broadcast and Media Solutions All rights reserved.

Grass Valley Web Site

The www.thomsongrassvalley.com web site offers the following:

Sales: (530) 478-3347

Support: (530) 478-3181

+852-2802-2996

Grass Valley

P.O. Box 599000

Nevada City,

CA 95959-7900

USA

www.thomsongrassvalley.com

Online User Documentation — Current versions of product catalogs, brochures, data sheets, ordering

guides, planning guides, manuals, and release notes in .pdf format can be downloaded.

FAQ Database — Solutions to problems and troubleshooting efforts can be found by searching our

Frequently Asked Questions (FAQ) database.

Software Downloads — Software updates, drivers, and patches can be downloaded.

2 Planning and Installation Manual

Page 3

Number: 510057.001

The Quality System of:

Thomson Broadcast & Media Solutions

TBMS TBMS

400 Providence Mine Road 17 rue du Petit Albi -BP 8244

Nevada City, CA 95945 95801 Cergy Pontoise

Cergy, France

TBMS

Weiterstadt, Germany TBMS

Brunnenweg 9 10 Presidential Way, 3rd Floor, Suite 300

D-64331 Weiterstadt, Germany Woburn, MA 08101

TBMS TBMS

15655 SW Greystone Ct. 2300 South Decker Lake Blvd.

Beaverton, OR 97006 Salt Lake City, UT 84119

TBMS TBMS - PCB

Nederland B.V. Rennes, France

4800 RP BREDA Rue du Clos Courtel

The Nederlands Cesson-Sevigne, Cedex

France

TBMS/Nextream TBMS/Nextream

Rennes, France Technopole Brest Iroise

Rue du Clos Courtel CS 73808

Cesson-Sevigne, Cedex 29238 Brest Cedex 3

France France

Including its implementation, meets the requirements of the standard:

ISO 9001:2000

Scope: The design, manufacture and support of video hardware and software products

and related systems.

This Certificate is valid until: June 14, 2006

Revision Date: September 9, 2003

Renewal Date: June 14, 2003

Issued for the first time: June 14, 2000

Page 4

KayakDD-2 Digital Production Switcher

Table of Contents

1 Preface .............................................................................................................................................................9

1.1 About This Manual.....................................................................................................................................9

1.2 Standard Documentation Set.....................................................................................................................9

1.3 Other Documentation.................................................................................................................................9

2 Regulatory Notices........................................................................................................................................11

2.1 Certifications and Compliances ...............................................................................................................11

2.1.1 FCC Emission Control......................................................................................................................11

2.1.2 Canadian EMC Notice of Compliance..............................................................................................11

2.1.3 FCC Emission Limits ........................................................................................................................11

2.1.4 Certification and Compliance............................................................................................................12

3 Safety Summary............................................................................................................................................15

3.1 Safety Terms and Symbols......................................................................................................................15

3.1.1 Terms in This Manual.......................................................................................................................15

3.1.2 Terms on the Product.......................................................................................................................15

3.1.3 Symbols on the Product....................................................................................................................16

3.2 Warnings..................................................................................................................................................17

3.3 Cautions...................................................................................................................................................18

4 Technical Specification ................................................................................................................................19

4.1 Power Supply Frame ...............................................................................................................................19

4.2 Power Supply Panel.................................................................................................................................19

4.3 Environmental Data .................................................................................................................................19

4.4 Video System Data ..................................................................................................................................20

4.5 Serial Digital Video Inputs........................................................................................................................20

4.6 Serial Digital Video Outputs.....................................................................................................................21

4.7 Analog Reference Input...........................................................................................................................21

4.8 Control Panel Connection........................................................................................................................21

4.9 Mechanical Data......................................................................................................................................22

5 System Overview...........................................................................................................................................23

5.1 Introduction ..............................................................................................................................................23

5.1.1 Features............................................................................................................................................23

5.1.2 Supported Control Protocols.............................................................................................................24

5.1.3 KayakDD-2 Ordering Information.....................................................................................................25

5.2 System Components................................................................................................................................27

5.3 Control Surface........................................................................................................................................28

5.4 Video Processor Frame...........................................................................................................................29

5.4.1 System Components ........................................................................................................................29

5.4.2 Video Processor Frame Options.......................................................................................................31

5.5 Functional Overview ................................................................................................................................32

5.5.1 Video Signal Flow.............................................................................................................................32

5.5.2 System Control.................................................................................................................................34

Planning and Installation Manual 3

Page 5

KayakDD-2 Digital Production Switcher

6 Installation..................................................................................................................................................... 35

6.1 Pre-Installation Procedures..................................................................................................................... 35

6.1.1 System Survey................................................................................................................................. 35

6.1.2 Line Voltage..................................................................................................................................... 35

6.1.3 Safety Requirements........................................................................................................................ 35

6.1.4 Installation Tasks ............................................................................................................................. 36

6.2 Mounting the Processor Frame............................................................................................................... 37

6.2.1 Video Processor Frame Measurements.......................................................................................... 37

6.2.2 General Rack Mounting Instructions................................................................................................ 38

6.2.3 Rack Mounting Procedure ............................................................................................................... 39

6.3 Mounting the Control Panel..................................................................................................................... 40

6.3.1 Control Panel Measurements .......................................................................................................... 40

6.3.2 Table Top Mounting......................................................................................................................... 42

6.3.3 Cut Out Dimensions for Surface Mounting...................................................................................... 42

6.3.4 Mounting Holes for Panel Fastening................................................................................................ 42

6.4 Control Panel Connectors....................................................................................................................... 45

6.5 Processor Frame Connectors................................................................................................................. 47

6.6 Pin Assignments...................................................................................................................................... 50

6.6.1 RS 485 Port...................................................................................................................................... 50

6.6.2 RS 232 Port...................................................................................................................................... 50

6.6.3 Panel DC Power In........................................................................................................................... 51

6.6.4 Frame DC Power In......................................................................................................................... 51

6.6.5 Frame DC Power Out.......................................................................................................................51

6.6.6 Frame GPI/O – Tally........................................................................................................................ 52

6.7 Cabling and Control.................................................................................................................................53

6.7.1 Cabling............................................................................................................................................. 53

6.7.2 Control Cabling ................................................................................................................................54

6.7.3 Video................................................................................................................................................56

6.7.4 Video Timing and Delay................................................................................................................... 57

6.7.5 GPI / Tally Outputs........................................................................................................................... 58

6.7.6 GPI Inputs........................................................................................................................................ 58

6.7.7 Tally Adapter.................................................................................................................................... 58

7 Service Instructions..................................................................................................................................... 59

7.1 Running Panel Tests............................................................................................................................... 59

7.1.1 Local Panel Test Mode 1 (Button Test):.......................................................................................... 60

7.1.2 Local Panel Test Mode 2 (LED Test):.............................................................................................. 60

7.1.3 Local Panel Test Mode 3 (Group Test / On Air Highlight Test):...................................................... 60

7.1.4 Local Panel Test Mode 4 (Connect Mode):..................................................................................... 60

7.1.5 Local Panel Test Mode 5 (Colour Test):.......................................................................................... 61

7.2 Software-Update ..................................................................................................................................... 62

7.2.1 Recommended Memory Sticks........................................................................................................ 62

7.2.2 Preparing the USB Memory Stick.................................................................................................... 62

7.2.3 Software Loading/Update ................................................................................................................ 66

7.2.4 Installation Procedure...................................................................................................................... 67

7.2.5 Updating the CPLD Firmware.......................................................................................................... 70

7.3 Device Configuration............................................................................................................................... 71

7.3.1 Configure Device Menu ................................................................................................................... 71

7.3.2 Reset / Check / Clear Device Menu................................................................................................ 72

4 Planning and Installation Manual

Page 6

KayakDD-2 Digital Production Switcher

7.4 Trouble Shooting......................................................................................................................................73

7.4.1 How to Calibrate the TouchScreen...................................................................................................73

7.4.2 Lost LAN Connection........................................................................................................................73

7.4.3 Problems with Network Configuration ..............................................................................................73

7.4.4 How to Connect a PC / Laptop to the KayakDD...............................................................................75

7.4.5 CPLD Update Trouble Shooting.......................................................................................................77

7.4.6 How to Install the Sidepanel Software to a PC / Laptop...................................................................78

7.4.7 Network Problems with Sidepanel....................................................................................................81

7.4.8 Lifetime of the Internal Battery..........................................................................................................83

7.4.9 Exchange the Battery .......................................................................................................................84

7.4.10 iButton Exchange for Spare Part Mainframe....................................................................................89

7.5 Control Interfaces.....................................................................................................................................90

7.5.1 Supported GVG100 Commands.......................................................................................................90

7.5.2 Supported GVG200 Commands.......................................................................................................92

Planning and Installation Manual 5

Page 7

KayakDD-2 Digital Production Switcher

Table of Figures

Figure 1 Video Processor Frame................................................................................................................... 27

Figure 2 Control Panel ................................................................................................................................... 27

Figure 3 KayakDD-2 Control Panel Surface .................................................................................................. 28

Figure 4 KayakDD-2 Video Processor Frame................................................................................................ 30

Figure 5 KayakDD-2 Simplified Video Flow Diagram .................................................................................... 33

Figure 6 KayakDD-2 Video Processor Frame Dimensions............................................................................ 37

Figure 7 KayakDD-2 Video Processor Frame Rack Mounting....................................................................... 39

Figure 8 KayakDD-2 Control Panel Measurements 1 of 2............................................................................. 40

Figure 9 KayakDD-2 Control Panel Measurements 2 of 2............................................................................. 41

Figure 10 Bottom View, Position of the Mounting Points................................................................................. 43

