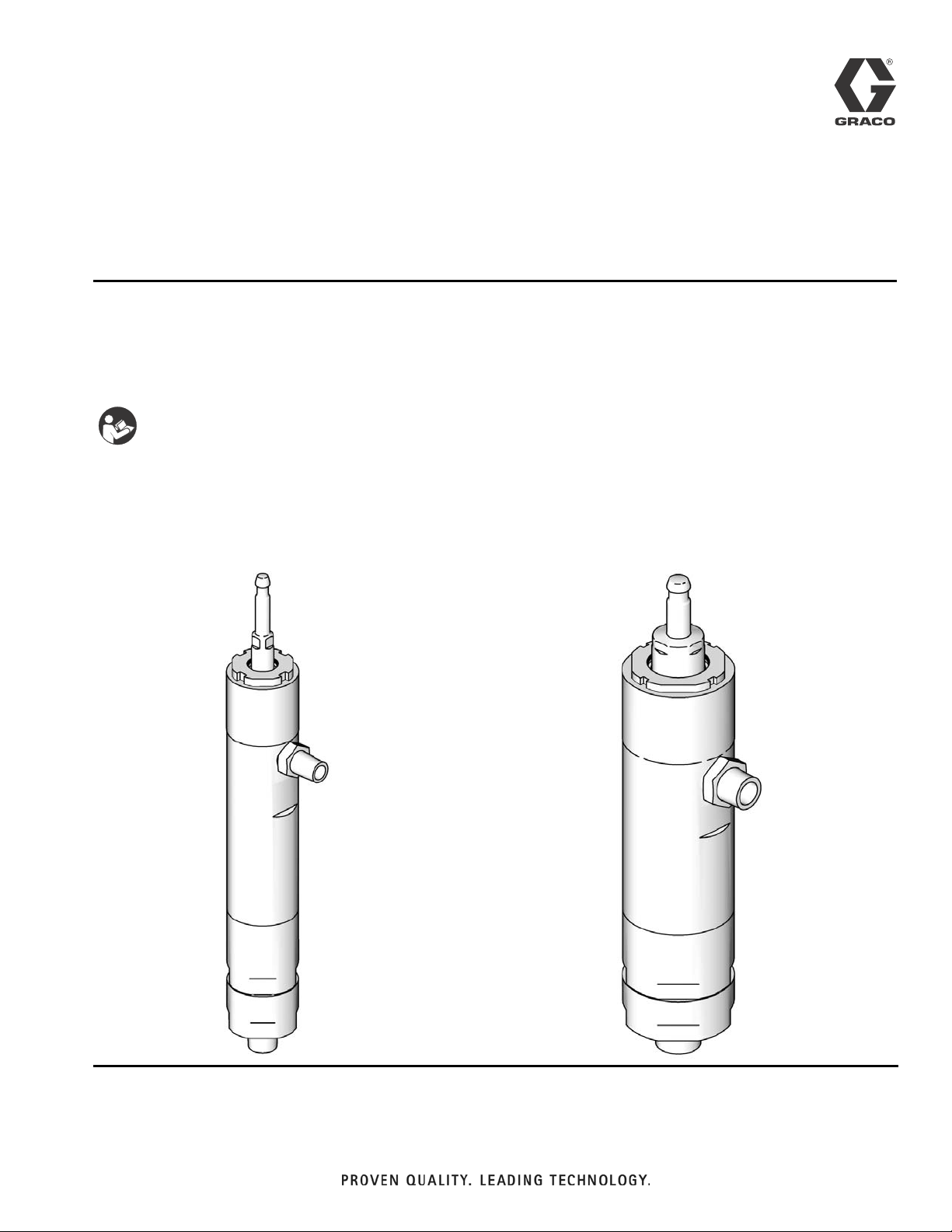

Graco Merkur A Series, Merkur LW025A, Merkur LW075A, Merkur LW100A, Merkur LW050A Repair And Parts Manual

...

Repair/Parts

Merkur

®

312792F

Displacement Pump

For use with high-performance finishing and coating pumps in hazardous and

non-hazardous locations. For professional use only.

