Graco Inc. 246639, 246752, 246753, 246365, 246760 Repair - Parts

...

Repair - Parts

309813H

Air Powered, Heated, Plural Component

Proportioners

For spraying polyurethane foam and polyurea coatings.

Not for use in explosive atmospheres.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

For model information, see page 3.

TI3699b

Manual Conventions

Contents

Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . 2

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Air Powered Reactors . . . . . . . . . . . . . . . . . . . . . 3

Supplied Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Before Beginning Repair . . . . . . . . . . . . . . . . . . . . 8

Flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . 9

Temperature Control Diagnostic Codes . . . . . . . 10

E01: High fluid temperature . . . . . . . . . . . . . . . 10

E02: High hose current . . . . . . . . . . . . . . . . . . . 10

E03: No hose current . . . . . . . . . . . . . . . . . . . . 11

E04: FTS or thermocouple not connected . . . . 11

E05: Board overtemperature . . . . . . . . . . . . . . . 11

Manual Conventions

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Proportioning Pump . . . . . . . . . . . . . . . . . . . . . . 15

Circuit Breaker Module . . . . . . . . . . . . . . . . . . . 16

Temperature Control Board . . . . . . . . . . . . . . . . 18

Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Heated Hose . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Fluid Temperature Sensor (FTS) . . . . . . . . . . . . 23

Display Module . . . . . . . . . . . . . . . . . . . . . . . . . 29

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 50

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 50

Warning

WARNING

A warning alerts you to possible serious injury or

death if you do not follow instructions.

Symbols, such as fluid injection (shown), alert you to a

specific hazard and direct you to read the indicated

hazard warnings on pages 6-7.

Caution

CAUTION

A caution alerts you to possible equipment damage or

destruction if you do not follow instructions.

Note

A note indicates additional helpful information.