Figure 11 Bottom View, Measurements of the Mounting Points...................................................................... 44

Figure 12 Panel Fastening Procedure ............................................................................................................. 44

Figure 13 Control Panel Connectors................................................................................................................ 45

Figure 14 Video Processor Frame Connectors................................................................................................ 47

Figure 15 KayakDD-2 Standard Cabling.......................................................................................................... 53

Figure 16 Timing and Delay............................................................................................................................. 57

Figure 17 Tally Adapter Cable.......................................................................................................................... 58

Figure 17 KayakDD Control Panel Detail – Transition Panel........................................................................... 59

Figure 18 Device Control Menu........................................................................................................................65

Figure 19 Device Control Menu with Software Update Dialog......................................................................... 66

Figure 20 Start Installation Procedure..............................................................................................................67

Figure 21 Installation Procedure...................................................................................................................... 67

Figure 22 Cancel Installation Procedure.......................................................................................................... 68

Figure 23 Device Control Installation Status.................................................................................................... 68

Figure 24 Finish Installation............................................................................................................................. 69

Figure 25 CPLD Update................................................................................................................................... 70

Figure 26 Configure Devices............................................................................................................................ 71

Figure 27 Reset/Clear/Check Devices Menu................................................................................................... 72

Figure 28 PC Connection................................................................................................................................. 75

Figure 29 Error Message during CPLD update................................................................................................ 77

Figure 30 Path to the NetCheck Software........................................................................................................ 81

Figure 31 NetCheck Window............................................................................................................................82

Figure 32 KayakDD-2 Frame Front.................................................................................................................. 84

Figure 33 KayakDD-2-Frame Without Front Plate........................................................................................... 84

Figure 34 KayakDD-2 Control Panel................................................................................................................ 85

Figure 35 Battery on the Board of the Control Panel....................................................................................... 85

Figure 36 PS2 and VGA sockets on the KayakDD-2 Frame ........................................................................... 86

Figure 37 PS2 and VGA sockets on the KayakDD-2 Panel............................................................................. 87

Figure 38 Config Device Menu......................................................................................................................... 88

Figure 39 KayakDD-1 Frame Front View......................................................................................................... 89

Figure 40 Position of the iButton...................................................................................................................... 89

6 Planning and Installation Manual

Page 8

KayakDD-2 Digital Production Switcher

Planning and Installation Manual 7

Page 9

KayakDD-2 Digital Production Switcher

8 Planning and Installation Manual

Page 10

1 Preface

1.1 About This Manual

This KayakDD-2 Planning and Installation Manual provides installation, configuration,

and service information for the Thomson Grass Valley KayakDD Digital Production

Switcher. This manual is designed for technical personnel responsible for installing and

maintaining KayakDD-2 systems.

1.2 Standard Documentation Set

The standard KayakDD-2 documentation set consists of a:

• Operating Instructions,

• Planning and Installation Manual, and

• Release Notes.

The Operating Instructions contains background information about the KayakDD-2

Digital Production switcher and describes operating procedures. This manual can be

used while learning about KayakDD-2 and for enhancing your basic knowledge of the

system.

The Planning and Installation Manual contains information about installing, configuring,

and maintaining the system. The service part in this current manual is in preparation.

The Release Notes contain information about new features and system enhancements

for a specific software version, and also includes software installation procedures.

Always check the release notes for your current system software before you begin

operating your system.

KayakDD-2 Digital Production Switcher

1.3 Other Documentation

Communication protocols of KayakDD-2 are available upon request for developers and

software engineers to use to design editor and other external interfaces to the

KayakDD-2 system.

Planning and Installation Manual 9

Page 11

KayakDD-2 Digital Production Switcher

10 Planning and Installation Manual

Page 12

KayakDD-2 Digital Production Switcher

2 Regulatory Notices

2.1 Certifications and Compliances

2.1.1 FCC Emission Control

This equipment has been tested and found to comply with the limits for a Class A

(Control Panel) and Class B (Mainframe) digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area

is likely to cause harmful interference in which case the user will be required to correct

the interference at his own expense.

Changes or modifications not expressly approved by Thomson Grass Valley can affect

emission compliance and could void the user’s authority to operate this equipment.

2.1.2 Canadian EMC Notice of Compliance

This digital apparatus does not exceed the Class A (Control Panel) and Class B

(Mainframe) limits for radio noise emissions from digital apparatus set out in the Radio

Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’emet pas de bruits radioélectriques dépassant hors

des limites applicables aux appareils numériques de la classe A pour des pupitre de

control et classe B pour le rack préscrites dans le Règlement sur le brouillage

radioélectrique édicte par le ministère des Communications du Canada.

2.1.3 FCC Emission Limits

This device complies with Part 15 of the FCC 47 Rules. Operation is subject to the

following two conditions: (1) This device may no cause harmful interference, and (2)

this device must accept any interference received, including interference that may

cause undesirable operation.

Planning and Installation Manual 11

Page 13

KayakDD-2 Digital Production Switcher

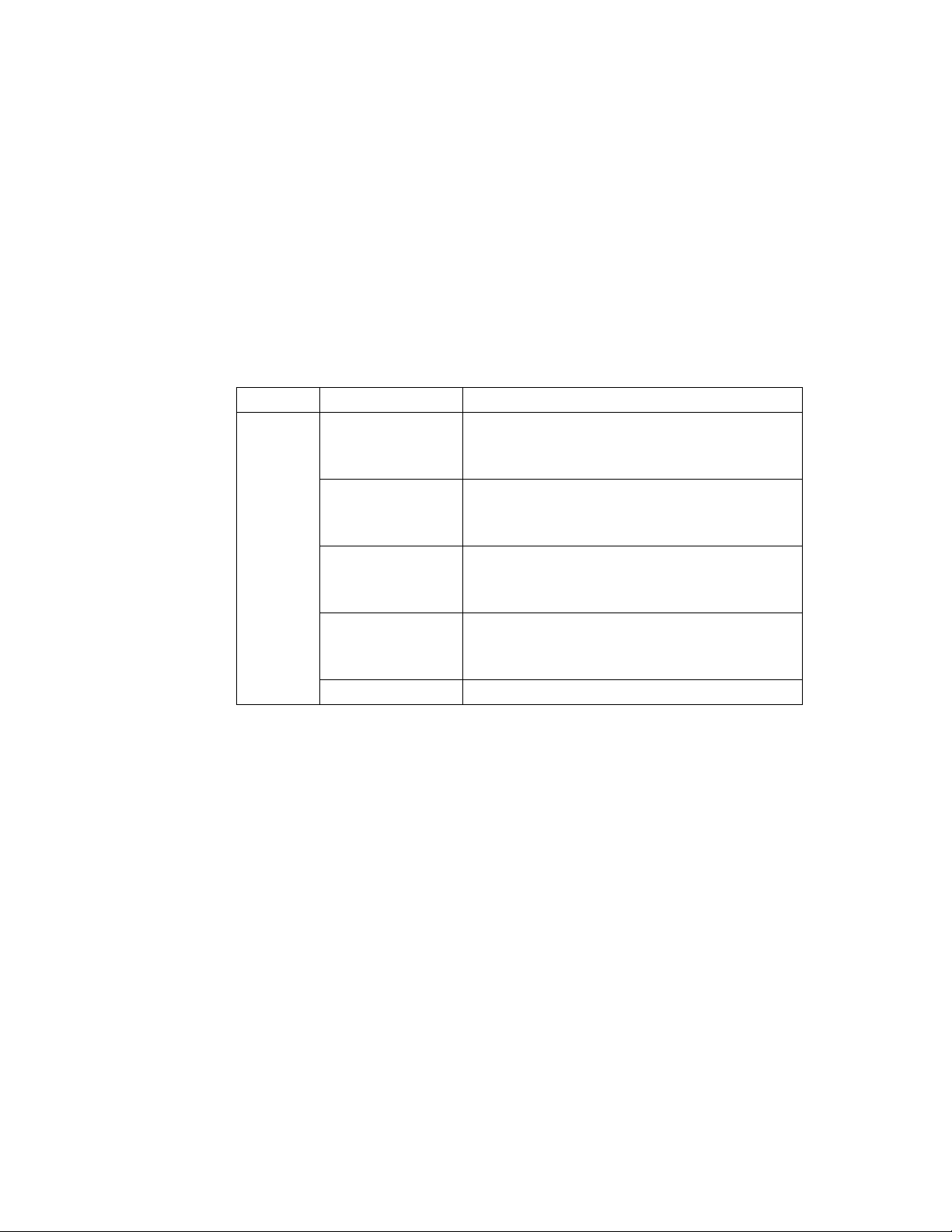

2.1.4 Certification and Compliance

This product has been evaluated for Electromagnetic Compatibility under the EN

55103-1/2 standards for Emissions and Immunity and meets the requirements for

E1/E2 environment.

This product complies with Class A (Control Panel) and Class B (Mainframe). In a

domestic environment this product may cause radio interference in which case the

user may be required to take adequate measures.