Important Safety Instructions

Read all warnings and instructions in this manual.

For complete warnings and instructions see your

pump or package manual. Hazard symbols refer to

specific procedure risks. Save all instructions.

See page 3 for model information, including maximum working pressures.

LW025A

LW150A

ENG

TI11643a

TI11645

Related Manuals

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Component Identification . . . . . . . . . . . . . . . . . . . . 4

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

General Information . . . . . . . . . . . . . . . . . . . . . . 5

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Related Manuals

Manual Description

312796

312794 Merkur Pump Assembly

312797 Merkur Spray Packages, ambient, AA

312798 Merkur Electrostatic Spray Packages

313255 Merkur Heated Spray Packages

™

NXT

Air Motor

and Airless

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Repair Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Optional Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 14

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 14

2 312792F

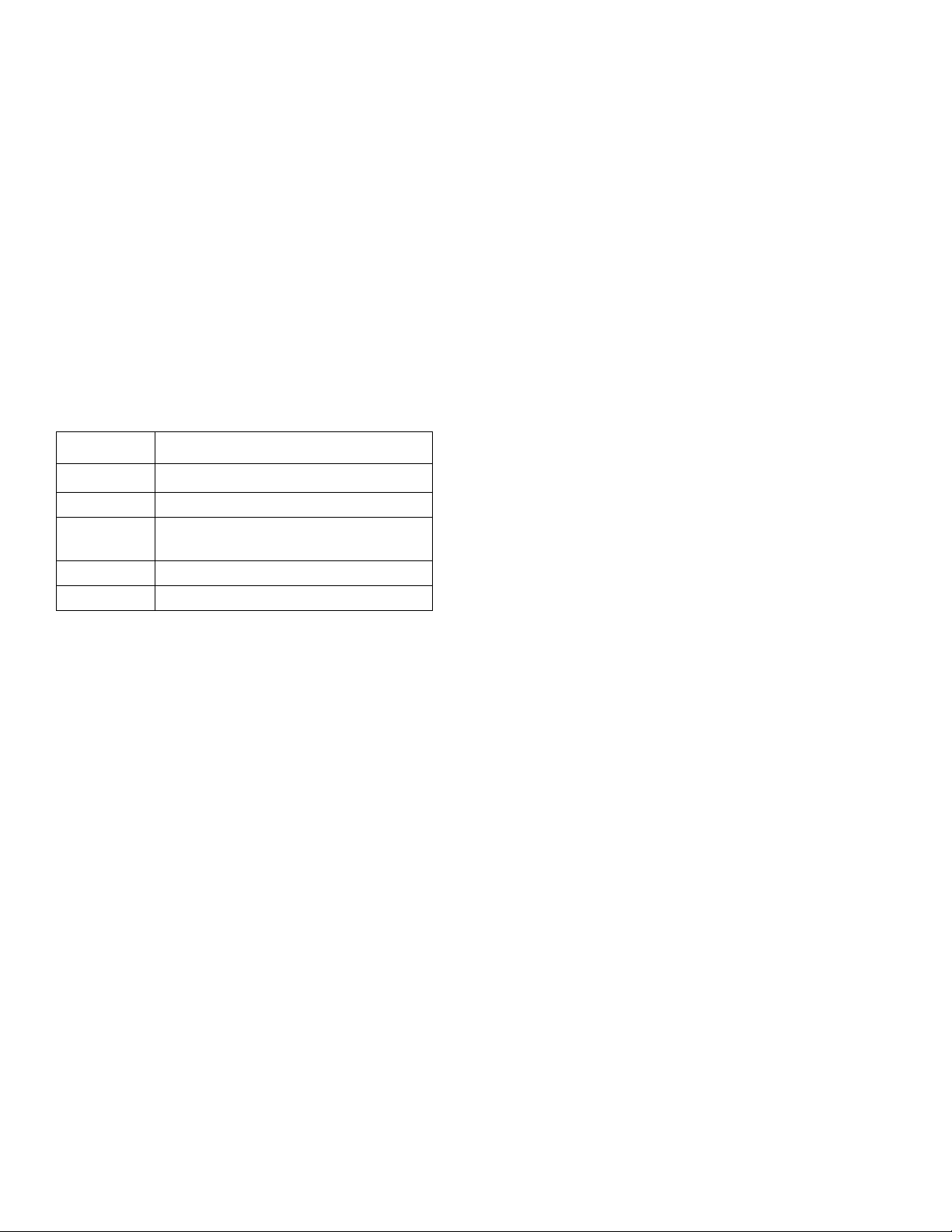

Models

Check your displacement pump’s identification marking for the 6-digit part

number. Use the following matrix to define the construction of your displacement pump. For example, displacement pump model LW025A represents a

wet-cup style stainless steel displacement pump, 25 cc, with a Chromex

coated rod and 3 UHMWPE, 2 PTFE packings.

To order replacement parts, see Parts section starting on page 9. The digits in

the matrix do not correspond to the reference numbers in the Parts drawings

and lists.

LW 025 A

Third, Fourth, and Fifth

Digits

First Digit

Second Digit

(Description)

(Displacement Pump

Volume Per Cycle* in cc)

(Packings; Displacement Rod Coating)

Sixth Digit

Models

ti12415a

L

(Lower)

W

Wet-cup style,

stainless steel

025 A

050

075

100

125

150

* Cycle refers to combination of one upstroke and one downstroke.