2 309813H

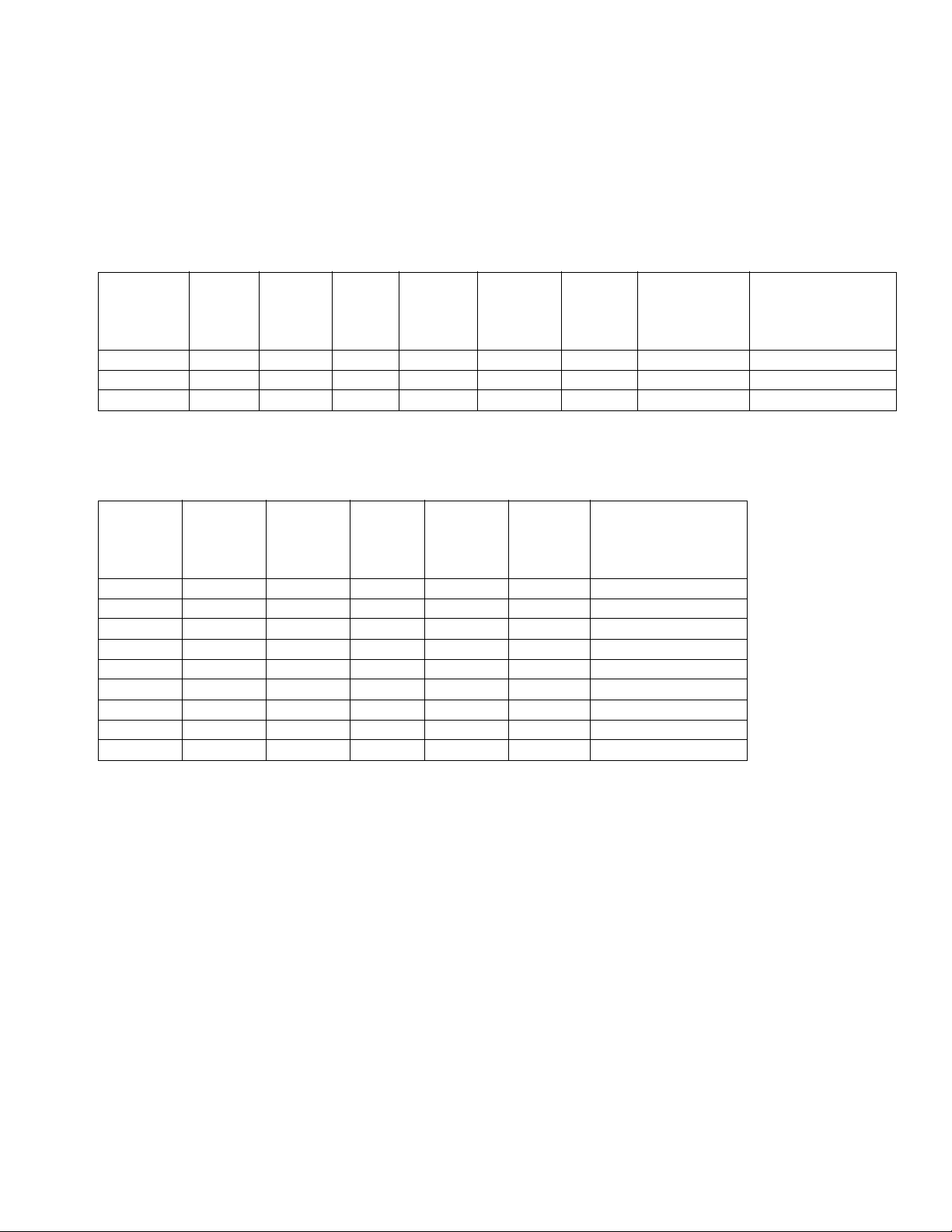

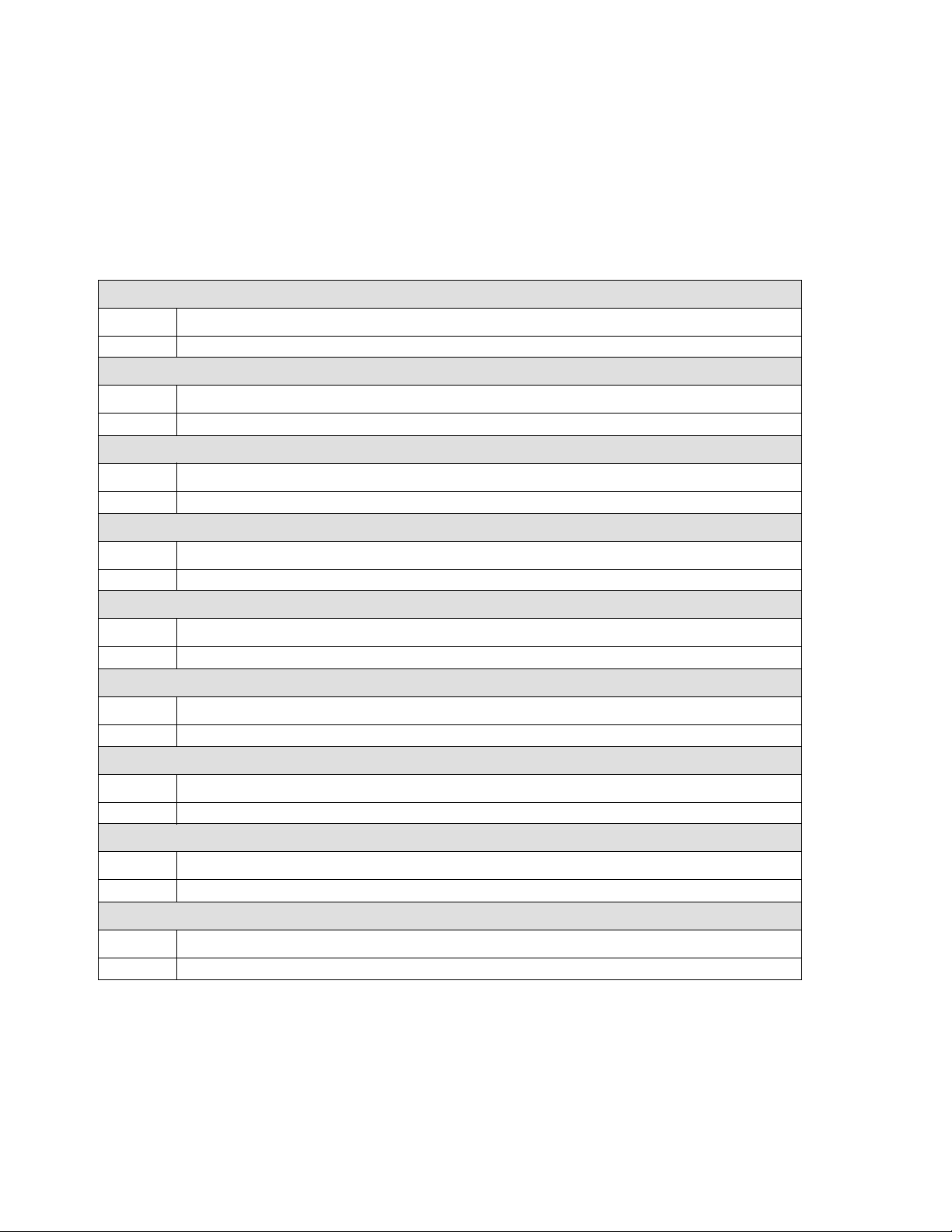

Models

Air Powered Reactors

A-XP SERIES

Models

Full

Load

Part No.,

Series Model

246639, B A-XP2 230V (1) 62 14,540 10,200 1 (3.8) .0193 (.073) 3000 (20.7, 207)

246752, B A-XP2 230V (3) 40 14,540 10,200 1 (3.8) .0193 (.073) 3000 (20.7, 207)

246753, B A-XP2 380V (3) 22 14,540 10,200 1 (3.8) .0193 (.073) 3000 (20.7, 207)

Voltag e

(phase)

Peak

Amps*

System

Watts**

Heater

Watts

(no hose)

Flow

gpm

(lpm) at

78 cpm

Output per

Cycle (A + B)

gal. (liter)

Maximum Fluid

Working Pressure

psi (MPa, bar)

Heat Packages (do not include proportioner)

Full

Load

Part No.,

Series Model

246365, B HT-6.0 230V (1) 44 10,340 6,000 3500 (24.1, 241)

246760, B HT-6.0 230V (3) 27 10,340 6,000 3500 (24.1, 241)

246761, B HT-6.0 380V (3) 18 10,340 6,000 3500 (24.1, 241)

246607, B HT-10.2 230V (1) 62 14,540 10,200 3500 (24.1, 241)

246762, B HT-10.2 230V (3) 40 14,540 10,200 3500 (24.1, 241)

246763, B HT-10.2 380V (3) 22 14,540 10,200 3500 (24.1, 241)

246364, B HT-15.3 230V (1) 84 19,640 15,300 3500 (24.1, 241)

246764, B HT-15.3 230V (3) 57 19,640 15,300 3500 (24.1, 241)

246765, B HT-15.3 380V (3) 33 19,640 15,300 3500 (24.1, 241)

Voltag e

(phase)

Peak

Amps*

System

Watts**

Heater

Watts

(no hose)

Maximum Fluid

Working Pressures

psi (MPa, bar)

* Full load amps with all devices operating at maximum capabilities. Fuse requirements at various flow rates and mix chamber

sizes may be less.