This product has been evaluated and meets the following Safety Certification

Standards:

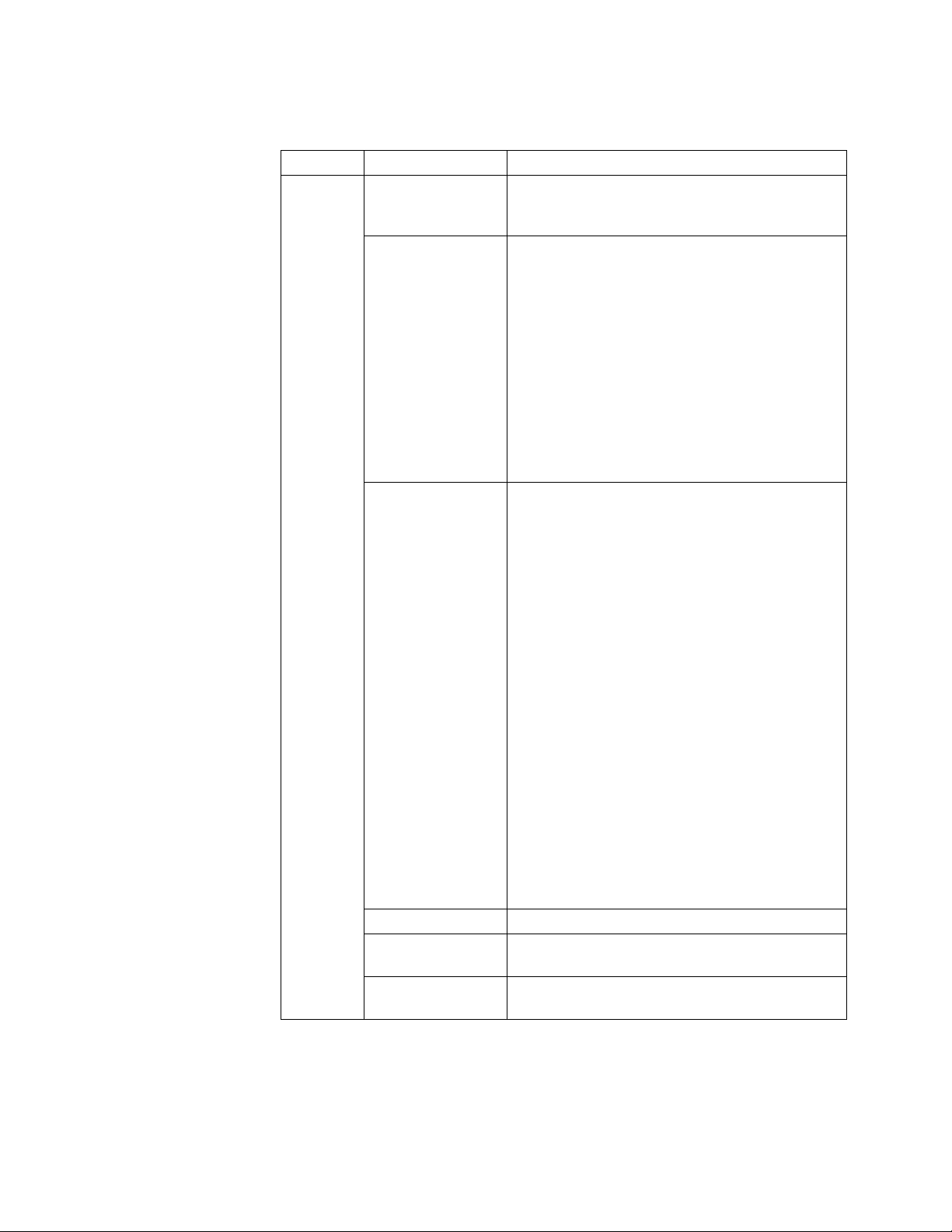

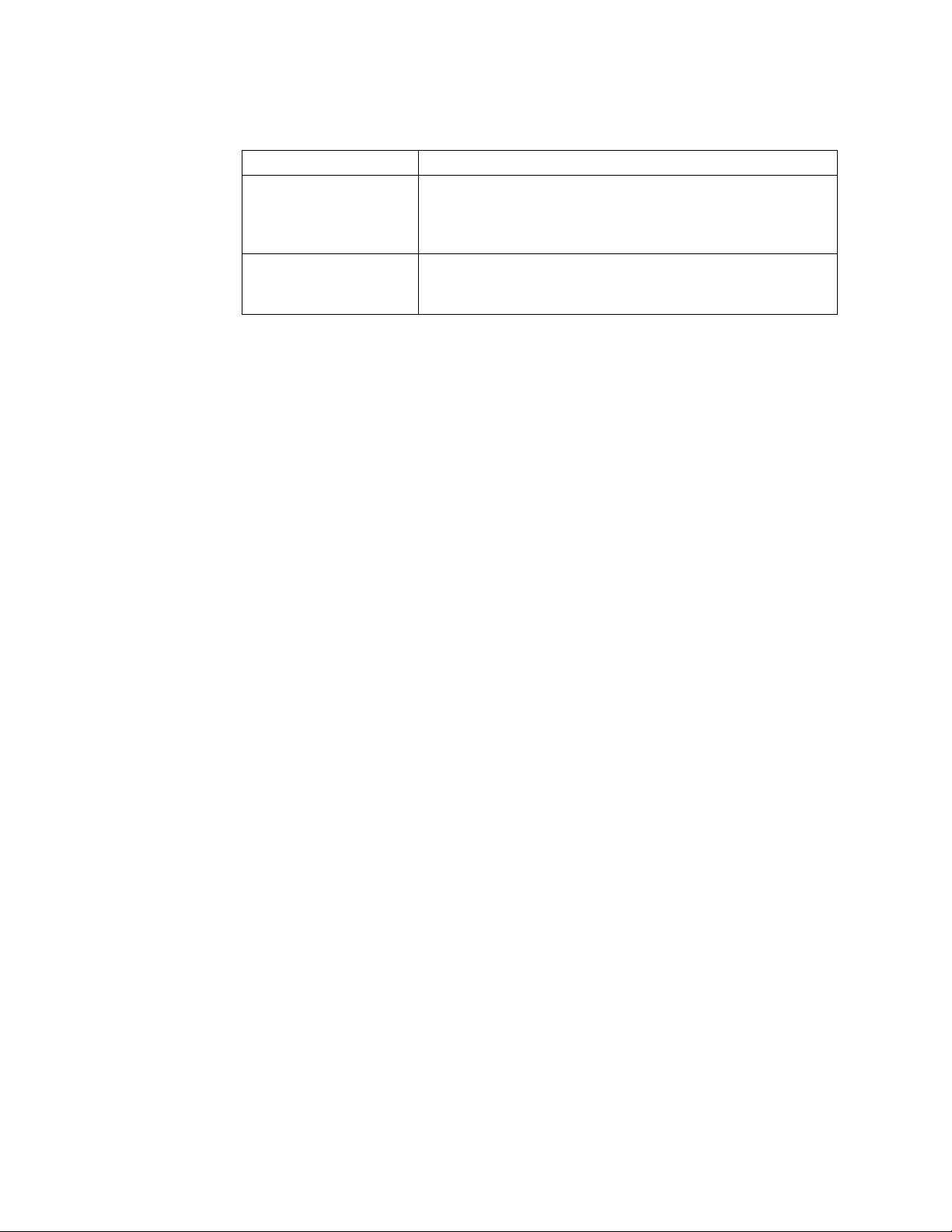

Category Standard Designed/tested for compliance with

Safety ANSI / UL60950

IEC 60950

73/23/EEC Low Voltage Directive

CAN/CSA C22.2,

No. 60950-00

Europe:

EN 60950

Safety of Information Technology Equipment,

including Electrical Business Equipment.

Safety of Information Technology Equipment,

including Electrical Business Equipment

Safety of Information Technology Equipment,

including Electrical Business Equipment.

Safety of Information Technology Equipment,

including Electrical Business Equipment.

12 Planning and Installation Manual

Page 14

KayakDD-2 Digital Production Switcher

Category Standard Designed/tested for compliance with

EMI

EMC Directive

89/336/EEC via

Audio, Video and Entertainment Lighting

Control for the European Community.

EN 55103-1 and 2

EN 55103-1

standards

Electromagnetic compatibility.

Product family standard for audio, video, audiovisual and entertainment lighting control

apparatus for professional use.

Part 1 Emissions, Environment E1/E2

EN 55022: Class A (Control Panel) and Class B

(Mainframe) Radiated and Conducted

Emissions

EN 61000-3-2: Power Line Harmonic

Emissions, Radiated Magnetic Field Emissions,

Peak Inrush Current

EN55103-2

standards

Electromagnetic compatibility--Product family

standard for audio, video, audio-visual and

entertainment lighting control apparatus for

professional use.

Part 2 Immunity, Environment E1/E2

EN 50082-1: Immunity

EN 61000-4-2:

Electrostatic Discharge “ESD” Immunity

EN 61000-4-3:

Radiated RF Electromagnetic Field Immunity

EN 61000-4-4:

Electrical Fast Transient/Burst “EFT” Immunity

EN 61000-4-5: Surge Immunity

EN 61000-4-6: Conducted RF Immunity

EN 61000-4-11: Voltage Dips, Short

Interruptions and Voltage Variations

Annex A - Radiated Magnetic Field Immunity

Note: This only applies to assemblies sensitive

to magnetic fields

US FCC Class A CISPR Pub. 22 (1985)

Canada FCC

Industry Canada

Australia &

New Zealand:

AS/NZS 3548

Planning and Installation Manual 13

Page 15

KayakDD-2 Digital Production Switcher

14 Planning and Installation Manual

Page 16

KayakDD-2 Digital Production Switcher

3 Safety Summary

Read and follow the important safety information below, noting especially those

instructions related to risk of fire, electric shock or injury to persons. Additional specific

warnings not listed here may be found throughout the manual.

WARNING!

Any instructions in this manual that require opening the equipment cover or

enclosure are for use by qualified service personnel only. To reduce the risk of

electric shock, do not perform any servicing other than that contained in the

operating instructions unless you are qualified to do so.

3.1 Safety Terms and Symbols

3.1.1 Terms in This Manual

Safety-related statements may appear in this manual in the following form:

WARNING!

Warning statements identify conditions or practices that may result in personal

injury or loss of life.

CAUTION!