Maximum Working

Pressure

Model, Series

LW025A, Series A

LW050A, Series A

LW075A, Series A

LW100A, Series A

psi (MPa, bar) Fluid Inlet Fluid Outlet

3000 (20.7, 207) 1/2 in. npt 3/8 in. npt

4500 (31.0, 310) 3/4 in. npt 3/8 in. npt

4800 (33.1, 331) 3/4 in. npt 3/8 in. npt

3600 (24.8, 248) 3/4 in. npt 3/8 in. npt

3 UHMWPE, 2 PTFE; Chromex™

LW125A, Series A

LW150A, Series A

312792F 3

2900 (20.0, 200) 1 in. npt 1/2 in. npt

2400 (16.5, 165) 1 in. npt 3/4 in. npt

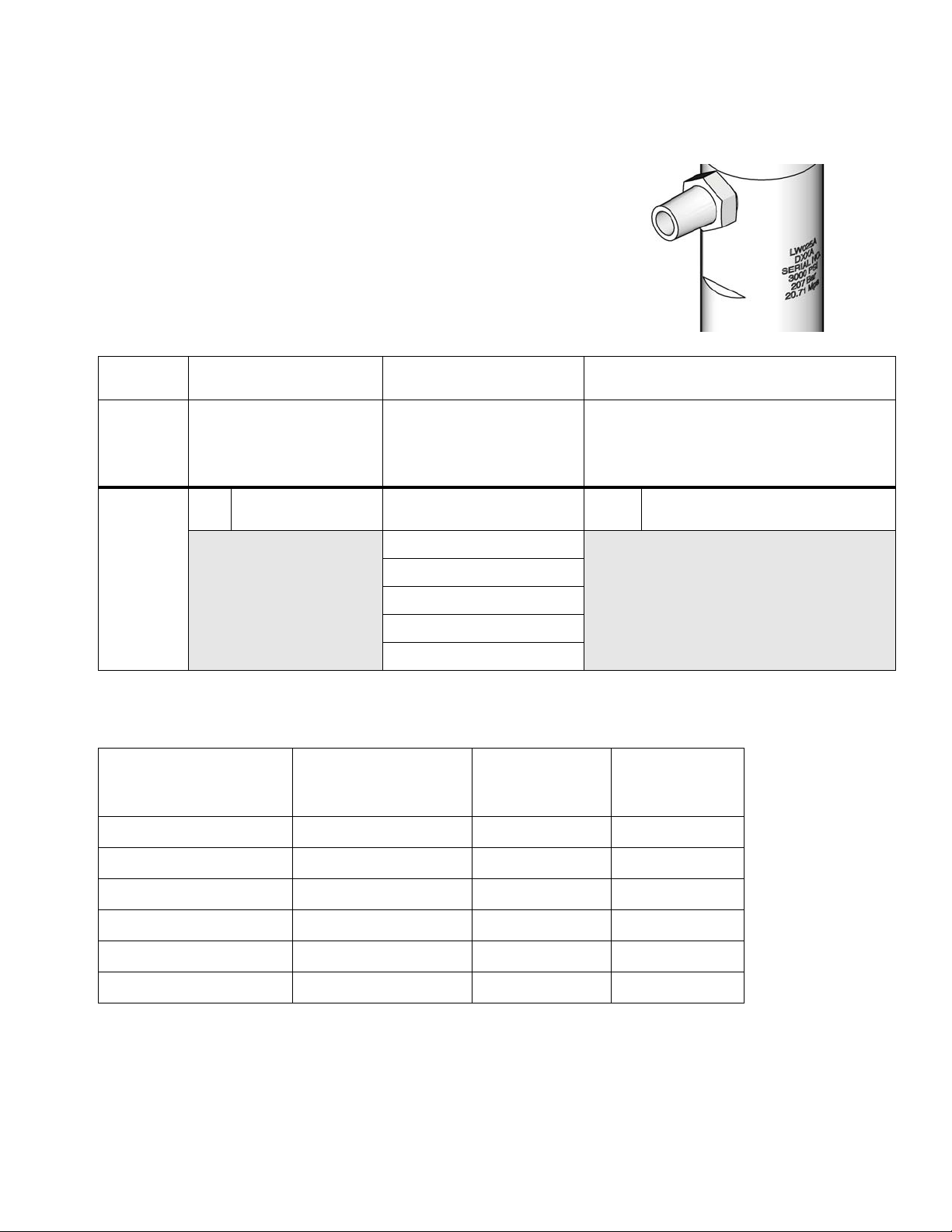

Component Identification

Component Identification

A

F

E

B

C

FIG. 1. Component Identification

Key:

A Piston/Rod Assembly

BWet Cup

C Fluid Outlet

D Fluid Inlet

E Lower Cylinder

F Upper Cylinder

G Intake Valve

G

D

ti11645a

4 312792F

Repair

General Information

Repair

Threads are very sharp. Use a rag to protect hands.

NOTICE

Reference numbers and letters in parentheses in the

text refer to the callouts in the figures and the parts

drawing.

Always use Genuine Graco Parts and Accessories,

available from your Graco distributor. If you supply

your own accessories, be sure they are adequately

sized and pressure rated for your system.

Preparation

Follow all warnings and instructions in your pump manual for the following preliminary steps:

1. Flush the equipment.

2. Relieve the pressure.

3. Remove the displacement pump from the pump

assembly.