**Total system watts for all units, using 310 ft (94.6 m) hose.

309813H 3

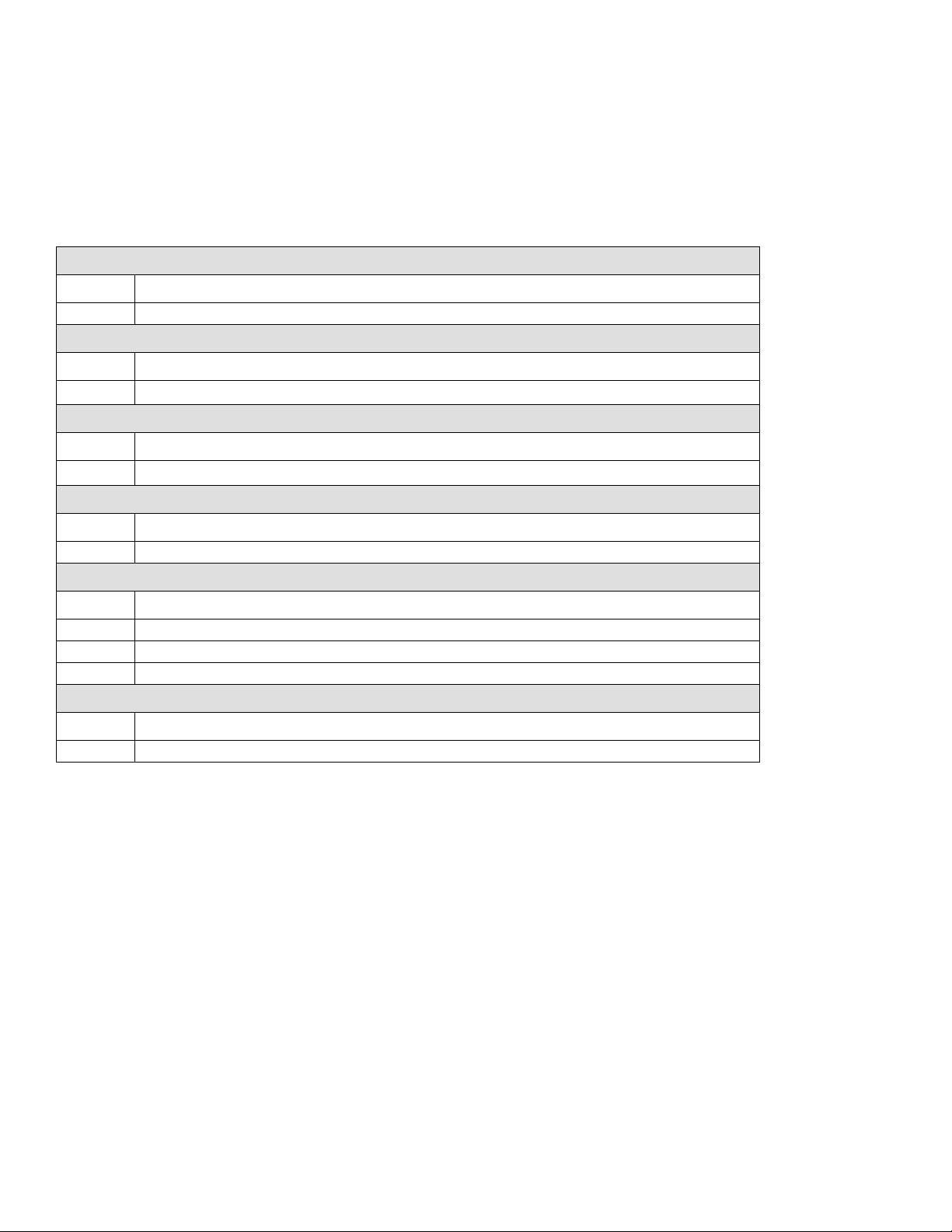

Supplied Manuals

Supplied Manuals

The following manuals are shipped with the Reactor™.

Refer to them for detailed equipment information.

Air and Hydraulic Reactors

Part No. Description

309812 Air and Hydraulic Reactors, Operation Manual (English)

Proportioning Pumps

Part No. Description

308224

Motors

Part No. Description

306982

Displacement Pumps

Part No. Description

307430 Displacement Pumps Repair-Parts Manual (English)

Reactor Electrical Diagrams (one of following included)

Part No. Description

309854 Electrical Diagrams, 230V 1 phase

309855 Electrical Diagrams, 230V 3 phase

309576 Electrical Diagrams, 380V 3 phase

Air Regulators (air powered units only)

President

President

®

Pump Repair-Parts Manual (English)

®

Air Motor Repair-Parts Manual (English)

Order Part No. 15B535 for a compact disk of Reactor

manuals translated in several languages.

Part No. Description

308168 Instruction-Parts Manual (English)

4 309813H

Related Manuals

Related Manuals

The following manuals are for accessories used with the

Reactor

™

.

Hydraulic Power Supply

Part No. Description

307550 Instruction-Parts Manual (English)

Feed Pump Kits

Part No. Description

309815 Instruction-Parts Manual (English)

Air Supply Kit

Part No. Description

309827 Instruction-Parts Manual (English) for Feed Pump Air Supply Kit

Circulation and Return Tube Kits

Part No. Description

309852 Instruction-Parts Manual (English)

Heated Hose

Order Part No. 15B535 for a compact disk of Reactor

manuals translated in several languages.

Order Part No. 15B381 for a compact disk of Fusion

manual translated in several languages.

Part No. Description

309572 Instruction-Parts Manual (English)

Fusion Air Purge Spray Gun

Part No. Description

309550 Instruction-Parts Manual (English)

Fusion Mechanical Purge Spray Gun

Part No. Description

309856 Instruction-Parts Manual (English)

Circulation Kit

Part No. Description

309818 Instruction-Parts Manual (English)

Data Reporting Kit

Part No. Description

309814 Instruction-Parts Manual (English)

309813H 5

Warning

WARNING

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point the gun at anyone or at any part of the body.

• Do not put your hand or fingers over the gun fluid nozzle.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Do not “blow back” fluid; this is not an air spray system.

• Follow Pressure Relief Procedure, page 9, when you stop spraying and before cleaning, checking,

or servicing equipment.

• Use lowest possible pressure when flushing, priming, or troubleshooting.

• Engage spray gun piston safety lock when not spraying.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately. High pressure hose cannot be recoupled; replace the entire hose.

FIRE, EXPLOSION, AND ELECTRIC SHOCK HAZARD

Solvent and fumes in work area can ignite or explode. High voltage components can cause electric

shock. To help prevent fire, explosion, and electric shock:

• Shut off main power switch and wait 5 minutes before opening Reactor cabinet door.

• All electrical wiring must be done by trained and qualified personnel and comply with all local codes.

• Ground equipment and conductive objects. See Grounding in the Operation manual.

• Use equipment only in well ventilated area.

• Eliminate all ignition sources, such as pilot lights, cigarettes and plastic drop cloths (potential static

arc).

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Keep the work area free of debris, including solvent, rags, and gasoline.

• Hold gun firmly to side of grounded pail when triggering into pail.

• Use only grounded hoses.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• To avoid chemical reaction and explosion, do not use 1,1,1-trichloroethane, methylene chloride,

other halogenated hydrocarbon solvents or fluids containing such solvents in pressurized aluminum

equipment.

6 309813H

Warning

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause serious injury or death.

• For professional use only.

• Use equipment only for its intended purpose. Call your Graco distributor for information.

• Read manuals, warnings, tags, and labels before operating equipment. Follow instructions.

• Check equipment daily. Repair or replace worn or damaged parts immediately.

• Do not alter or modify equipment. Use only Graco parts and accessories.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not use hoses to pull equipment.

• Comply with all applicable safety regulations.

BURN HAZARD

This equipment is used with heated fluid, which can cause equipment surfaces to become very hot. To

avoid severe burns:

• Do not touch hot fluid or equipment.

• Allow equipment to cool completely before touching it.

• Wear gloves if fluid temperature exceeds 110°F (43°C).