Caution statements identify conditions or practices that may result in damage

to equipment or other property, or which may cause equipment crucial to

your business environment to become temporarily non-operational.

3.1.2 Terms on the Product

The following terms may appear on the product:

DANGER!

A personal injury hazard is immediately accessible as you read

the marking.

WARNING!

A personal injury hazard exists but is not immediately accessible

as you read the marking.

CAUTION!

A hazard to property, product, and other equipment is present.

Planning and Installation Manual 15

Page 17

KayakDD-2 Digital Production Switcher

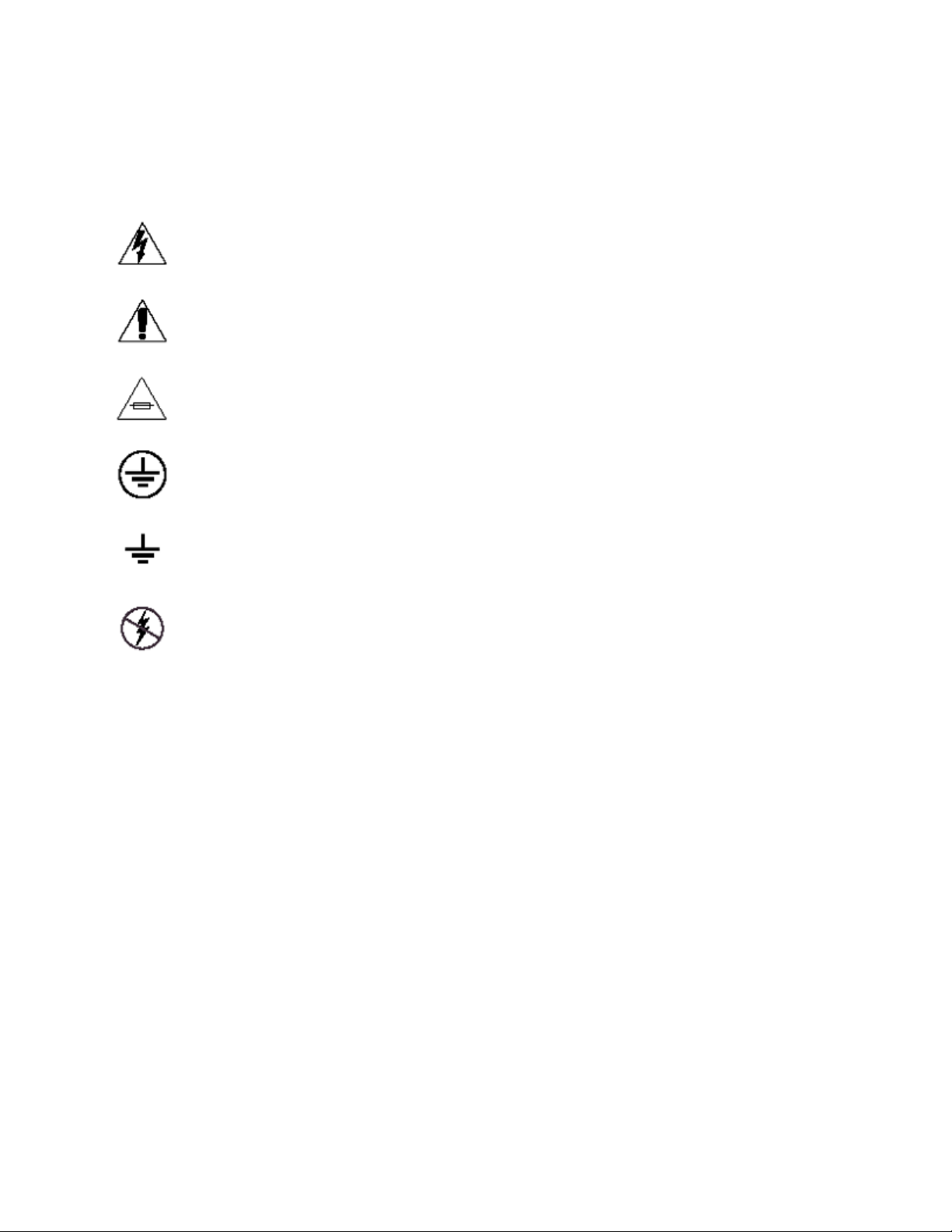

3.1.3 Symbols on the Product

The following symbols may appear on the product:

Indicates that dangerous high voltage is present within the equipment enclosure that

may be of sufficient magnitude to constitute a risk of electric shock.

Indicates that user, operator or service technician should refer to product manual(s) for

important operating, maintenance, or service instructions.

This is a prompt to note fuse rating when replacing fuse(s). The fuse referenced in the

text must be replaced with one having the ratings indicated.

Identifies a protective grounding terminal which must be connected to earth ground

prior to making any other equipment connections.

Identifies an internal Protective Bounding Conductor (PBC) terminal proper earthing of

metal parts auf the unit (EN 60950 / 1.1.13.9).

Indicates that static sensitive components are present which may be damaged by

electrostatic discharge. Use anti-static procedures, equipment and surfaces during

servicing.

16 Planning and Installation Manual

Page 18

3.2 Warnings

The following warning statements identify conditions or practices that can result in

personal injury or loss of life.

WARNING — To reduce the risk of electrical shock, do not remove cover or back. No

user-serviceable parts inside. Refer to qualified service personnel.

• Dangerous voltage or current may be present — Disconnect power and remove

battery (if applicable) before removing protective panels, soldering, or replacing

components.

• Do not service alone — Do not internally service this product unless another

person capable of rendering first aid and resuscitation is present.

• Remove jewelry — Prior to servicing, remove jewelry such as rings, watches, and

other metallic objects.

• Avoid exposed circuitry — Do not touch exposed connections, components or

circuitry when power is present.

• Use proper power cord — Use only the power cord supplied or specified for this

product.

• Ground product — Connect the protective conductor of the power cord to earth

ground.

• Operate only with covers and enclosure panels in place — Do not operate this

product when covers or enclosure panels are removed.

• Use correct fuse — Use only the fuse type and rating specified for this product.

• Use only in dry environment — Do not operate in wet or damp conditions.

• Use only in non-explosive environment — Do not operate this product in an

explosive atmosphere.

• High leakage current may be present — Earth connection of product is essential

before connecting power.

• Dual power supplies may be present — Be certain to plug each power supply

cord into a separate branch circuit employing a separate service ground.

Disconnect both power supply cords prior to servicing.

• Double pole neutral fusing — Disconnect mains power prior to servicing.

• Use proper lift points — Do not use door latches to lift or move equipment.

• Avoid mechanical hazards — Allow all rotating devices to come to a stop before

servicing.

KayakDD-2 Digital Production Switcher

Planning and Installation Manual 17

Page 19

KayakDD-2 Digital Production Switcher

3.3 Cautions

The following caution statements identify conditions or practices that can

result in damage to equipment or other property:

• Use correct power source — Do not operate this product from a power source

that applies more than the voltage specified for the product.

• Use correct voltage setting — If this product lacks auto-ranging power supplies,

before applying power ensure that each power supply is set to match the power

source.

• Provide proper ventilation — To prevent product overheating, provide equipment

ventilation in accordance with installation instructions.

• Use anti-static procedures — Static sensitive components are present which

may be damaged by electrostatic discharge. Use anti-static procedures, equipment

and surfaces during servicing.

• Do not operate with suspected equipment failure — If you suspect product

damage or equipment failure, have the equipment inspected by qualified service

personnel.

• Ensure mains disconnect — If mains switch is not provided, the power cord(s) of

this equipment provide the means of disconnection. The socket outlet must be

installed near the equipment and must be easily accessible. Verify that all mains

power is disconnected before installing or removing power supplies and/or options.

• Route cable properly — Route power cords and other cables so that they are not

likely to be damaged. Properly support heavy cable bundles to avoid connector

damage.

• Use correct power supply cords — Power cords for this equipment, if provided,

meet all North American electrical codes. Operation of this equipment at voltages

exceeding 130 VAC requires power supply cords which comply with NEMA

configurations. International power cords, if provided, have the approval of the

country of use.

• Use correct replacement battery — This product may contain batteries. To

reduce the risk of explosion, check polarity and replace only with the same or

equivalent type recommended by manufacturer. Dispose of used batteries

according to the manufacturer’s instructions.

• Troubleshoot only to board level — Circuit boards in this product are densely

populated with surface mount technology (SMT) components and application

specific integrated circuits (ASICs). As a result, circuit board repair at the

component level is very difficult in the field, if not impossible. For warranty

compliance, do not troubleshoot systems beyond the board level.

18 Planning and Installation Manual

Page 20

KayakDD-2 Digital Production Switcher

4 Technical Specification

4.1 Power Supply Frame

Line voltage 100V-240V AC +/-10% autorange,

power factor corrected

(48V / 5A DC Input for ext. redundancy)

Line frequency 50/60Hz +/- 5%

Power consumption max. 250W (max. 310W with 48V DC supply for panel)

Leakage current < 2 mA

RAMRecorder buffer voltage: 6…8V DC approx. 150 mA.