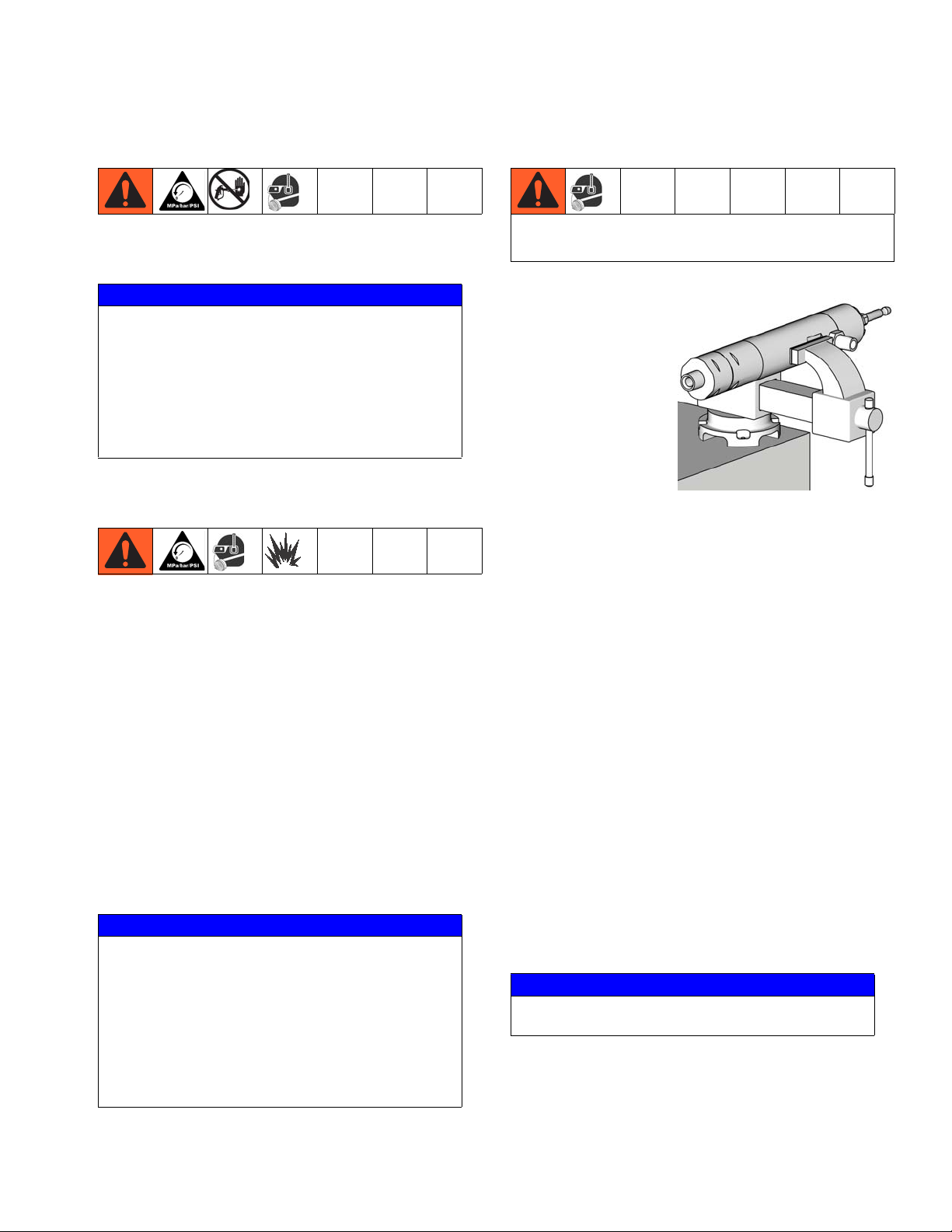

1. Place cylinder (1)

sideways in a

vise with soft

jaws.

2. Use an adjustable

wrench on hex of

intake housing

(23) to unscrew it

from the lower

cylinder (2).

Loosen vice

briefly and tip out

the ball (24◆).

3. Remove the seat (22†) and use an o-ring pick to

remove the seal (26†) from the intake housing. See

F

IG. 7.

4. Use an adjustable wrench on hex of lower cylinder

(2) to remove it from the upper cylinder (1) and slide

it straight off the pump. Be careful not to damage

the piston/rod assembly (3).

5. Remove the o-ring (21*†) from the top of the lower

cylinder.

ti12918a

6. Loosen the wet cup (5).

Disassembly

Lay out all removed parts in sequence to ease

reassembly. Clean all parts with a compatible solvent

and inspect them for wear or damage.

NOTICE

Repair Kits are available. See the chart on page 11

to order the correct kit(s) for your pump.

• Parts included in the Seal Repair Kit are marked

with an *, for example 8*.

• Parts included in the Seat Repair Kit are marked

with a †.

• Parts included in the Check Ball Kit are marked

with a ◆.

312792F 5

7. Pull the piston/rod assembly out the bottom of the

upper cylinder. Remove the spring (10*), piston

packings (12* and 13*) and glands (11* and 14*).

8. Remove the wet cup (5).

9. Remove the throat packings (7*, 8*) and glands (6*,

9*) from the bottom of the wet cup.

NOTICE

The jam nut can remain attached to the upper cylinder.

10. Remove the spring (4*) from the top of the upper

cylinder (1).

Loading...

Loading...