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read Material Safety Data Sheet (MSDS) to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

You must wear proper protective equipment when operating, servicing, or when in the operating area of

the equipment to help protect you from serious injury, including eye injury; inhalation of toxic fumes; and

hearing loss. This equipment includes but is not limited to:

• Protective eyewear.

• Gloves, clothing, and respirator as recommended by the fluid and solvent manufacturer.

• Hearing protection.

309813H 7

Before Beginning Repair

Before Beginning

Repair

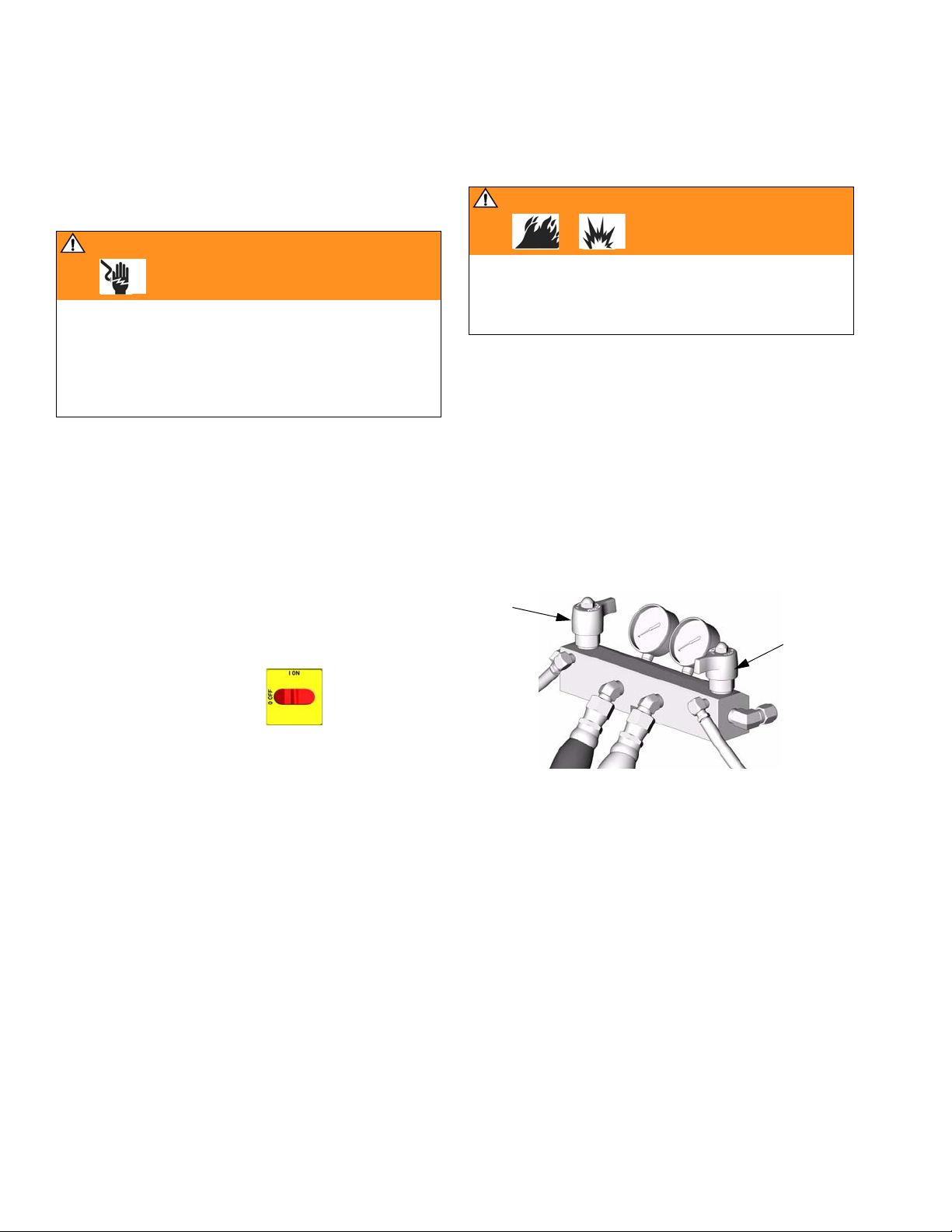

WARNING

Repairing this equipment requires access to parts

which may cause electric shock or other serious injury

if work is not performed properly. Have a qualified

electrician connect power and ground to main power

switch terminals, see the Operation manual. Be sure

to shut off all power to the equipment before repairing.

1. Flush if necessary, see right.

2. Trigger gun to park pumps at bottom of stroke.

Flushing

WARNING

Read warnings, page 6. Flush equipment only in a

well-ventilated area. Do not spray flammable fluids. Do

not turn on heaters while flushing with flammable solvents.

• Flush out old fluid with new fluid, or flush out old

fluid with a compatible solvent before introducing

new fluid.

• Use the lowest possible pressure when flushing.

• All fluid components are compatible with common

solvents. Use only moisture-free solvents.

• To flush feed hoses, pumps, and heaters separately

from heated hoses, set PRESSURE

RELIEF/SPRAY valves (SA, SB) to PRESSURE

RELIEF.

3. Fill wet-cups. See operation manual.

4. Turn main power OFF .

5. Close red-handled valve to shut off power to

motor.

6. Relieve pressure, page 9.

SA

SB

TI3593a

• To flush entire system, circulate through gun fluid

manifold (with manifold removed from gun).

• Always leave some type of fluid in system. Do not

use water.

8 309813H

Pressure Relief Procedure

Pressure Relief

Procedure

1. Relieve pressure in gun and perform gun shutdown

procedure. See gun manual.

2. Verify gun fluid manifold valves A and B are closed.

TI2421A

6. Engage gun piston safety lock.

TI2409A

7. Disconnect gun air line and remove gun fluid manifold.

TI2543A

3. Shut off feed pumps and agitator, if used.

4. Check that red-handled valve is closed, to shut off

power to motor.

5. Turn PRESSURE RELIEF/SPRAY valves (SA, SB)

to PRESSURE RELIEF. Route fluid to waste containers or supply tanks. Ensure gauges drop to 0.

SA

SB

TI3593a

Pump throat seals work best under pressure.

Close fluid inlet valves (VA, VB) when Reactor is

depressurized, to prevent drum head pressure

from leaking past pump piston seals.

8. Close fluid inlet valves (VA, VB).

VA

VB

TI3698b

309813H 9

Temperature Control Diagnostic Codes

Temperature Control Diagnostic Codes

Temperature control diagnostic codes E01 through E05

appear on temperature display.