DC-OUT for control panel 48V DC, max 1.6A

4.2 Power Supply Panel

DC-IN 48V DC In, max 1.3A

Power consumption max. 60W

4.3 Environmental Data

Storage temperature -20°C to +70°C (-4°F to 158°F)

Operating temperature +5°C to +40°C (41°F to 104°F)

Relative humidity ≤ 95% non-condensing

Electromagnetic

environment E2 (according to EN55103-1, -2)

Planning and Installation Manual 19

Page 21

KayakDD-2 Digital Production Switcher

4.4 Video System Data

Standards Interlaced 525 lines (59.94/60Hz)

or 625 lines (50Hz) switchable or autosensing

Data rate 270Mbit

Aspect Ratio 4:3 or 16:9 switchable

Signal Processing 4:2:2 in conformity with ITU-R 601

Minimum Delay 20 µsec

Blanking horizontal Transparent for background signal

Blanking vertical Transparent for background signal,

except for lines 6 and 319 (625/50Hz)

Number Bits 10

4.5 Serial Digital Video Inputs

Number & format 32 inputs according to ITU-R656, 270Mbit/s

Return loss > 15dB, 5-270MHz

Type of Connector 75 ohm BNC (SMPTE 259M)

Nominal Amplitude 800mV peak-to-peak terminated

Autophasing range 43 µsec

Channel Coding conforms to SMPTE RP-259M

Ancillary Data Blanked or passed (user selectable)

Embedded audio Blanked or passed (user selectable)

EDH Blanked

Input Impedance 75 ohm

Max cable length 225 meters (738ft) (inputs 1..24)

Inputs 25..32 150m.

20 Planning and Installation Manual

Page 22

4.6 Serial Digital Video Outputs

Number & format 20 outputs according to ITU-R656, 270Mbit/s

Return loss > 15dB, 5-270MHz

Type of Connector 75 ohm BNC (SMPTE 259M)

Nominal Amplitude 800mV peak-to-peak +/-10% (SMPTE 259M)

Rise & Fall Times 400 to 1400picoseconds 75 ohm termination

between 20% and 80% amplitude

Jitter ITU R 601/656

Output Impedance 75 ohm

DC Offset < 50mV with 75 ohm termination

KayakDD-2 Digital Production Switcher

4.7 Analog Reference Input

Video Standard 525 line (59.94Hz/60Hz) or 625 line (50Hz)

BNC, 0.3V sync, black-burst or CCVS

Return loss > 40dB, up to 5MHz

Connectors 2 BNC loop through

Impedance 75 ohm external

4.8 Control Panel Connection

Type of connection 10/100 Base T

Protocol TCP(UDP)/IP as in XtenDD

Cable and connectors CAT5 UTP, RJ45 connectors;

1 Frame and 1 Panel connect without use of external hub/switch.

max. Cable length 100m / 300ft

Planning and Installation Manual 21

Page 23

KayakDD-2 Digital Production Switcher

4.9 Mechanical Data

KayakDD-2 Control Panel

Width 809 mm (31.8 inch)

Depth 418 mm (16.5 inch)

Mounting Depth 33 – 81 mm (1.3 - 3.2 inch)

Weight 10 kg (22 lb)

KayakDD-2 Mainframe

Height 3 RU 134 mm (5.3 inch)

Width 482 mm (19 inch)

Depth 430 mm (17 inch)

Weight 8.3 kg (18.3 lb)

22 Planning and Installation Manual

Page 24

5 System Overview

5.1 Introduction

The Grass Valley KayakDD™ digital production switcher is an affordable, compact, and

flexible system that offers an array of high-end features for everything from live studio

and mobile production to small corporate studios and editing applications.

The KayakDD switcher leverages many of the features found in the Thomson Grass

Valley XtenDD

image quality and features not found in any other product.

Switchable between 525-line and 625-line formats, the KayakDD system includes four

high-quality keyers and complete machine control functionality. It features 32 inputs,

10 fixed outputs, and 10 timed auxiliary buses. And it accommodates such options as

Chromatte

Manipulators for sophisticated digital video effects.

For ease of operation, the KayakDD system features an intuitive menu using an

integrated touch-screen color display. It also offers a networking capability that enables

different frames to be delegated to a single panel as well as multiple panels to share a

single frame.

Only 3 RU high, the lightweight KayakDD-2 switcher is designed to be highly portable.

™ and Zodiak™ switchers. The result is a compact system with superior

™ Chroma Keying, RGB color correction, and up to eight Digital Picture

KayakDD-2 Digital Production Switcher

5.1.1 Features

• Switchable between 525-line and 625-line formats

• Fully digital 10-bit, 4:2:2 inputs, outputs, and video processing

• Compact, lightweight 3 RU frame

• Low power consumption

• Intuitive menu with touch screen

• 32 inputs

• 10 fixed M/E outputs (2x PGM, 1x Preview, 1x Clean, 1x CleanPVW per M/E)

• 10 timed auxiliary buses

• Internal frame optional RAMRecorder holds short clips and stills and works as

frame synchronizer

• Remote monitoring support via optional NetCentral software

• Four keyers, each with linear, luminance and optional Chromatte

functionality per M/E

• Optional RGB color correction

• Four channels of high-end digital effects (Option) per M/E

™ chroma key

Planning and Installation Manual 23

Page 25

KayakDD-2 Digital Production Switcher

5.1.2 Supported Control Protocols

• Supports extensive list of control protocols, including those for:

• VTRs (BVW-75)

• Servers (Louth VDCP, Odetics BVS)

• Routers/Routing Control Systems (Trinix

routers; Jupiter

• Control Systems (Grass Valley Andromeda

• Grass Valley under monitor displays

• Grass Valley external auxiliary panels

• ESAM II for audio-follow-video applications

• Edit controllers (native and Grass Valley Model 100 and 200)

™, Venus™, Triton™, and third-party

™ and Encore™ {future} router control systems)

™ and third-party systems)

24 Planning and Installation Manual

Page 26

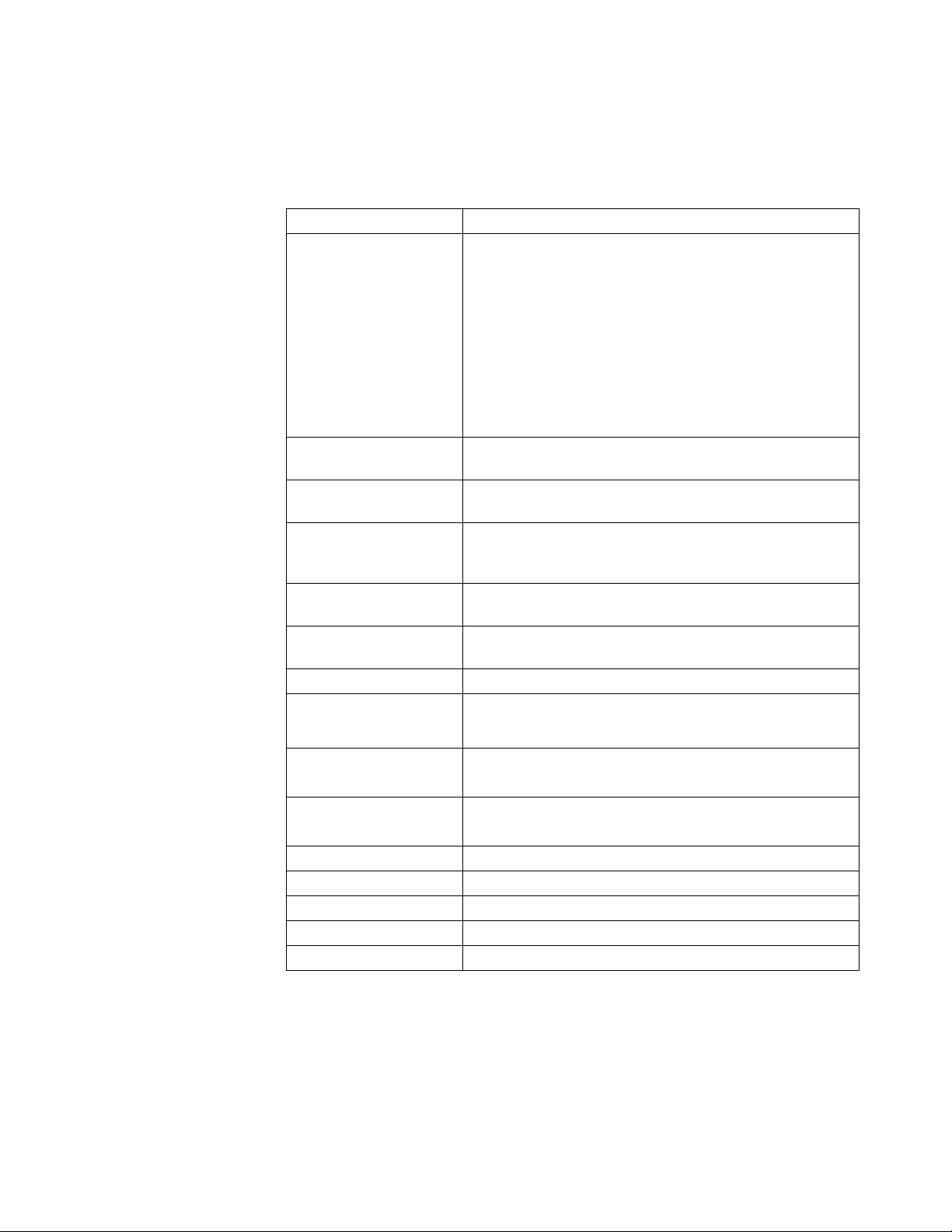

5.1.3 KayakDD-2 Ordering Information

Type Description

KAYAK-DD-2

KDD2-DPM-1

KDD2-DPM-P

KDD2-RAMREC

KDD2-RGB

KDD2-CHROMA

KDD2-NETCEN

KDD2-MNEMO-KIT

KDD2-WHITEKEYS

KDD2-COLORKEYS

KDD-DC-CABLE-100

KDD-DC-CABLE-50

KDD-PSU

KDD-PSU-CABLE-5

KDD-PSU-CABLE-20

Frame: 2 M/Es, all inputs and outputs, 8 keyers

(2 ChromaKeyers ME1 Key1 and ME1 Key2),

2V/K Channels TE (DVE) = 1 per bank),

YUV color corrector,

Frame store (fill and key) per keyer,

Serial ports, all protocols, GPI/Tally.