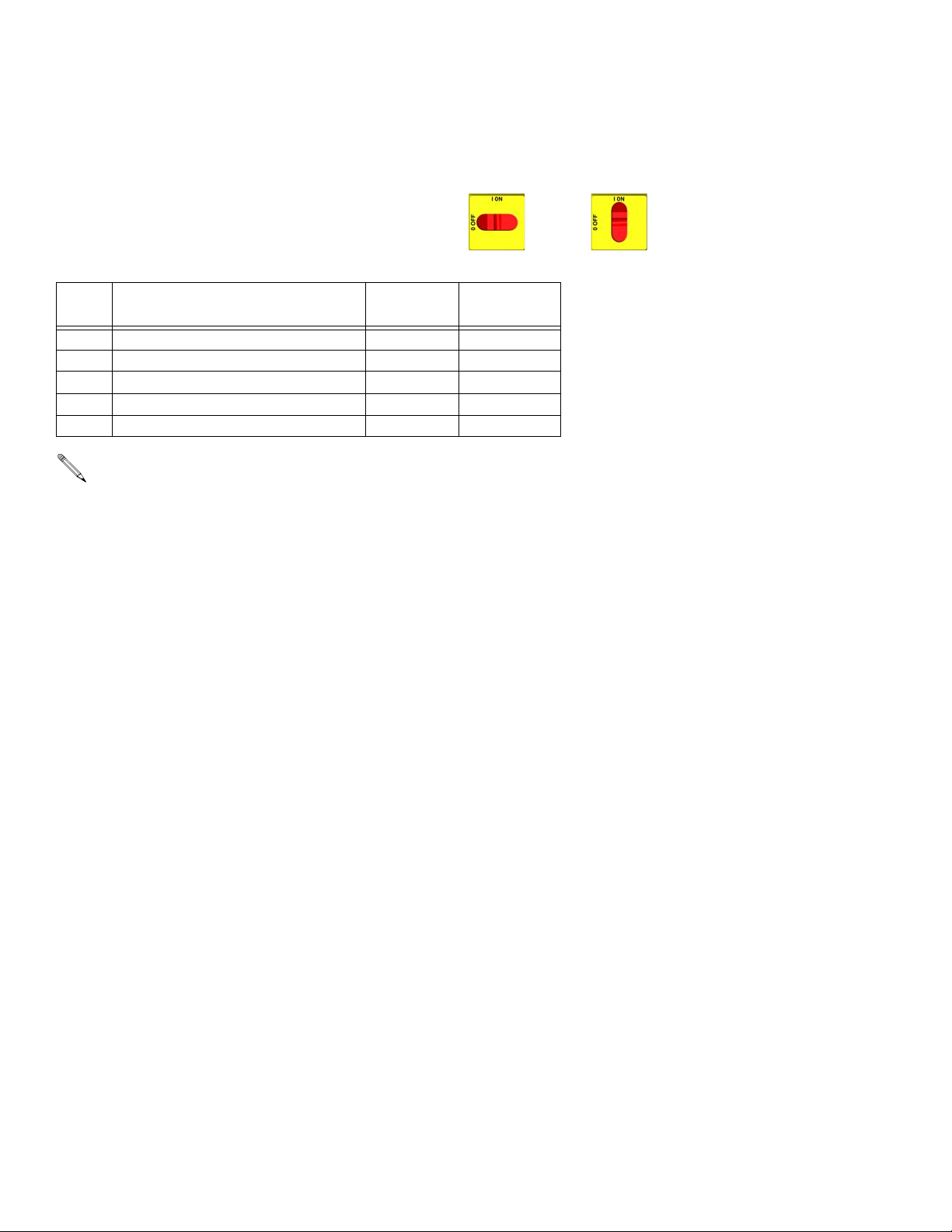

Code

No.

01 High fluid temperature Individual 10

02 High hose current Hose only 10

03 No hose current with hose heater on Hose only 11

04 FTS or thermocouple not connected Individual 11

05 Board overtemperature All 11

For hose zone only, if FTS is disconnected at startup, display will show hose current 0A.

Code Name Alarm Zone Corrective

These alarms turn off heat. Turn main power OFF

then ON to clear.

Action page

E01: High fluid temperature E02: High hose current

a. Check connections between temperature control

board and heater overtemperature switches,

page 22.

a. Check tap connection at transformer, see opera-

tion manual.

b. Check temperature sensors, page 21.

c. Check temperature sensor is contacting heater

element, page 21.

b. Check hose connections for electrical short,

page 22.

c. Move to lower hose length on transformer.

d. Replace temperature control board, page 18.

10 309813H

Temperature Control Diagnostic Codes

E03: No hose current

Do steps in order. Do not skip any step.

a. Check hose connectors for broken electrical

connection, page 22.

b. Test hose continuity, page 25.

c. Test transformer wire harness continuity, page

25.

d. Check 50A (806) and 20A (817A) circuit break-

ers, page 16.

e. Test current sensor continuity, page 25.

f. Do In-Rush Current Limiter Check (380V

only), page 27

e. Use manual current control mode; see operation

manual.

E05: Board overtemperature

a. Check fan operation.

b. Check electrical cabinet door is properly

installed.

c. Check for obstructions blocking cooling holes in

bottom of Reactor.

d. Ambient temperature too high. Reduce gun mix

chamber size, or move Reactor to a cooler location.

g. Do Transformer Primary Check, page 27.

h. Do Transformer Secondary Check, page 27.

E04: FTS or thermocouple

not connected

a. Check FTS operation by connecting directly to

Reactor.

b. Check cable connections between all hose

lengths.

c. Check temperature sensor connection at J1 on

temperature control board, page 18.

d. Check thermocouple with ohmmeter, page 23.

309813H 11

Troubleshooting

Troubleshooting

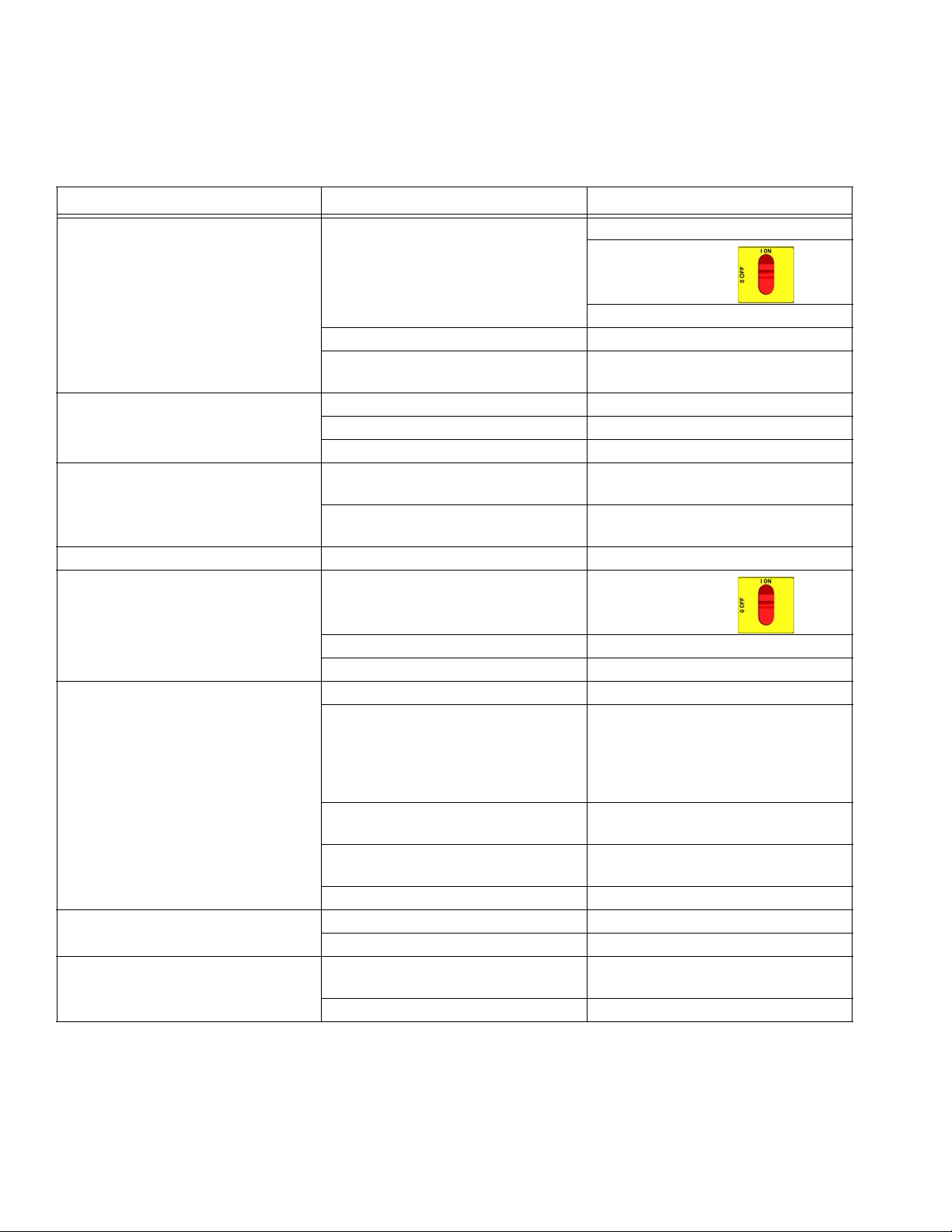

PROBLEM CAUSE SOLUTION

Reactor does not operate. No power. Plug in power cord.

Tur n m ain pow er O N .

Turn circuit breakers ON, page 16.

No air or hydraulic power. Open red-handled valve.

Red stop button circuit open. Check button connections. See page

29 and electrical diagrams.

Fan not working. Blown fuse. Replace, page 17.

Loose wire. Check.

Defective fan. Replace, page 17.

Pump output low. Obstructed fluid hose or gun; fluid

hose ID too small.

Worn piston valve or intake valve in

displacement pump.

Fluid leak in pump packing nut area. Worn throat seals. Replace. See pump manual.

No display. Main power OFF. Turn main power ON .

Open, clear; use hose with larger ID.

See pump manual.

Loose display cable. Check cable connections, page 29.

Display board failed. Check board, replace; page 29.

No temperature display. Loose display cable. Check cable connections, page 29.

Failed temperature control board. Open cabinet. Check if board LED is

blinking. If not, check power wiring

connections to ensure board has

power. If board has power and LED is

not blinking, replace board, page 18.

Inadequate power to temperature

board.

Loose power cable (internal to dis-

play).

Defective display board. Replace, page 29.

No cycle counter display. Loose display cable. Check cable connections, page 29.

Defective counter. Replace, page 29.

Does not count. Magnet (26) missing from pump

yoke.

Defective reed switch (27). Replace.

Check that power supply meets

requirements.

Check cable connections, page 29.

Replace.