Control Panel: 2ME, 24Source buttons.

Source mnemonics

TFT menu display with touchscreen;

standard length DC-CABLE (20m),

crossover LAN cable (20m)

License to operate additional 3 DVE (iDPM) channels

plus non-linear effects in ME1

License to operate additional 3 DVE (iDPM) channels

plus non-linear effects in PP

KayakDD Four-Channel RAM-Recorder incl.

FileTransfer. RAM-Recorder can also be used to

synchronize incoming non-synchronous signals

License for RGB color correction for all ME and PP

buses = 14 Color correctors

License for two additional flexible ChromaKeyers six

additional ChromaKeyers

License for NetCentral agent

Source Mnemonics upgrade kit. Material only.

Installation only by Authorized Service Provider (addtl.

Expense for labor time)

White keycaps for multicolor illumination

This option is initial order only and not field upgradeable

GV style colorkeys

This option is initial order only and not field upgradeable

100m DC power cable

50m DC power cable

Same external power supply as for KayakDD-1

5m cable PSU to mainframe

20m cable PSU to mainframe

KayakDD-2 Digital Production Switcher

Planning and Installation Manual 25

Page 27

KayakDD-2 Digital Production Switcher

Type Description

KDD2-FRAME

KDD2-PANEL

For later order of any combination of KDD2-DPM, KDD2-DPM-P, KDD2-RAMREC,

KDD2-RGB, KDD2-CHROMA and KDD2-NETCEN order KDD2-SW-OPT once per

switcher and include iButton ID and serial number in the order.

Frame: 2 M/Es, all inputs and outputs, 8 keyers

(2 ChromaKeyers), 2V/K Channels iDPM (DVE) = 1 per

bank), YUV color corrector, frame store (fill and key) per

keyer, serial ports, all protocols, GPI/Tally.

Control Panel: 2ME, 24Source buttons.

Source mnemonics

TFT menu display with touchscreen

26 Planning and Installation Manual

Page 28

5.2 System Components

A KayakDD-2 Production Switcher system consists of a control panel with integrated

menu display (color TFT with touch-screen) and a Video Processor Frame with three

rack units (3 RU) height.

Figure 1 Video Processor Fram e

KayakDD-2 Digital Production Switcher

Figure 2 Control Panel

Planning and Installation Manual 27

Page 29

KayakDD-2 Digital Production Switcher

5.3 Control Surface

Figure 3 KayakDD-2 Control Panel Surface

The panel is organized into subpanels that contain groups of related controls. The

panel provides real time button, knob, and lever arm control of one full function

mix/effects (PGM/PST with full M/E capability).

Connectors to the KayakDD Video Processor frame and to other components of the

KayakDD Control Surface are located on the rear of the panel.

28 Planning and Installation Manual

Page 30

5.4 Video Processor Frame

5.4.1 System Components

The KayakDD-2 Video Processor frame houses most of the system electronics in a

very compact design. A built-in fan system allows cooling of the frame. The frame

contains the following modules:

• Mainboard RY 3910

• Expansion Board RY 3920

• M/E Processor Board RY 3720

• Power Supply Unit

• Fan Unit RC 3740

• Cable Set RC 3950

The figure below shows the frame with opened housing.

The KayakDD system has been designed for easy maintenance. There are no

serviceable parts inside. Modules and power supplies should be removed and

replaced from Thomson Grass Valley service personnel only!

KayakDD-2 Digital Production Switcher

Planning and Installation Manual 29

Page 31

KayakDD-2 Digital Production Switcher

Fan Unit

M/E Processor Board

Main Board

Power

Supply

Unit

Air flow

Figure 4 KayakDD-2 Video Processor Frame

30 Planning and Installation Manual

Page 32

5.4.2 Video Processor Frame Options

Digital Pictures Manipulator

The KayakDD Digital Pictures Manipulators (iDPM) per keyer provide the following

internal digital effects capability:

• 2-D effects in 3-D space with perspective (= 3D-planar),

• Border, outline, and extrude effects,

• Independent drop shadow,

with the (KDD2-DPM-1 resp. KDD2-DPM-P option which includes the KURL™

functionality)

• Page turn, Page Rolls

• Splits, mirrors and slits.

RGB Color Correction

In addition to the standard solarization, posterization, mosaic capabilities and YUV

color correction, RGB color correction can be added to all M/E background, keyer fill,

and utility buses.

Chroma Keyers

In addition to the two standard chroma keyers, two more chroma keyers are added to

the system with the KDD-RGB option.

KayakDD-2 Digital Production Switcher

Planning and Installation Manual 31

Page 33

KayakDD-2 Digital Production Switcher

5.5 Functional Overview

5.5.1 Video Signal Flow

The basic system architecture (Figure 5) of the KayakDD system has been designed

for operational flexibility. For example, all the outputs from the M/E are routed back to

the video crosspoint matrix, making all these signals accessible to the entire system.

The 32 video inputs to the Video Processor frame can be mapped to any of the 24

crosspoint buttons.

Internally generated white, black and three color backgrounds are also available

sources, as are the four RAMRecorder outputs. This source-to-button mapping is done

through the touch screen menu and can be stored as a user profile for any number of

individual users. Button mapping is the same on all buses.

The system has a full M/E with PGM/PST being a full M/E as well.

The selected video on each bus is deserialized and reclocked before entering the

video processing circuitry. Video processing is available for each separate M/E

background, Key, and Utility bus, providing built-in solarization, posterization and

mosaic effects. In addition, contrast, brightness, and hue can be adjusted on a bus-bybus basis.

Each M/E has four full-function keyers with optional internal Digital Picture Manipulator

effects. Each keyer has access to its own wipe generator as well as a pair of standard

floating chroma keyers which may be assigned to any keyers in the system. Two

complex wipe generators serve each M/E, providing a wide range of wipe choices with

modulation, rotation and multiplication of each one. Wipe signals can also be taken

from the Utility bus on the M/E.

The outputs from M/E Program and Preview are fed to dedicated BNCs and sent back

to the crosspoint circuitry for the Auxiliary buses as well as the clean feed output.

The 10 Aux bus outputs can be utilized in a number of ways. Every Aux bus provides

individually adjustable safe area and crosshair (center cross) capability. Each AUX bus

has a line synchronizer.

32 Planning and Installation Manual

Page 34

KayakDD-2 Digital Production Switcher

Main Board RY 3910

ME: Single Mixer Effect (Plug-In Board) RY 3930

iDPM

Video

Proc

PP: Single Mixer Effect (Plug-In Board) RY 3720

iDPM

Video

Proc

AUX

Proc

Figure 5 KayakDD-2 Simplified Video Flow Diagram

Planning and Installation Manual 33

Page 35

KayakDD-2 Digital Production Switcher

5.5.2 System Control

KayakDD-2 system control is designed for flexibility and simplicity. Ethernet, serial,

parallel, and USB are used for system component interconnections. Tally and GPI

control are available.

34 Planning and Installation Manual

Page 36

6 Installation

6.1 Pre-Installation Procedures

Before you physically install the KayakDD-2 system, familiarize yourself with the tools

required, physical specifications, and safety and power requirements covered in this

section.

6.1.1 System Survey

Check all parts received against the packing list enclosed with your shipment, and

examine the equipment for any shipping damage. Immediately report any missing or

damaged items to the carrier and to your Thomson Grass Valley Service

Representative.

KayakDD-2 Digital Production Switcher

6.1.2 Line Voltage

KayakDD-2 components utilize auto-ranging power supplies which accommodate

100 - 240V. No switch settings are required, nor are any possible.

6.1.3 Safety Requirements

To prevent injury or equipment damage, read, understand, and follow all installation

safety precautions.

WARNING!

The Video Processor frame weighs approximately 8.3 kg (18.3 lb). Provide appropriate

equipment to support the frame during installation.

WARNING!

Electrical potential is still applied to some internal components even when power to the

frame is off. To prevent electrical shock when working on this equipment, disconnect

the AC line cords from the AC source before working on any internal components.

Residual voltage may be present immediately after unplugging the system; wait thirty

seconds to allow capacitors to discharge before working on the system.

CAUTION!

To avoid static damage to sensitive electronic devices, protect the KayakDD-2 system

from static discharge. Avoid handling frame modules in a high static environment. Use

a grounding strap when handling modules, and touch the frame before you remove

any modules.

Planning and Installation Manual 35

Page 37

KayakDD-2 Digital Production Switcher

6.1.4 Installation Tasks

After completing the Pre-Installation procedures, the recommended installation tasks

given in this section are:

1. Unpack the equipment,

2. Install the KayakDD-2 Video Processor frame,

3. Install the KayakDD-2 control panel,

4. Connect all cables between KayakDD-2 devices,

5. Connect cables to video inputs and outputs, and

6. Connect the power cables.

Power up and configuration, including setting IP addresses, is covered in detail in the

next sections of this manual.

36 Planning and Installation Manual

Page 38

6.2 Mounting the Processor Frame

6.2.1 Video Processor Frame Measurements

482mm / 19inch

465mm / 18.3inch

KayakDD-2 Digital Production Switcher

h

c

n

i

5

2

.

2

/

m

m

5

1

,

7

5

438mm / 17.2inch

h

c

i

5

.

5

1

/

m

m

9

,

1

0

4

h

c

n

i

2

.

5

/

m

m

5

9

,

2

3

1

h

c

n

i

6

.

5

1

/

m

m

4

7

,

0

2

4

h

c

n

i

3

.