12 309813H

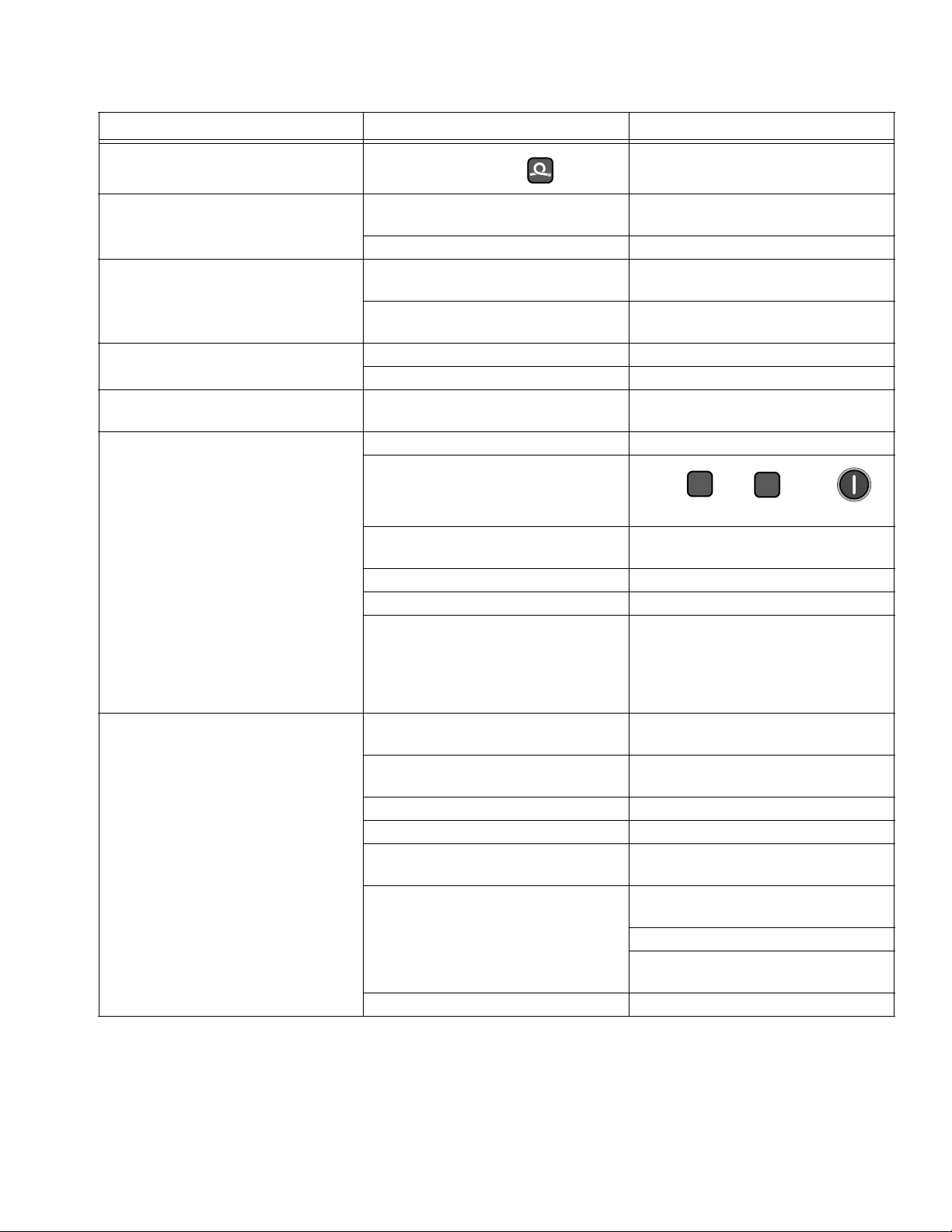

PROBLEM CAUSE SOLUTION

Hose display reads 0A on startup.

FTS not installed and zone off.

Troubleshooting

Install FTS (see operation manual),

or adjust current to desired setting.

Erratic display; display turns on and

off.

Display buttons do not work properly;

cannot get out of an operation.

Red stop button does not work. Broken button (fused contact). Replace, page 29.

No heat in any zone. Red stop button circuit open. Check button connections. See page

No heat in A or B zones. Circuit breaker(s) tripped. Reset breaker CB3 or CB4, page 16.

Low heat in A or B zones. A and B temperature setpoints too

Cable not grounded. Ground cable, page 29.

Extension cable too long. Must not exceed 100 ft (30.5 m).

Broken membrane switch. Replace, page 29.

Ribbon cable disconnected or broken.

Loose wire. Check connections, page 29.

Heat turned off.

Temperature control alarm. Check temperature displays for diag-

Defective heater. Replace, page 20. Check resistance.

Loose connectors or wire nuts. Check connections.

Failed temperature control board. Open cabinet. Check if board LED is

low.

Flow too high. Use smaller mix chamber. Decrease

Defective heater. Replace, page 20. Check resistance.

Loose connectors or wire nuts. Check connections.

Low voltage. Check that power supply meets

Overheated temperature control

board.

Fluid too cold. Preheat fluid.

Connect cable, or replace.

29 and electrical diagrams.

Press or zone

keys.

nostic code, page 10.

blinking. If not, check power wiring

connections to ensure board has

power. If board has power and LED is

not blinking, replace board, page 18.

Check setpoint. Increase if necessary.

pressure.

requirements.

Check fan operation.

Check if door is open; close.

Check that cooling holes are not

clogged or obstructed.

A

B

309813H 13

Troubleshooting

PROBLEM CAUSE SOLUTION

No hose heat. 380V units only - In-rush current lim-

iter contactor not closing when hose

heat is turned on.

Loose hose electrical connections. Check connections. Repair as neces-

Circuit breakers tripped. Reset breakers (CB1 or CB2), page

Hose zone not turned on.

Check to be sure contactor in 288359

is closing when hose heat is turned

on. If not, check fuse (198). If fuse is

not blown, perform transformer

checks.

sary.

16.

Press zone key.

A and B temperature setpoints too

low.

Failed temperature control board. Open cabinet. Check if board LED is

Low hose heat. A and B temperature setpoints too

low.

Hose temperature setpoint too low. Check. Increase if necessary to

Flow too high. Use smaller mix chamber. Decrease

Low current; FTS not installed. Install FTS, see operation manual.

Hose heat zone not turned on long

enough.

Loose hose electrical connections. Check connections. Repair as neces-

Check. Increase if necessary.

blinking. If not, check power wiring

connections to ensure board has

power. If board has power and LED is

not blinking, replace board, page 18.

Increase A and B setpoints. Hose

designed to maintain temperature,

not increase temperature.

maintain heat.

pressure.

Allow hose to heat up, or preheat

fluid.

sary.

14 309813H

Repair

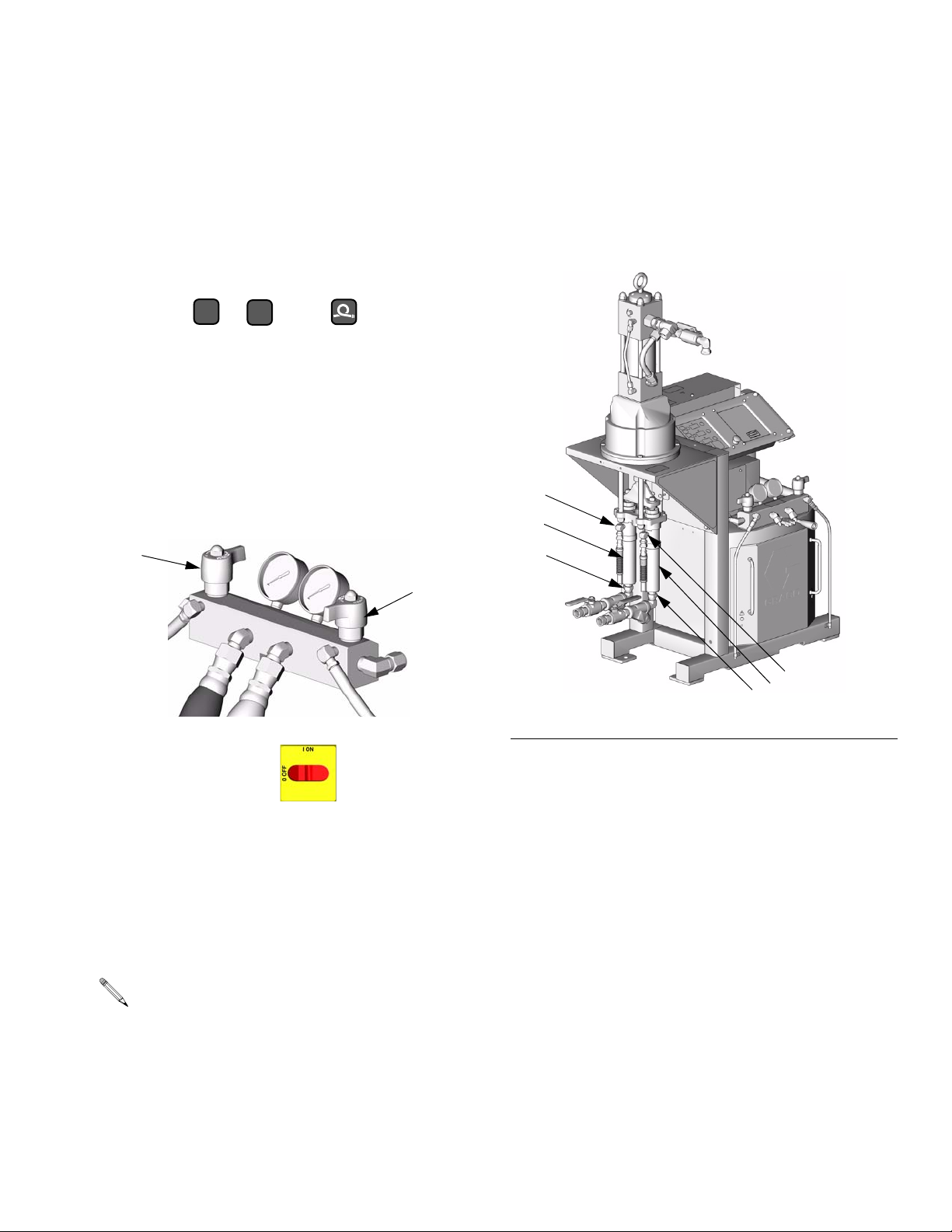

Proportioning Pump

Removal

Repair

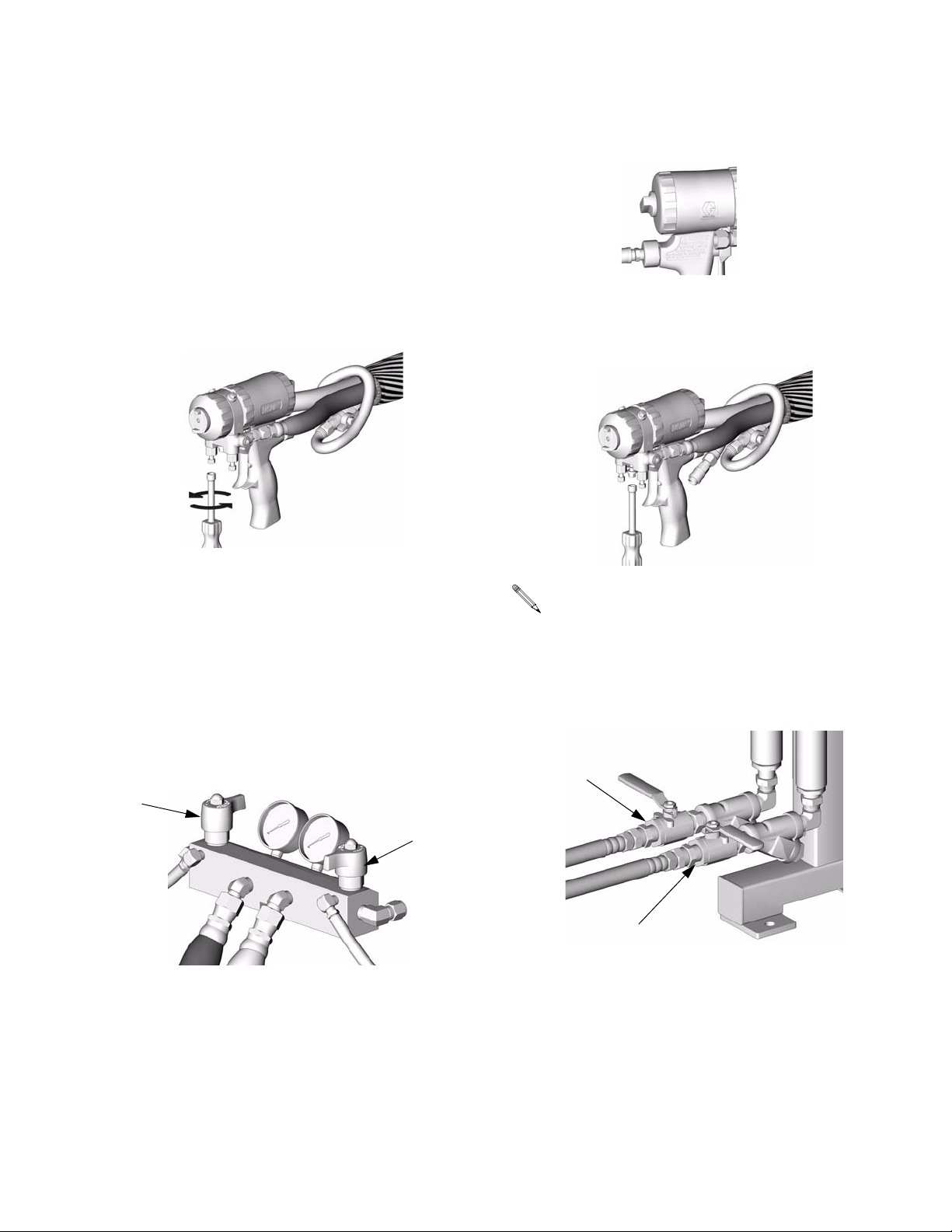

1. Shut off , , and heat zones.

2. Flush pump, page 8.

3. Relieve pressure, page 9.

4. Turn PRESSURE RELIEF/SPRAY valves (SA, SB)

to PRESSURE RELIEF.

SA

A

B

SB

TI3593a

D

E

C

FIG. 1. Pump Removal

D

E

C

TI3582b

5. Turn main power OFF . Disconnect power

supply.

6. Disconnect hoses and fittings from fluid inlets (C)

and outlets (D). See F

7. Remove pump. See applicable manuals, supplied.

See page 4 for applicable pump and motor

repair-parts manuals. Displacement pumps (E)

may be removed without removing entire proportioning pump.

8. Reinstall in reverse order.

309813H 15

IG. 1.

Loading...

Loading...