0

/

m

m

5

,

7

Figure 6 KayakDD-2 Video Processor Frame Dimensions

Planning and Installation Manual 37

Page 39

KayakDD-2 Digital Production Switcher

6.2.2 General Rack Mounting Instructions

• The maximum ambient temperature for this unit is 40°C (104°F).

• Installing the unit in a closed or multi-unit rack assembly, together with other units

could increase the maximum ambient for this unit.

• If the unit is installed in a rack, no ventilation openings should be blocked or

otherwise covered. Ensure a sufficient amount of airflow. Airflow through KayakDD

is from the left side of the frame to the right side of the frame.

• Mounting of the unit in the rack should be such that a hazardous condition is not

achieved due to uneven mechanical loading.

• When connecting the unit to the supply circuit be sure that the supply circuit of the

rack is not overloaded. For ratings see chapter Technical Specifications.

• The unit must be grounded to a good earth ground using a wire as specified by the

local electrical code. This wire is attached to the protective earth connector on the

rear.

• When connecting the unit in a closed or multi-unit rack assembly together with

other units be sure that the summation of the touch (leakage) currents for each

power supply circuit is not higher than 3.5 mA . In this case the rack must be

permanently connected with an earth terminal. Earth connection is essential before

connecting supply voltage! For details see chapter Technical Specifications.

The video processor frame has to be mounted in a rack using the delivered screws.

For mobile application, using of slide rails are strongly recommended. For installation,

Thomson Grass Valley optionally provides a 19-inch cabinet with mounting

accessories. When using cabinets of other manufacturers, observe the respective

mounting instructions.

38 Planning and Installation Manual

Page 40

6.2.3 Rack Mounting Procedure

KayakDD-2 Digital Production Switcher

Slide rails

Recommended for mobil applications!

Not part of delivery!

Figure 7 KayakDD-2 Video Processor Frame Rack Mounting

• Place the right and left bottom ends of the KayakDD-2 on the slide rails, and slide

the equipment to the rear.

• Fix the rack angles of the video processor frame to the rack using the delivered

four screws.

WARNING!

For normal rack mounting the rack angle are strong enough. If the video processor

frame is fixed with at the rack angles only, do not load the frame with other equipment

or the cables. For mobile application (flight case, OB van), it is not allowed to fix the

video processor frame using the rack angles only!

Planning and Installation Manual 39

Page 41

KayakDD-2 Digital Production Switcher

6.3 Mounting the Control Panel

6.3.1 Control Panel Measurements

Bold dimensions are [mm]

(16.46 inch)

(5.69 inch)

(10.23 inch)

(0.60 inch)

(2.55 inch)

(1.31 inch)

(3.19 inch)

(0.39 inch)

(15.66 inch)(0.40 inch)

Figure 8 KayakDD-2 Control Panel Measurements 1 of 2

40 Planning and Installation Manual

Page 42

KayakDD-2 Digital Production Switcher

-

10mm

h

c

n

i

5

.

6

1

/

m

m

8

1

4

789mm / 31.1inch

809mm / 31.9inch

10mm

0.4inch0.4inch

809mm / 31.9inch

Figure 9 KayakDD-2 Control Panel Measurements 2 of 2

Planning and Installation Manual 41

Page 43

KayakDD-2 Digital Production Switcher

6.3.2 Table Top Mounting

In many cases the panel can just be put on a table. Gummed feet prevent accidental

movement of the panel.

6.3.3 Cut Out Dimensions for Surface Mounting

For surface mounting of the control panel the cutout dimensions are:

791 mm x 400 mm

CAUTION!

Regardless of mounting method or cutout dimensions, ensure that there is at least

2 inch (50 mm) of clear space at the rear of the panel below the mounting surface for

proper cable clearance and air flow.

6.3.4 Mounting Holes for Panel Fastening

For fastening the panel in a table there are four M4 thread drillings on the panel. Those

allow to fasten the panel from below the table. The length of the screws is dependent

on the respective thickness of the tabletop (see Figure 9 and 10 with mounting details

below).

The figure below shows the position of the mounting holes.

42 Planning and Installation Manual

Page 44

KayakDD-2 Digital Production Switcher

Figure 10 Bottom View, Position of the Mounting Points

Planning and Installation Manual 43

Page 45

KayakDD-2 Digital Production Switcher

M4 thread drilling

(2.95 inch)

Thread drillings

for panel fastening

(10.55 inch)

799

(17.24 inch)

(0.2 inch)

Bold dimensions are [mm]

Figure 11 Bottom View, Measurements of the Mounting Points

Washer

Lock nut

Fastening screw

Panel Fastening Procedure:

The length of the screw is dependent on the

thickness of the tabletop! The M4 screw

should be approx. 25 mm of (1 inch) longer

than the thickness of the tabletops.

Screw lock nut completely on the fastening

screw and put on a washer.

Then turn the fastening screw from below

through the drillings in the table in the

thread drillings of the frame.

At least turn the locking nut up to fix the

panel.

Figure 12 Panel Fastening Procedure

44 Planning and Installation Manual

Page 46

6.4 Control Panel Connectors

Figure 13 Control Panel Connectors

The rear of the KayakDD-2 Panel provides the power and system control connectors

for the system:

Jack Designation Note

J1-A DC POWER IN

J1-B

M4 threaded pin

RED. DC

POWER IN

KayakDD-2 Digital Production Switcher

DC power input connector for 48V operating voltage.

Connecting with the DC POWER OUT at the

Processor Frame. An interconnecting cable with a

length of 10 m (32ft.) is enclosed.

Alternatively optional cables of 50m (164 ft) and 100m

(328 ft.) length can be used.

In case of longer distances (e.g. using fiberoptic

cabling (not supplied by Thomson Broadcast & Media

Solutions) ) a separate 48V Power Supply Unit has to

be connected.

NOTE!

The external power supply unit must comply with

the SELV (Safety Extra Low Voltage) standard

exclusively. ELV and TNV standard is not

permitted!

DC power input connector for 48V operating voltage

from Redundant Power Supply Unit KDD-PSU.

An interconnecting cable with a length of 5 m (16ft.) is

delivered with KDD-PSU.

Alternatively optional cables of 20m (64 ft) length can

be used.

Screw terminal for additional unit earthing

Planning and Installation Manual 45

Page 47

KayakDD-2 Digital Production Switcher

Jack Designation Note

J2

USB 1

J3

USB 2

J4 LAN

J5 RS 485

J6 RS 232

Additional connectors at the rear of the menu display.

Spare, for future use!

Connectors for USB devices, e.g. CD-ROM Drive,

Mouse, Keyboard or Memory Stick.

Only recommended devices are supported.

For recommended Memory Stick refer to chapter

7.2.1 below.

Function of other devices can not be guaranteed.

RJ45 connector for connection to the Processor

Frame. An crossed interconnecting cable with a

length of 20 m is enclosed. Cables with lenghs of 20m

or 50m can be ordered optionally.

RS422/RS485 interface for connecting an external

devices. The software control automatically switches

over the interface to master or slave (bus

control/tributary), depending on which unit driver has

been selected in the menu.

RS232 interface for connecting a diagnosis computer

or other external devices.

These connectors are operator accessible!

Jack Designation Note

USB 3

USB 4

Spare, for future use!

Connectors for USB devices, e.g. CD-ROM Drive,

Mouse, Keyboard or Memory Stick.

Only recommended devices are supported.

For recommended Memory Stick refer to chapter

below.

P/S 2

Possibility to connect a P/S 2 Mouse or Keyboard.

46 Planning and Installation Manual

Page 48

6.5 Processor Frame Connectors

KayakDD-2 Digital Production Switcher

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause undesired operation.

IN 8

IN 10

IN 9

J 32

J 34

J 33

M/E

0

2

1

-

0

PGM CLEANPVW CLEAN-PVW AUX 1 AUX 2 AUX 3 AUX 4 AUX 5 AUX 6 AUX 7 AUX 8 AUX 9 AUX 10

D

0

D

9

3

K

A

2

1

Y

0

2

A

0

K

0

1

y

e

l

l

a

v

s

s

.

.

a

r

O

O

g

N

N

.

T

E

R

R

P

J 4 J 5 J 6 J 7 J 8

E

A

Y

T

S

P

AC POWER IN

100 - 240 V

max. 4A

50/60 Hz

Caution: For continued protection against risk

of fire, repplace only with same type and rating of fuse.

J1

2*T6,3A /H

250V

DD-2

grass valley

P/P

IN 2

IN 1

IN 3

J 26

J 25

J 27

DC POWER

J2

J3

KAYAK

2 M/E DIGITAL SWITCHER

J 9 J 10 J 11 J 12 J 13 J 14 J 15 J 16 J 17 J 18

IN 4

IN 6

IN 5

IN 7

J 30

J 29

J 31

J 45 J 46 J 47 J 48 J 49

PGM CLEANPVW CLEAN-PVW

IN

48V / 5A max.

OUT

48V / 1,6A

J 28

INPUT 1-16

Figure 14 Video Processor Frame Connectors

Jack Designation Note

J1 AC POWER IN

AC POWER IN

INPUT

J25

IN1 – IN16

:

J40

INPUT

J50

IN17 – IN32

:

J65

AUX 1-10

IN 12

IN 14

IN 16

IN 11

IN 13

J 36

J 35

IN 17

IN 25

IN 15

J 38

J 40

J 37

J 39

IN 18

IN 19

IN 20

J 50

J 51

IN 26

J 58

J 52

IN 27

IN 28

J 59

J 60

Port 1 Port 2 Port 3

Port 4 Port 5 Port 6

ANALOG

J 42

J 41

REFERENCE

INPUT 17-32

IN 21

J 53

IN 29

J 61

N4067

IN 22

J 54

IN 30

J 62

J 19 J 20 J 21

J 22 J 24J 23

GPI/O - Tally

J 55

J 63

RS 485

R

Listed

Prof. Vid. Equipm.

3S13

IN 23

IN 24

J 56

IN 31

IN 32

J 64

LAN

J 44J 43

J 57

J 65

Mains connector (IEC-320, CEE-22) for power supply

to the Video Processor Frame.

Operating Voltage: 100V-240V AC +/-10% widerange

Caution!

Double-pole or neutral fusing.

After operation of the protective device, parts of

the equipment that remain under voltage might

represent a hazard during servicing.

Caution!

For continued protection against risk of fire,

replace only with same type and rating of fuse!

2x T 6.3A /H 250

Frame power switch

BNC / Serial Comp (ITU-R 656) video inputs

Maximum cable length 225m (738 ft)

BNC / Serial Comp (ITU-R 656) video inputs

In 17 …24: Maximum cable length 225m (738 ft)

In 25 …32: Maximum cable length 150m (492 ft)

Planning and Installation Manual 47

Page 49

KayakDD-2 Digital Production Switcher

Jack Designation Note

M/E OUTPUTS

J45/J46

J47

J48

J49

J4/J5

J6

J7

J8

J9

PGM

PVW-A

CLEAN

CLEAN PVW

P/P OUTPUTS

PGM

PVW-A

CLEAN

CLEAN PVW

AUX 1 – AUX10

:

J18

J41

REFERENCE

J42

J19

RS 485 PORTS

:

J24

J43 GPI/O - TALLY

J44 LAN

BNC / Serial Comp (ITU-R 656)

Double Program output

Preview output

Clean output

Clean Preview output

BNC / Serial Comp (ITU-R 656)

Double Program output

Preview output

Clean output

Clean Preview output

Auxiliary Outputs, BNC / Serial Comp (ITU-R 656)

Reference input, BNC / 75 ohms

Loop through sync input for analog Blackburst or

CCVS signal.

Six control ports, 9-pin D-type female

RS485 serial ports for devices such as DVEs, Editors,

Routers and for Machine Control (Disk Servers, VTR).

50-pin D-type female

General-purpose interface connector with 8 input

channels and 32 output channels.

The connector is used for Tally also.

Refer table below for respective pin assignment.

RJ45 connector for connection to the Control Panel.

An interconnecting cable with a length of 10 m is

enclosed. Cables with lengths of 20m or 50m can be

ordered optionally.

48 Planning and Installation Manual

Page 50

KayakDD-2 Digital Production Switcher

Jack Designation Note

J2 DC POWER IN

Input connector for external DC Power Supply Unit

(KDD-PSU) for redundancy (High current D-Sub,

female).

Input voltage: 48V/ 5A

Note:

The external power supply unit must comply with

the SELV (Safety Extra Low Voltage) standard

exclusively. ELV and TNV standard is not

permitted!

Additionally the 8V DC voltage for RAM Recorder

buffering can be supplied via this socket.

Refer table below for respective pin assignment.

J3

DC POWER

OUT

Output connector for Panel DC Power Supply.

(High current D-Sub, male).

Output voltage: 48V/ 1.6A max

An DC power interconnecting cable with a length of

10 m is enclosed.

Planning and Installation Manual 49

Page 51

KayakDD-2 Digital Production Switcher

6.6 Pin Assignments

6.6.1 RS 485 Port

Socket Pin Bus Controller Tributary

D-9 Female

Pin 1Pin 5

Pin 6Pin 9

1 Chassis Ground Chassis Ground

2

3 TxB (+) RxB (+)

4 Signal Ground Signal Ground

5 Not used Not used

6 Signal Ground Signal Ground

7 RxB (+) TxB (+)

8

9 Chassis Ground Chassis Ground

RxA (−) TxA (−)

TxA (−) RxA (−)

6.6.2 RS 232 Port

Socket Pin Signal

D-9 Female

Pin 1Pin 5

Pin 6Pin 9

1 Chassis Ground

2 Transmit Data

3 Receive Data

4 Not used

5 Signal Ground

6 Not used

7 Clear to Send

8 Request to Send

9 Not used

50 Planning and Installation Manual

Page 52

6.6.3 Panel DC Power In

Socket Pin Signal

D-Sub Male

Pin A1

6.6.4 Frame DC Power In

Socket Pin Signal

D-Sub Male

Pin A1

Pin 2Pin 1

Pin 5Pin 3

Pin 2Pin 1

Pin 5Pin 3

Pin A2

Pin A2

KayakDD-2 Digital Production Switcher

A1 48 V (+)

A2

48 V (−)

1 2 3 4 -

5 -

A1 48 V (+)

A2

48 V (−)

1 Ground

2 Return Sense

*

3 + 7 V (RAM Rec)

*

Note: Pins 2 and 5 must be connected in the plug

4 -

5 48V Return

*

of the external power supply unit.

6.6.5 Frame DC Power Out

Socket Pin Signal

D-Sub female

D-Sub Female

Pin 1Pin 2

Pin A2

Pin 3Pin 5

Pin A1

Planning and Installation Manual 51

A1 48 V (+)

A2

48 V (−)

1 2 3 4 -

5 -

Page 53

KayakDD-2 Digital Production Switcher

6.6.6 Frame GPI/O – Tally

Socket Ribbon Cable 50-Pin D-Sub Signal

D-50 Female

Pin 18

Pin 1

Pin 34

Pin 33

Pin 17

Pin 50

1 1 GPIInCom

2 34 GPIInCom

3 18 GPIIn1

4 2 GPIIn2

5 35 GPIIn3

6 19 GPIIn4

7 3 GPIIn5

8 36 GPIIn6

9 20 GPIIn7

10 4 GPIIn8

11 37 GPIOutComA

12 21 GPIOut1A

13 5 GPIOut2A

14 38 GPIOut3A

15 22 GPIOut4A

16 6 GPIOutComB

17 39 GPIOut5B

18 23 GPIOut6B

19 7 GPIOut7B

20 40 GPIOut8B

21 24 GPIOutComC

22 8 GPIOut9C

23 41 GPIOut10C

24 25 GPIOut11C

25 9 GPIOut12C

26 42 GPIOutComD

27 26 GPIOut13D

28 10 GPIOut14D

29 43 GPIOut15D

30 27 GPIOut16D

31 11 GPIOutComE

32 44 GPIOut17E

33 28 GPIOut18E

34 12 GPIOut19E

35 45 GPIOut20E

36 29 GPIOutComF

37 13 GPIOut21F

38 46 GPIOut22F

39 30 GPIOut23F

40 14 GPIOut24F

41 47 GPIOutComG

42 31 GPIOut25G

43 15 GPIOut26G

44 48 GPIOut27G

45 32 GPIOut28G

46 16 GPIOutComH

47 49 GPIOut29H

48 33 GPIOut30H

49 17 GPIOut31H

50

50 GPIOut32H

52 Planning and Installation Manual

Page 54

6.7 Cabling and Control

6.7.1 Cabling

The cabling of a standard KayakDD-2 application is illustrated in figure below.

KayakDD-2 Digital Production Switcher

DC Power Supply

48V (Redundancy)

Keyboard

0

2

1

-

0

D

0

D

9

PGM CLEANPVW CLEAN-PVW

3

K

A

2

y

1

Y

0

e

l

2

A

l

0

a

1

0

K

v

.

.

s

O

O

s

a

N

N

r

g

.

T

E

R

R

P

E

A

Y

J 4 J 5 J 6 J 7 J 8

S

T

P

AC POWER IN

100 - 240 V

max. 4A

50/60 Hz

Caution:For continued protection against risk

of fire, repplace only with same type and rating of fuse.

2*T6,3A /H

J1

250V

J2

J3

grass valley

P/P

IN 1

J 25

DC POWER

IN 2

IN 3

J 26

J 27

IN

48V / 5A max.

OUT

48V / 1,6A

Mouse

USBP/S 2

3

4

Control Panel

Video Processor Frame

DD-2

KAYAK

2 M/E DIGITAL SWITCHER

AUX 1 AUX 2 AUX 3 AUX 4 AUX 5 AUX 6 AUX 7 AUX 8 AUX 9 AUX 10

J 9 J 10 J 11 J 12 J 13 J 14 J 15 J 16 J 17 J 18

IN 4

IN 6

IN 5

J 28

J 30

J 29

J 31

J 45 J 46 J 47 J 48 J 49

PGM CLEANPVW CLEAN-PVW

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause undesired operation.

AUX 1-10

IN 8

IN 10

IN 12

IN 7

IN 9

IN 11

J 32

J 34

J 36

J 33

INPUT 1-16

J 35

IN 17

M/E

IN 25

IN 14

IN 13

J 38

J 37

IN 18

J 50

IN 26

J 58

Note:

Keyboard and Mouse not

mandatory and not supplied.

CAT5 Crossover Cable

Port 1 Port 2 Port 3

J 19 J 20 J 21

Port 4 Port 5 Port 6

J 22 J 24J 23

IN 16

ANALOG

IN 15

J 39

IN 19

J 51

IN 27

J 59

J 42

J 40

J 41

REFERENCE

INPUT 17-32

IN 20

IN 21

J 52

J 53

IN 28

IN 29

J 60

J 61

RS 485

LAN

R

Listed

Prof. Vid. Equipm.

3S13

IN 24

J 56

IN 32

J 64

J 44J 43

J 57

J 65

GPI/O - Tally

N4067

IN 22

IN 23

J 54

J 55

IN 30

IN 31

J 62

J 63

AC Power Supply

110-240V

DC Power Supply

48V (Redundancy)

Figure 15 KayakDD-2 Standard Cabling